Method for preparing three-dimensional ordered porous material

A porous material, three-dimensional ordered technology, applied in the field of material preparation, can solve the problems of limited application, low energy density, etc., and achieve the effect of guaranteed rate performance, good application prospects, and adjustable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

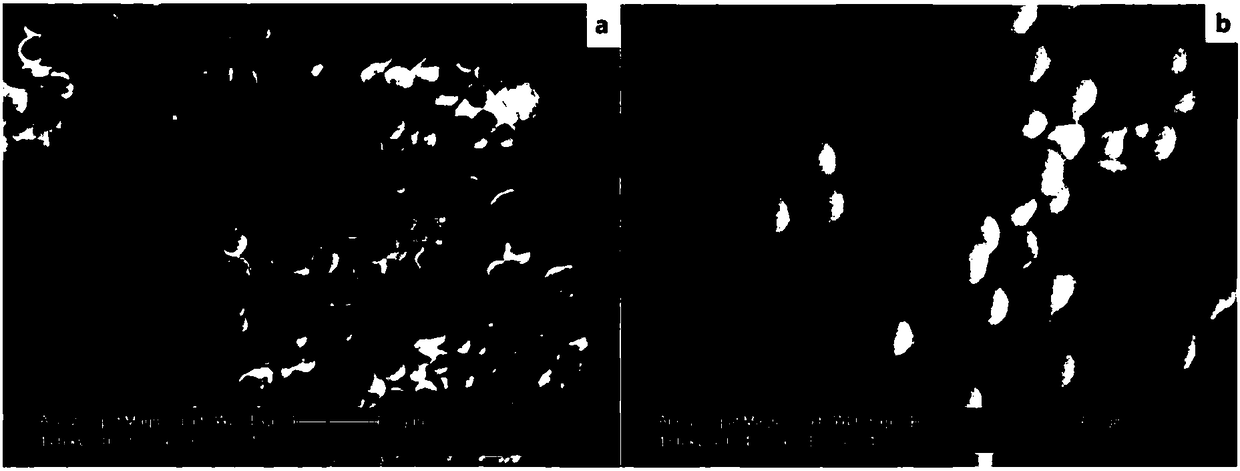

Image

Examples

Embodiment 1

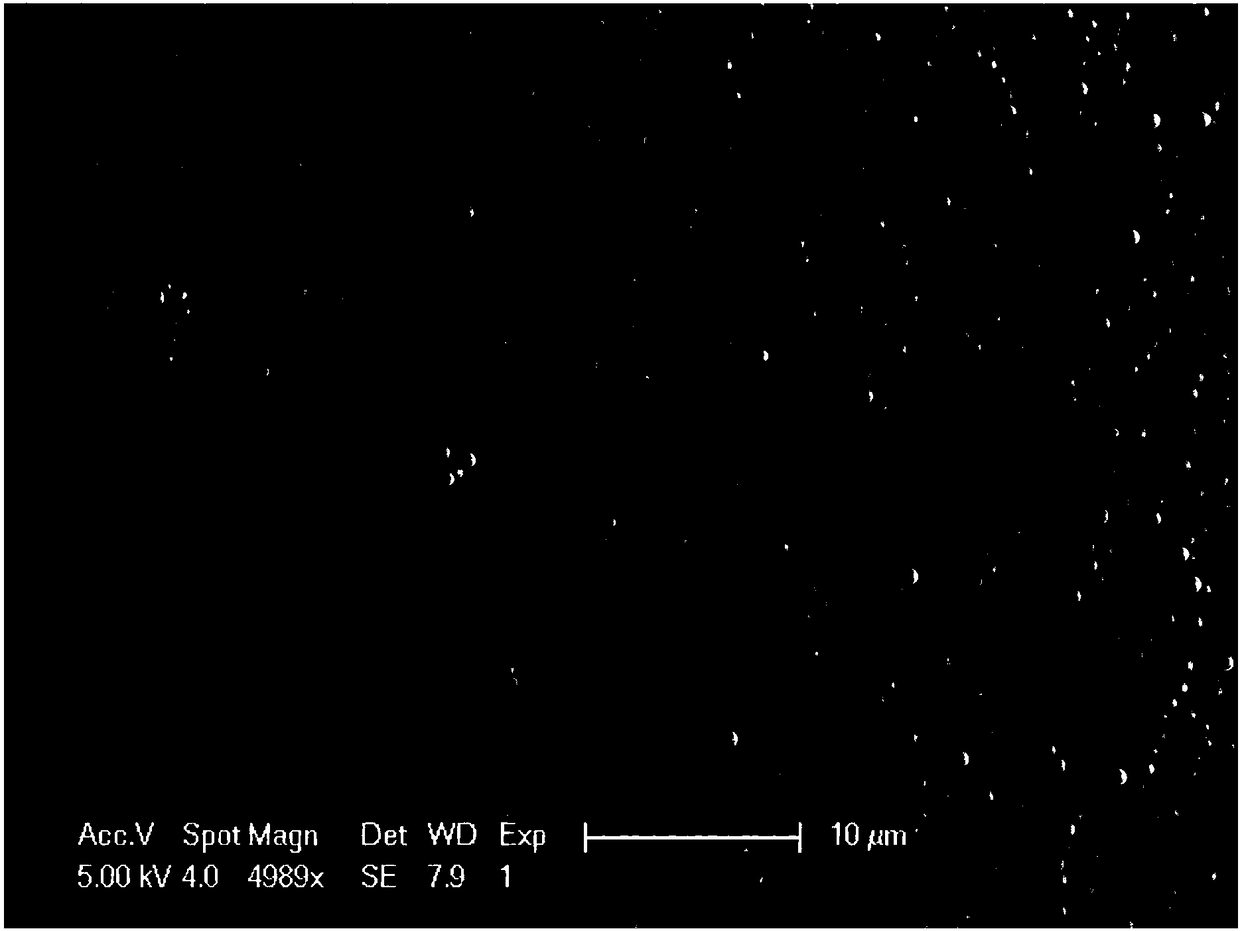

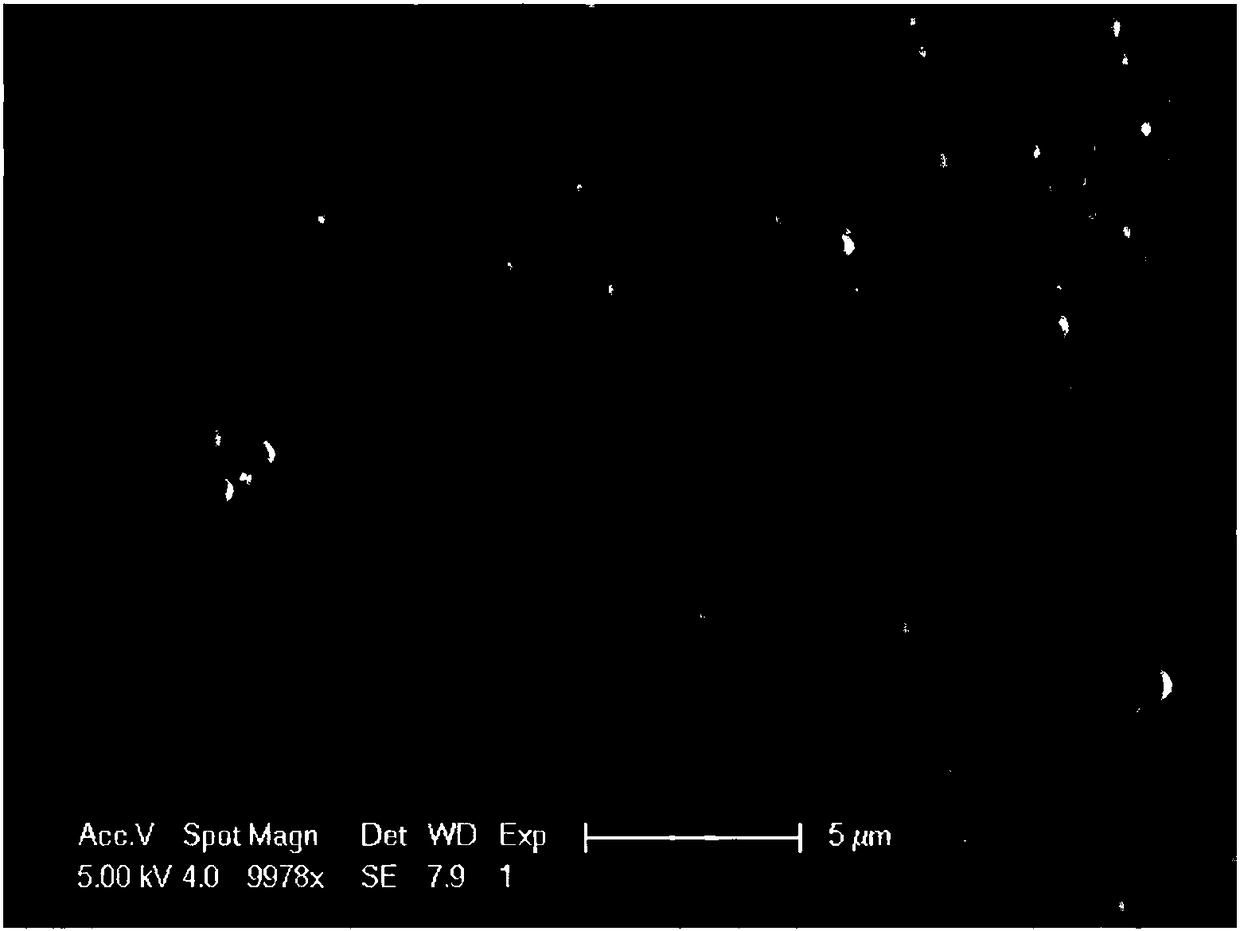

[0069] Monodisperse polystyrene microspheres were synthesized by soap-free emulsion polymerization. Styrene was purified by vacuum distillation before use. Add 150ml of deionized water, 0.175g of sodium chloride, and 25g of styrene monomer into a 250ml three-neck flask, stir in a water bath at 70°C, and add nitrogen to the flask after 20 minutes. 0.2g of potassium persulfate was polymerized at a constant temperature of 70°C for 20h under the protection of nitrogen. After the reaction, the obtained emulsion was repeatedly centrifuged and washed with ethanol and deionized water to remove salts and monomers, and finally prepared into a polystyrene microsphere emulsion with a mass fraction of 1% for future use. The prepared emulsion was ultrasonicated with an ultrasonic cell pulverizer for 1 h before use. The copper sheet was cut into a pole piece with a diameter of 14 mm (thickness 0.2 mm), and ultrasonically used for 15 min with acetone, ethanol, and deionized water respectively...

Embodiment 2

[0072] The carbon cloth is cut into a pole piece (thickness is 1 mm) with a diameter of 14 mm, ultrasonicated with acetone, ethanol, and isopropanol for 20 min respectively, and the treated carbon cloth is clamped with tweezers and immersed in the polystyrene microsphere emulsion prepared in Example 1 30S and dry at room temperature, and repeat this process until the required number of assembled layers (2 layers), the number of assembled layers of microspheres depends on the number of times the carbon cloth is immersed in the emulsion.

[0073] Add 1ml of titanium tetrachloride dropwise to 50ml of absolute ethanol to make a titanium tetrachloride solution, take 15μl of the titanium tetrachloride solution and drop it on the above carbon cloth, place it at room temperature for 6h, and then sinter the above sample (300 DEG C for 2 hours, 450 DEG C for 2 hours, and a heating rate of 1 DEG C / min), so that a titanium dioxide inverse opal structure is produced on the carbon cloth, tha...

Embodiment 3

[0076] Using the method of dispersion polymerization, add 15ml of purified styrene monomer and 0.27g of initiator azobisisobutylcyanide into a 250ml three-necked flask, turn on the water bath to heat, set the temperature at 75°C, and Add 120ml of methanol and 30ml of deionized water to the flask, stir evenly, add 0.3g of stabilizer methyl acyloxyethyltrimethylammonium chloride to the flask, and stabilize the rotation speed at 300rpm, and heat in a water bath for 8h. The obtained emulsion was centrifuged and washed 3 times with ethanol and deionized water to form a microsphere emulsion with a mass fraction of 2%. The prepared emulsion was sonicated with an ultrasonic cleaner for 2 h before use.

[0077] A 4cm×4cm copper sheet (thickness 0.2mm) was sonicated in a mixed solvent of deionized water, acetone, ethanol and water for 15min, then briefly cleaned in 4M hydrochloric acid solution for 20s and dried under argon atmosphere. Take a 100ml beaker, add 50ml of the polystyrene m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com