Lithium-sulfur battery separator membrane as well as preparation method and application thereof

A lithium-sulfur battery and diaphragm technology, applied in the field of lithium-sulfur battery diaphragm and its preparation, can solve the problems of the electronic conductivity and capacity retention of the diaphragm that need to be further improved, and achieve the goals of suppressing the shuttle effect, good rate performance, and improving conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the above-mentioned lithium-sulfur battery diaphragm of the present invention comprises the following steps:

[0043] Step 1. Disperse the conductive carbon material and dispersant in the solvent, and ultrasonically treat it for 1-2 hours to obtain a conductive carbon material dispersion. The concentration of the dispersion, that is, the mass percentage of the conductive carbon material in the dispersion is 5‰-5%. The amount of dispersant added is 0.1-5% of the weight of the conductive carbon material;

[0044] Step 2. Disperse the nanocellulose and dispersant in the solvent, and mechanically stir for 1.5-2.5 hours to obtain a nanocellulose dispersion. The concentration of the dispersion, that is, the mass percentage of the nanocellulose in the dispersion is 4%-10%. , the amount of dispersant added is 0.1-5% of the mass of nanocellulose;

[0045] Step 3, disperse the sulfide and dispersant in the solvent, mechanically stir (rotating speed is c...

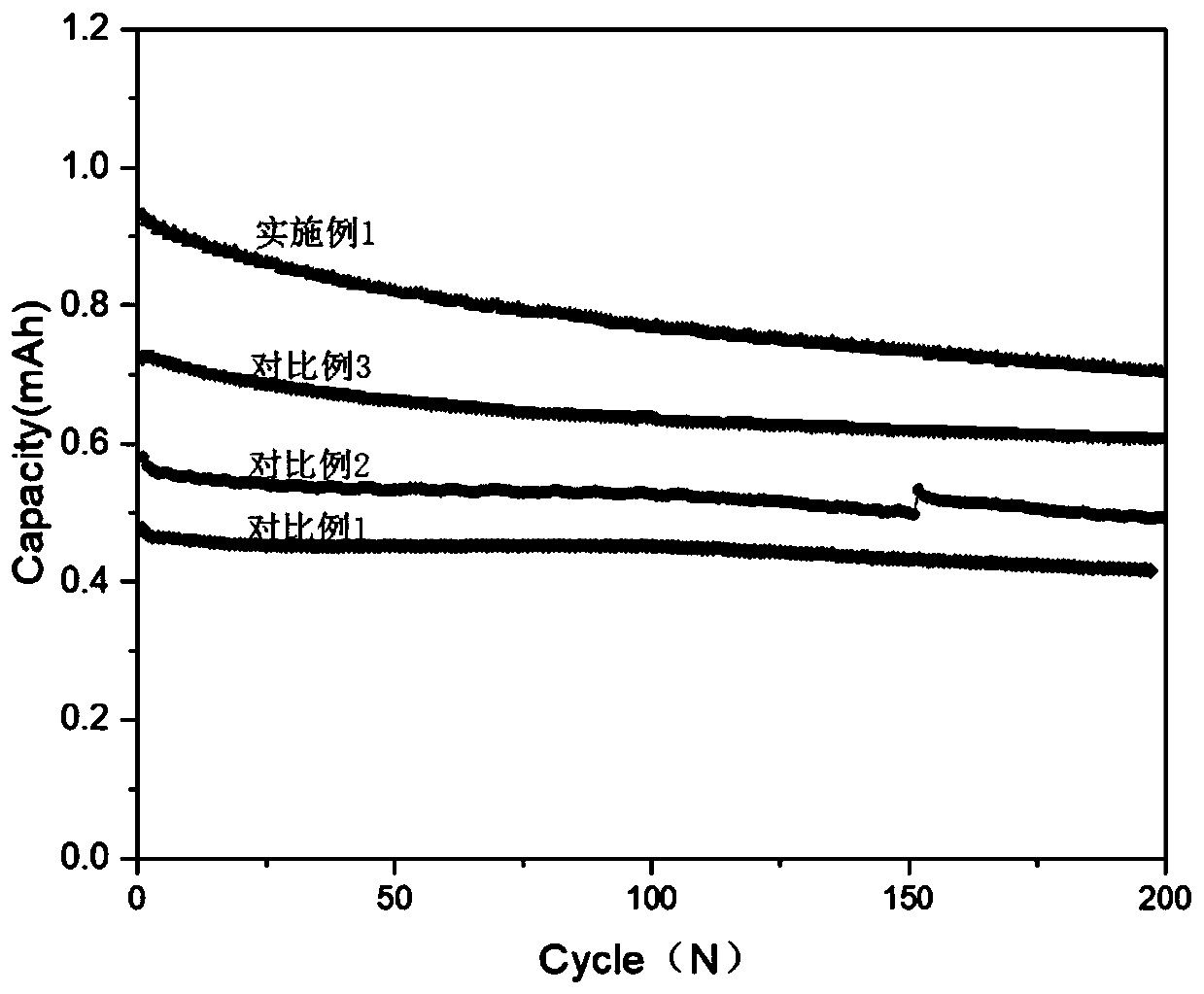

Embodiment 1

[0050] A separator for a lithium-sulfur battery in this embodiment includes a separator base film and a functional layer coated on both sides of the base film, the components of the functional layer include functional materials and additives, and the functional material includes a layered structure Sulfides, conductive carbon materials, and nanocellulose. Specifically, the layered structure sulfide of this embodiment is molybdenum disulfide (MoS 2 ), its addition is 20% of the total weight of the functional structural layer (slurry); the conductive carbon material is conductive graphene, and its addition is 5% of the functional structural layer gross weight; nanocellulose is carboxymethyl nanocellulose , and its added amount is 8% of the total weight of the functional structure layer.

[0051] The additives in this embodiment include dispersants, binders, surfactants and lithium ion additives, wherein the dispersant is polyvinylpyrrolidone, and its added amount is 10% of the ...

Embodiment 2

[0069] A separator for a lithium-sulfur battery in this embodiment includes a separator base film and a functional layer coated on both sides of the base film, the components of the functional layer include functional materials and additives, and the functional material includes a layered structure Sulfides, conductive carbon materials, and nanocellulose. Specifically, the layered structure sulfide of this embodiment is molybdenum disulfide (MoS 2 ), its addition is 35% of the total weight of the functional structure layer; the conductive carbon material is conductive carbon black, and its addition is 5% of the total weight of the functional structure layer; nanocellulose is nano ceramic fiber, and its addition is the functional structure 5% of the total layer weight.

[0070] The additives in this embodiment include dispersants, binders, surfactants and lithium ion additives, wherein the dispersants are alkyl sulfonates, and the added amount is 5% of the total weight of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com