600 MPa-level thick-specification hot rolling spoke steel and manufacturing method thereof

A technology with thick specifications and spokes, which is applied in the field of iron and steel material engineering, can solve the problems of easy delamination, large springback, rough shape stability punching section, etc., and achieve good shape stability, small springback, and high popularization and application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

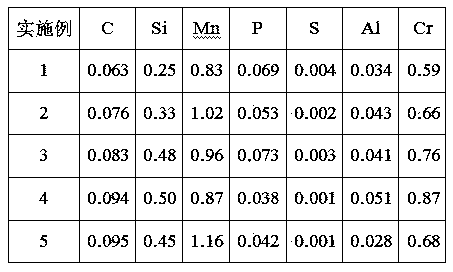

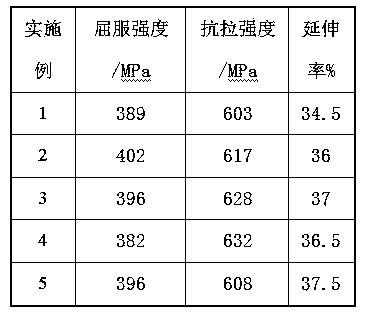

[0029] A 600MPa-grade thick specification steel for hot-rolled spokes, the chemical composition of which is shown in Table 1.

[0030] The invention discloses a method for manufacturing 600MPa-level thick gauge steel for hot-rolled spokes, comprising molten iron pretreatment-converter smelting-LF-continuous casting-hot continuous rolling. The hot continuous rolling process is as follows: slab thickness 135mm, heating temperature 1170°C, holding time 2h, rough rolling start temperature 1120°C, finish rolling temperature 1040°C, 3-pass rolling to 38mm intermediate billet, finish rolling stage The rolling start temperature is 1010°C, the final rolling temperature is 830°C, air-cooled for 3S and then cooled to the target coiling temperature at a cooling rate of 41°C / S, the coiling temperature is 326°C, and the thickness of the finished steel plate is 8mm.

Embodiment 2

[0032] A 600MPa-grade thick specification steel for hot-rolled spokes, the chemical composition of which is shown in Table 1.

[0033] The invention discloses a method for manufacturing 600MPa-level thick gauge steel for hot-rolled spokes, comprising molten iron pretreatment-converter smelting-LF-continuous casting-hot continuous rolling. The hot continuous rolling process is as follows: slab thickness 135mm, heating temperature 1160°C, holding time 2.5h, rough rolling start temperature 1100°C, finish rolling temperature 1000°C, 3-pass rolling to a 38mm intermediate billet, finish rolling The stage start rolling temperature is 1000°C, the final rolling temperature is 820°C, air cooling for 5S and then cooling to the target coiling temperature at a cooling rate of 32°C / S, the coiling temperature is 272°C, and the thickness of the finished steel plate is 10.0mm.

Embodiment 3

[0035] A 600MPa-grade thick specification steel for hot-rolled spokes, the chemical composition of which is shown in Table 1.

[0036] The invention discloses a method for manufacturing 600MPa-level thick gauge steel for hot-rolled spokes, comprising molten iron pretreatment-converter smelting-LF-continuous casting-hot continuous rolling. The hot continuous rolling process is as follows: slab thickness 135mm, heating temperature 1210°C, holding time 1.5h, rough rolling start temperature 1140°C, finish rolling temperature 1050°C, 3-pass rolling to a 38mm intermediate billet, finish rolling Stage start rolling temperature is 1020°C, finish rolling temperature is 810°C, after air cooling for 6S, cool at a cooling rate of 35°C / S to the target coiling temperature, the coiling temperature is 234°C, and the thickness of the finished steel plate is 11.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com