Three-dimensional network water-based composite binder and application thereof in lithium ion battery

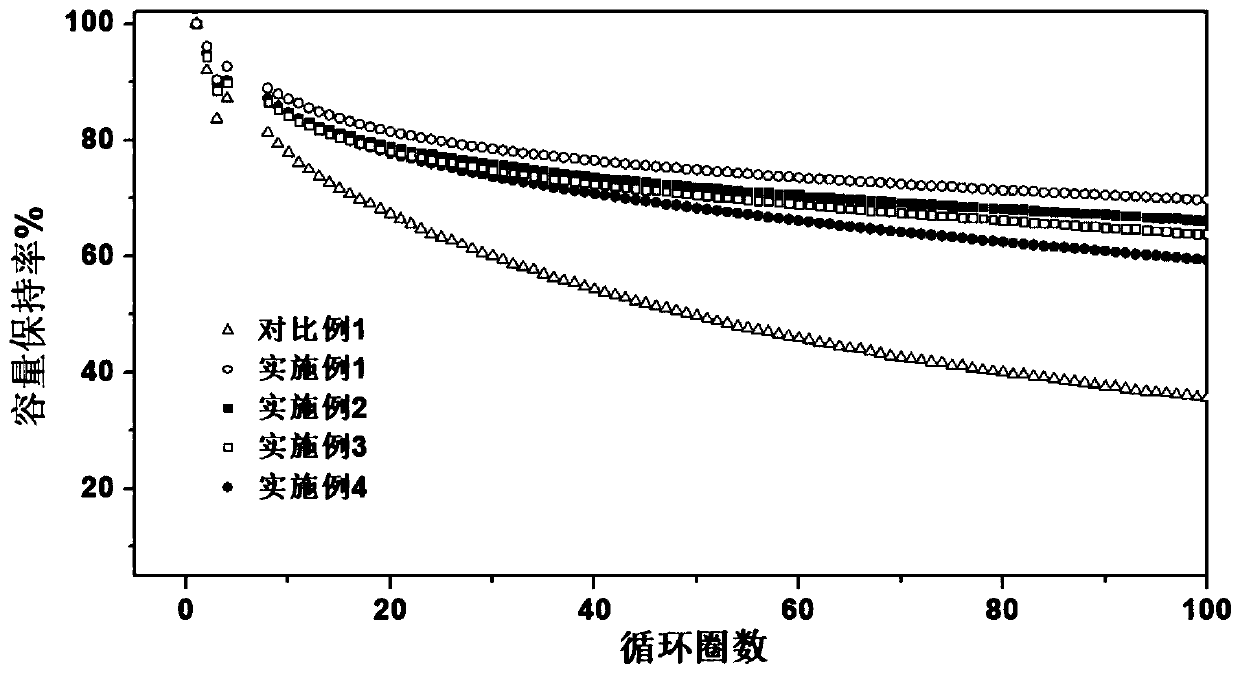

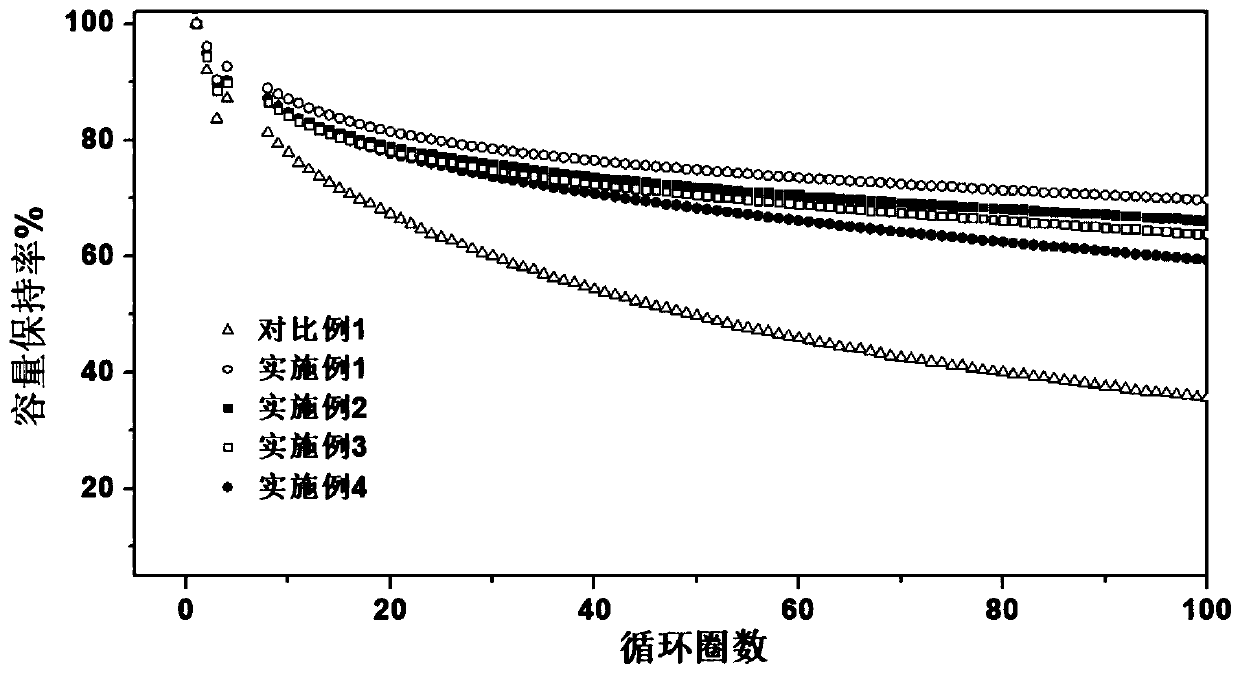

A lithium-ion battery and three-dimensional network technology, which is applied in the field of new energy and new materials, can solve the problems of insufficient cycle stability of lithium-ion batteries, and achieve the effects of ensuring rate performance, alleviating damage, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In a 1L reactor, add 1g of polyvinyl alcohol into 200mL of deionized water, raise the temperature to 80°C, and cool down to room temperature after the polyvinyl alcohol is completely dissolved. Add 2.5g nonylphenol polyoxyethylene ether, 90g vinyl acetate and 5g acrylic acid, add sodium bicarbonate solution to adjust the pH to 6-7, stir at high speed to emulsify. After vacuuming, nitrogen gas was introduced for 30 minutes, then 1.5 g of potassium persulfate was added, and the temperature was raised to 70° C. for 6 hours to prepare an aqueous polymer emulsion.

[0033]Take 20 g of the prepared water-based polymer emulsion and mix with 75 g of sodium alginate solution, then add 5 g of calcium acetate solution, and mix evenly to prepare a three-dimensional network water-based composite binder.

[0034] Mix SiC450, conductive agent Super P, and the prepared three-dimensional network water-based composite binder at a mass ratio of 95:1:4, and use an appropriate amount of dei...

Embodiment 2

[0036] In a 1L reactor, add 1g of polyvinyl alcohol into 200mL of deionized water, raise the temperature to 80°C, and cool down to room temperature after the polyvinyl alcohol is completely dissolved. Add 5g of sodium lauryl sulfate, 80g of vinyl acetate, add sodium bicarbonate solution to adjust the pH to 6-7, stir at high speed for emulsification. After evacuating, nitrogen gas was introduced for 30 minutes, and then ethylene was introduced into the reactor so that the amount of ethylene added was 12.5 g. After the ethylene pressure reached a constant value, 1.5 g of azobisisobutylamidine was added, and the temperature was raised to 100° C. for 5 h.

[0037] Take 30g of the prepared water-based polymer emulsion and mix with 60g of polyacrylic acid solution, then add 10g of γ-aminopropyl triethoxysilane solution, and mix evenly to prepare a three-dimensional network water-based composite binder.

[0038] Mix SiC450, conductive agent Super P, and the prepared three-dimensional...

Embodiment 3

[0040] In a 1L reactor, add 1g of polyvinyl alcohol into 200mL of deionized water, raise the temperature to 80°C, and cool down to room temperature after the polyvinyl alcohol is completely dissolved. Add 35g of vinyl acetate, 15g of acrylate, and dropwise add 5% lithium hydroxide solution to adjust the pH to neutral. After vacuuming, nitrogen gas is introduced for 30 minutes, 0.8g of potassium persulfate is added, and the temperature is raised to 70°C for 2 hours. Then add a mixed solution of 35g vinyl acetate, 12.5g acrylate and 0.5g potassium persulfate drop by drop, strictly control the dropping speed, make the mixed solution drop for 2h, and continue to react for 3h. Finally, continue to add 0.2 g of potassium persulfate solution to react for 2 h, take it out, and add 5% lithium hydroxide solution to adjust the pH of the solution to neutral.

[0041] Take 40 g of the prepared water-based polymer emulsion and mix with 55 g of sodium alginate solution, then add 5 g of calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com