Preparation method of thick electrode with excellent electrochemical performance and lithium ion battery

An electrode and positive electrode technology, applied in the field of high energy density lithium-ion batteries, can solve the problems of uneven conductivity of electrode sheets, poor long-term cycle performance and rate performance of batteries, and poor electrolyte infiltration, etc., to reduce surface tension, improve Rate performance and long cycle performance, the effect of enhancing absorption and retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

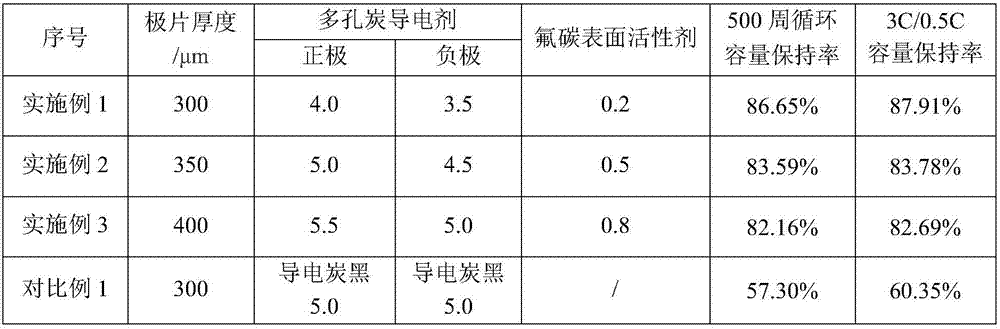

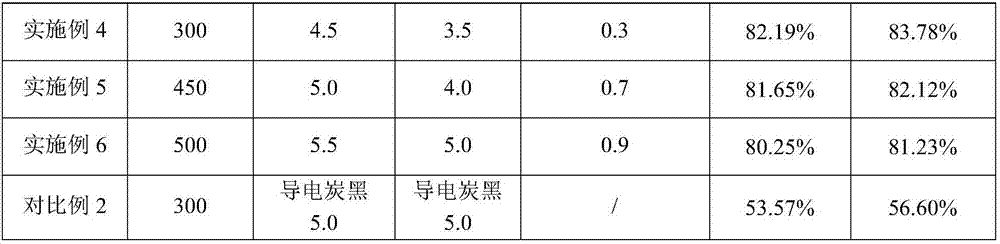

Embodiment 1

[0026] Production of positive thick pole piece:

[0027] a. The cathode active material LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 , porous carbon conductive agent (Heraeus Lion), positive electrode binder PVDF in a weight ratio of 93:4:3, mixed and stirred evenly to obtain positive electrode powder;

[0028] b. Add fluorocarbon surfactant (Shanghai Huiping New Energy Co., Ltd. WA1600) to N-methyl-2-pyrrolidone solution and mix evenly, wherein fluorocarbon surfactant: N-methyl-2-pyrrolidone: positive electrode powder =0.2:85:100 (weight ratio), add to the above positive electrode powder, stir for 1 to 5 hours to obtain positive electrode slurry;

[0029] c. Coating the positive electrode slurry on the aluminum foil current collector, the coating thickness is 300 μm, and drying to obtain the positive electrode sheet;

[0030] d. The pole piece is rolled and then divided into strips to obtain a positive thick pole piece with an overall thickness of about 300 μm.

[0031] Production of n...

Embodiment 2

[0040] Production of positive thick pole piece:

[0041] a. The positive electrode active material NMC (111), porous carbon conductive agent (Heraeus Lion), positive electrode binder PVDF in a weight ratio of 92:5:3, mixed and stirred evenly to obtain positive electrode powder;

[0042] b. Add fluorocarbon surfactant (Shanghai Huiping New Energy Co., Ltd. WA1600) to N-methyl-2-pyrrolidone solution and mix evenly, wherein fluorocarbon surfactant: N-methyl-2-pyrrolidone: positive electrode powder =0.5:85:100 (weight ratio), add to the above positive electrode powder, stir for 1 to 5 hours to obtain positive electrode slurry;

[0043] c. Coating the positive electrode slurry on the aluminum foil current collector, the coating thickness is 350 μm, and drying to obtain the positive electrode sheet;

[0044] d. The pole piece is rolled and divided into strips to obtain a positive thick pole piece with an overall thickness of about 350 μm.

[0045] Production of negative thick pol...

Embodiment 3

[0054] Production of positive thick pole piece:

[0055] a. The positive electrode active material NMC (111), porous carbon conductive agent (Heraeus Lion), positive electrode binder PVDF in a weight ratio of 91.5:5.5:3, mixed and stirred evenly to obtain positive electrode powder;

[0056] b. Add fluorocarbon surfactant (Shanghai Huiping New Energy Co., Ltd. WA1600) to N-methyl-2-pyrrolidone solution and mix evenly, wherein fluorocarbon surfactant: N-methyl-2-pyrrolidone: positive electrode powder =0.8:85:100 (weight ratio), add to the above positive electrode powder, stir for 1 to 5 hours to obtain positive electrode slurry;

[0057] c. Coating the positive electrode slurry on the aluminum foil current collector, the coating thickness is 400 μm, and drying to obtain the positive electrode sheet;

[0058] d. The pole piece is rolled and then divided into strips to obtain a positive thick pole piece with an overall thickness of about 400 μm.

[0059] Production of negative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com