Preparation method of metal-clad S/Ni-Co-Mn-Li oxide electrode material

A nickel-cobalt-manganese-lithium, electrode material technology, applied in active material electrodes, positive electrodes, battery electrodes, etc., can solve the problems of restricting widespread use, reducing the tap density of sulfur electrode materials, and high prices, achieving convenient operation and beneficial to The effect of industrialized production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The composition of a metal-coated lithium sulfide / nickel-cobalt-manganese lithium oxide electrode material is designed as:

[0019] LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , 10wt%; Sulfur, 75wt%; Copper, mass fraction 15wt%;

[0020] A preparation method of a copper-coated sulfur / nickel-cobalt-manganese lithium oxide electrode material: comprising the following steps:

[0021] 1) Weigh sulfur, nickel-cobalt-manganese-lithium oxide according to a certain ratio; argon atmosphere, mechanical ball milling for 10 hours;

[0022] 2) Disperse the product of step 1 in a soluble cupric chloride solution and add surfactant, stir for 5h; then slowly add sodium hydroxide solution dropwise; stir for 2h; control the molar ratio of sodium hydroxide to cupric chloride at 2.1; filter and dry dry, and stand at 100°C for 10 hours to obtain copper oxide-coated sulfur / nickel-cobalt-manganese lithium oxide electrode materials;

[0023] 3) Heating the copper oxide-coated sulfur / nickel-cobalt-mangane...

Embodiment 2

[0026] The composition of a silver-coated lithium sulfide / nickel-cobalt-manganese lithium oxide electrode material is designed as:

[0027] LiNi 0.4 co 0.2 mn 0.4 o 2 , 15wt%; Sulfur, 70%; Silver, mass fraction 15wt%;

[0028] A preparation method of a silver-coated sulfur / nickel-cobalt-manganese lithium oxide electrode material: comprising the following steps:

[0029] 1) Weigh sulfur, nickel-cobalt-manganese-lithium oxide according to a certain ratio; in argon atmosphere, mechanically ball mill for 5 hours;

[0030] 2) Disperse the product of step 1 in a soluble silver nitrate solution and add a surfactant, stir for 10 h; then slowly add potassium hydroxide solution dropwise; stir for 5 h; control the molar ratio of potassium hydroxide to silver nitrate at 3; filter and dry, Stand still at 80°C for 10 hours to obtain a silver oxide-coated sulfur / nickel-cobalt-manganese lithium oxide electrode material;

[0031] 3) Heating the silver oxide-coated sulfur / nickel-cobalt-ma...

Embodiment 3

[0034] The composition of a tungsten-coated lithium sulfide / nickel-cobalt-manganese lithium oxide electrode material is designed as:

[0035] LiNi 05 co 0.2 mn 0.3 o 2 , 20wt%; Sulfur, 65%; Tungsten, mass fraction 15wt%;

[0036] A preparation method of a tungsten-coated sulfur / nickel-cobalt-manganese lithium oxide electrode material: comprising the following steps:

[0037] 1) Weigh sulfur, nickel-cobalt-manganese-lithium oxide according to a certain ratio; argon atmosphere, mechanical ball milling for 10 hours;

[0038] 2) Disperse the product of step 1 in soluble tungsten nitrate solution and add surfactant, stir for 5h; then slowly add sodium hydroxide solution dropwise; stir for 2h; control the molar ratio of sodium hydroxide to tungsten nitrate at 2.1; filter and dry, Stand at 100°C for 10 hours to obtain a sulfur / nickel cobalt manganese lithium oxide electrode material coated with tungsten oxide;

[0039] 3) Heat the tungsten oxide-coated sulfur / nickel-cobalt-mang...

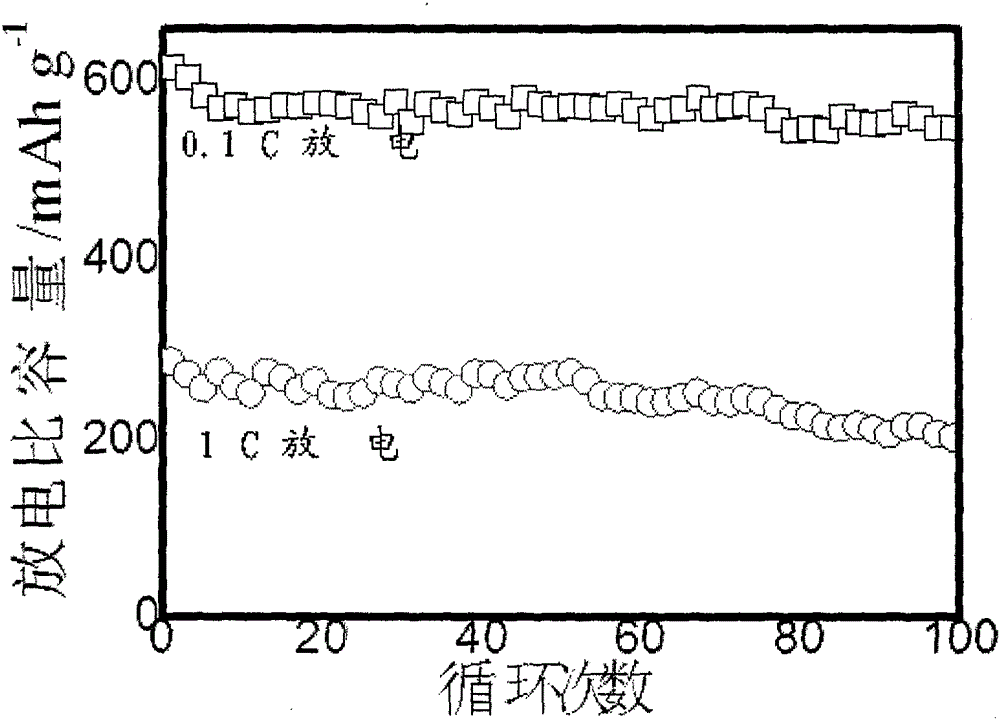

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com