Patents

Literature

713results about How to "Improved shape stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

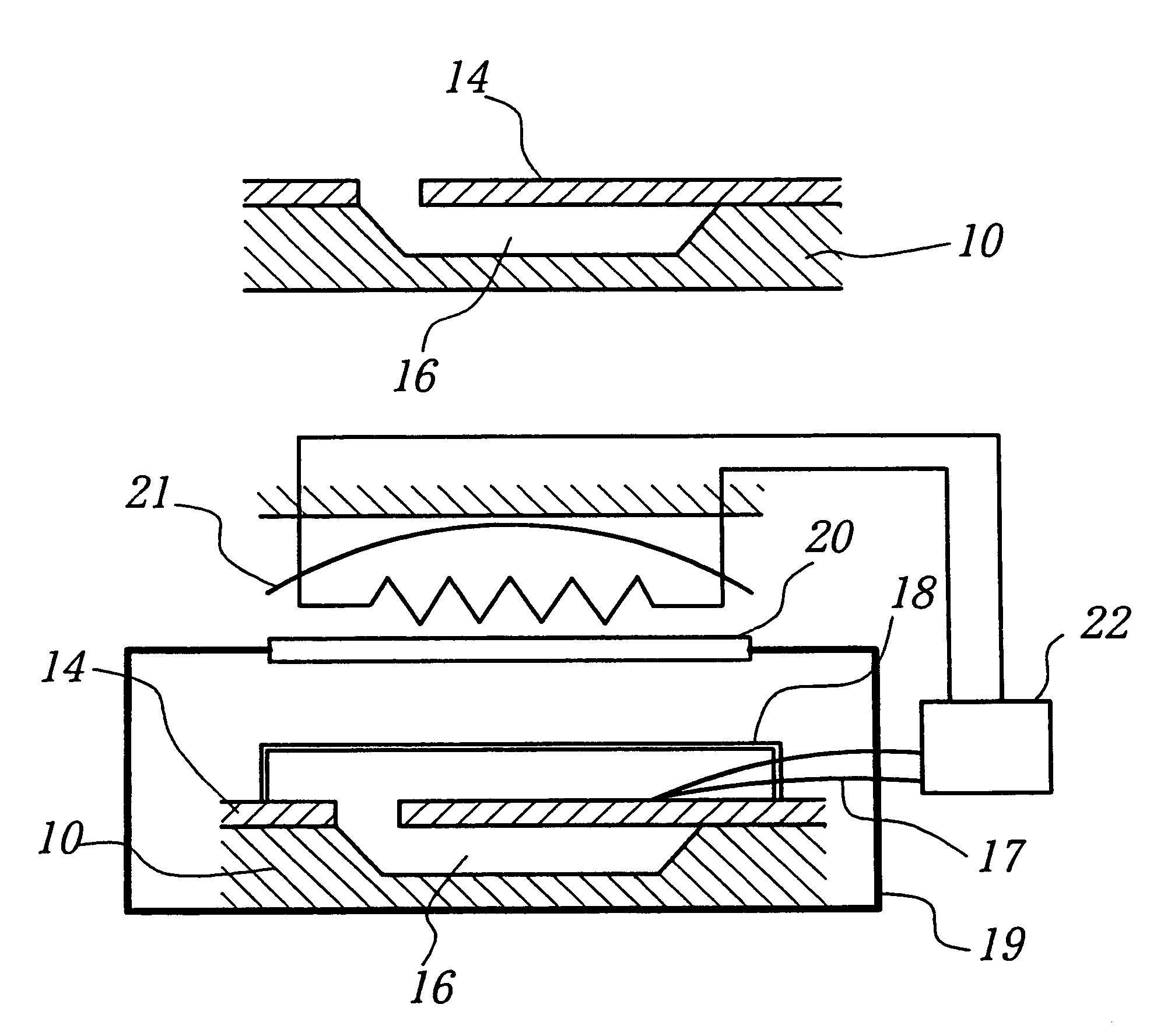

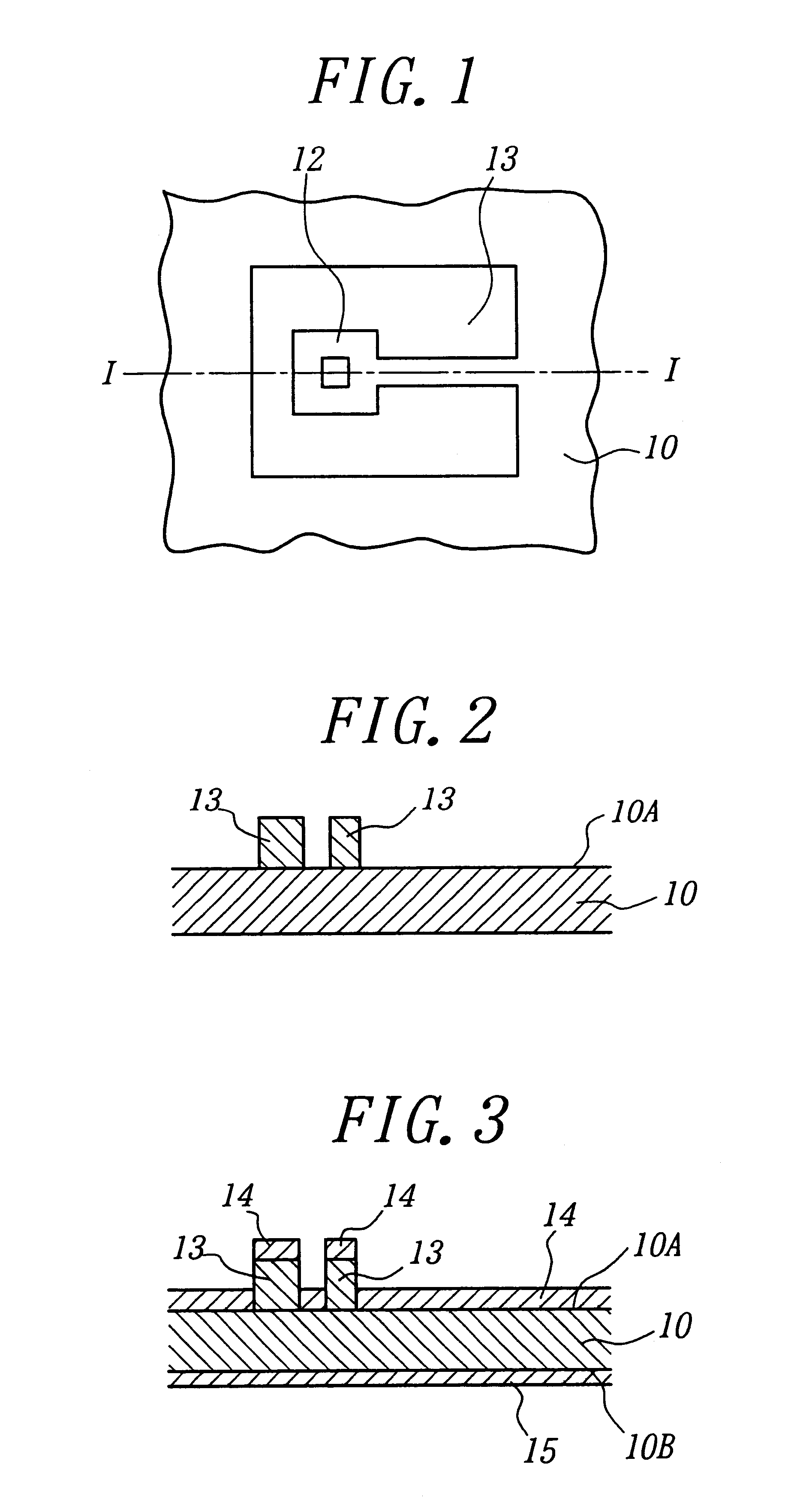

Thin film-structure and a method for producing the same

InactiveUS6759261B2Increase productivityGood reproducibilityLiquid-phase epitaxial-layer growthElectrical measurement instrument detailsRoom temperatureCooling down

A thin film made of an amorphous material having supercooled liquid phase region is formed on a substrate. Then, the thin film is heated to a temperature within the supercooled liquid phase region and is deformed by its weight, mechanical external force, electrostatic external force or the like, thereby to form a thin film-structure. Thereafter, the thin film-structure is cooled down to room temperature, which results in the prevention of the thin film's deformation.

Owner:TOKYO INST OF TECH

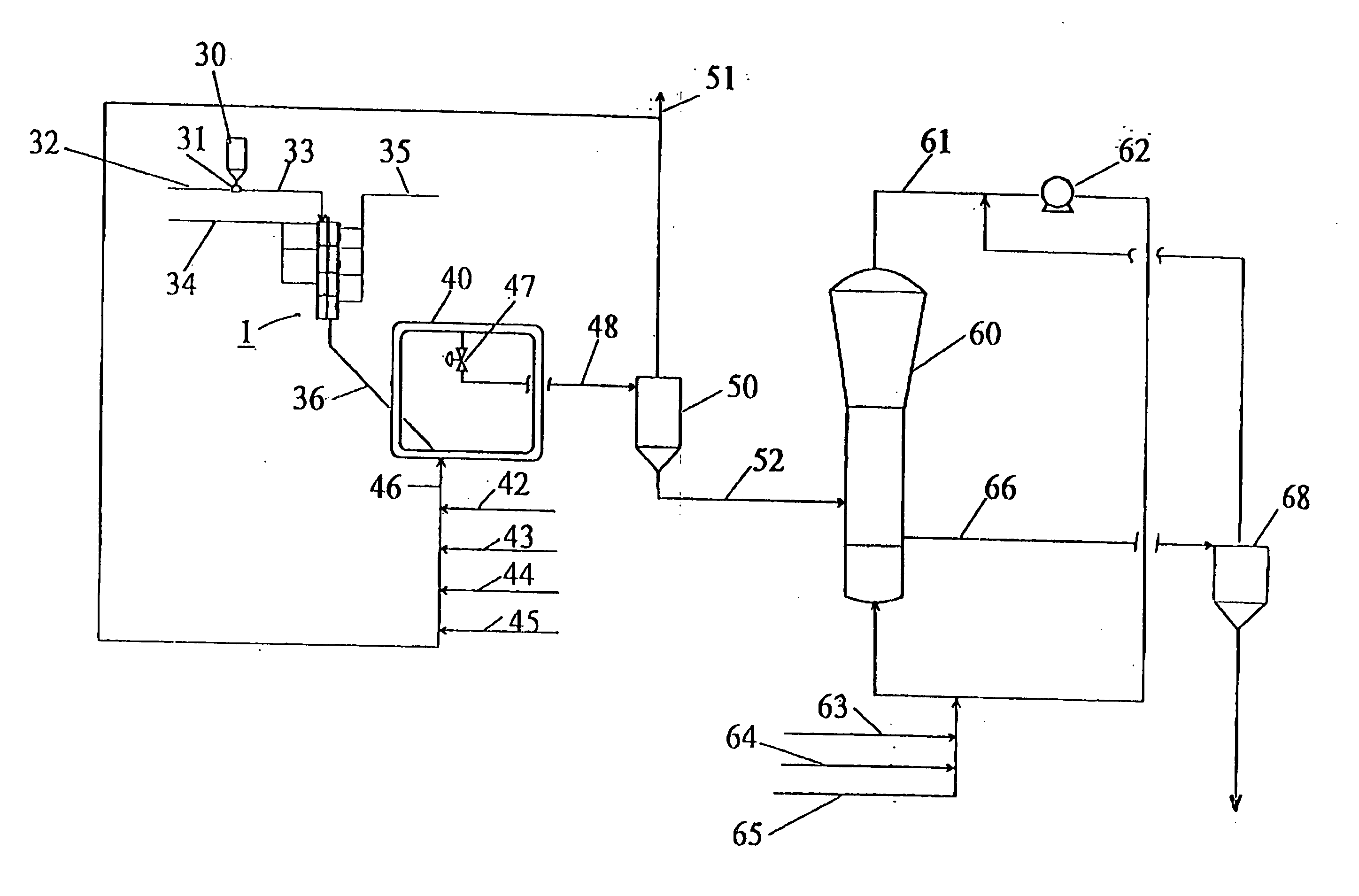

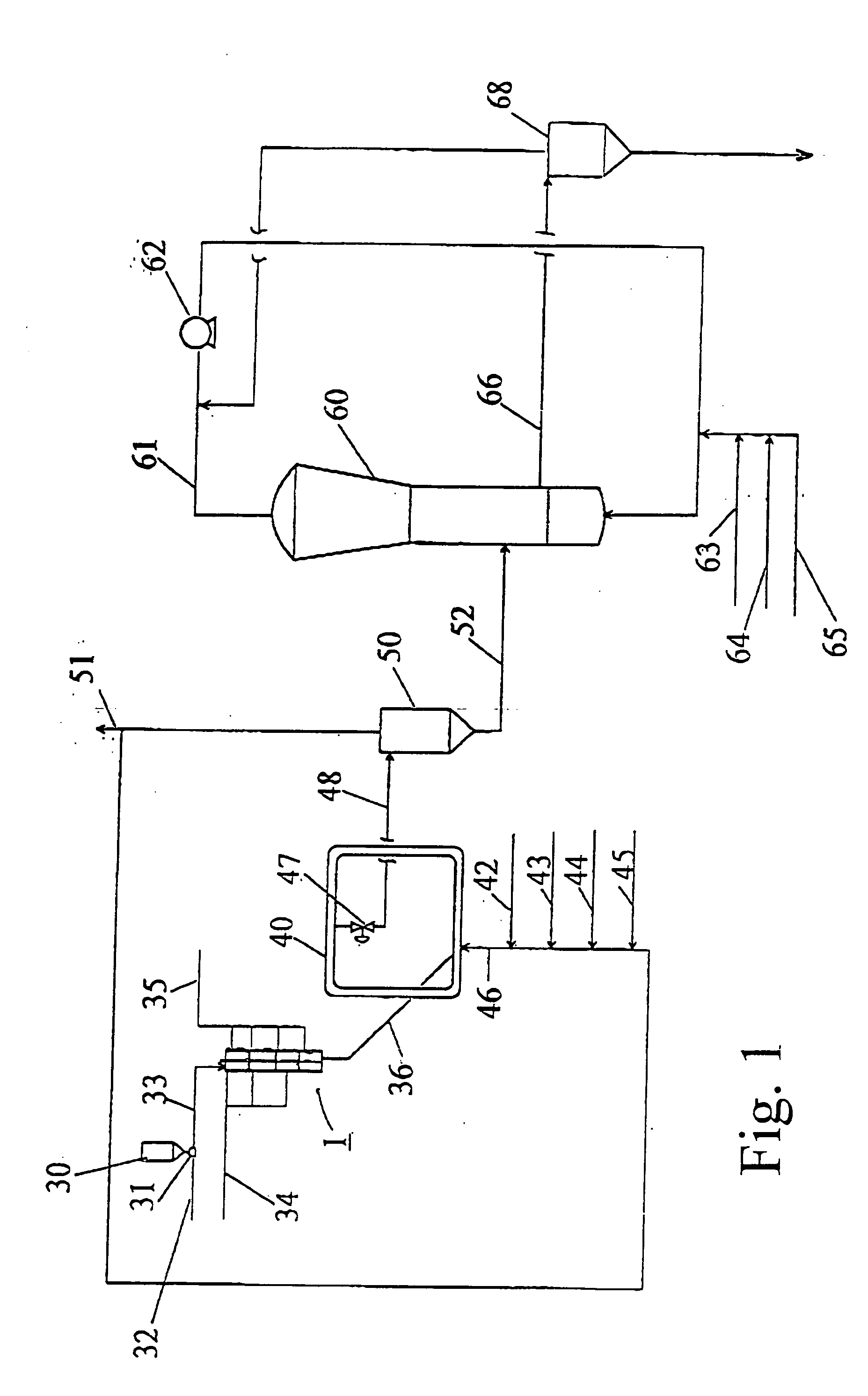

High melt strength polypropylene

InactiveUS7365136B2Improve melt strengthHigh viscosityChemical/physical/physico-chemical stationary reactorsPolymer sciencePtru catalyst

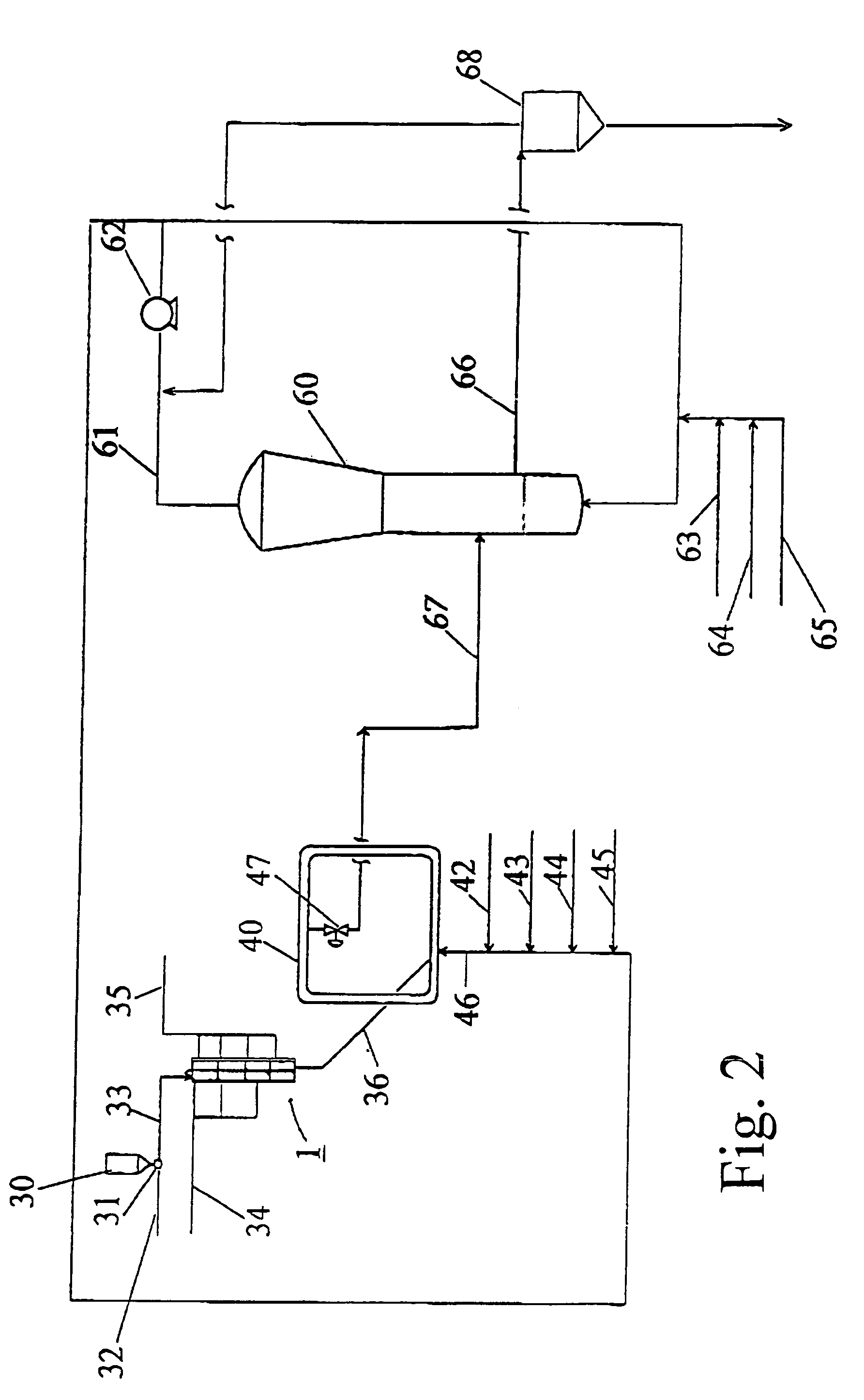

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / 10 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

Base material for artificial leather and process for producing the same

ActiveUS20110039055A1Improve compactnessFlat surfaceSynthetic resin layered productsFilament/thread formingFiber bundleEngineering

Owner:KURARAY CO LTD

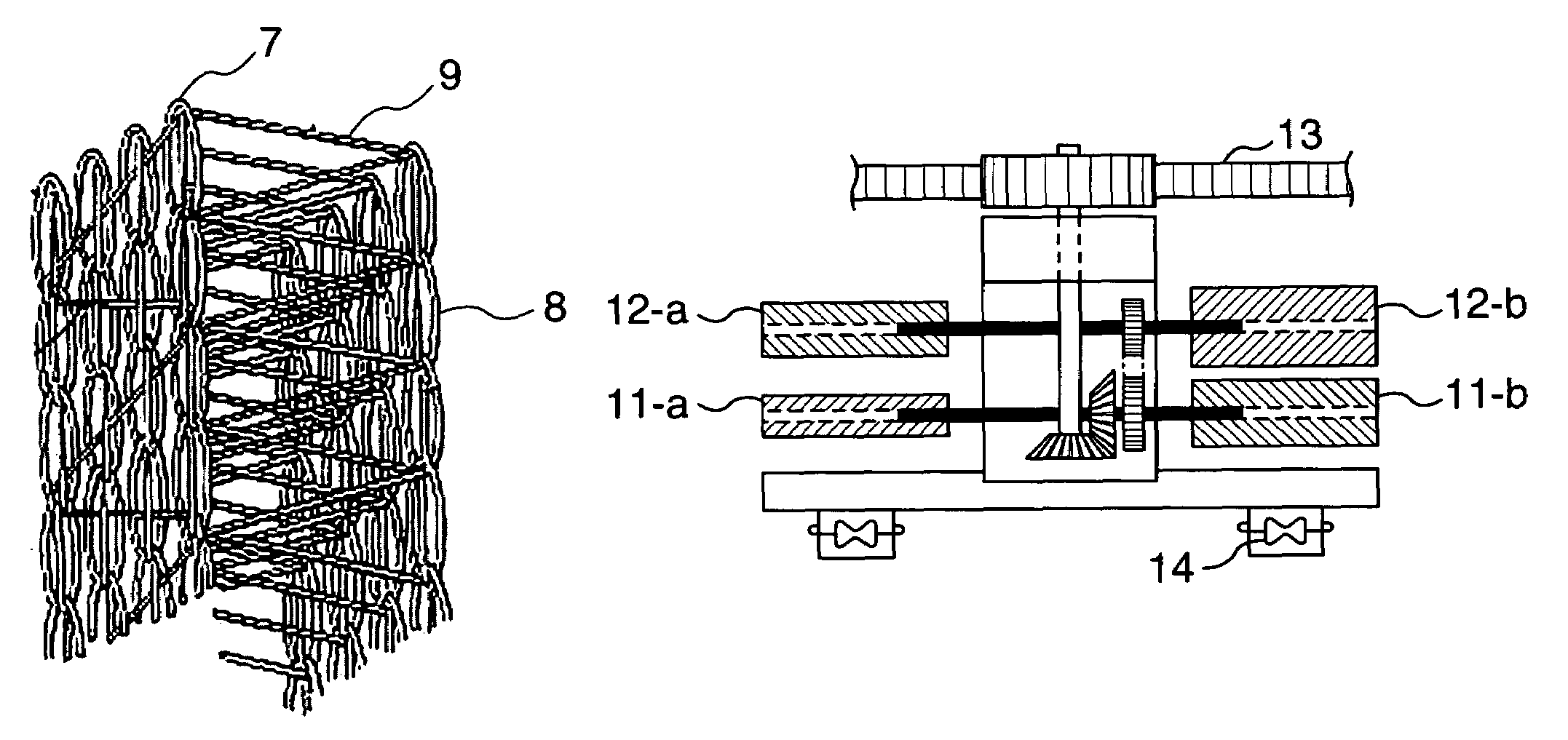

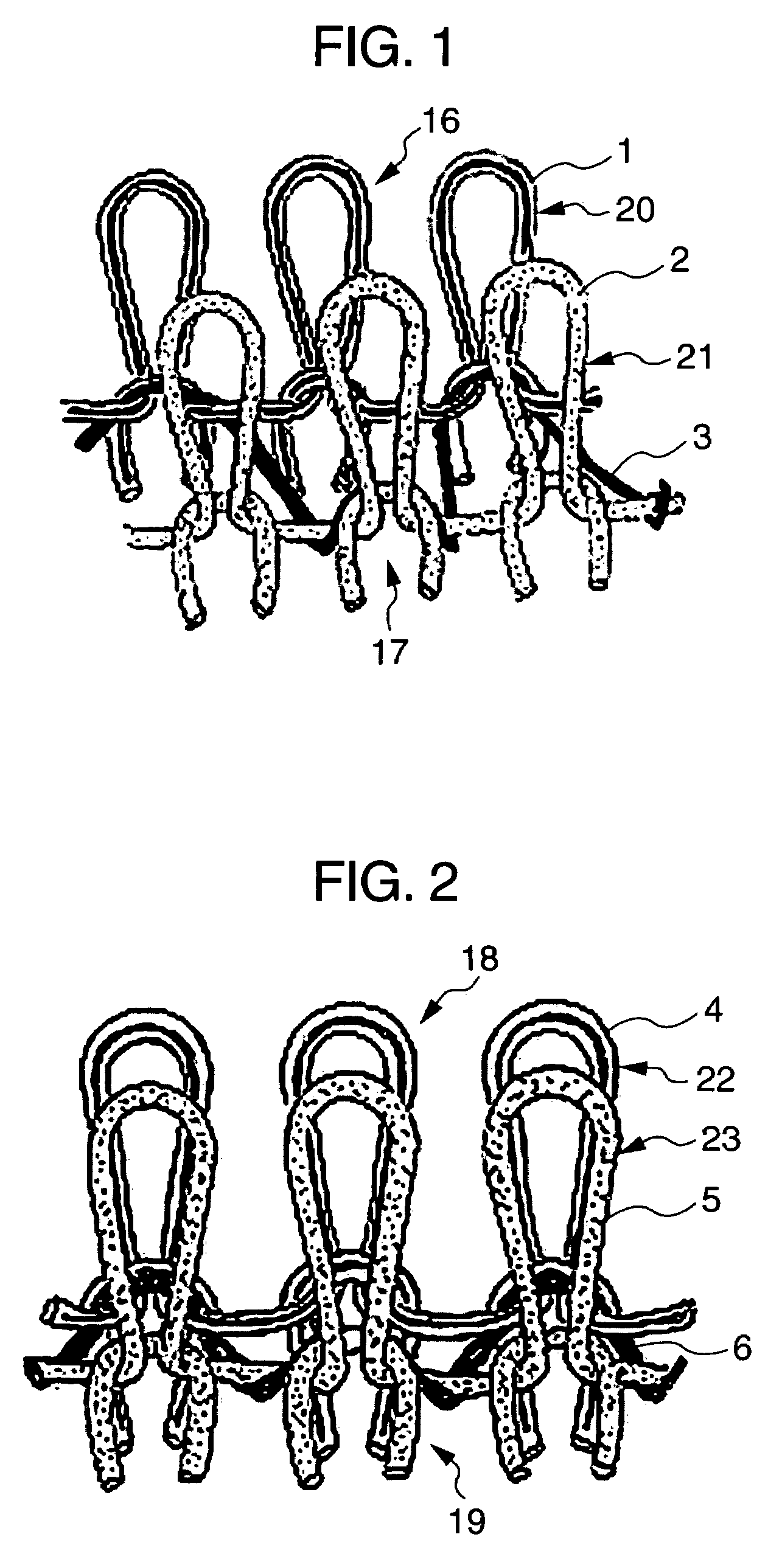

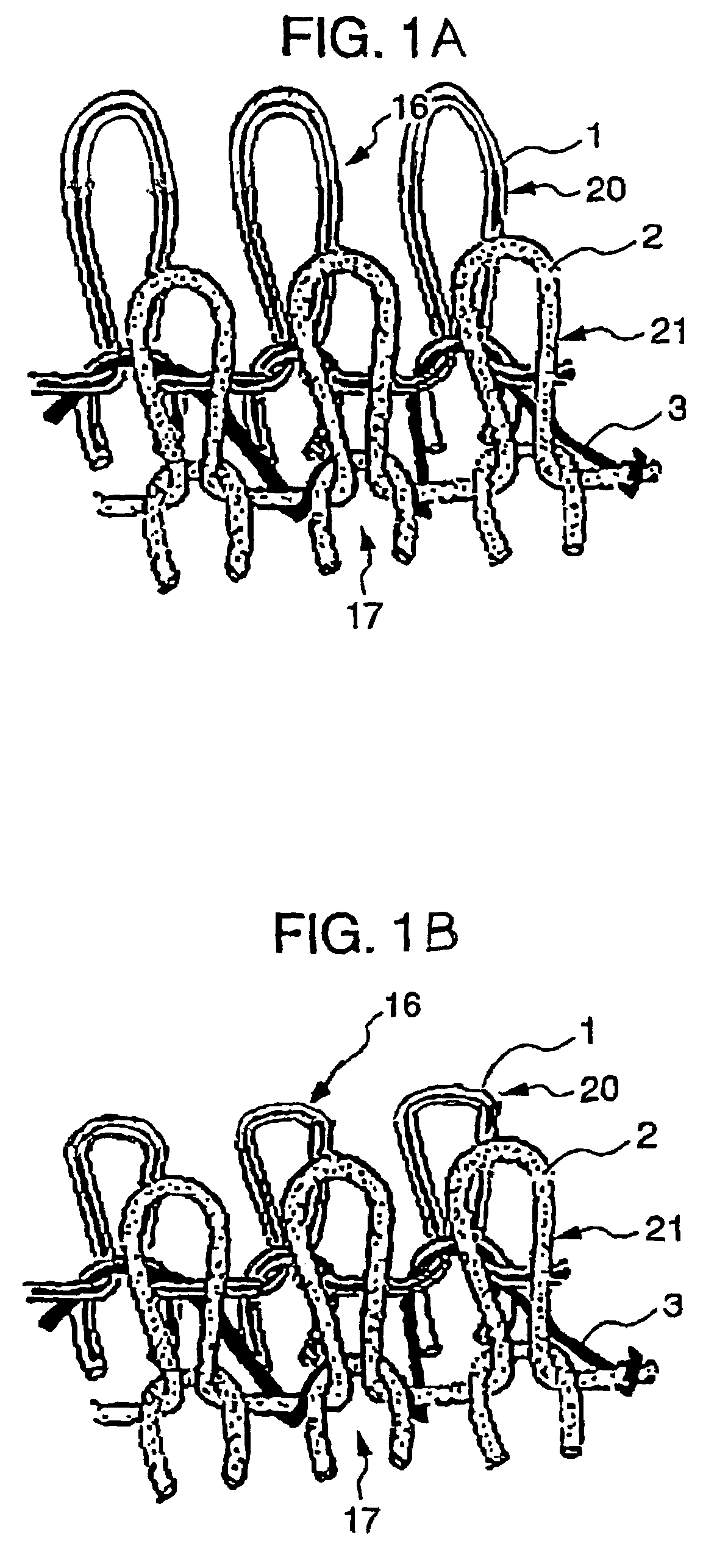

Elastic knitting fabric having multilayer structure

InactiveUS7240522B2Improve tensile propertiesImproved shape stabilityOrnamental textile articlesStraight-bar knitting machinesFiberElastic fiber bundle

An elastic knitted fabric having a multilayer structure, made by binding separate front and back two-layer ground knitted fabrics together, wherein the above described two-layer ground knitted fabrics are bound together with only a bare string(s) of polyurethane based elastic fibers of 17 to 3000 decitexes.

Owner:ASAHI KASEI FIBERS CORPORATION

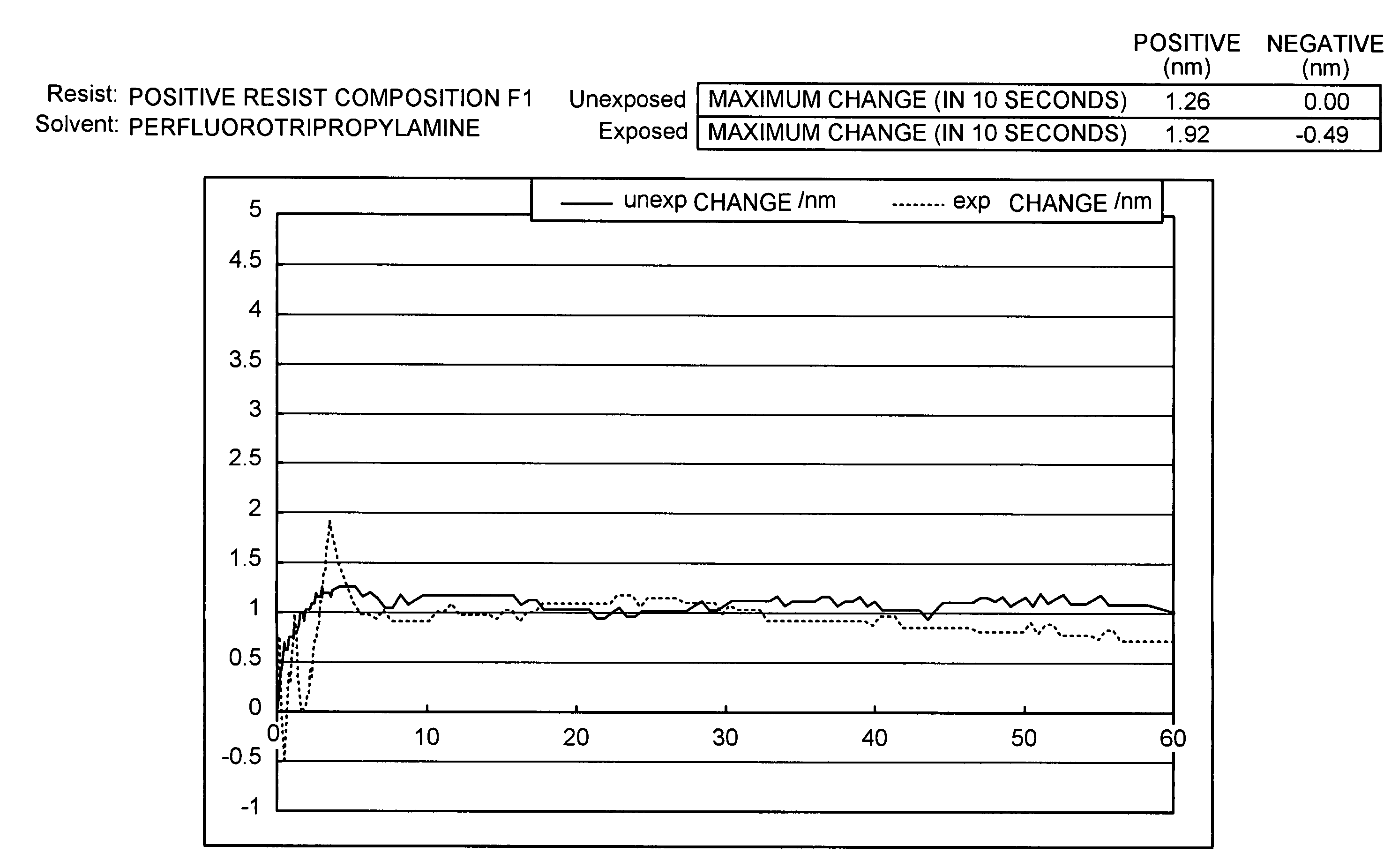

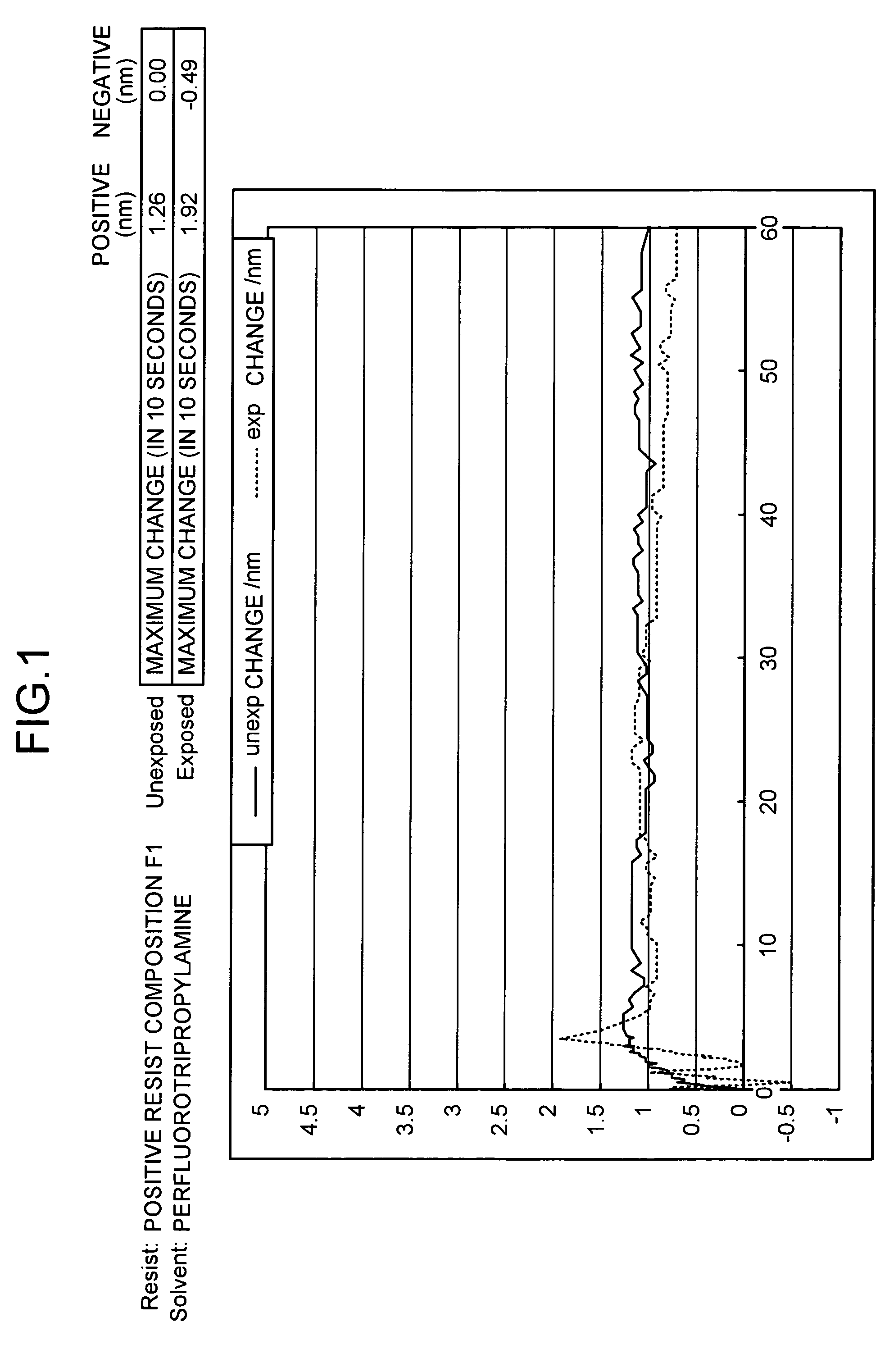

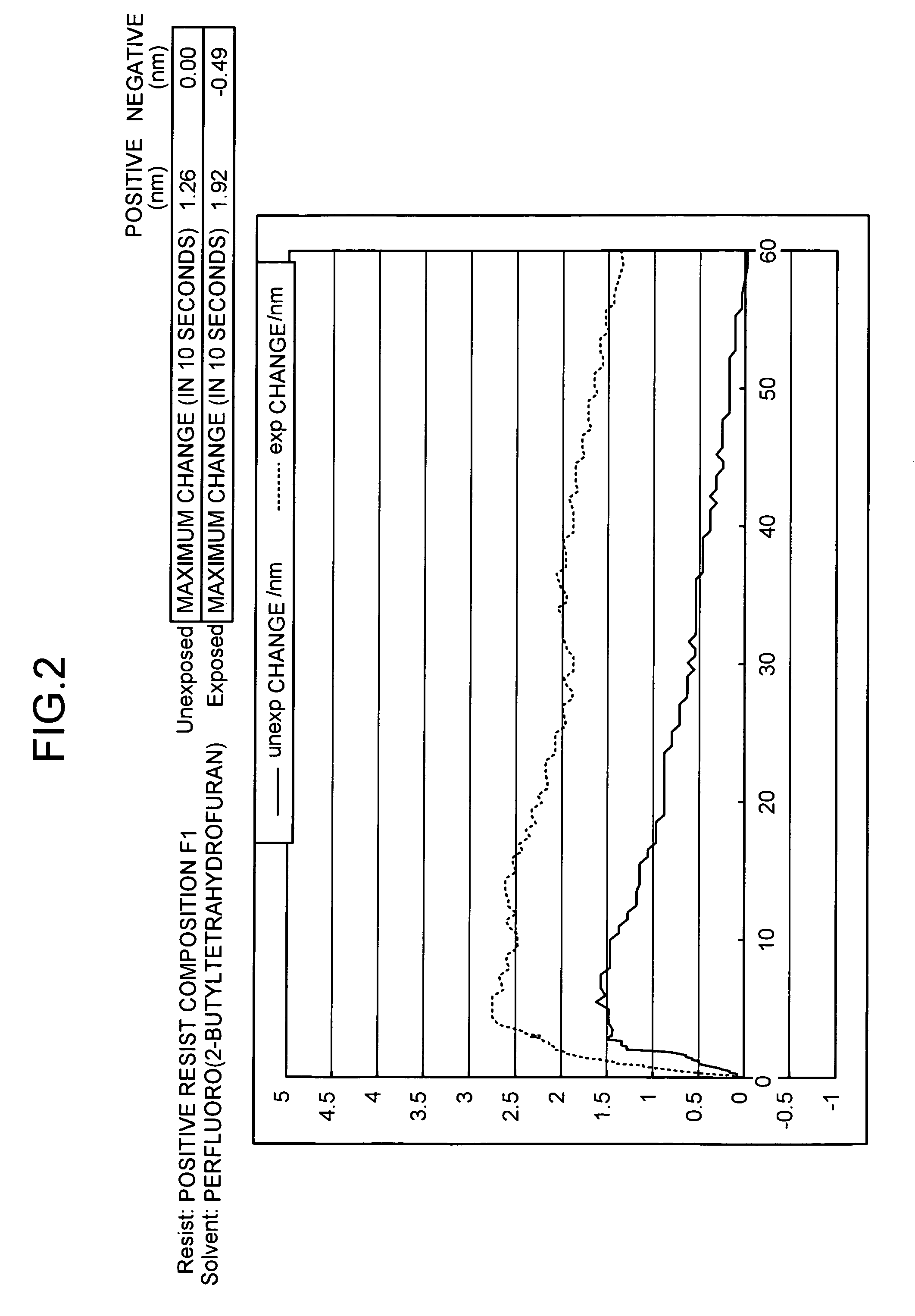

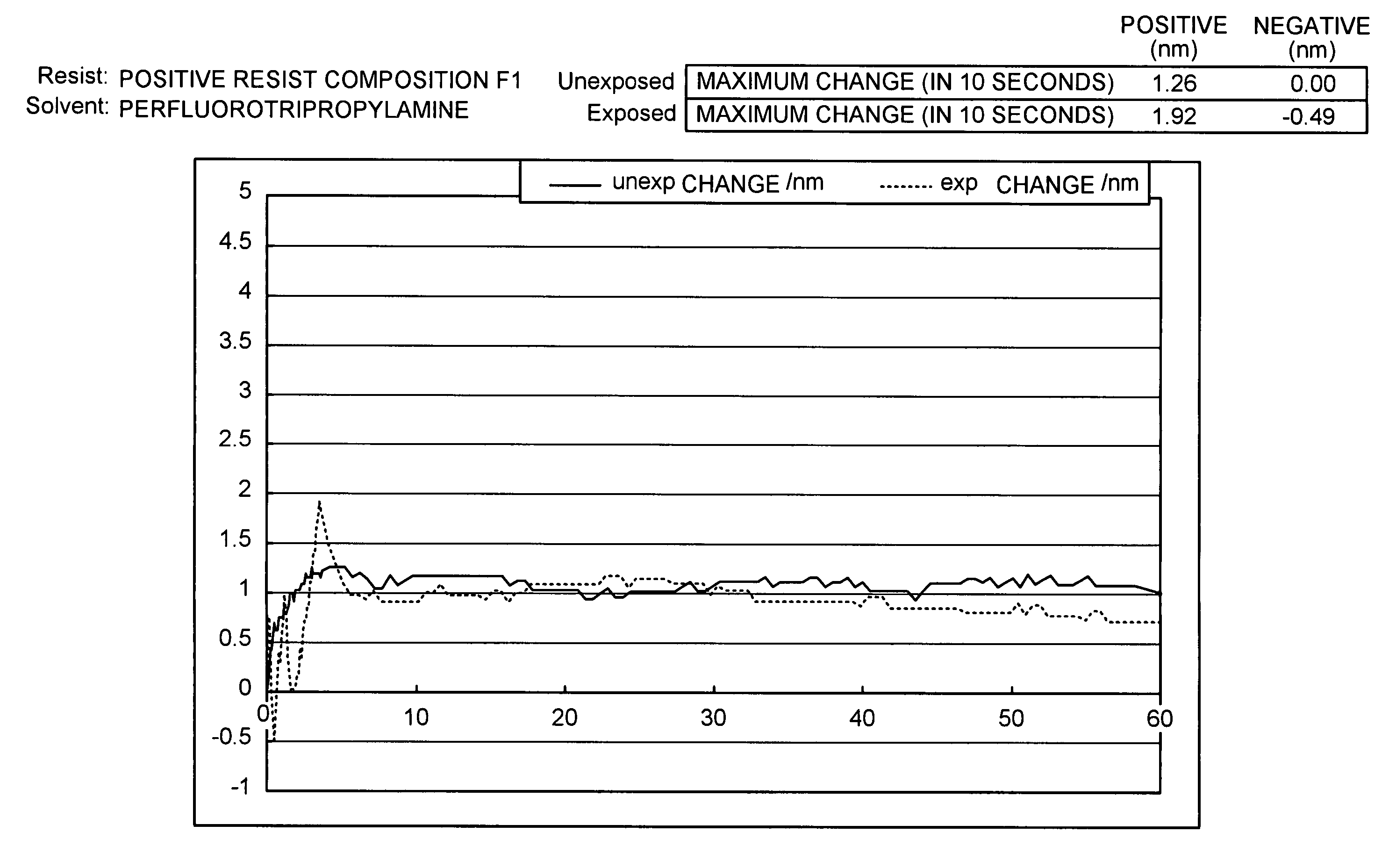

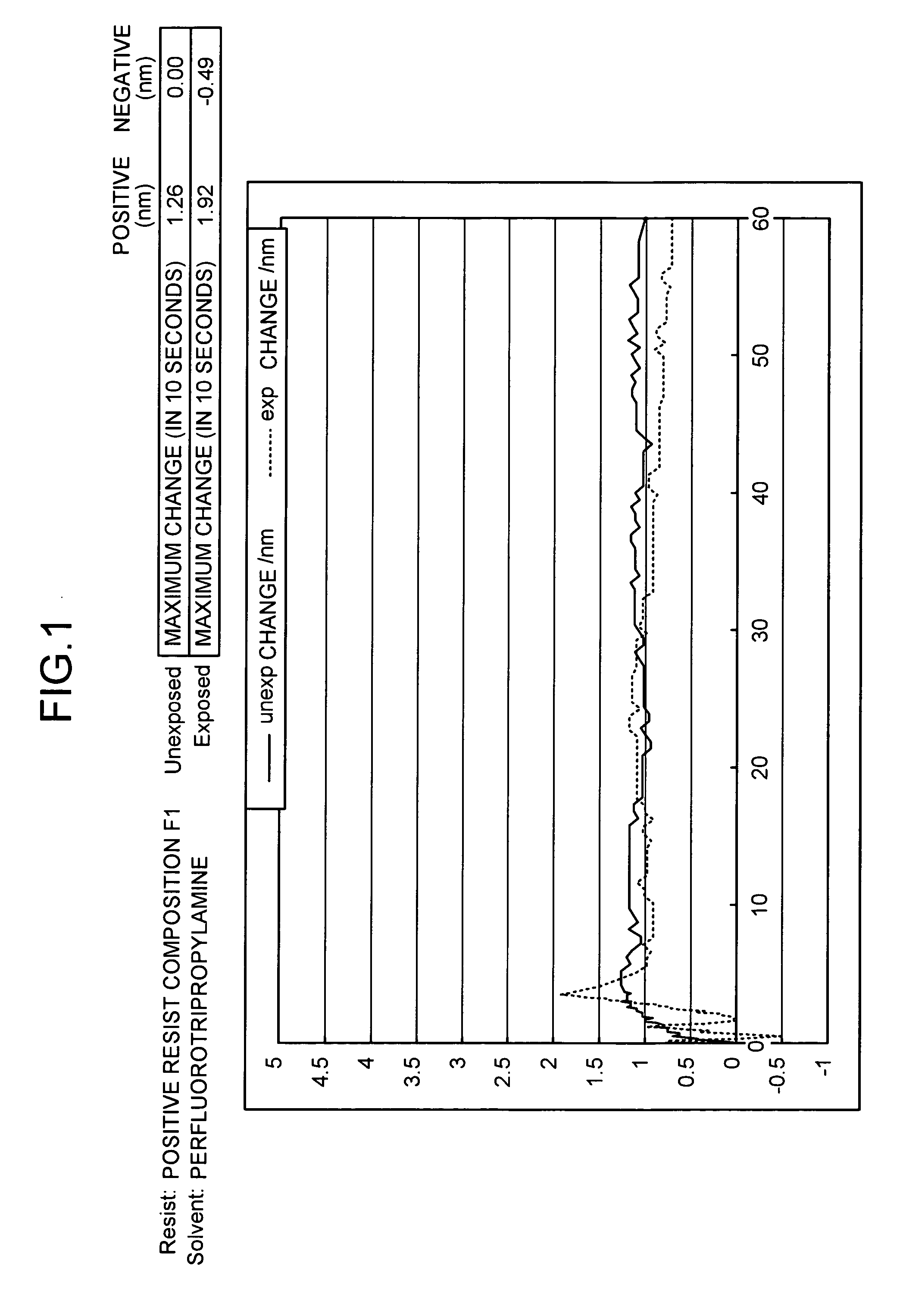

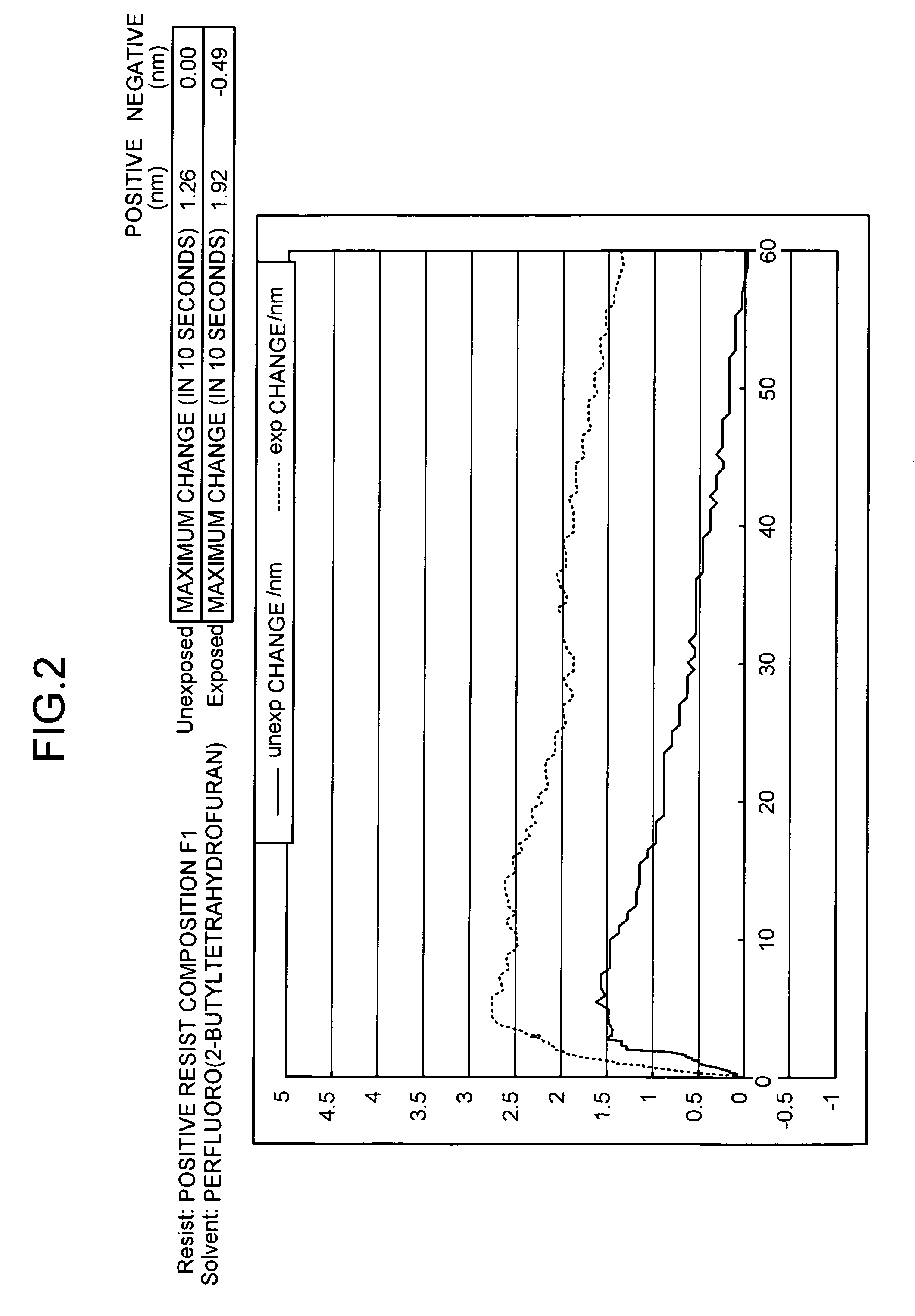

Resist composition for liquid immersion exposure process and method of forming resist pattern therewith

ActiveUS7264918B2Large investment in equipmentLow costPhotosensitive materialsPhoto-taking processesSolubilityStructural unit

Owner:TOKYO OHKA KOGYO CO LTD

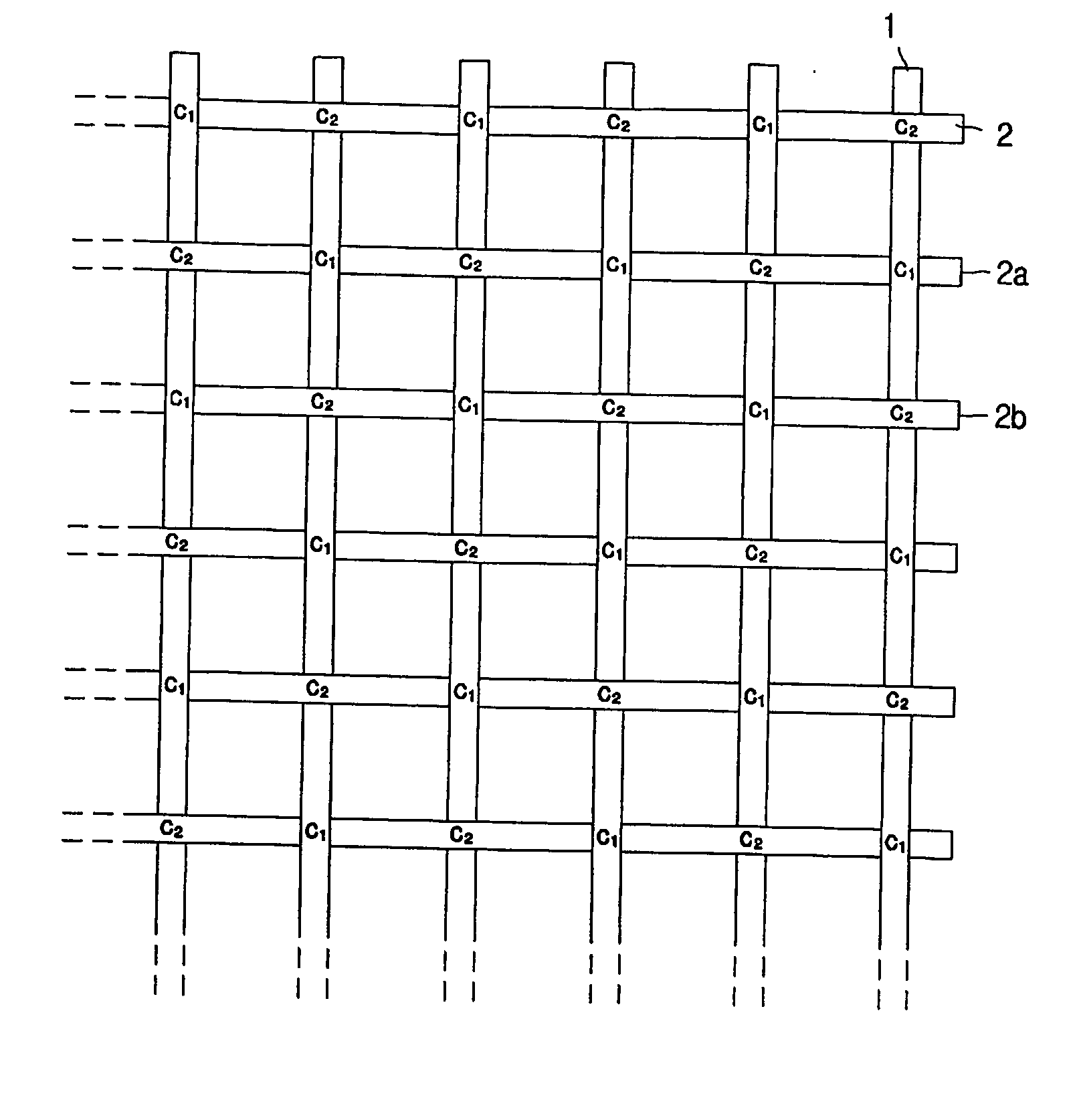

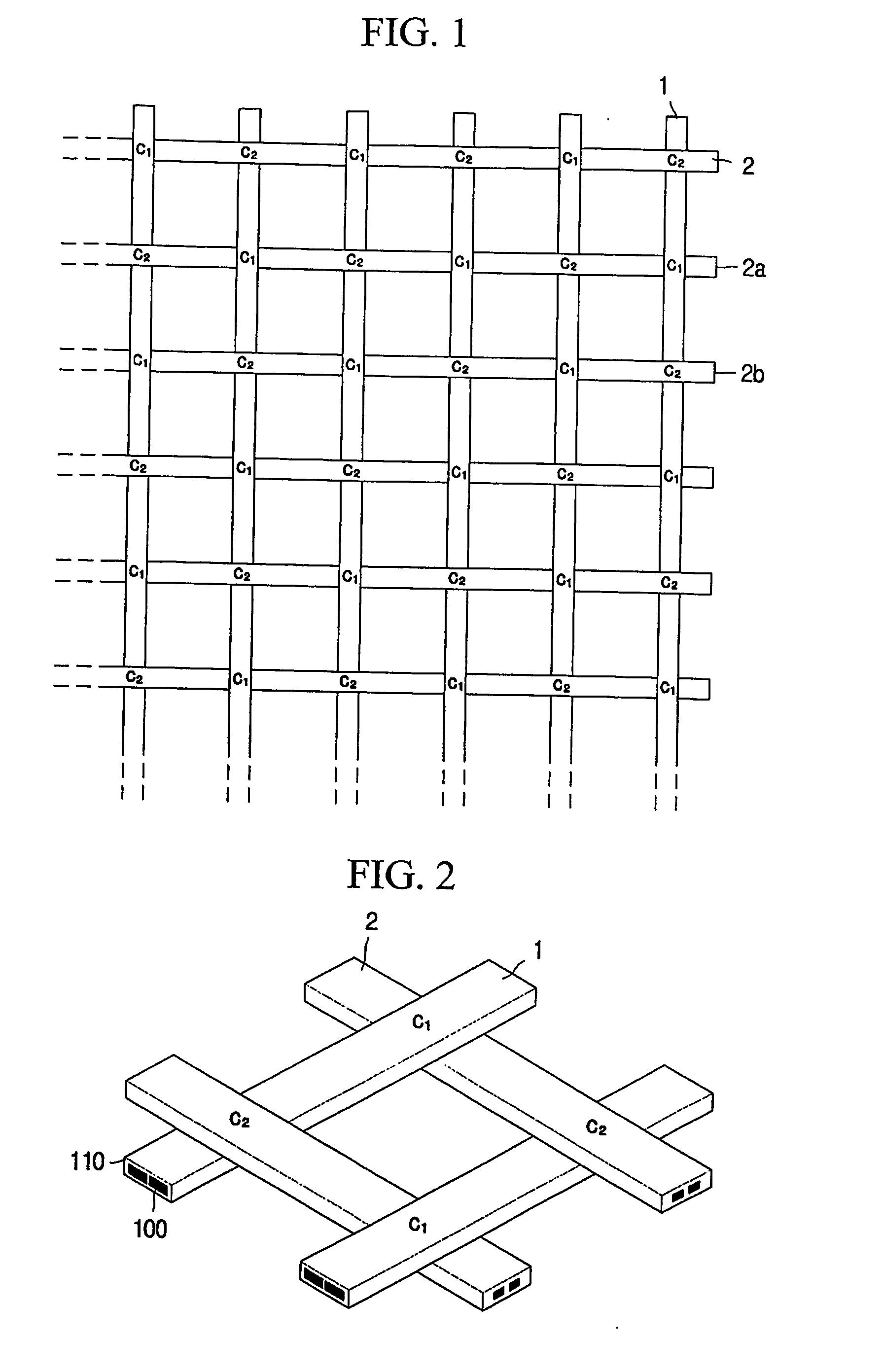

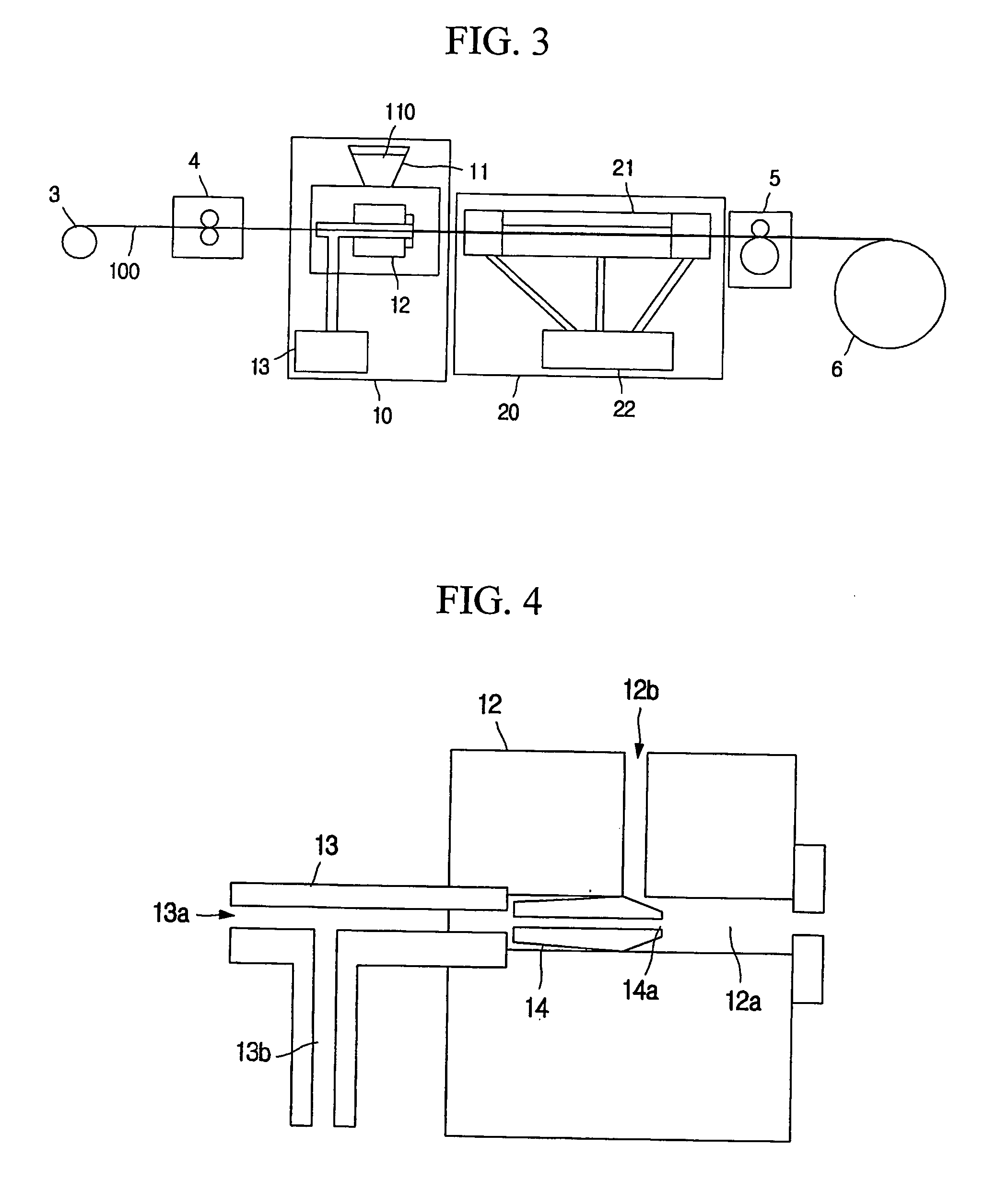

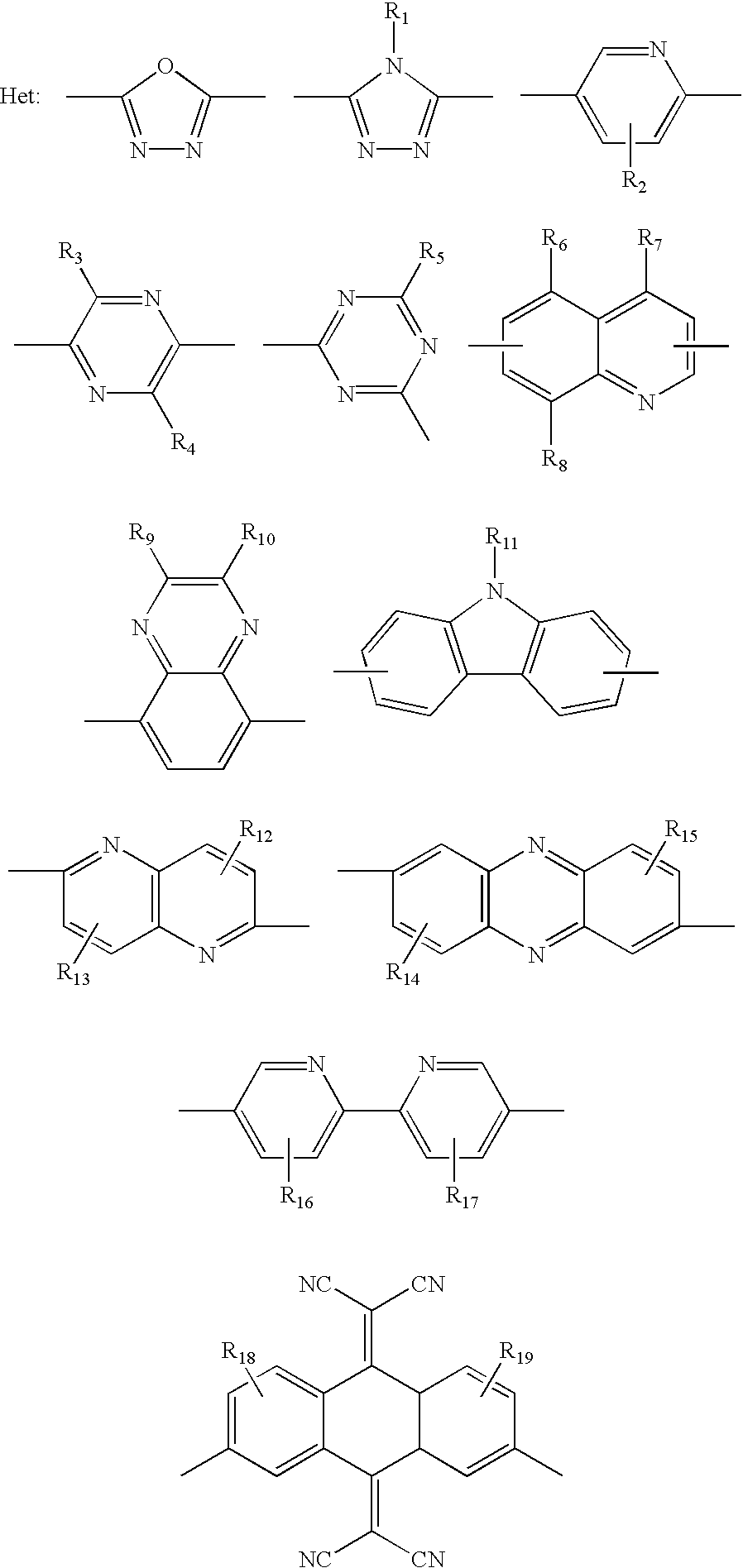

Geogrid composed of fiber-reinforced polymeric strip and method for producing the same

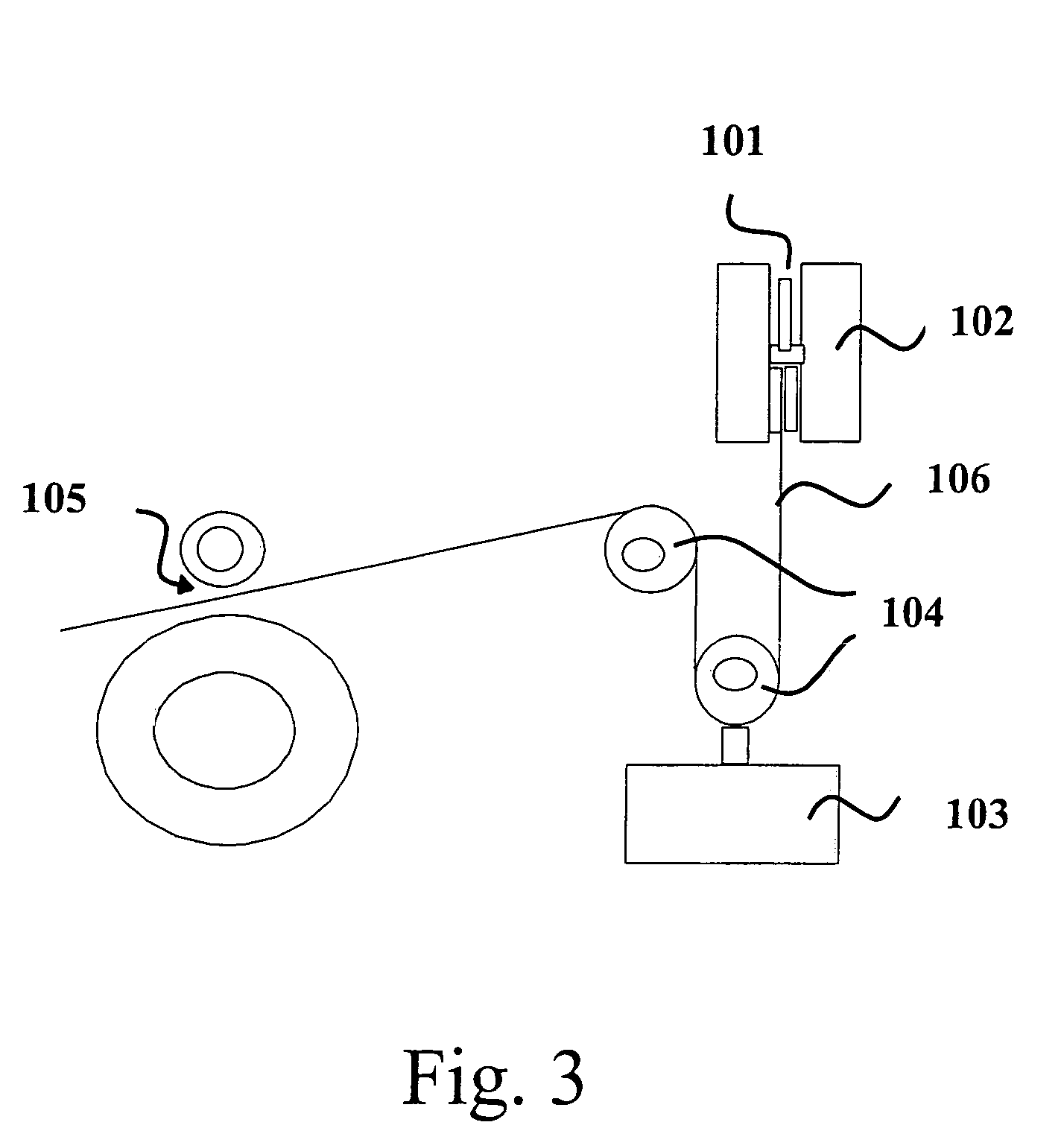

InactiveUS20060116040A1Increase resistance against vertical loadIncrease friction forceWarp knittingWelding/cutting auxillary devicesTensile strainGeogrid

A geogrid using fiber-reinforced polymeric strips and its producing method are disclosed. The geogrid of a lattice shape includes plural longitudinal fiber-reinforced polymeric strips longitudinally arranged in parallel at regular intervals and formed by reinforcing fiber in a thermoplastic polymer resin, and plural lateral fiber-reinforced polymer strip laterally arranged in parallel at regular intervals and formed by reinforcing fiber in a thermoplastic polymer resin. Each longitudinal fiber-reinforced polymer strip has at lease one first contact point crossed with the lateral fiber-reinforced polymer strip on the upper surface and at least one second contact point crossed with the lateral fiber-reinforced polymer strips on the lower surface. The contact points are fixed by welding the longitudinal and lateral fiber-reinforced polymer strips. The geogrid is excellent in installation capacity, frictional feature and shape stabilisation and shows high tensile strength and low tensile strain and low creep deformation.

Owner:SAMSANG CORP

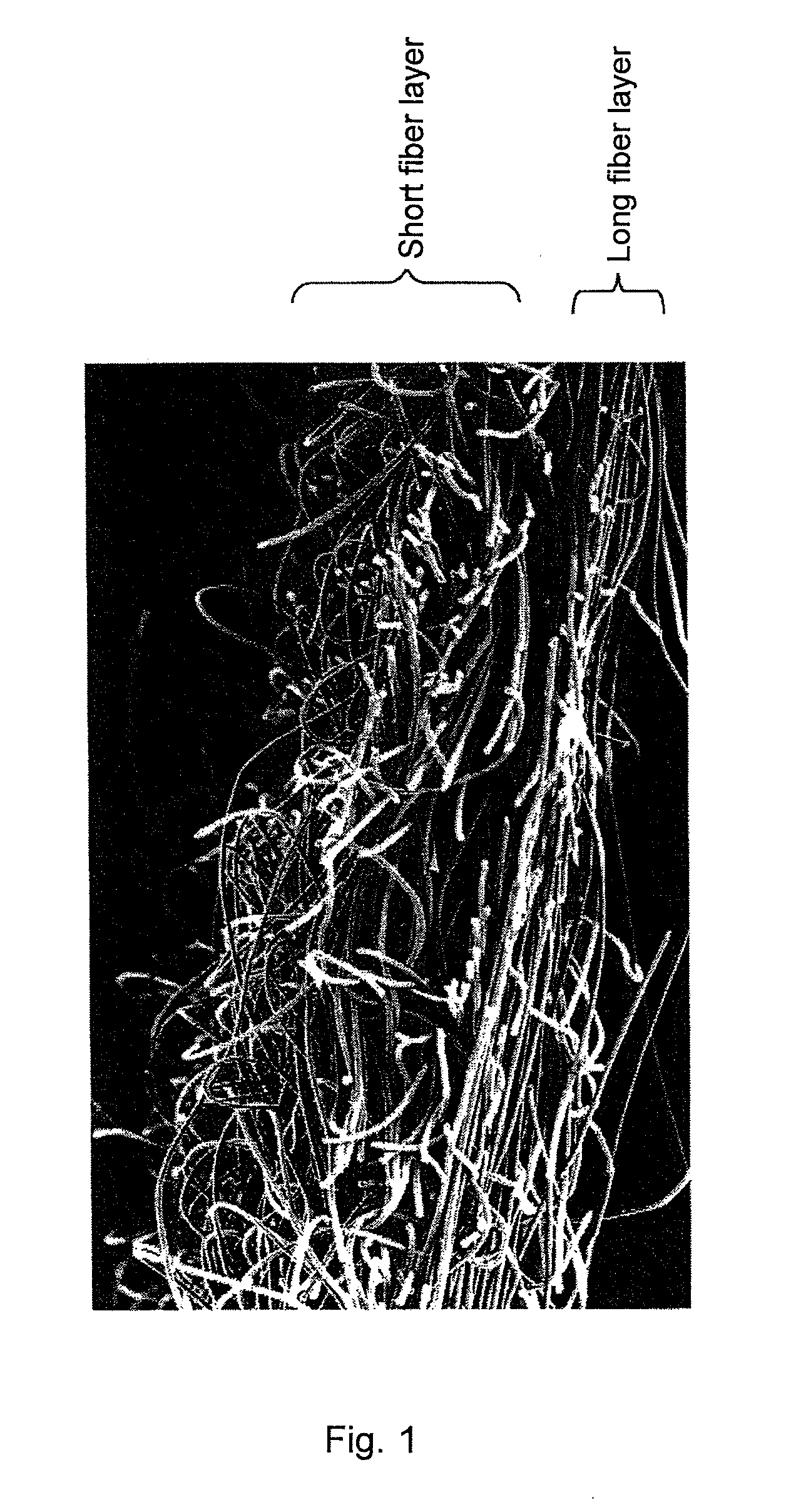

Method for manufacturing high-breathability non-woven wallpaper body paper and product

The invention discloses a method for manufacturing high-breathability non-woven wallpaper body paper and a product. The existing non-woven wallpaper has the disadvantages that the hand feel thereof is not soft enough, the principal plane stereoscopic impression is not strong and the opacity degree is low. The method of the invention comprises the following steps: beating plant fiber containing chemical wood pulp until the beating degree is 20-30OSR, and mixing with non-plant fiber containing chemical fiber; adding chemical addition agent into the mixed fiber; manufacturing the mixed fiber containing the chemical addition agent into body paper semi-finished products by utilizing a fourdrinier wire or inclined wire paper machine; mixing pigment, chemical addition agent and adhesive to form coating liquor, carrying out dip coating on the body paper semi-finished products inside or outside the machine; and drying and finishing the body paper subject to dip coating, and rolling the body paper to form finished paper of body paper, thus obtaining non-woven wallpaper which contains continuous fiber, has high breathability, and can be directly printed. The principal plane has natural lines; and the finished paper has the advantages of soft hand feel, good processability, excellent shape stability, rich color, distinct image and strong stereoscopic impression.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

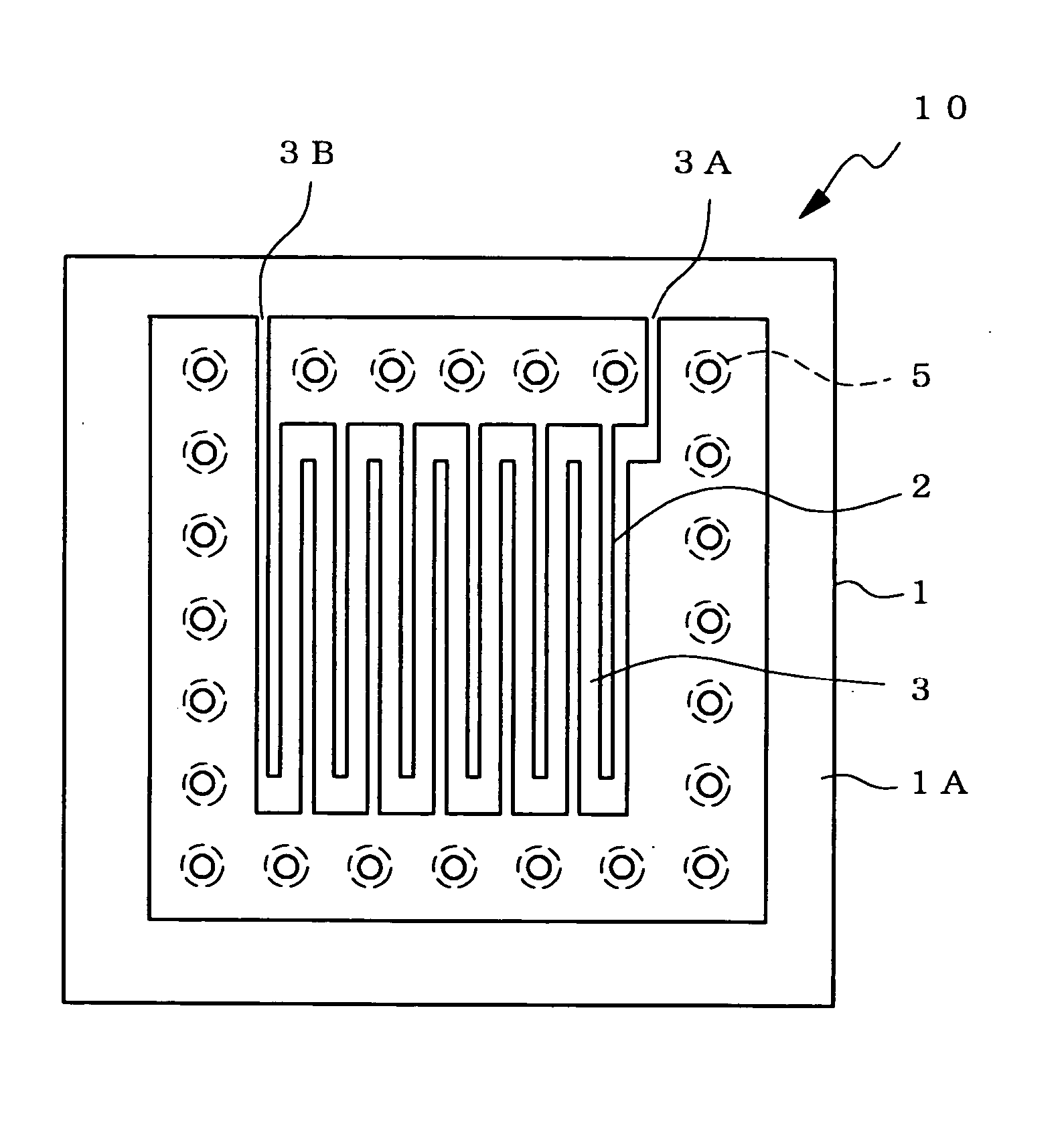

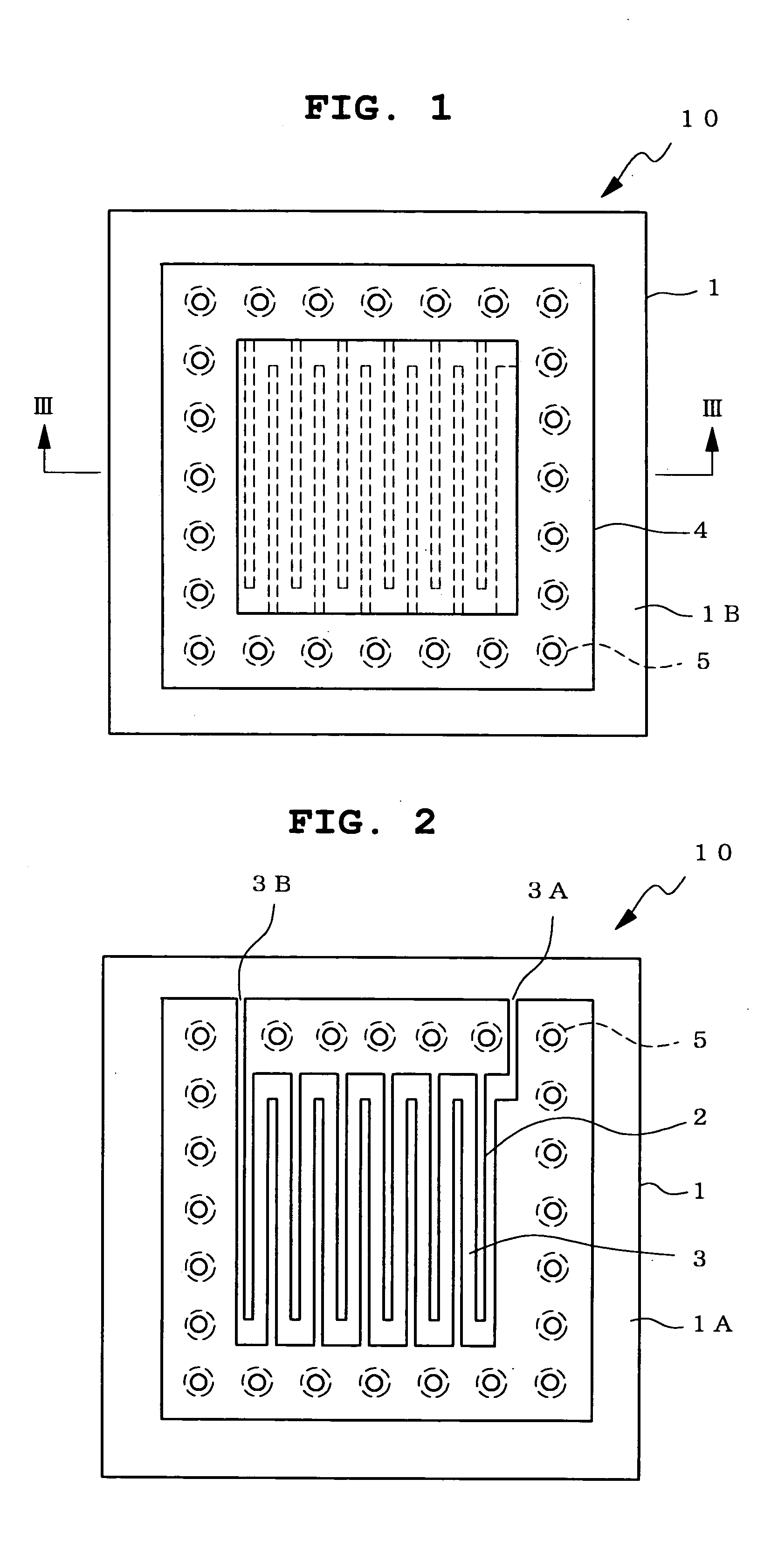

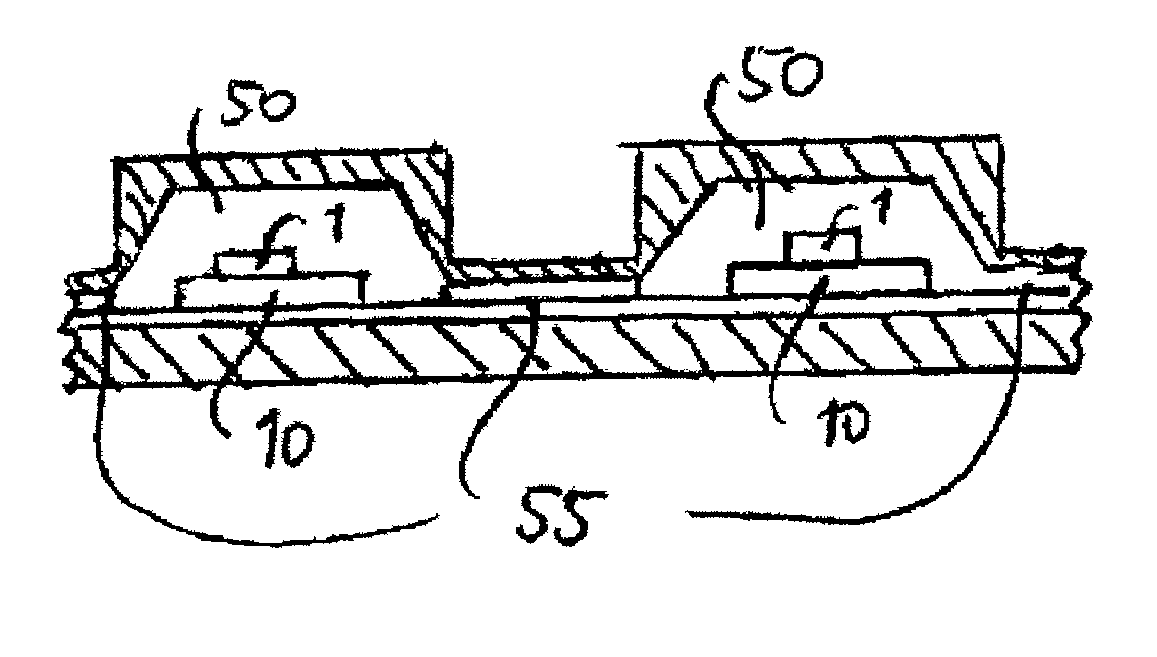

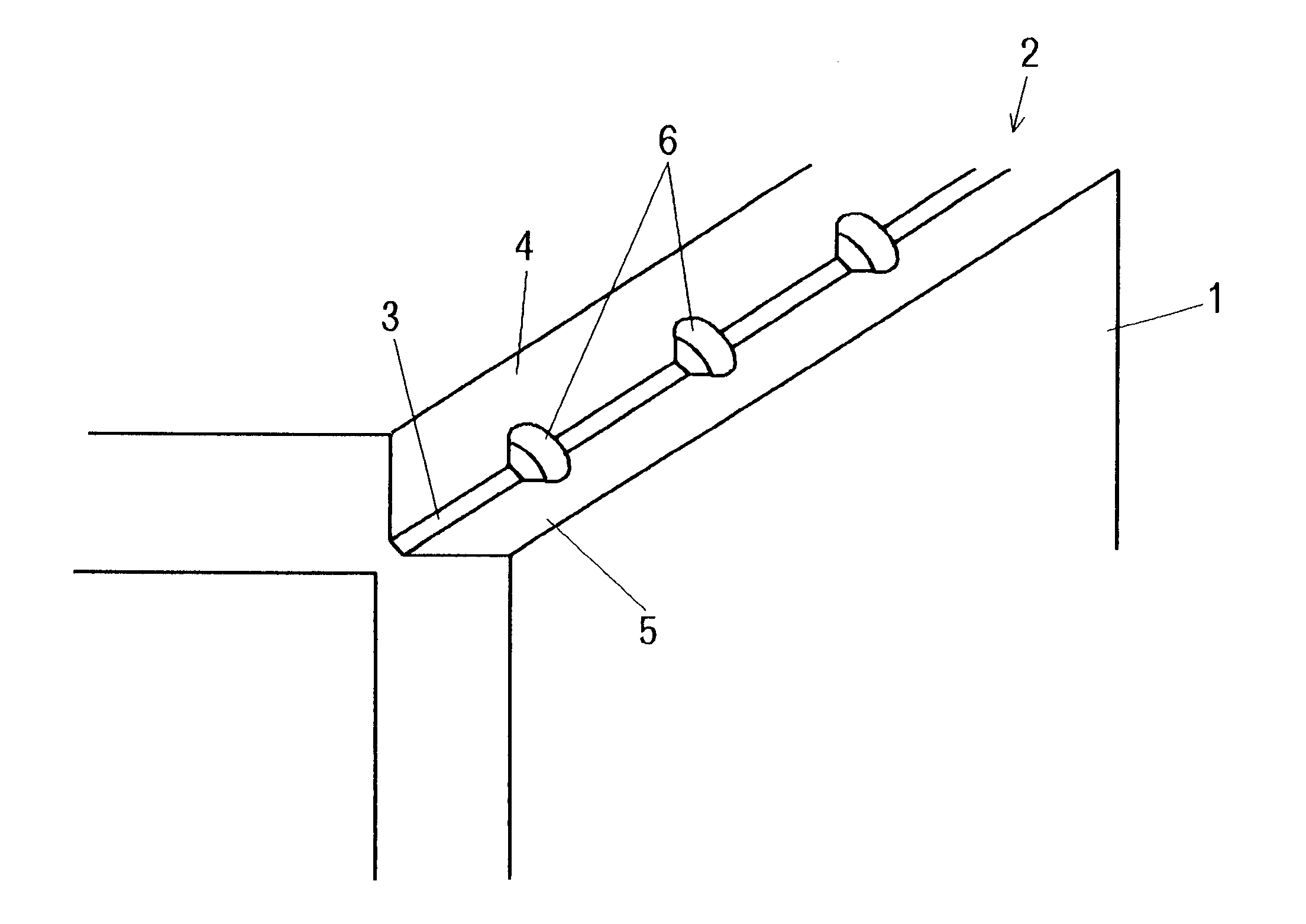

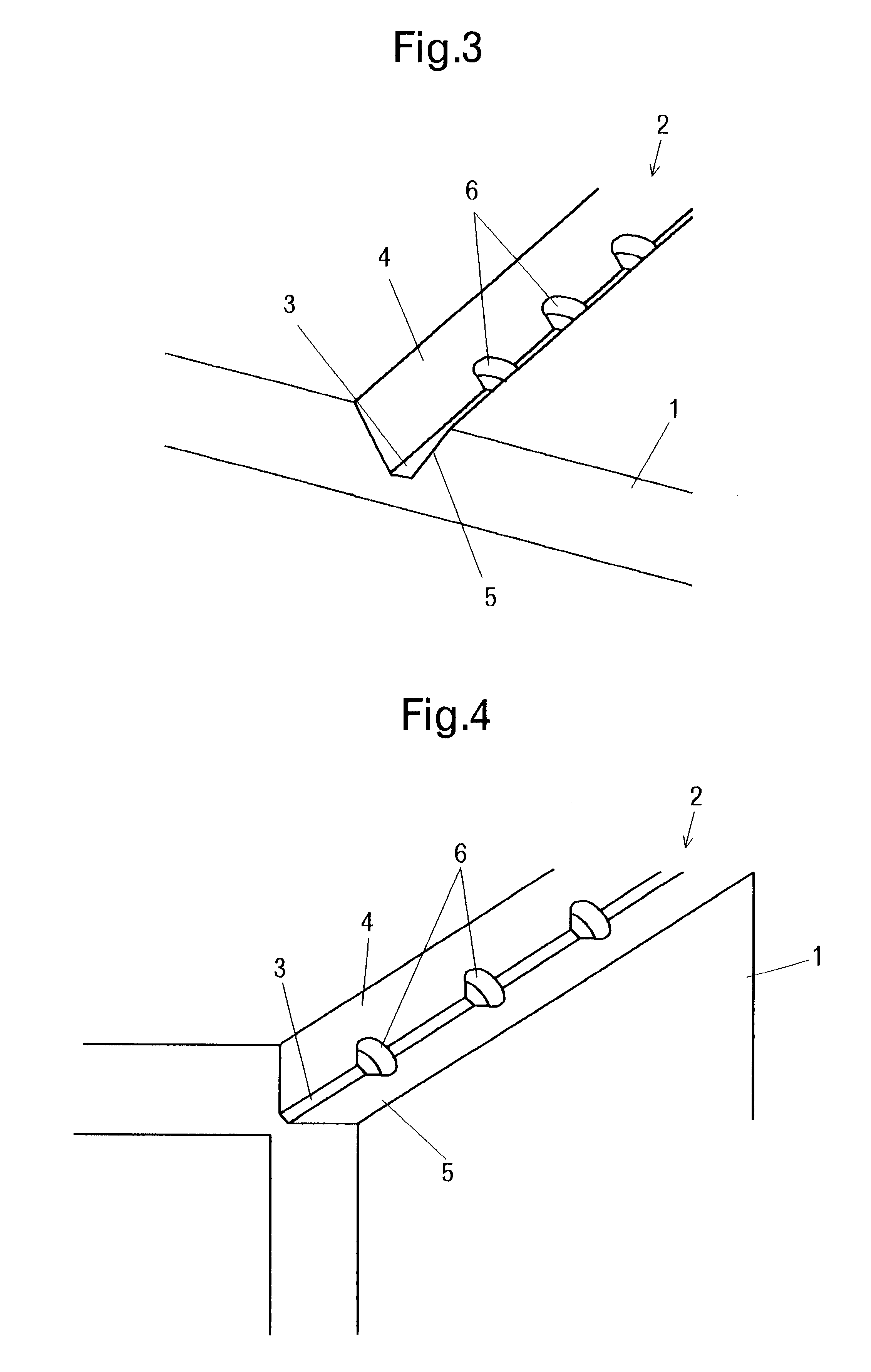

Separator for fuel cell and fuel cell using the same

InactiveUS20050026028A1Simple processMaintain strengthFuel cells groupingFuel cell auxillariesFuel cellsElectrical conductor

The present invention provides, as a separator for fuel cell which is lightweight, can be easily made thin, and which has superior corrosion resistance and shape stability, a fuel cell 100 containing a separator for fuel cell 10, wherein a conductor pattern 2 is formed on one principal plane 1A of an insulation layer 1 to form a groove for a gas flow path 3 sectioned by the conductor pattern 2 on this principal plane, a conductor terminal 4 is formed on the other principal plane 1B of the insulation layer 1, and this conductor terminal 4 and the conductor pattern 2 are electrically connected by a via hole 5 penetrating the insulation layer 1, and a membrane electrode assembly (complex having an electrolyte membrane and an electrode (fuel electrode, oxygen electrode) laminated thereon) 14 having the separator for fuel cell disposed on both surfaces.

Owner:NITTO DENKO CORP

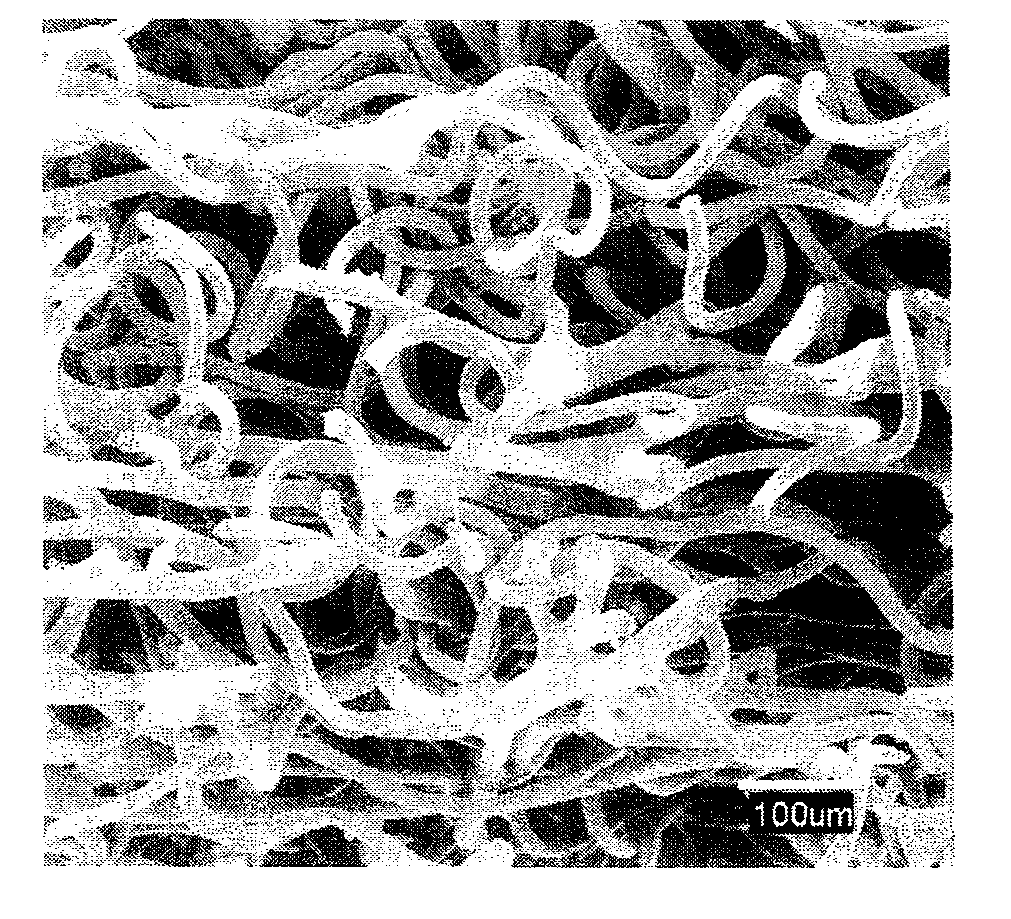

Buffer substrate and use thereof

ActiveUS20100203788A1Improve breathabilityImprove buffering effectInsolesLaminationFiberPolymer science

In a nonwoven fiber assembly which comprises a fiber comprising a thermal adhesive fiber under moisture and in which the fiber are entangled with each other, the fibers are bonded at contacting points of the fibers by melting the thermal adhesive fiber under moisture to distribute the bonded points approximately uniformly, thereby obtaining a buffer substrate. The buffer substrate may further comprises a conjugated fiber comprising a plurality of resins which are different in thermal shrinkage and form a phase separation structure, and the conjugated fibers may have an approximately uniform crimps having an average curvature radius of 20 to 200 μm and are entangled with the fibers constituting the nonwoven fiber assembly. The buffer substrate can be obtained by a method comprising the steps of: forming a web from the fiber comprising the thermal adhesive fiber under moisture; and subjecting the obtained fiber web to a heat and moisture treatment with a high-temperature water vapor to melt the thermal adhesive fiber under moisture for bonding the fibers. The buffer substrate has a high air-permeability, an excellent cushion property and softness.

Owner:KURARAY CO LTD

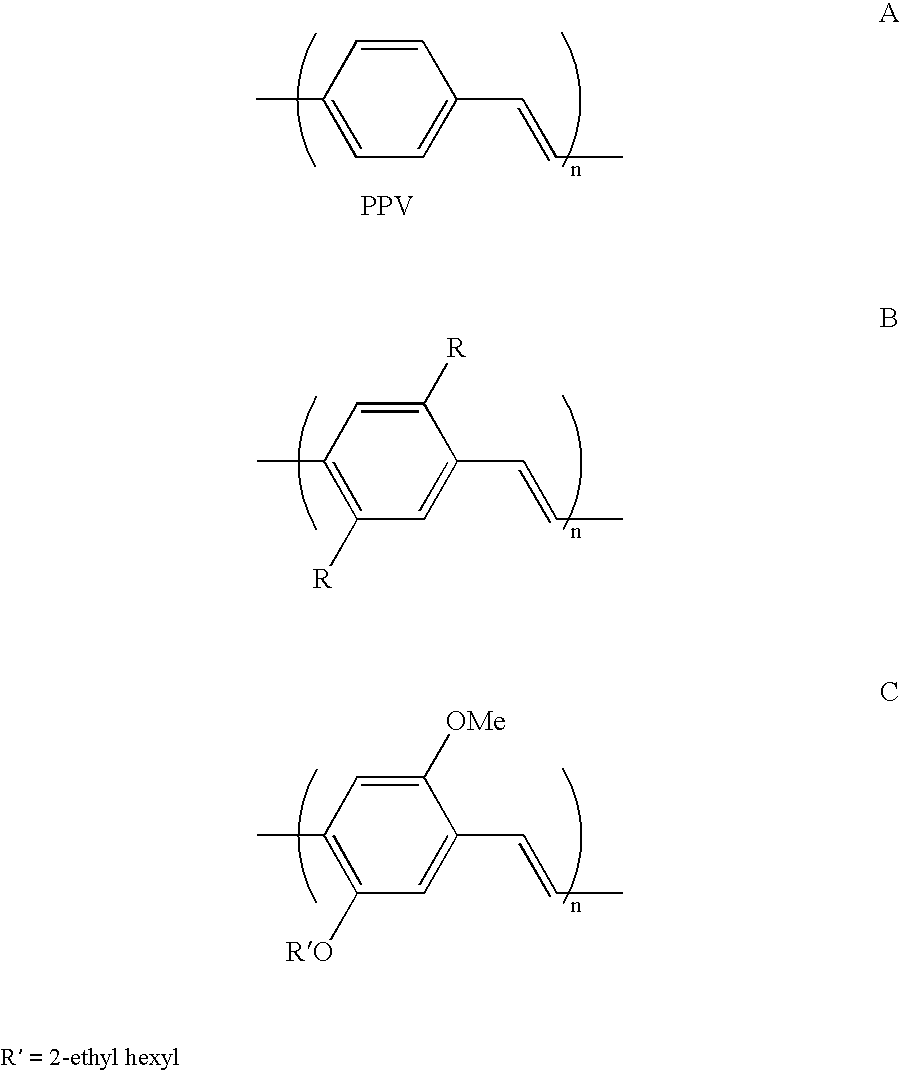

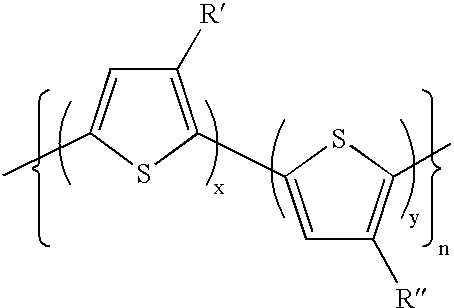

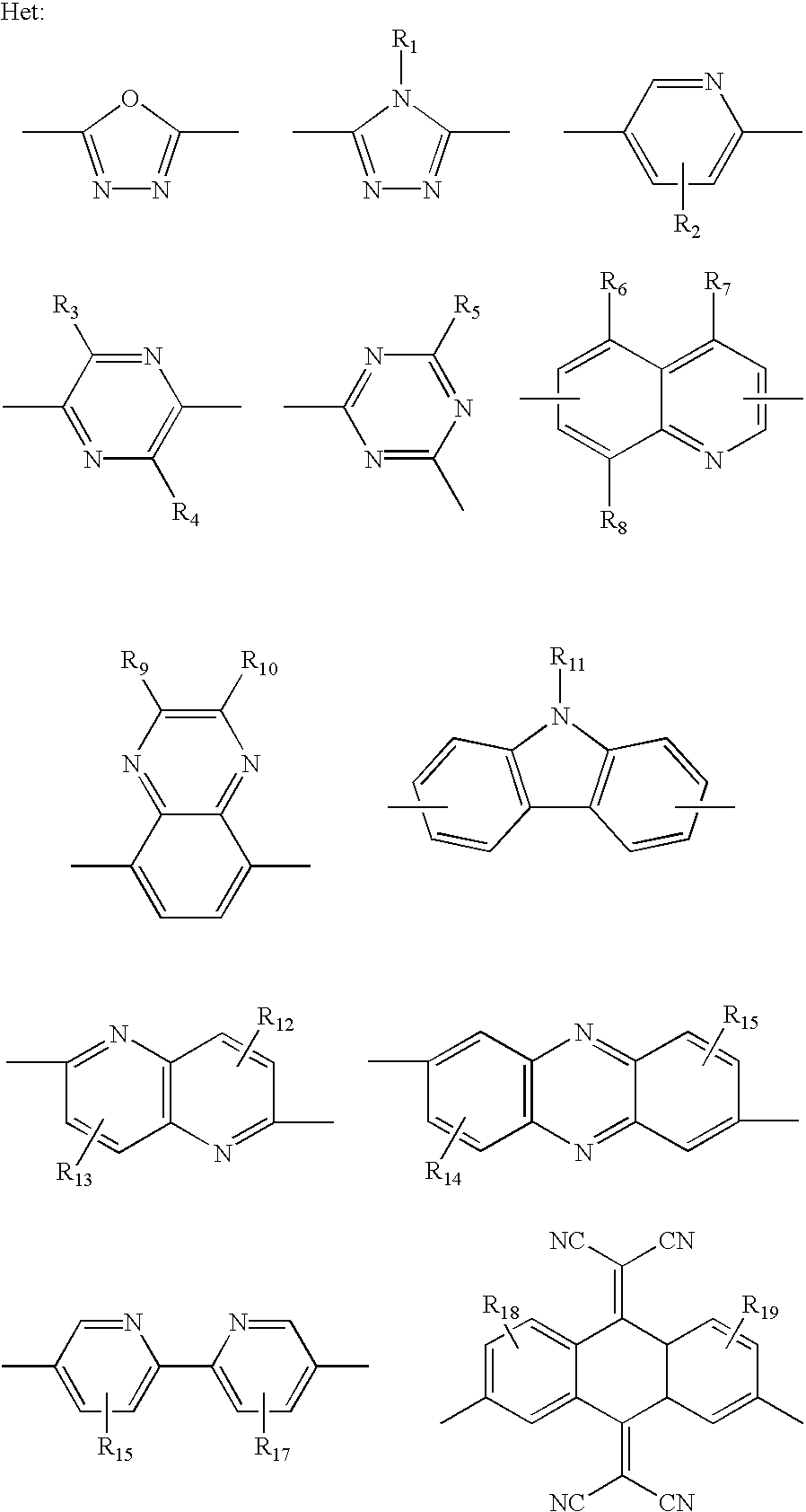

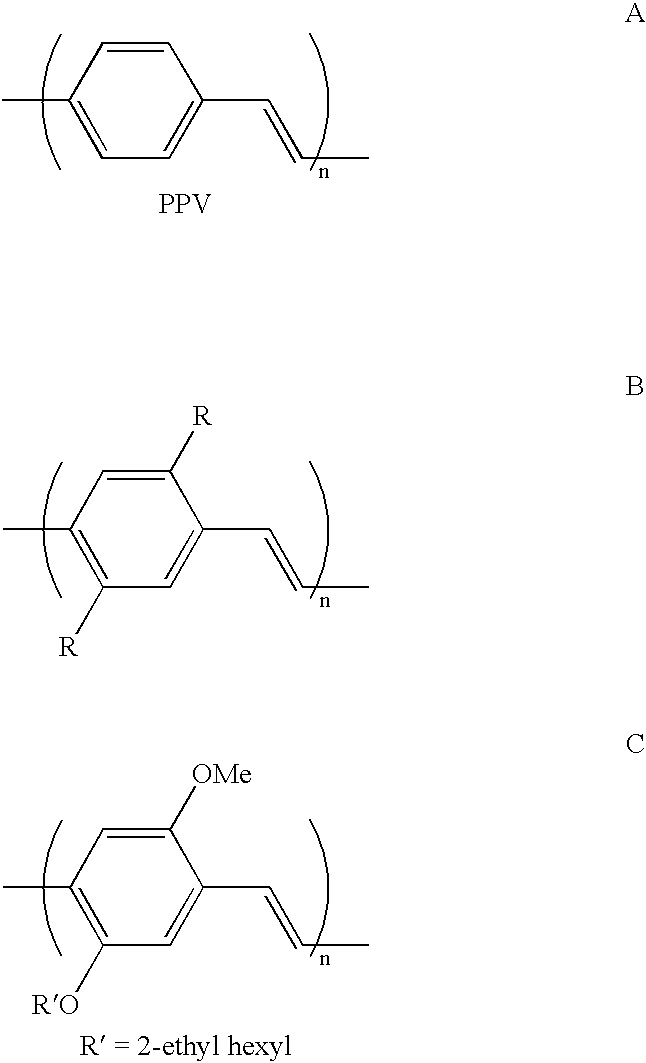

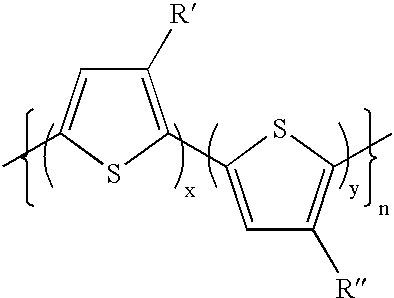

Polymers for use in optical devices

InactiveUS6559256B2Improved shape stabilityQuality improvementElectroluminescent light sourcesConductive materialCross-linkPolymer science

Optical devices fabricated from solvent processible polymers suffer from susceptibility to solvents and morphological changes. A semiconductive polymer capable of luminescence in an optical device is provided. The polymer comprises a luminescent film-forming solvent processible polymer which contains cross-linking so as to increase its molar mass and to resist solvent dissolution, the cross-linking being such that the polymer retains semiconductive and luminescent properties.

Owner:CAMBRIDGE DISPLAY TECH LTD

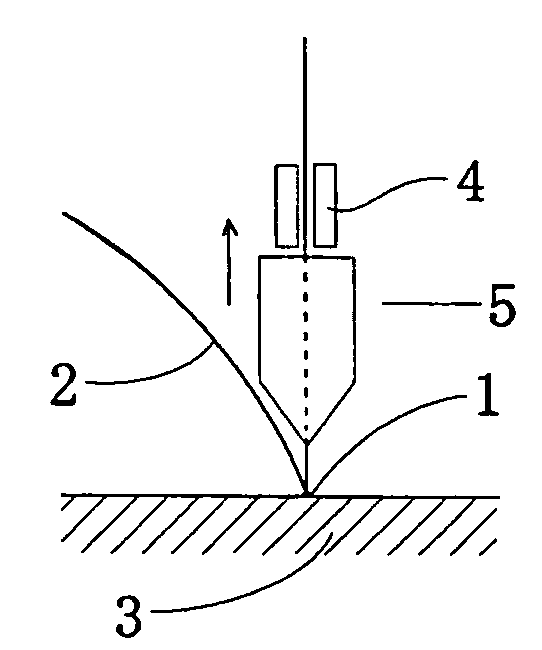

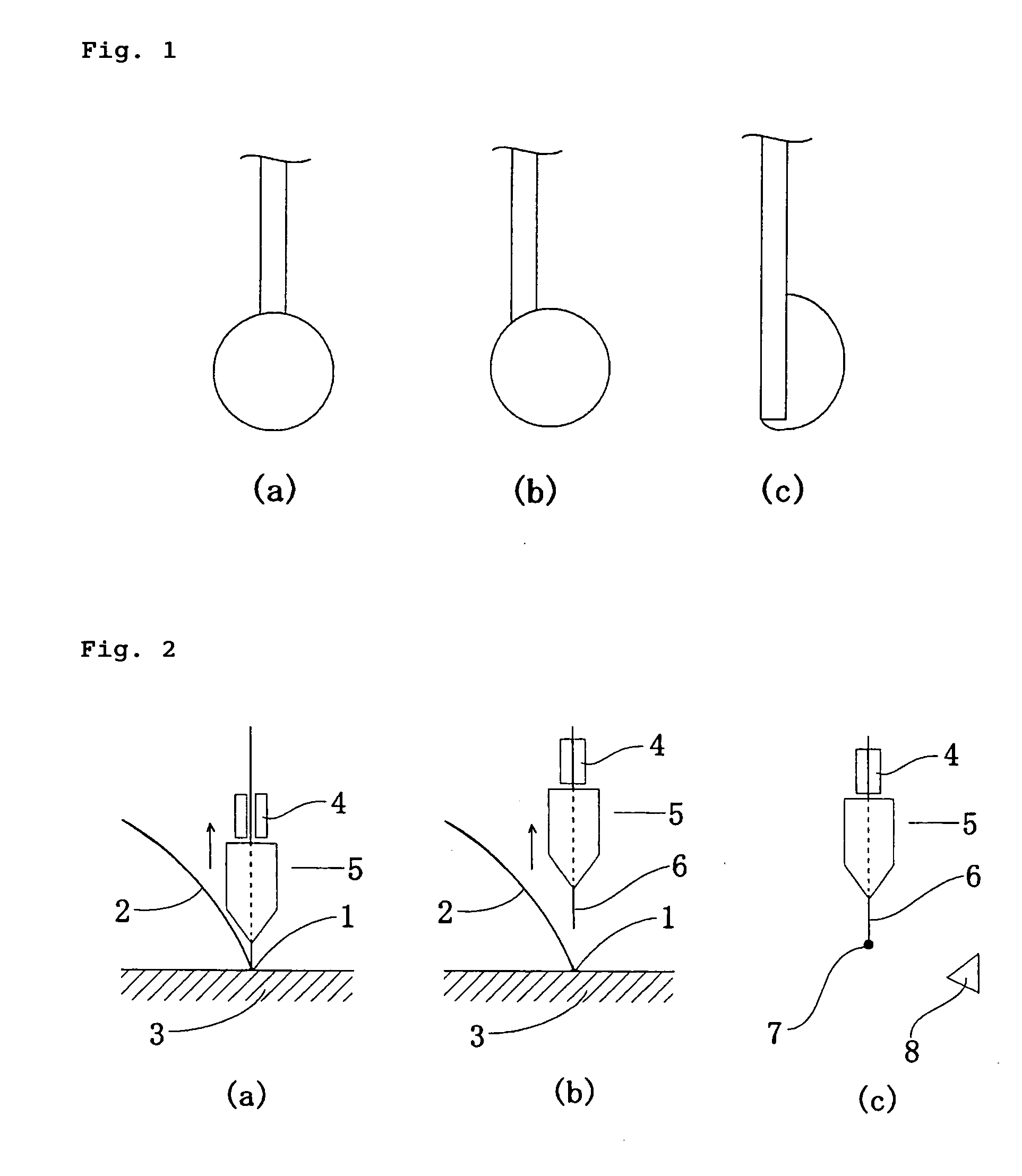

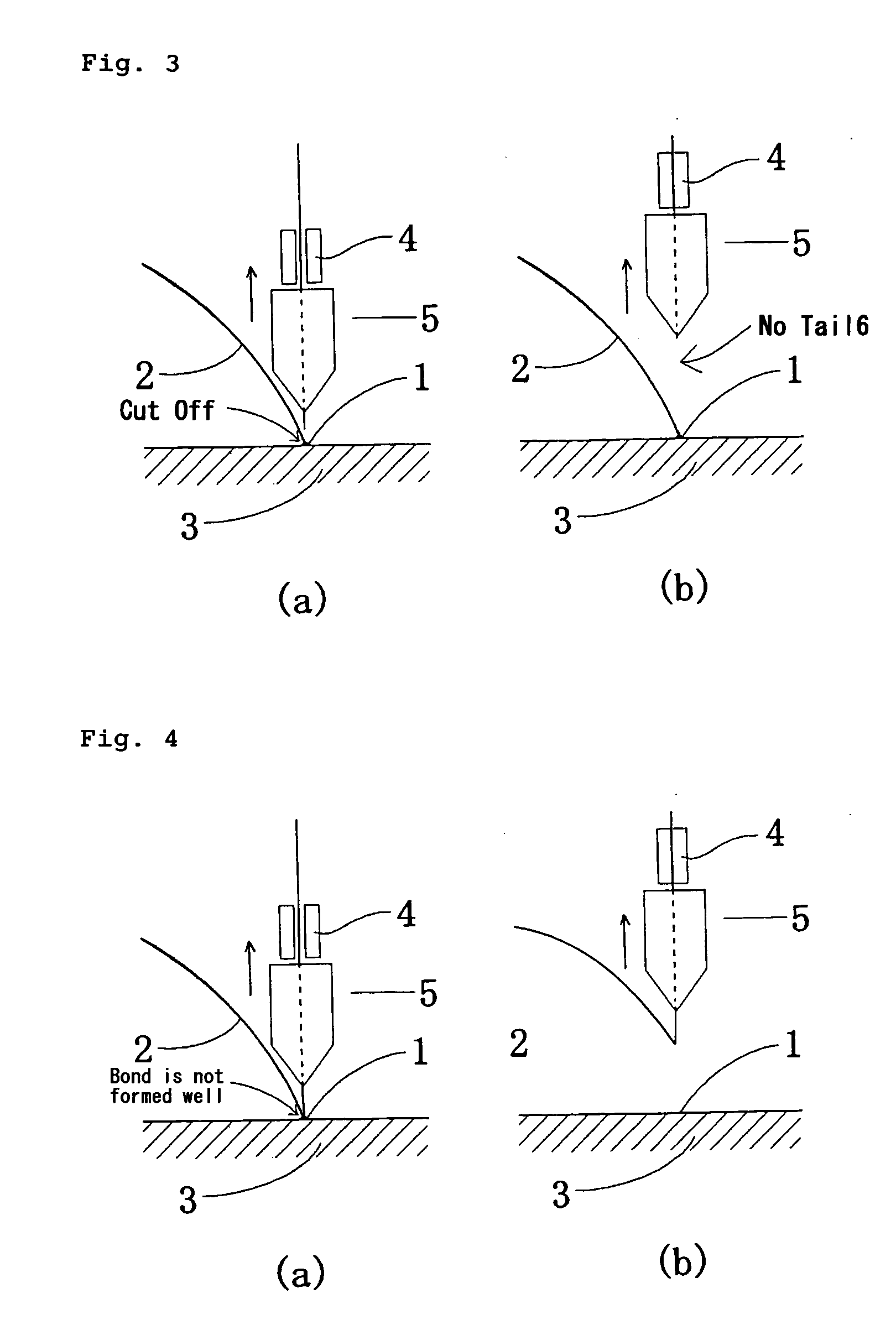

Bonding wire for semiconductor device

ActiveUS7952028B2Improve linearityImprove stabilityNon-insulated conductorsSoldered/welded conductive connectionsEngineeringThinning

A high-performance bonding wire that is suitable for semiconductor mounting technology, such as stacked chip bonding, thinning, and fine pitch mounting, where wire lean (leaning) at an upright position of a ball and spring failure can be suppressed and loop linearity and loop height stability are excellent. This bonding wire for a semiconductor device includes a core material made of a conductive metal, and a skin layer formed on the core material and containing a metal different from the core material as a main component; wherein a relationship between an average size (a) of crystal grains in the skin layer on a wire surface along a wire circumferential direction and an average size (b) of crystal grains in the core material on a normal cross section, the normal cross section being a cross section normal to a wire axis, satisfies an inequality of a / b≦0.7.

Owner:NIPPON MICROMETAL CO LTD +1

Resist composition for liquid immersion exposure process and method of forming resist pattern therewith

ActiveUS20060154170A1Improved shape stabilityLarge investment in equipmentPhoto-taking processesRadiation applicationsSolubilityStructural unit

A resist composition for liquid immersion lithography process, which comprises: (A) a polymer comprising (a1) alkali-soluble constitutional units each comprising an alicyclic group having both (i) a fluorine atom or a fluoroalkyl group and (ii) an alcoholic hydroxyl group, wherein the polymer changes in alkali-solubility due to the action of acid; and (B) an acid generator which generates acid due to exposure to light, and a method for forming a resist pattern using the resist composition. By the resist composition or the method, an adverse effect of the immersion liquid can be avoided while achieving high resolution and high depth of focus.

Owner:TOKYO OHKA KOGYO CO LTD

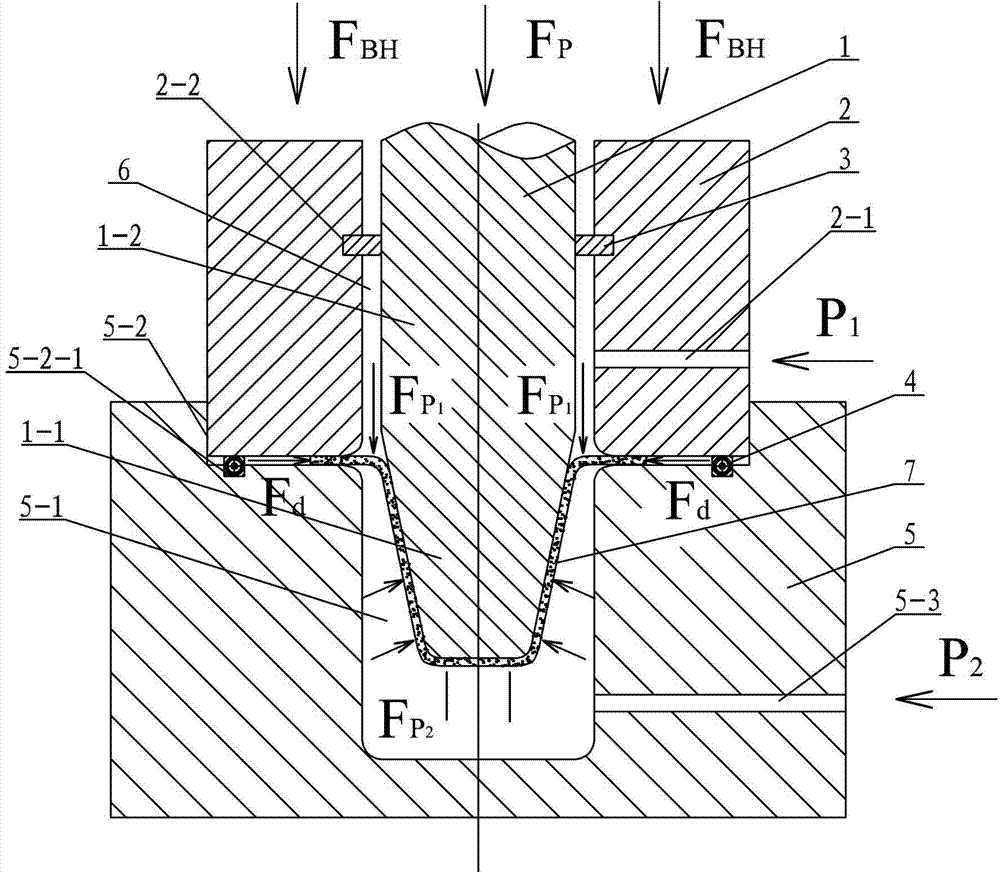

Procesing equipment capable of improving plate part formation limitation and method therefor

Owner:HARBIN INST OF TECH

Bonding Wire and Integrated Circuit Device Using the Same

InactiveUS20070235887A1Excellent characteristicsLow production costNon-insulated conductorsSemiconductor/solid-state device detailsHardnessUltimate tensile strength

A bonding wire comprising a core and a coating layer formed on the core, wherein the coating layer is formed from a metal having a higher melting point than the core, and further has at least one of the following characteristics; 1. the wet contact angle with the coating layer when the core is melted is not smaller than 20 degrees; 2. when the bonding wire is hung down with its end touching a horizontal surface, and is cut at a point 15 cm above the end and thus let drop onto the horizontal surface, the curvature radius of the formed arc is 35 mm or larger; 3. the 0.2% yield strength is not smaller than 0.115 mN / μm2 but not greater than 0.165 mN / μm2; or 4. the Vickers hardness of the coating layer is 300 or lower.

Owner:SUMITOMO ELECTRIC IND LTD

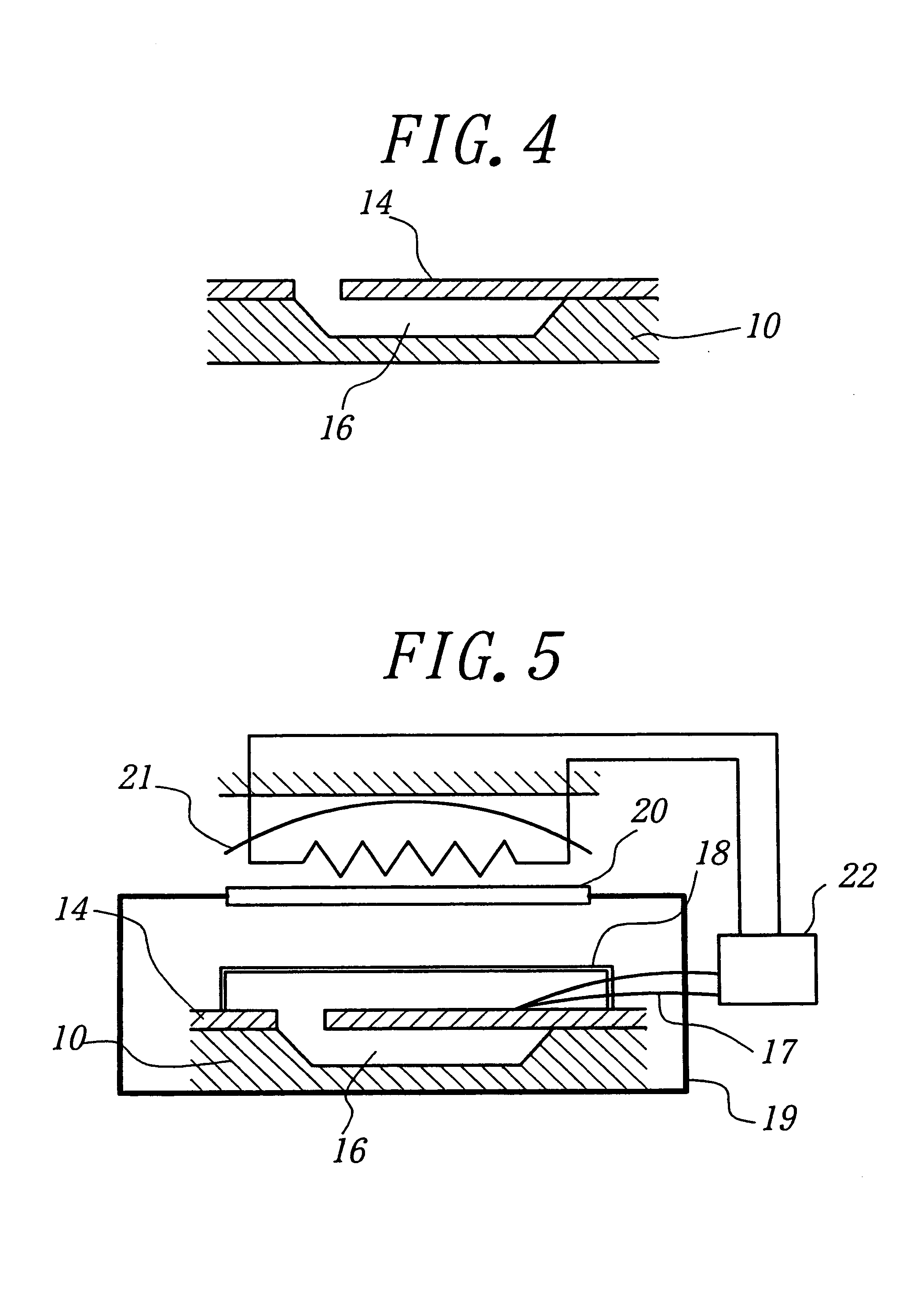

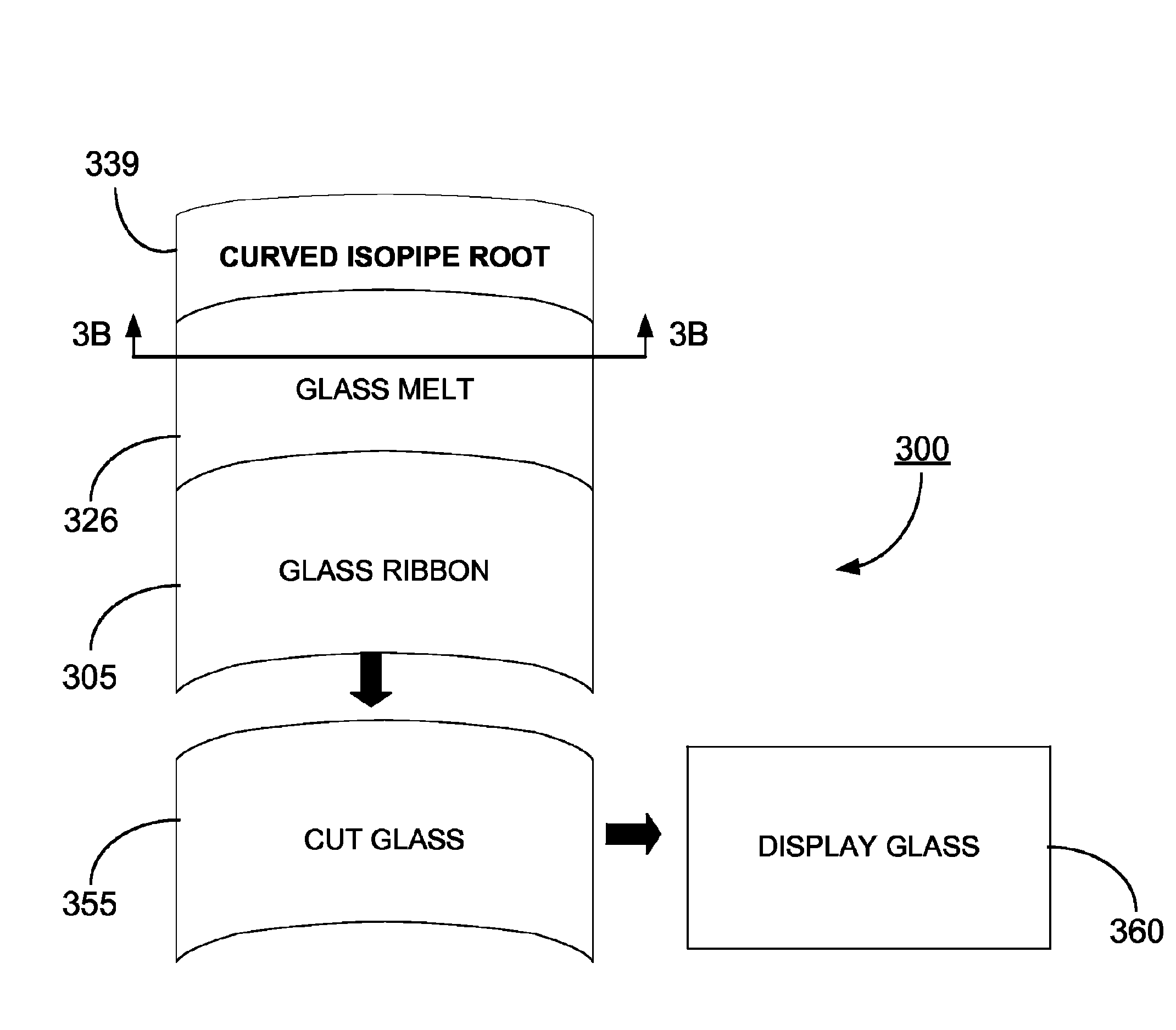

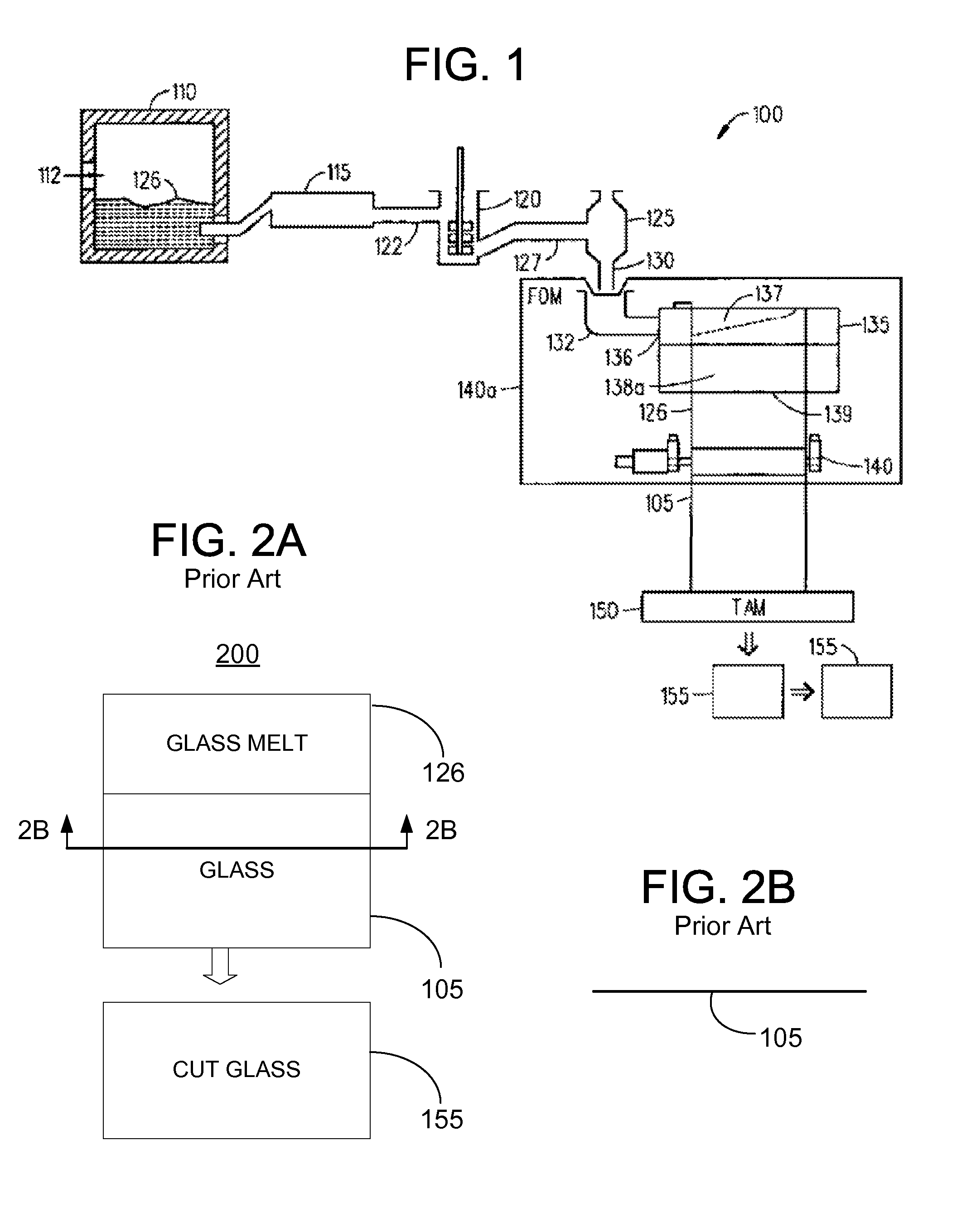

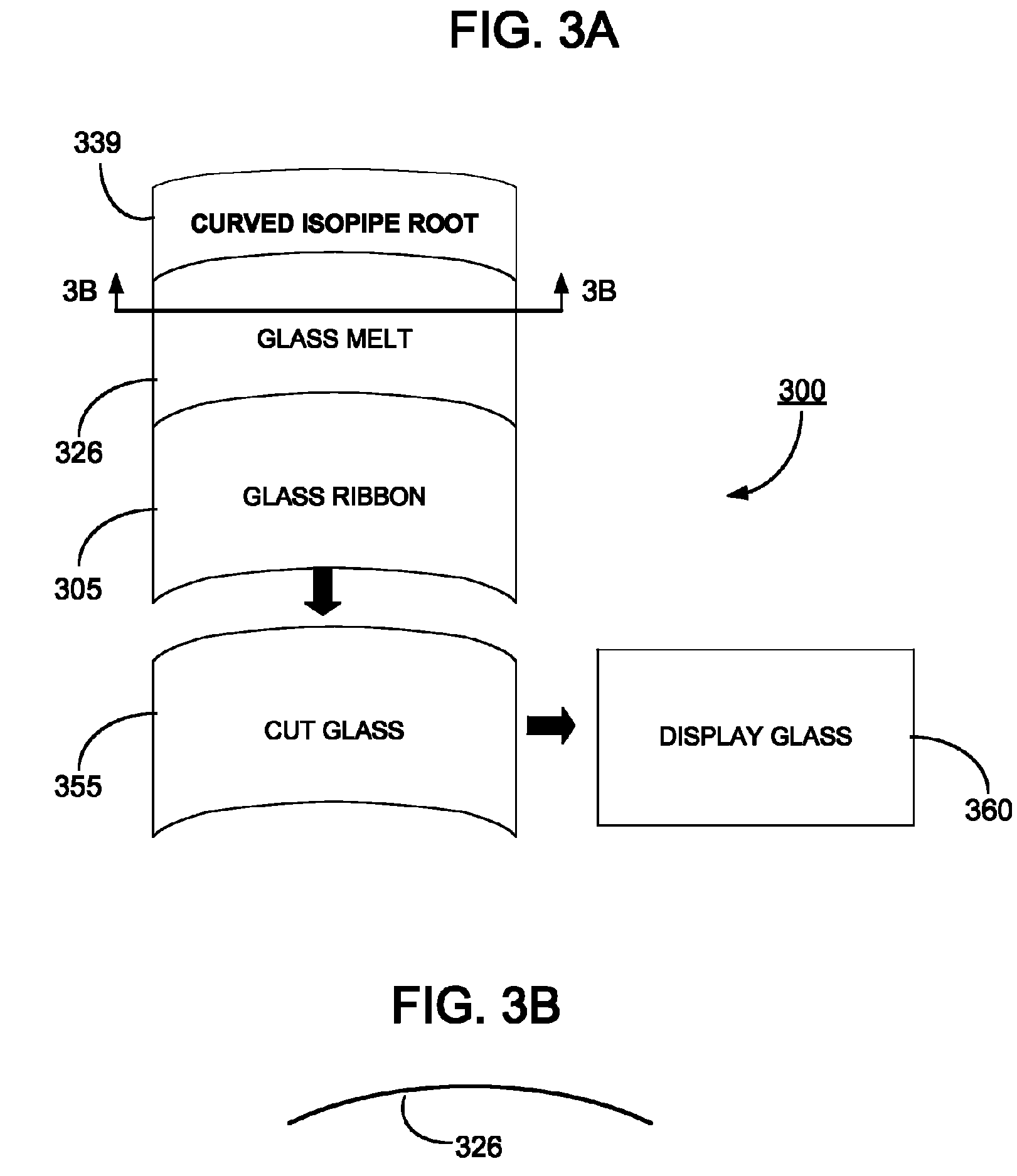

Forming glass sheets with improved shape stability

InactiveUS7818980B2Improved shape stabilityRelieve pressureLayered productsGlass furnace apparatusDisplay deviceEngineering

Owner:CORNING INC

High melt strength polypropylene

InactiveUS20050159564A1Improve melt strengthHigh viscosityChemical/physical/physico-chemical stationary reactorsPolymer scienceHydrogen

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / 10 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

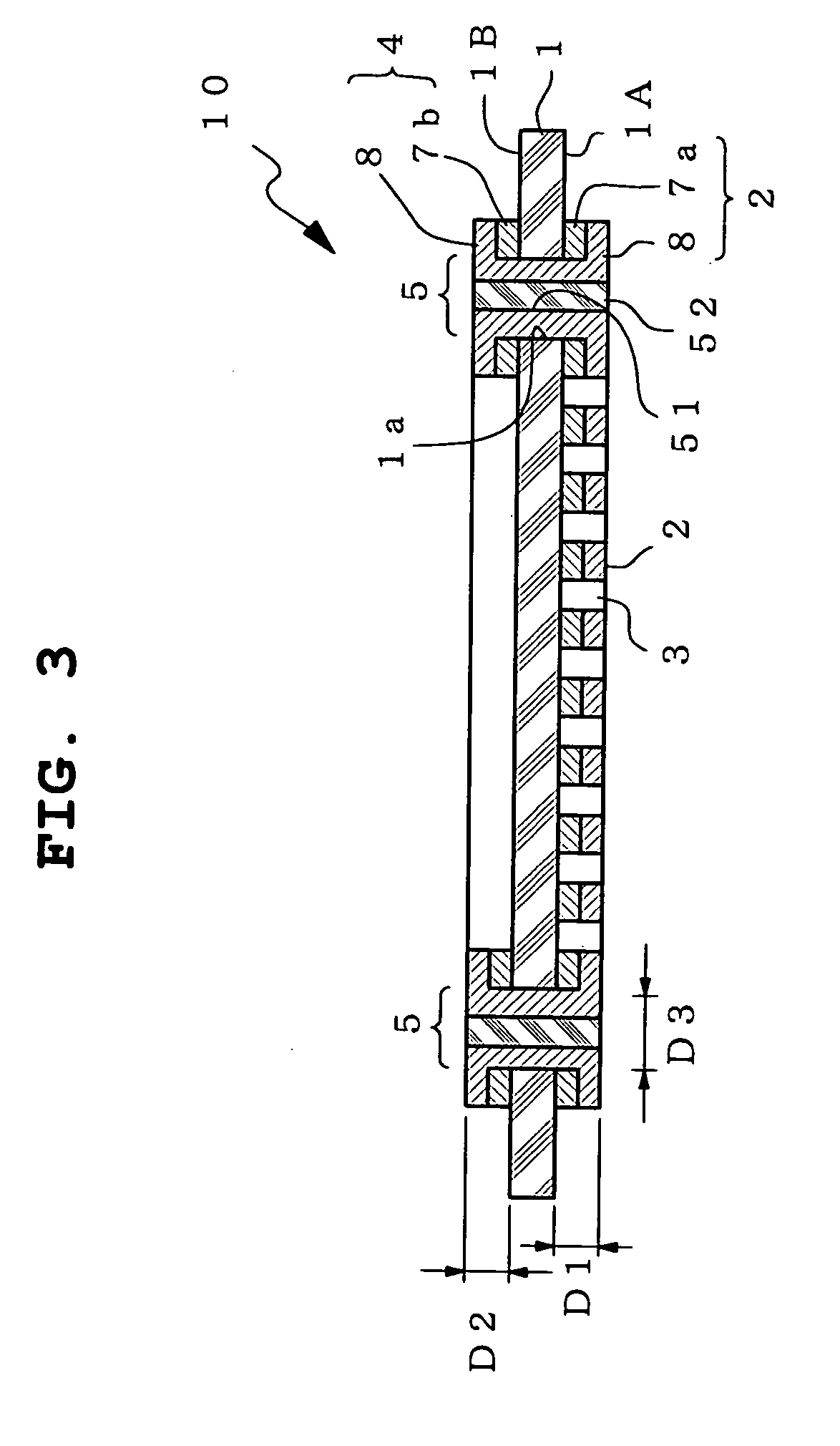

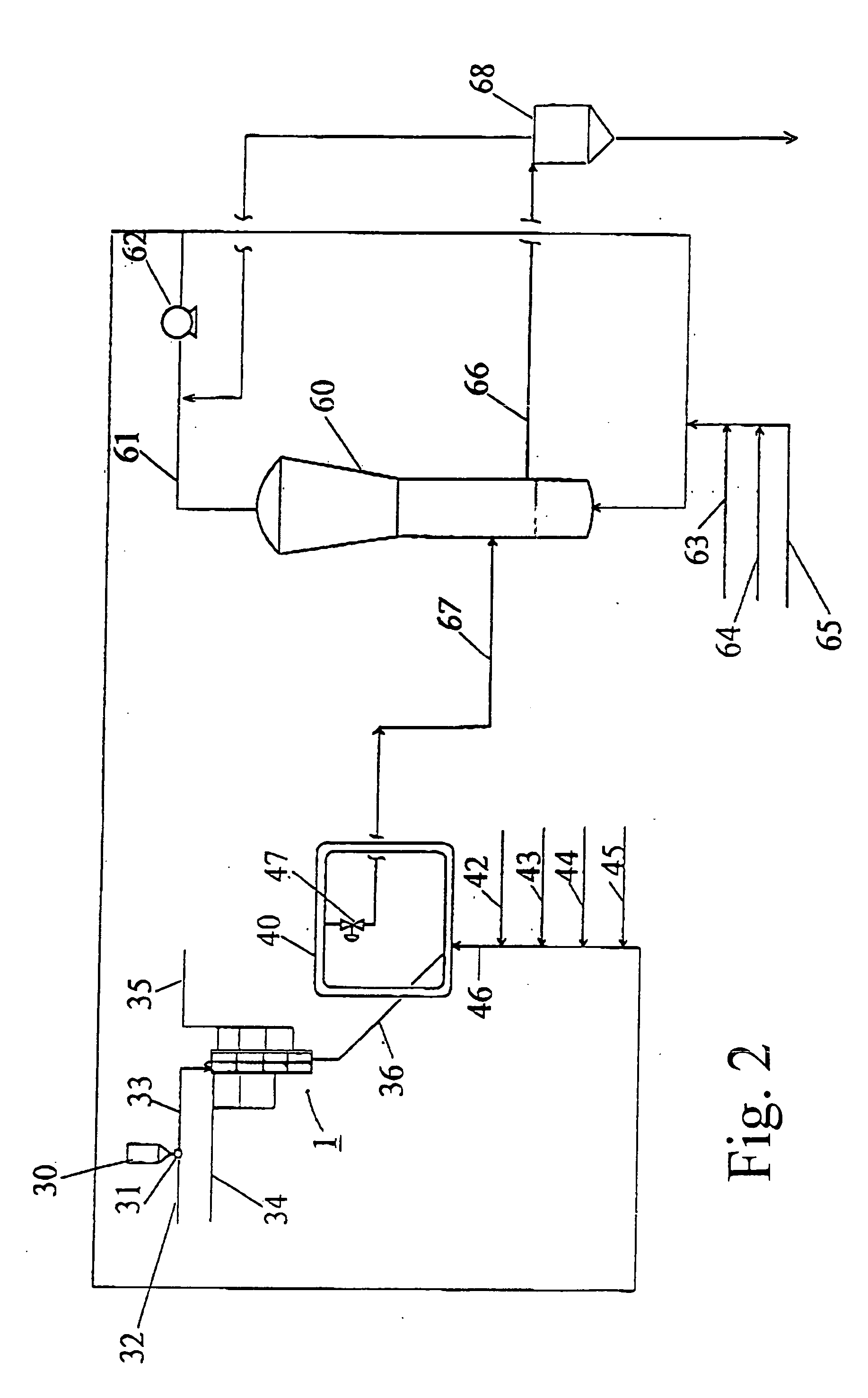

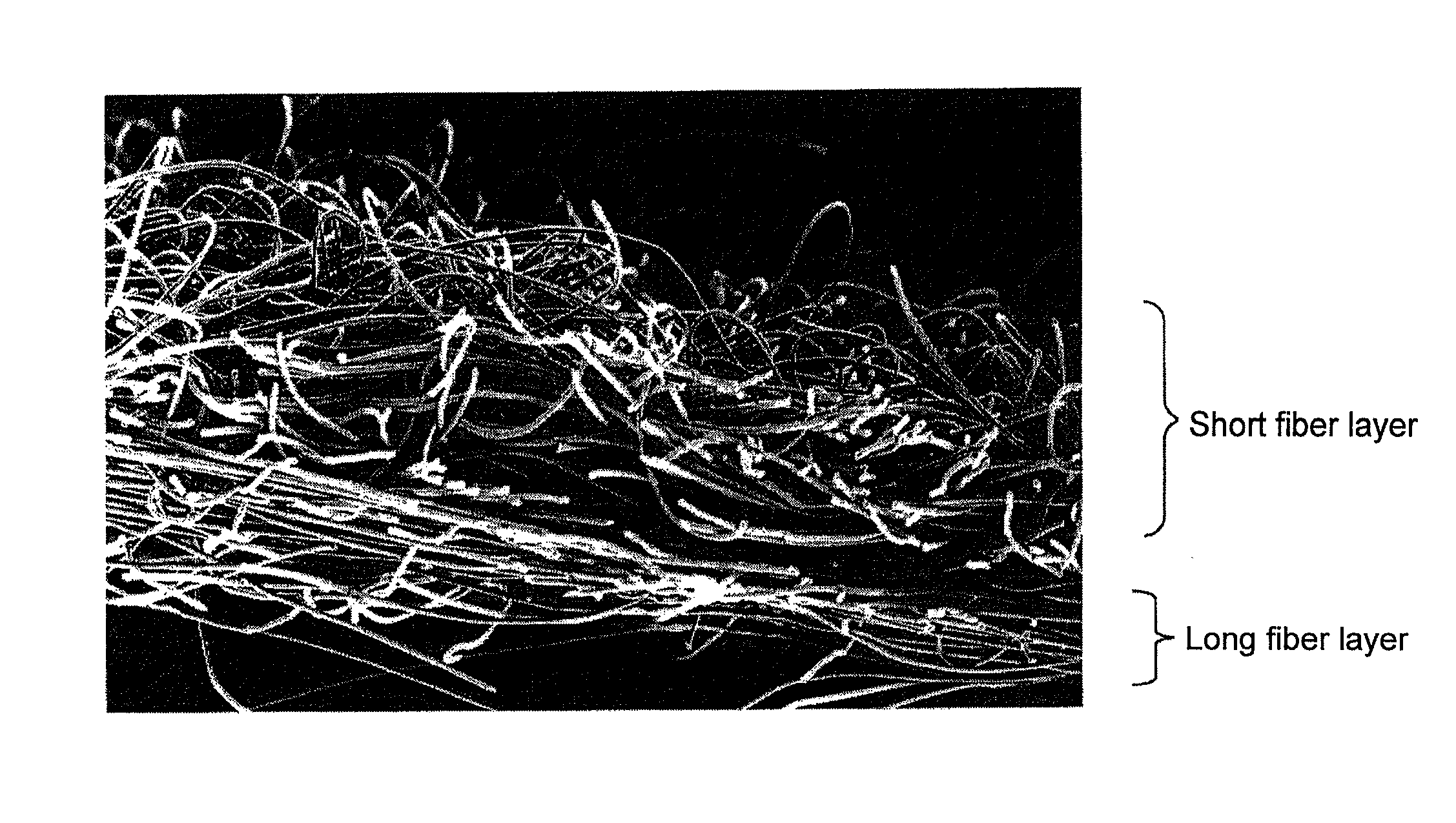

Filter material for removing aggregates and method of filtering blood product

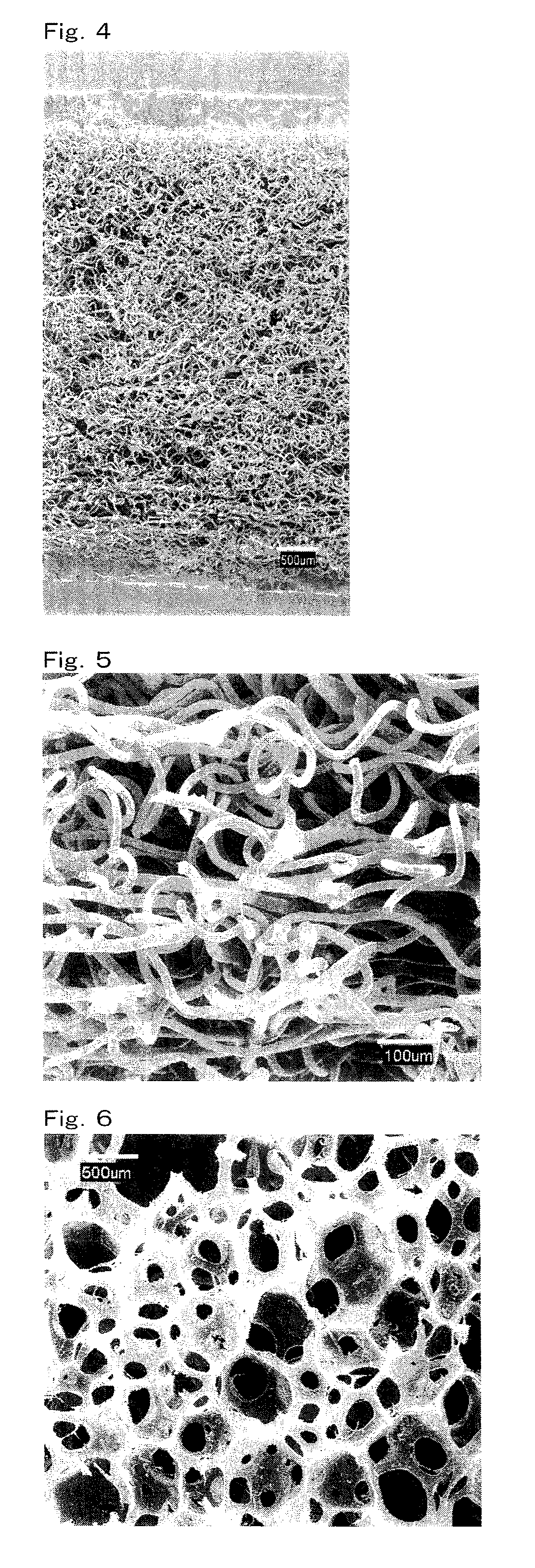

InactiveUS20110031191A1Efficient removalAvoid cloggingSemi-permeable membranesDialysis systemsWhole blood productMedicine

An aggregate-removing filter material efficiently removes aggregates that are contained in a blood product for transfusion and may cause transfusion reactions without clogging, and exhibits excellent quality stability, and a blood product filtration method uses a filter apparatus that includes the aggregate-removing filter material and a leukocyte-removing filter material. The aggregate-removing filter material includes short fibers having a fineness of 0.7 to 4.0 dtex and a fiber length of 1 to 80 mm, and a ground fabric that includes long fibers, a fiber axis of the long fibers being oriented in a planar direction of the ground fabric, the short fibers being entangled with the ground fabric so that the aggregate-removing filter material has a total weight per unit area of 10 to 80 g / m2, and a layer of the short fibers forming a three-dimensional structure.

Owner:ASAHI KASEI MEDICAL CO LTD

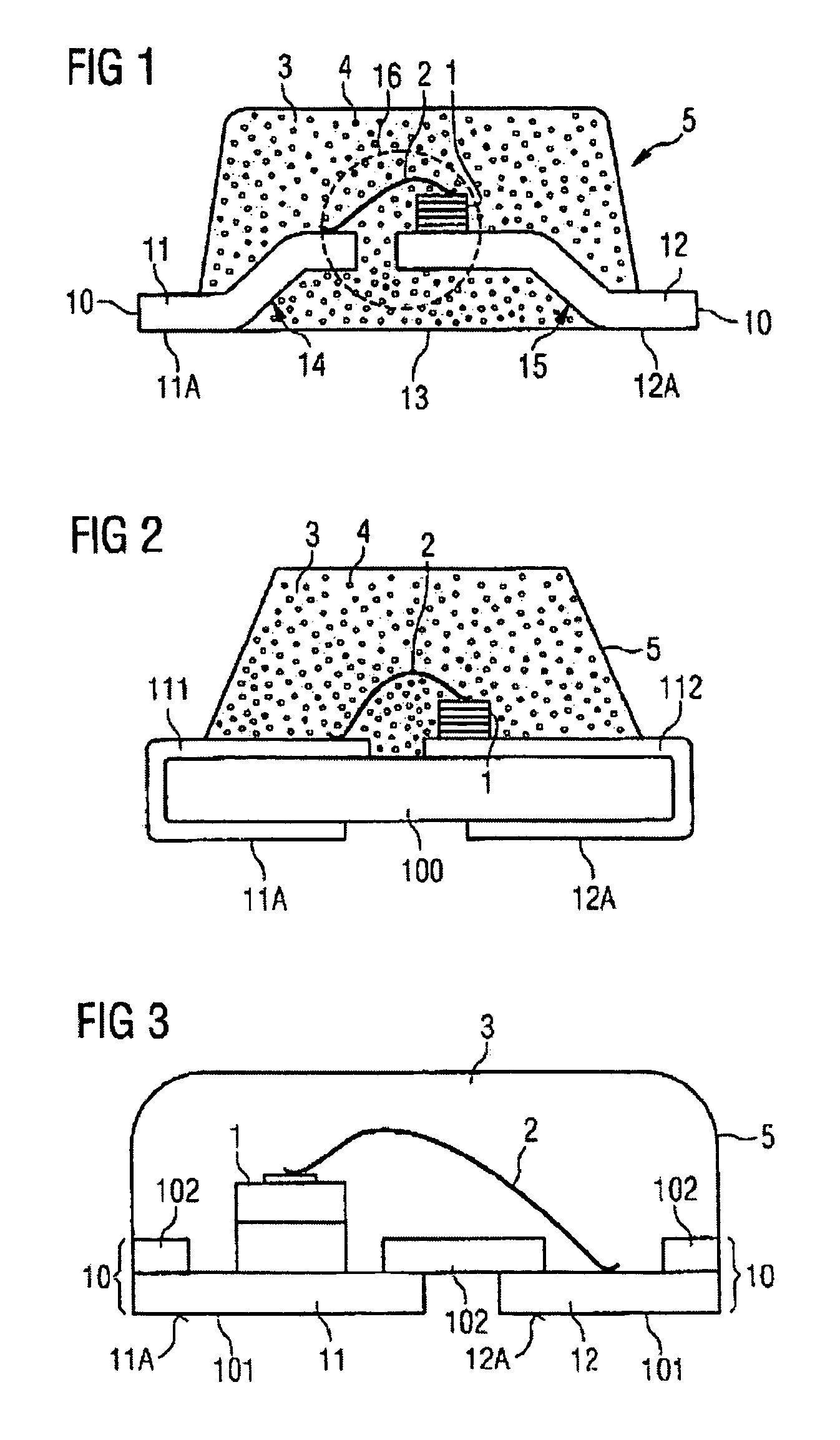

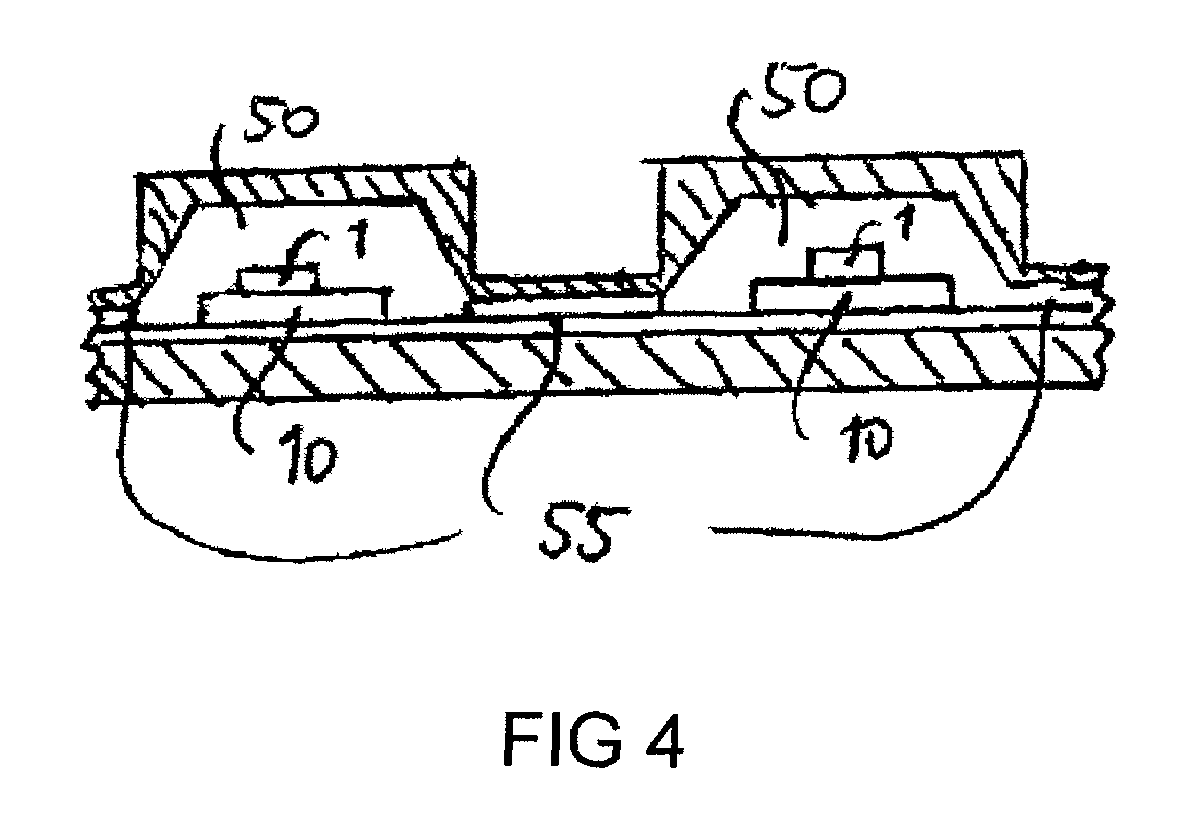

Radiation-emitting and/or radiation-receiving semiconductor component and method for the production thereof

ActiveUS7666715B2Simple processSolve the lack of resistanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipElectromagnetic radiation

A radiation-emitting and / or radiation-receiving semiconductor component comprising a radiation-emitting and / or radiation-receiving semiconductor chip, a molded plastic part which is transparent to an electromagnetic radiation to be emitted and / or received by the semiconductor component and by which the semiconductor chip is at least partially overmolded, and external electrical leads that are electrically connected to electrical contact areas of the semiconductor chip. The molded plastic part is made of a reaction-curing silicone molding compound. A method of making such a semiconductor component is also specified.

Owner:OSRAM OLED

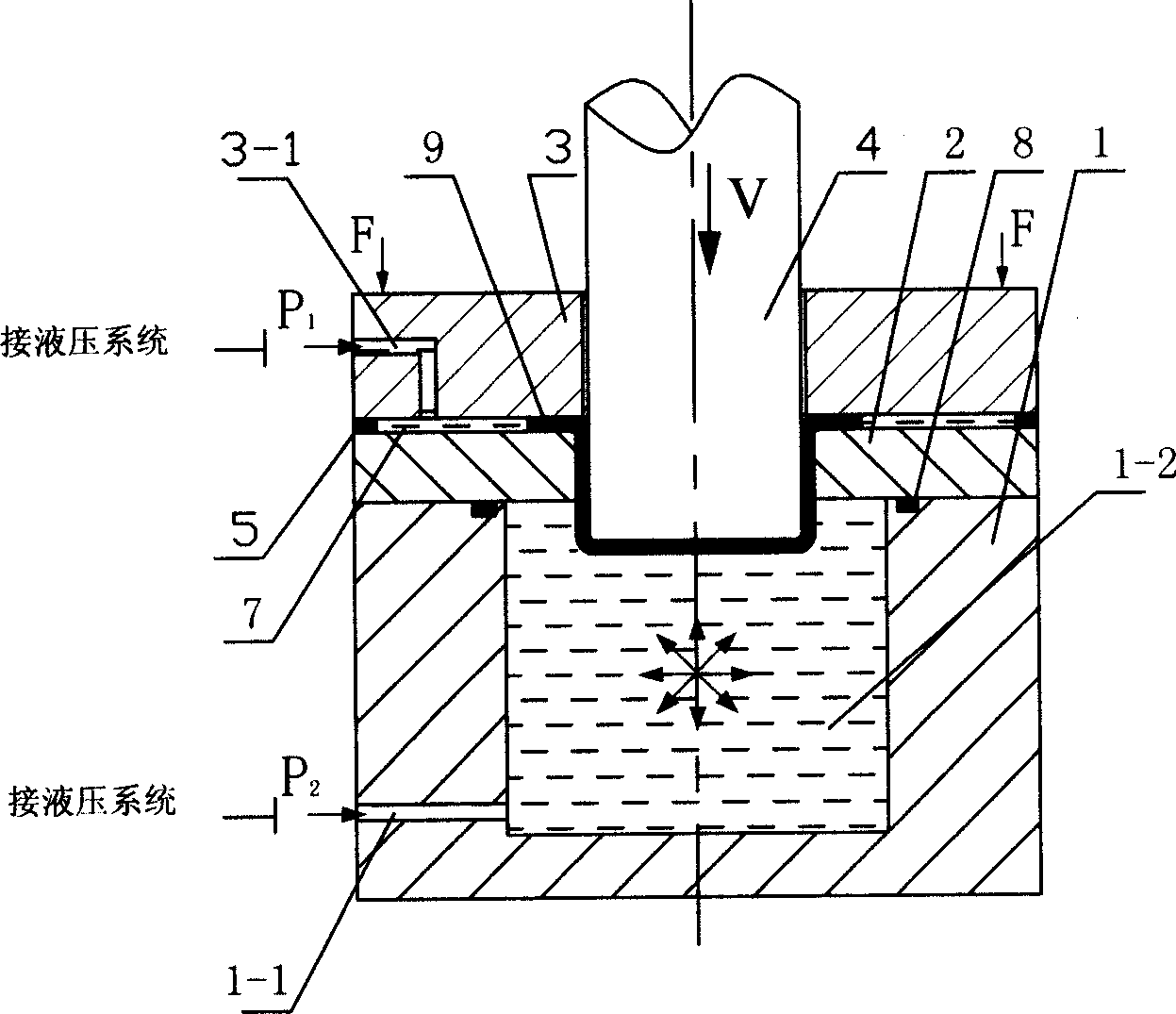

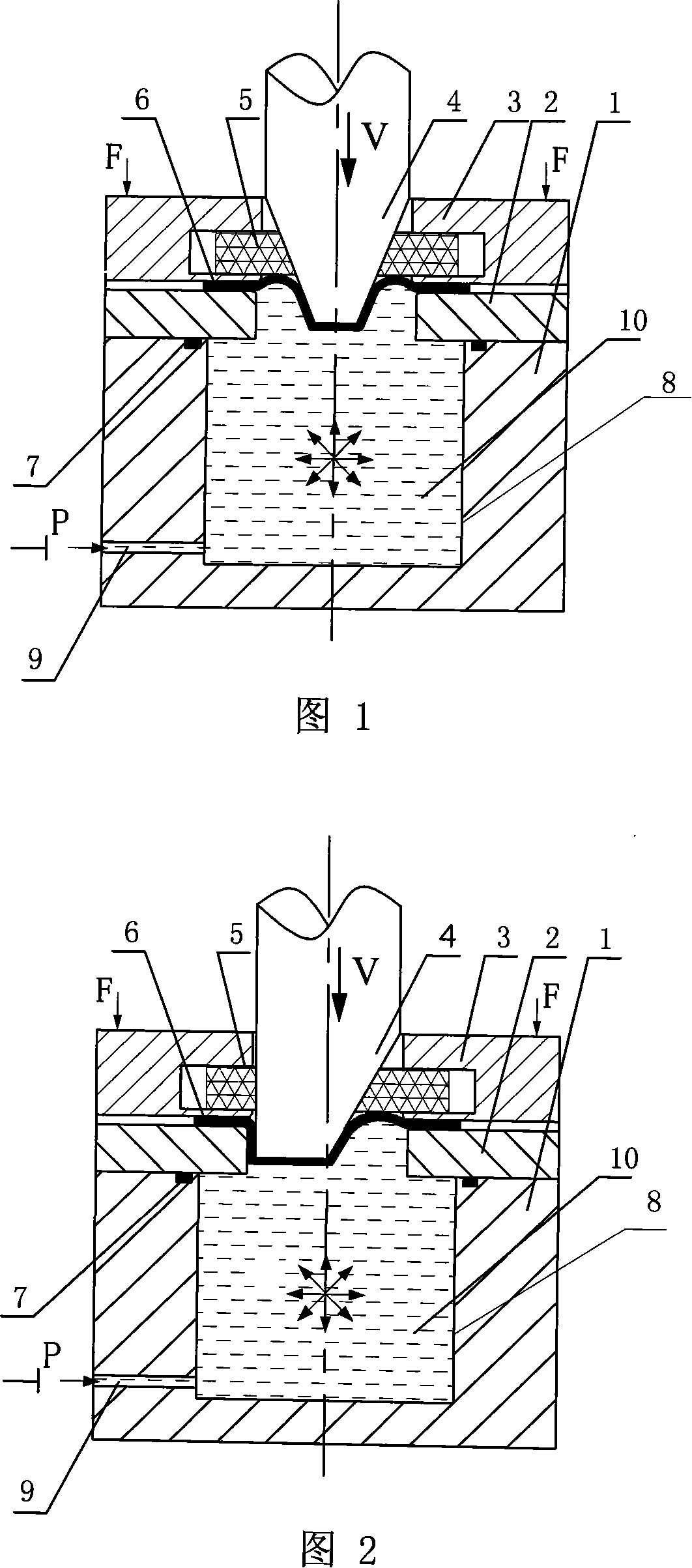

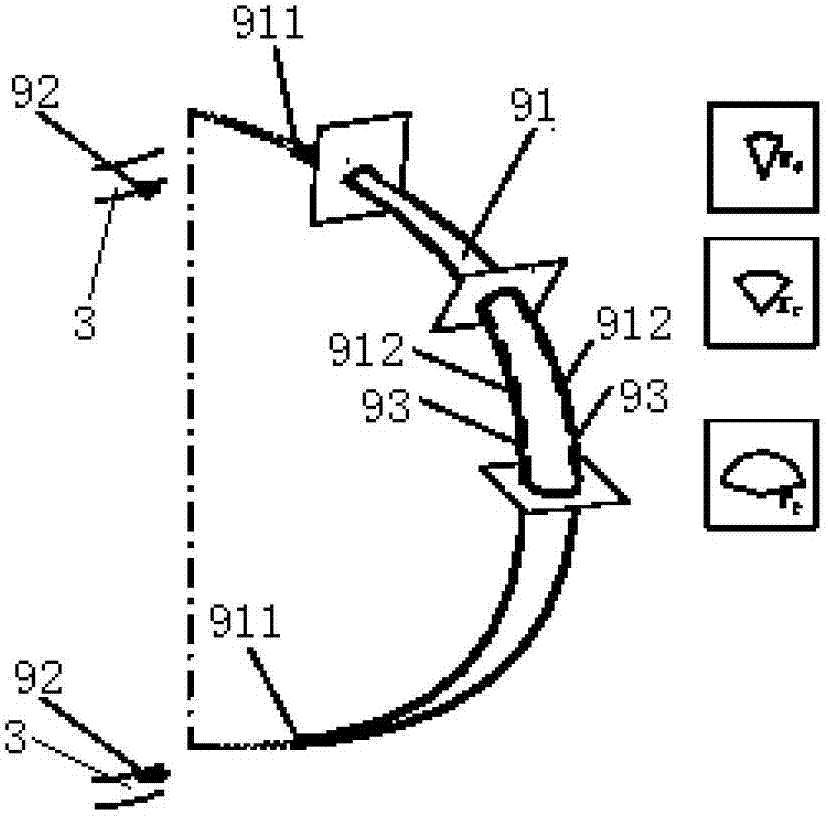

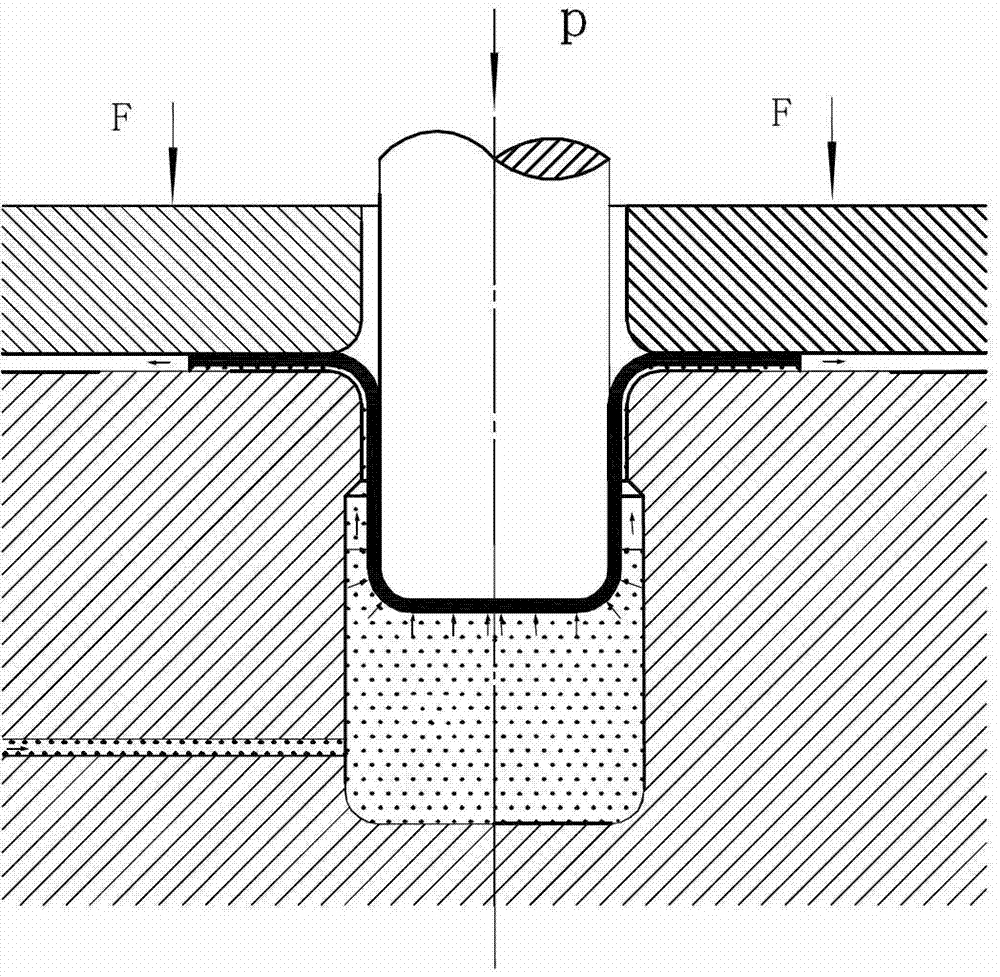

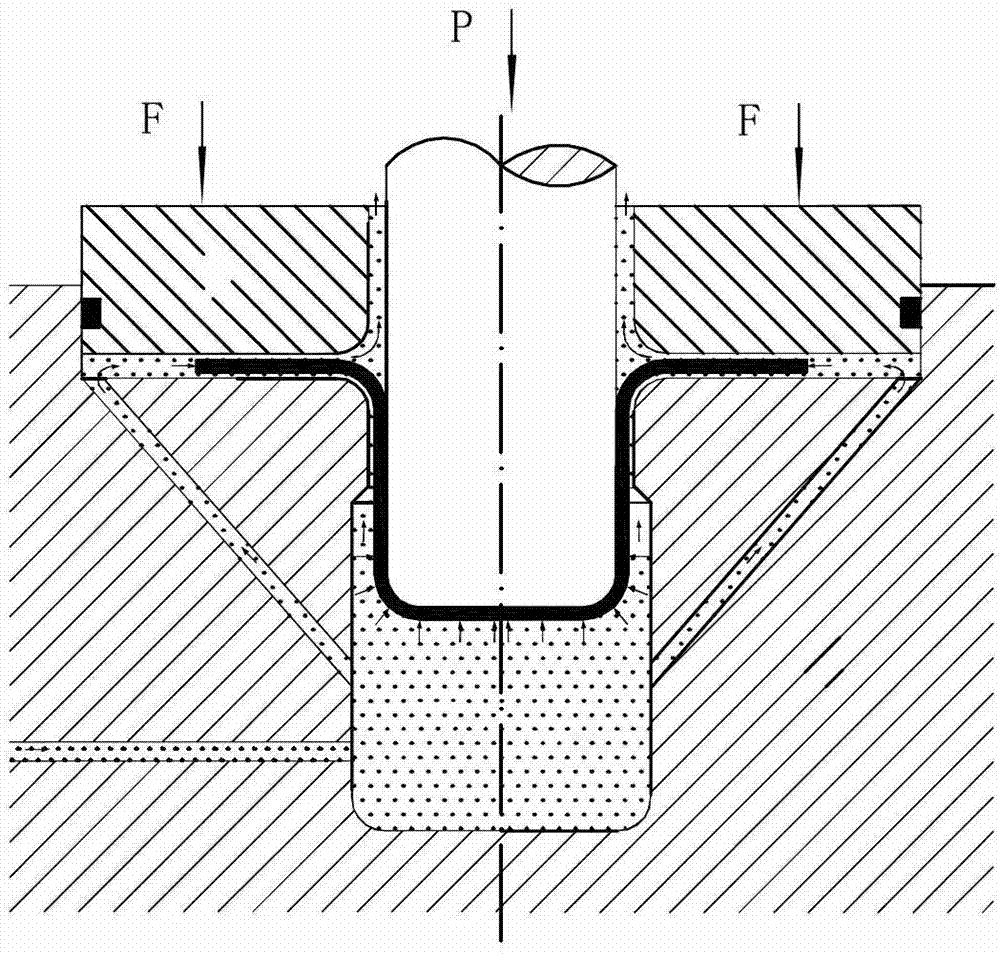

Device for preventing suspension area from breaking while taper piece filling liquid and drawing deep forming and forming method

InactiveCN101147940AReduce frictionReduce friction, so that the surface of the billet is fully protectedShaping toolsEngineeringMechanical engineering

The present invention relates to a conical component forming device capable of preventing floating zone from being broken when the conical component is formed by adopting liquid-charging and drawing process and its forming method. Said conical component forming device is characterized by that its rigid edge-pressing ring is set over a concave die, in said rigid edge-pressing ring interior a recessed groove is cut, a flexible supporting ring is placed in the recessed groove interior, said concave die is placed on the fluid medium cavity, and its liquid-injecting hole is connected with its hydraulic system. Its forming method includes the following steps; (1), making the liquid-injecting hole on the cavity body be communicated with the hydraulic system; (2), placing a plate blank on the concave die; (3), making the rigid edge-pressing ring be moved downwards and apply edge-pressing force; and (4), making convex die be downwards moved until the plate blank is drawn into the concave die interior with the convex die so as to obtain a formed conical component.

Owner:HARBIN INST OF TECH

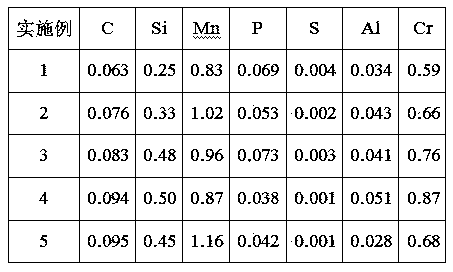

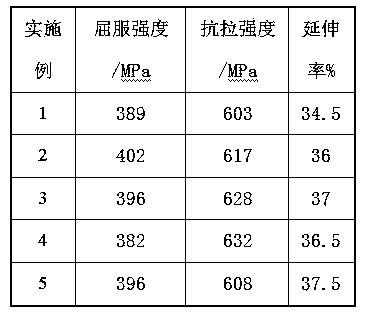

600 MPa-level thick-specification hot rolling spoke steel and manufacturing method thereof

The invention provides 600 MPa-level thick-specification hot rolling spoke steel and a manufacturing method thereof. The spoke steel comprises the following chemical constituents in mass percent: 0.06-0.12% of C, 0.20-0.60% of Si, 0.80-1.20% of Mn, 0.02-0.06% of Alt, 0.50-1.00% of Cr, 0.03-0.08% of P, smaller than or equal to 0.005% of S, smaller than or equal to 0.006% of N, and the balance of Fe and inevitable impurities. In the manufacturing method of the spoke steel, the billet heating temperature is 1,150-1,250 DEG C, and the finish rolling temperature is 760-840 DEG C; after rolling, a conventional cooling technology is used to cool the steel at a cooling rate of 20-100 DEG C per second to 350 DEG C below, and then the steel is reeled. The steel plate is good in processability and fatigue performance, and free of Nb, V, Mo, Ni and other elements, so as to save the production cost. The steel plate provided by the invention can be widely applied to the spoke production of steel wheels of commercial vehicles.

Owner:SHANDONG IRON & STEEL CO LTD

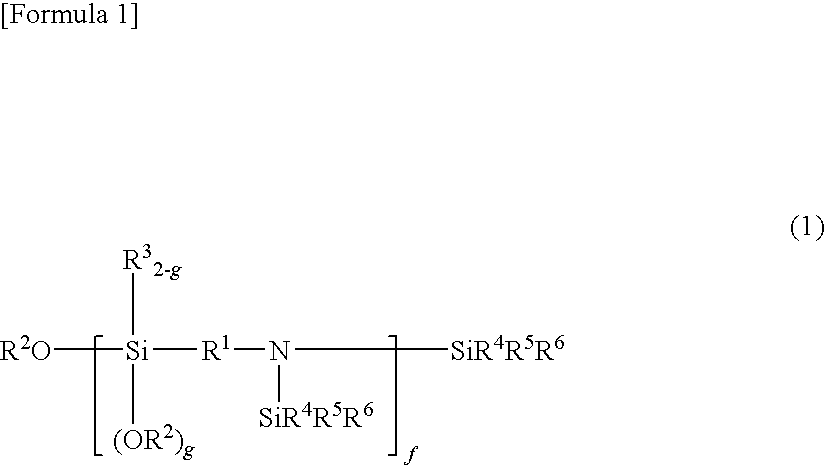

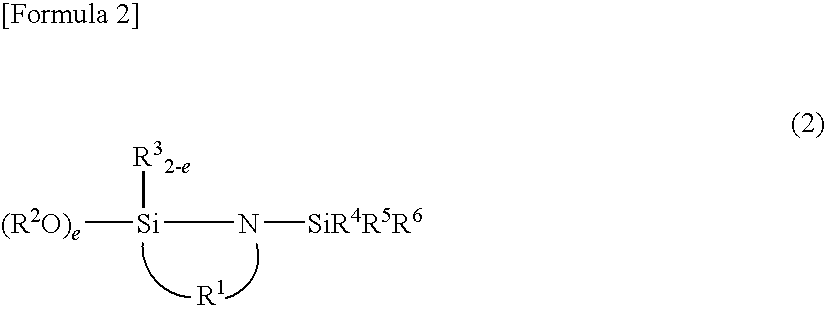

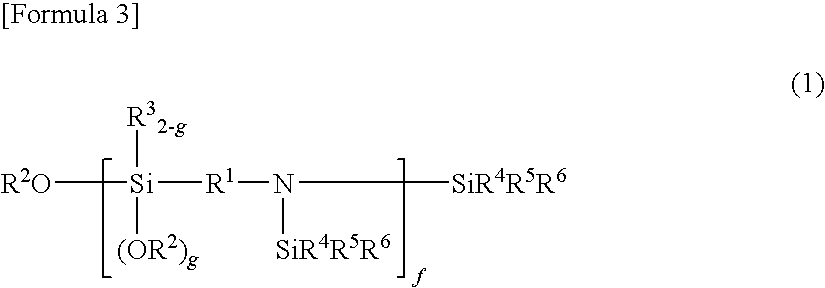

Method for producing modified conjugated diene based (CO)polymer, modified conjugated diene based (CO)polymer, and rubber composition

The method for producing a modified conjugated diene based (co)polymer, according to the present invention comprises(a) obtaining a primarily modified polymer by carrying out a primary modification reaction wherein at least one member selected from the group consisting of an alkoxysilane compound and a silanol compound is introduced into the active alkali metal terminal of a conjugated diene based (co)polymer having an active alkali metal terminal, and(b) obtaining a secondarily modified polymer (a modified conjugated diene based (co)polymer) by subjecting the above-obtained primarily modified polymer to reactions comprising (b1) and (b2).(b1): a reaction with a condensation accelerator comprising a metal element.(b2): a reaction with at least one member selected from the group consisting of inorganic acids and metal halides.

Owner:ENEOS MATERIALS CORP +1

Bonding wire for semiconductor device

ActiveUS20100282495A1Suppress problemImprove linearityNon-insulated conductorsSolid-state devicesCrystalliteThinning

An object of the present invention is to provide a high-performance bonding wire that is suitable for semiconductor mounting technology, such as stacked chip bonding, thinning, and fine pitch mounting, where wire lean (leaning) at an upright position of a ball and spring failure can be suppressed and loop linearity and loop height stability are excellent. This bonding wire for a semiconductor device includes a core material made of a conductive metal, and a skin layer formed on the core material and containing a metal different from the core material as a main component; wherein a relationship between an average size (a) of crystal grains in the skin layer on a wire surface along a wire circumferential direction and an average size (b) of crystal grains in the core material on a normal cross section, the normal cross section being a cross section normal to a wire axis, satisfies an inequality of a / b≦0.7.

Owner:NIPPON MICROMETAL CO LTD +1

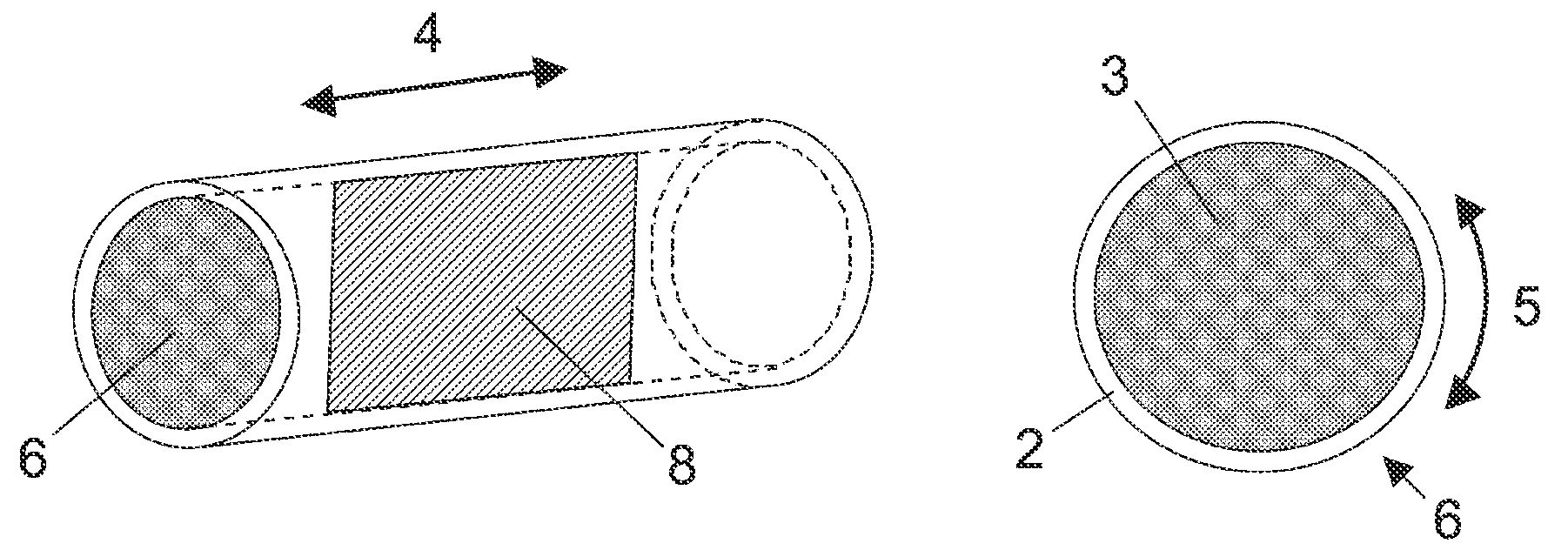

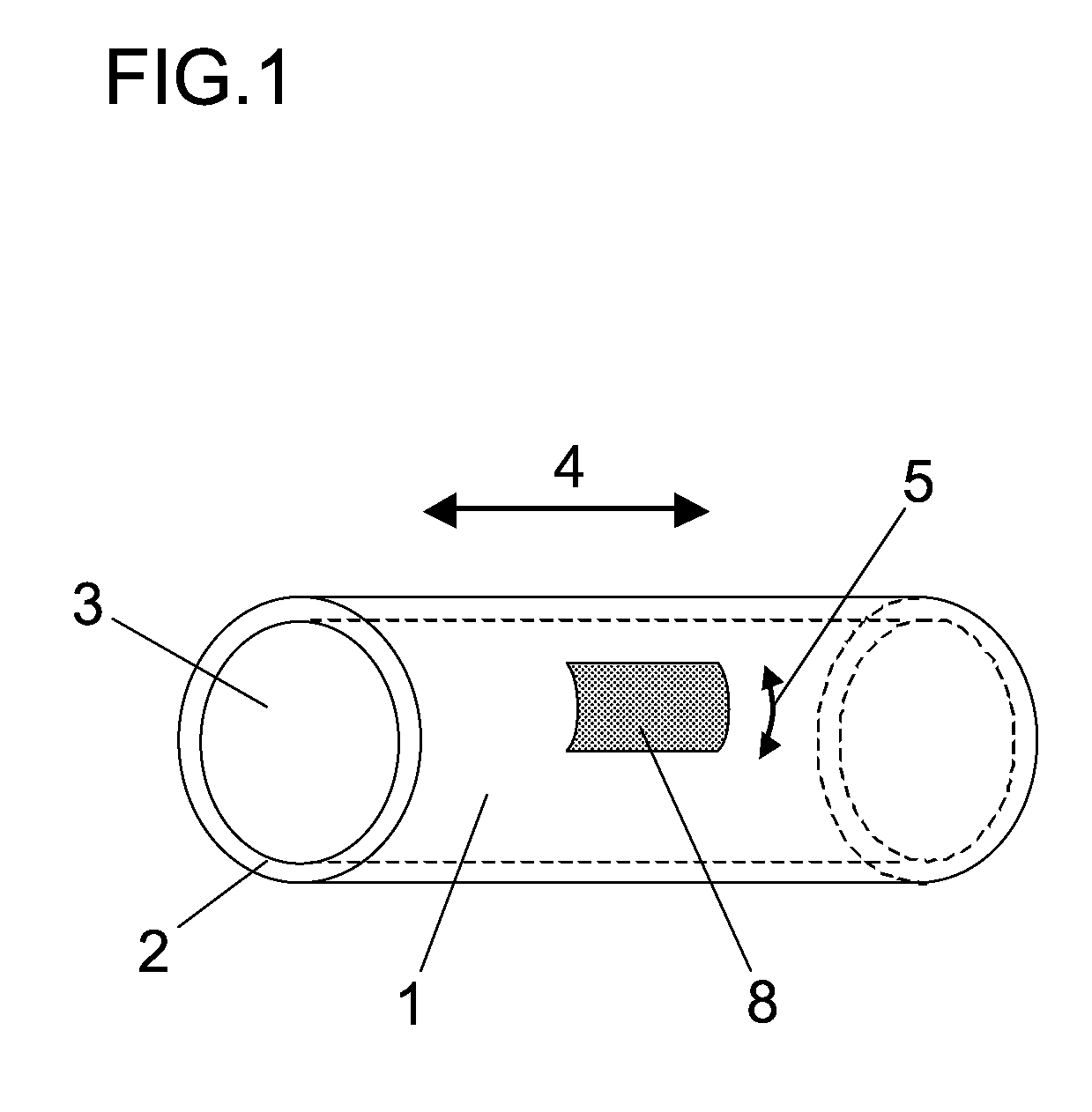

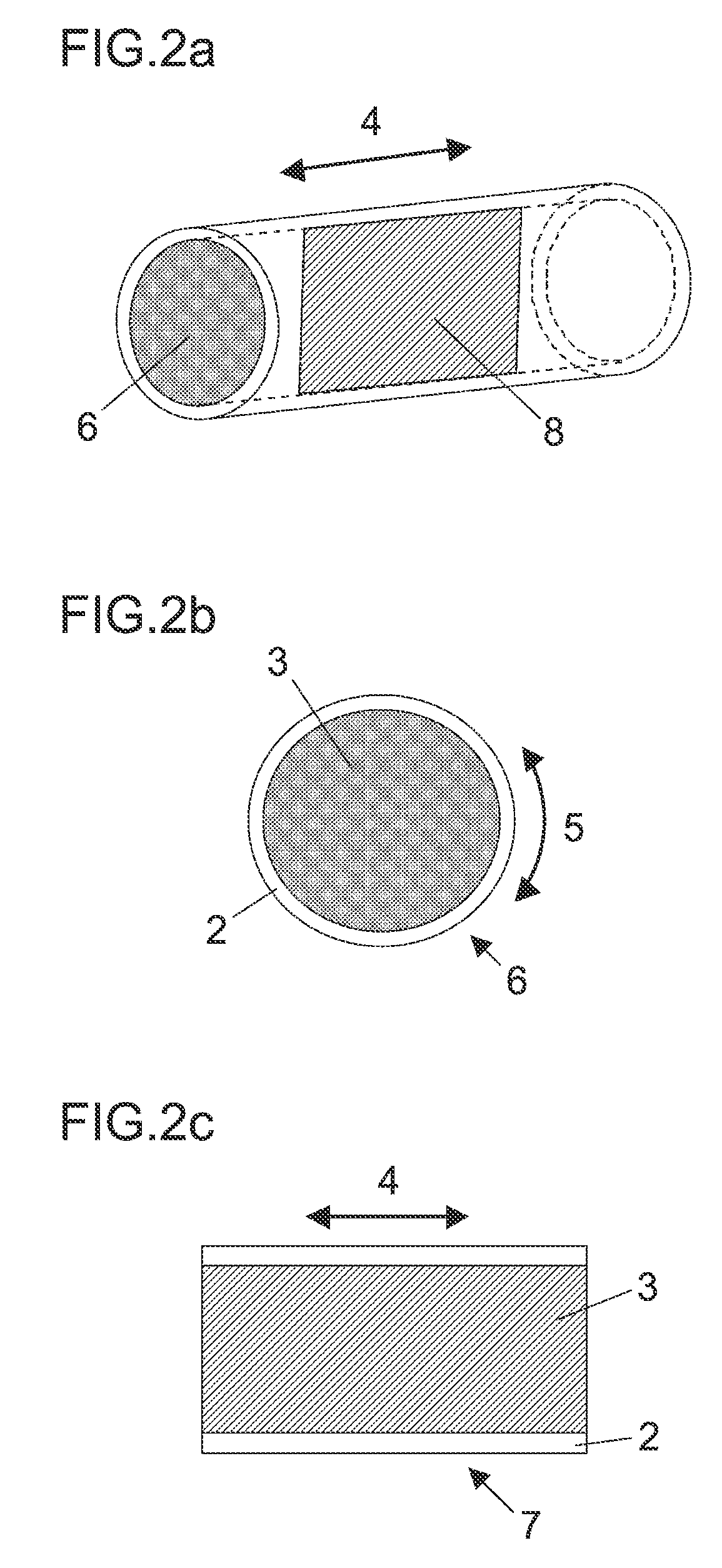

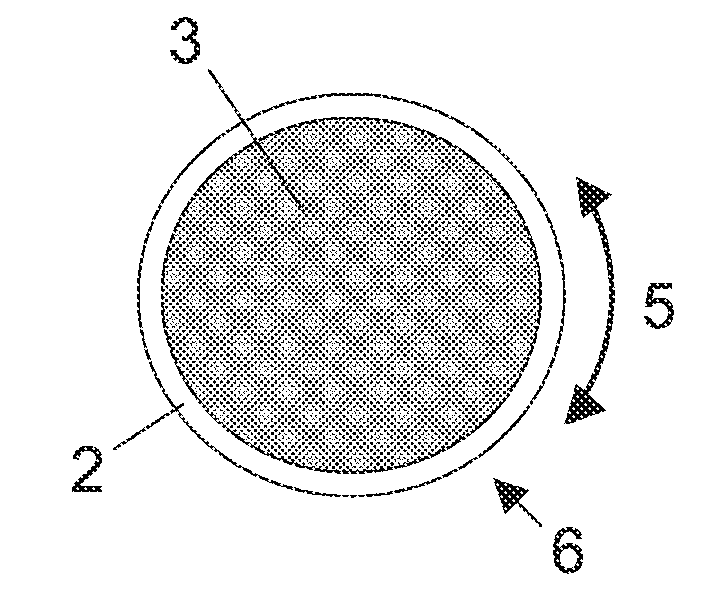

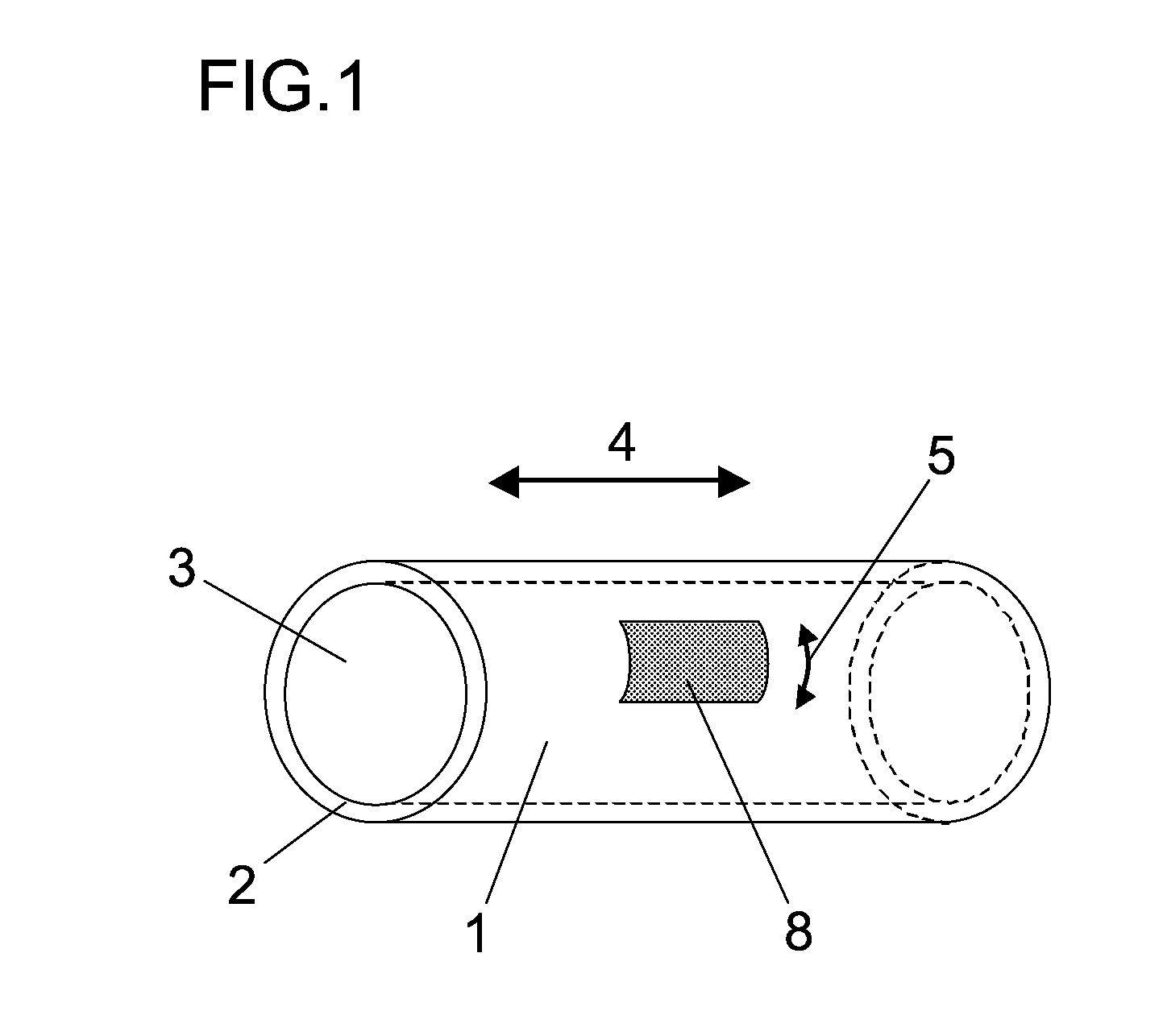

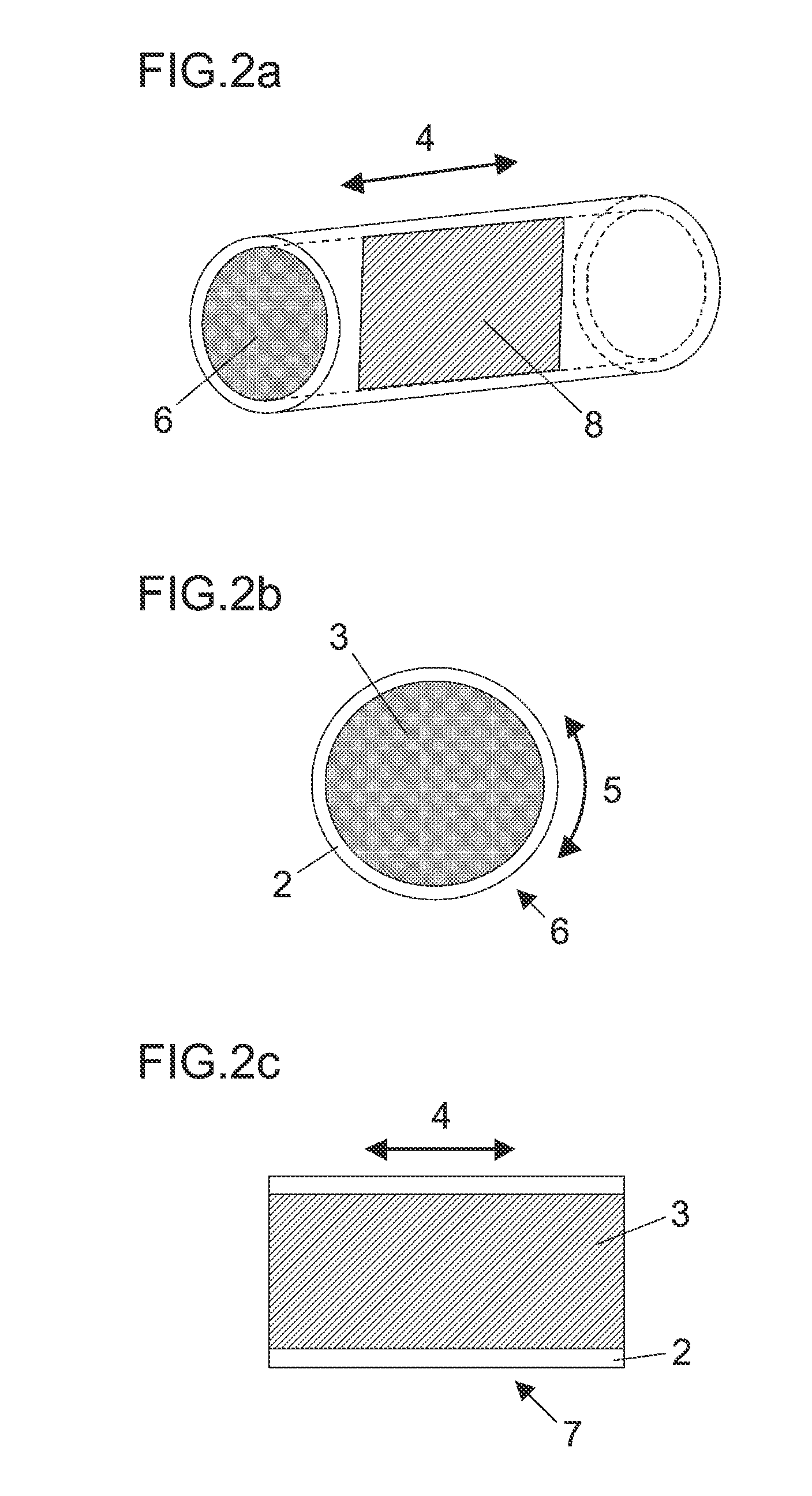

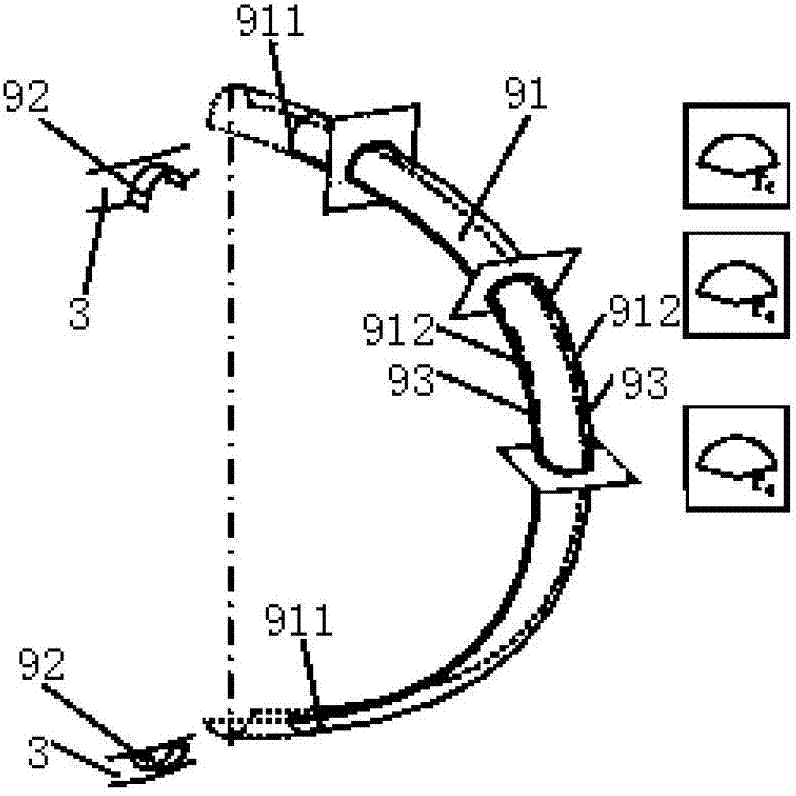

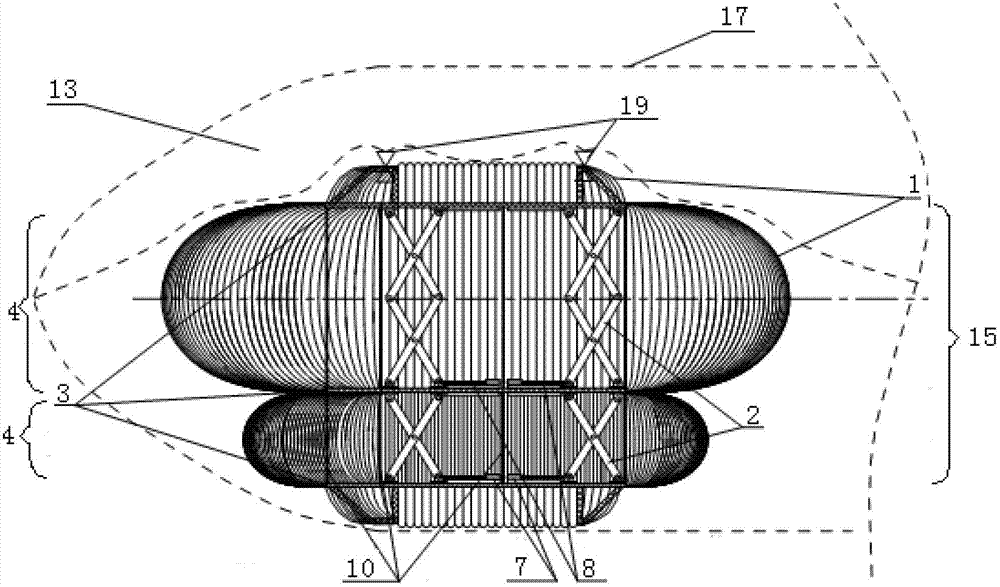

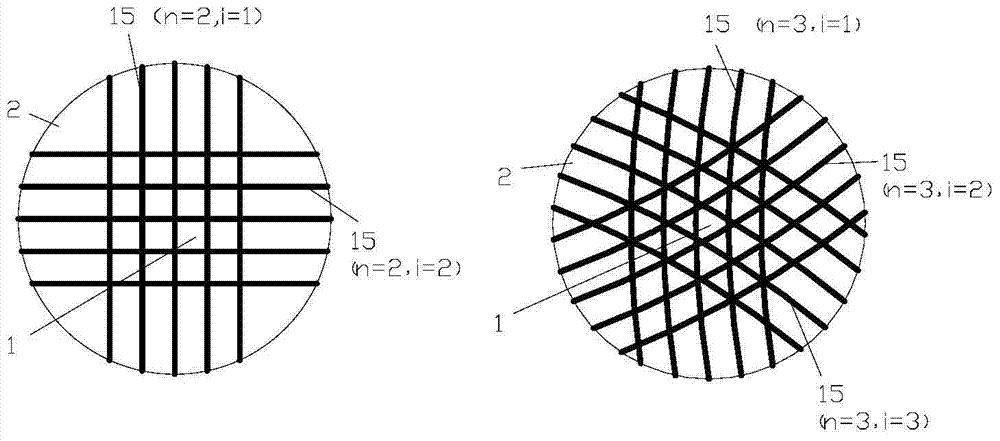

Airship airbag with shape-control frames

The invention relates to an airship airbag with shape-control frames. The airship airbag with the shape-control frames comprises an airbag casing (1) and the shape-control frames; the airtight flexible airbag casing (1) is arranged on the outer layer of the air bag, is of a laminated structure on the whole and consists of a plurality of layered structures; the inside of every layered structure is fixedly connected with the shape-control frames which comprises a plurality of pairs of vertically-arranged folding frames (2) and two pairs of shaping frames (3) respectively hinged to two ends of the folding frames (2); the airbag casing (1) of every layered structure (4) is formed by splicing the airtight film covering pieces (91) of a plurality of convex curved surface unit (9), and every convex curved surface unit (9) not only comprises one elongated airtight film covering piece (91) but also comprises a pair of end-edge fixing parts (92) on the shaping frames (3) and a pair of pulling-resistant straps (93). The airship airbag with the shape-control frames can make full use of the space inside an airship, is good in regularity of expansion and shrinkage deformation and good in repeatability and stability, and can bear relative large overpressure when being inflated and expanded fully.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Polymers for use in optical devices

InactiveUS20030008991A1Improved shape stabilityQuality improvementElectroluminescent light sourcesConductive materialCross-linkPolymer science

Optical devices fabricated from solvent processible polymers suffer from susceptibility to solvents and morphological changes. A semiconductive polymer capable of luminescence in an optical device is provided. The polymer comprises a luminescent film-forming solvent processible polymer which contains cross-linking so as to increase its molar mass and to resist solvent dissolution, the cross-linking being such that the polymer retains semiconductive and luminescent properties.

Owner:CAMBRIDGE DISPLAY TECH LTD

High air permeability non-woven base wallpaper and products thereof

The invention discloses high air permeability non-woven base wallpaper. The traditional non-woven wallpaper has the defects of insufficient flexibility, poor paper surface third dimension and lower opacity. The high air permeability non-woven base wallpaper comprises the following components in percent by mass of 20-72 percent of plant fiber, 10-40 percent of non-plant fiber, 10-30 percent of pigment, 2.5-10 percent of adhesive and 0.1-1.5 percent of chemical addition agent, wherein the mass percent of the components is 100 percent in sum; the plant fiber contains chemical wood pulp, the non-plant fiber contains chemical fiber, and the pigment contains at least one inorganic pigment or organic pigment with covering function. The non-woven wallpaper contains the long fiber, can be directly printed, and has the advantages of high air permeability, natural grains in paper surface, soft hand feel of finished paper, good processing property, better shape stability, good printing effect, rich color, clear pattern and strong three dimension.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

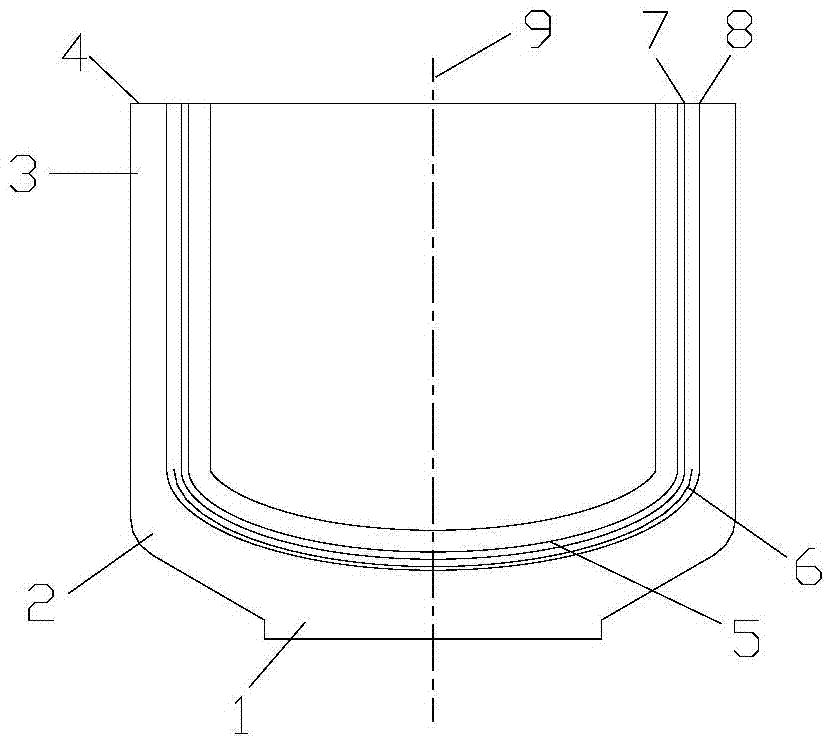

Continuous carbon fiber reinforced crucible preform and preparation method thereof

ActiveCN103482995AIncrease contentAvoid crackingAfter-treatment apparatusCarbon fibersStress conditions

The invention discloses a continuous carbon fiber reinforced crucible preform and a preparation method thereof. The preform is molded from basic unit layers and continuous fiber reinforced layers through needle punching; the bottom of a crucible and a connection area of the side and the bottom of the crucible are respectively reinforced by using the continuous fiber winding and laying technology, so the content of continuous fibers connected in an integral structure is effectively increased, strength needed during high load and high swelling stress conditions is guaranteed, cracking of the crucible or disconnection of the connection area of the side and the bottom of the crucible is prevented, and excellent shape stability can be maintained. Thus, the preform has excellent mechanical properties and a stable structure; after carbon / carbon composition, the crucible has good resistance to expansion, good structural stability, high thermal conduction efficiency and a long service life under a high load condition and can meet usage requirements of large-size crystalline silicon furnace crucibles.

Owner:JIANGSU TIANNIAO HIGH TECH

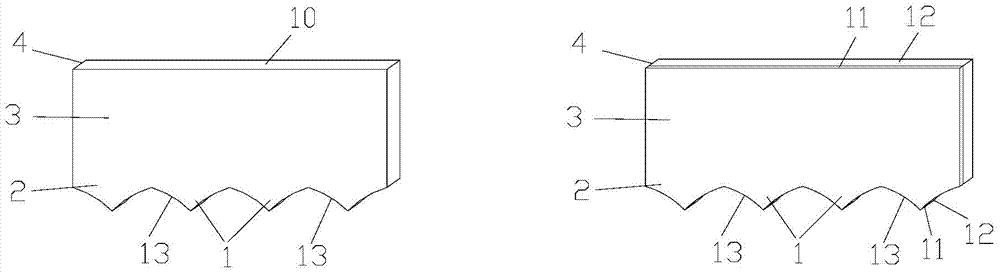

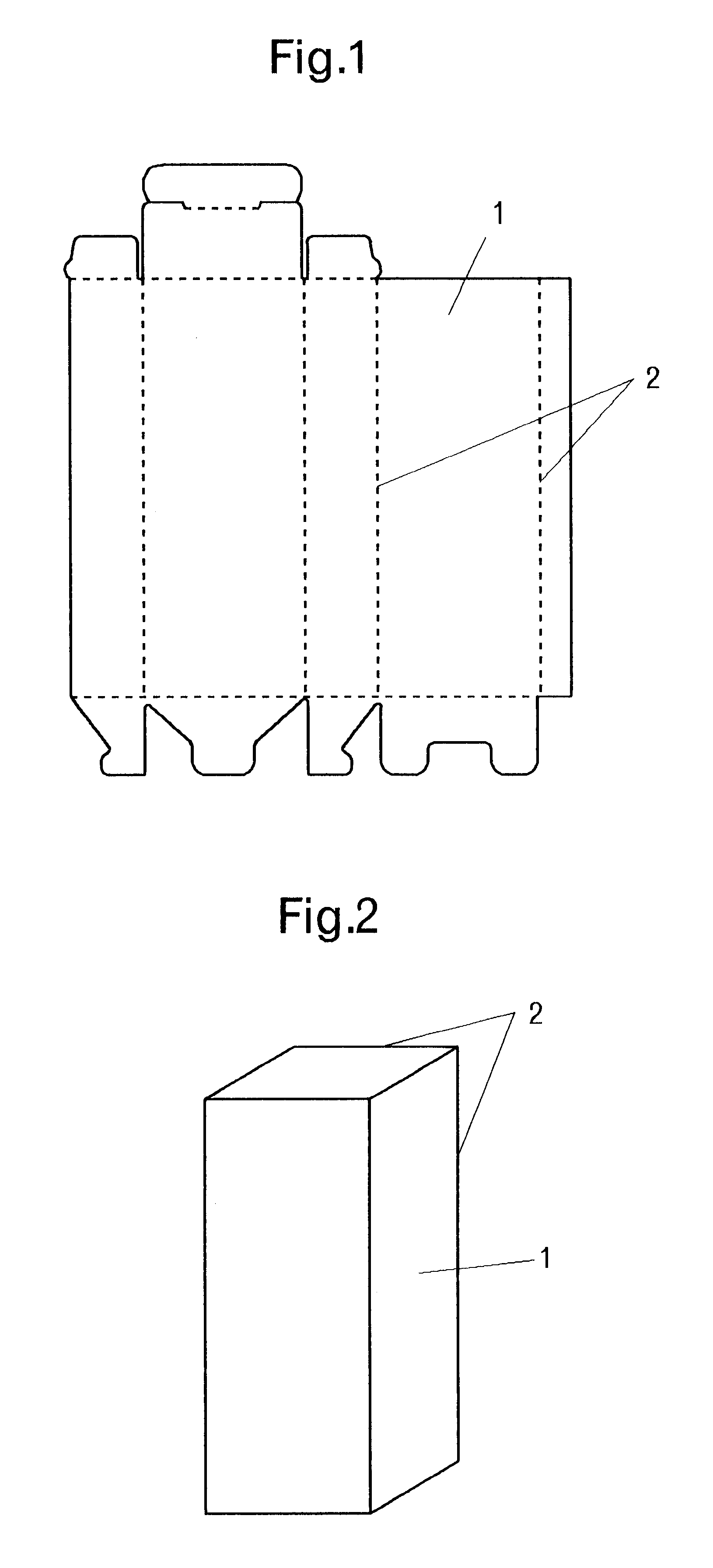

Plastic sheet having creasing lines

InactiveUS6391424B1Enable formationImprove stabilityLayered productsPaper-makingEngineeringPlastic film

Owner:SUZUKI KUNITSUGU

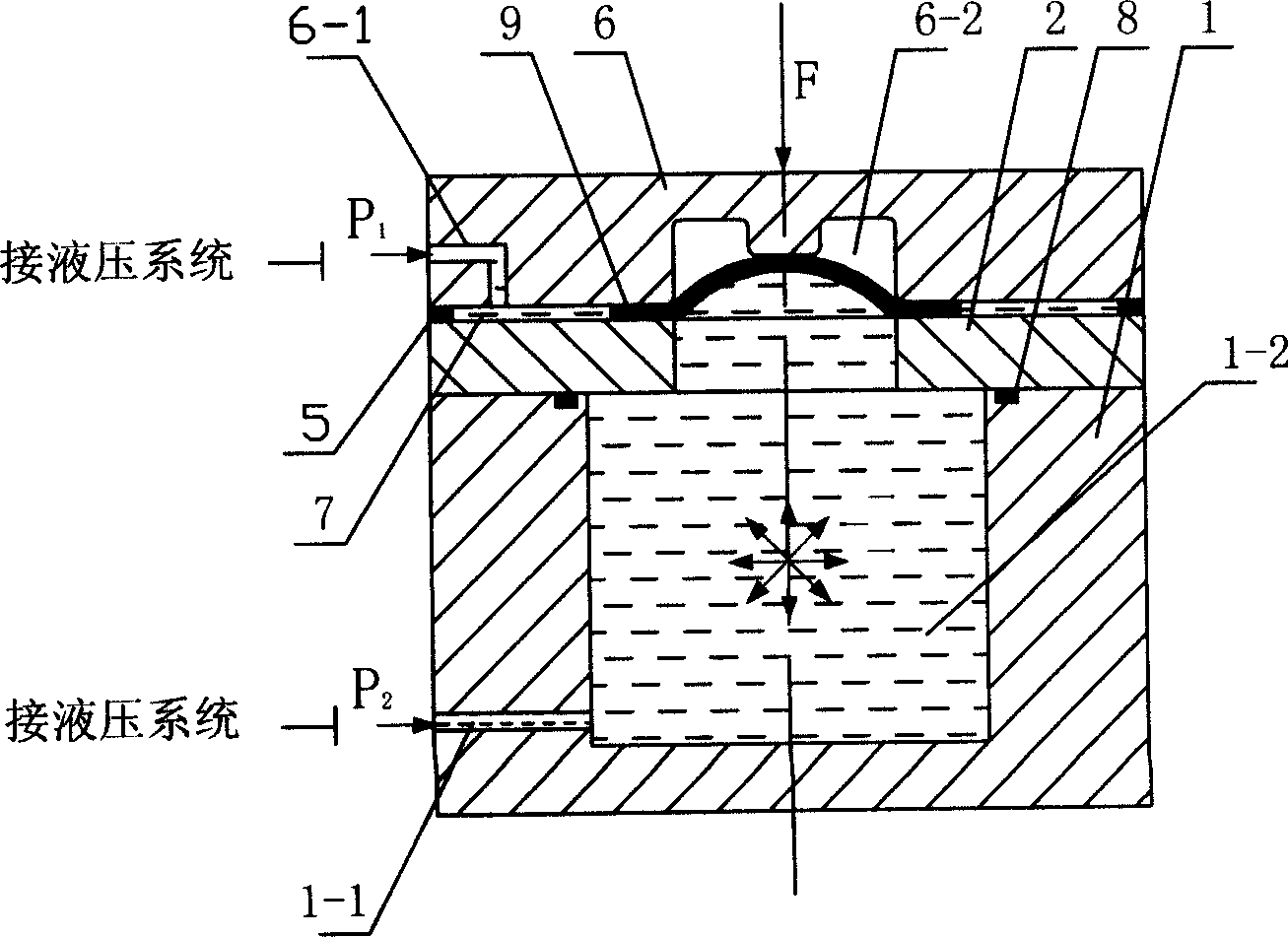

Electromagnetism-assisted forming device and method for dissimilar metal composite boards

The invention relates to an electromagnetism-assisted forming device and method for dissimilar metal composite boards and aims to solve the problem that existing metal composite boards are severely lapped and even broken in a drawing process. According to the forming device, a coil is arranged in an annular coil groove, a liquid channel is disposed between the inner wall of a blank holder and a cylinder, an upper liquid inlet channel is transversely arranged on the side wall of the blank holder, and a lower liquid inlet channel is transversely arranged on the side wall of a female die. The method includes placing the composite boards on the bottom surface of the blank holder; filling forward liquids into the liquid channel, filling reverse liquids into the female die, and exerting radial electromagnetic force Fd on the periphery of a flange of the composite board through the coil; forming the composite board under the combined action of a reverse pressure Fp2, a forward pressure Fp1 and the radial electromagnetic force Fd; and unloading a forward liquid pressure P1 and then a reverse liquid pressure P2, returning a male die and taking the formed part.

Owner:HARBIN INST OF TECH

Method for producing modified conjugated diene based (CO)polymer, modified conjugated diene based (CO)polymer, and rubber composition

The method for producing a modified conjugated diene based (co)polymer, according to the present invention comprises a step of reacting a conjugated diene based (co)polymer with a metal halide compound to obtain a modified conjugated diene based (co)polymer, the conjugated diene based (co)polymer having a weight-average molecular weight of 150,000 to 2,000,000 and being obtained by bonding, to a polymer having at least a conjugated diene unit, an alkoxysilyl group and an optionally protected primary amino group. The method can satisfactorily produce a conjugated diene based (co)polymer which has a high Mooney viscosity, excellent shape stability and good processability.

Owner:ENEOS MATERIALS CORP

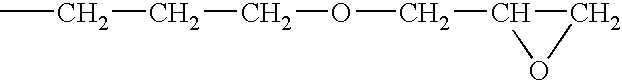

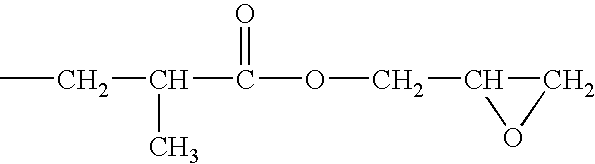

Active Energy Ray-Curable, Organopolysiloxane Resin Composition, Light-Transmitting Component, And Method For Manufacturing The Light-Transmitting Component

ActiveUS20080058441A1Fast curingImproved shape stabilityOrganic chemistryOptical fibre with graded refractive index core/claddingChemistrySilorane Resins

The present invention relates to an active energy ray-curable organopolysiloxane resin composition that comprises an organopolysiloxane resin having an epoxy group and an aromatic hydrocarbon group and a photopolymerization initiator, as well as to a light-transmitting component that comprises cured bodies produced by irradiating the aforementioned organopolysiloxane resin with active-energy rays in the presence of the aforementioned photopolymerization initiator, and to a method for manufacturing the aforementioned light-transmitting component.

Owner:DOW TORAY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com