Ink composition, recording method using the same, and recorded matter

An ink composition and ink technology, applied in the direction of copying/marking method, ink, application, etc., can solve the problems of drastic increase and decrease of viscosity, excessive increase of voltage signal of inkjet head, significant ink bleeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

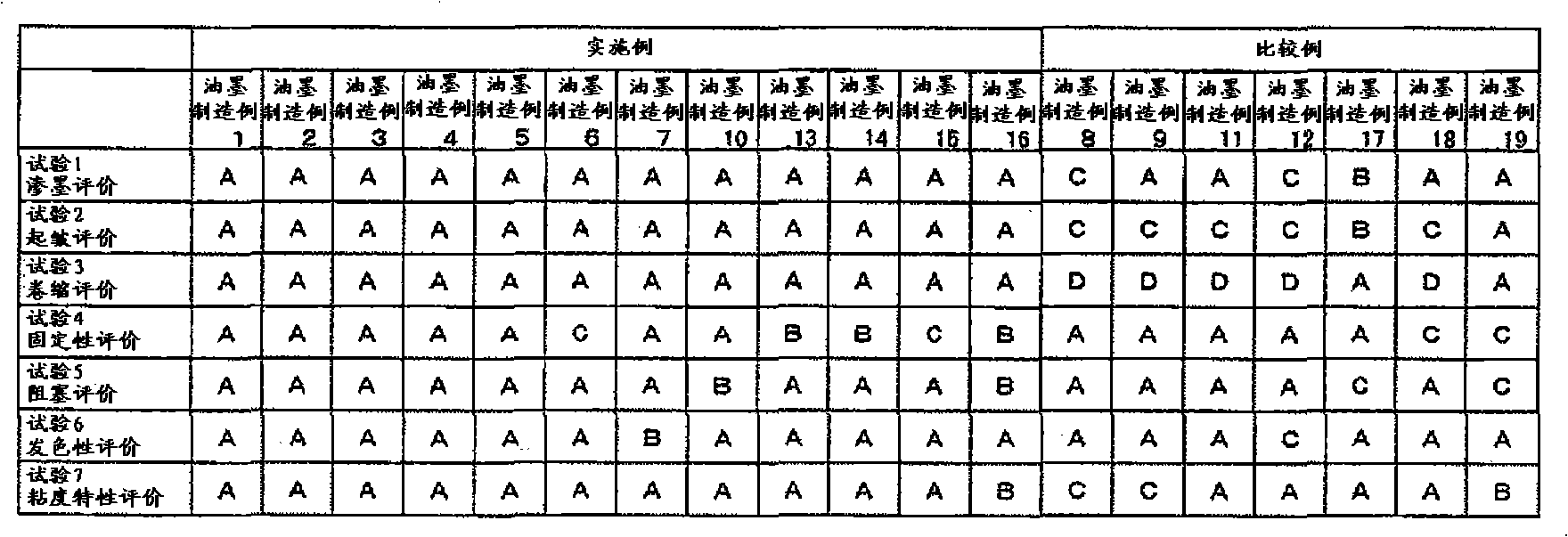

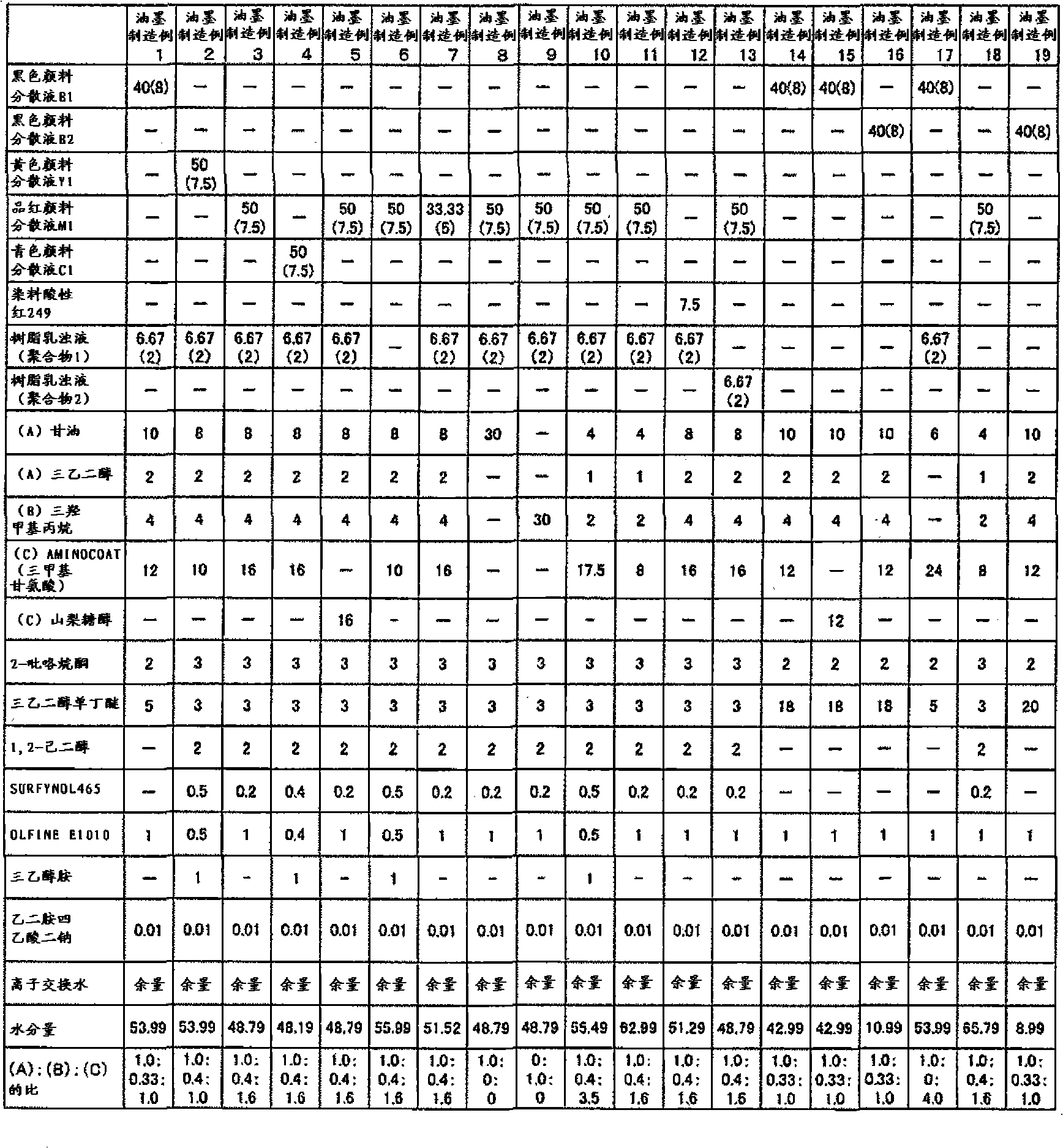

Examples

Embodiment Construction

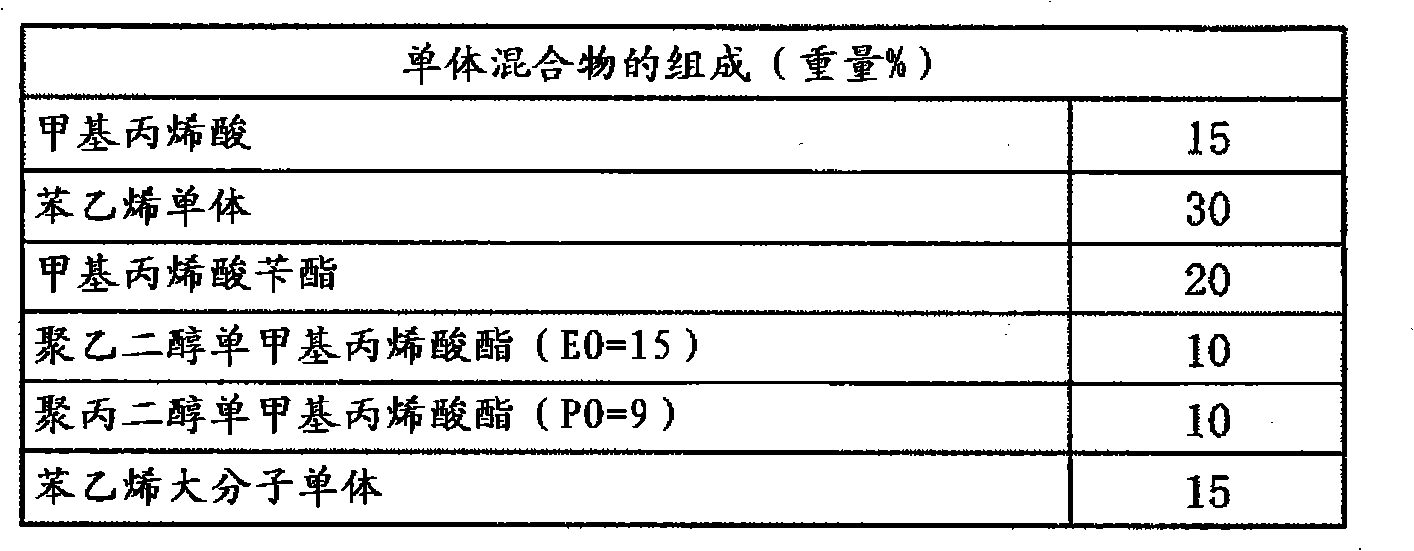

[0030] The ink composition of the present invention will be described in detail below based on preferred embodiments thereof.

[0031] From the viewpoint of safety and operability, the ink composition of the present embodiment is preferably a water-based ink in which the main solvent of the ink is water, and the water is preferably pure water such as ion-exchanged water, ultra-filtered water, reverse osmosis water, distilled water, or ultra-pure water. water. It is particularly preferable to use water sterilized by ultraviolet irradiation or hydrogen peroxide addition from the viewpoint of preventing the generation of mold and bacteria and enabling long-term storage of the ink. From the viewpoint of ensuring proper physical properties (viscosity, etc.) of the ink, stability and reliability of the ink, it is preferable to contain 60% by weight to 10% by weight of water in the ink.

[0032] By setting the amount of water contained in the ink composition within the above range, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com