Modifying diaphragm for lithium-sulfur battery and preparation method thereof

A technology for lithium-sulfur batteries and diaphragms, which is applied in the field of modified diaphragms for lithium-sulfur batteries and its preparation. It can solve the problems of reducing the coulomb rate of lithium-sulfur batteries, reducing the utilization rate of active materials, and the capacity decay of lithium-sulfur batteries. Conductivity, improvement of electrochemical performance, effect of preventing dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) NH 2 -MIL-101(Al) was put into a tube furnace, and under the protection of nitrogen, the temperature was raised to 900°C at 10°C / min and kept for 5 hours. That is, NH carbonized at 900°C 2 -MIL-101(Al), marked NH 2 -MIL-101(Al)-900.

[0028] (2) NH 2 -MIL-101(Al)-900 and PVDF at a ratio of 9:1 and N-methylpyrrolidone are added to mix uniformly to obtain coating slurry; evenly coat the slurry on the surface of Celgard2400 diaphragm, and dry it in vacuum at 60°C for 12 hours. Modified septum, labeled NH 2 - MIL-101(Al)-900 modified diaphragm.

[0029] (3) Sulfur and carbon black are mixed and ball-milled at a mass ratio of 7:3, and the sulfur / carbon black after ball milling is placed in a tube furnace at 155° C. for 12 hours under a nitrogen atmosphere, and the above-mentioned sulfur / carbon black composite material is bonded with Add N-methylpyrrolidone at a mass ratio of 9:1 and mix evenly to obtain a coating slurry; coat the slurry evenly on the surface of alu...

Embodiment 2

[0032] NH in embodiment 1 (2) 2 -MIL-101(Al)-900 changed to NH 2 -MIL-101 (Al), the NH in the step (4) of embodiment 1 2 -MIL-101(Al)-900 modified diaphragm changed to NH2 -MIL-101 (Al) modified diaphragm, the others are the same as in Example 1.

Embodiment 3

[0034] With the NH in the step (4) of embodiment 1 2 -MIL-101 (Al)-900 modified diaphragm was changed to original diaphragm, and the others were the same as in Example 1.

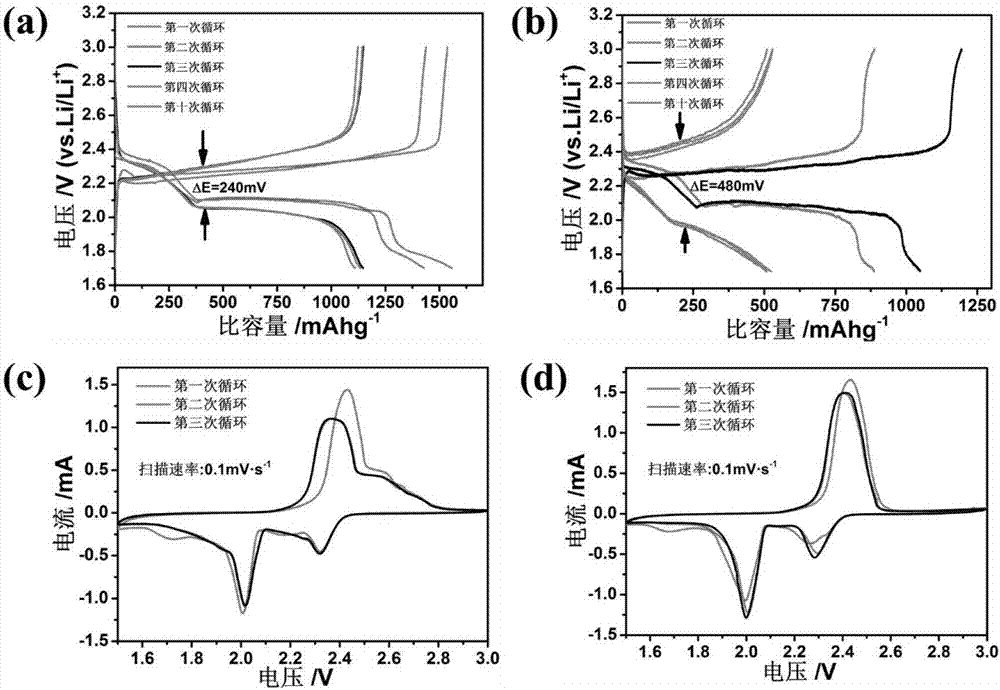

[0035] results and analysis

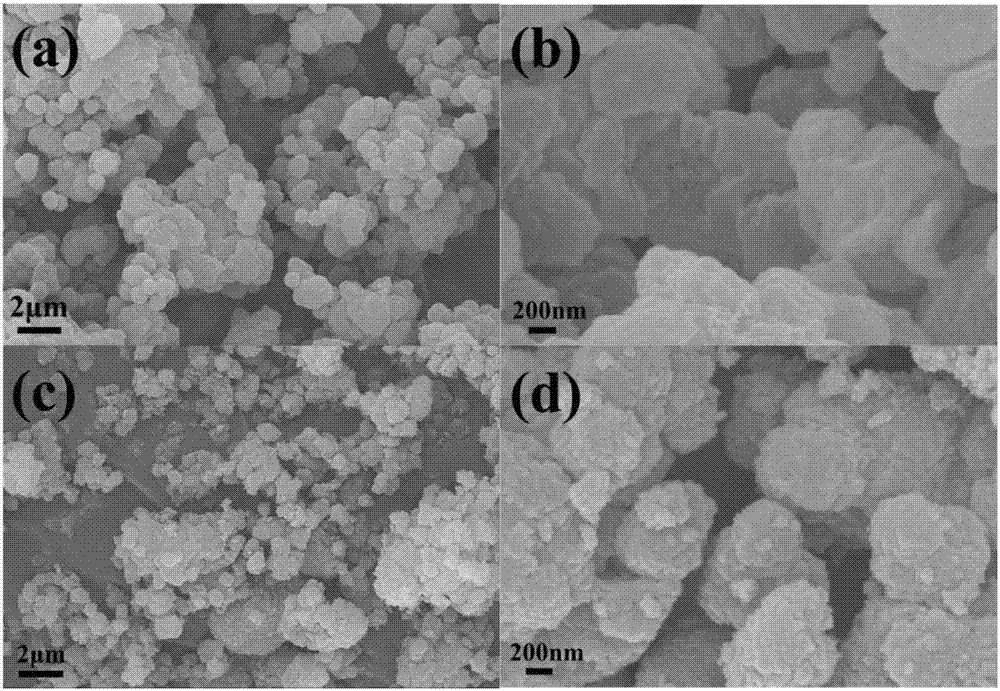

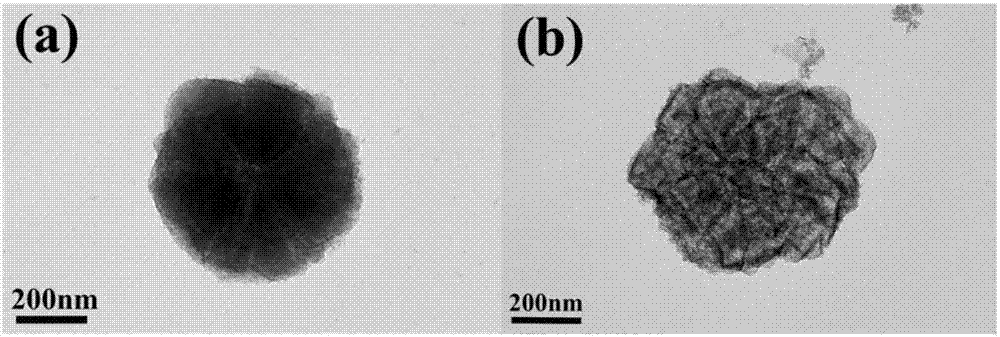

[0036] From figure 1 (a), (b) it can be seen that NH 2 -The shape of MIL-101(Al) is spherical and regular, figure 1 (c), (d) NH after carbonization at 900°C 2 -The morphology of MIL-101(Al)-900 remains basically unchanged, indicating that the skeleton structure of the material remains good after high-temperature carbonization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com