A kind of preparation method of lithium battery diaphragm

A lithium battery diaphragm and thick film technology, which is applied in the field of lithium battery diaphragm containing lithium-based montmorillonite and its preparation, can solve the problems of loss of electrical performance, failure to meet electrical performance and safety, and blockage at the same time, and achieve porosity Wide control range, excellent rate charge and discharge performance and safety, uniform pore size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] 1. Preparation of lithium battery separator

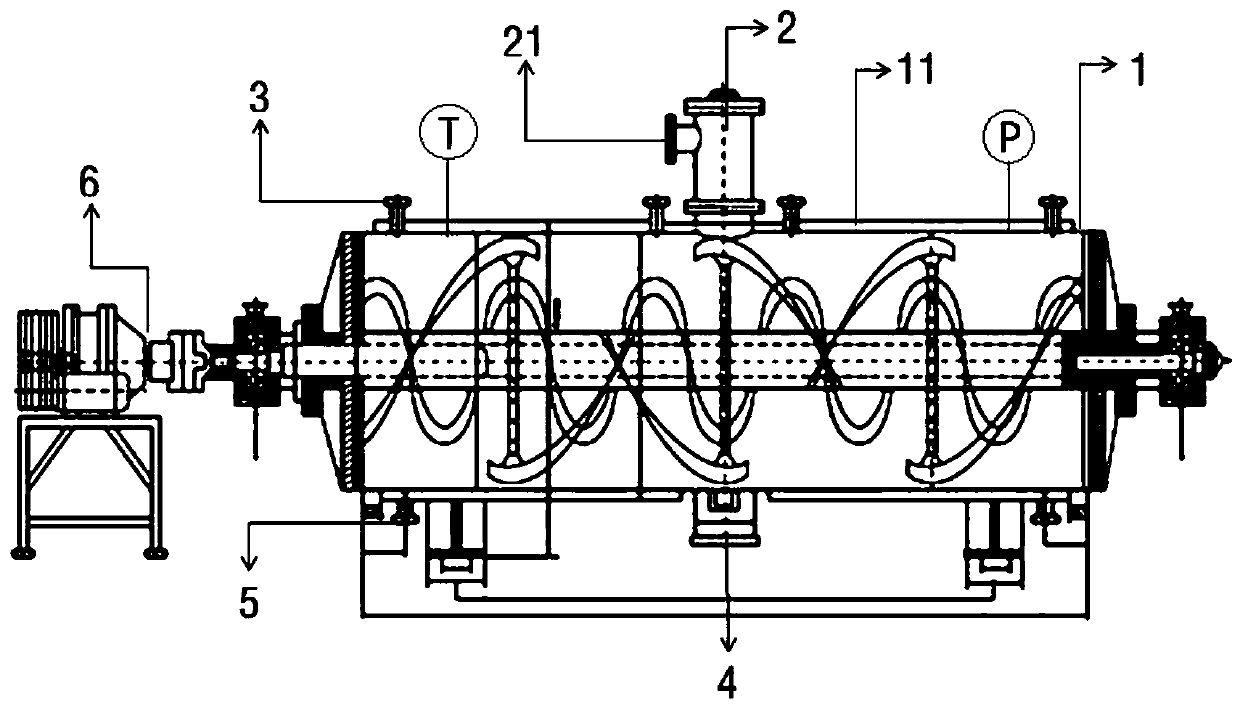

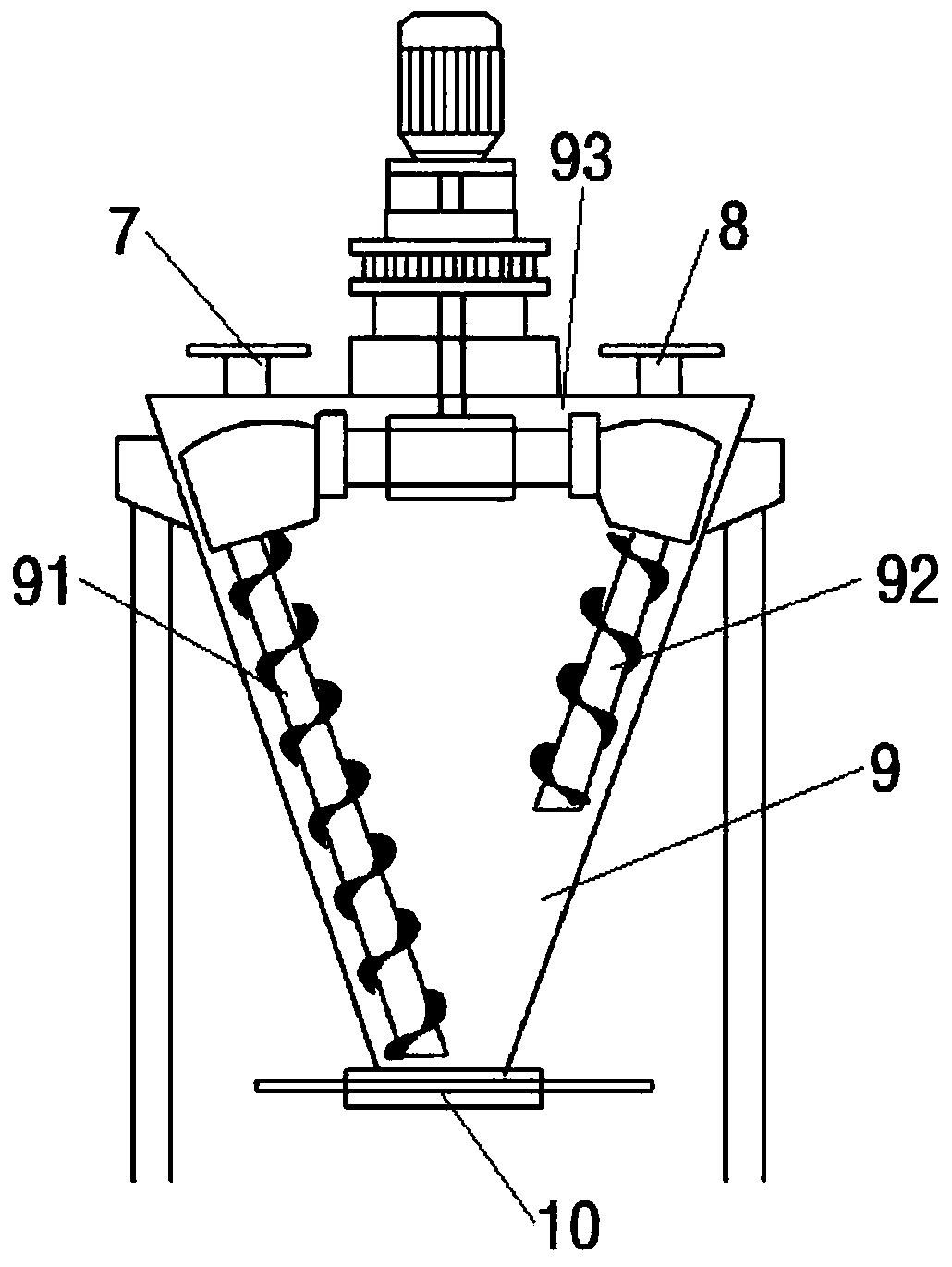

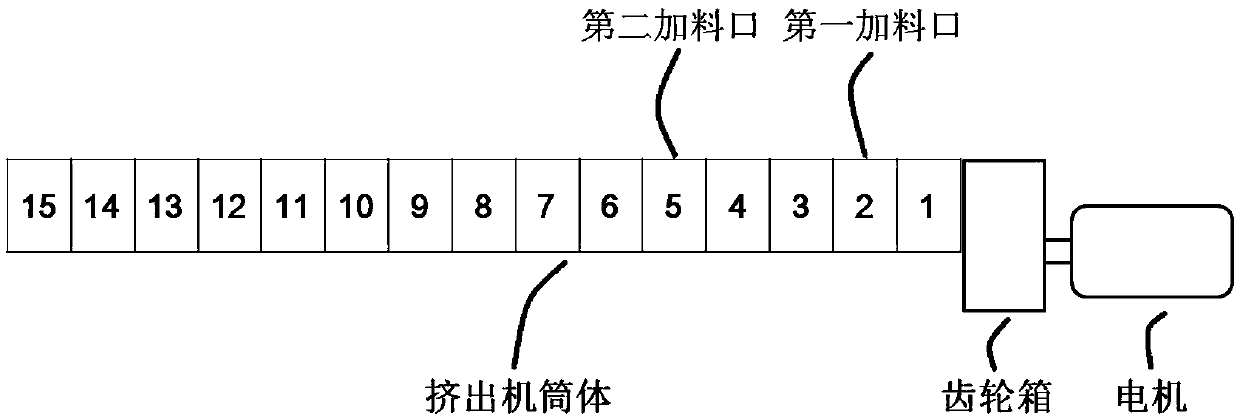

[0039] Such as Figure 1-Figure 3 Shown are the structural diagrams of the vacuum rake dryer for drying lithium-based montmorillonite, the high mixer for premixing materials and the twin-screw extruder for extruding materials provided by the present invention.

[0040] There is a steam jacket 11 on the outer periphery of the cylinder 1 of the vacuum rake dryer. The feed port 2, the vacuum port 21, the temperature detection element and the pressure detection element all pass through the steam jacket 11, and the feed port 2 is located in the cylinder 1. In the middle position of the top, the vacuum port 21 is located at the outer circumference of the feed port 2, the commercially available lithium-based montmorillonite passes through the feed port 2 inside the cylinder 1, and is evenly distributed in the cylinder 1 through the horizontal stirring shaft, and the hot steam flows from the cylinder The steam inlet 3 at the top ...

Embodiment 1

[0046] Composition of lithium montmorillonite with a particle size of 2um and a water content of 8% and antioxidant tetrakis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol in a weight ratio of 10:0.5 dry powder in figure 2 In the high-mixer shown, under the protection of nitrogen, the rotation speed is 200rpm, mix evenly, the total weight of dry powder is 1kg, divide 25kg white oil with a viscosity of 50Cst at 40℃ into 4 batches and add it to the In the high mixer, mix with the dry powder mixed uniformly in the high mixer. The mixing method is: each time a batch of dry powder is added, it is mixed at 300rpm for 5 minutes, cooled for 10 minutes, and then another batch of pore-forming agent is added until All white oils are evenly mixed with dry powder, and finally a premix with an average particle size of less than 3mm is obtained.

[0047] Transport the premixed material to such as image 3 The first feeding port of the twin-screw extruder shown is loc...

Embodiment 2

[0049] The particle size is 2um water content is 11% lithium base montmorillonite, antioxidant tetrakis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol according to the ratio of 20:0.5 composition dry powder in figure 2 In the shown high mixer, under the protective effect of nitrogen, mix evenly at a speed of 200rpm, the total weight of dry powder is 2kg, divide 25kg white oil with a viscosity of 50Cst at 40°C into 4 batches and add it to the high In the mixer, mix with the dry powder mixed uniformly in the high mixer. The mixing method is: each time a batch of dry powder is added, it is mixed at 200rpm for 20 minutes, cooled for 10 minutes, and then another batch of pore-forming agent is added until all The white oil is evenly mixed with the dry powder, and finally a premixed material with an average particle size of less than 3mm is obtained.

[0050] Transport the premixed material to such as image 3 The shown twin-screw extruder is located in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com