High-nickel core-shell structure gradient nickel-cobalt-manganese ternary cathode material and preparation method thereof

A core-shell structure and cathode material technology, applied in the field of nickel-cobalt-manganese ternary cathode materials and their preparation, can solve the problems of unfavorable large-scale production, cumbersome synthesis process, poor rate and cycle performance of high-nickel ternary materials, etc. Guaranteed cycle and rate performance, simple process, and the effect of improving material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

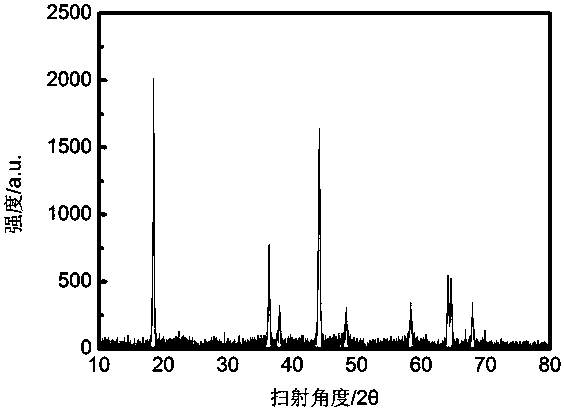

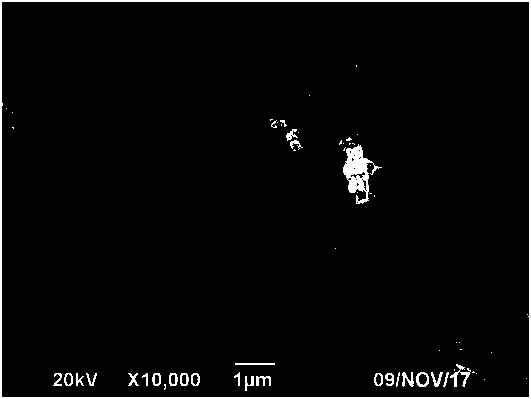

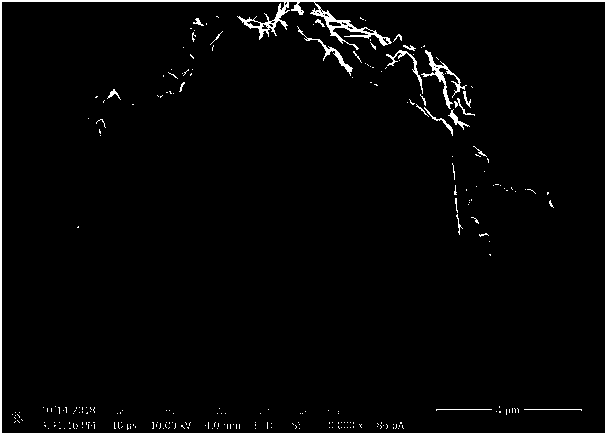

[0070] The chemical formula of the high-nickel core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material is: LiNi 0.78 co 0.11 mn 0.11 o 2 , is a core-shell structure particle with an average particle size of 8 μm composed of a high-nickel primary nucleus, a middle layer and a shell; the high-nickel primary nucleus is LiNi 0.9 co 0.1 o 2 , with an average diameter of 1.2 μm; the middle layer is nickel-cobalt-manganese lithium manganate obtained by mixing lithium after co-precipitation with nickel-cobalt-manganese sodium hydroxide precipitation agent, and the average thickness is 5.8 μm; the shell layer is nickel-cobalt-manganese sodium carbonate precipitation agent The nickel-cobalt lithium manganese oxide obtained by mixing lithium after co-precipitation has an average thickness of 1.0 μm; the nickel element is uniformly distributed in the high-nickel primary nucleus, and gradually decreases from the middle layer to the shell layer; the cob...

Embodiment 2

[0083] The chemical formula of the high-nickel core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material is: LiNi 0.75 co 0.11 mn 0.14 o 2 , is a core-shell structure particle with an average particle size of 7.5 μm composed of a high-nickel primary nucleus, a middle layer and a shell; the high-nickel primary nucleus is LiNi 0.9 co 0.1 o 2 , with an average diameter of 0.8 μm; the middle layer is nickel-cobalt-manganese lithium manganate obtained by mixing lithium after co-precipitation with nickel-cobalt-manganese sodium hydroxide precipitation agent, with an average thickness of 5.2 μm; the shell layer is nickel-cobalt-manganese sodium carbonate precipitation agent The nickel-cobalt lithium manganese oxide obtained by mixing lithium after co-precipitation has an average thickness of 1.5 μm; the nickel element is evenly distributed in the high-nickel primary nucleus, and gradually decreases from the middle layer to the shell layer; the coba...

Embodiment 3

[0096] The chemical formula of the high-nickel core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material is: LiNi 0.79 co 0.11 mn 0.1 o 2 , is a core-shell structure particle with an average particle size of 7.5 μm composed of a high-nickel primary nucleus, a middle layer and a shell; the high-nickel primary nucleus is LiNi 0.9 co 0.1 o 2, with an average diameter of 0.7 μm; the middle layer is nickel-cobalt-manganese lithium manganate obtained by mixing lithium after co-precipitation with nickel-cobalt-manganese potassium hydroxide precipitation agent, with an average thickness of 5.5 μm; the shell layer is nickel-cobalt-manganese potassium carbonate precipitation agent The nickel-cobalt lithium manganese oxide obtained by mixing lithium after co-precipitation has an average thickness of 1.3 μm; the nickel element is uniformly distributed in the high-nickel primary nucleus, and gradually decreases from the middle layer to the shell layer; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com