Method for producing lithium manganate

A technology for the production of lithium manganate and lithium carbonate, applied in the directions of manganate/permanganate, electrical components, battery electrodes, etc. Problems such as poor thermal conductivity, to achieve the effect of ensuring rate performance and cyclability, easy firing, and increased contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of method of producing lithium manganate of the present invention comprises the following steps:

[0034] (a) Mixing of raw materials: Take 174 kg of electrolytic manganese dioxide with an average particle size of 6 microns and 40 kg of lithium carbonate, mix them by dry method, and add 0.214 kg of diboron trioxide as a sintering aid; that is, the electrolytic manganese dioxide With Lithium Retard, be 2:1.08 with the mol ratio of Mn:Li, the consumption of described diboron trioxide is 0.1% by weight percentage, carries out proportioning mixing, obtains the fully mixed raw material;

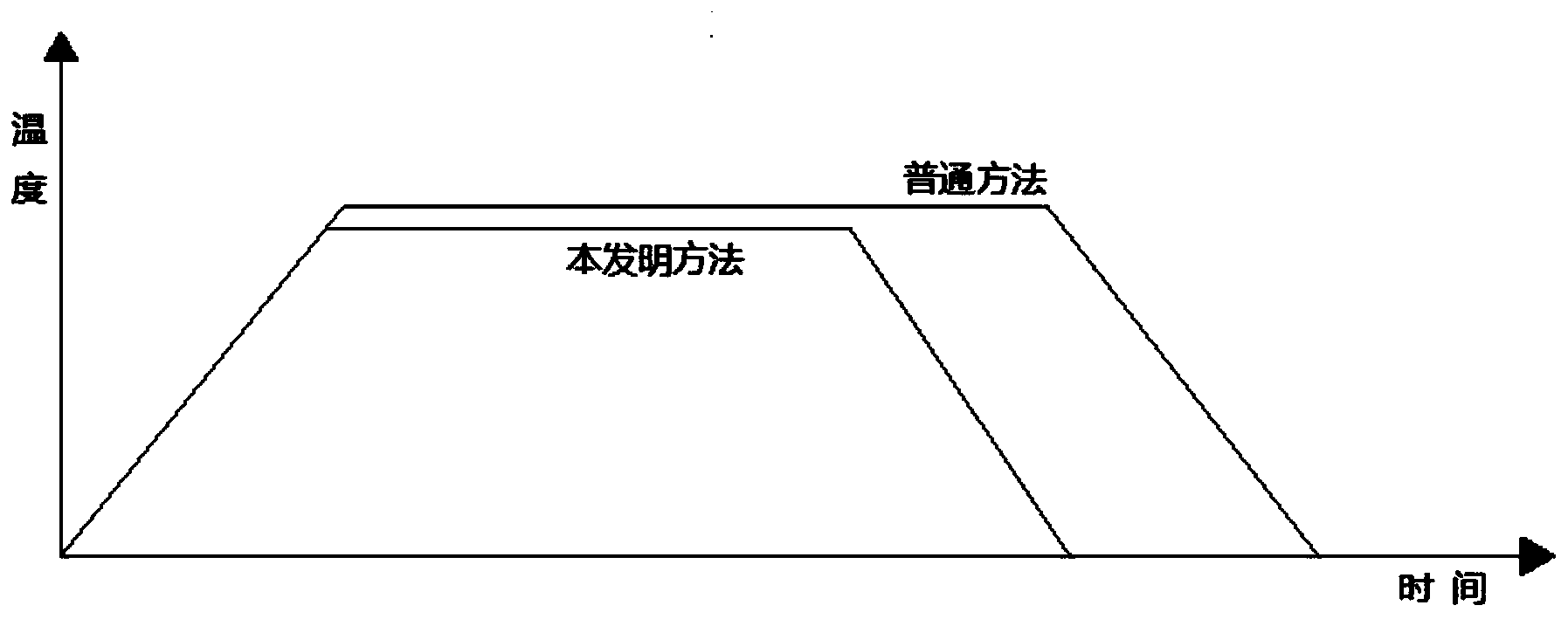

[0035] (b) Pre-burning: heat the mixed raw materials to 550°C and keep it warm for 2 hours;

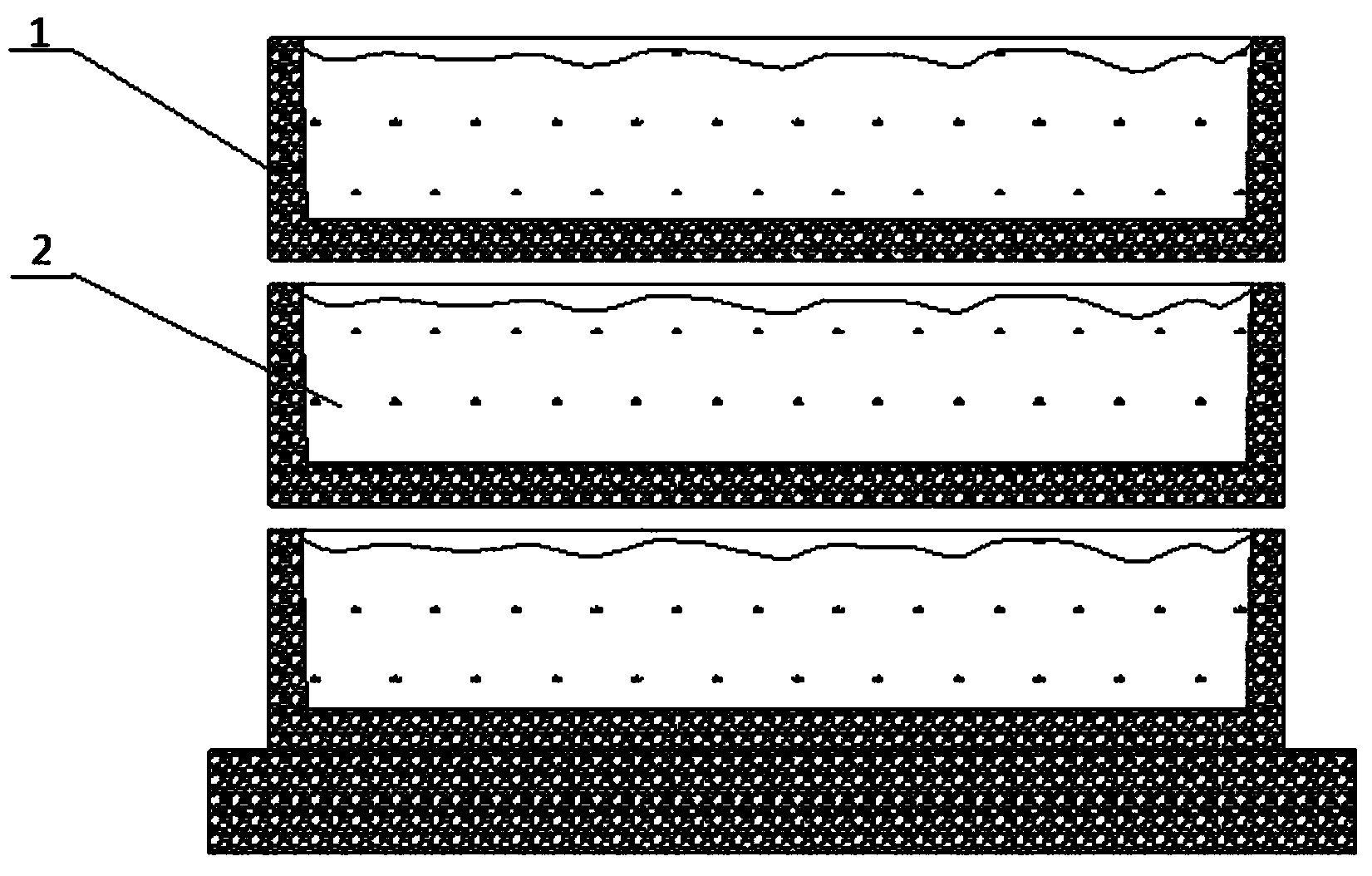

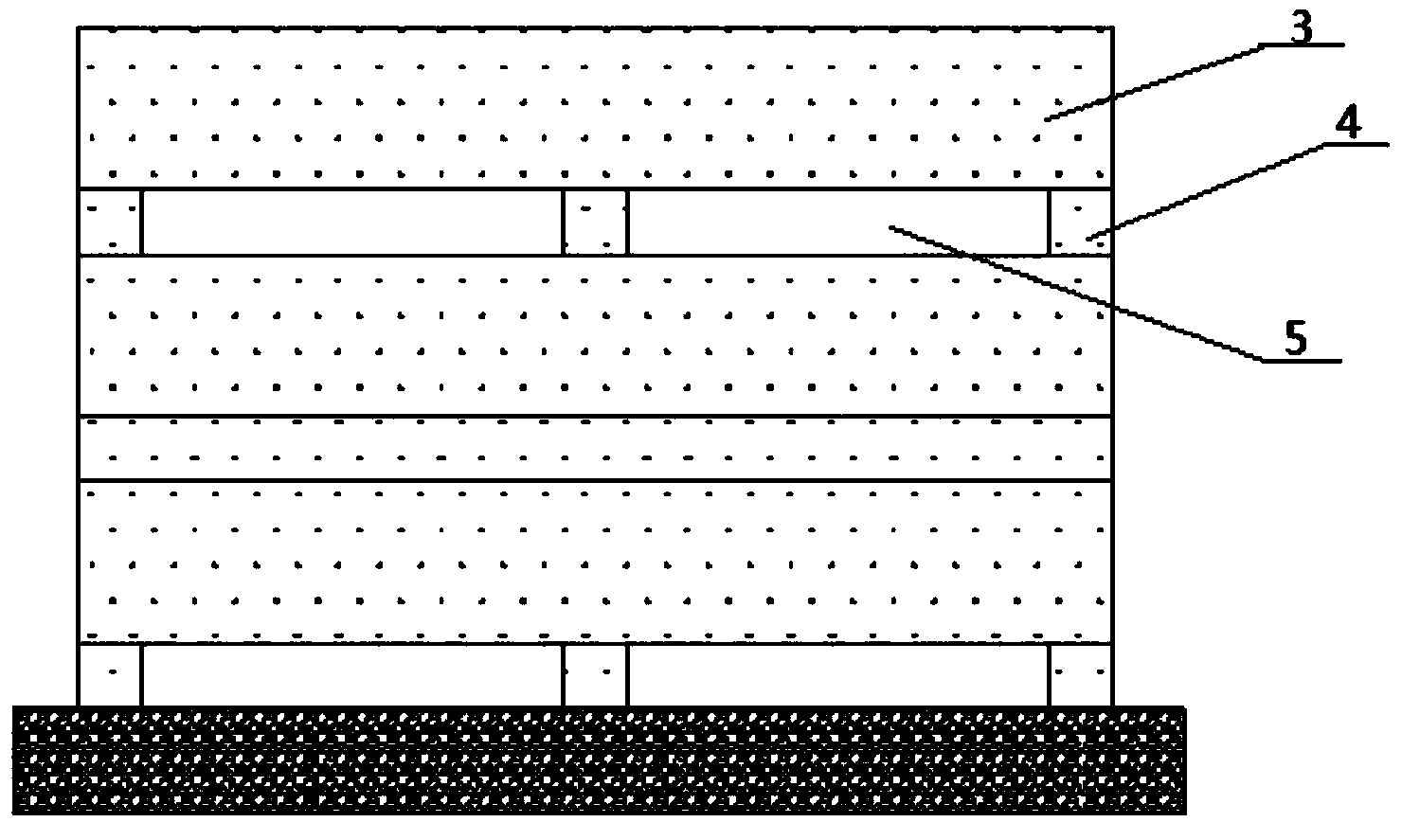

[0036] (c) Briquetting treatment: add an aqueous solution of polyvinyl alcohol as an adhesive to the above-mentioned pre-calcined material, the amount of the adhesive added is 2% by mass percentage, and the concentration is 0.2% by mass fraction, and then mixed with The material of the adhe...

Embodiment 2

[0040] A kind of method of producing lithium manganate of the present invention comprises the following steps:

[0041] (a) Mixing of raw materials: 174 kg of electrolytic manganese dioxide with an average particle size of 10 microns and 63.7 kg of lithium hydroxide were mixed by dry method, and 0.238 kg of boron trioxide was added as a sintering aid; Manganese oxide and lithium hydroxide, with the molar ratio of Mn:Li being 2:1.08, the consumption of the described diboron trioxide is 0.1% by weight percentage, carry out proportioning mixing, obtain the raw material that fully mixes;

[0042] (b) Pre-burning: heat the mixed raw materials to 600°C and keep it warm for 2 hours;

[0043] (c) Briquetting treatment: adding an aqueous solution of polyvinyl alcohol as an adhesive to the above-mentioned calcined material, the amount of the adhesive added is 5% by mass percentage, and the concentration is 0.5% by mass fraction, and then mixed with The material of the adhesive is press...

Embodiment 3

[0047] A kind of method of producing lithium manganate of the present invention comprises the following steps:

[0048](a) Mixing of raw materials: Take 174kg of electrolytic manganese dioxide and 103.7kg of lithium oxalate with an average particle size of 16 microns, mix them by dry method, and add 0.278kg of diboron trioxide as a sintering aid; that is, the electrolytic dioxide Manganese and lithium oxalate are 2:1.08 with the molar ratio of Mn:Li, and the consumption of described diboron trioxide is 0.1% by weight percentage, carries out proportioning mixing, obtains the fully mixed raw material;

[0049] (b) Pre-burning: heat the mixed raw materials to 650°C and keep it warm for 2 hours;

[0050] (c) Briquetting treatment: adding an aqueous solution of polyvinyl alcohol as an adhesive to the above-mentioned calcined material, the amount of the adhesive added is 5% by mass percentage, and the concentration is 0.5% by mass fraction, and then mixed with The material of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com