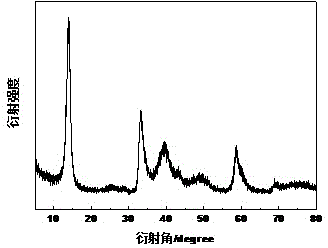

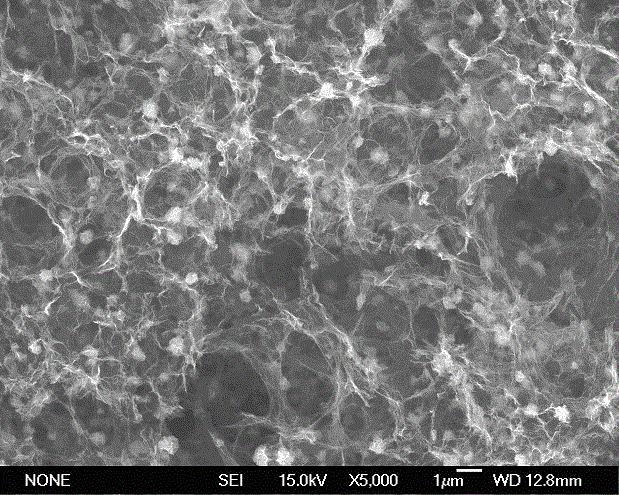

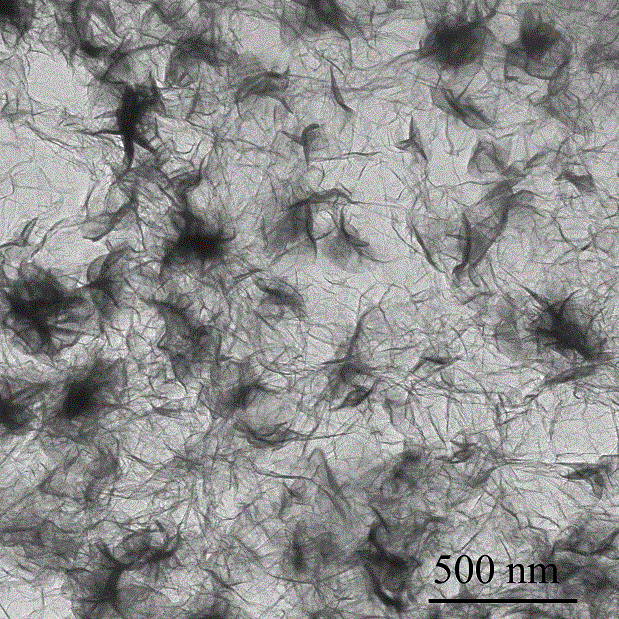

Flake MoS2/graphene composite aerogel and preparation method thereof

A graphene airgel and graphene composite technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low electronic conductivity and poor cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Used graphene oxide is to adopt traditional process method to make, and its preparation method is as follows:

[0030] Potassium persulfate (K 2 S 2 o 8 ) 2.5g, phosphorus pentoxide (P 2 o 5 ) 2.5g, dissolved in 12mL of concentrated sulfuric acid, heated to 80°C; then 3g of natural graphite was added to the above solution, kept at 80°C for 4.5 hours; cooled to room temperature, diluted with 500mL of deionized water, and left standing overnight; filtered, Use a 0.2mm filter to float the residual acid; dry it in a vacuum oven at 60°C; add the obtained preoxide to 120mL of ice-bathed concentrated sulfuric acid, and slowly add 15g of KMnO under stirring 4 , Keep the temperature below 20°C during the addition process. Then the temperature was controlled at 35°C and stirred for 2h. Add 250mL deionized water to dilute, and keep the temperature below 50°C in an ice bath during the dilution process. Stir for another 2 h, add 0.7 L of deionized water, and immediately add 2...

Embodiment 2

[0042] The preparation method of graphene oxide is the same as embodiment 1.

[0043] Preparation of flake MoS 2 / Graphene composite airgel material:

[0044] 1) Measure 25mL of graphene oxide solution with a concentration of 3mg / mL and pour it into a 100mL beaker, add 20mL of deionized water and magnetically stir for 30min to mix well;

[0045] 2) Weigh 0.45g ammonium molybdate and dissolve it in 15mL deionized water, stir it magnetically for 20min, and pour it into the graphene oxide solution in step 1);

[0046] 3) Weigh 0.57g of thiourea and dissolve it in 15mL of deionized water. Thiourea is both a sulfur source and a reducing agent. Stir magnetically for 20 minutes, pour into the solution obtained in step 2), and stir magnetically for 1 hour;

[0047] 4) Measure 1 mL of ethylenediamine solution and pour it into the mixed solution in step 3), and stir magnetically for 20 minutes;

[0048] 5) Transfer the mixed solution obtained in step 4) into a polytetrafluoroh...

Embodiment 3

[0052] The preparation method of graphene oxide is the same as embodiment 1.

[0053] Preparation of flake MoS 2 / Graphene composite airgel material:

[0054] 1) Measure 50mL graphene oxide solution with a concentration of 3mg / mL and pour it into a 100mL beaker, add 40mL deionized water and magnetically stir for 30min to mix well;

[0055] 2) Weigh 0.91g sodium molybdate and dissolve it in 15mL deionized water, stir it magnetically for 20min, and pour it into the graphene oxide solution in step 1);

[0056] 3) Weigh 1.14g of thiourea and dissolve it in 15mL of deionized water. Thiourea is both a sulfur source and a reducing agent. Stir magnetically for 20 minutes, pour into the solution obtained in step 2), and stir magnetically for 1 hour;

[0057] 4) Measure 3 mL of triethylamine solution and pour it into the mixed solution in step 3), and stir magnetically for 20 minutes;

[0058] 5) Transfer the mixed solution obtained in step 4) into a polytetrafluorohydrotherma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com