A lithium ion battery and a preparation method thereof

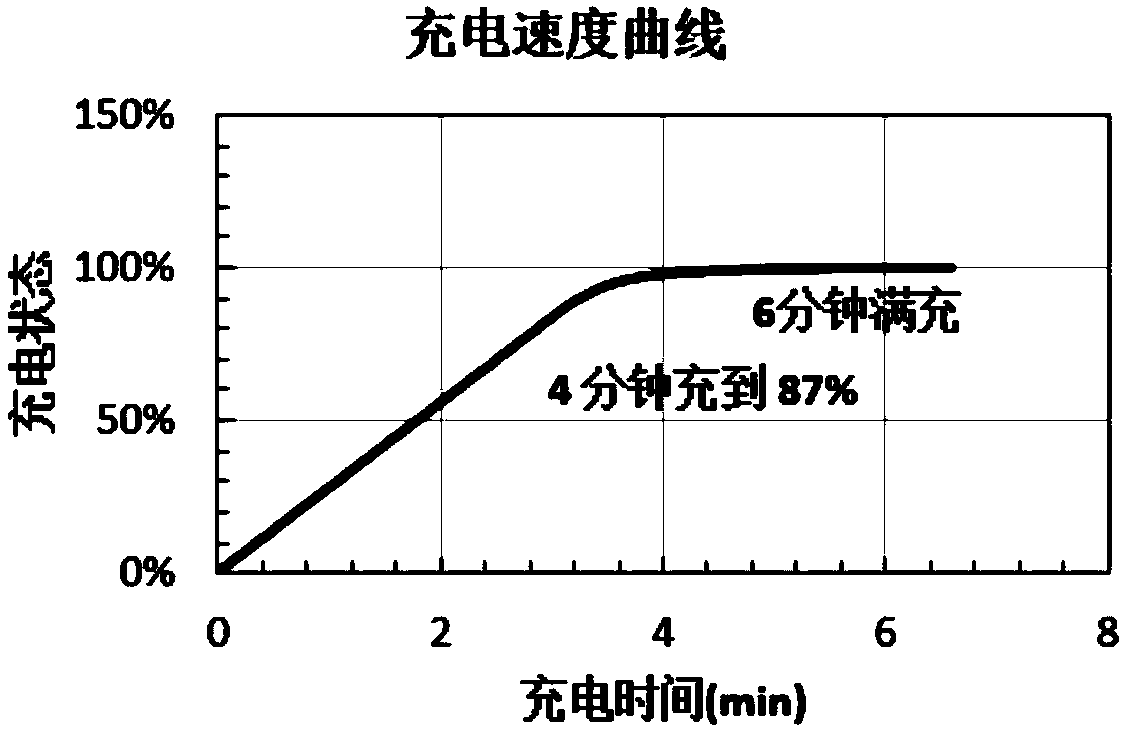

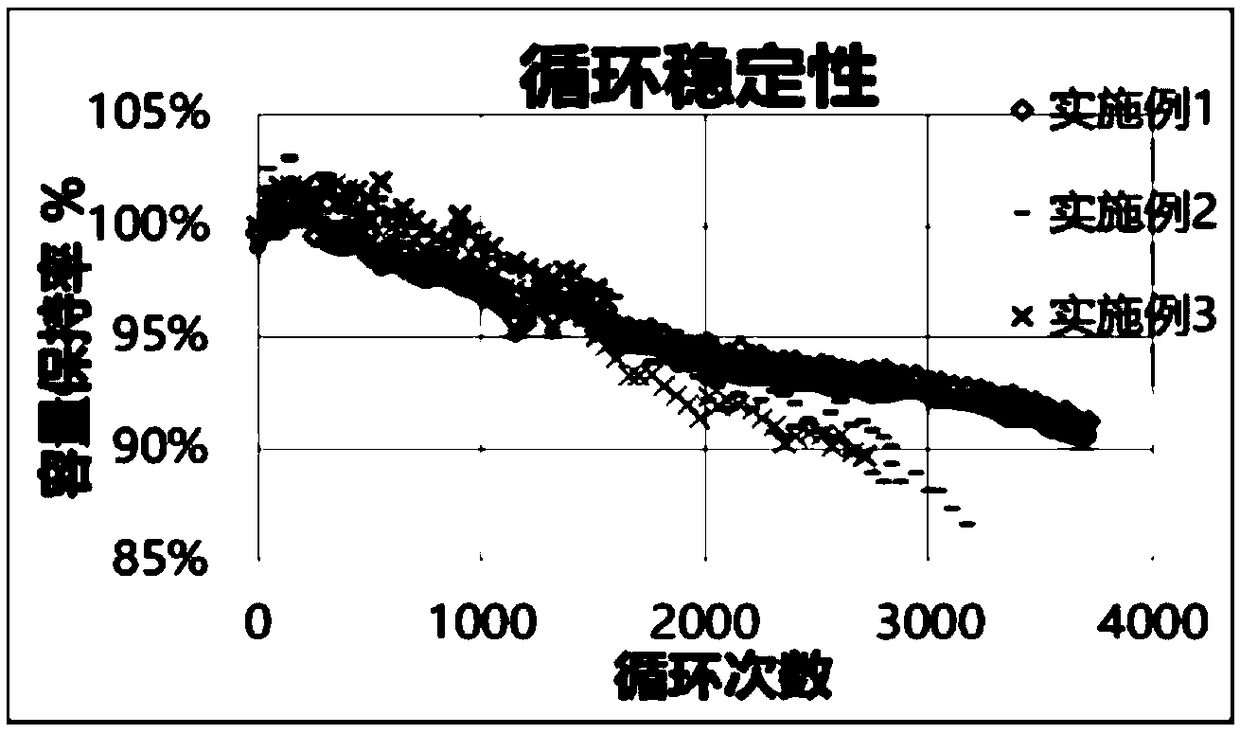

A lithium-ion battery and conductive agent technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of short cycle life and slow charging speed, and achieve the effects of extending service life, simple production and reduced expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

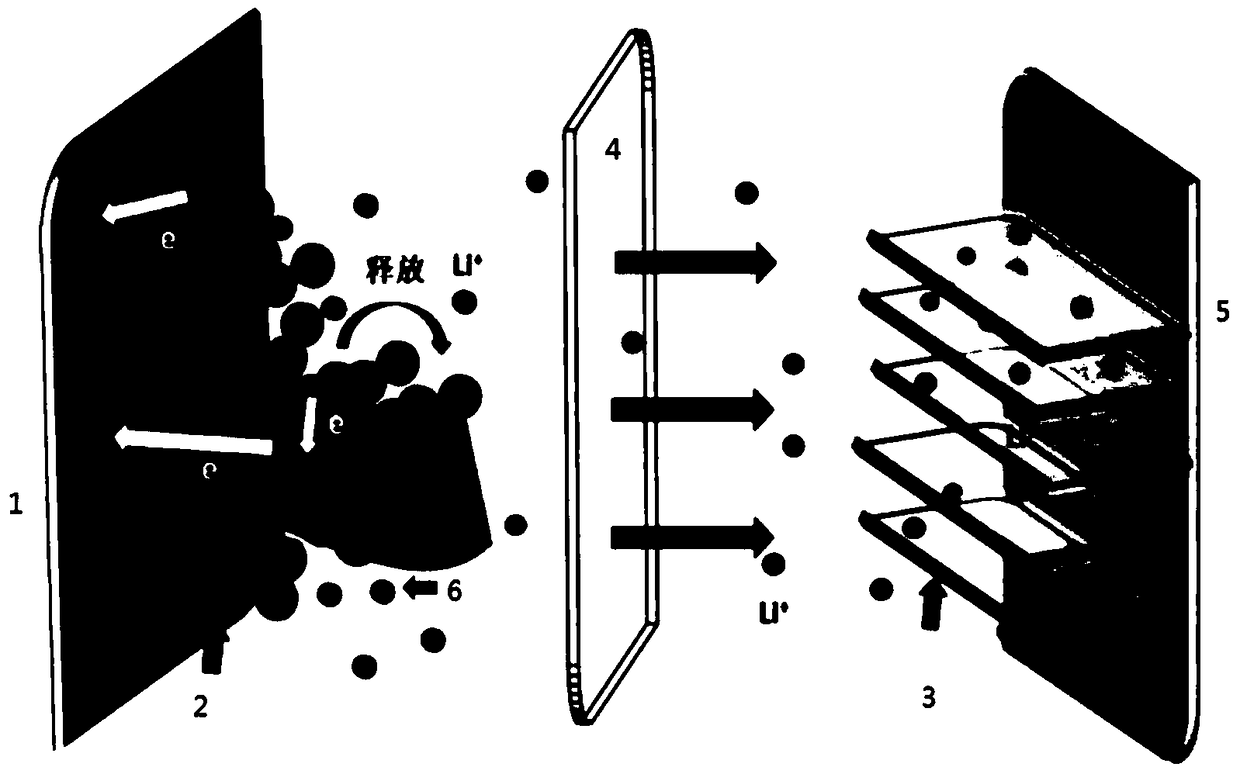

Image

Examples

Embodiment 1

[0040] Preparation of positive electrode ingredients: LiFePO 4 , SP, rGO, PVDF were dissolved in the NMP solution according to the mass ratio of 96:1.5:1.5:1, fully stirred for 10 hours to make it evenly dispersed, and the mixed slurry was mixed at 100g / m 2 The density of one side of the aluminum foil is coated on the surface of the aluminum foil, dried at 120°C, and rolled and compacted at room temperature;

[0041] Preparation of negative electrode ingredients: Dissolve hard carbon, SP, dispersant (CMC), and binder (SBR) in deionized water at a ratio of 95:2:1.5:1.5, stir for 10 hours to disperse evenly, and mix The slurry is 50g / m 2 Coated on the surface of the copper foil with a density of one side, dried at 100°C, and rolled at room temperature for compaction;

[0042] Assembly and packaging of lithium-ion batteries: stack a certain number of negative electrodes (16 pieces), separators, and positive electrodes (15 pieces) in order to ensure that the length and width of ...

Embodiment 2

[0046] Preparation of positive electrode ingredients: LiFePO 4 , SP, and PVDF were dissolved in NMP solution at a mass ratio of 96:3:1, stirred thoroughly for 10 hours to make them evenly dispersed, and the mixed slurry was mixed at 100g / m 2 The density of one side of the aluminum foil is coated on the surface of the aluminum foil, dried at 120°C, and rolled and compacted at room temperature;

[0047] Preparation of negative electrode ingredients: Dissolve hard carbon, SP, dispersant (CMC), and binder (SBR) in deionized water at a ratio of 95:2:1.5:1.5, stir for 10 hours to disperse evenly, and mix The slurry is 50g / m 2 Coated on the surface of the copper foil with a density of one side, dried at 100°C, and rolled at room temperature for compaction;

[0048] Assembly and packaging of lithium-ion batteries: stack a certain number of negative electrodes (16 pieces), separators, and positive electrodes (15 pieces) in order to ensure that the length and width of the negative ele...

Embodiment 3

[0051] Preparation of positive electrode ingredients: LiFePO 4 , SP, rGO, PVDF were dissolved in the NMP solution according to the mass ratio of 96:1.5:1.5:1, fully stirred for 10 hours to make it evenly dispersed, and the mixed slurry was mixed at 100g / m 2 The density of one side of the aluminum foil is coated on the surface of the aluminum foil, dried at 120°C, and rolled and compacted at room temperature;

[0052] Preparation of negative electrode ingredients: Dissolve graphite, SP, dispersant (CMC), and binder (SBR) in deionized water at a ratio of 95:2:1.5:1.5, stir for 10 hours to disperse evenly, and mix the Slurry at 50g / m 2 Coated on the surface of the copper foil with a density of one side, dried at 100°C, and rolled at room temperature for compaction;

[0053] Assembly and packaging of lithium-ion batteries: stack a certain number of negative electrodes (16 pieces), separators, and positive electrodes (15 pieces) in order to ensure that the length and width of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com