Electrolyte carrier membrane, electrolyte, preparation method of two and lithium ion battery

A technology of electrolyte and carrier film, which is applied in the field of lithium-ion batteries, can solve problems such as poor compatibility of lithium anodes, deterioration of gel electrolyte, and deterioration of mechanical stability, so as to improve compatibility, inhibit dissolution, and reduce polarization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] For the preparation methods of other mesoporous oxide particles, refer to the preparation method of the above mesoporous silicon oxide particles, and details will not be repeated here!

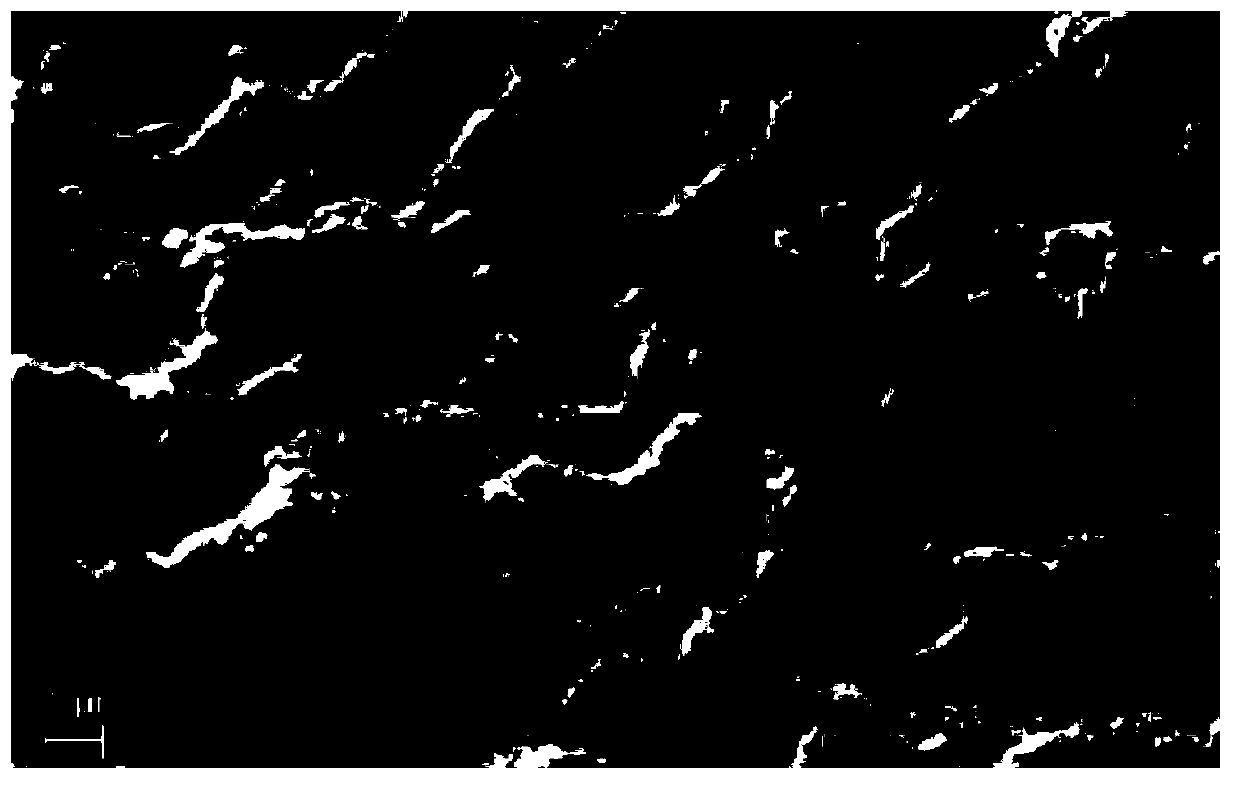

[0065] The electrolyte carrier membrane of the present invention is a microporous membrane, on which many fine pores are distributed, and the liquid electrolyte can be absorbed in the pores.

[0066] Among them, the matrix polymer is selected to have certain mechanical properties, chemical stability, electrochemical stability, and a polymer with good affinity with the electrolyte.

[0067] The matrix polymer of the present invention includes polyvinylidene fluoride-hexafluoropropylene copolymer PVDF-HFP and organosilane-substituted polymethyl methacrylate PMMA.

[0068] Polymethyl methacrylate PMMA substituted by organosilane has a high degree of crosslinking. Introducing it into the matrix polymer can make the distribution of pores more uniform, effectively improve the electrolyte abso...

Embodiment 1

[0116] Matrix polymer: 70wt% PVDF-HFP and 30wt% trimethoxysilane substituted polymethyl methacrylate f-PMMA.

[0117] The BET specific surface area of mesoporous silica particles is 804.15m 2 / g, pore volume 0.86cm 3 / g, the average pore size is 3.83nm, and the particle size range is 200-400nm.

[0118] Preparation of electrolyte carrier membrane:

[0119] Add 85wt% matrix polymer and 15wt% mesoporous silica particles into the organic solvent acetone, and stir for 24h. Then ultrasonic treatment was performed for 1 h to form a uniform dispersion system at room temperature. Then add tert-butyl methyl ether, a pore-forming agent, and stir evenly to form a uniform dispersion system.

[0120] Pour the above dispersion into a clean vessel. After natural air-drying of the organic solvent acetone and tert-butyl methyl ether as a pore-forming agent, they were finally further dried in a vacuum oven at 65 °C for 24 h to remove the residual solvent and pore-forming agent. An elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com