Electrolyte for over 4.2V high-voltage system battery

An electrolyte and high voltage technology, applied in electrolytes, secondary batteries, organic electrolytes, etc., can solve problems such as unsatisfactory battery rate performance, low conductivity, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

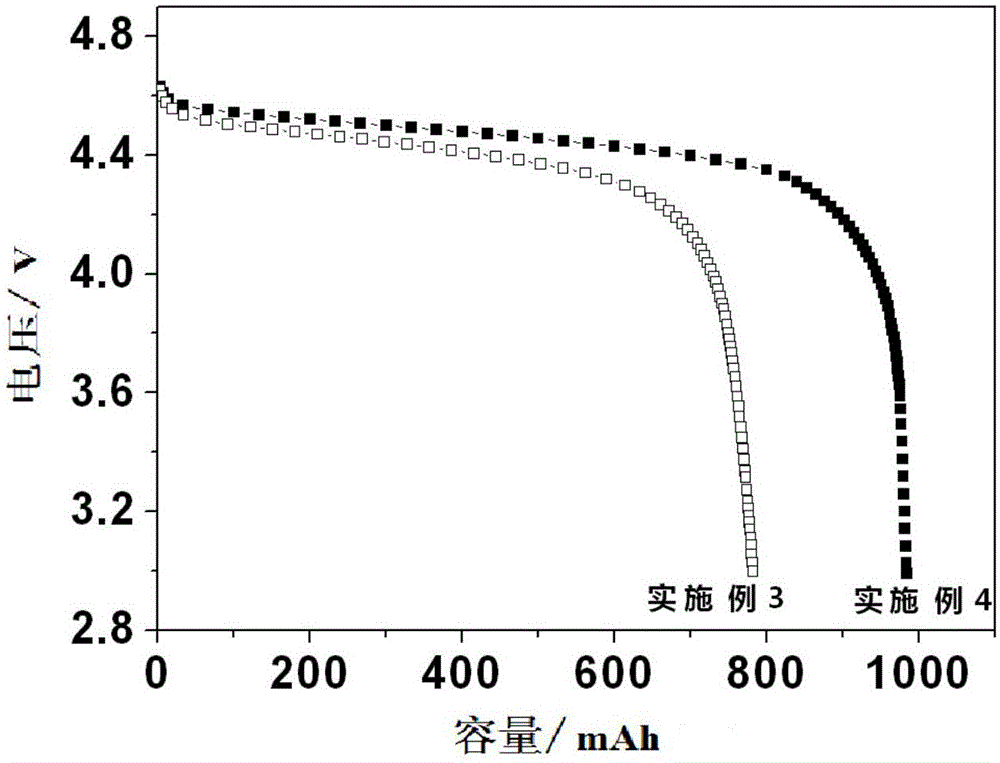

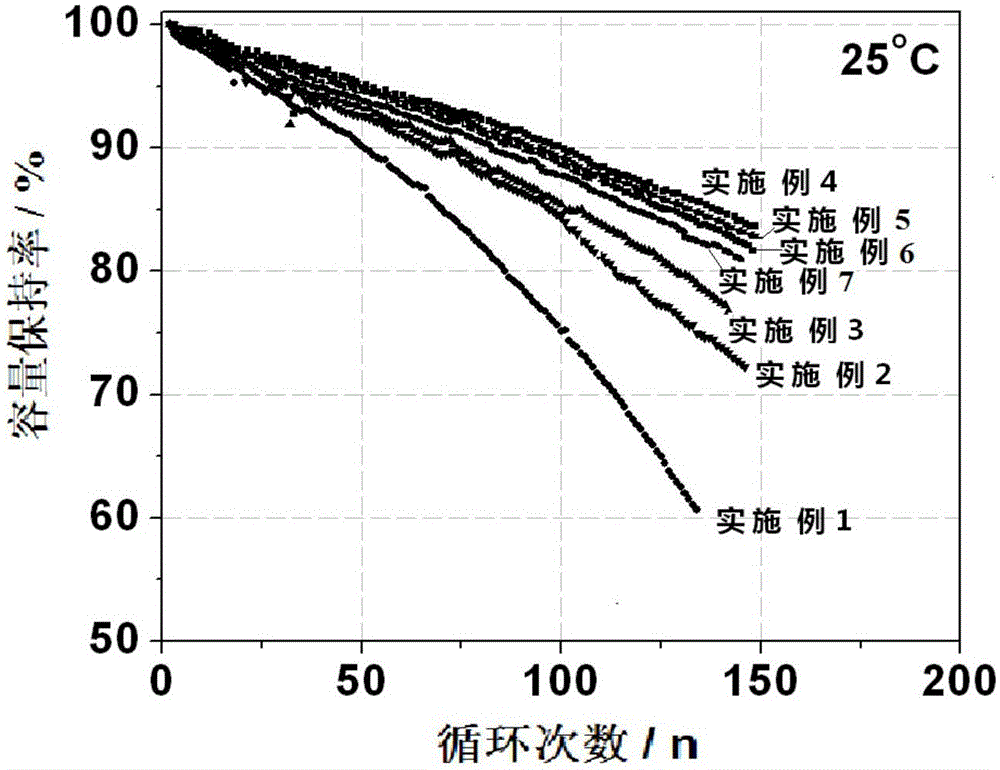

[0017] The present invention will be further described below in conjunction with the examples, and the implementation of the present invention includes but not limited to the following examples of implementation. Some substances in the examples are represented by the abbreviations in brackets after the substance in the summary of the invention.

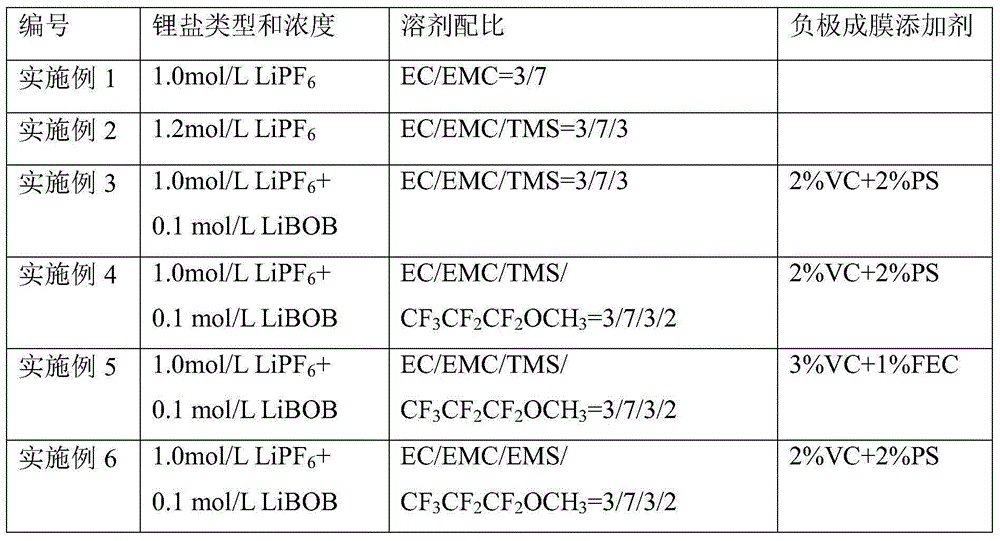

[0018] The preparation of the electrolyte is carried out in a dry room at 20°C and a dew point of -50°C. The preparation process is as follows: First, mix the solvents (non-aqueous organic solvents, sulfone solvents and fluoroether solvents) in proportion, and after fully stirring, add lithium salt according to the designed formula ratio, and after fully stirring and mixing, add film-forming Additives, stir and mix again to obtain the required electrolyte. The proportioning of concrete comparative example and embodiment is shown in Table 1:

[0019] Table 1 The formula table of the electrolyte comparison sample and the implementatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com