Silicon, silicon-oxygen-carbon and graphene-based composite material, and preparation method and application thereof

A composite material and graphene-based technology, applied in the field of lithium-ion batteries, can solve the problems that hinder the large-scale application of lithium-ion battery anode materials made of silicon materials, poor electrochemical cycle stability of batteries, and loss of electrochemical activity, etc., to achieve good lithium-ion batteries. Transmission performance, improved cycle efficiency, stable performance, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

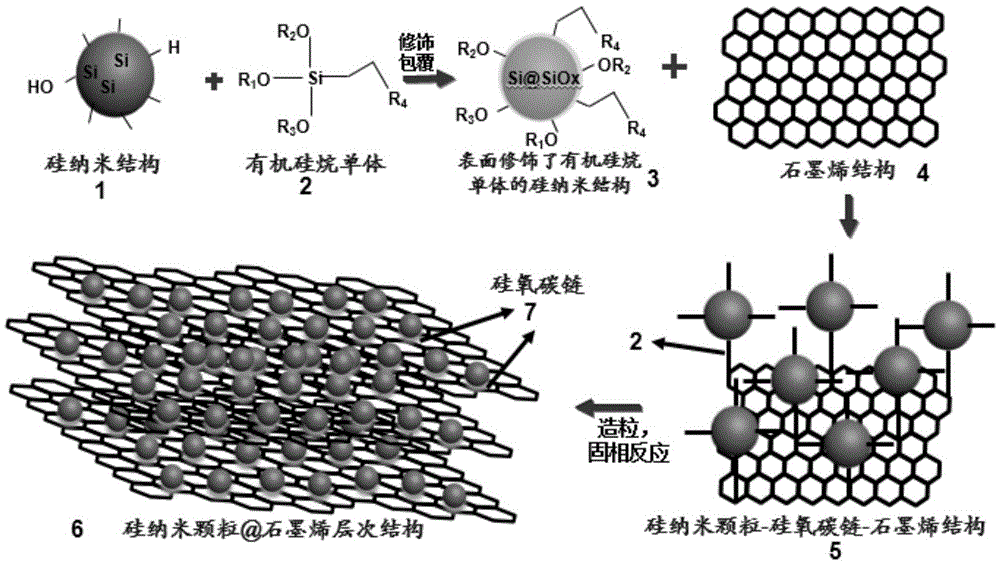

[0035] This embodiment provides a silicon-silicon-oxycarbon-graphene-based composite material, and the theoretical stoichiometric formula of the composite material is Si-0.1SiO3 C 2 -46G; Among them, Si is the particle size D 50 is 100nm silicon nanoparticle, G represents graphene oxide with 12 carbon atoms; the specific surface area of the graphene oxide is 300m 2 / g or so.

[0036] The present embodiment further provides a preparation method of silicon-silicon-oxycarbon-graphene-based composite material, specifically:

[0037] (1) Take the particle size D 50 5g of 100nm silicon nanoparticles, dispersed in a solution containing 5g of liquid vinyl tris (2-methoxyethoxy) silane monomer compound, after stirring for 6h, add 1mL of oxalic acid solution with a pH of 6 while stirring, And keep stirring for 24h to obtain a mixed solution;

[0038] (2) adding the mixed solution to a specific surface area of 300m containing 100g 2 In the graphene oxide dispersion of about / g, ...

Embodiment 2

[0042] This embodiment provides a silicon-silicon-oxycarbon-graphene-based composite material, and the theoretical stoichiometric formula of the composite material is Si-0.02SiO 3 C 2 -4.6G; where Si is the particle size D 50 is 500nm silicon nanoparticle, G represents 12 carbon atoms of carboxylic acid-terminated graphene; the specific surface of the carboxylic acid-terminated graphene is 429m 2 / g or so.

[0043] The present embodiment further provides a preparation method of silicon-silicon-oxycarbon-graphene-based composite material, specifically:

[0044] (1) Take the particle size D 50 50g of 500nm silicon nanoparticles, dispersed in a solution containing 10g of liquid vinyl tris (2-methoxyethoxy) silane monomer compound, after stirring for 2h, add 1mL of oxalic acid solution with a pH of 6 while stirring, And keep stirring for 8h to obtain a mixed solution;

[0045] (2) Add the mixed solution to a specific surface area of 429m containing 100g 2 In the dispersion...

Embodiment 3

[0048] This embodiment provides a silicon-silicon-oxycarbon-graphene-based composite material, and the theoretical stoichiometric formula of the composite material is Si-0.2SiO 3 C 2 -93G; wherein, Si is a silicon nanowire with a diameter of 30 nm, and G represents graphene oxide with 12 carbon atoms; the specific surface of the graphene oxide is 300 m 2 / g or so.

[0049] The present embodiment further provides a preparation method of silicon-silicon-oxycarbon-graphene-based composite material, specifically:

[0050] (1) Take 5 g of silicon nanowires with a diameter of 30 nm, disperse it in a solution containing 10 g of liquid vinyl tris(2-methoxyethoxy) silane monomer compound, stir for 6 h, add 1 mL of pH while stirring 6 of the oxalic acid solution, and kept stirring for 48h to obtain a mixed solution;

[0051] (2) Add the mixed solution to a specific surface area of 300m containing 200g 2 In the graphene oxide dispersion of about / g, continue to stir for 24 hours, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com