Composite structure for lithium ion battery cathode and preparation method thereof

A lithium-ion battery and composite structure technology, applied in battery electrodes, nanotechnology for materials and surface science, structural parts, etc., can solve the problem that the charge-discharge capacity and cycle performance need to be improved, and it is difficult to meet the performance requirements of power batteries. Synthesis Problems such as complicated steps, to achieve the effect of increasing conductivity, ensuring stability, and alleviating the effect of volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

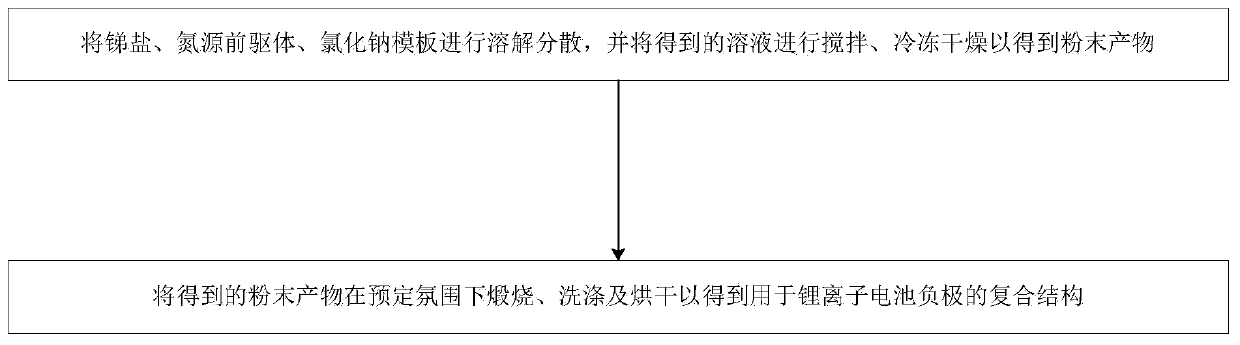

[0031] see figure 1 , the present invention also provides a kind of preparation method for the composite structure of negative electrode of lithium ion battery, and this preparation method comprises the following steps:

[0032] Step 1, dissolving and dispersing antimony salt, nitrogen source precursor, and sodium chloride template, stirring and freeze-drying the obtained solution to obtain a powder product.

[0033] Specifically, the natural polymer carbon source precursor, the nitrogen source precursor and sodium chloride are dissolved in a certain volume of water to form a natural polymer carbon source precursor with a concentration of 0.01mol / L to 0.03mol / L. It is a mixed solution of nitrogen source precursor of 0.005mol / L~0.01mol / L and sodium chloride with a concentration of 0.02g / mL~0.1g / mL; The ethanol solution of antimony salt is slowly added dropwise to the above mixed solution, and then magnetically stirred at 60°C-80°C for 10h-20h, and freeze-dried when the solutio...

Embodiment 1

[0040] The preparation method for the composite structure of the lithium-ion battery negative electrode provided in Example 1 of the present invention mainly includes the following steps:

[0041] S1, take the natural polymer carbon source precursor, nitrogen source precursor and sodium chloride and dissolve them in 300ml of water to make the natural polymer carbon source precursor with a concentration of 0.01mol / L and the nitrogen source precursor with a concentration of 0.01mol / L, the concentration of sodium chloride is a mixed solution of 0.02g / mL; then, 100ml of ethanol solution of antimony salt with a concentration of 0.01mol / L is slowly added dropwise to the above mixed solution, and the resulting solution is heated at 60°C Under magnetic stirring for 12 h to obtain a milky white homogeneous solution.

[0042] S2. Warm up the solution obtained in step S1 to 80°C and evaporate it with open stirring until the solution is reduced to one-eighth of the original solution (i.e...

Embodiment 2

[0045] The preparation method for the composite structure of the lithium-ion battery negative electrode provided by Example 2 of the present invention mainly includes the following steps:

[0046] S1, take the natural polymer carbon source precursor, nitrogen source precursor and sodium chloride and dissolve them in 300ml of water to make the natural polymer carbon source precursor with a concentration of 0.02mol / L and the nitrogen source precursor with a concentration of 0.008mol / L, the concentration of sodium chloride is a mixed solution of 0.08g / mL; then, 100ml of ethanol solution of antimony salt with a concentration of 0.1mol / L is slowly added dropwise to the above mixed solution, and the resulting solution is heated at 70°C Under magnetic stirring for 10 h to obtain a milky white homogeneous solution.

[0047] S2, warm up the solution obtained in step S1 to 80°C and open to stir and evaporate until the solution is 1 / 4 of the original solution (i.e. 160ml), then transfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com