Preparation device and production method for sulfur electrode material

A technology for preparing devices and production methods, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of reducing battery energy density and unimproved rate performance of sulfur/carbon composite materials, and achieve enhanced heat transfer, convenient operation, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

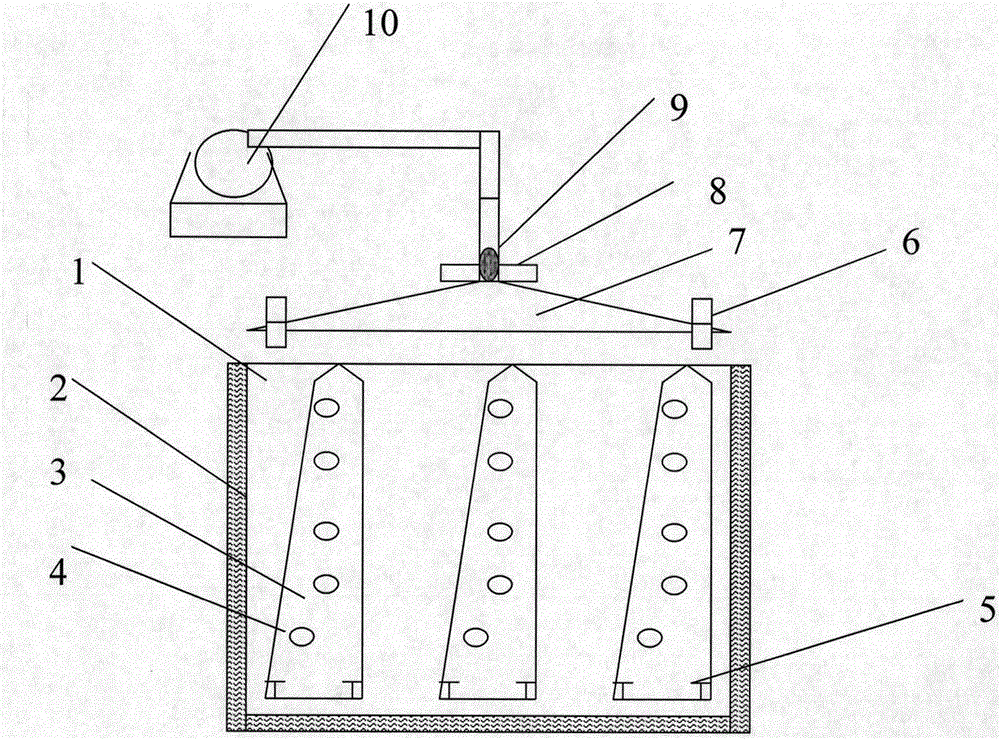

[0022] A sulfur electrode material preparation device includes a mixer, a sulfur storage device, a heating system, and a vacuum system; the mixer includes an upper cover, a fixing flange, and a mixer body; the heating system includes a heating sheet, a sensor, and a controller; the vacuum system includes a vacuum pump and alloy separation membrane; the heating plate and the sensor are stacked together, set on the surface of the mixer shell and covered with heat insulation layer; the controller is set at the bottom of the mixer; the vacuum pump is connected to the upper cover of the mixer through the alloy separation membrane and stainless steel tube; the mixer Stainless steel pipes are set on the left and right sides where the upper cover is connected to the alloy separation membrane, and the stainless steel pipes are connected to the circulating water; the sulfur storage device is an inverted flat hollow steel plate with porous stainless steel pipes, the number of porous stainl...

Embodiment 2

[0033] A kind of sulfur electrode material comprises following system:

[0034] 4) hollow vanadium pentoxide nanopowder (particle size, 200nm), mass fraction 30%; sulfur element, mass fraction 60%; polyaniline, mass fraction 10%;

[0035] 5) hollow vanadium pentoxide nanopowder (particle size, 200nm), mass fraction 40%; sulfur element, mass fraction 50%; polyaniline, mass fraction 10%;

[0036] 6) Hollow vanadium pentoxide nanopowder (particle size, 200nm), mass fraction 50%; sulfur element, mass fraction 40%; polyaniline, mass fraction 10%;

[0037] A sulfur electrode material preparation device and production method: it comprises the following steps:

[0038]1) Weigh the porous electrode material and elemental sulfur according to a certain ratio; put the elemental sulfur into the stainless steel tube of the sulfur storage device, and fix it to the flat hollow steel plate of the sulfur storage device and the bottom of the mixer body through movable bolts; place the porous el...

Embodiment 3

[0043] Operate with embodiment 1,

[0044] A kind of sulfur electrode material comprises following system:

[0045] 7) Hollow nickel-cobalt-lithium oxide nanopowder (particle size, 150nm), mass fraction 40%; sulfur element, mass fraction 40%; polythiophene, mass fraction 20%;

[0046] 8) hollow vanadium pentoxide nanopowder (particle size, 200nm), mass fraction 70%; sulfur element, mass fraction 20%; polyaniline, mass fraction 10%;

[0047] 9) Hollow vanadium pentoxide nanopowder (particle size, 200nm), mass fraction 59%; sulfur element, mass fraction 40%; polyaniline, mass fraction 1%;

[0048] Preparation and performance test of sulfur electrode; sulfur electrode material, acetylene black and PVDF were mixed in NMP at a mass ratio of 80:10:5, coated on aluminum foil as electrode film, metal lithium sheet as counter electrode, and CELGARD 2400 as diaphragm , 1mol / L LiPF6 / EC+DMCWEI as the electrolyte, assembled into a button battery in a glove box filled with Ar, and used th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com