Graphene/polyaniline/sulfur composite cathode material and preparation method thereof, lithium sulfur battery

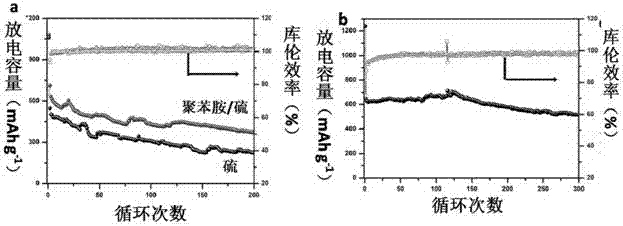

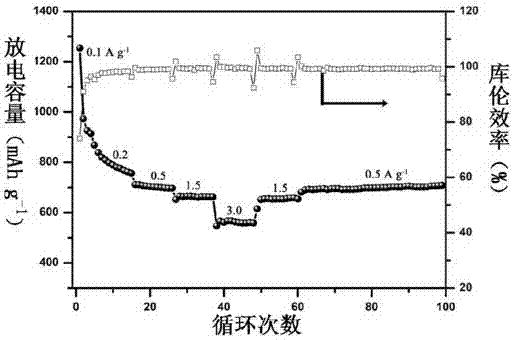

A composite positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor stability, poor performance stability of lithium-sulfur batteries, structural stability and low conductivity, etc., to achieve excellent electrical conductivity High performance, guaranteed cycle stability and rate performance, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

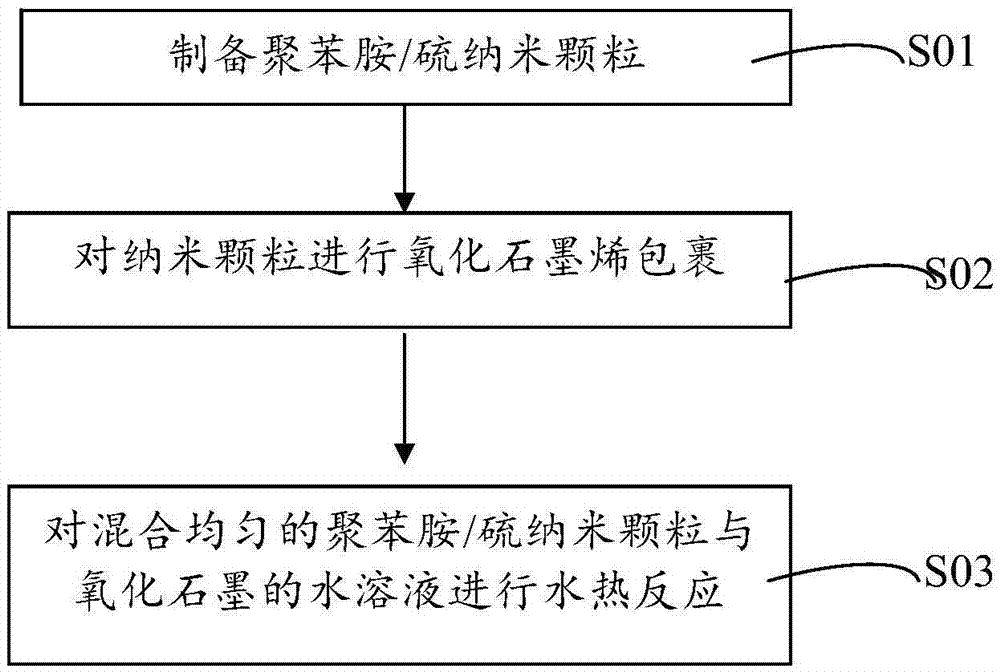

[0031]On the other hand, the example of the present invention provides a simple and efficient method for preparing a structurally stable graphene / aniline / sulfur composite positive electrode material. Please refer to the technical process of the graphene / aniline / sulfur composite cathode material method figure 1 , which includes the following steps:

[0032] Step S01. Preparation of polyaniline / sulfur nanoparticles:

[0033] adding polyaniline and sulfur into a solvent for mixing treatment, and then removing the solvent to obtain polyaniline-supported sulfur composite particles;

[0034] Step S02. wrapping the nanoparticles with graphene oxide:

[0035] The polyaniline-supported sulfur composite particles and graphene oxide are formulated into a mixed solution of water;

[0036] Step S03. Carry out hydrothermal reaction to the aqueous solution of polyaniline / sulfur nanoparticles and graphite oxide mixed homogeneously:

[0037] The mixed solution is subjected to hydrothermal ...

Embodiment 1

[0068] The above-mentioned graphene / polyaniline / sulfur composite cathode material and a preparation method thereof. The graphene / polyaniline / sulfur composite cathode material is prepared by the following method:

[0069] S11. Preparation of polyaniline / sulfur nanoparticles:

[0070] The columnar polyaniline / sulfur nanoparticles were prepared by first emulsification-post-polymerization, the specific method is as follows:

[0071]Dissolve 0.3g of polyvinylpyrrolidone in 20mL of hydrochloric acid solution, dissolve 200 microliters of aniline and 0.3g of sulfur element in 2mL of carbon disulfide solution, mix the two solutions together, and stir for 1 hour at a speed of 1000 rpm to fully emulsify step. Then add 1 mL of an aqueous solution in which 0.45 g of ammonium persulfate is dissolved to initiate a polymerization reaction. After stirring for 5 hours, the carbon disulfide solution is slowly evaporated at room temperature. The stirring time is 6 hours, and then the remaining ...

Embodiment 2

[0077] The above-mentioned graphene / polyaniline / sulfur composite cathode material and a preparation method thereof. The graphene / polyaniline / sulfur composite cathode material is prepared by the following method:

[0078] S21. Preparation of polyaniline / sulfur nanoparticles:

[0079] The columnar polyaniline / sulfur nanoparticles were prepared by first emulsification-post-polymerization, the specific method is as follows:

[0080] 0.5g of polyvinylpyrrolidone was dissolved in 30mL of hydrochloric acid solution, 300 microliters of aniline solution and 0.3g of sulfur element were dissolved in 3mL of carbon disulfide solution, the two solutions were mixed together, and stirred for 2 hours at a speed of 1000 rpm, fully Carry out the emulsification step. Then add 1.5mL of aqueous solution with 0.55g of ammonium persulfate dissolved therein to initiate the polymerization reaction. After fully stirring for 6 hours, the carbon disulfide solution is slowly evaporated at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com