Patents

Literature

213results about How to "Excellent color development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Imitation wool composite textured yam and method for producing the same

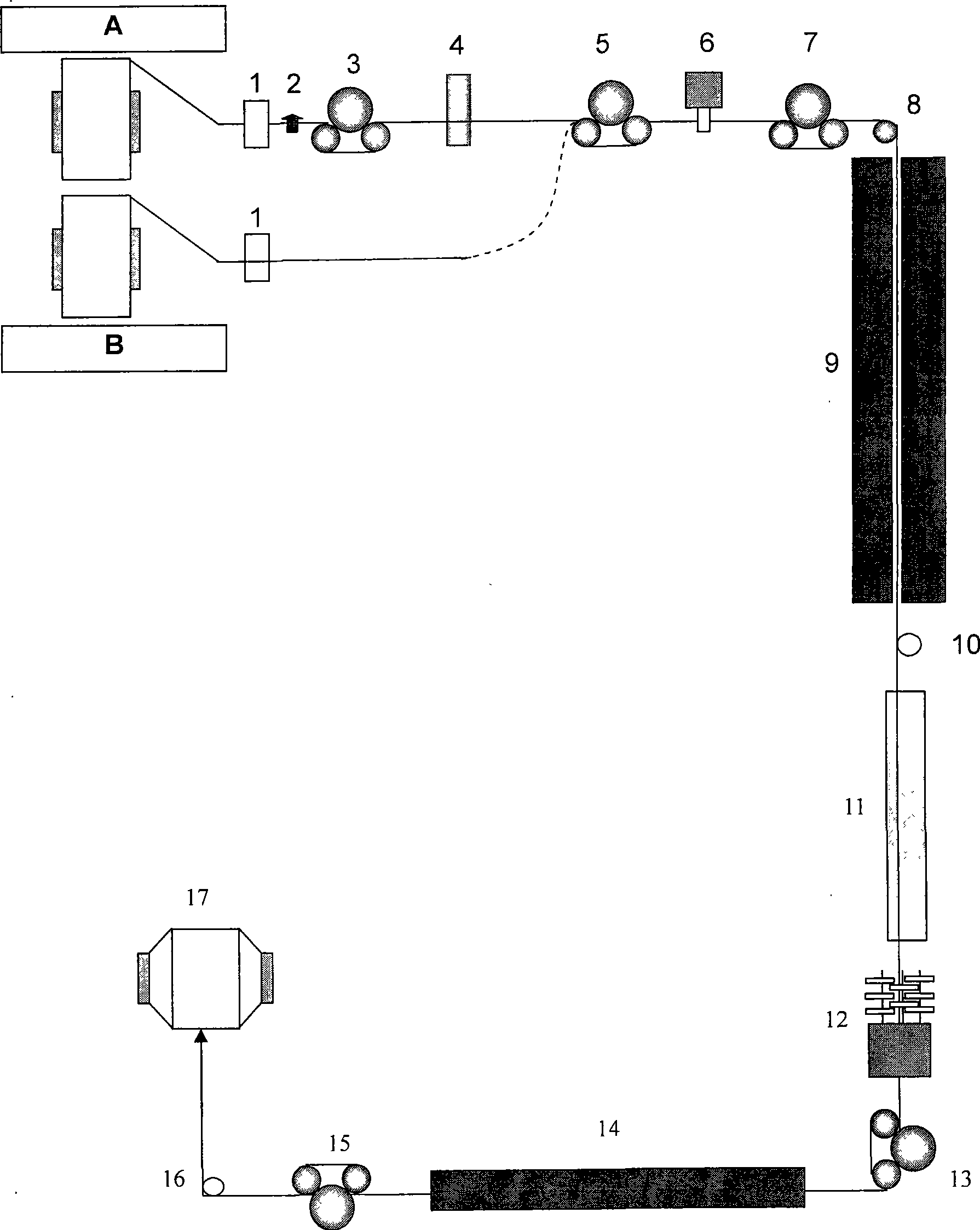

The invention discloses a wool-like composite textured yarn and a manufacturing method thereof. The composite textured yarn is provided with a core-sheath structure, and a core part and a sheath part of the composite textured yarn have different filament length differences and different extents. The manufacturing method is as follows: 2 POYs are taken as raw materials, wherein one POY raw material is heated to be stretched by a heater between a first yarn feeding roller and a second yarn feeding roller, and merged with the second POY raw material in front of the second yarn feeding roller, enters into a network nozzle between the second yarn feeding roller and a third yarn feeding roller by means of certain overfeeding, forms a network through air blowing and twisting, and is heated, stretched and textured to form the composite textured yarn. The prepared yarn has low manufacturing cost; and textile fabrics which are woven by the yarn after twisting have good wool-like effect, soft, dry and comfortable hand feeling and good rebound resilience and color emissivity after being subjected to alkali decrement, and are good fabrics of black formal dresses.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Tandem white OLED with efficient electron transfer

ActiveUS20100253209A1Excellent color developmentLow voltage requirementOrganic chemistryDischarge tube luminescnet screensArylFluoranthene

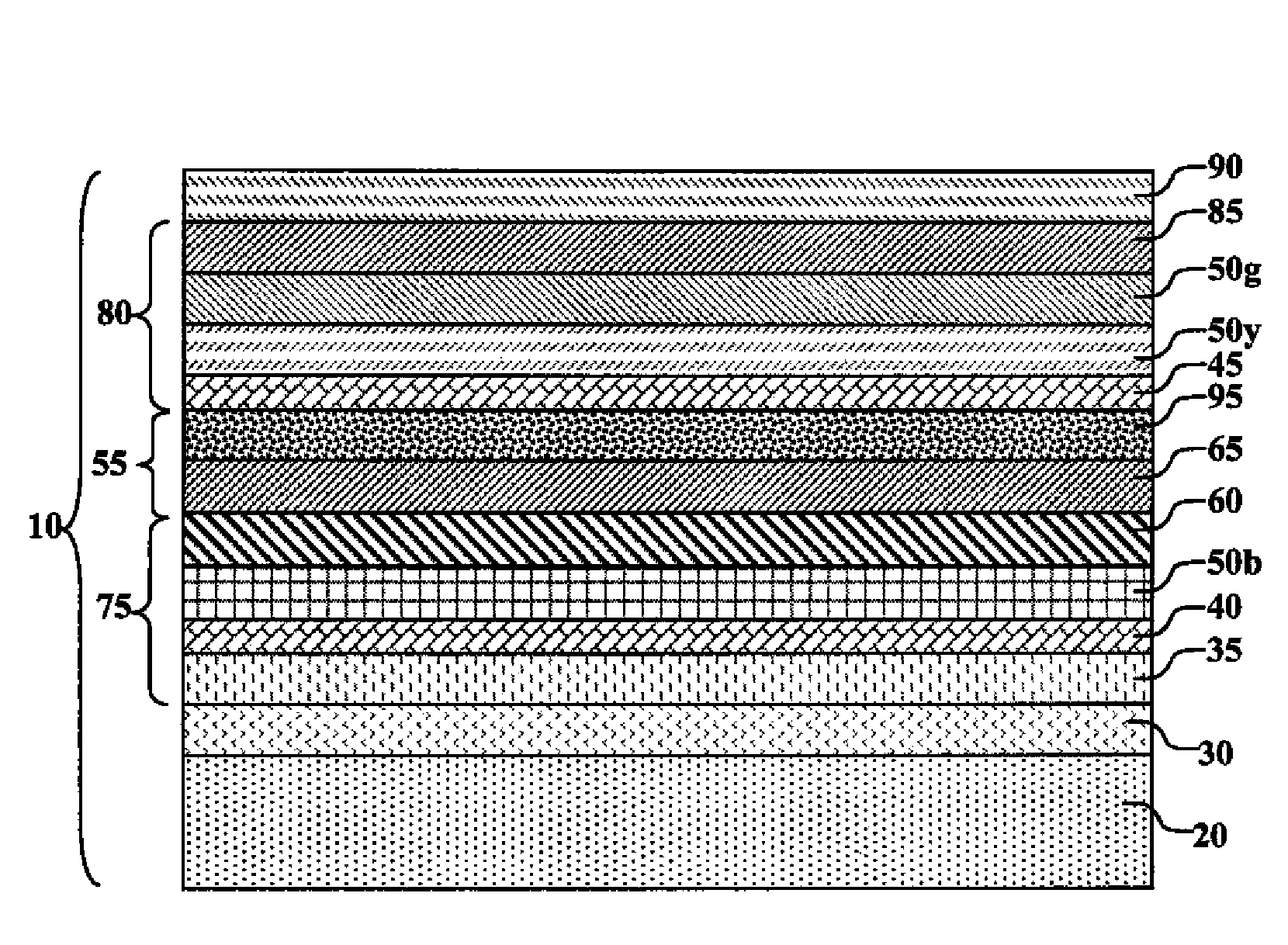

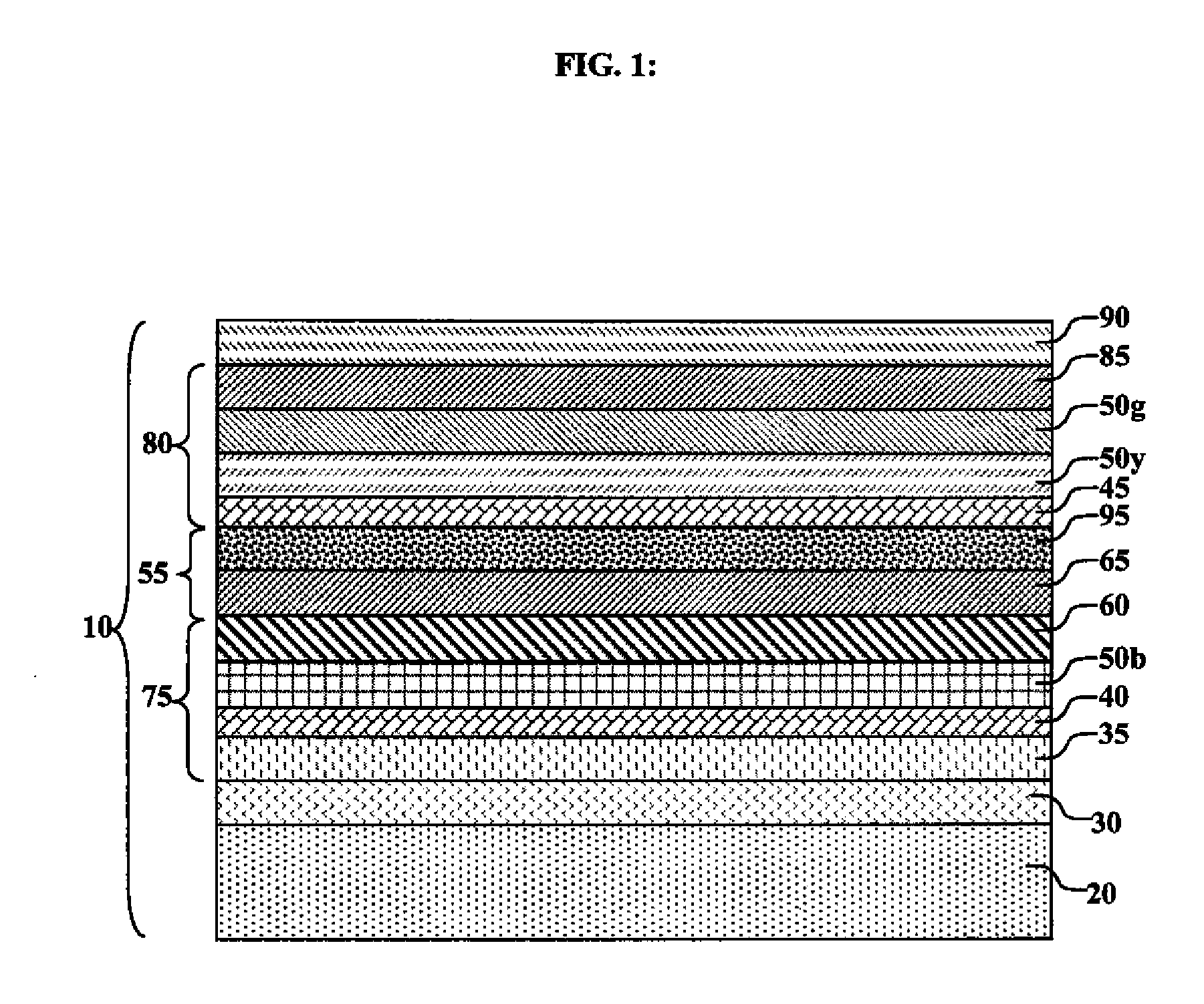

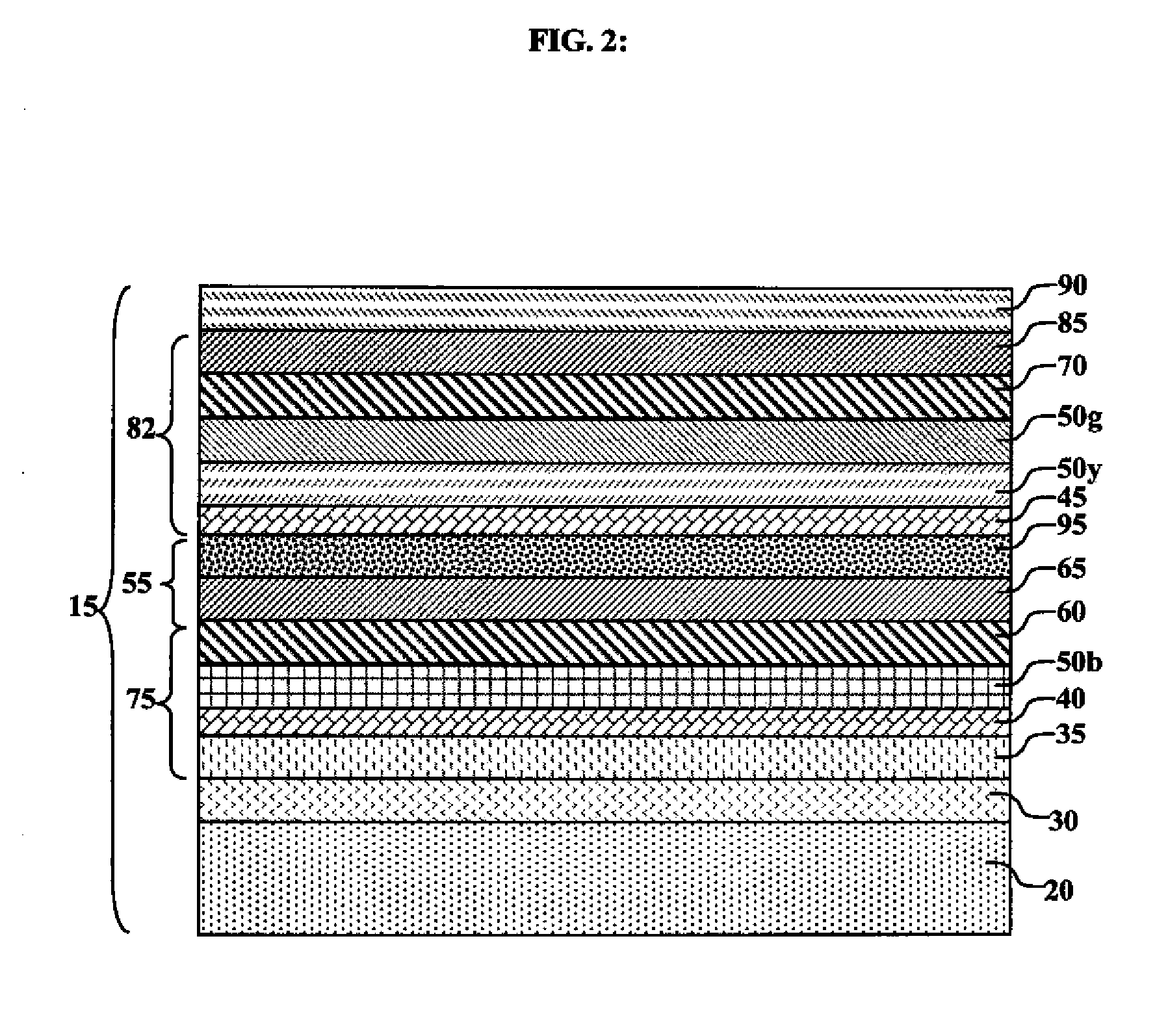

A white-light-emitting tandem OLED device having spaced anode and cathode including: first and second light-emitting units disposed between the anode and cathode; an intermediate connector including an n-type layer and a p-type layer disposed between the first and second light-emitting units; and a fluoranthene-containing electron-transporting layer adjacent to the n-type layer of the intermediate connector and including at least 25% of a 7,10-diaryl-substituted fluoranthene compound having no aromatic rings annulated to the fluoranthene nucleus.

Owner:GLOBAL OLED TECH

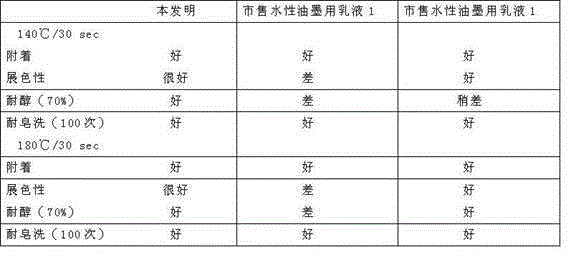

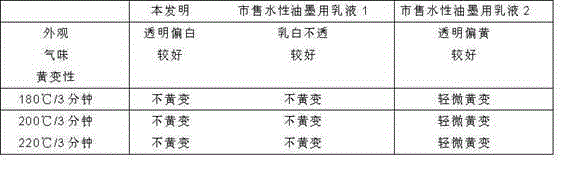

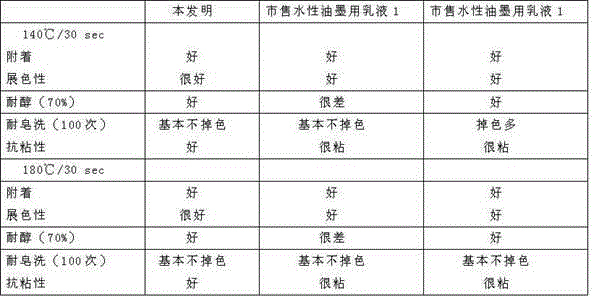

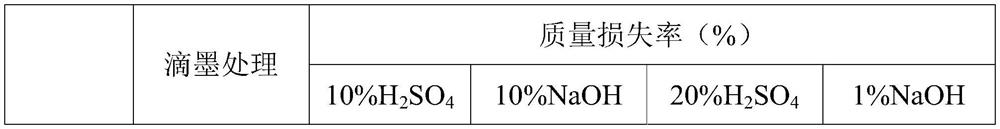

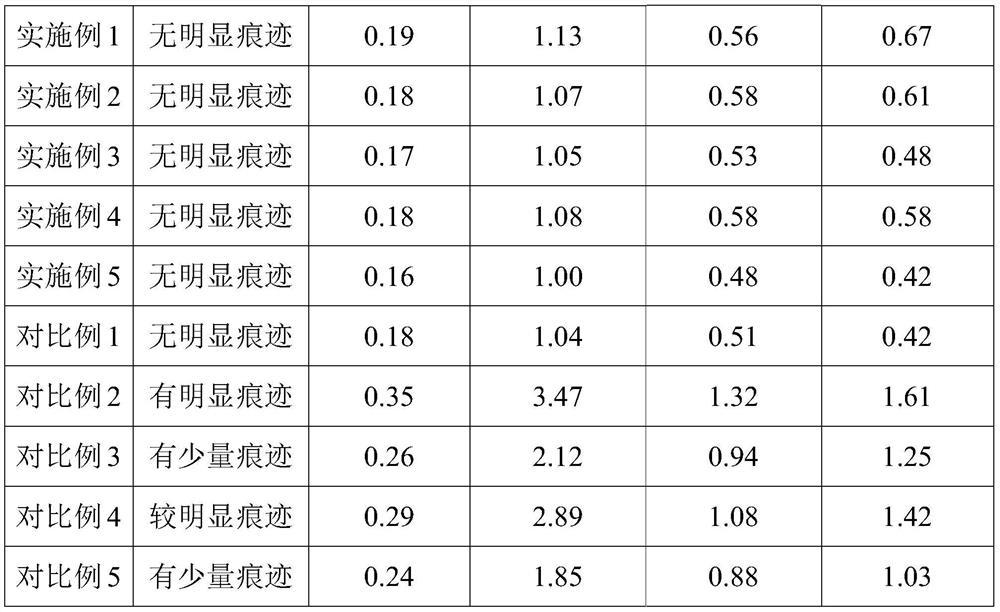

Anti-after tack acrylic latex for water-based ink

ActiveCN102911559AGood yellowing resistanceExcellent color paste stabilityInksMethacrylatePolymer science

The invention discloses anti-after tack acrylic latex for water-based ink. The latex comprises 5-18% of water, 0.1-0.8% of initiator, 40-60% of self-made alkali-soluble resin solution, 4-20% of C4-C12 alkyl acrylate monomer, 15-40% of C4-C20 methacrylate monomer and 0.2-5% of functional monomer. In a preparation method of the latex, firstly (methyl) acrylic acid, methyl methacrylate and C4-C12 alkyl acrylate are used as comonomers, persulfate is used as the initiator, a chain transfer agent is adopted, and then the alkali-soluble resin solution is obtained through emulsion polymerization; and then, the C4-C12 alkyl acrylate unsaturated monomer, the C4-C20 methacrylate unsaturated monomer and the functional monomer are used as comonomers, the alkali-soluble resin serves as a protective colloid, and then the anti-after tack acrylic latex is prepared by soap-free emulsion polymerization. According to the invention, the technology is simple, the operation is convenient, and the energy consumption and cost of production are reduced; and the latex has excellent yellowing resistance and color paste stability, and can effectively improve the alcohol resistance, soaping resistance, color development property and anti-after tack property of the water-based ink.

Owner:NANJING REGAL POLYMER +1

Two-component polyester sheath core compound fibre and production method

InactiveCN1912199AImprove dyeabilityImproved color developmentFilament/thread formingConjugated synthetic polymer artificial filamentsChemistryPolyester

The invention discloses bi-component polyester sheath core complex fiber and its producing method. The core is ultra complete extinction polyester with 5-10% titanium dioxide. The sheath is polyester with dye-ability cationic dyes. The method includes the following steps: putting the sheath and core respectively; distributing into assembly; mixing and extruding by nozzle plate; spinning. The invention uses cationic dyeable polyester to increase fabric dye-ability and color emissivity, titanium dioxide to improve fiber permeability resistance. The produced fiber which can be used to make swimming cloth has the advantages of good fabric performance, color emissivity, permeability resistance etc. The technology is simple and easy to operate.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

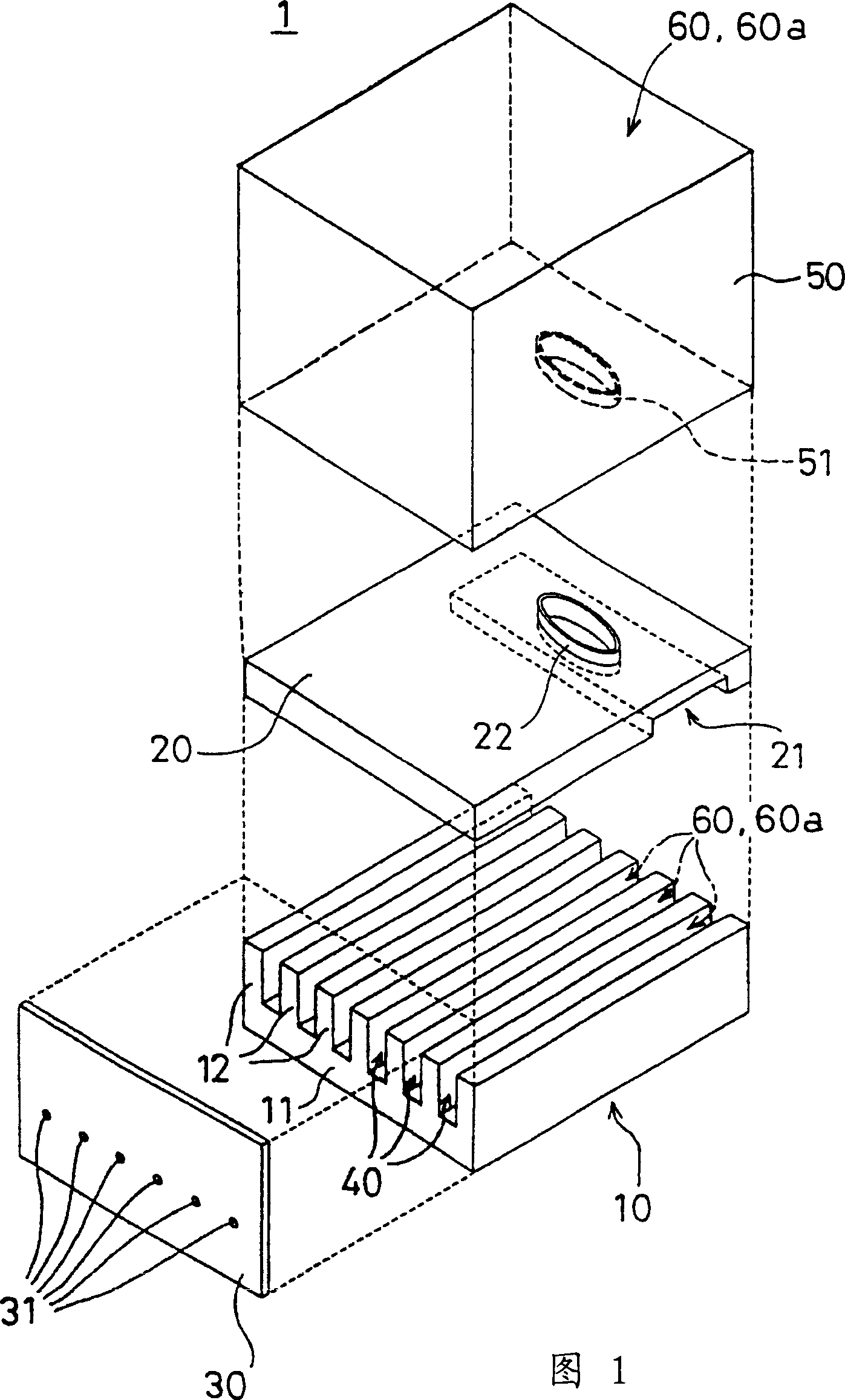

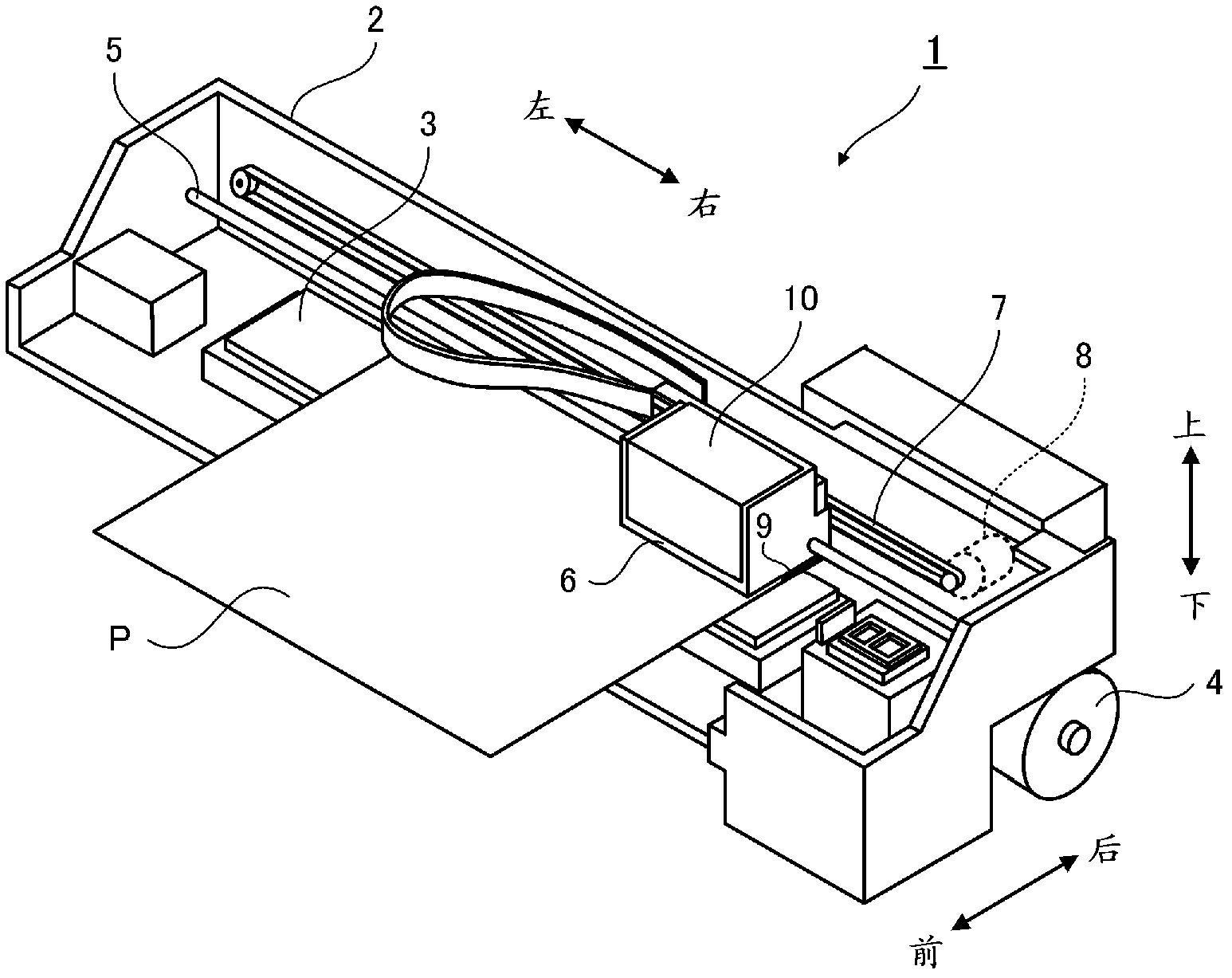

Ink composition, recording method using it and recording image, ink group and ink jet head

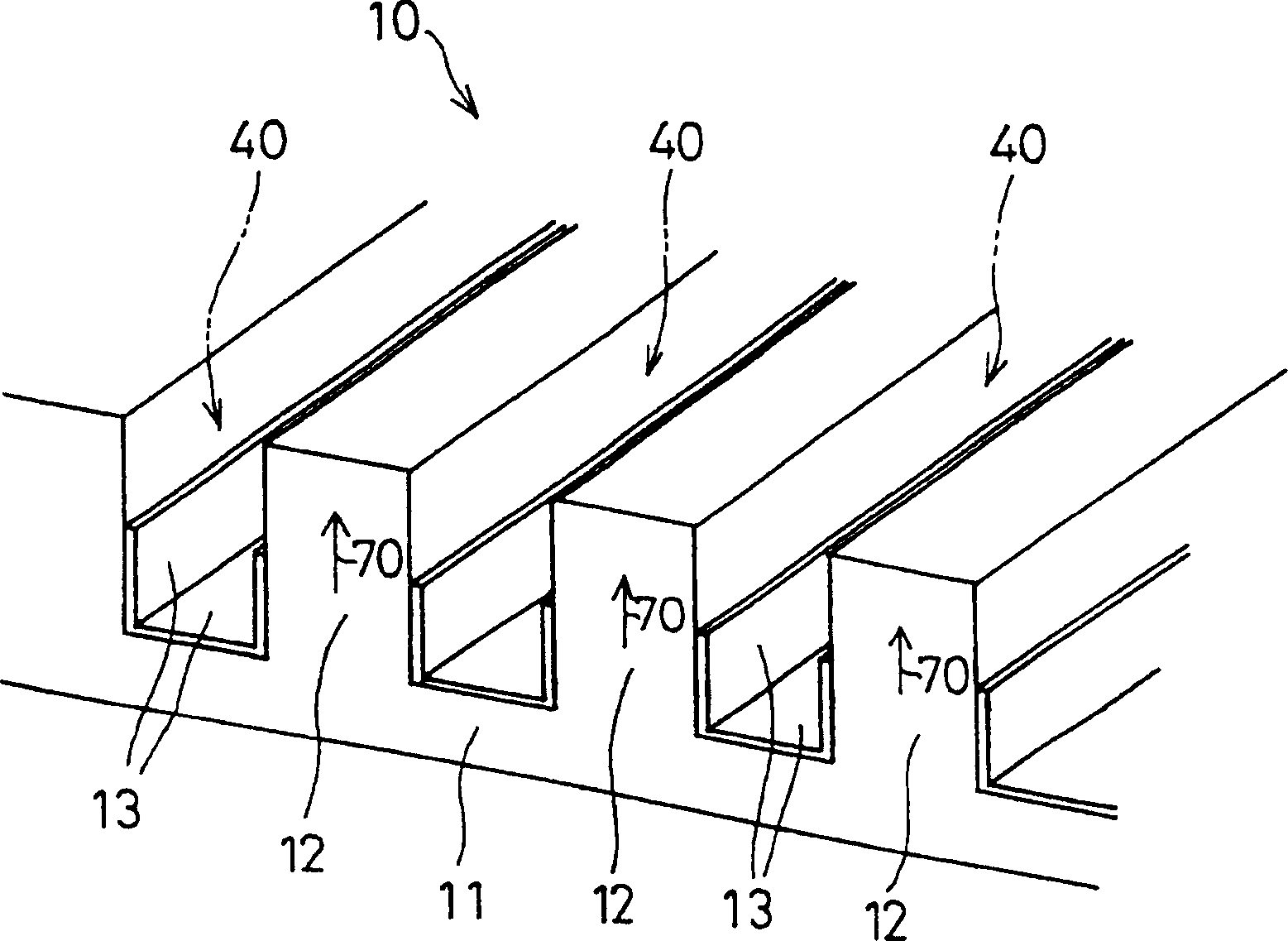

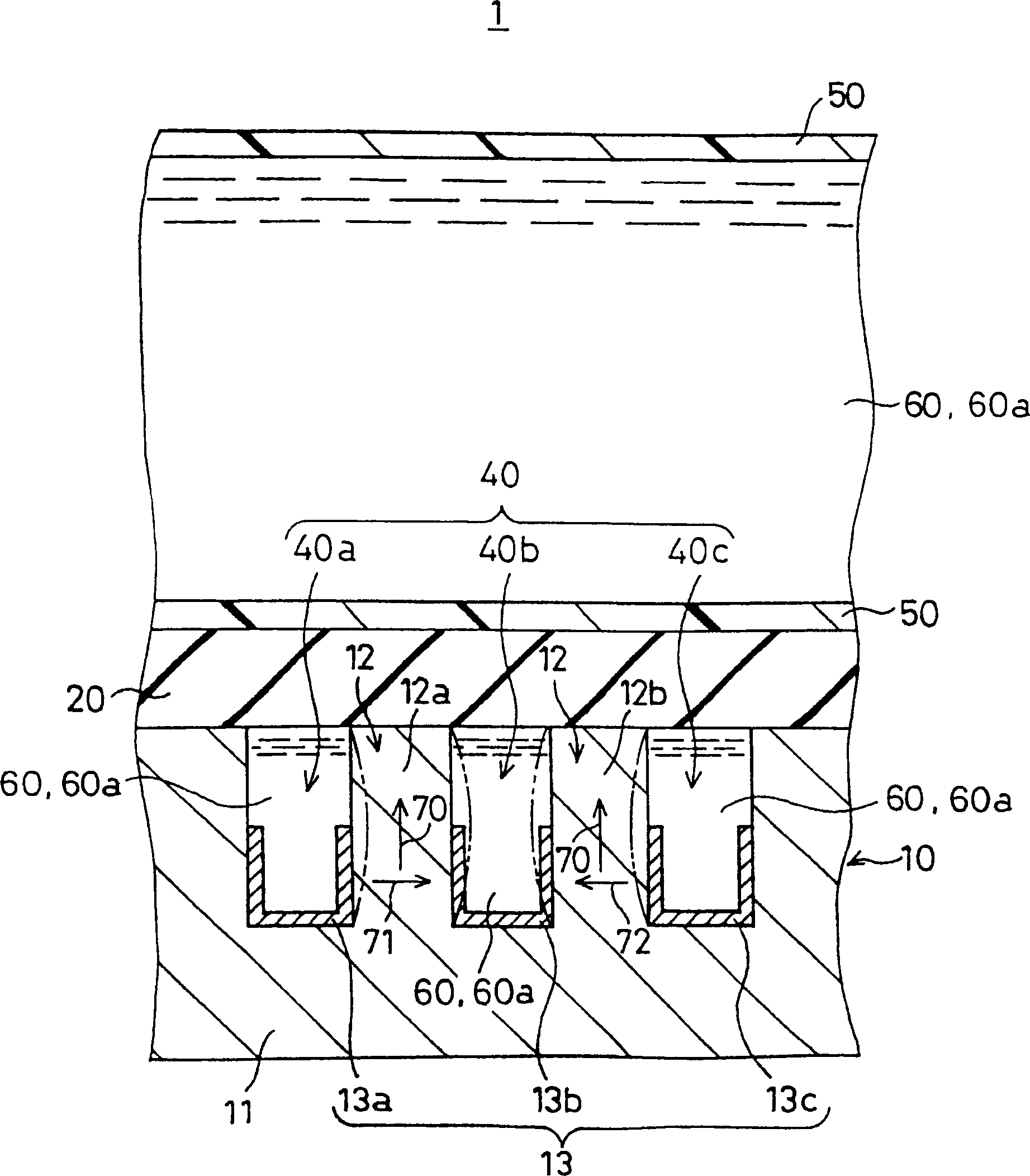

The ink composition 60 is produced in such a way that the difference between dynamic surface tension(mN / m) and static surface tension(mN / m) determined at 24-26[deg.]C by maximum foam pressure method is 0-7(mN / m). The printing method comprises the following process. The ink composition 60 is reserved in the ink tank 50 of the ink head 1 and fed from the ink tank 50 into an ink chamber 40 with a jet nozzle 31, voltage is applied on a diaphragm section 12 formed of a piezoelectric material and pressure is applied on the ink composition 60 filled in the ink chamber 40 through the diaphragm section 12 to jet droplets of the ink composition 60 via the jet nozzle 31, and the droplets are put on a printing material to print images on the printing material.

Owner:SHARP KK

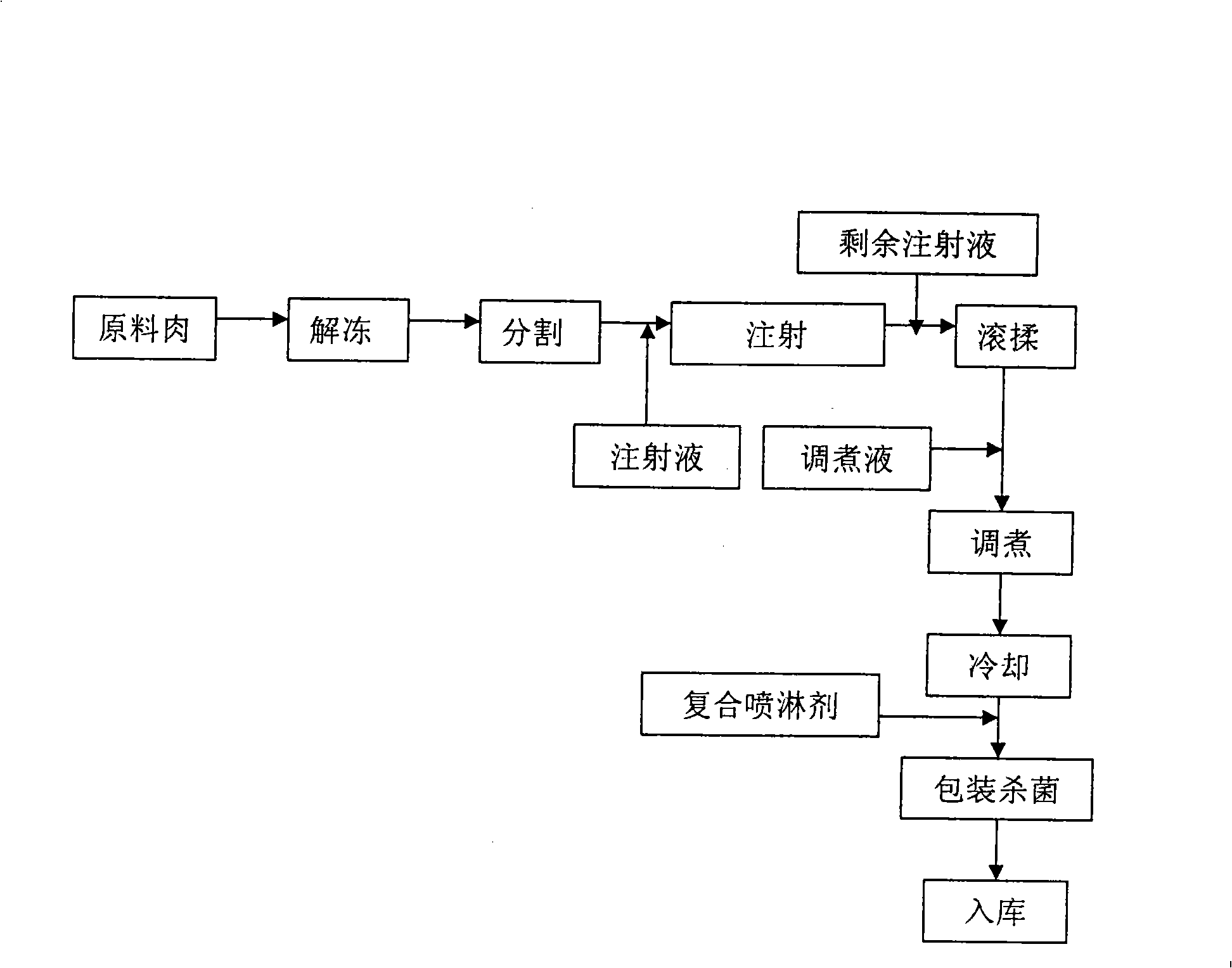

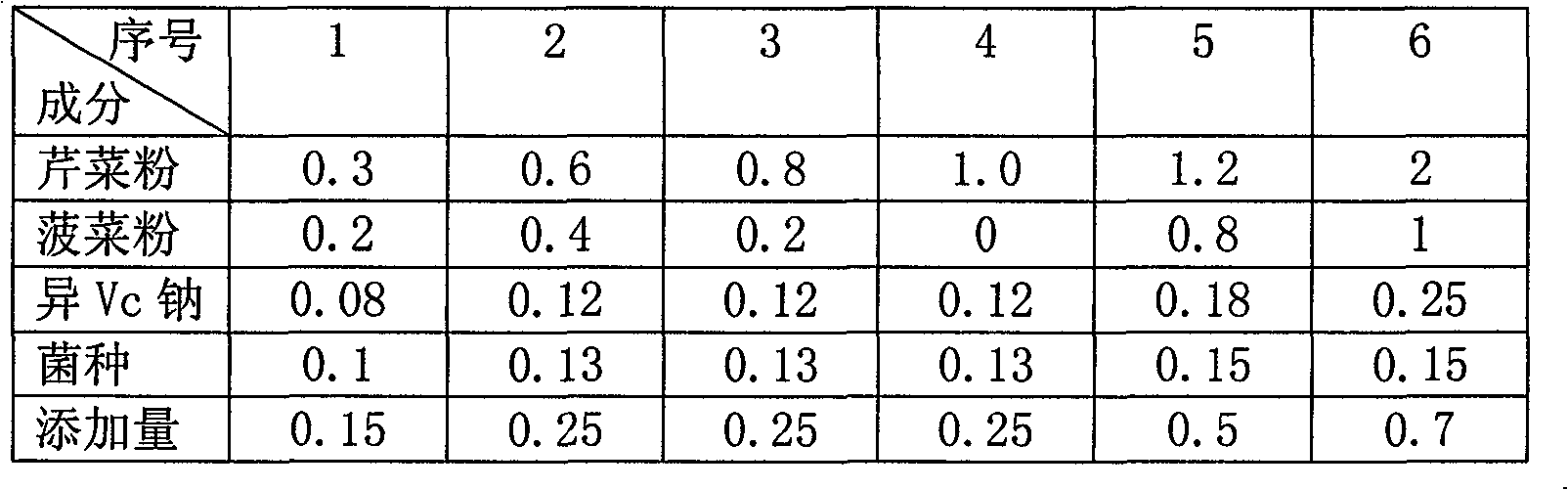

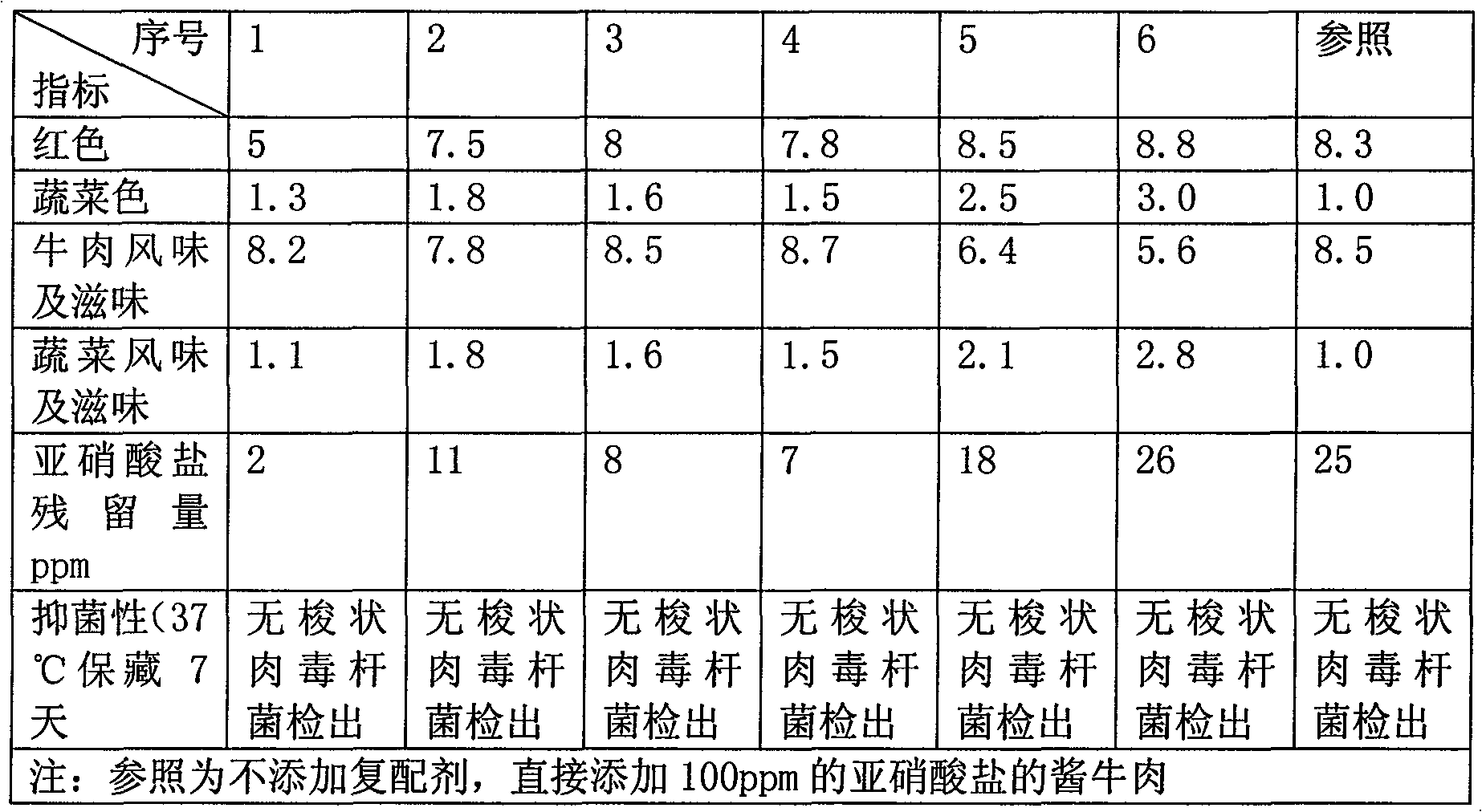

Green composite additive agent for sauced beef

InactiveCN101406296AExcellent color developmentImprove antioxidant capacityFood preparationSodium lactateEconomic benefits

The invention relates to a green composite additive for sauced beef, which is characterized in that the green composite additive is prepared by a composite curing agent and a composite spraying agent, wherein the composite curing agent contains 0.6 to 1.2 weight portions of celery powder, 0 to 0.4 weight portion of spinach powder, 0.08 to 0.15 weight portion of nitrate reducing bacteria and 0.08 to 0.015 weight portion of abnormal VC sodium; and the composite spraying agent contains 0.05 to 0.15 percent of tea polyphenol and 0.7 to 2 percent of sodium lactate aqueous solution. The composite additive is nutritious, healthy and widely applied, and not only can be applied to the sauced beef but also can be applied to meat products such as smoked sausages, smoked hams, fermented sausages, and so on. Moreover, the green composite additive accords with the requirements of consumers on safe and green foodstuffs, has larger realistic meaning in industrial production, provides a novel concept for production of the green meat products, and simultaneously creates good economic benefit for enterprises.

Owner:江苏迈斯克食品有限公司

Chamois initation artificial leather and manufacturing method thereof

InactiveCN1497098AExcellent color developmentHigh fastnessDyeing processWoven fabricsElastomerChamois leather

Provided is sueded artificial leather having good color developing properties and color fastness to light in a wide range of color tones, having a good sueded feel, surface touch, and feeling, and therefore having a sense of high quality. This suedey artificial leather is composed of a three-dimensionally interwoven material formed out of ultrafine fibers having a dtex of <=0.2 and a polymeric elastic material A and satisfies the following requisites (1) to (4): (1) the three-dimensionally interwoven material contains 0-8wt.% of at least one pigment A selected from an organic pigment having an average particle diameter of 0.01-0.3[mu]m and carbon black having an average particle diameter of 0.01-0.3[mu]m, (2) the polymeric elastic material A contains 1-20wt.% of at least one of another pigment selected from another organic pigment having an average particle diameter of 0.05-0.6[mu]m and the other carbon black having an average particle diameter of 0.05-0.6[mu]m, or of pigment particles containing the other organic pigment and having the average particle diameter of 0.05-0.6[mu]m, as a pigment B; (3) the polymeric elastic material A and the three-dimensionally interwoven material are contained in a weight ratio of 15:85 to 60:40; and (4) the ultrafine fibers existing at the surface have raised fluffs of which the average length is 10-200[mu]m.

Owner:KURARAY CO LTD

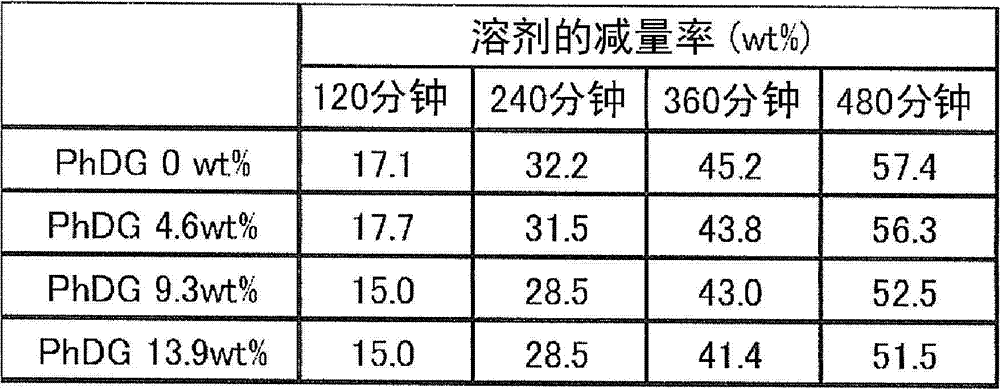

Solvent-free urethane composition

ActiveCN1894299AReduce loadHigh hardnessPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyolSolvent free

A solvent-free composition is prepared, which is a composition comprising a polyol component (A) and a polyisocyanate component (B), wherein the polyol component (A) is composed of a low-molecular-weight polyol (A1) with a molecular weight of 350 or less. The viscosity of the aforementioned low-molecular polyol (A1) may be 500 mPa·s or less at 25°C. The aforementioned low-molecular polyol (A1) may be, for example, C2-6 alkylene glycol or the like. In addition, the polyol component (A) may be composed of a low-molecular polyol (A1) and a polymer polyol (A2) as a diluent. The aforementioned polyisocyanate component (B) may be a modified product or a derivative of polyisocyanate (for example, a multimer of diisocyanate, etc.). The aforementioned solvent-free composition may further contain an epoxy group-containing compound (aliphatic diol glycidyl ether, aliphatic polyhydric alcohol glycidyl ether having a hydroxyl group, etc.) (C) that may have a hydroxyl group. Such a solvent-free composition has a small load on the environment, has excellent coating film properties, and has high application efficiency.

Owner:日本硅石株式会社

Ink jet recording method, ink set, and recorded article

InactiveCN102729676AIncrease brightnessExcellent color developmentMaterial nanotechnologyDuplicating/marking methodsColor imageImage formation

An ink jet recording method includes forming a glittering image on a recording medium by ejecting a glittering ink containing silver onto the recording medium by an ink jet method, applying a protective ink containing a resin and substantially no coloring material onto the glittering image, and forming a color image by ejecting a color ink containing a coloring material to the glittering image by an ink jet method. The protective ink is applied between the glittering image and the color image.

Owner:SEIKO EPSON CORP

Method for producing dry type duplicating body paper

InactiveCN103103863AHigh opacityGood light transmissionNatural cellulose pulp/paperWater-repelling agents additionWet strengthSizing

The invention belongs to a papermaking technology, and relates to a method for producing dry type duplicating body paper. The method comprises the following steps of: making finished paper by crushing, grinding and mixing basic raw materials of bleached chemical broad-leaved wood pulp and bleached chemical softwood pulp, sizing, dehydrating, pre-drying, performing surface sizing, post-drying, glossing and coiling; during manufacturing, adding fillers, an inner sizing agent, a wet-strength agent and a surface sizing agent, wherein the two basic raw materials comprise 65-85 percent of bleached chemical broad-leaved wood pulp and 15-35 percent of bleached chemical softwood pulp, and the fillers comprise titanium dioxide and calcium carbonate; adding the titanium dioxide during pulp crushing, wherein the adding amount is 20-60 kilograms for per ton of paper; and adding the calcium carbonate during pulp mixing, wherein the adding amount is 120-280 kilograms for per ton of paper. With the method, the production cost can be reduced, the yield is improved, and the non transparency of a product is improved.

Owner:ZHENJIANG DADONG PULP & PAPER

Method for preparing ceramic pigment titanium dioxide

ActiveCN106186054AOvercome hair color difference (grayOvercome the dark)Titanium dioxideHydrolysisImpurity

The invention discloses a method for preparing ceramic pigment titanium dioxide. An introduced purifying technology after ilmenite acidolysis comprises the following steps: 1) adding a certain amount of a polyacrylamide anionic surfactant in an acidolysis fluid suspension; 2) adding a certain amount of a polyacrylamide cationic surfactant and an inorganic salt flocculating agent; and 3) standing for 4-6 hours, extracting half part of clear liquid and conveying the half part of clear liquid to a filter press for solid-liquid separating, performing titanium liquid purification, and then introducing into a vacuum crystallization system for crystallization. A titanyl sulfate hydrolysis technology comprises the following steps: 1) adding seed crystal titanium liquid in liquid alkali to prepare seed crystal; 2) neutralizing the material and aging the material; and 3) adding preheated hydrolysis titanium liquid, heating the material to a boiling state for keeping for 3 hours, and stopping hydrolysis. The purifying technology after ilmenite acidolysis and titanyl sulfate hydrolysis technology are optimized and improved, impurity content in the product is low, product particle size is controlled in D50=2-2.5 [mu]m, and D90 is less than 5[mu]m.

Owner:GUANGXI JINMAO TITANIUM

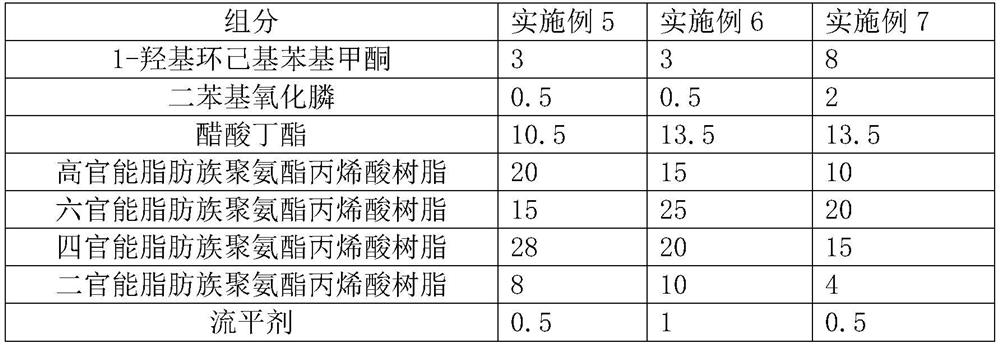

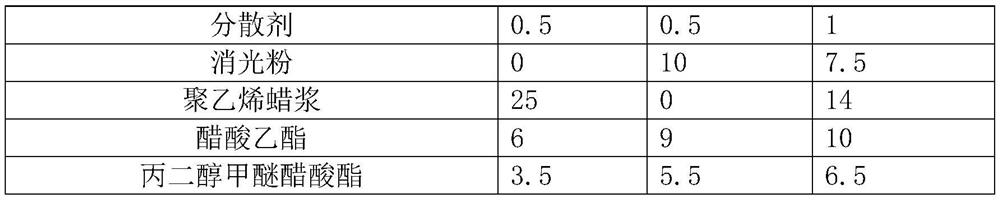

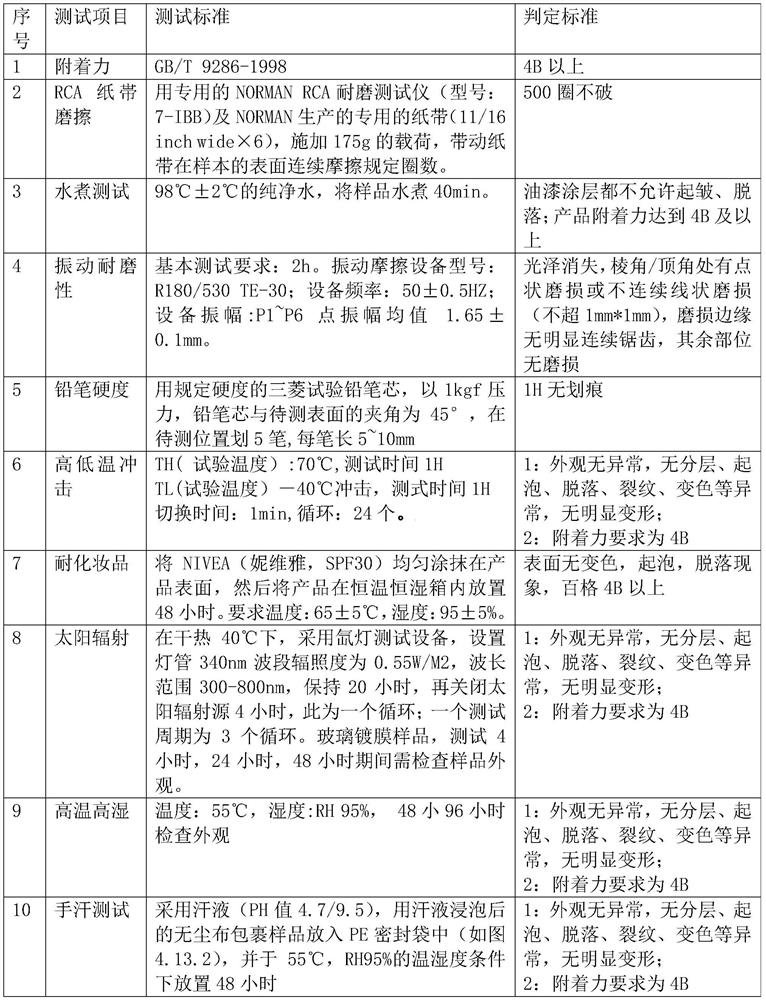

Vibration wear-resistant coating and preparation method and spraying process thereof

ActiveCN112538293AInhibit sheddingSolve the phenomenon of uncertain performance such as sheddingPretreated surfacesPolyurea/polyurethane coatingsCellulosePolymer science

The invention provides a vibration wear-resistant coating and a preparation method and a spraying process thereof. The vibration wear-resistant coating comprises PU type primer and UV photocurable finish coating. The PU type primer is prepared from 40-50 parts of thermoplastic acrylic resin, 10-20 parts of hydroxy acrylic resin, 1-3 parts of cellulose acetate butyrate, 1-2 parts of adhesion promoter, 2-4 parts of auxiliaries, 15-25 parts of pigment filler and 20-30 parts of mixed solvent; and the UV photocurable finish coating comprises the following components in parts by weight: 10-20 partsof high-functionality polyurethane acrylate, 15-25 parts of six-functionality polyurethane acrylate, 15-28 parts of four-functionality polyurethane acrylate, 4-10 parts of two-functionality polyurethane acrylate, 0.5-1 part of a dispersing agent, 0.5-1 part of a leveling agent, 0-10 parts of extinction powder, 0-25 parts of wax liquor, 0-10 parts of a photoinitiator and 20-30 parts of a mixed solvent. When the vibration wear-resistant coating is applied to a mobile phone (plastic material) frame or a mobile phone side key, the vibration wear resistance and durability of the product can be improved, and a coating film can be prevented from falling off after long-time use.

Owner:东莞市贝特利新材料有限公司

Cation dyeable tight spot yarn textile

InactiveCN101165244AExcellent color developmentSmooth fabric surfaceDyeing processWoven fabricsYarnDyeing

The fabric of twitty yarn capable of being dyed with cationic dye features that the fabric contains twitty yarn comprising PET fiber capable of being dyed with cationic dye and common PET fiber. The fabric has relatively lower dyeing temperature, excellent color emissivity and capacity of obtaining dark and light stripe effect. When the fabric is heterochrosis dyed with both cationic dye and one other dye capable of dyeing partial yarn, it will exhibit different colors in different directions. When it is dyed with only cationic dye, it will exhibit jean-like effect and have dispersed white dots.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Ink jet recording sheet

InactiveCN1765638AExcellent color developmentPrint clearDuplicating/marking methodsEngineeringPigment

The present invention provides an inkjet recording medium, which is provided with an ink receiving layer on a support, and is characterized in that, in the ink receiving layer, a pigment, a binder, an ink fixer, and Terpolymer of alkyl methacrylate and N-methylolacrylamide and styrene.

Owner:OJI PAPER CO LTD

Ecological environment-friendly sepiolite functional wall material and preparation method thereof

The invention discloses an ecological environment-friendly sepiolite functional wall material. The wall material is prepared from the following raw materials in parts by weight: 5-35 parts of sepiolite, 0.1-5.0 parts of surfactant, 10-50 parts of inorganic mineral filler, 5-40 parts of a gelling material, 0.5-5.0 parts of functional additives, 0.5-5.0 parts of an antimildew antibacterial material,5-25 parts of titanium dioxide, 0.1-5.0 parts of pigment and 0.2-5.0 parts of cellulose. The preparation method comprises the following steps: (1) preparing an aqueous solution having a concentrationof 1 percent from the surfactant, stirring the high-purity sepiolite in an electrical heating variable-frequency dispersing machine, completely and uniformly spraying the aqueous solution to the surface of the sepiolite, increasing the temperature in a tank, drying until the moisture is lower than 5 percent, and filtering through a 120-mesh vibrating screen to obtain modified sepiolite; (2) stirring the functional additives, antimildew antibacterial material, titanium dioxide, pigment and cellulose into a high-speed mixer, and stirring the modified sepiolite, inorganic mineral filler, gellingmaterial and surfactant in a stirring container; and (3) adding clear water into a drum in 0.9 time mass of the powder, pouring the wall material powder into the water, and dispersing the powder withthe high-speed stirrer into paste. The ecological environment-friendly sepiolite functional wall material has high adsorption capacity on harmful gases.

Owner:湘潭海泡石科技有限公司

Fine concave-convex surface matte ceramic tile and preparation method thereof

ActiveCN113799531AHigh mechanical strengthGood flexibilityDecorative surface effectsSpecial ornamental structuresGlazeSuspending Agents

The invention provides a fine concave-convex surface matte ceramic tile and a preparation method thereof, wherein the ceramic tile comprises a green body layer with a concave-convex texture, a cover coat composed of feldspar calcium glaze is arranged on the green body layer, a pattern layer is arranged on the cover coat, and a dry granular glaze layer is arranged on the pattern layer, wherein according to the parts by mass, a glaze material of the dry granular glaze layer comprises the following components including, 20-50 parts of low-temperature glaze slip, 10-50 parts of high-temperature dry granules, 50-100 parts of medium-temperature dry granules, 30-50 parts of high-temperature matte powder and 200-400 parts of a dry granular suspending agent, wherein the specific gravity of the low-temperature glaze slip is 1.85-1.95 g / ml. According to the ceramic tile, the composition proportioning scheme of the components of the dry granular glaze layer and cover glaze is originally provided; and in the technological process of the matte ceramic tile, the manufacturing processes of fine molds, fine dry granular glaze pouring and brushing and polishing are adopted, the matte ceramic tile is further matte, the ceramic tile which is good in stereoscopic impression and layering sense, obvious in glimmer and matt contrast, smooth and fine is obtained, and the comfort of the whole decoration space is improved.

Owner:GUANGDONG NEWPEARL CERAMIC GRP CO LTD +4

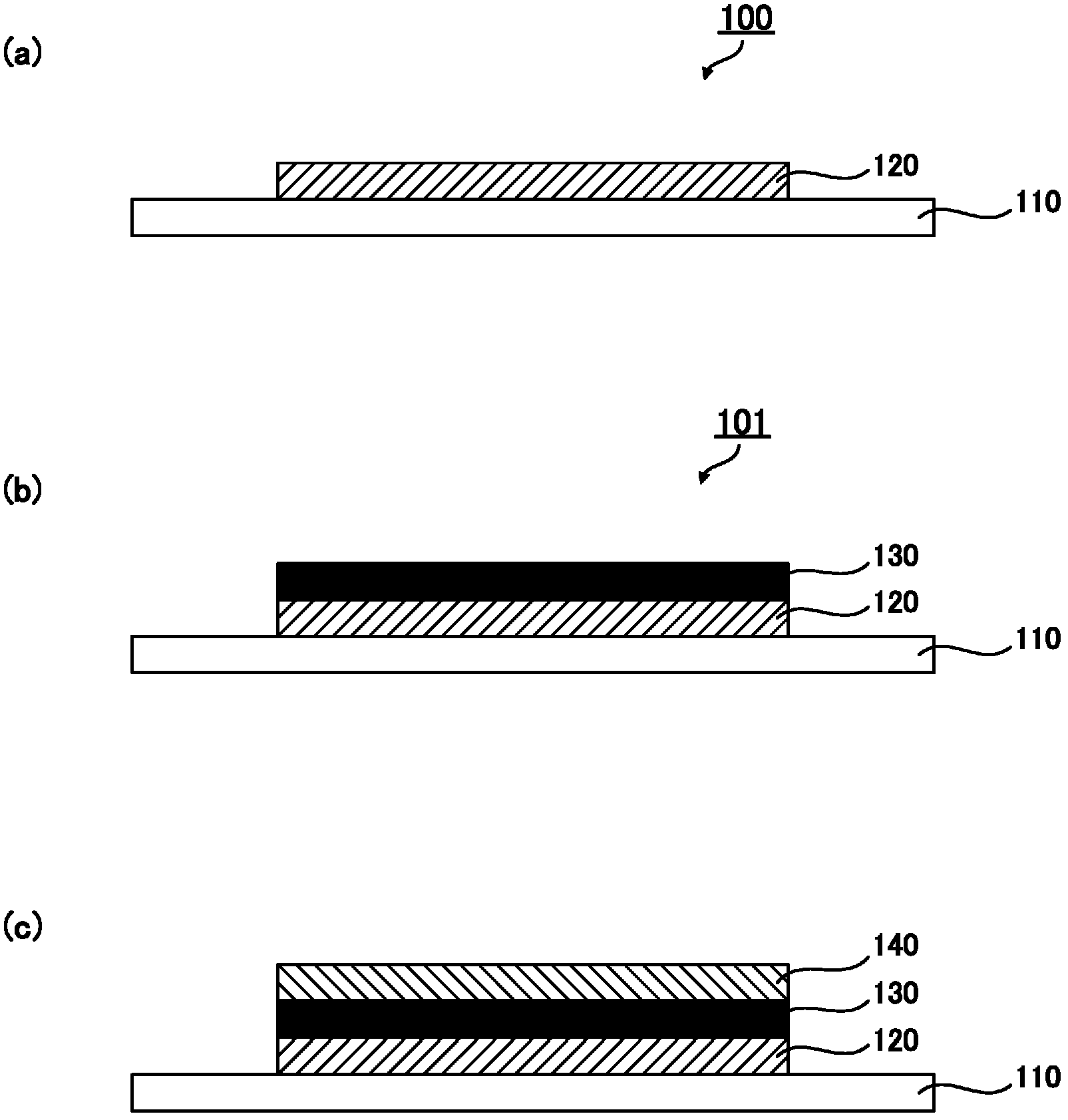

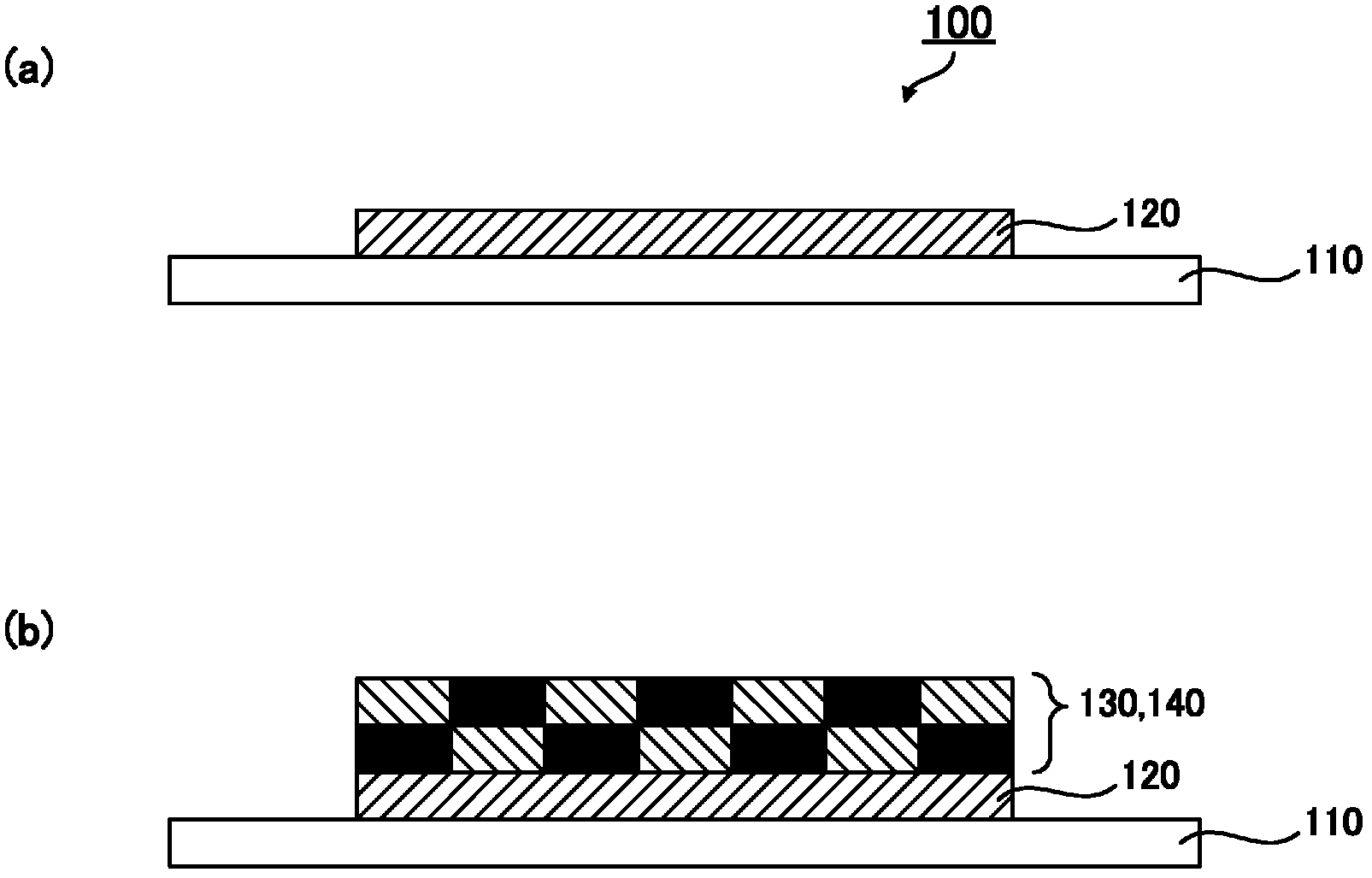

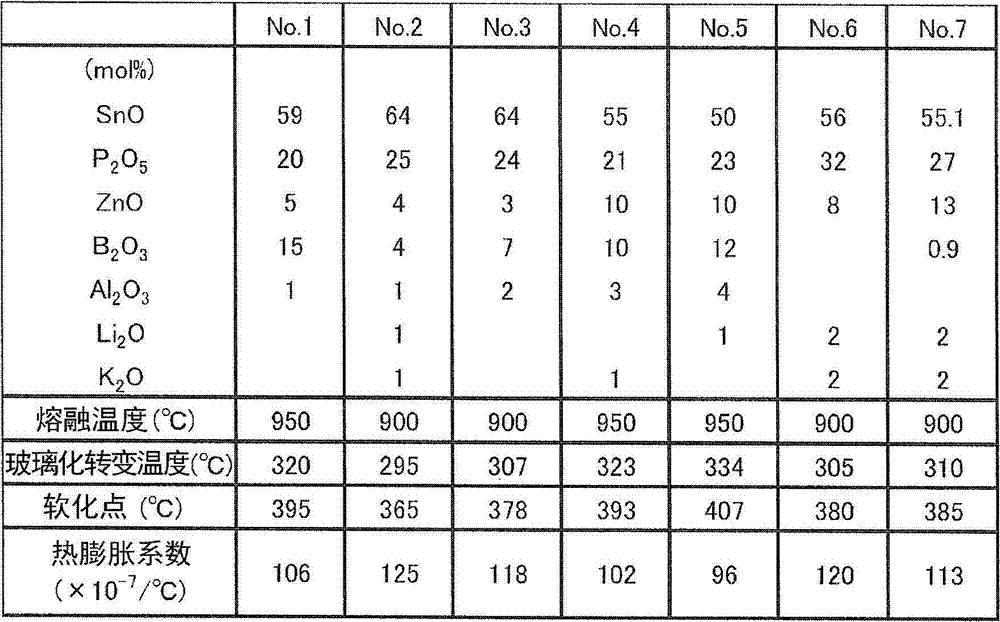

Sealing material and paste material using same

InactiveCN102822109AImprove reliabilitySmall coefficient of thermal expansionElectroluminescent light sourcesSolid-state devicesPigmentMaterials science

Disclosed is a sealing material suitable for laser sealing whereby long-term reliability of devices such as organic EL displays is increased. This sealing material contains 80 - 99.7% by mass of an inorganic powder containing glass powder that contains SnO and 0.3 - 20% by mass of a pigment and is characterized by being used for laser sealing.

Owner:NIPPON ELECTRIC GLASS CO LTD

Composite food colored preservative and preparation method thereof

InactiveCN101120772AResidue reductionGood colorMeat/fish preservation using chemicalsFood preparationSodium acetrizoateSodium sorbate

The present invention provides a compound food coloring preservative and the making method. The compositions of the present invention based on weight ratio are: cooked cured-meat pigment 30-35 percent, nisin 1-1.5 percent, sodium dehydroacetate 10-15 percent, potassium sorbate 10-15 percent, D- gluconic acid-triangle-lactone 30-35 percent and ascorbic acid 10-15 percent. The present invention uses cooked cured-meat pigment, which is made by the reaction of hemoglobin and sodium nitrate, and a certain quantity of nisin, sodium dehydroacetate, sodium sorbate, D- gluconic acid-triangle-lactone and ascorbic acid to completely compound based on a certain ratio, and then the present invention shows a good effect of replacing sodium nitrite, which not only can make the meat products have good color, but also can extend the shelf life of products. The results show that the compound food coloring preservative has good functions of colorizing and bacteriostasis, can obviously restrain the growth of microorganism in the meat products, can reduce the residue of the nitrate, can extent the shelf life of the meat products, and can produce meat products in place of sodium nitrate.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Smell-free styrene-acrylic emulsion and clean-smell coating with emulsion as film forming matter

ActiveCN105884963ASmall smellSolve technical bottlenecksEvaporator accessoriesCoatingsPolymer scienceEmulsion

The invention provides a preparation method of a styrene-acrylic emulsion with VOC lower than 100 ppm and a coating containing the emulsion. The VOC of the final emulsion coating can be controlled to be lower than 100 ppm. The emulsion has excellent color contrast properties, mechanical stability and water resistance, alkali resistance and scrubbing resistance of a paint film, and is suitable for being used as a building coating emulsion.

Owner:HENGSHUI XINGUANG CHEM

Water-based narrow coated paper flexible printing ink and method for preparing same

InactiveCN102964914ALower minimum film forming temperatureHigh glossInksPolymer scienceAcrylic resin

The invention relates to the ink technical field, and in particular relates to water-based narrow coated paper flexible printing ink and a method for preparing the same. The water-based narrow coated paper flexible printing ink comprises the following raw materials in parts weight: 30-45 parts of self-crosslinking water-based acrylic emulsion, 20-28 parts of modified water-based acrylic resin, 15-20 parts of yellow pigment powder, 1-3 parts of pigment dispersant, 0.2-0.8 parts of organic silicon defoamer, 1-4 parts of nonionic organic surfactant, 2-6 parts of dodecanol ester, 3-8 parts of PH stabilizer, 3-5 parts of anionic surfactant and 5-10 parts of water. The water-based narrow coated paper flexible printing ink provided by the invention is environment-friendly and non-toxic, good in use security, stable in performance and good in printing adaptability to coated paper, and has excellent color rendering property, good glossiness and good product quality.

Owner:东莞市佳烨化工科技有限公司

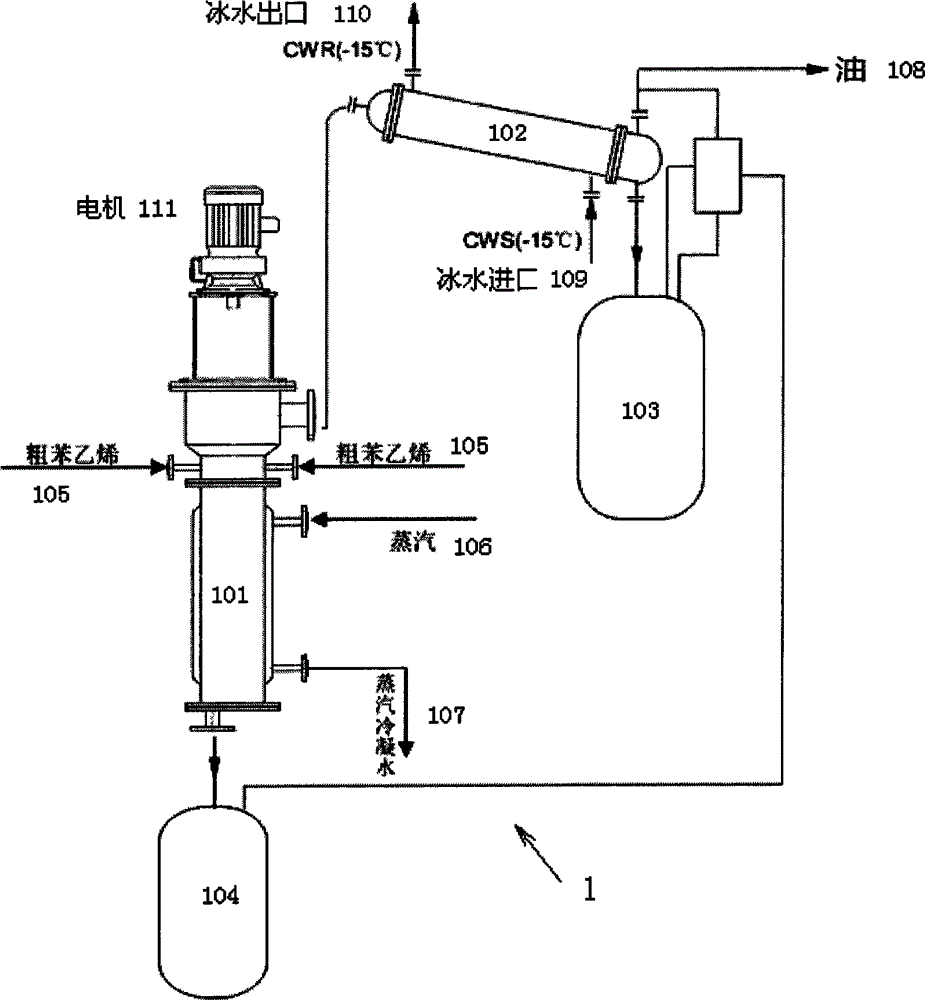

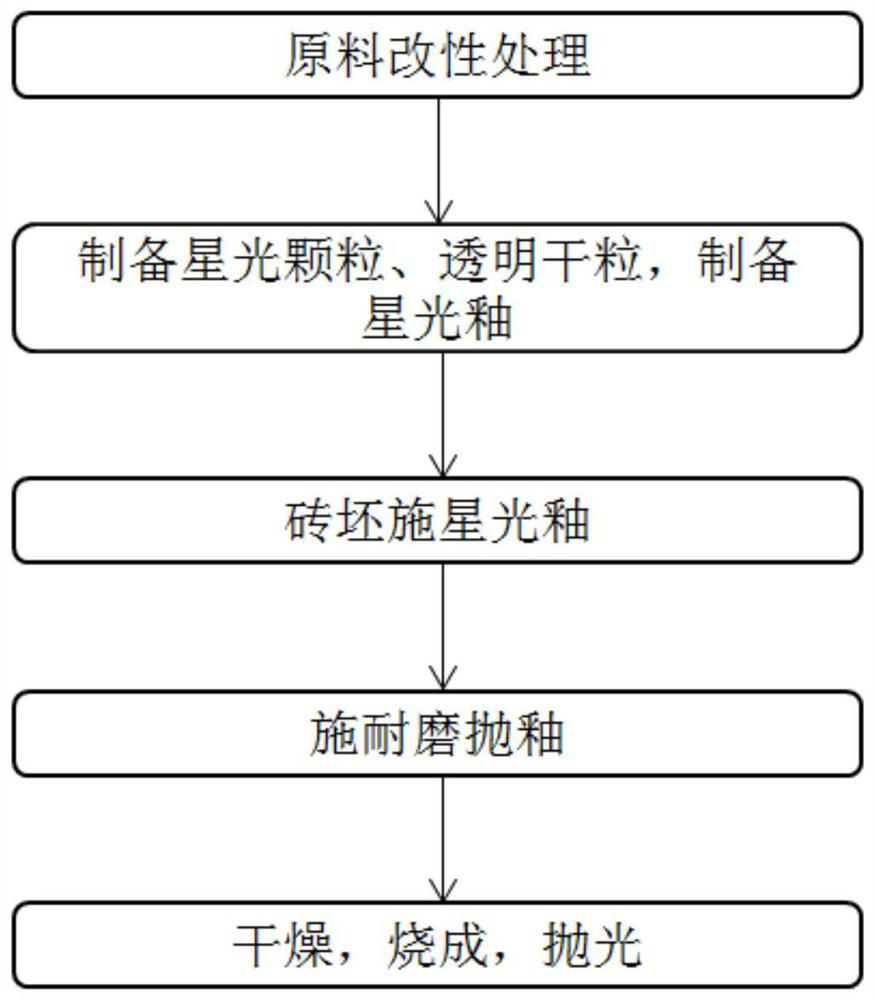

Wear-resistant antifouling ceramic starlight glazed brick and preparation method thereof

ActiveCN112979349AWide firing temperature rangeMild conditions for crystallizationBrickWear resistance

The invention relates to the technical field of preparation of ceramic glazed bricks, and provides a wear-resistant antifouling ceramic starlight glazed brick and a preparation method thereof. The glittering effect is achieved through multiple reflection, dispersion and refraction methods of crystals in the glaze, a glaze layer of the glazed brick has the multi-layer glittering effect and the three-dimensional decoration effect, and the grade and decoration of the product are improved; and an excellent flashing effect can be achieved only by polishing according to a conventional polishing process of a glazed product. The glazed brick disclosed by the invention has relatively high hardness and excellent antifouling property and wear resistance.

Owner:江西金唯冠建材有限公司

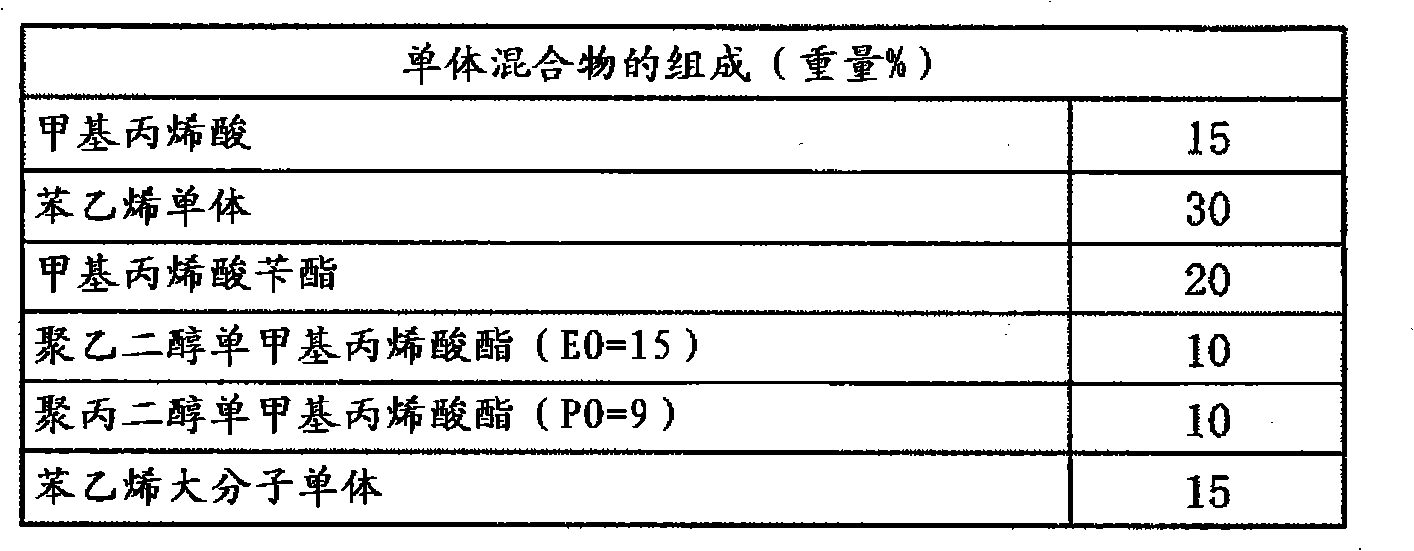

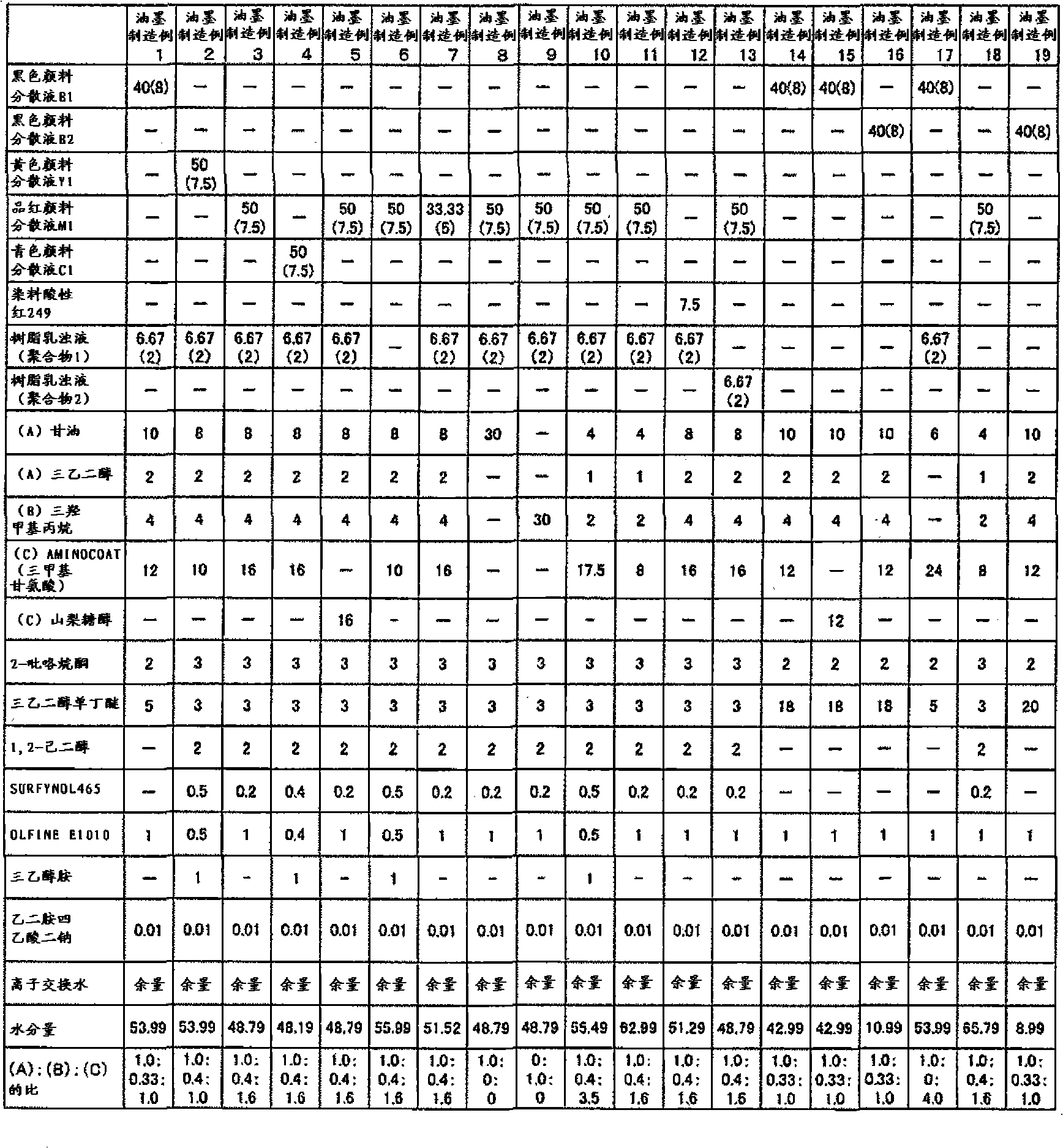

Ink composition, recording method using the same, and recorded matter

ActiveCN101845250AReduce viscosity differenceEasy to curlDuplicating/marking methodsInksBetaineEmissivity

The invention provides an ink composition which reduces viscosity difference caused by temperature as well as has excellent suitability for curl and crinkle, excellent ink penetration resistance, suitability for two-sides printing and color emissivity, and also a recording method using the same and a recorded matter are disclosed. The ink composition includes at least a pigment, a humectant, and water in from 10 to 60% by weight to the total amount of ink. The humectant is a mixture of (A) at least one compound selected from glycerin, 1,2,6-hexanetriol, diethylene glycol, triethylene glycol, tetraethylene glycol, and dipropylene glycol; (B) either trimethylol propane or trimethylol ethane, or a mixture thereof; and (C) at least one compound selected from betaines, saccharides, and ureas and having a molecular weight in the range of from 100 to 200, at a content weight ratio of (A):(B):(C) of 1.0:0.1 to 1.0:1.0 to 3.5.

Owner:SEIKO EPSON CORP

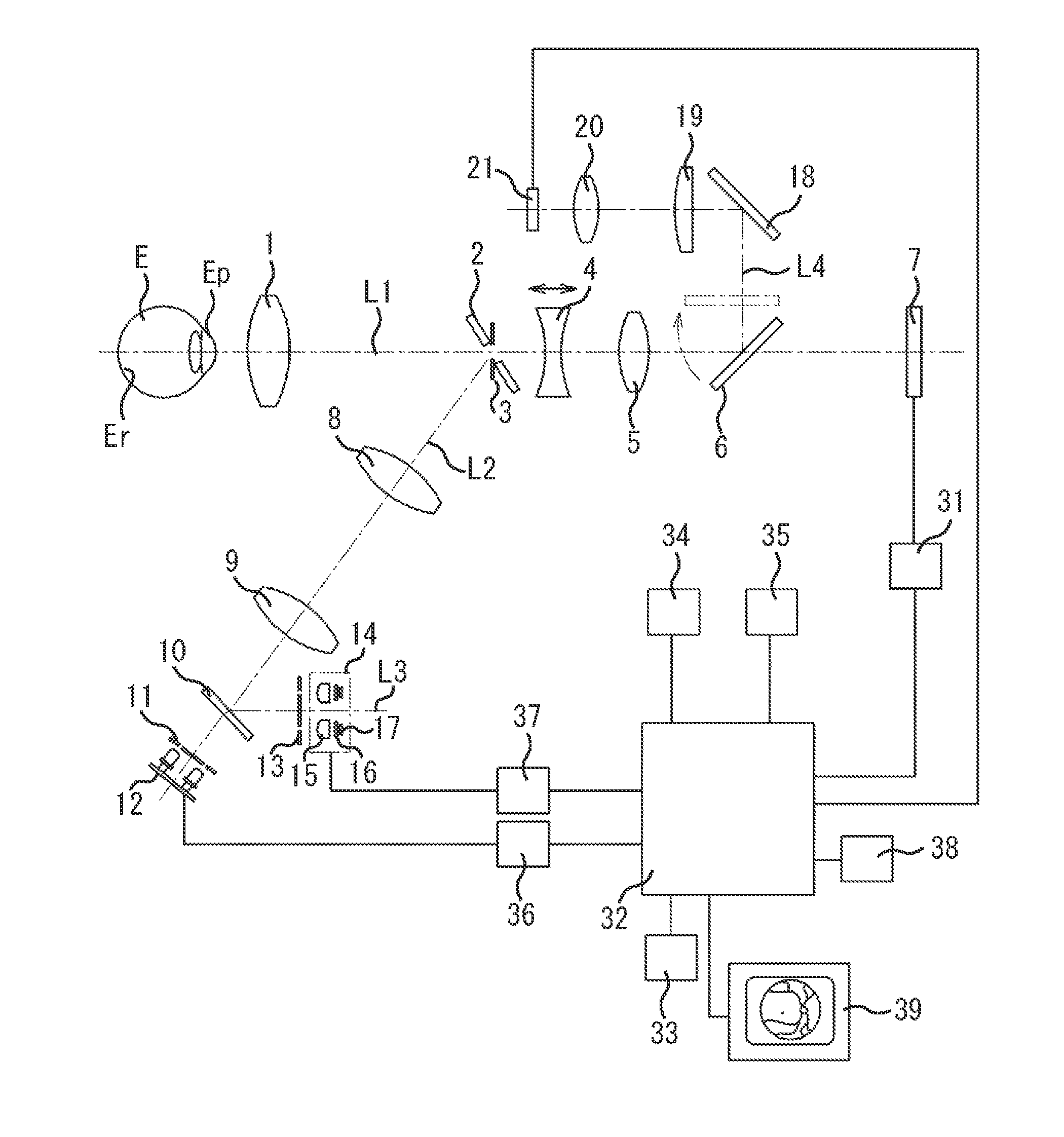

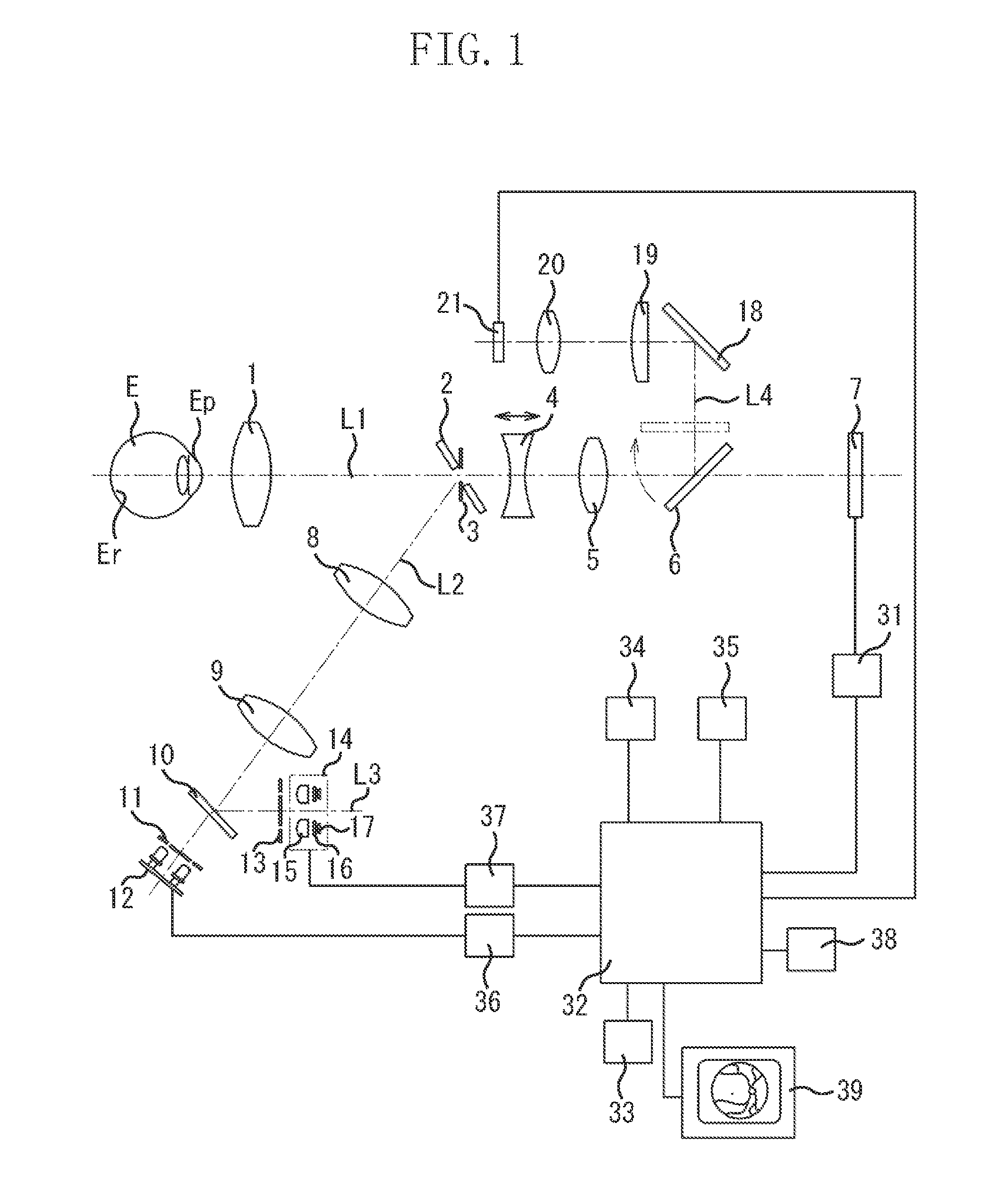

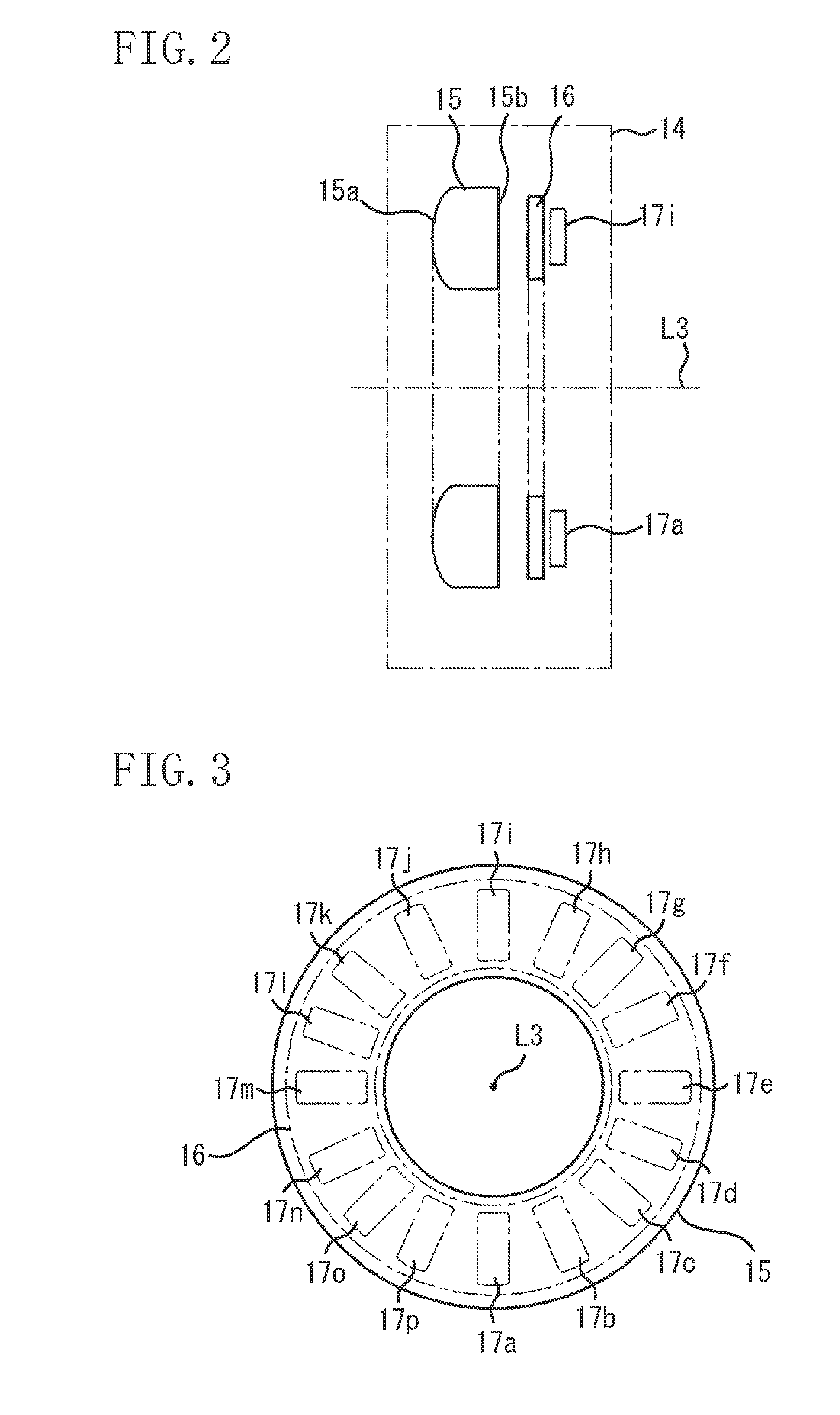

Fundus camera

A fundus camera includes an illumination unit which includes an optical element configured to irradiate an eye fundus with visible light from a position conjugate with an anterior eye portion of an eye to be examined, and an imaging unit configured to take an image of the eye fundus with light which is emitted from the illumination unit and reflected from the eye fundus, wherein the illumination unit includes a blue LED chip and a fluorescent member that is excited by light emitted from the blue LED chip and emits fluorescence, and the fluorescent member is irradiated again with apart of the light reflected by the optical element.

Owner:CANON KK

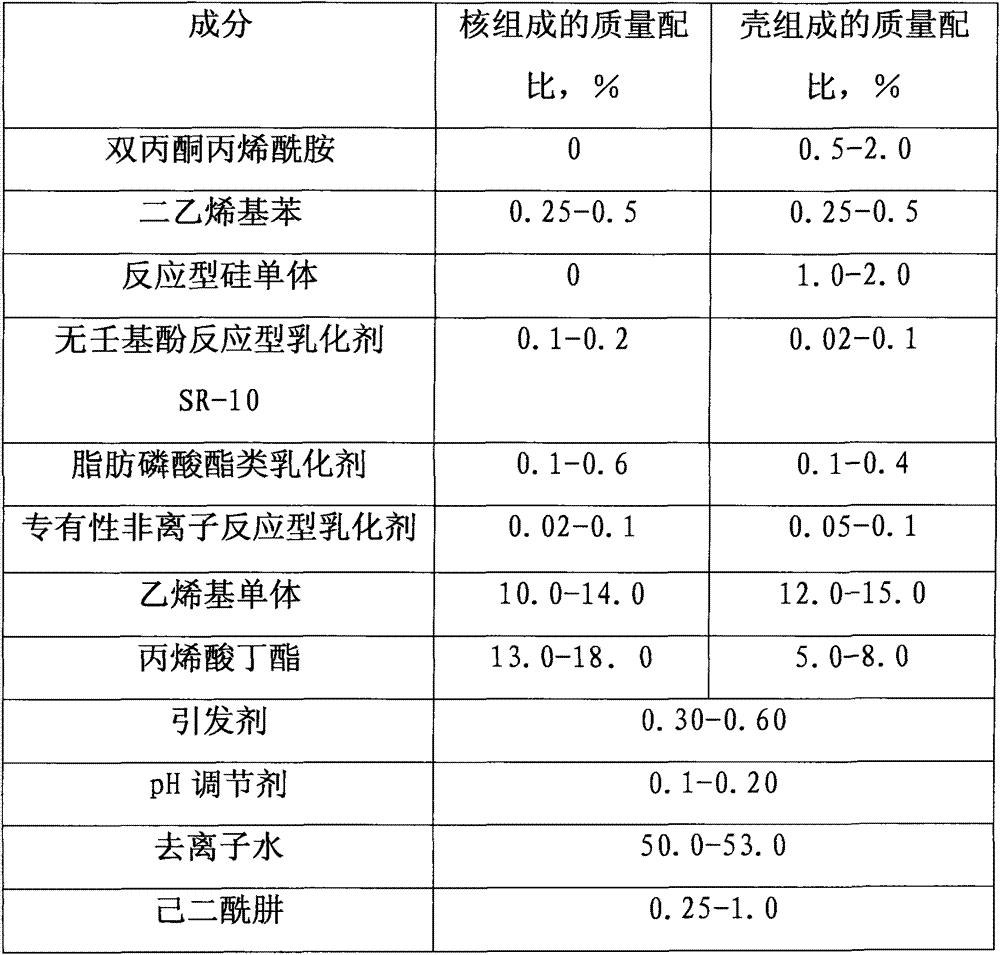

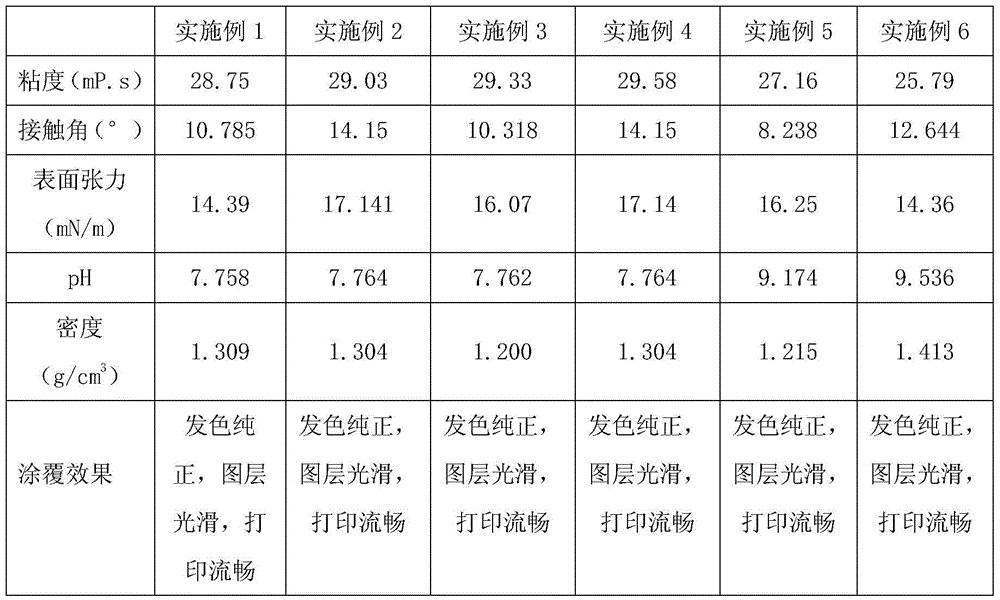

Interpenetrating polymer network core-shell emulsion and preparation method thereof

InactiveCN103936939AGood scrub resistanceIncrease the addition ratioPhosphoric Acid EstersSodium bicarbonate

The invention discloses an interpenetrating polymer network core-shell emulsion and a preparation method thereof. The core-shell emulsion is prepared from a monomer, emulsifiers, an initiator, a PH regulating agent and water. The core-shell emulsion is characterized in that the monomer consists of a functional monomer and a mixed monomer, wherein the mixed monomer consists of a vinyl monomer and butyl acrylate, and the functional monomer consists of diacetone acrylamide, adipic dihydrazide, divinyl benzene and a reactive type silicon monomer; the emulsifiers refer to a nonylphenol-free reactive type emulsifier SR-10, a fatty phosphoric acid ester emulsifier and an exclusive non-ion reactive type emulsifier; the initiator refers to sodium persulfate; the PH regulating agent refers to sodium hydrogen carbonate; water refers to deionized water. The preparation method comprises the following steps: (1) in a raw material ratio, preparing a monomer mixed liquid for later use, preparing deionized water and an initiator and stirring to form an initiator mixed liquid for later use; and (2) polymerizing the emulsion. The core-shell emulsion and the method have the beneficial effects of being environmental-friendly and safe, the technology is simple, the scrubbing-resisting capability and the pigment filler bearing capability are strong and the stability of electrolyte and freeze thawing is high.

Owner:HEBEI SUNRISING CHEM CORP

White glass ink used for ink-jet printing and preparation method thereof

The invention belongs to the field of glass decoration materials and in particular relates to white glass ink used for ink-jet printing and a preparation method thereof. The white glass ink comprises the following components by mass percent: 25-35% of solid components, 50-65% of solvents, 3-11% of surfactants and 0-5% of admixtures, wherein the solid components are prepared by founding, quenching and grinding an anatase TiO2 white pigment and Bi2O3-B2O3-SiO2 system glass powder. The white glass ink and the preparation method have the beneficial effects that the solid components of the glass ink are uniformly dispersed in the solvents, a suspended phase is not easy to flocculate or precipitate and has good stability, and being in smaller grain sizes, the solid components can not block or abrase printer nozzles; the white glass ink has good color development effects; the preparation process is simple, is low in production cost and equipment requirements and is convenient to popularize and use by enterprises.

Owner:WUHAN UNIV OF TECH

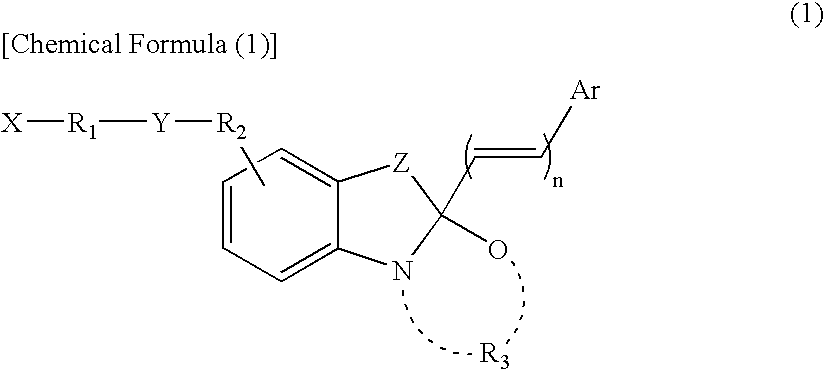

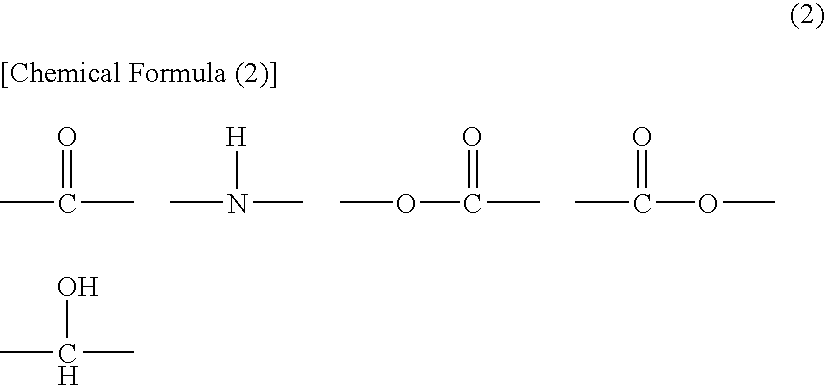

Reversible recording material and displaying element

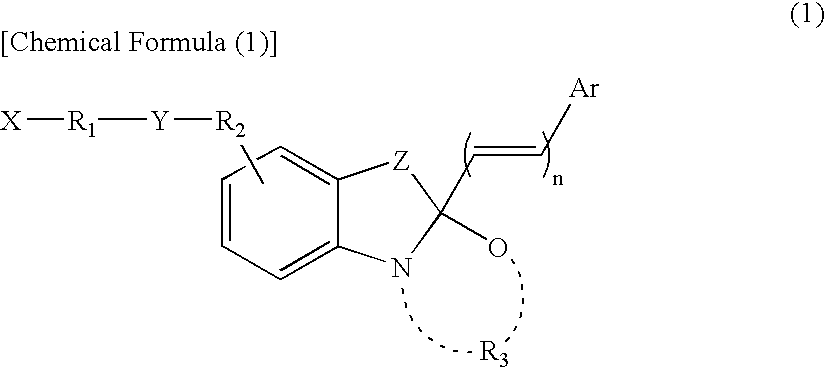

A reversible recording material is disclosed. The reversible recording material includes one or more kinds of compounds having a structure shown in Chemical Formula (1) on a surface of metal oxide particles.In Chemical Formula (1), X shows a linkage including an element selected from Si, Ti, and Al; Y shows a linkage including a structure selected from Chemical Formula (2); Z shows a methylene group or a sulfide group capable of having a substituent group; Ar shows an aromatic group capable of having a substituent group; R1 and R2 show corresponding alkylene groups; R3 shows an alkylene group capable of forming a ring structure linked with —N—C—O— and able to have a substituent group; and “n” is an integer which is 1 or more.

Owner:RICOH KK

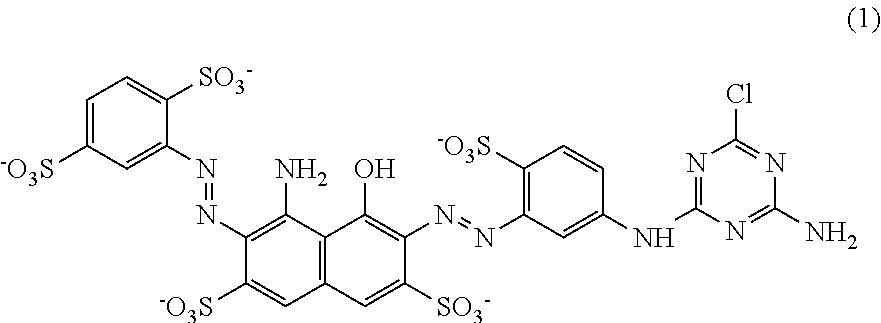

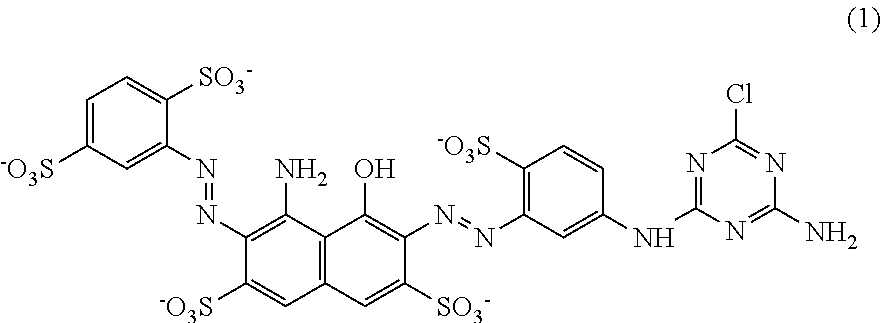

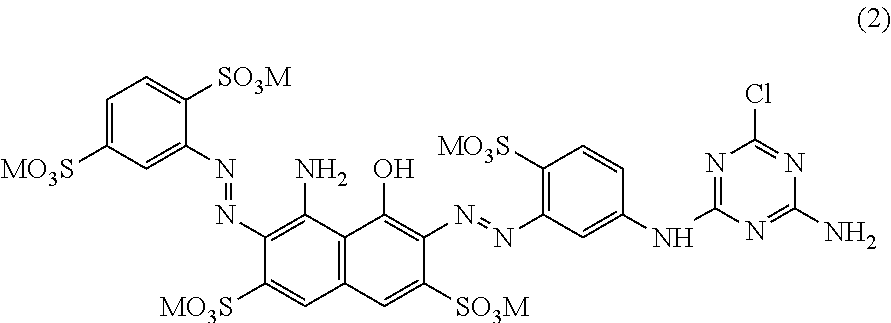

Ink jet textile printing ink composition, ink set, and printing method

ActiveUS20170275485A1Excellent color developmentReliable ejectionDisazo dyesReactive dyesPrinting inkPolymer chemistry

An ink jet textile printing ink composition according to the invention contains Li+, Na+, and a compound represented by the following formula (1):

Owner:SEIKO EPSON CORP

Ground glaze suitable for quick firing of glazed tile, glazed tile and preparation method thereof

The invention provides a ground glaze suitable for quick firing of a glazed tile. The ground glaze comprises the following components by mass percentage: 27-35% of potash feldspar, 8-14% of albite, 1-4% of calcined talc, 2.5-4.8% of a medium temperature frit, 0.5-2.2% of a high expansion frit, 20-35% of quartz, 10-14% of kaolin, and 7-15% of calcined alumina. In addition, the invention also provides a glazed tile containing the ground glaze. According to the formula design of the ground glaze provided by the invention, the dosages of the quartz and calcined alumina are increased simultaneously, firstly the color development effect and firing temperature of the formula are improved, and then the method of adding the medium temperature frit is adopted to realize the purpose of formula cooling, thus not only broadening the firing range of the glazed tile, meeting the requirement of quick firing, but also reaching a good color development effect.

Owner:HUBEI HANGRUI CERAMIC CO LTD

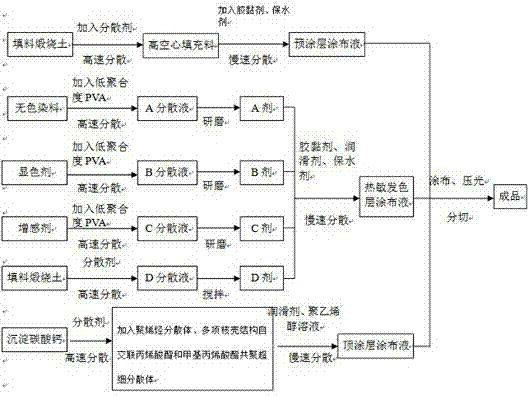

Scratch-resistant thermal-sensitive paper manufacturing method

ActiveCN104846695AGood flexibilityGood impact resistanceNon-fibrous pulp additionCoatings with pigmentsPolyolefinPaper manufacturing

The present invention discloses a scratch-resistant thermal-sensitive paper manufacturing method, which comprises: a) preparing a pre-coating layer coating liquid: b) preparing an agent A; c) preparing an agent B; d) preparing an agent C; e) preparing an agent D; f) preparing a thermal-sensitive color generating layer coating liquid; g) preparing a top coating layer coating liquid; and h) coating. According to the present invention, the polyolefin dispersion with characteristics of excellent flexibility and excellent impact resistance is developed and utilized in the top coating layer so as to obtain the excellent scratch resistance; the multiple core-shell structure self-crosslinked acrylate and methacrylate copolymer ultrafine dispersions are developed and utilized in the top coating layer formula, such that the excellent wet friction resistance can be obtained after the coating layer is dried; and with the optimization, the colorless dye, the coloring agent and the sensitizer used by the color generating layer are selected to match and are subjected to optimization with the optimal ratio, such that the paper achieves good coloring performance, good storage performance, and a certain protection performance.

Owner:JIANGSU WANBAO RUIDA HI TECH CO LTD

Waterborne ink for ceramic inkjet printing and preparation method thereof

The invention relates to waterborne ink for ceramic inkjet printing. The waterborne ink is prepared from the following raw materials: 20-50 parts of ceramic pigment, 2-7 parts of a dispersing agent, 2-5 parts of a surface active agent, 2-3 parts of a resin bonding agent, 2-6 parts of a regulating agent, 0.1-0.5 part of an auxiliary and the balance of water. The waterborne ink provided by the invention contains no toxic organic solvent, achieves certain physical and chemical indexes through mechanical dispersion process treatment, is excellent in comprehensive performance, lower in cost, strongin practicability and can adapt to most of inkjet printers on the market.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com