Diamond wire saw rubber injection molding method

A technology of rubber injection and molding method, applied in the coating and other directions, can solve the problems of positioning beads rotation, poor rubber bonding of positioning beads, broken ropes, etc., to ensure bonding stability and avoid poor bonding between positioning beads and rubber. , to avoid the effect of coating failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

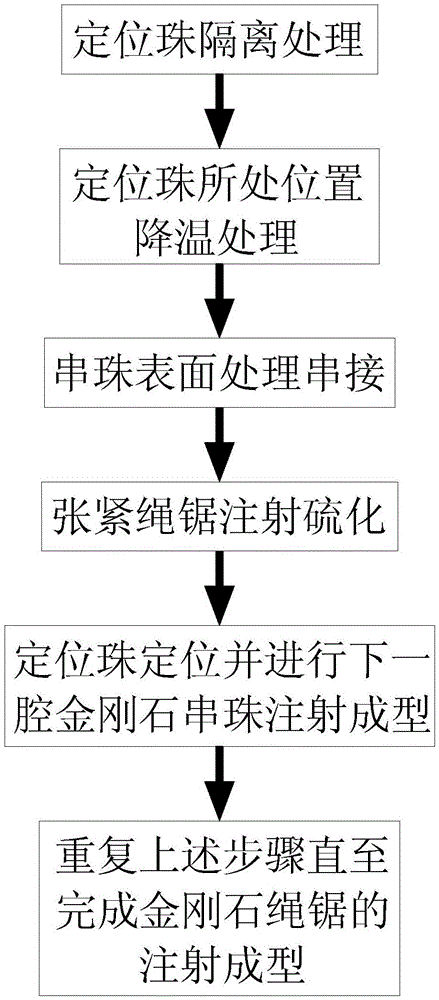

[0020] figure 1 It is a flow chart of steps of diamond rubber wire saw rubber injection molding in a preferred embodiment of the present invention. Such as figure 1 As shown, the diamond rubber wire saw rubber injection molding method of the present embodiment includes the following steps: a. In the injection molding cavity, the bead placement position of the positioning beads of the diamond rubber wire saw to be processed in the next cavity is isolated; b. The position of the positioning bead is cooled and the temperature is measured until the position of the positioning bead reaches the predetermined temperature and enters the next process; c. Sandblasting, K-coating and rope preparation are performed on the beading in sequence; d. Tensioning is ready Wire saw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com