Gel electrolyte precursor and application thereof

A gel electrolyte and precursor technology, applied in solid electrolyte, non-aqueous electrolyte, electrolyte immobilization/gelation, etc., can solve the problems of insufficient rate performance and cycle performance, complex preparation process, high cost, etc., to achieve guaranteed rate performance, improvement of safety performance, effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

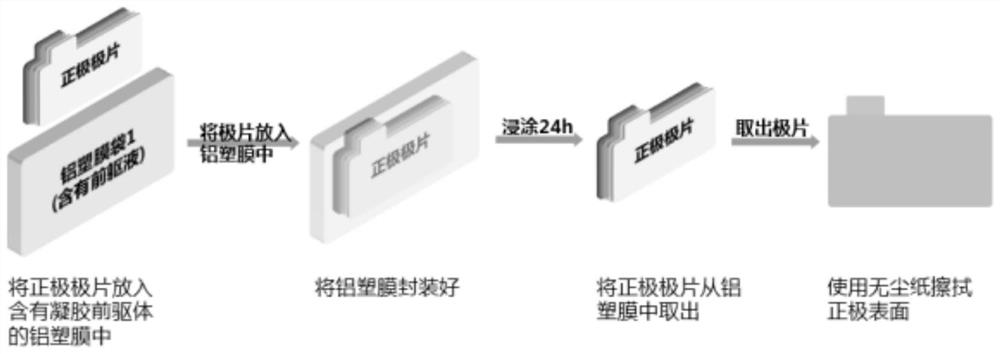

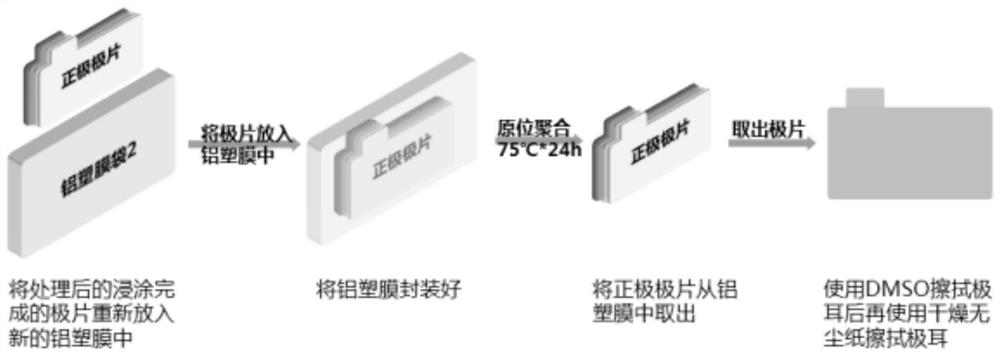

Method used

Image

Examples

Embodiment 1

[0105] In this embodiment, the gel electrolyte precursor contains the following components: gel skeleton monomer, flexible additive, polymerization initiator and lithium salt;

[0106] Wherein, the gel skeleton monomer is an acrylonitrile monomer;

[0107] The flexible additive is succinonitrile;

[0108] The polymerization initiator is azobisisobutyronitrile;

[0109] The lithium salt is lithium bistrifluoromethanesulfonylimide.

[0110] Based on the sum of the mass of the gel skeleton monomer, the flexible additive and the polymerization initiator as 100%, the gel electrolyte precursor includes the following components:

[0111] Gel backbone monomer 58%

[0112] Flexible Additives 38%

[0113] Polymerization initiator 4%;

[0114] The ratio of the molar weight of the lithium salt to the volume of the gel skeleton monomer is 1mol / L;

[0115] The composition of the electrolyte: the solvent is the volume ratio EC:DMC:EMC=2:4:4, LiPF 6 Content 1.15mol / L, also contains 7% ...

Embodiment 2

[0134] The difference between this embodiment and Example 1 is that, based on the sum of the mass of the gel skeleton monomer, the flexible additive and the polymerization initiator as 100%, the gel electrolyte precursor includes the following components:

[0135] Gel backbone monomer 75%

[0136] Soft Additive 20%

[0137] Polymerization initiator 5%;

[0138] The ratio of the molar weight of the lithium salt to the volume of the gel skeleton monomer is 2mol / L;

[0139] Other parameters and conditions are exactly the same as in Example 1.

Embodiment 3

[0141] The difference between this embodiment and Example 1 is that, based on the sum of the mass of the gel skeleton monomer, the flexible additive and the polymerization initiator as 100%, the gel electrolyte precursor includes the following components:

[0142] Gel skeleton monomer 30%

[0143] Flexible Additive 60%

[0144] Polymerization initiator 10%;

[0145] The ratio of the molar weight of the lithium salt to the volume of the gel skeleton monomer is 0.1mol / L;

[0146] Other parameters and conditions are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com