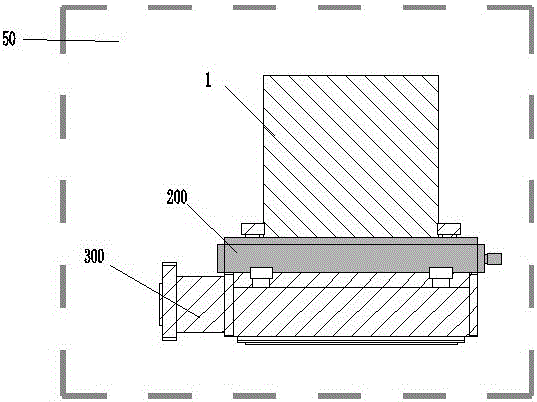

3D (three-dimensional) printing powder delivery and paving linkage type bidirectional powder paving device and equipment

A powder spreading device and 3D printing technology, applied in the field of 3D printing, can solve the problems of stroke waste, more powder spreading in one direction, and a small amount of powder blowing in the forming space, etc., and achieve the effect of simple and convenient operation, avoiding working methods, and reducing the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

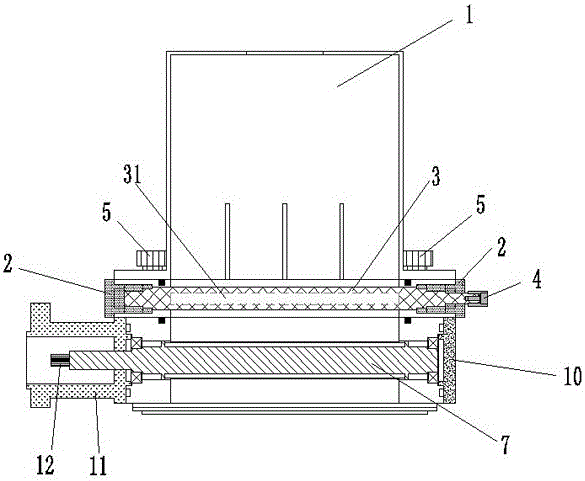

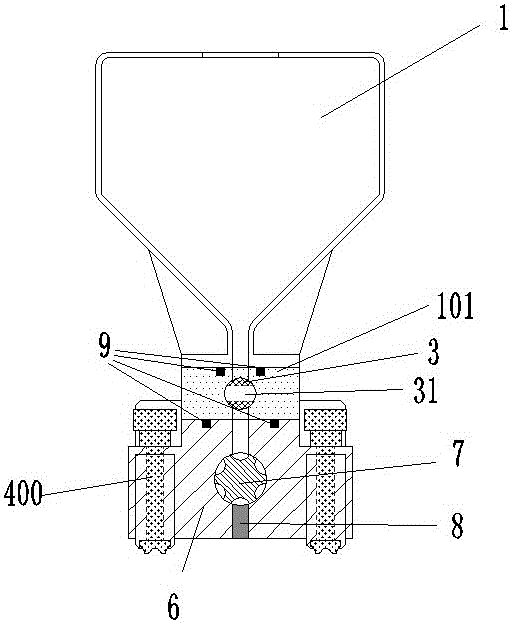

[0032]The advantages of a 3D printing powder feeding and powder spreading linkage type two-way powder spreading device are: ①The upper powder feeding structure, the motor quantitatively controls the quantitative powder feeding roller rotation, the overall structure is closed, and the powder is lowered from the bottom to reduce dust splashing and powder waste. ②The quantitative powder feeding roller in the powder feeding and powder spreading linkage structure is equipped with 6 semicircular grooves evenly extending the busbar, which can realize quantitative and high-precision powder spreading in the process of linkage with the powder spreading transmission device; ③The end of the powder roller shaft Made into a spline structure, it is convenient to replace the powder. The powder feeding and spreading components are taken out through the spline structure as a whole. After cleaning, the whole is inserted into the output shaft of the motor to work. This structure design is simple an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com