Manufacturing method of field-effect regulated supercapacitor

A supercapacitor and field effect technology, applied in the field of capacitors, can solve the problems of high manufacturing cost, complex manufacturing process, and poor method universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation process of the field effect regulation supercapacitor of the present invention:

[0021] Deposit a layer of dielectric layer material on the substrate; disperse the electrode material on the dielectric layer material; coat the resist on the dielectric layer and channel to prepare a source, drain and capacitor electrode; coating photoresist on the source electrode and the drain electrode; encapsulating with polydimethylsiloxane as a whole, injecting electrolyte solution, and obtaining a field effect control supercapacitor.

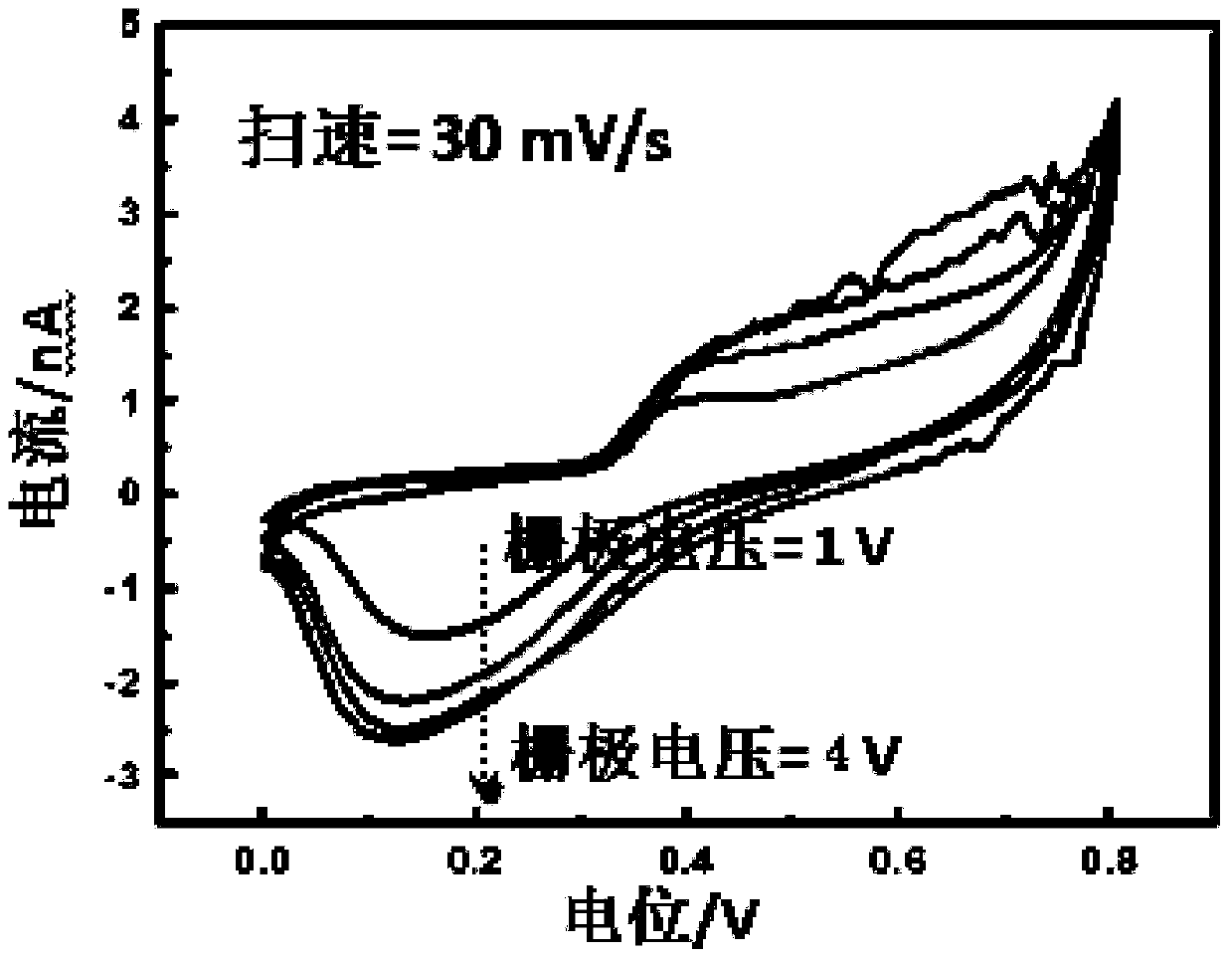

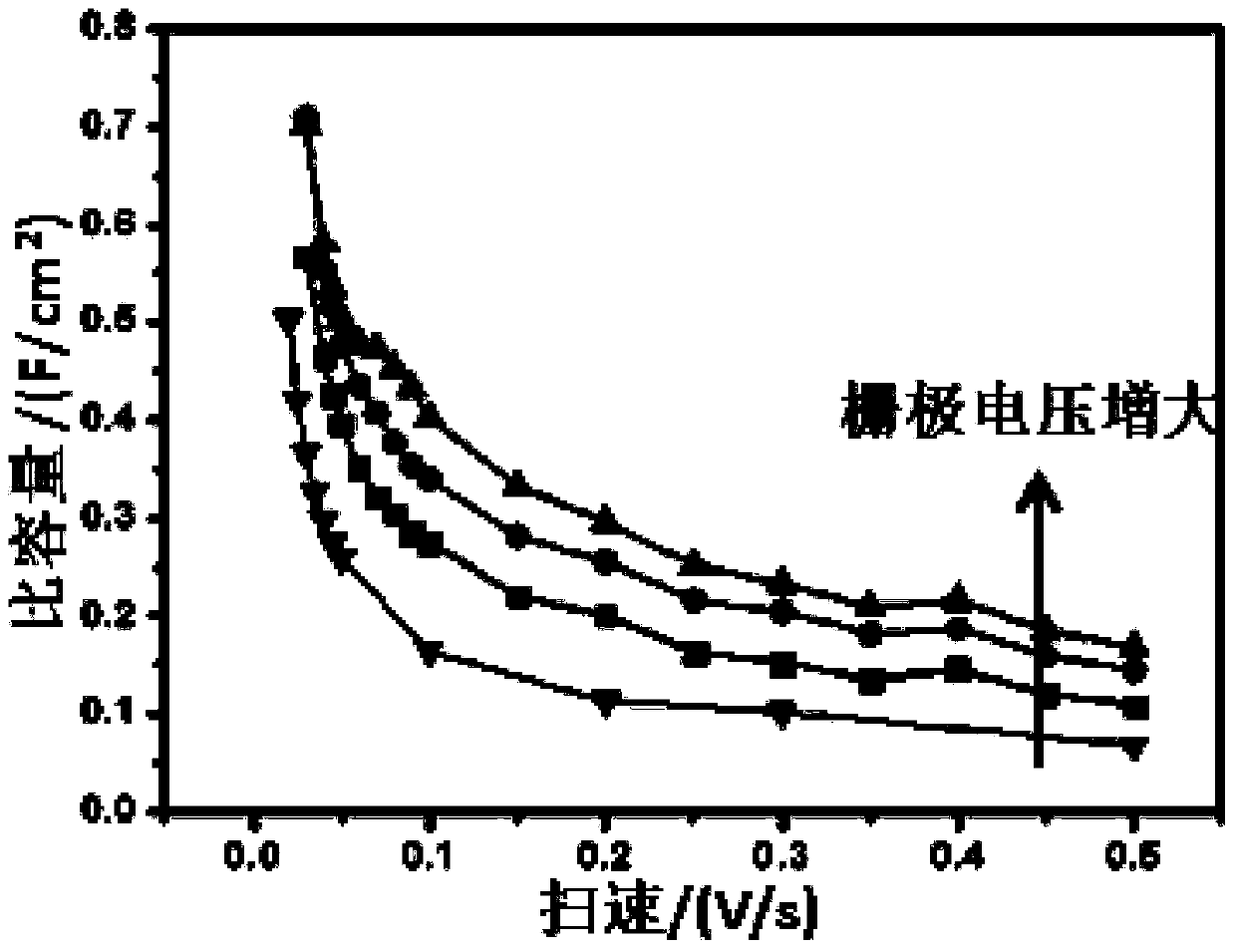

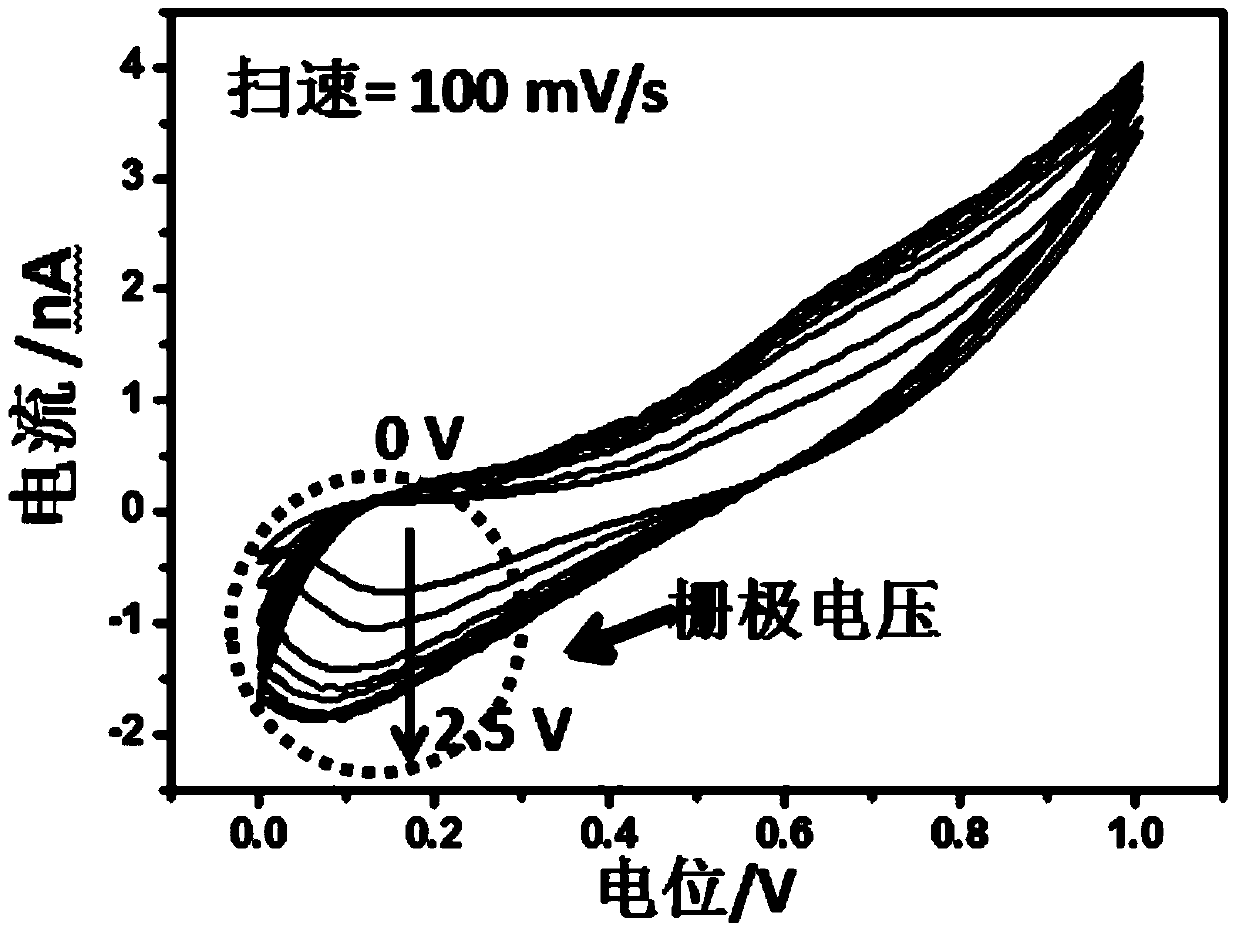

[0022] The energy storage device is optimized by changing the carrier distribution and conductivity of the material itself through the external field effect. Under the regulation of the gate electric field, the capacity of the supercapacitor is increased by an average of 3 to 5 times, and the original capacity is maintained. rate performance.

Embodiment 1

[0024] 1) Select a silicon substrate with a 300nm thermal oxide layer, cut the silicon substrate into an appropriate size, then ultrasonically clean the silicon substrate with isopropanol (IPA) for about 30 seconds, and dry it with nitrogen.

[0025] 2) Use a spin coater to spin coat a layer of MMA on the substrate, the spin coating speed is 4000rpm, the spin coating time is 90s, use a hot plate to bake, 180°C, 5min; then spin coat a layer of PMMA on the substrate, The rotational speed of the spin coating is 4000rpm, the spin coating time is 90s, and a hot plate is used for baking at 180°C for 5min.

[0026] 3) Etch the pattern of external electrodes and marks on the spin-coated silicon wafer using an electron beam exposure machine (EBL), with an exposure dose of 380 μC / cm 2 , the electron beam accelerating voltage is 30kV, and the electron beam current is 400pA.

[0027] 4) Developing: soak the substrate after electron beam exposure in methyl isobutyl ketone (MIBK) solution ...

Embodiment 2

[0047] Preparation process of field-effect regulated supercapacitor nanodevices:

[0048] Select a silicon substrate and use ALD to deposit Al with a thickness of 80nm 2 o 3 , as a dielectric layer.

[0049] Use a spin coater to spin-coat a layer of MMA on the substrate, the spin-coating speed is 4000rpm, the spin-coating time is 90s, use a hot plate to bake, 180°C, 5min; then spin-coat a layer of PMMA on the substrate, spin-coat The rotating speed is 4000rpm, the spin-coating time is 90s, and baked on a hot plate at 180°C for 5min.

[0050] Use electron beam exposure machine (EBL) to etch the pattern of external electrodes and marks on the spin-coated silicon wafer, the exposure dose is 380μC / cm 2 , the electron beam accelerating voltage is 30kV, and the electron beam current is 400pA.

[0051] Developing: soak the substrate after electron beam exposure in methyl isobutyl ketone (MIBK) solution for 1 min, then in isopropanol for 30 s, and blow dry with nitrogen.

[0052] P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com