Patents

Literature

36results about How to "Good lithium ion transport performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion solid electrolyte and preparation method and application thereof

ActiveCN107425218AExcellent lithium ion conductivityHigh thermodynamic stabilityCell electrodesSecondary cellsHalogenPhysical chemistry

The invention relates to a lithium ion solid electrolyte and a preparation method application thereof, and belongs to the technical field of a lithium ion battery. The lithium ion solid electrolyte has the chemical formula shown as follows: Li<3+a>MA<m>B<n>Y<1-b>, wherein a is more than or equal to -0.25 but less than or equal to 0.25, b is more than or equal to 0 but less than or equal to 0.5, m is more than or equal to 0 but less than or equal to 1.25, n is more than or equal to 0 but less than or equal to 1.25, M is one of Ca, Ba, Mg, Al and Ti, A and B are separately selected from one of O, S, Se, Te, N, P, Si, C, Sb, Bi, F, Cl, Br and I, and Y is one of halogen, minus monovalent ionic group or vacancy. The lithium ion solid electrolyte has a stable structure and favorable lithium ion transmission performance and has favorable electrochemical performance and safety performance when used as a solid electrolyte of the lithium ion battery.

Owner:ZHENGZHOU NEW CENTURY MATERIALS GENOME INST CO LTD

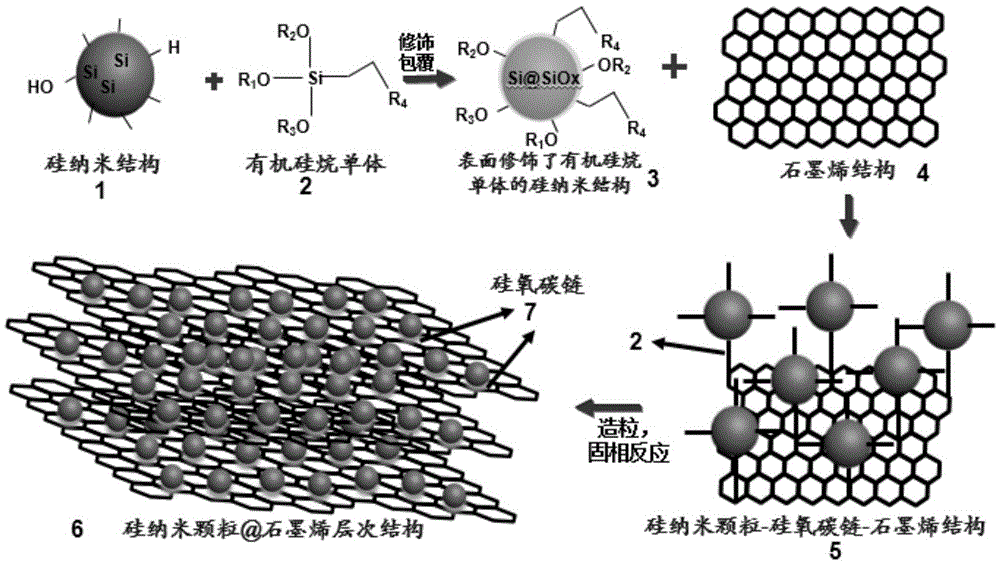

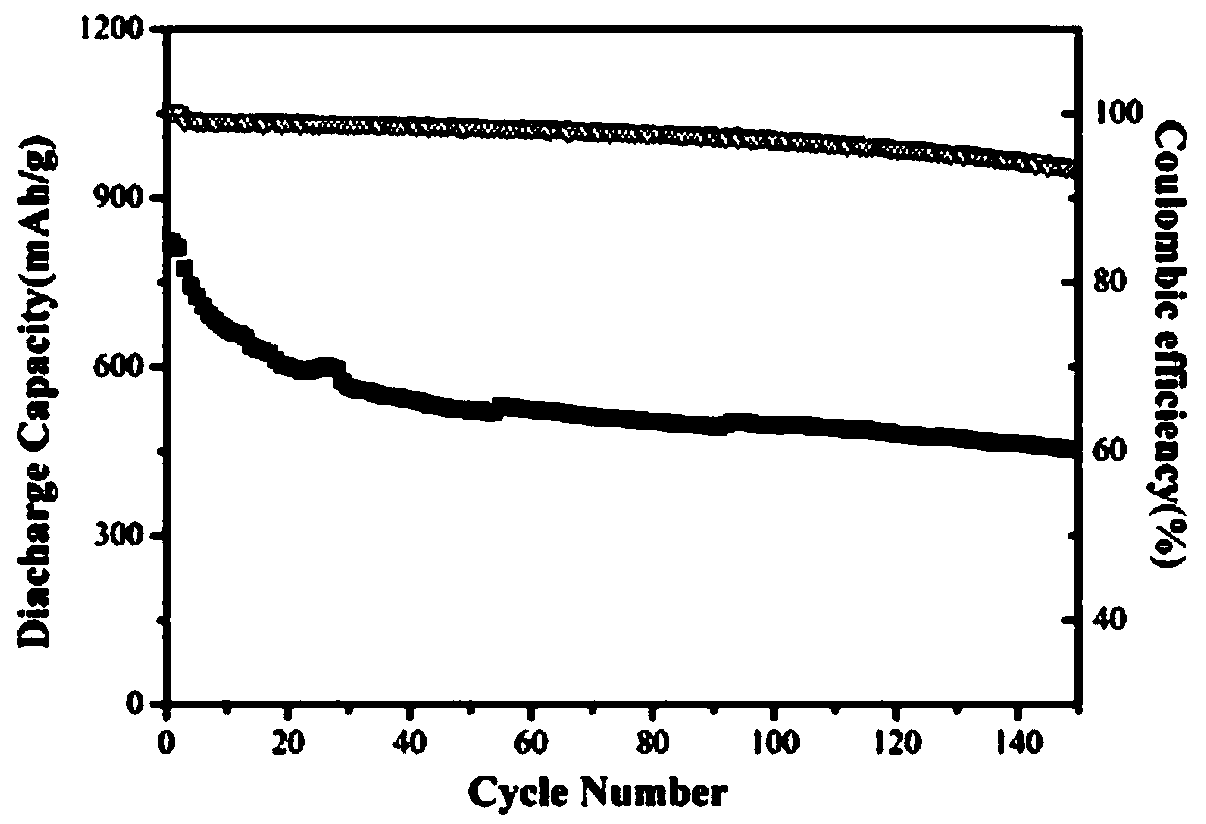

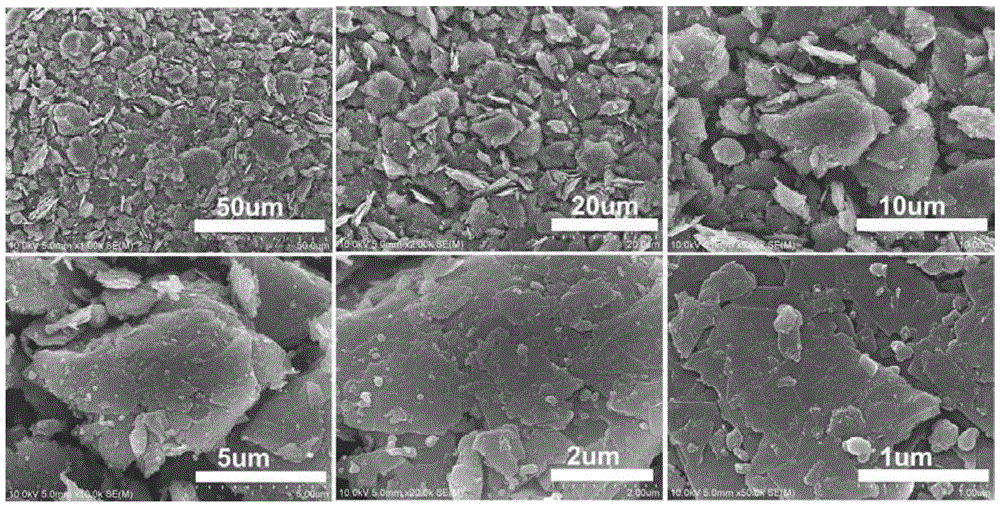

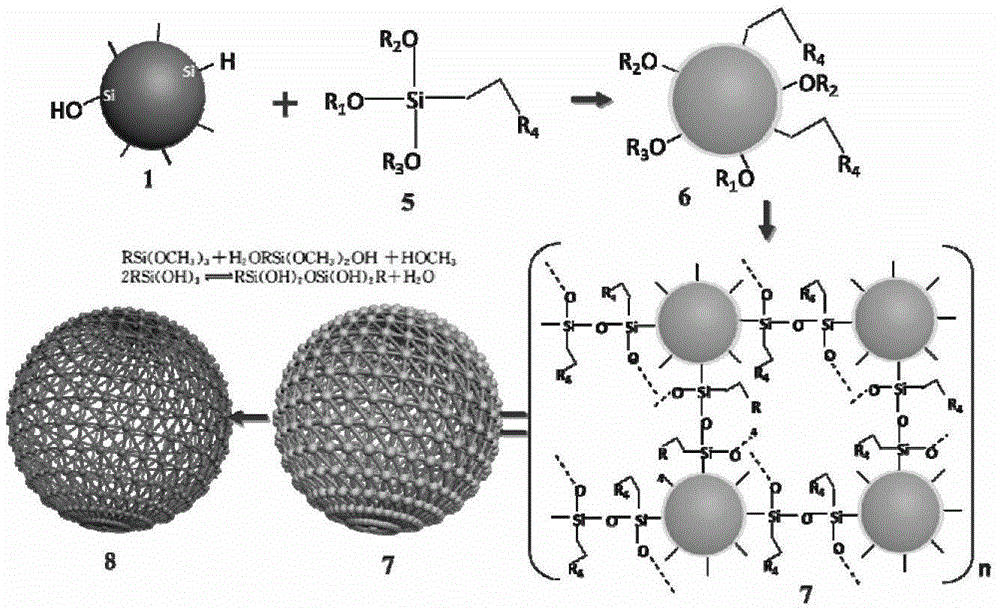

Silicon/silicon oxycarbide/graphite composite negative electrode material

ActiveCN104466142AAdjustable capacityStable structureElectrode carriers/collectorsSecondary cellsSilicon oxygenLithium-ion battery

The invention relates to a silicon / silicon oxycarbide / graphite composite negative electrode material which is a silicon-containing material which has the size being lower than 3 microns uniformly and is firmly distributed on the surface of a negative electrode of graphite. The invention further provides a preparation method of the composite negative electrode material. The preparation method comprises the steps of dispersing a silicon-containing material in a liquid organo-siloxane monomer, sequentially adding an acid liquid of alcohol and water, a curing agent and a graphite negative electrode material, then carrying out ball milling or mechanical stirring, pinching and mixing to obtain a paste-type mixture; calcining the paste-type mixture at high temperature under a protective atmosphere, crushing and sieving to obtain different-particle-size silicon / silicon oxycarbide / graphite lithium-ion battery negative electrode material. The silicon-containing materials of the silicon / silicon-oxygen carbon / graphite composite negative electrode material are firmly and uniformly distributed on the surface of a graphite material; due to the structure, the silicon-containing materials can be effectively adsorbed on the surface of the graphite, the self agglomeration of the silicon-containing material can be avoided and the silicon-containing material is prevented from peeling off from the graphite; the silicon / silicon oxycarbide / graphite composite negative electrode material has the characteristics that the charge and discharge specific capacities are adjustable, and the electrochemical cycle stability is high.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

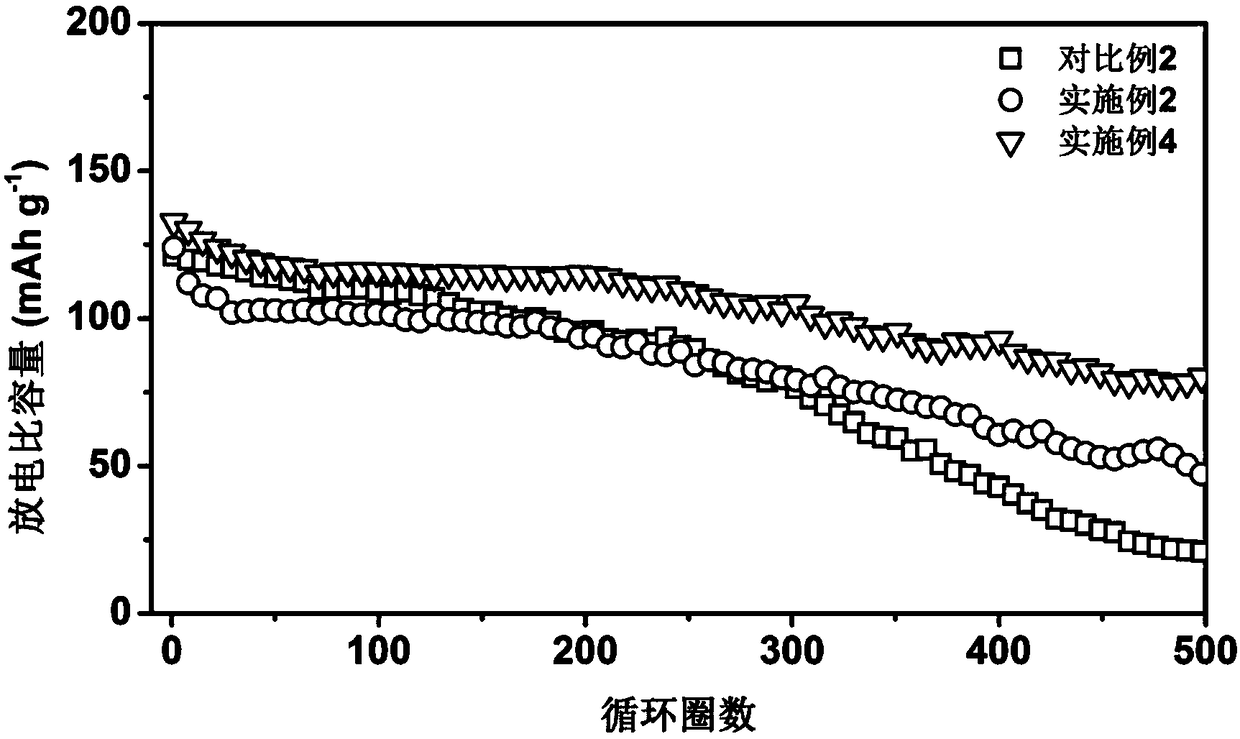

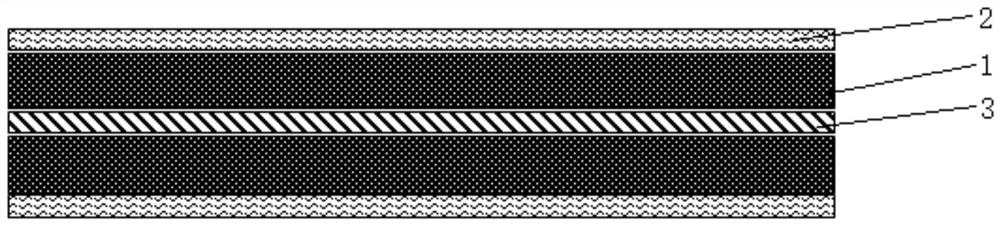

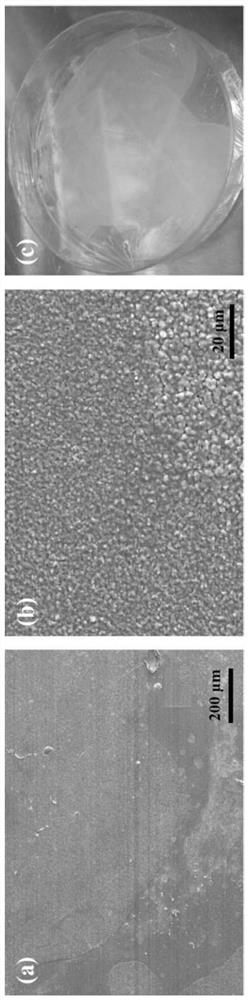

Diaphragm and preparation method thereof, and lithium ion battery

ActiveCN102623658AThe absolute value of the surface potential is largeEvenly distributedSecondary cellsCell component detailsHexafluoropropyleneLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to an inorganic and organic composite multihole diaphragm. The diaphragm comprises a multihole diaphragm base material and an active coating layer attached to at least one surface of the multihole diaphragm base material, wherein the active coating layer comprises inorganic particles, vinylidene fluoride and hexafluoropropylene copolymer, cellulose based polymer with the molecular weight of 100,000 to 1,000,000 and at least one of polyacrylic acid and polyacrylate. Compared with the prior art, the diaphragm keeps relatively high air permeability and lithium ion transmission capacity; the active coating layer and the multihole diaphragm base material are well bonded; and the overheating contraction performance and the puncture strength of a diaphragm base can be improved remarkably. Furthermore, the invention also discloses a preparation method for the diaphragm and a lithium ion battery with the diaphragm.

Owner:NINGDE AMPEREX TECH +1

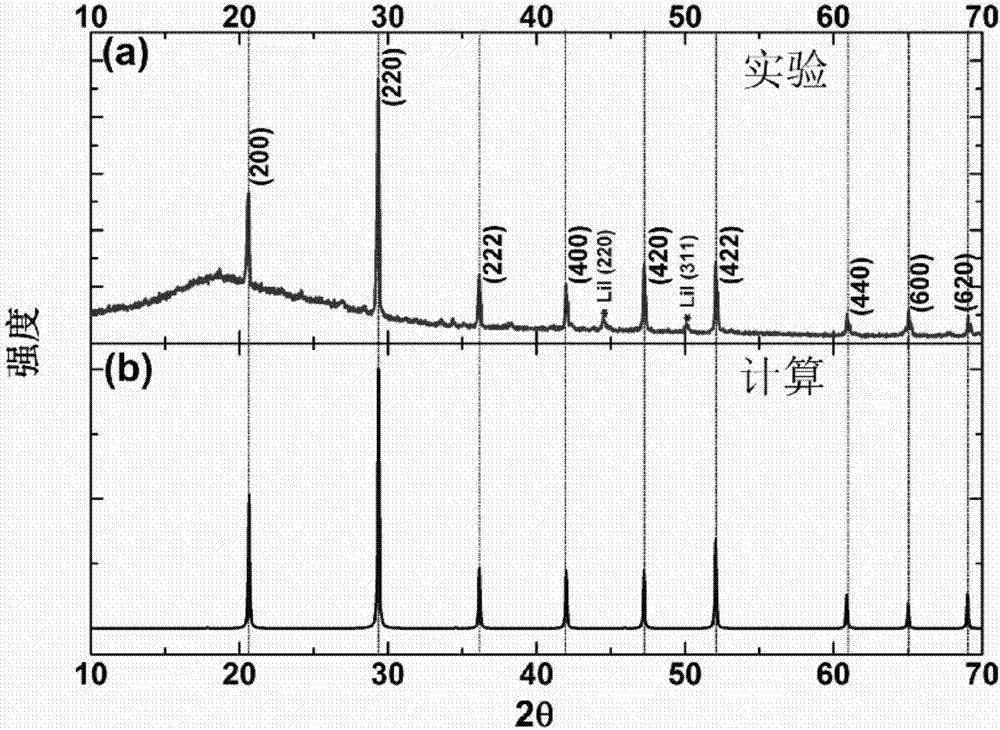

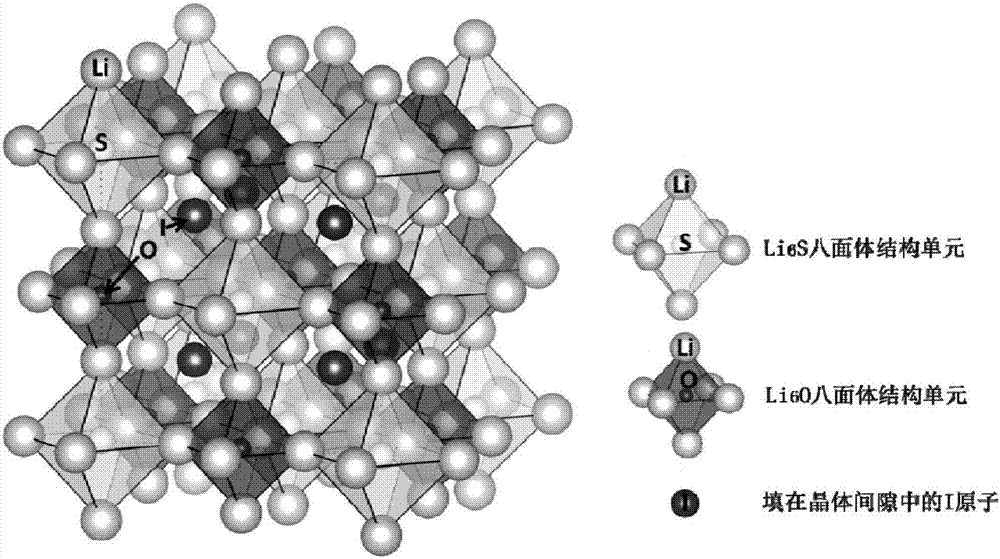

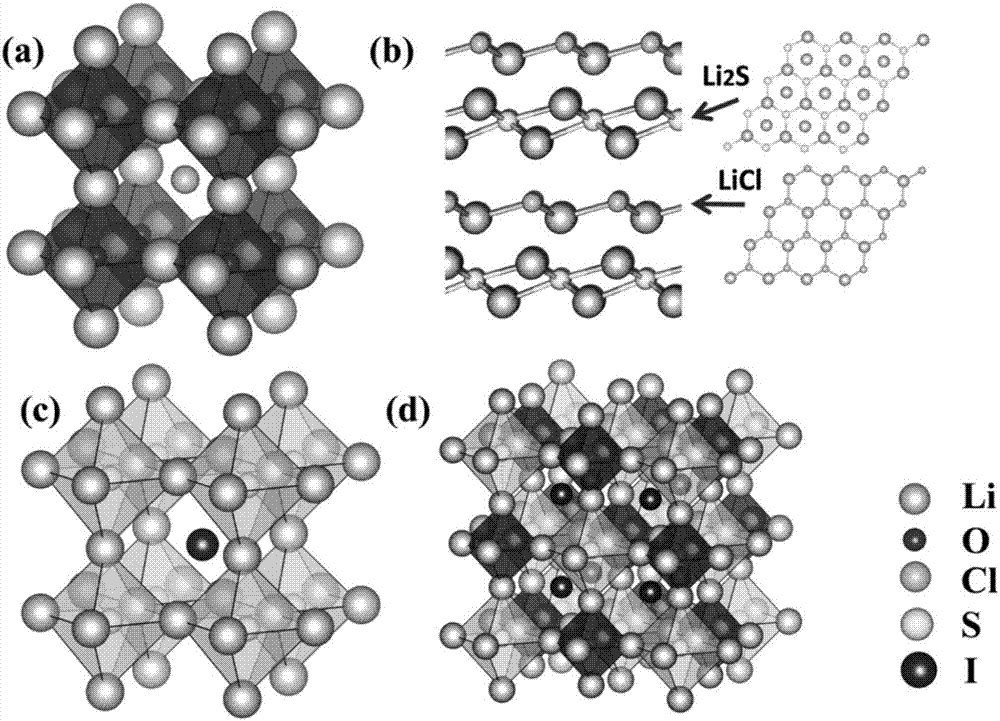

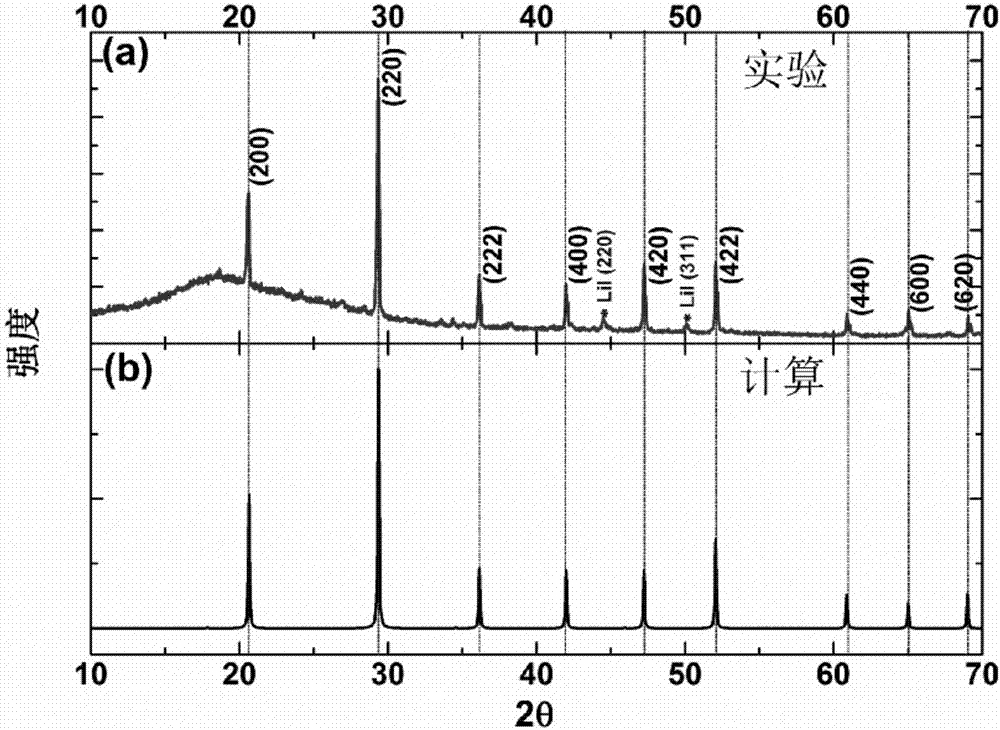

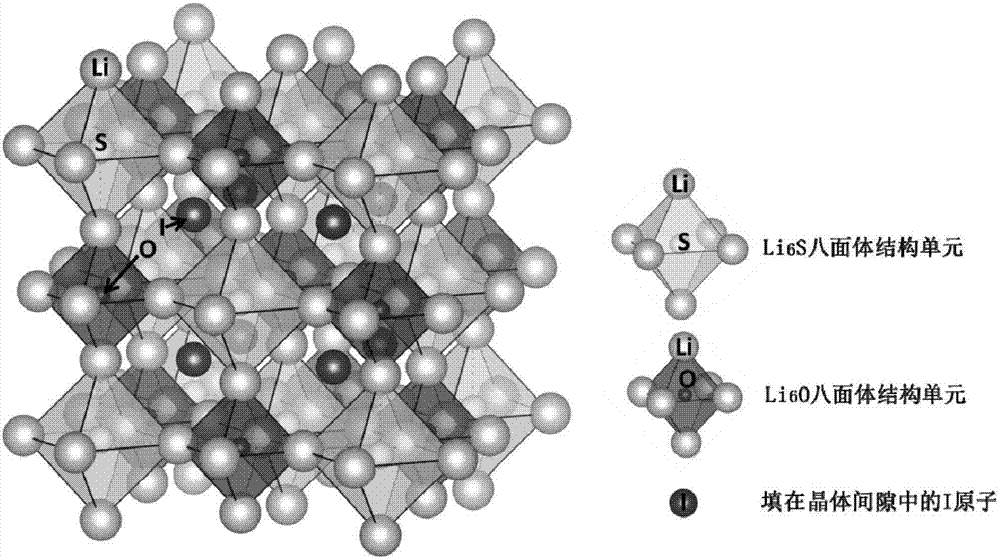

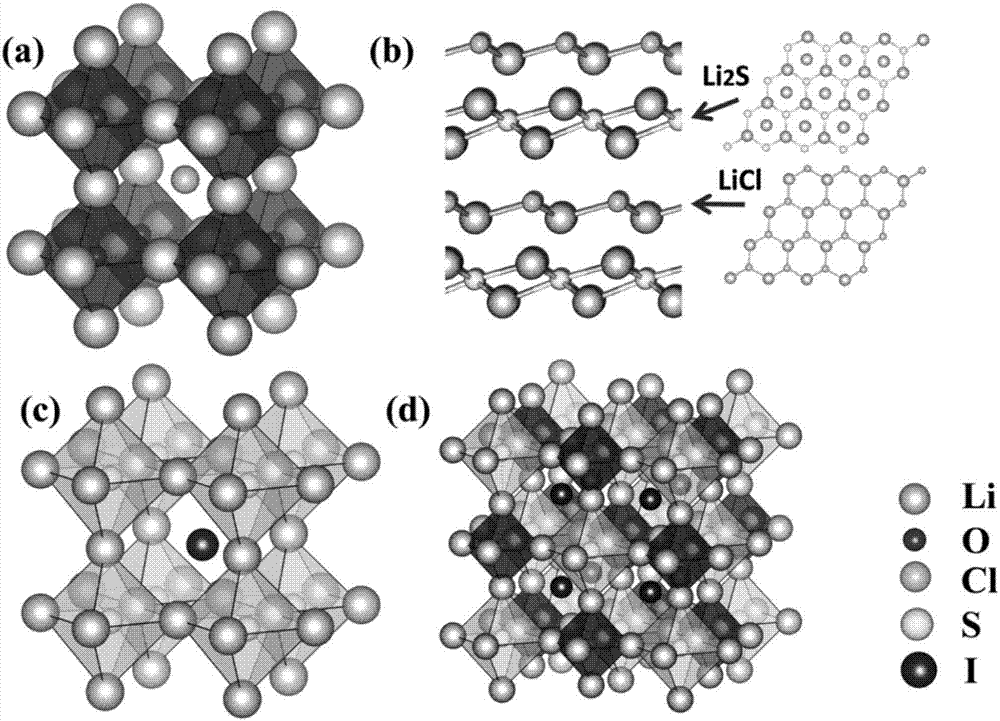

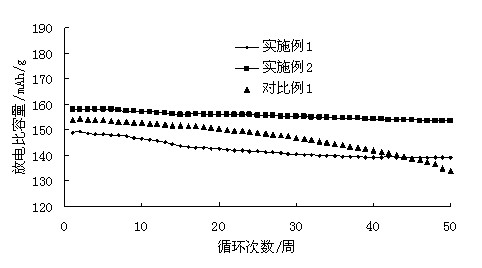

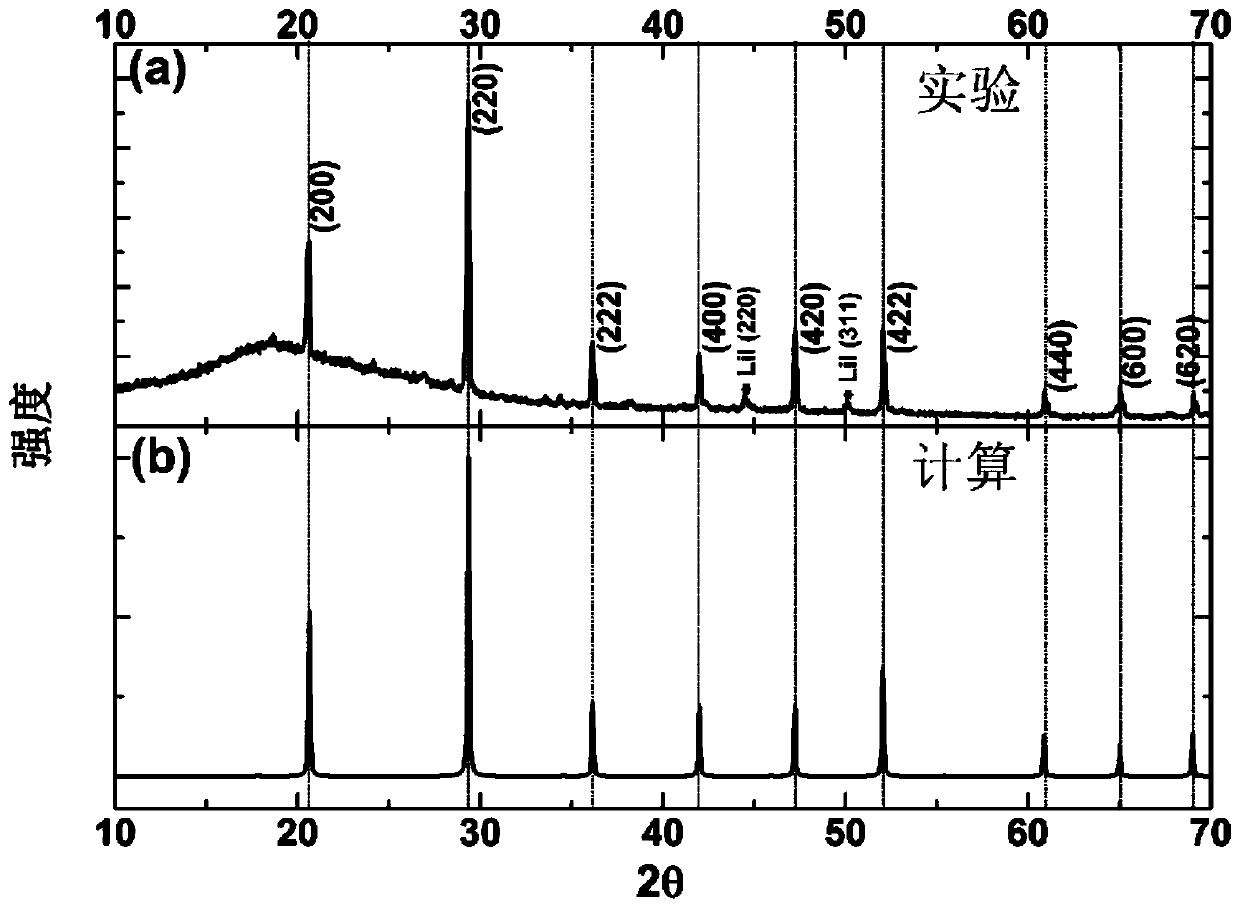

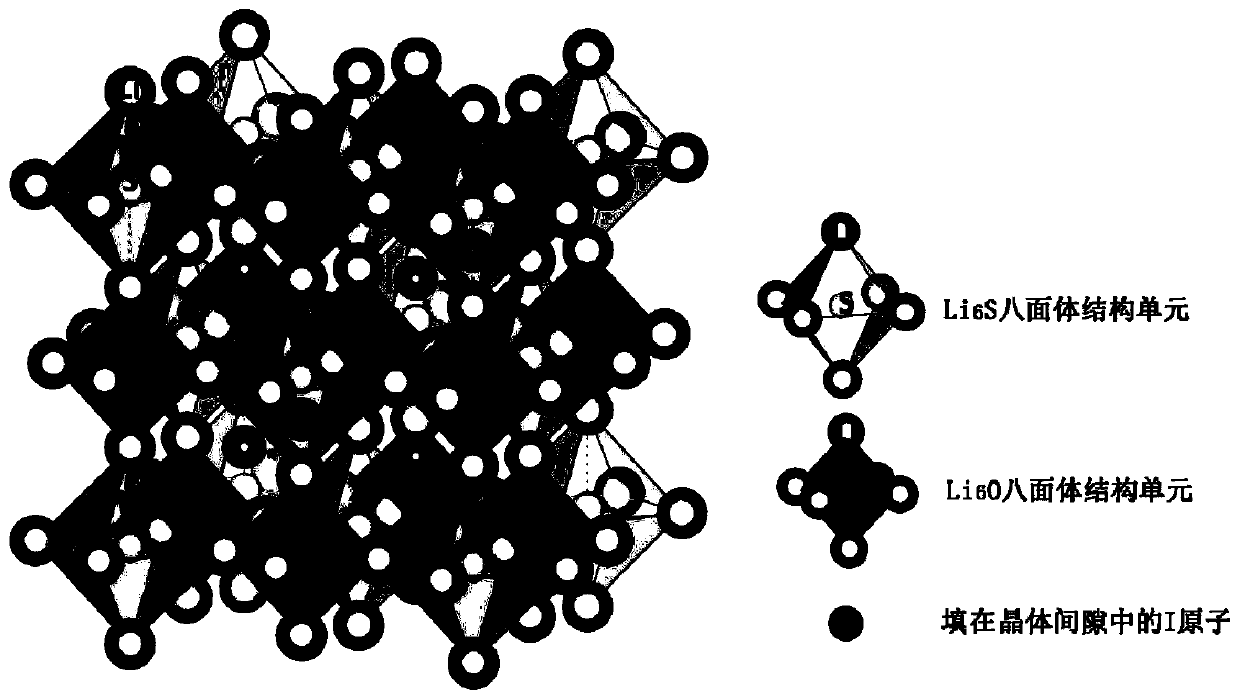

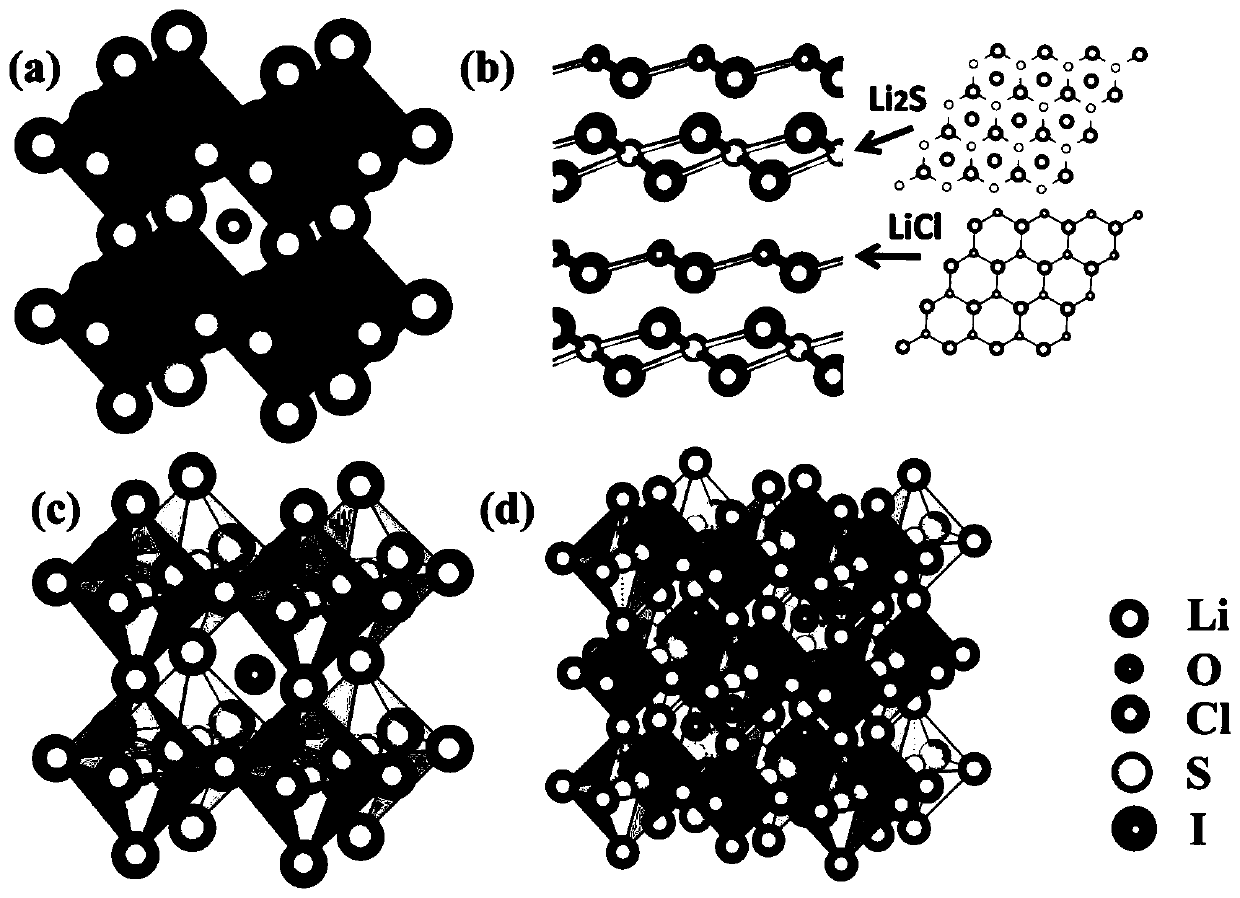

Double-type antiperovskite lithium-ion solid electrolyte as well as preparation method and application thereof

ActiveCN107403955AImprove ionic conductivityStable structureSolid electrolytesSecondary cellsHalogenElectrical battery

The invention relates to double-type antiperovskite lithium-ion solid electrolyte as well as a preparation method and application thereof, and belongs to the technical field of lithium ion batteries. The lithium-ion solid electrolyte disclosed by the invention has the chemical formula shown as follows: Li[3+a]MpAmBn(XxYy)[1-b], wherein a is greater than or equal to -0.25 and less than or equal to 0.25; b is greater than or equal to 0 and less than or equal to 0.5; p is greater than or equal to 0 and less than or equal to 0.5; m is greater than 0 and less than or equal to 1.25; n is greater than 0 and less than or equal to 1.25; x is greater than or equal to 0 and less than or equal to 1; y is greater than or equal to 0 and less than or equal to 1; M is any one of Ca, Ba, Mg, Al and Ti; A and B is any two of O, S, Se, Te, N, P, Si, C, Sb, Bi, F, Cl, Br and I; X and Y are separately selected from one of halogen or a negative univalent ionic group or vacancy. The structure of the lithium-ion solid electrolyte disclosed by the invention is a double-type antiperovskite structure, is stable in structure and has a good lithium-ion transmission property.

Owner:ZHENGZHOU NEW CENTURY MATERIALS GENOME INST CO LTD

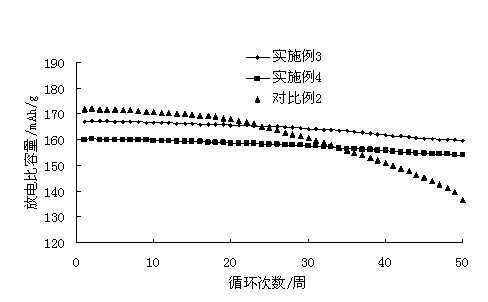

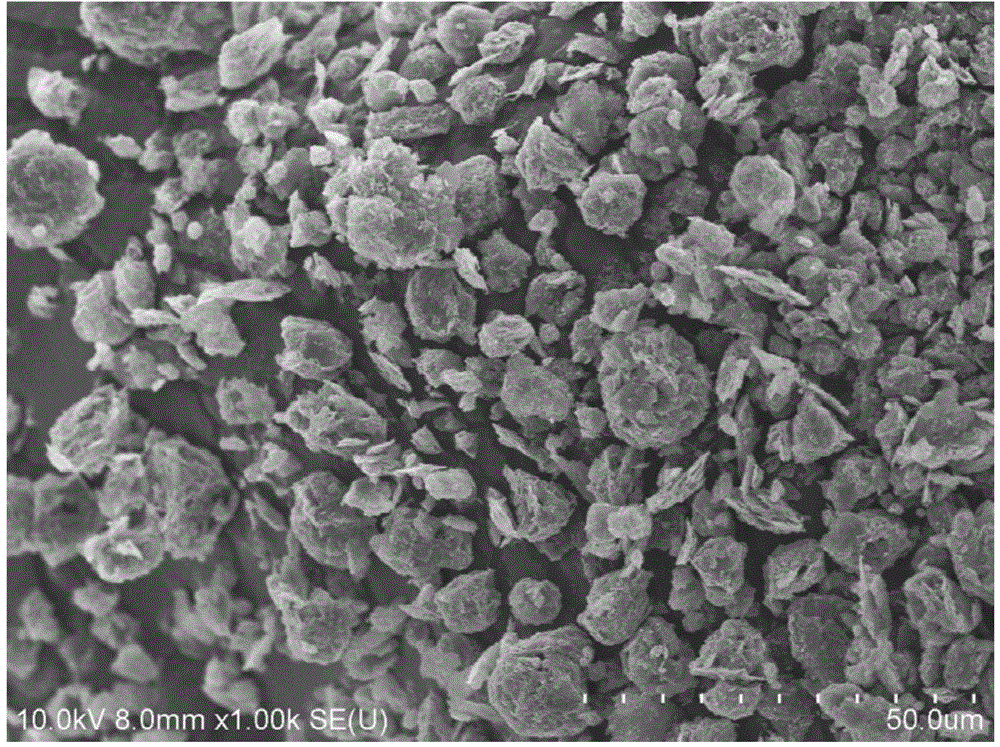

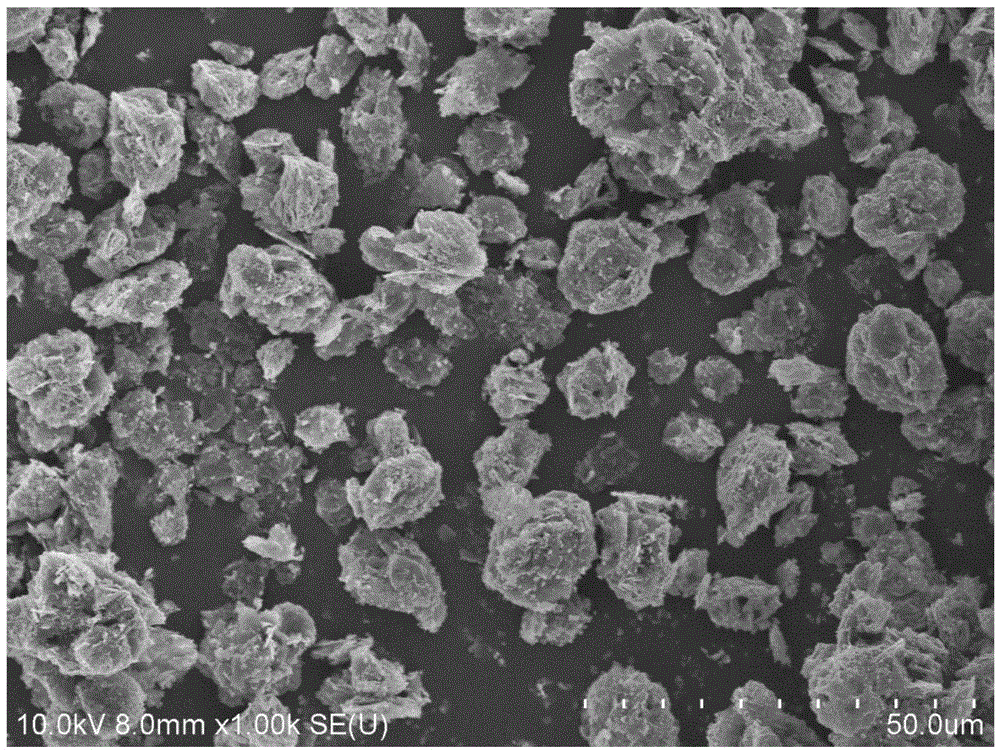

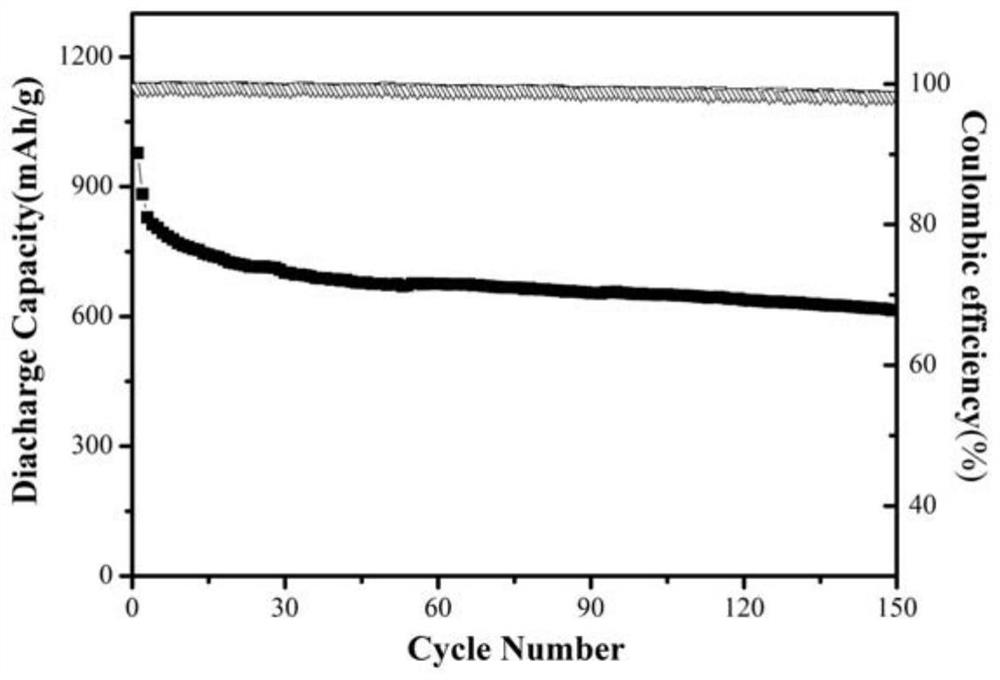

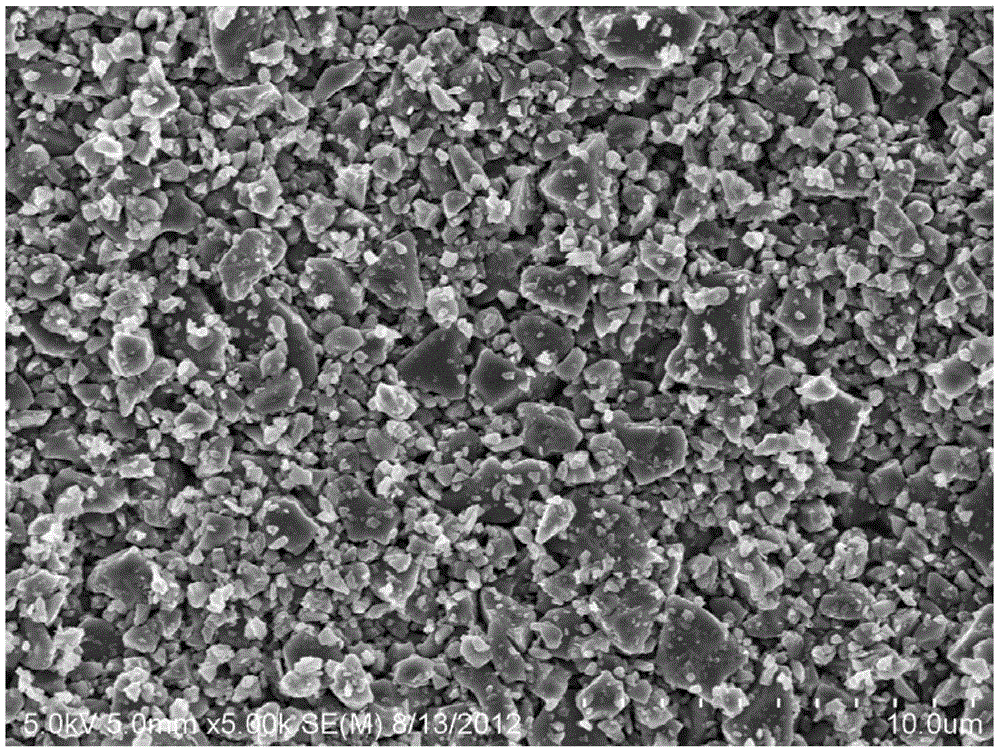

Lithium ion battery anode material and manufacturing method thereof

InactiveCN102637877AUniform particle sizeHas a layered crystal structureCell electrodesPhosphateManganese

The invention discloses a lithium ion battery anode material and a manufacturing method of the lithium ion battery anode material. The anode material is cobalt nickel oxide manganese with a layer structure and has the chemical composition of LiNil-x-yCoxMnyO2, wherein x is equal to and larger than 0.15 and is equal to and less than 0.3, and y is equal to and larger than 0.2 and is equal to and less than 0.4. The manufacturing method provided by the invention has the following steps: the cobalt nickel oxide manganese powder is manufactured through a coprecipitation method, metal phosphate is adopted as a cladding material with the cladding quantity as 0.5-1.5% of the anode material; and the cobalt nickel oxide manganese is externally cladded by zinc phosphate through fluidization. The cladded battery material after modification with the manufacturing method has high special capacity and has good cycling stability at high temperature.

Owner:KUNMING UNIV OF SCI & TECH

Silicon-based composite anode material for lithium ion battery and preparation method thereof

ActiveCN105762329AAdjustable capacityStable structureElectrode manufacturing processesInsulation ProblemSodium-ion battery

The invention discloses a silicon-based composite anode material for a lithium ion battery and a preparation method thereof. The anode material comprises a graphite skeleton and an amorphous carbon layer which coats the graphite skeleton. The graphite skeleton is filled with a silicon material coated with a carbon-containing structure. The silicon material and the graphite skeleton are combined through a loose carbon material. The preparation method at least comprises the following steps: (1) preparing the silicon material coated with the carbon-containing structure; (2) preparing spherical particles with graphite as the main body; (3) coating the spherical particles with the amorphous carbon layer; and (4) granulating. According to the invention, the electric insulation problem of silicon anode due to its volume change can be solved, and it can be guaranteed that silicon active component can always be electrically contacted with a current collector during the charge-discharge cycle process. Meanwhile, huge stress effect caused by volume expansion / shrinkage of the active material silicon is further buffered. Then, the composite material has characteristics of high electrochemical cycle stability and regulable specific capacity.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

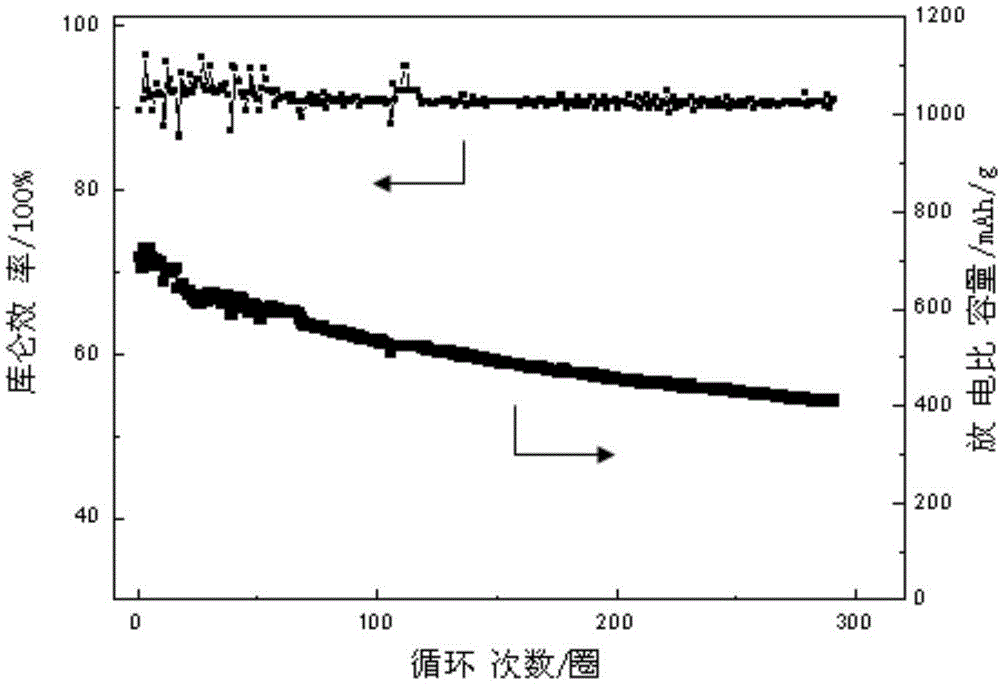

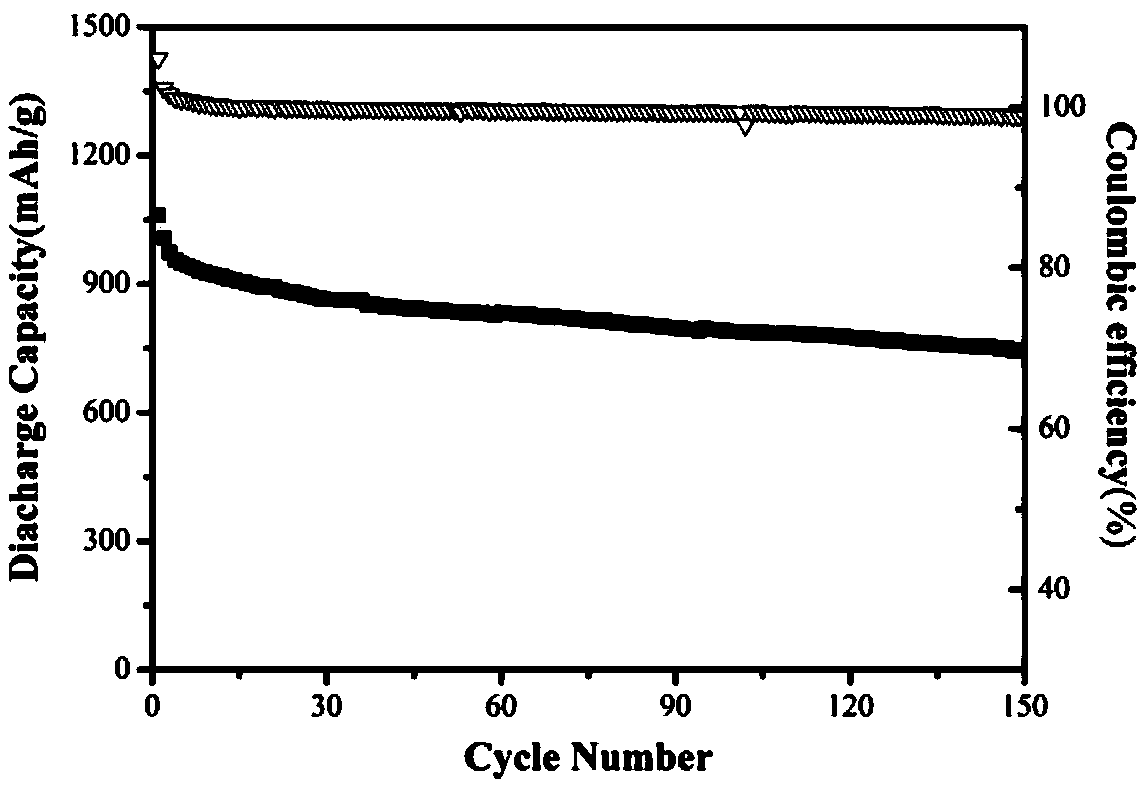

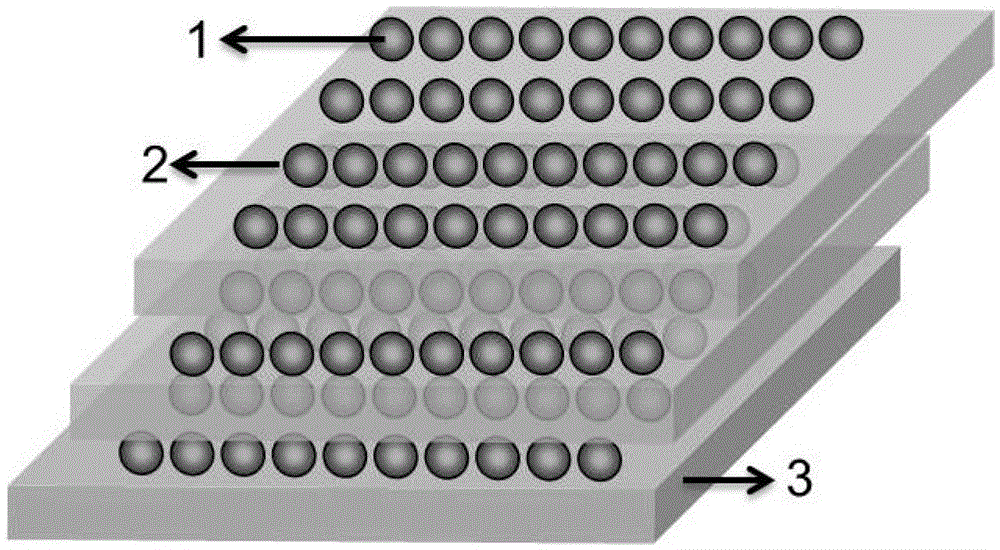

Silicon/carbon composite anode material for lithium ion batteries and preparation method thereof

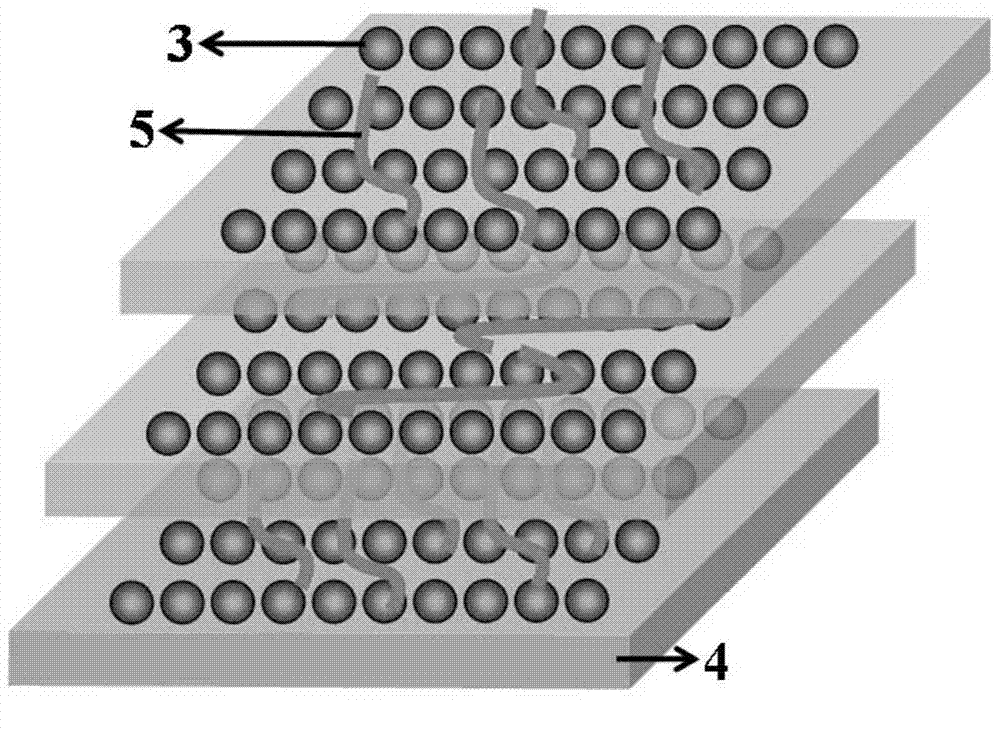

ActiveCN104752691AAdjustable capacityStable structureSecondary cellsNegative electrodesCarbon compositesFiber

The invention relates to a silicon / carbon composite anode material for lithium ion batteries and a preparation method thereof. The material is composed of a graphite framework material, a middle buffer layer SiOC material, carbon fiber and a silicon-containing material with the carbon-coated surface, wherein the silicon-containing material with the carbon-coated surface is combined with the graphite framework material through the buffer layer SiOC and carbon fiber. Stoichiometric equation of the composite anode material is aSiOz@dAC-bSiOxCy&cCF-C, wherein a is less than or equal to 0.2 and greater than 0; b is less than or equal to 0.4 and greater than 0; c is less than or equal to 0.1 and greater than 0; d is less than or equal to 0.1 and greater than 0; z is less than or equal to 2 and greater than or equal to 0; x is less than 4 and greater than 0; and y is less than or equal to 20 and greater than 0. In the composite material, the amorphous carbon-coated silicon material is effectively contacted with graphite under the action of SiOC and carbon fiber so as to avoid agglomeration of the silicon material itself and peeling of graphite. According to the invention, charge-discharge specific capacity is adjustable, and electrochemical cyclic stability is high.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

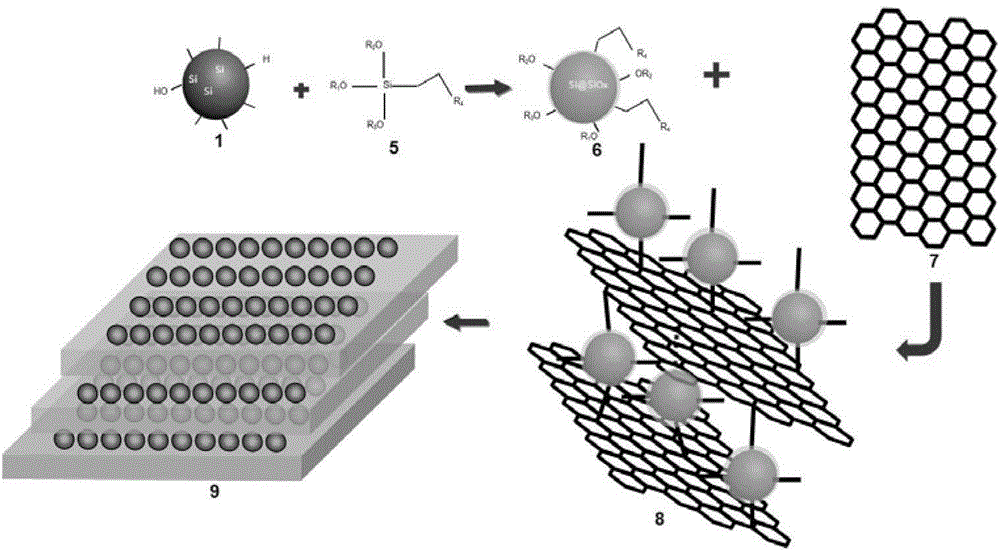

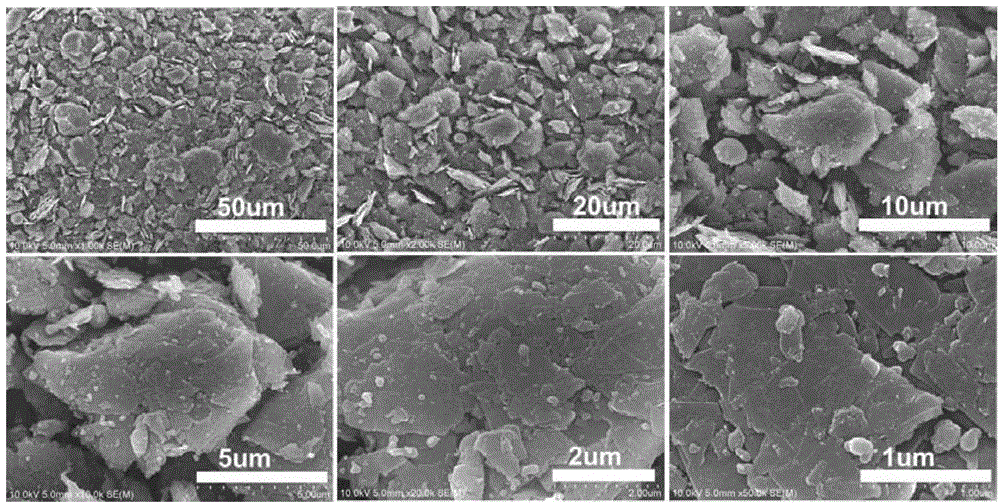

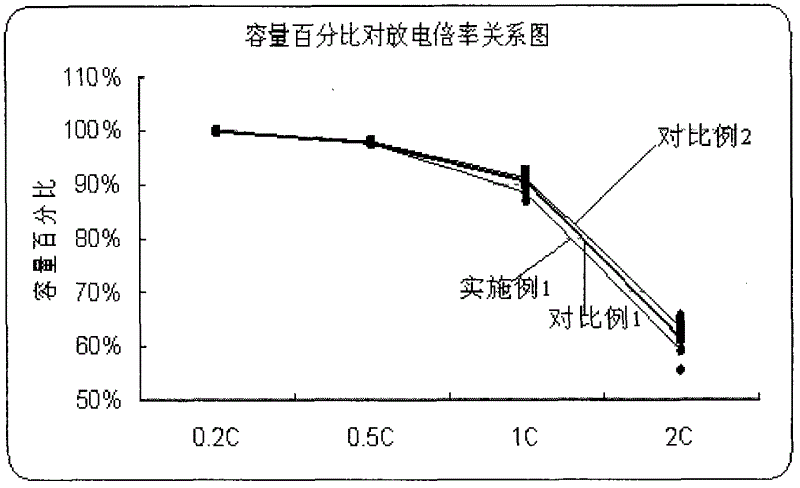

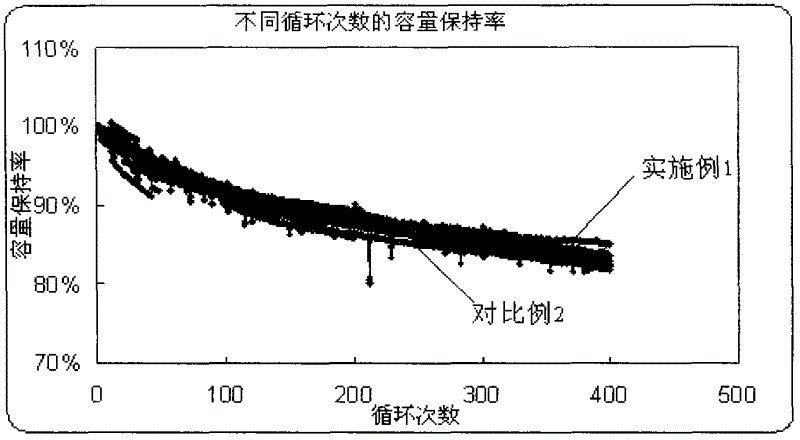

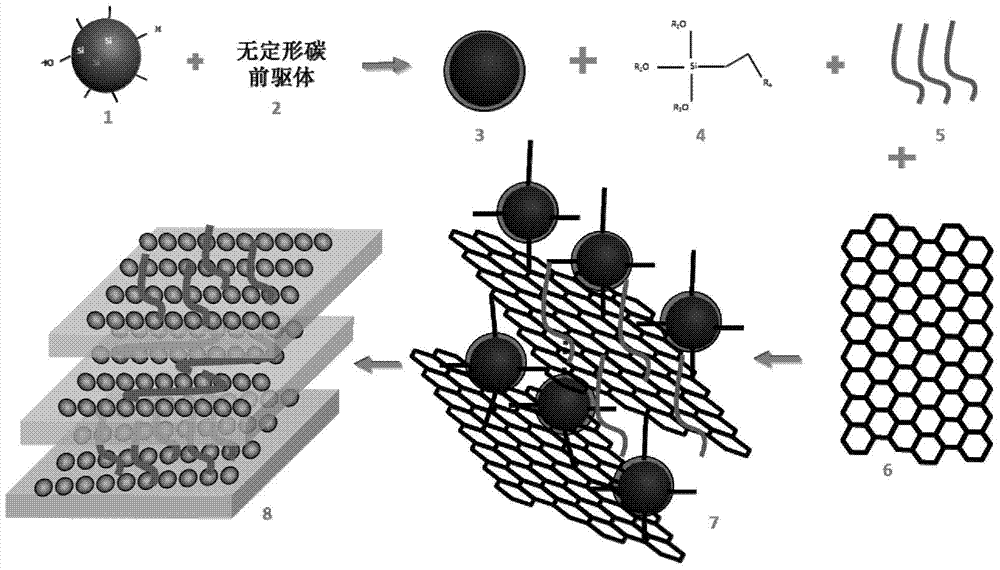

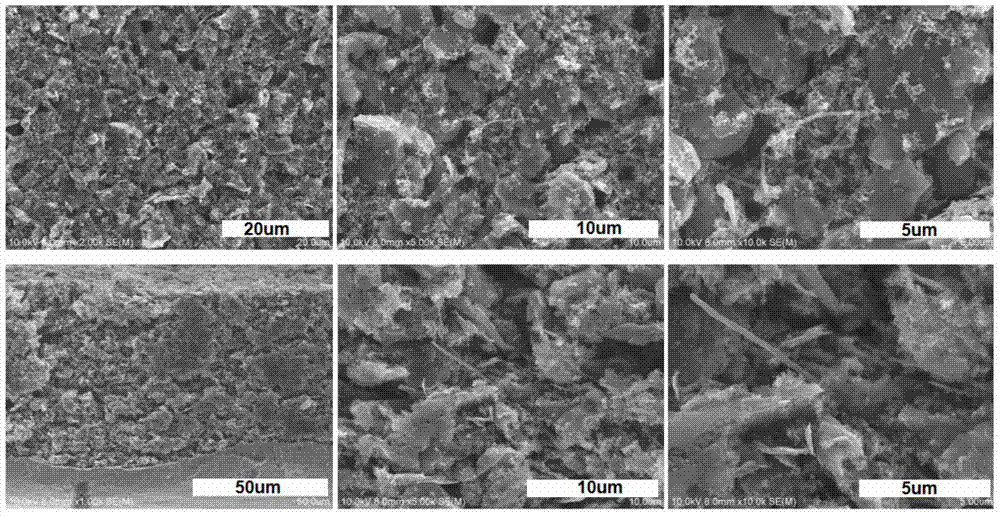

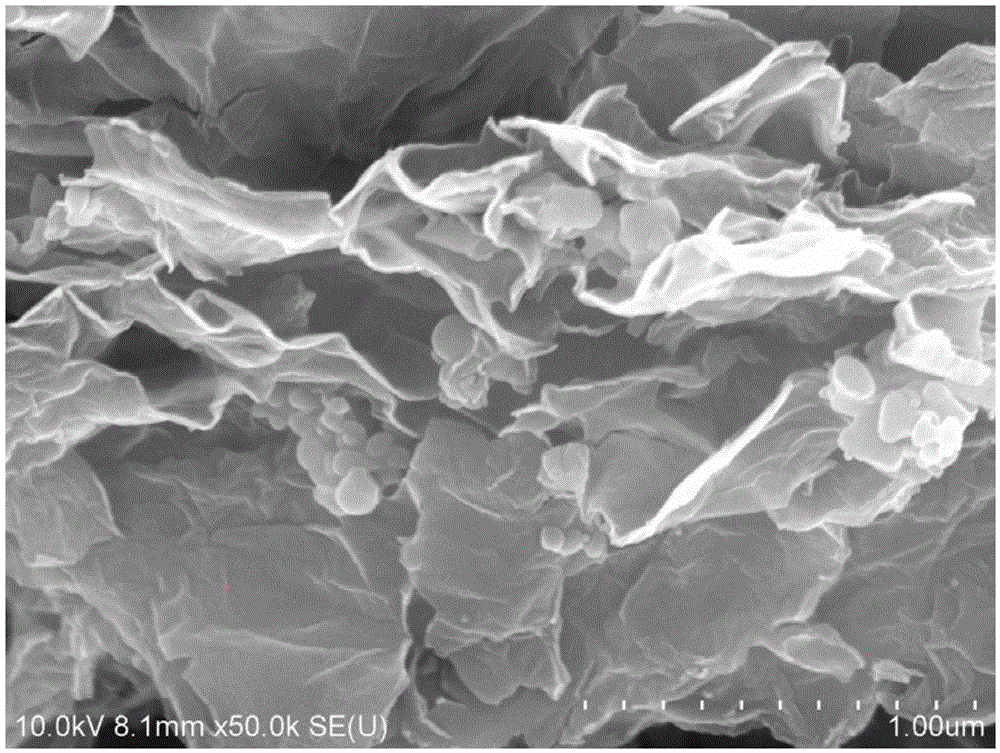

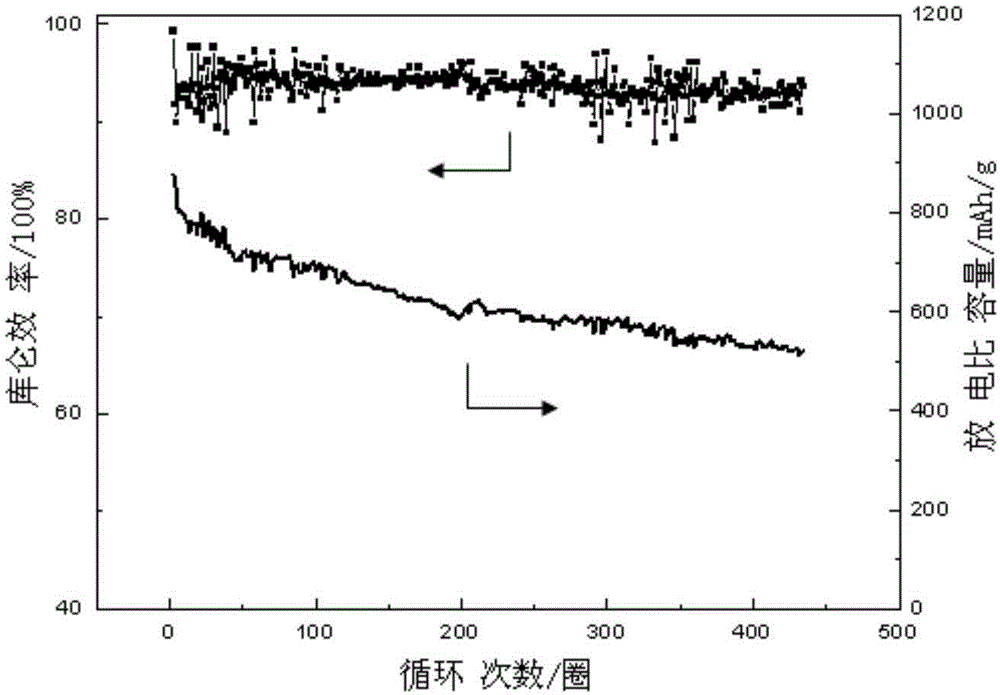

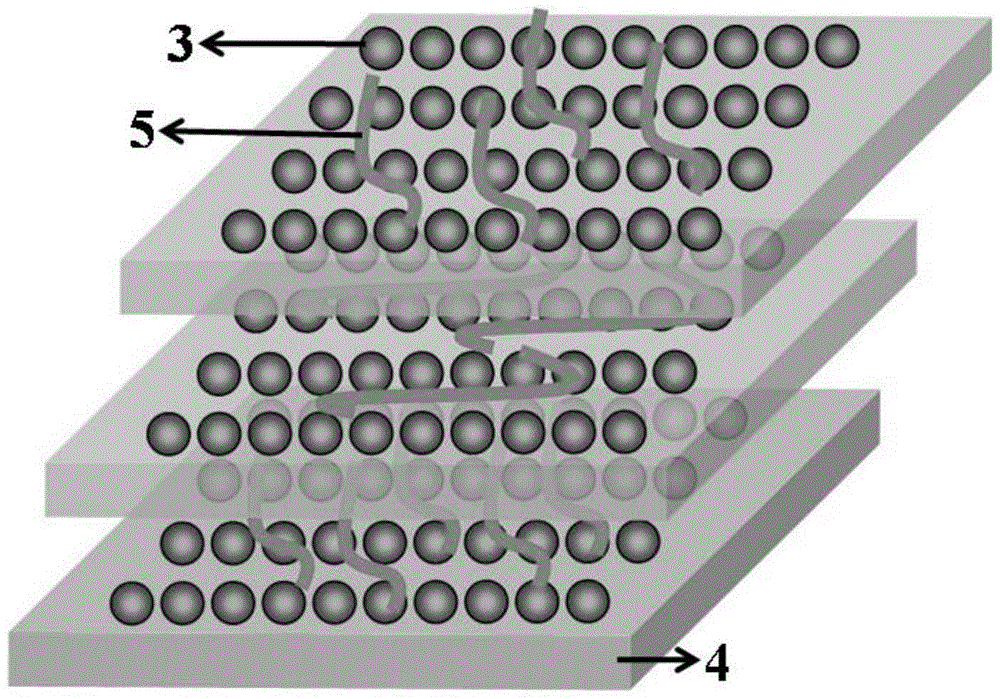

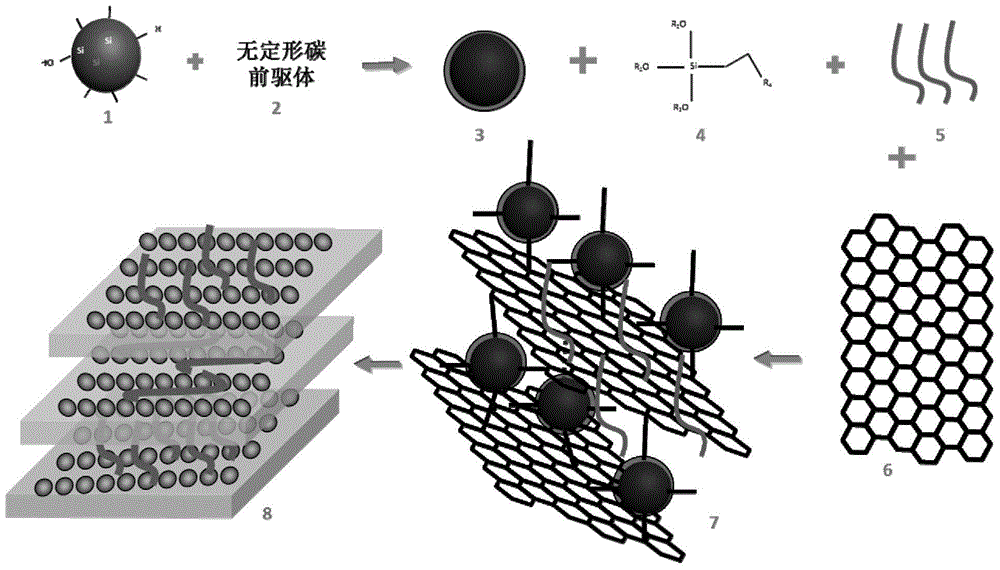

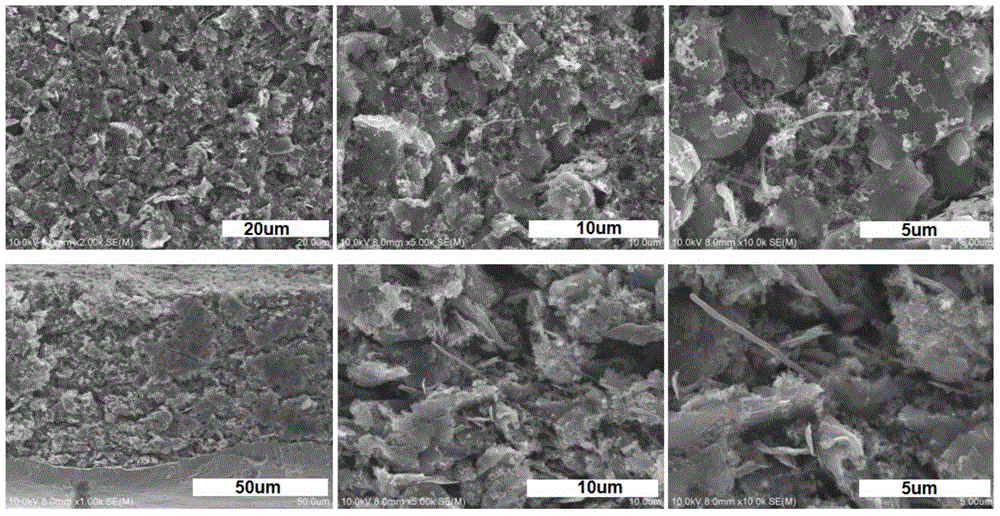

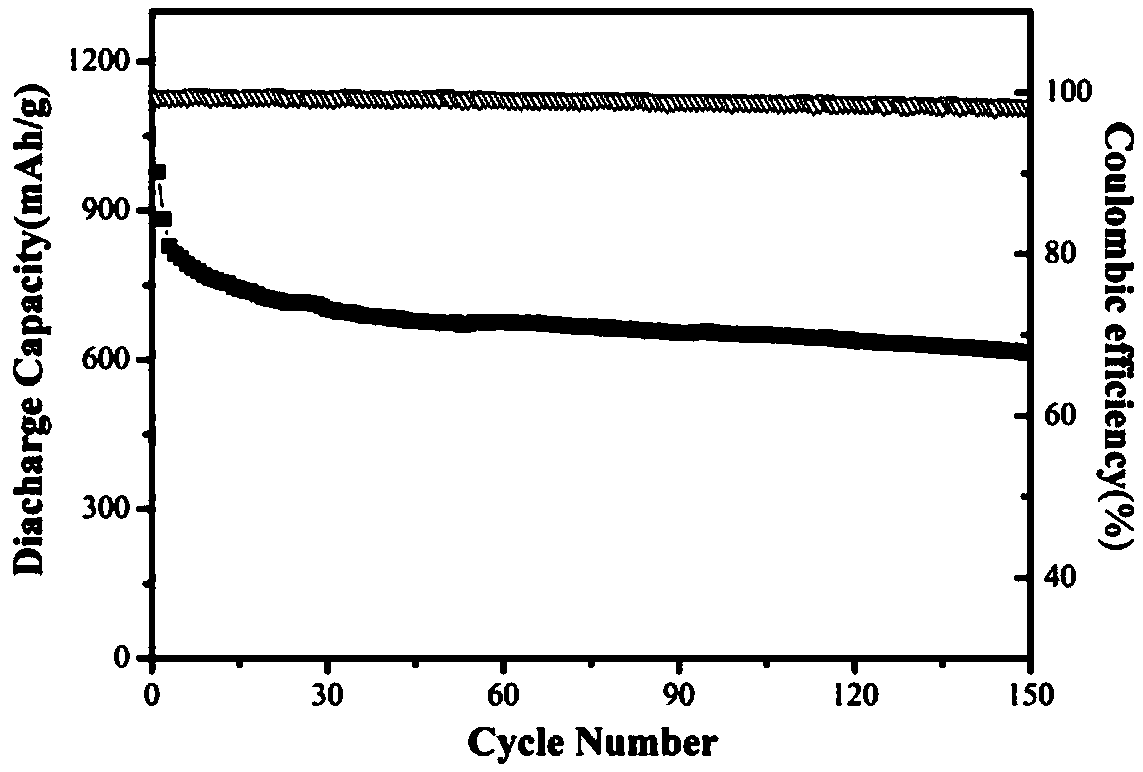

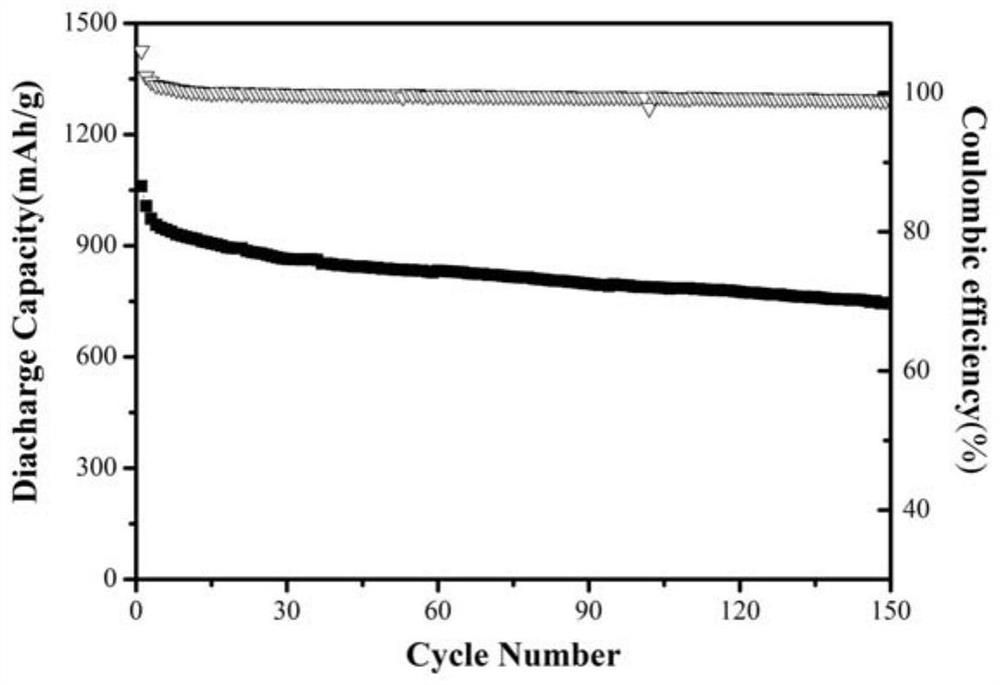

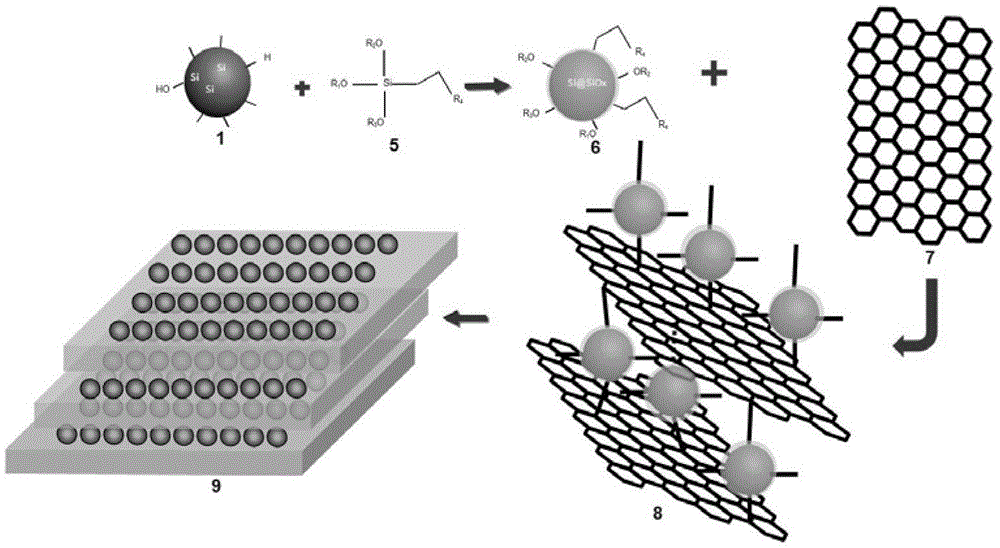

Silicon, silicon-oxygen-carbon and graphene-based composite material, and preparation method and application thereof

InactiveCN105489871AStable structureGood lithium ion transport performanceCell electrodesSecondary cellsGraphiteCarbon chain

The invention relates to a silicon, silicon-oxygen-carbon and graphene-based composite material, which comprises a graphene-based material and a silicon nano-material, wherein the silicon nano-material is attached to the surface of the graphene-based material; and the silicon nano-material is connected with the graphene-based material through a silicon-oxygen-carbon chain structure. The invention further provides a preparation method of the composite material. The silicon-oxygen-carbon structure contained in the composite material provided by the invention can ensure that the silicon material is relatively uniformly and firmly distributed on the surface of a graphene-based material, and can still electrically contact the conductive graphene-based material in the charge-discharge process after a relatively large volume change; and the graphene-based material not only can ensure the overall conductivity of the material, but also can relieve stress of the silicon material caused by the volume change in the charge-discharge process through folds. The composite material provided by the invention is excellent in overall performance, and has the characteristics of high electrochemical cycle stability and adjustable specific capacity.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD +1

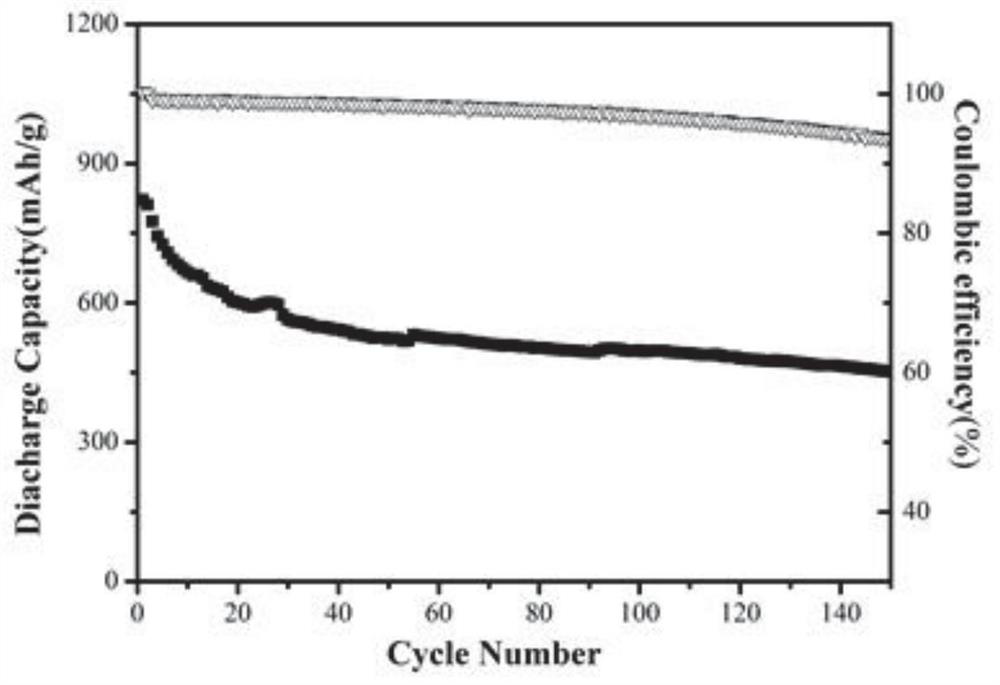

Cathode material for lithium-sulfur battery and preparation and application

ActiveCN105226259AGuaranteed normal transmissionGood lithium ion transport performanceCell electrodesSemiconductor propertiesLithium–sulfur battery

The invention relates to a cathode material for a lithium-sulfur battery and preparation and an application of the cathode material. The cathode material comprises elemental sulfur particles and metal sulfides, wherein one or more than two metal sulfides coat the surfaces of the elemental sulfur particles; and the metal of the metal sulfides is one or more than two of Zn, Fe, Cd, Pb, Cu or Ag. The metal sulfides have semiconductor properties, so that certain electron conductivity can be provided; the metal sulfides have good lithium ion transmission capabilities; lithium ion transmission in a tight coating condition is ensured; coating of the metal sulfides on the elemental sulfur surface can be achieved in a mild chemical environment; and the method is simple and feasible.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

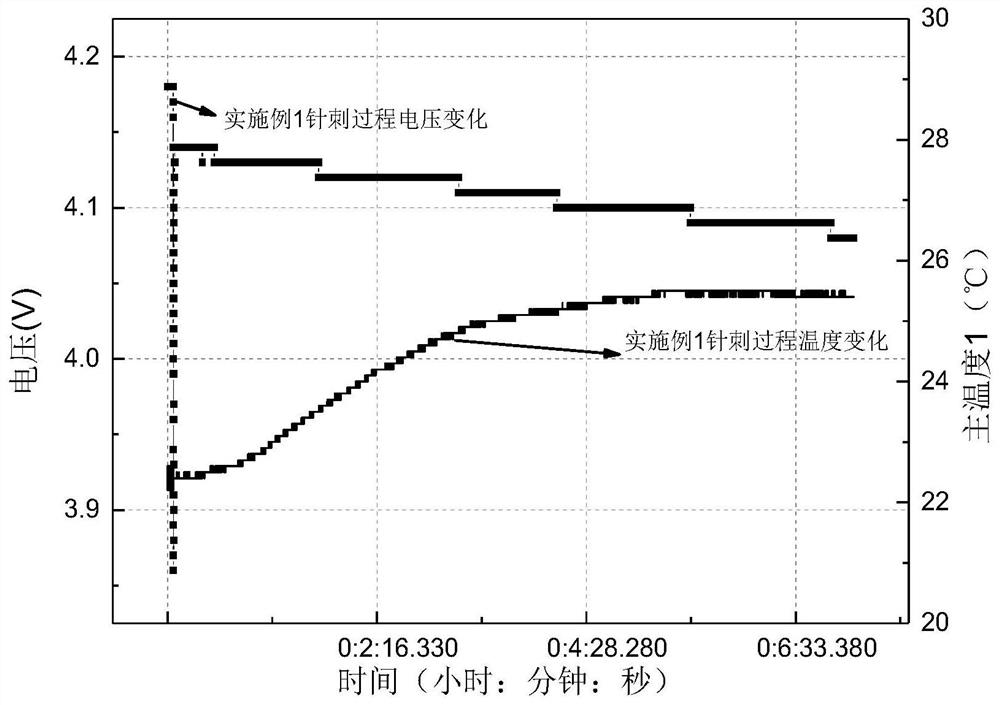

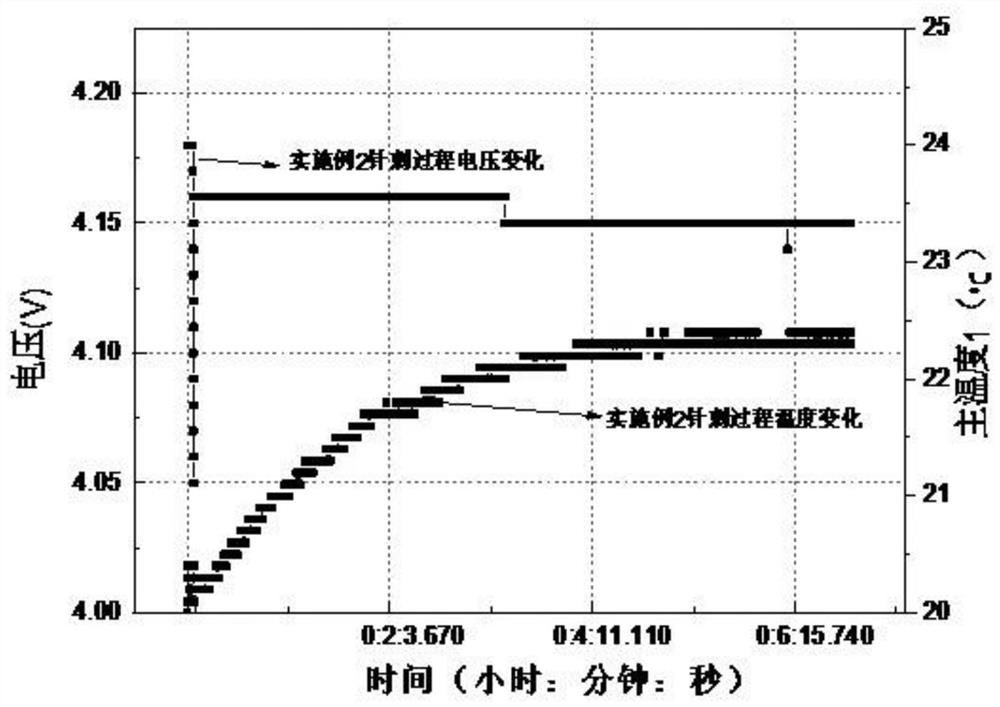

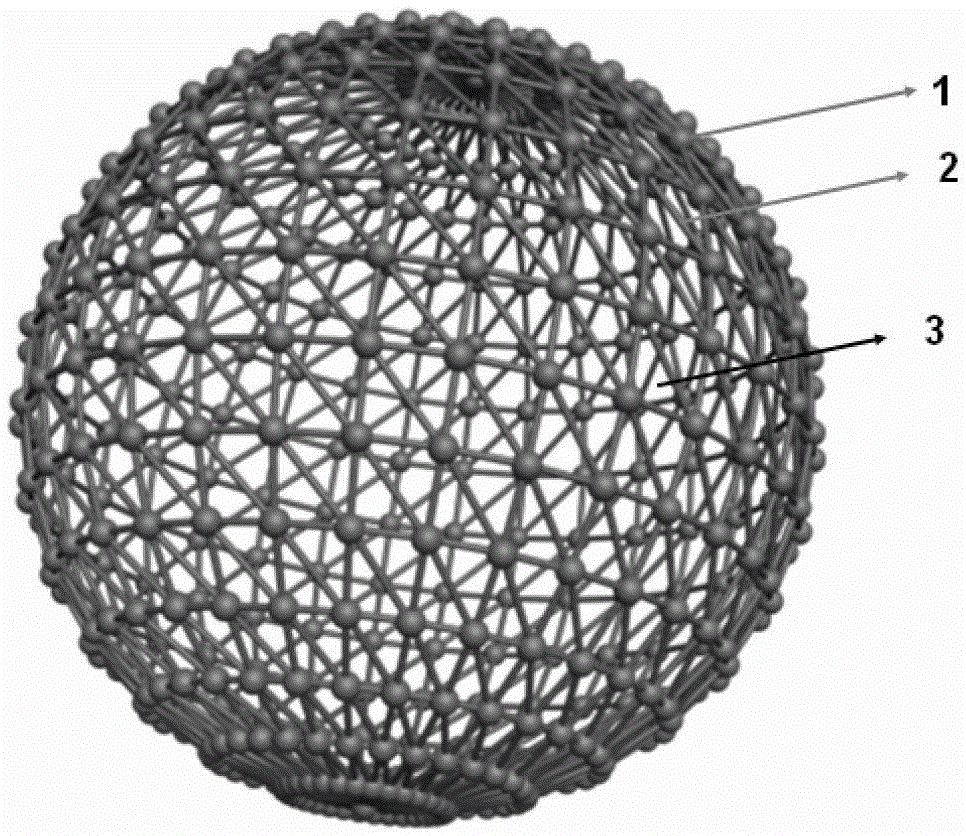

Lithium battery with multiple network structures

InactiveCN109119694AImprove performanceImprove securityFinal product manufactureElectrolyte accumulators manufactureNetwork structureEngineering

The invention discloses a lithium battery with multiple network structures, multiple network structures are constructed in situ between a positive electrode and a negative electrode, between an electrolyte and the positive electrode, and between the electrolyte and the negative electrode in an interpenetration or semi-interpeneration form, the multi-network structure can effectively prevent liquidleakage due to the use of a liquid electrolyte, contributing to stabilization of an electrode, the electrode is avoided from structure collapse, pulverization and separation from the current collector due to the volume change of the electrode, the interface performance between the electrolyte and electrode is improved, enhance the effective migration and diffusion of lithium ions between electrolyte, electrolyte and electrode as well as inside electrode, restrain or weaken the generation and growth of lithium dendrites, so as to improve the battery performance and safety performance of a lithium battery system.

Owner:SHANGHAI UNIV

Negative electrode composite slurry and preparation method thereof, lithium battery negative electrode sheet

ActiveCN109768281BImprove heat resistanceImprove thermal stabilityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsGlass fiberMaterials science

The invention discloses negative electrode composite slurry and a preparation method thereof, and a lithium battery negative electrode plate. The negative electrode composite slurry comprises the following components in percentage by weight: 1.00 to 3.20% of superfine glass fibers, 16.20 to 23.50% of ceramic powder, 0.90-3.50% of a binder I, 0.10 to 0.80% of a binder II, 0.05 to 0.30% of styrene-butadiene emulsion or styrene-acrylic emulsion and 71.20 to 81.75% of water. A preparation method of the negative electrode composite slurry comprises the following steps: 1) obtaining a dispersed aqueous solution; 2) obtaining premixed slurry; and 3) obtaining the negative electrode composite slurry. The scheme of the invention has the advantages that the superfine glass fibers and the ceramic powder are mixed in the negative electrode composite slurry, so that the superfine glass fibers and the ceramic powder are evenly dispersed, the safety performance of the lithium battery is effectively improved, a negative electrode coating has a good lithium ion transmission effect, and the rate performance of the lithium battery is ensured.

Owner:ETRUST POWER ETP GRP LTD

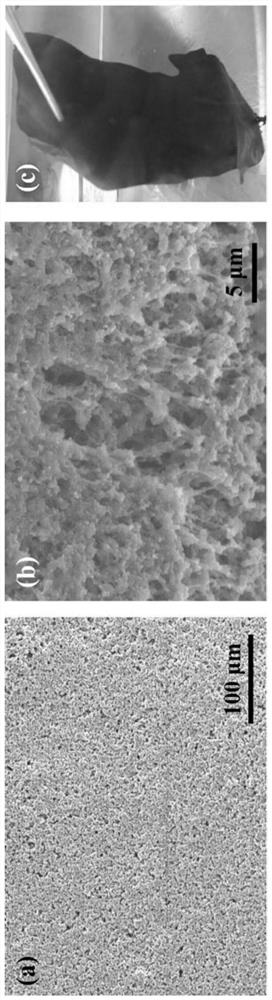

Preparation method of all-solid-state lithium-air battery cathode

InactiveCN112186203AImprove performanceRich pore structureFuel and secondary cellsCell electrodesPolymer electrolytesAll solid state

The invention belongs to the technical field of batteries, and particularly discloses a preparation method of an all-solid-state lithium air battery cathode with a flexible characteristic. Through reasonable design of the positive electrode structure and introduction of the polymer electrolyte as a lithium ion transmission skeleton, the cathode with high lithium ion transmission capability, high electronic conductivity and rich pore structures is prepared, so that the performance of the solid-state lithium air battery is improved. The prepared cathode has a flexible characteristic and can be applied to a flexible solid-state lithium-air battery. The invention provides a new way for efficient and controllable preparation of the cathode of the all-solid-state lithium-air battery, and has a wide application prospect.

Owner:JIANGSU UNIV

High-voltage-resistant composite solid electrolyte, preparation method thereof and all-solid-state lithium battery

PendingCN114744291AResistantIncrease transfer rateFinal product manufactureLi-accumulatorsElectrolysisLithium metal

The invention discloses a high-voltage-resistant composite solid electrolyte, a preparation method of the high-voltage-resistant composite solid electrolyte and an all-solid-state lithium battery, and relates to the technical field of lithium ion batteries, and the high-voltage-resistant composite solid electrolyte is formed by hot pressing of a first composite solid electrolyte layer and a second composite solid electrolyte layer; the first composite solid electrolyte layer comprises a COFs matrix and a polymer electrolyte A loaded on the surface of the COFs matrix, and the polymer electrolyte A comprises polyoxyethylene, bismuth trioxide, a lithium salt and polyvinylidene fluoride; the second composite solid electrolytic layer comprises a COFs matrix and a polymer electrolyte B loaded on the surface of the COFs matrix; and the polymer electrolyte B comprises polymethyl methacrylate, bismuth trioxide, lithium salt and polyvinylidene fluoride. According to the composite solid electrolyte, the electrochemical window of the solid electrolyte is widened, the interface resistance is reduced, the interface stability of the positive electrode and the negative electrode and the lithium ion transmission performance are improved, the composite solid electrolyte can be simultaneously suitable for a lithium metal negative electrode and a high-voltage ternary positive electrode, and the cycle performance of a battery is improved.

Owner:WANXIANG 123 CO LTD

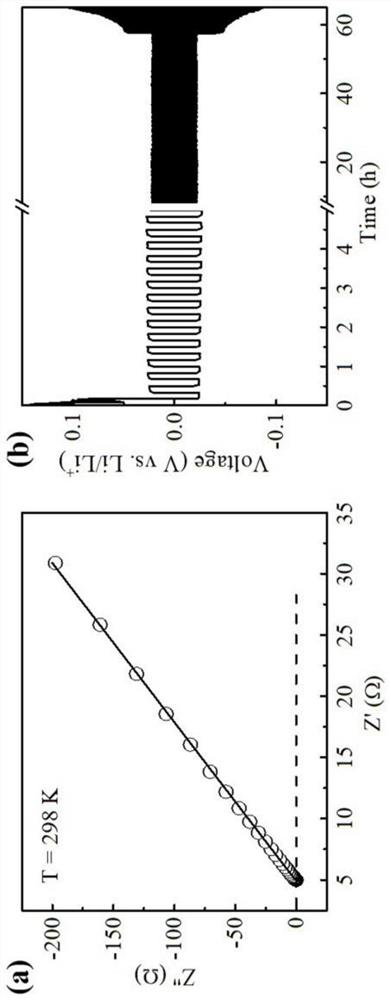

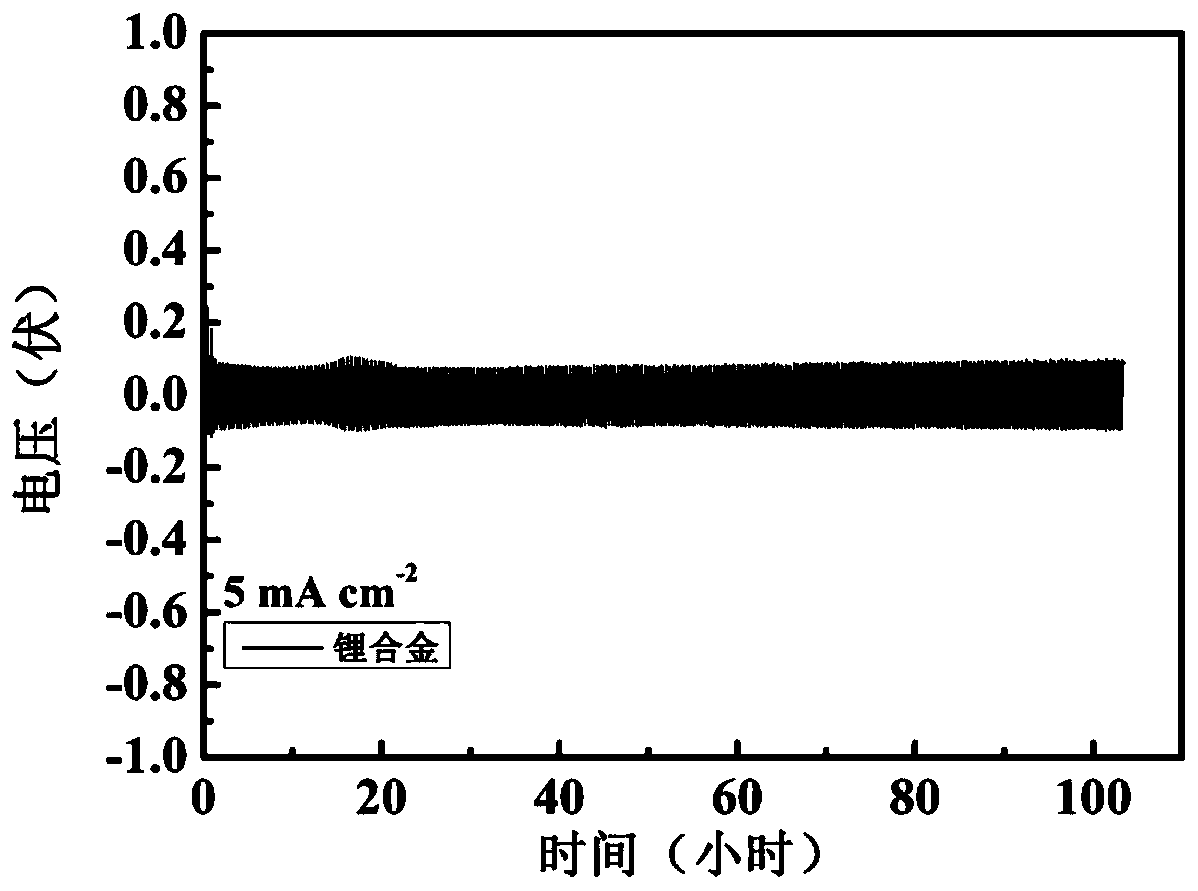

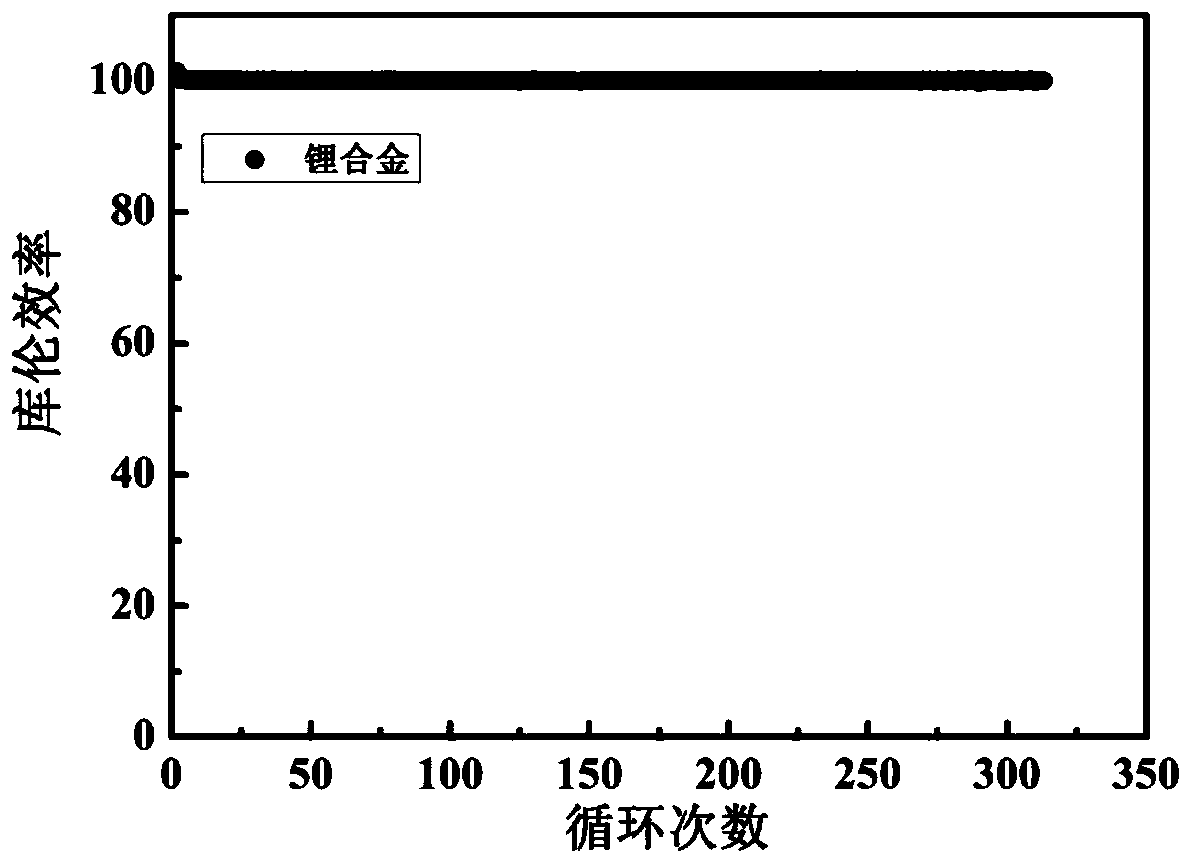

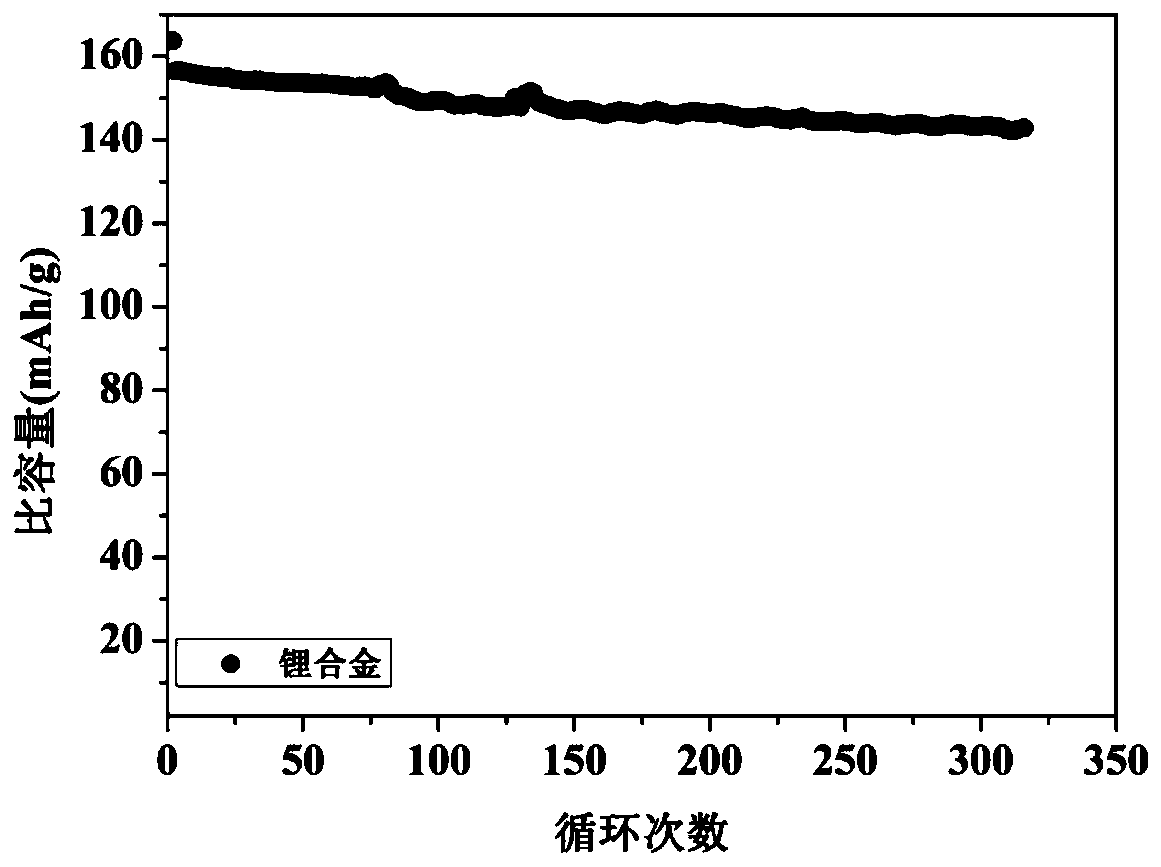

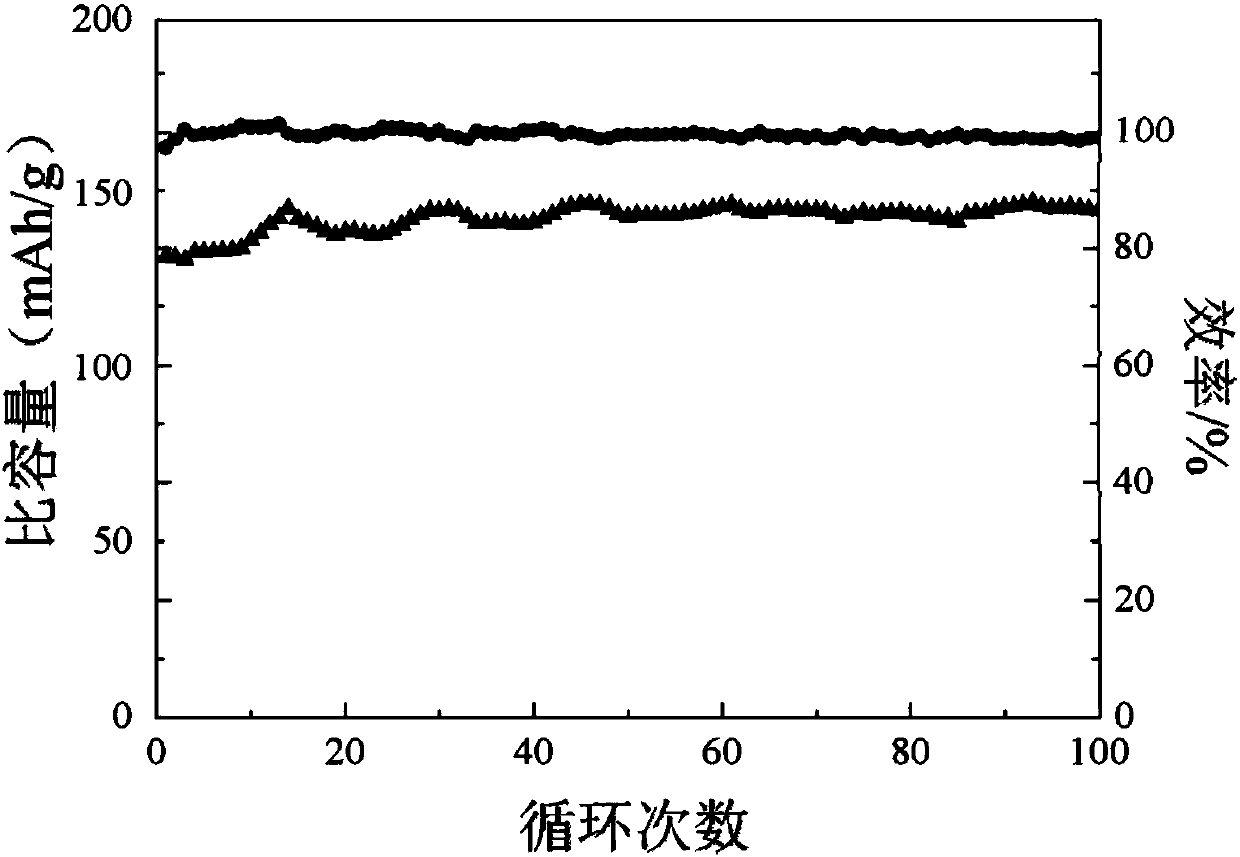

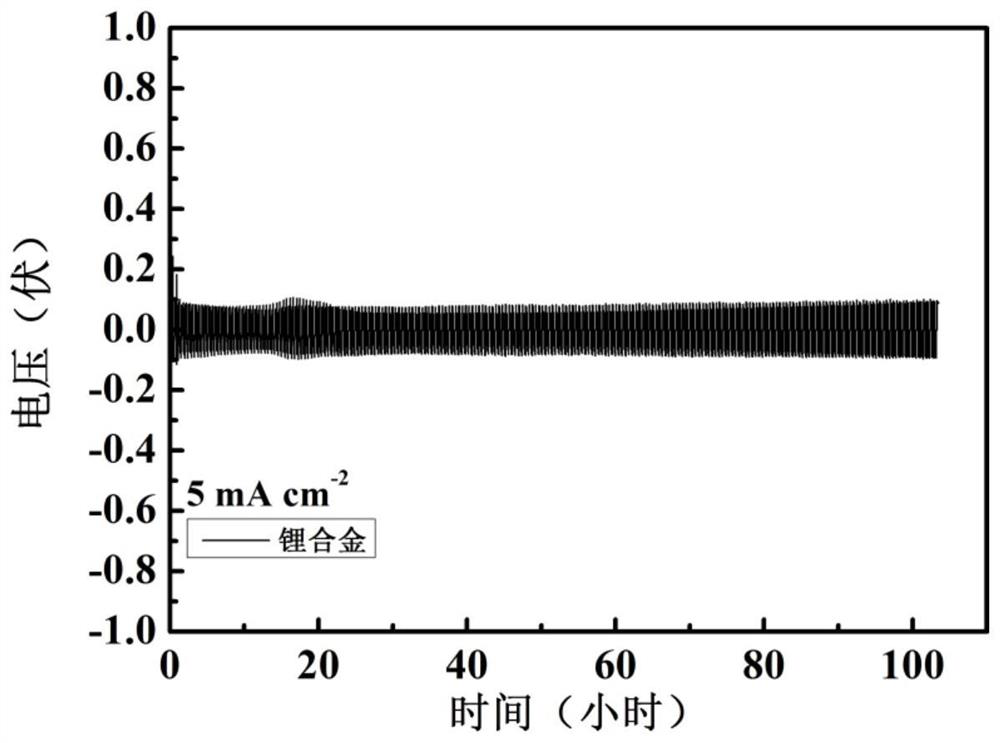

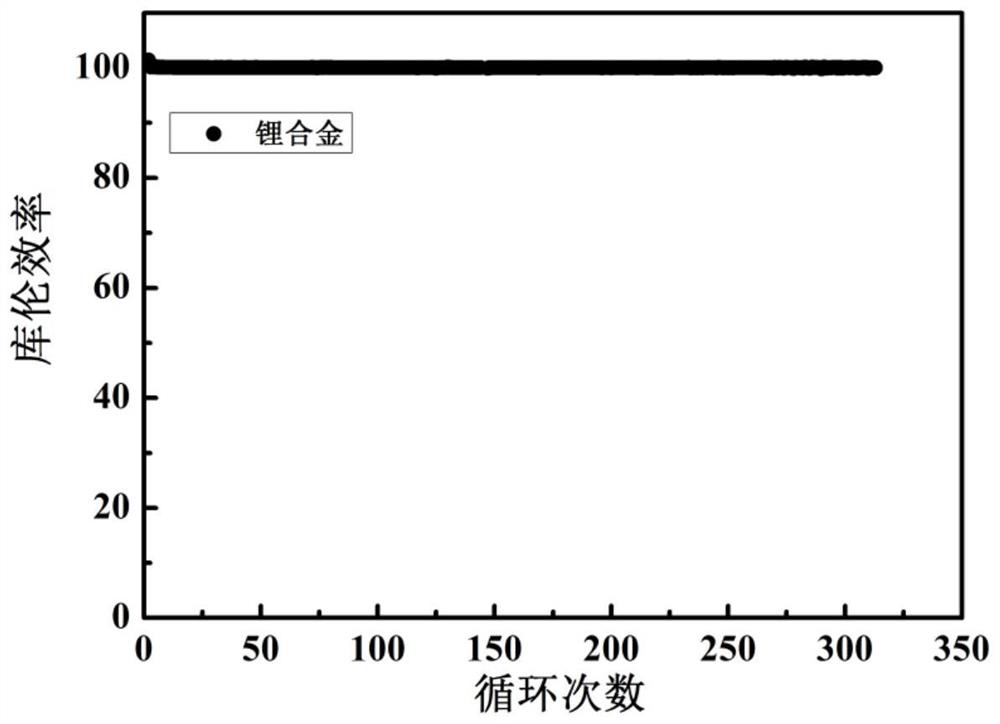

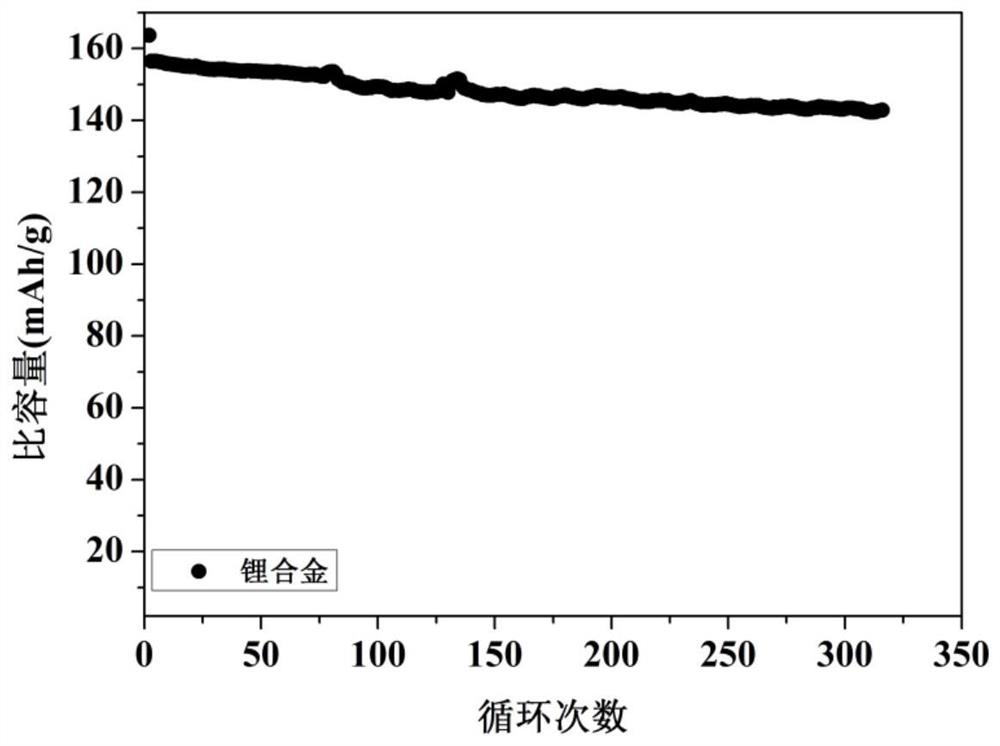

Lithium metal alloy and preparation method and application thereof

ActiveCN110311107ALow melting pointLower lattice energySecondary cellsNegative electrodesElectrolysisLithium metal

The invention provides a lithium metal alloy and a preparation method and an application thereof. The method comprises steps that alkali metal salt solid is extracted from lithium ore lixivium or purified lithium brine; the alkali metal salt solid is heated under inert gas till the alkali metal salt solid is completely melted; the melted alkali metal salt solid is melt-electrolyzed under inert gas for 1-10 hours to obtain the metal lithium alloy. The method is advantaged in that the method is simple in process, easy to operate and can realize comprehensive utilization of resources. The prepared lithium alloy has good electrochemical stability, excellent lithium ion transport capacity and mechanical properties and can be applied to metal lithium batteries to improve coulombic efficiency, specific capacity and cycle stability of the batteries.

Owner:CENT SOUTH UNIV

A kind of silicon/carbon composite negative electrode material for lithium ion battery and preparation method thereof

ActiveCN104752691BAdjustable capacityStable structureNegative electrodesSecondary cellsFiberCarbon composites

The invention relates to a silicon / carbon composite anode material for lithium ion batteries and a preparation method thereof. The material is composed of a graphite framework material, a middle buffer layer SiOC material, carbon fiber and a silicon-containing material with the carbon-coated surface, wherein the silicon-containing material with the carbon-coated surface is combined with the graphite framework material through the buffer layer SiOC and carbon fiber. Stoichiometric equation of the composite anode material is aSiOz@dAC-bSiOxCy&cCF-C, wherein a is less than or equal to 0.2 and greater than 0; b is less than or equal to 0.4 and greater than 0; c is less than or equal to 0.1 and greater than 0; d is less than or equal to 0.1 and greater than 0; z is less than or equal to 2 and greater than or equal to 0; x is less than 4 and greater than 0; and y is less than or equal to 20 and greater than 0. In the composite material, the amorphous carbon-coated silicon material is effectively contacted with graphite under the action of SiOC and carbon fiber so as to avoid agglomeration of the silicon material itself and peeling of graphite. According to the invention, charge-discharge specific capacity is adjustable, and electrochemical cyclic stability is high.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Metal thio compound @ S composite material and preparation and application thereof in lithium-sulfur battery

ActiveCN111063867AGood lithium ion transport performanceGuaranteed normal transmissionPositive electrodesLi-accumulatorsThio-Lithium sulfur

The invention relates to a metal thio compound @ S composite material and preparation and application thereof in a lithium-sulfur battery. The material is characterized in that the metal thio compound@ S composite material comprises a core and a coating material for coating the core; the core is made of elemental sulfur; the coating material is at least one metal thio compound with a right figurestructural formula, wherein R is alkyl, tertiary amino or ether, M is a metal element of Li, Zn, Cu, Cd, Ca, Bi, Pb, Ni, Sn, Fe, Co or Ag, and n is the chemical value of M. The organic metal thio compound has good lithium ion transmission capacity. Lithium ion transmission under the tight coating condition is guaranteed, and certain electronic conductivity can be provided. Compared with the existing inorganic coating layer, the coating layer provided by the invention is more elastic, and can relieve the cracking and falling of the coating layer caused by the volume change in the charging anddischarging process of elemental sulfur. The organic metal thio compound can provide a certain capacity.

Owner:CENT SOUTH UNIV

A metal thio compound@s composite material and its preparation and application in lithium-sulfur batteries

ActiveCN111063867BGood lithium ion transport performanceGuaranteed normal transmissionPositive electrodesLi-accumulatorsThio-Lithium sulfur

The invention relates to a metal thio compound @S composite material and its preparation and application in lithium-sulfur batteries, characterized in that it includes a core and a coating material covering the core; the material of the core is sulfur Simple substance; the coating material is at least one metal thio compound with the structural formula on the right; wherein R is a hydrocarbon group, a tertiary amino group or an ether group, and M is Li, Zn, Cu, Cd, Ca, Bi, Pb, Ni , Sn, Fe, Co or Ag metal elements, n is the chemical valence of M. The organometallic thio compound has good lithium ion transmission ability, ensures lithium ion transmission under tight coating conditions, and can provide a certain electronic conductivity; the coating layer of the present invention is compared with the existing inorganic coating The layer is more elastic, which can alleviate the volume change during the charging and discharging process of elemental sulfur, which causes the coating layer to break and fall off. The organometallic thio compounds themselves can provide a certain capacity.

Owner:CENT SOUTH UNIV

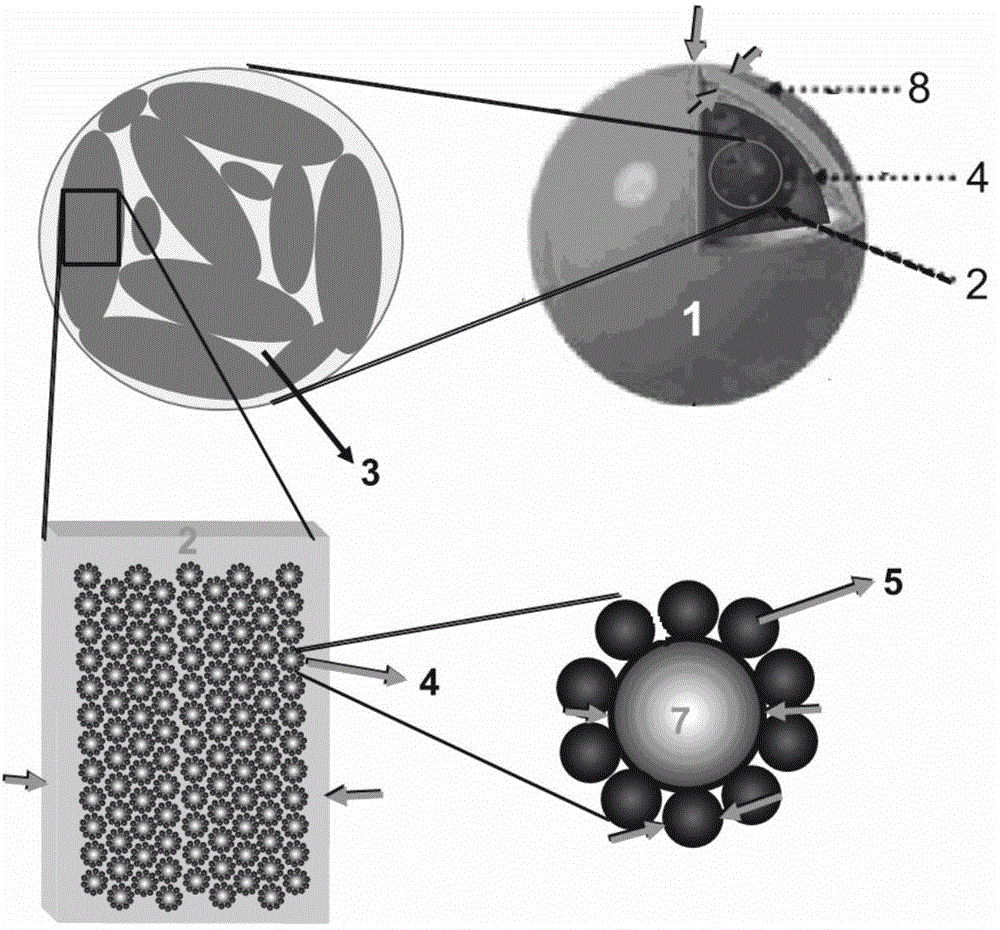

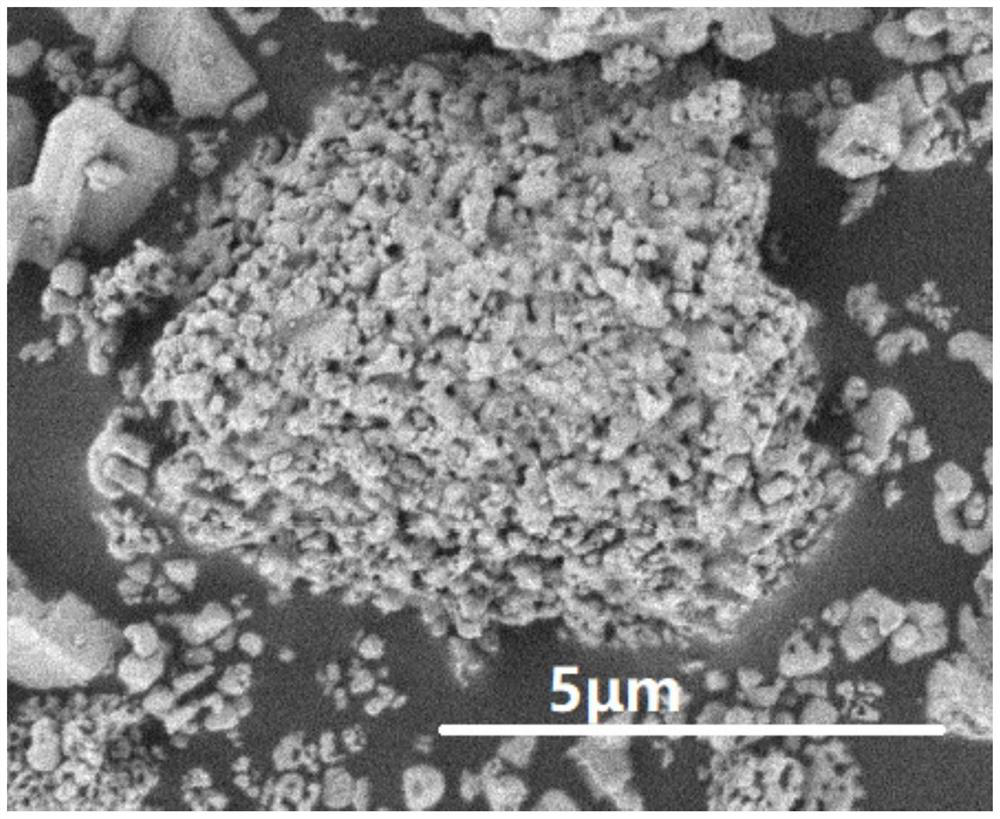

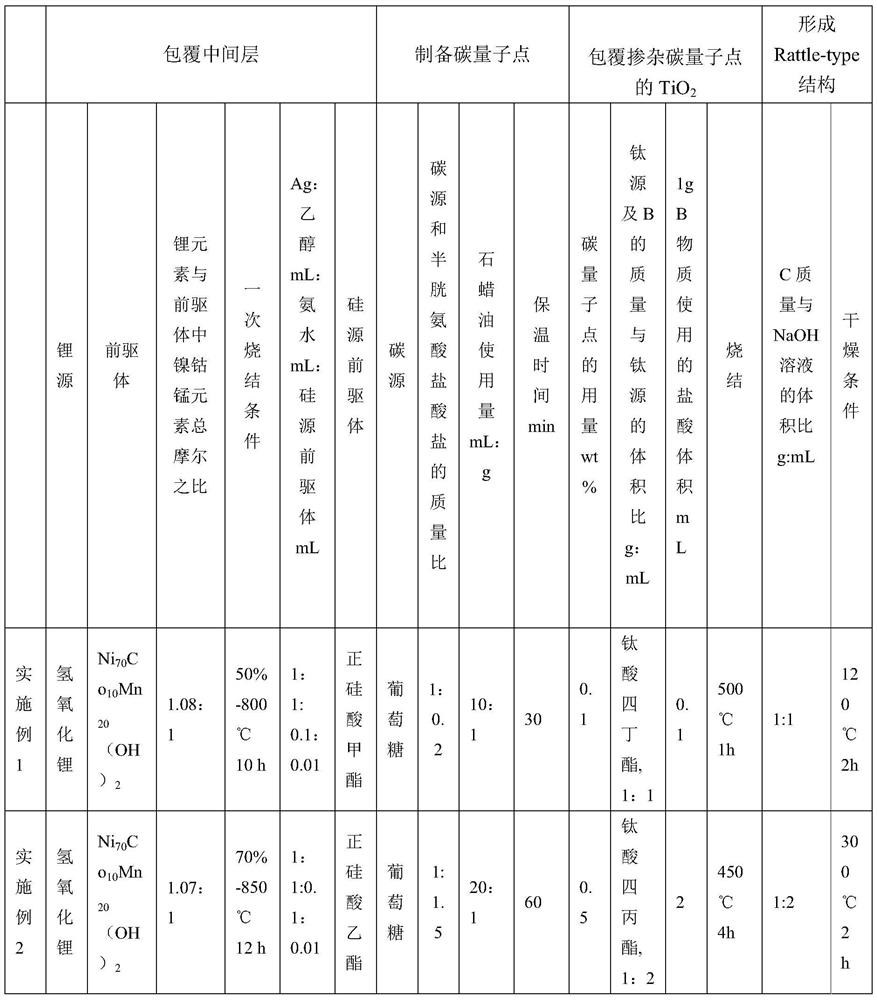

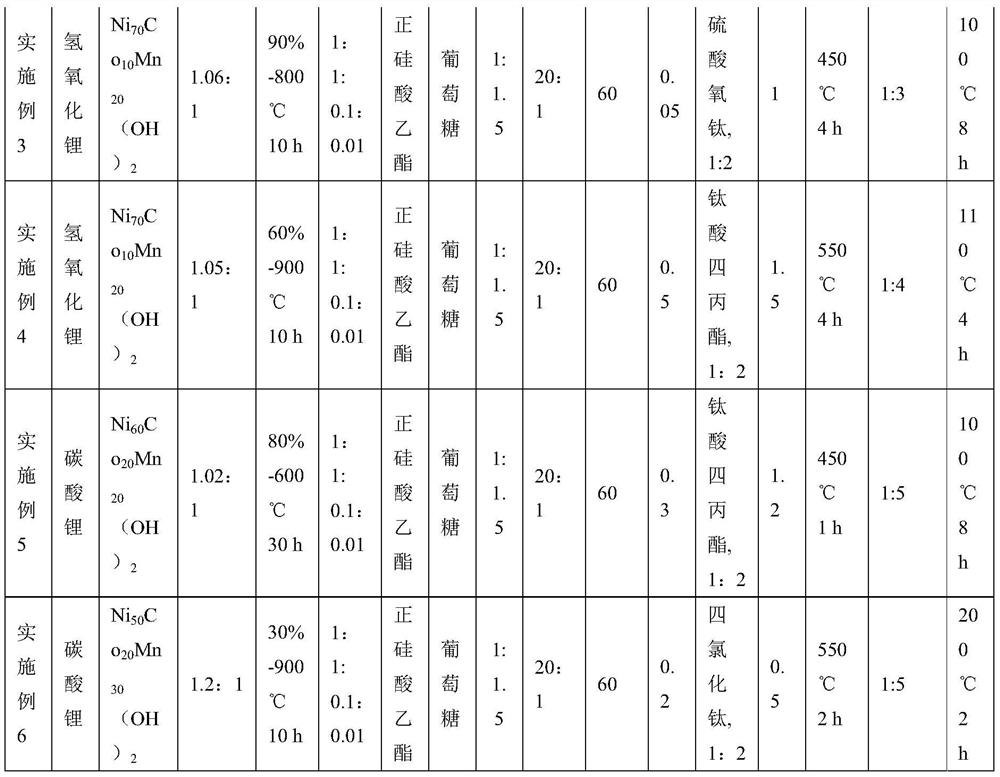

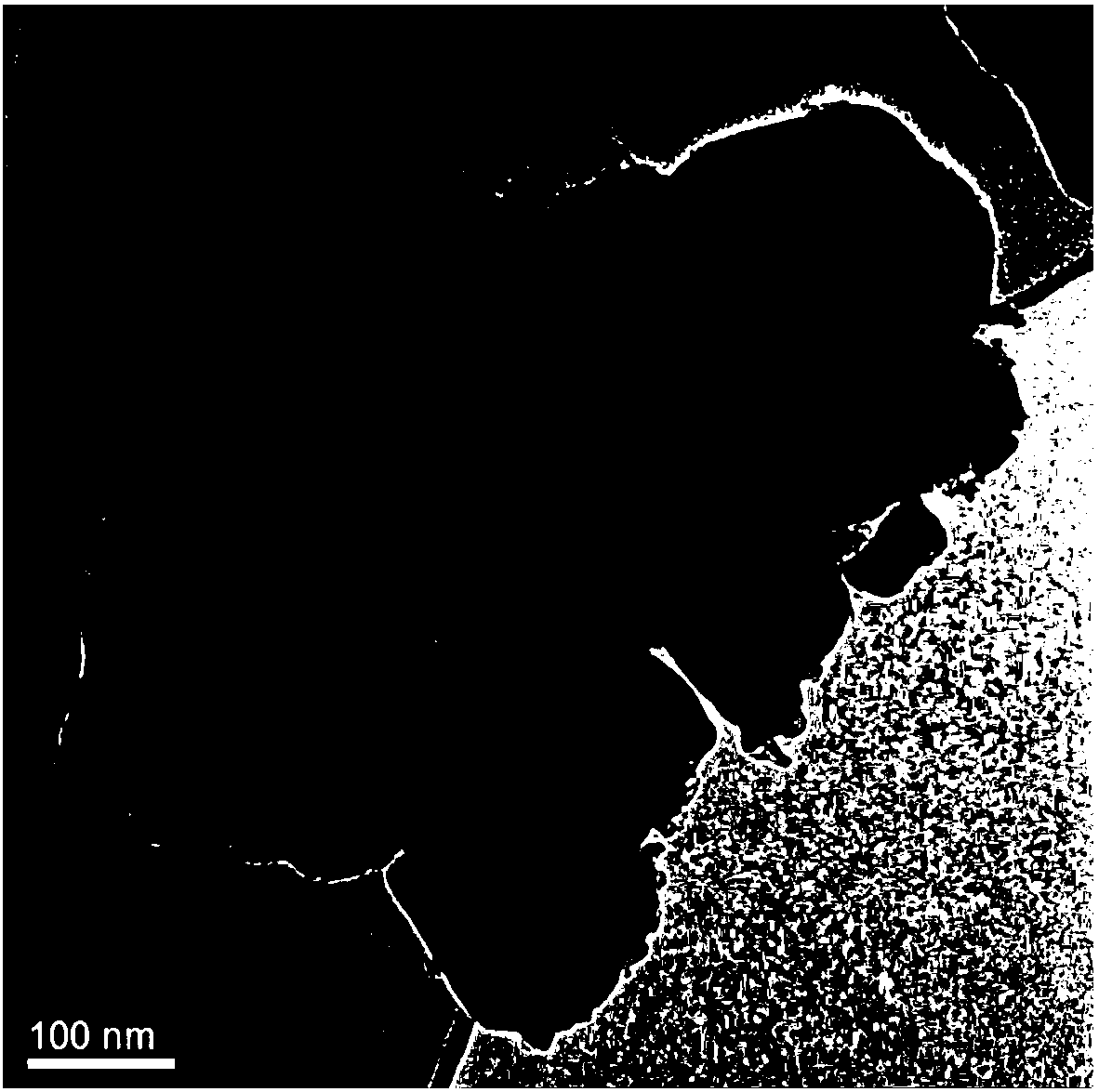

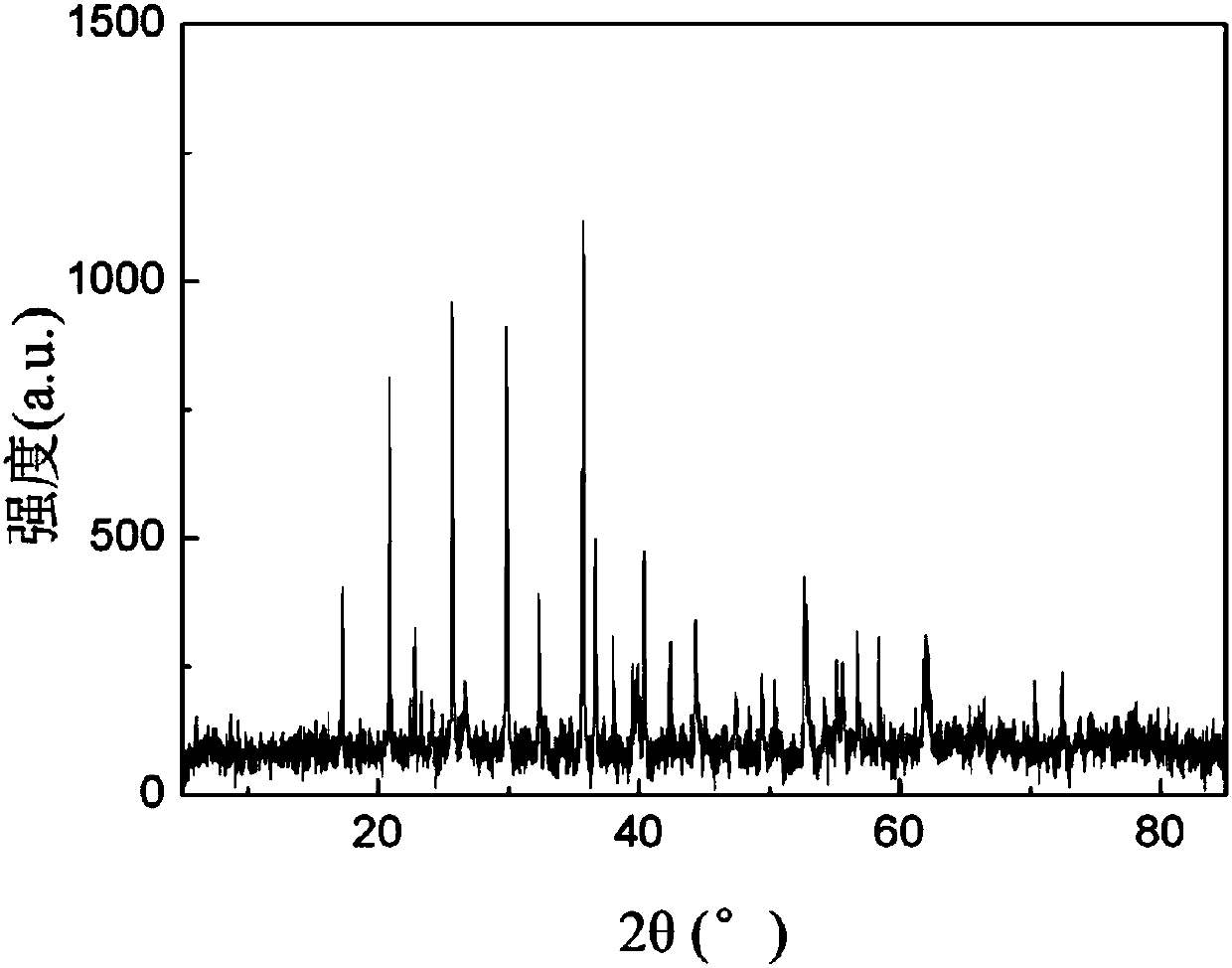

Preparation method of carbon quantum dot modified NCM ternary positive electrode material and prepared NCM ternary positive electrode material

ActiveCN113921789AImprove conductivityIncrease gram capacitySecondary cellsPositive electrodesAlkaline etchingElectrode material

The invention discloses a preparation method of a carbon quantum dot modified NCM ternary positive electrode material, and relates to the technical field of ternary positive electrode materials, and the preparation method comprises the following steps: (1) coating an intermediate layer; (2) coating TiO2 doped with carbon quantum dots; (3) carrying out alkaline etching. The invention has the beneficial effects that the NCM is used as an inner core of the material, the TiO2 is used as a shell of the material, a cavity structure is formed in the middle, and the TiO2 is doped into the carbon quantum dots while protecting and supporting the inner core of the NCM, so that the conductivity of the material is enhanced. Therefore, the stability and the rate capability of the material are improved in two aspects.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Graphene nano-ribbon-based lithium iron phosphate composite material and preparation method and application thereof

InactiveCN110085809ALarge specific surface areaImprove thermal conductivityMaterial nanotechnologySecondary cellsEnvironmental resistanceSolvent

The invention discloses a graphene nano-ribbon-based lithium iron phosphate composite material and a preparation method and an application thereof. The preparation method comprises steps that the graphene oxide nanoribbon, the ferric compound, a lithium source, a phosphorus source, a carbon source and the solvent are uniformly mixed and dried to obtain precursor powder; the precursor powder is sintered at the high temperature in the protective atmosphere, and the graphene nano-ribbon-based lithium iron phosphate composite material is obtained. The method is advantaged in that the process is simple, the graphene nanoribbon is utilized together with the amorphous carbon as a reducing agent to convert ferric iron into divalent iron, the formation of impurities can be reduced, the short time is taken, the method is safe, environmentally friendly and non-toxic, the graphene nano nanoribbon and the amorphous carbon are utilized to composite a conductive carbon shell, electronic conductivitycan be improved without hindering insertion and extraction of lithium ions, and the obtained graphene nano-ribbon-based lithium iron phosphate composite material has high specific capacity, superior electrical conductivity and electrochemical performance and good rate performance and has a wide range of applications in the battery field.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

A kind of metallic lithium alloy and its preparation method and application

ActiveCN110311107BLow melting pointLower lattice energyNegative electrodesSecondary cellsMetallic lithiumElectrolysis

The invention provides a metal lithium alloy and its preparation method and application. The preparation method comprises: extracting alkali metal salt solid from lithium ore leaching solution or purified lithium brine; heating the alkali metal salt solid under inert gas until completely melted ; The molten alkali metal salt solid is melted and electrolyzed under an inert gas for 1-10 hours to obtain a metal lithium alloy. The preparation method of the lithium alloy provided by the invention is simple in process, easy to operate, and can realize the comprehensive utilization of resources. The prepared lithium alloy has good electrochemical stability, excellent lithium ion transmission capacity and mechanical properties, and can be applied in The coulombic efficiency, specific capacity and cycle stability of the metal lithium battery can be improved in the metal lithium battery.

Owner:CENT SOUTH UNIV

Lithium ion battery anode material and manufacturing method thereof

InactiveCN102637877BUniform particle sizeHas a layered crystal structureCell electrodesElectrical batteryPhosphate

The invention discloses a lithium ion battery anode material and a manufacturing method of the lithium ion battery anode material. The anode material is cobalt nickel oxide manganese with a layer structure and has the chemical composition of LiNil-x-yCoxMnyO2, wherein x is equal to and larger than 0.15 and is equal to and less than 0.3, and y is equal to and larger than 0.2 and is equal to and less than 0.4. The manufacturing method provided by the invention has the following steps: the cobalt nickel oxide manganese powder is manufactured through a coprecipitation method, metal phosphate is adopted as a cladding material with the cladding quantity as 0.5-1.5% of the anode material; and the cobalt nickel oxide manganese is externally cladded by zinc phosphate through fluidization. The cladded battery material after modification with the manufacturing method has high special capacity and has good cycling stability at high temperature.

Owner:KUNMING UNIV OF SCI & TECH

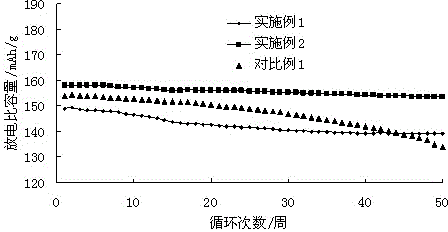

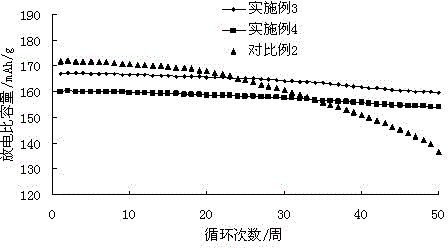

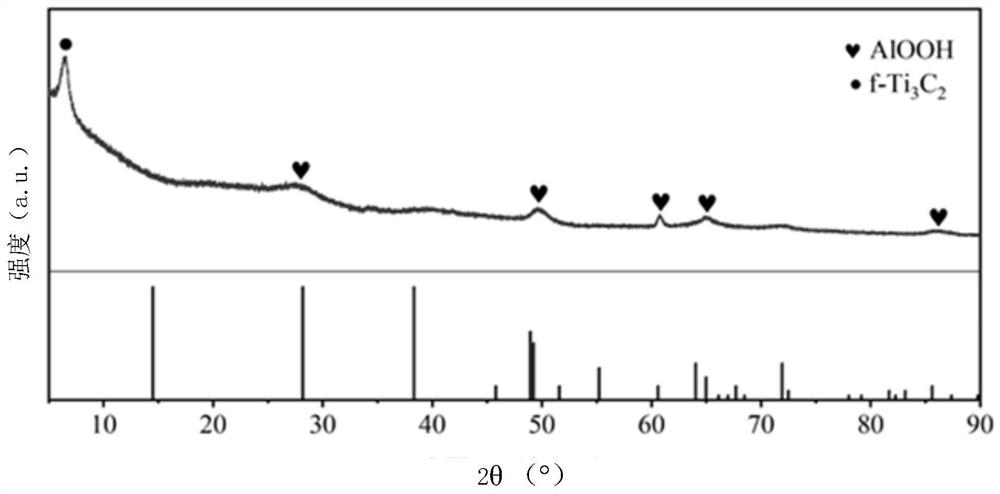

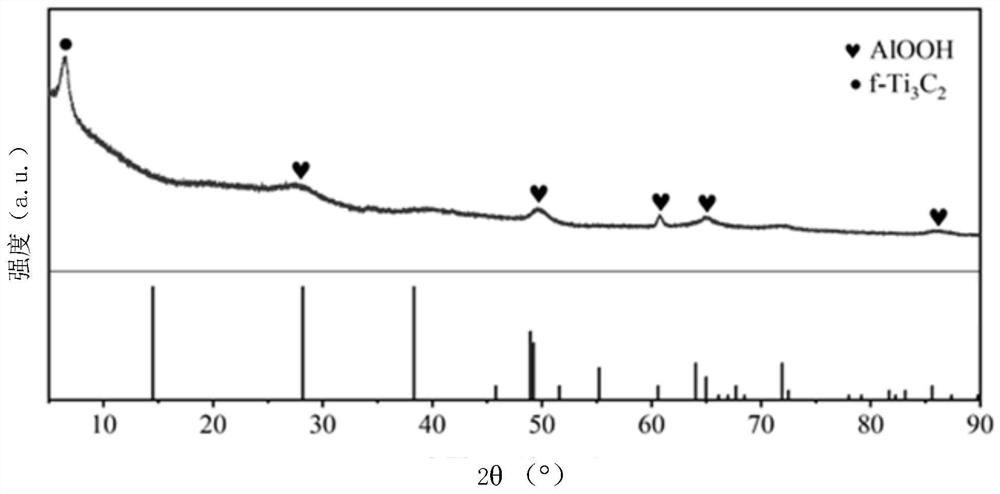

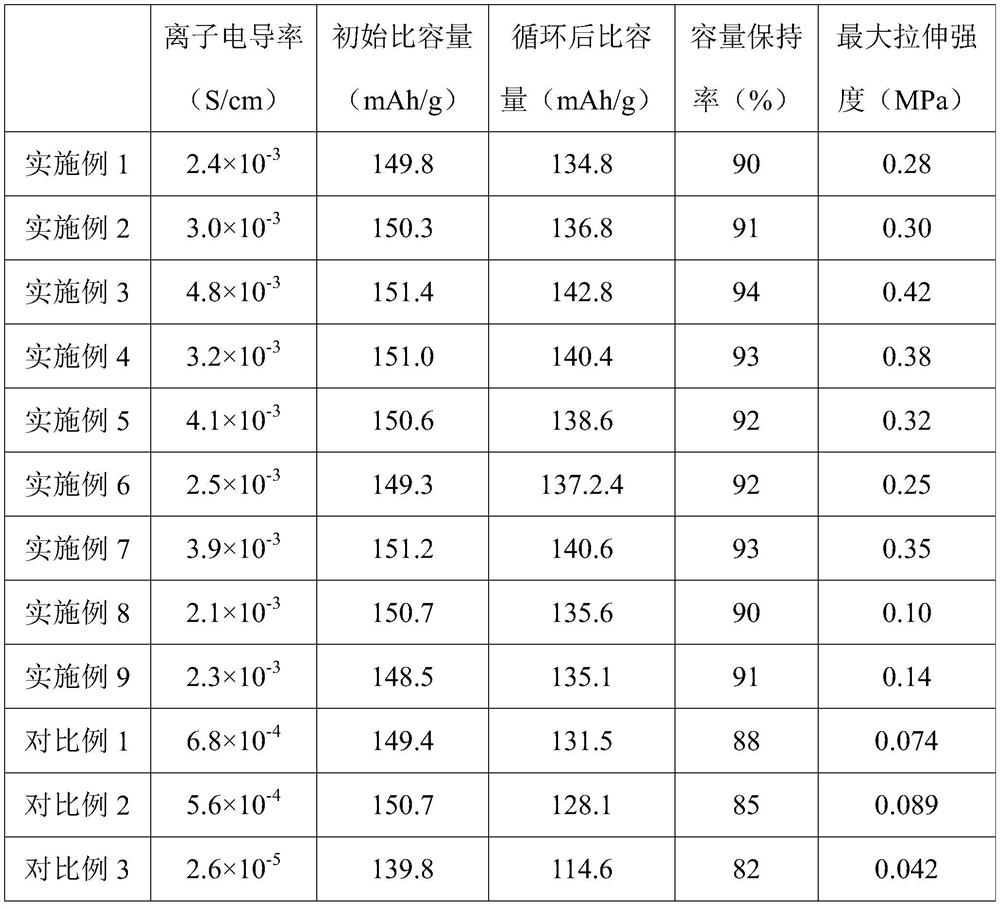

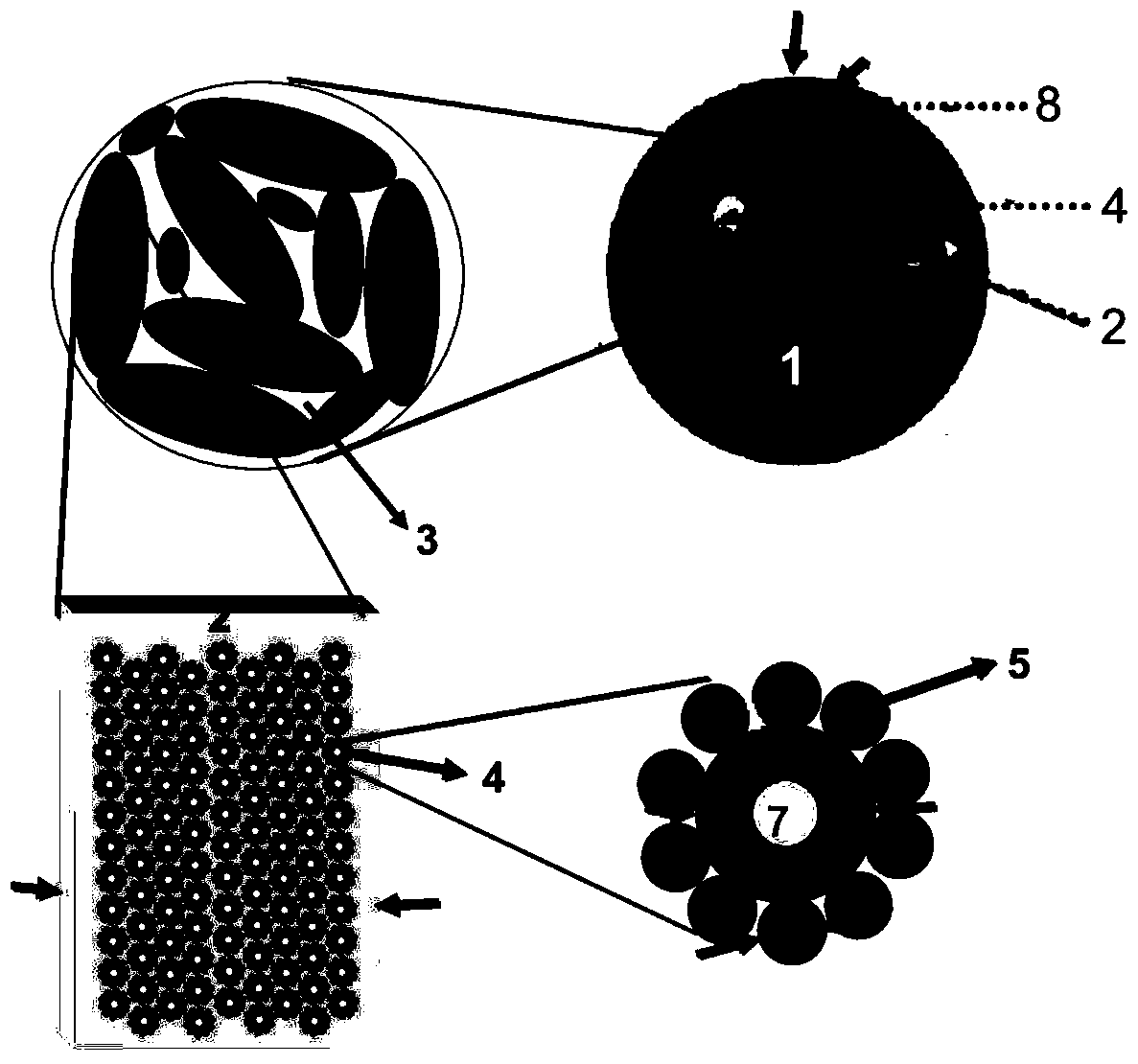

Composite solid electrolyte as well as preparation method and application thereof

ActiveCN113471522AImprove conductivityGood compatibilitySecondary cellsSolid state electrolytePlasticizer

The invention relates to a composite solid electrolyte as well as a preparation method and application thereof. The composite solid electrolyte comprises the following components: polyoxyethylene, a lithium salt, a plasticizer and a 2D flaky inorganic substance, wherein the 2D flaky inorganic substance is an MXene-AlOOH compound. The composite solid electrolyte is high in conductivity, good in electrode and electrolyte interface compatibility and excellent in mechanical property, and the formed lithium ion battery has excellent lithium ion transmission performance and cycling stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

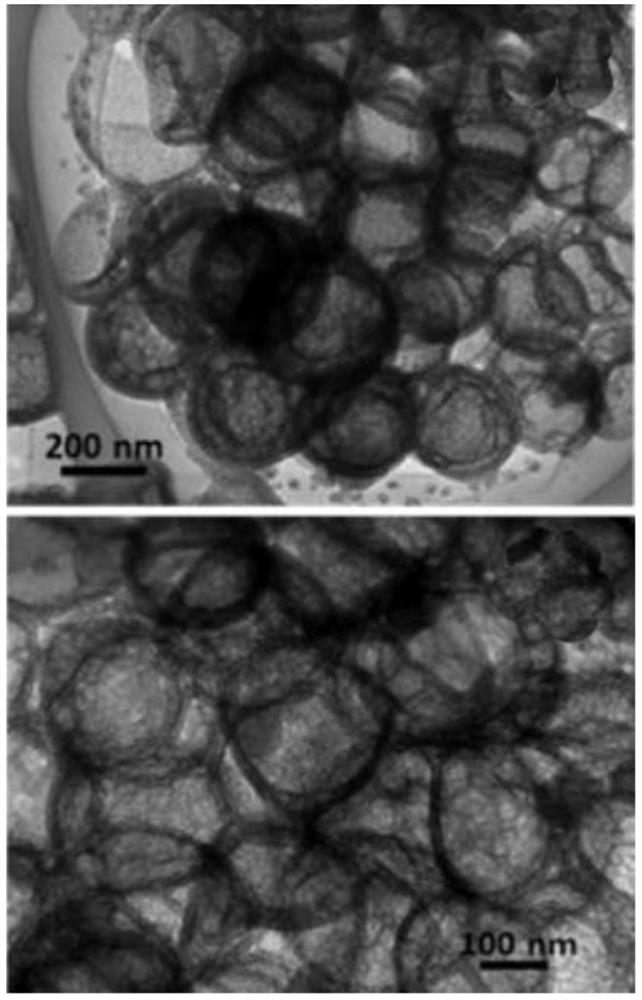

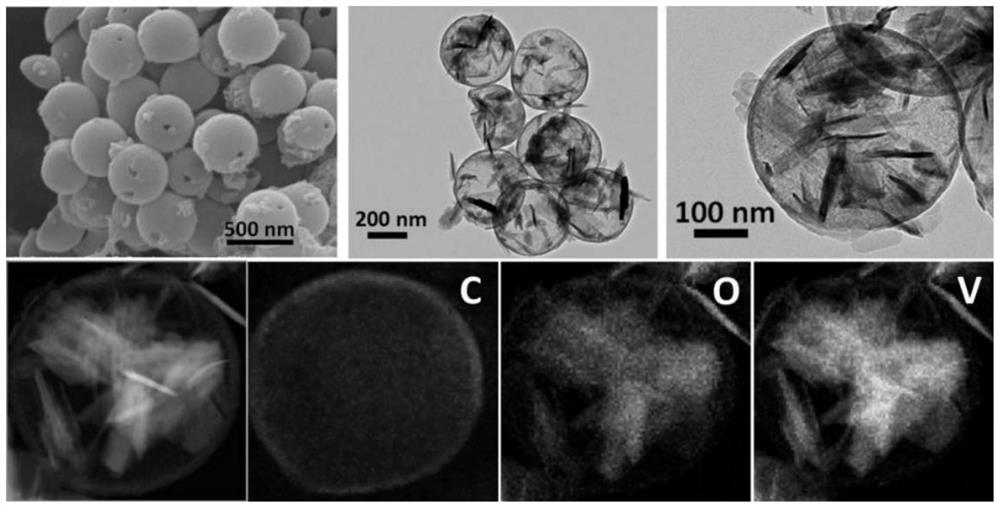

Porous carbon sphere-encapsulated vanadium oxide heterogeneous core-shell sphere structure material and preparation method, lithium-sulfur battery separator and lithium-sulfur battery

ActiveCN113036311BReduce manufacturing costEasy to operateLi-accumulatorsCell component detailsPorous carbonSilicic acid

Owner:TONGJI UNIV

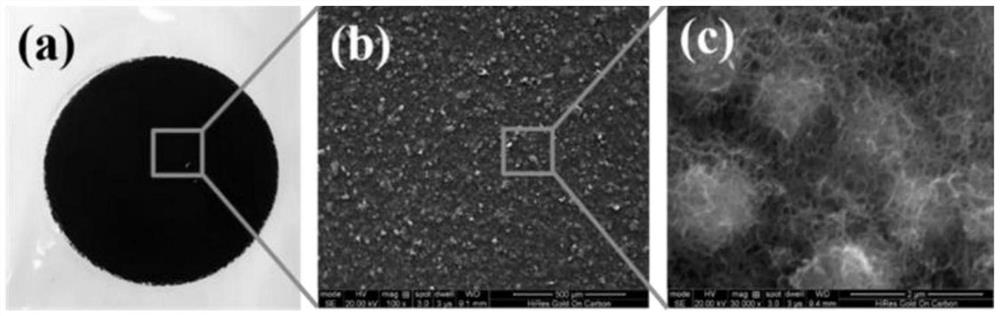

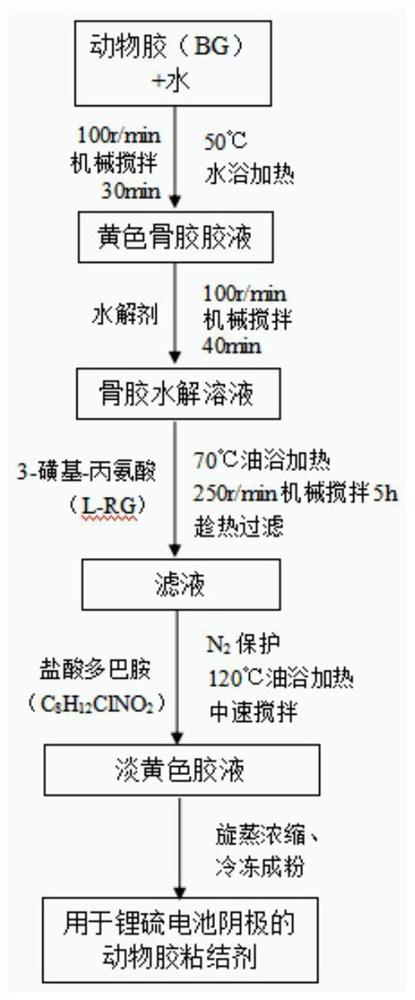

Animal glue binder for lithium-sulfur battery cathode and preparation method of animal glue binder

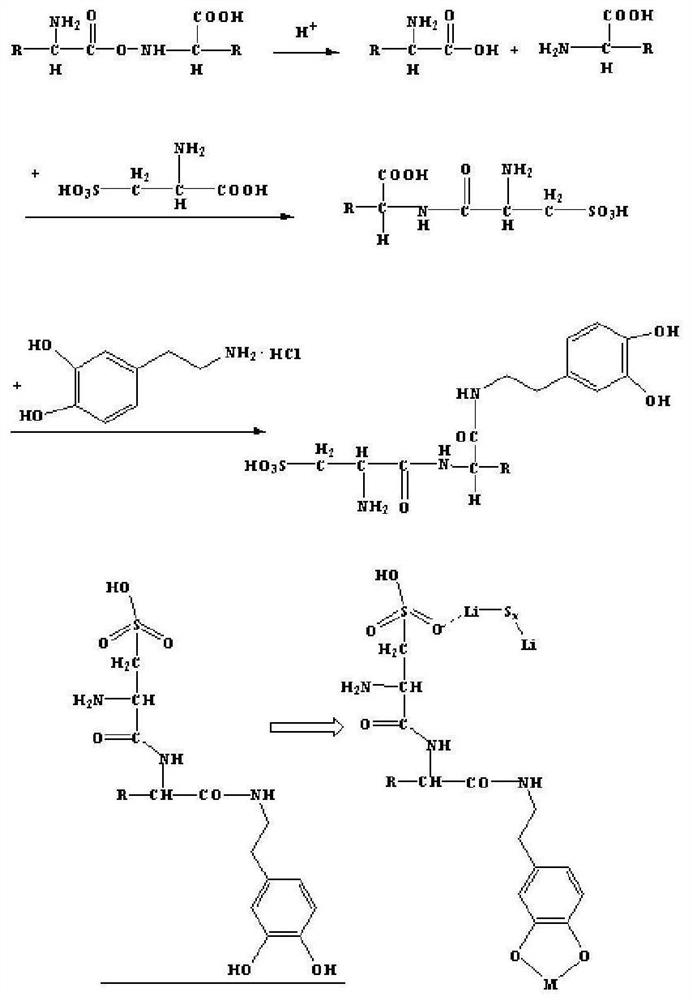

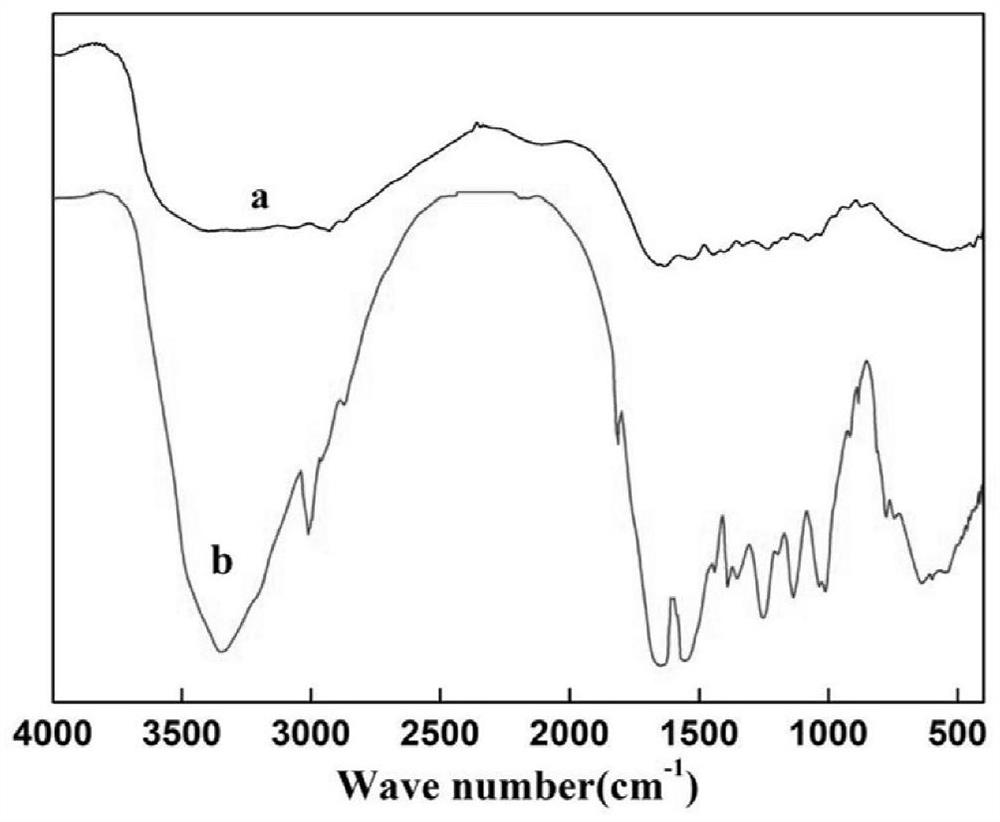

ActiveCN113363491ALow costThe synthesis process is simpleCell electrodesLi-accumulatorsChemistryAnimal glue

The invention discloses an animal glue binder for a cathode of a lithium-sulfur battery and a preparation method of the animal glue binder. The animal glue binder for the cathode of the lithium-sulfur battery is formed by compounding and modifying animal glue by 3-sulfo-alanine and dopamine hydrochloride. The novel composite binder of the lithium-sulfur battery is prepared from natural biopolymer animal glue to replace polyvinylidene chloride as a traditional binder, and amino and carboxyl in animal glue molecules are respectively subjected to amidation reaction with carboxyl in 3-sulfo-alanine molecules and amino in dopamine hydrochloride molecules; the cathode active material can be fixed by a-SO3H group in the 3-sulfo-alanine molecule through a substitution reaction, so that the utilization rate of the sulfur active material is increased; and catecholamine groups in dopamine hydrochloride can more firmly protect the structural integrity of the sulfur cathode. The animal glue composite modified binder not only can be used as a binder, but also can be used as a strong dispersant of a cathode material, and the binder is simple to prepare and synthesize, and has good electrochemical stability and longer cycle life.

Owner:SHANDONG JIAOTONG UNIV

A double-type anti-perovskite lithium-ion solid electrolyte and its preparation method and application

ActiveCN107403955BImprove ionic conductivityStable structureSolid electrolytesSecondary cellsPhysical chemistryLithium-ion battery

The invention relates to double-type antiperovskite lithium-ion solid electrolyte as well as a preparation method and application thereof, and belongs to the technical field of lithium ion batteries. The lithium-ion solid electrolyte disclosed by the invention has the chemical formula shown as follows: Li[3+a]MpAmBn(XxYy)[1-b], wherein a is greater than or equal to -0.25 and less than or equal to 0.25; b is greater than or equal to 0 and less than or equal to 0.5; p is greater than or equal to 0 and less than or equal to 0.5; m is greater than 0 and less than or equal to 1.25; n is greater than 0 and less than or equal to 1.25; x is greater than or equal to 0 and less than or equal to 1; y is greater than or equal to 0 and less than or equal to 1; M is any one of Ca, Ba, Mg, Al and Ti; A and B is any two of O, S, Se, Te, N, P, Si, C, Sb, Bi, F, Cl, Br and I; X and Y are separately selected from one of halogen or a negative univalent ionic group or vacancy. The structure of the lithium-ion solid electrolyte disclosed by the invention is a double-type antiperovskite structure, is stable in structure and has a good lithium-ion transmission property.

Owner:ZHENGZHOU NEW CENTURY MATERIALS GENOME INST CO LTD

A kind of silicon/silicon carbon/graphite composite negative electrode material for lithium ion battery

ActiveCN104466142BAdjustable capacityStable structureElectrode carriers/collectorsSecondary cellsCarbon graphiteLithium-ion battery

The invention relates to a silicon / silicon carbon / graphite composite negative electrode material for a lithium ion battery, which is a silicon-containing material with a uniform and firm dispersion size below 3 μm on the surface of the graphite negative electrode. The present invention also provides a preparation method for the composite negative electrode material, comprising: dispersing the silicon-containing material in a liquid organosiloxane monomer, sequentially adding an acidic solution of ethanol-water, a curing agent and graphite negative electrode material, and then performing ball milling or Mechanical stirring and kneading are mixed to obtain a paste mixture. The paste is calcined at high temperature and crushed and sieved in a protective atmosphere to obtain silicon / silicon carbon / graphite lithium ion battery negative electrode materials with various particle sizes. The silicon-containing material in the silicon / silicon carbon / graphite composite negative electrode material is firmly and evenly distributed on the surface of the graphite material. This structure can make the silicon material effectively adsorb on the surface of the graphite, avoiding the agglomeration of the silicon material itself and the interaction with the graphite. It has the characteristics of adjustable charge-discharge specific capacity and high electrochemical cycle stability.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

A kind of composite solid electrolyte and its preparation method and application

ActiveCN113471522BImprove conductivityGood compatibilitySecondary cellsSolid state electrolytePolyethylene oxide

The invention relates to a composite solid electrolyte and its preparation method and application. The composite solid electrolyte includes the following components: polyethylene oxide, lithium salt, plasticizer and 2D sheet-like inorganic matter; the 2D sheet-like inorganic matter is MXene‑AlOOH complex. The composite solid electrolyte of the invention has high electrical conductivity, good interfacial compatibility between electrodes and the electrolyte, and excellent mechanical properties, and the formed lithium ion battery has both excellent lithium ion transmission performance and cycle stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A silicon-based composite negative electrode material for lithium-ion batteries and its preparation method

ActiveCN105762329BAdjustable capacityStable structureElectrode manufacturing processesInsulation ProblemSodium-ion battery

The invention discloses a silicon-based composite anode material for a lithium ion battery and a preparation method thereof. The anode material comprises a graphite skeleton and an amorphous carbon layer which coats the graphite skeleton. The graphite skeleton is filled with a silicon material coated with a carbon-containing structure. The silicon material and the graphite skeleton are combined through a loose carbon material. The preparation method at least comprises the following steps: (1) preparing the silicon material coated with the carbon-containing structure; (2) preparing spherical particles with graphite as the main body; (3) coating the spherical particles with the amorphous carbon layer; and (4) granulating. According to the invention, the electric insulation problem of silicon anode due to its volume change can be solved, and it can be guaranteed that silicon active component can always be electrically contacted with a current collector during the charge-discharge cycle process. Meanwhile, huge stress effect caused by volume expansion / shrinkage of the active material silicon is further buffered. Then, the composite material has characteristics of high electrochemical cycle stability and regulable specific capacity.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

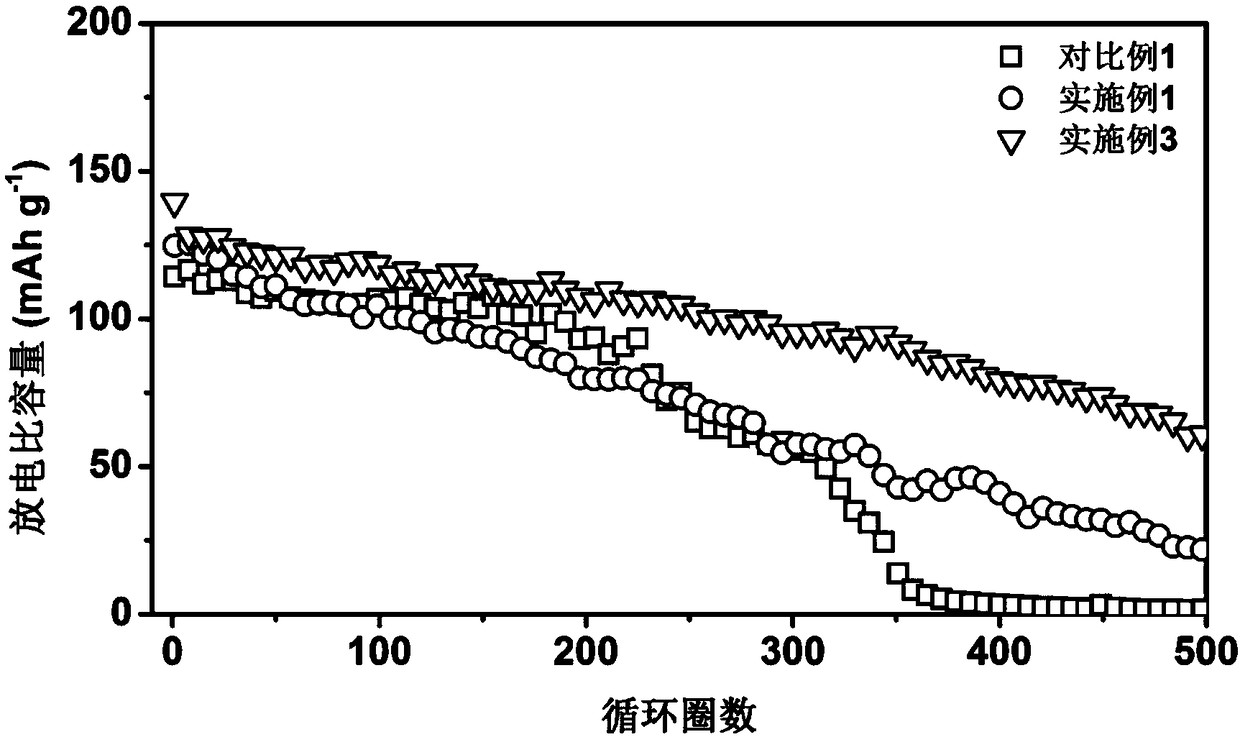

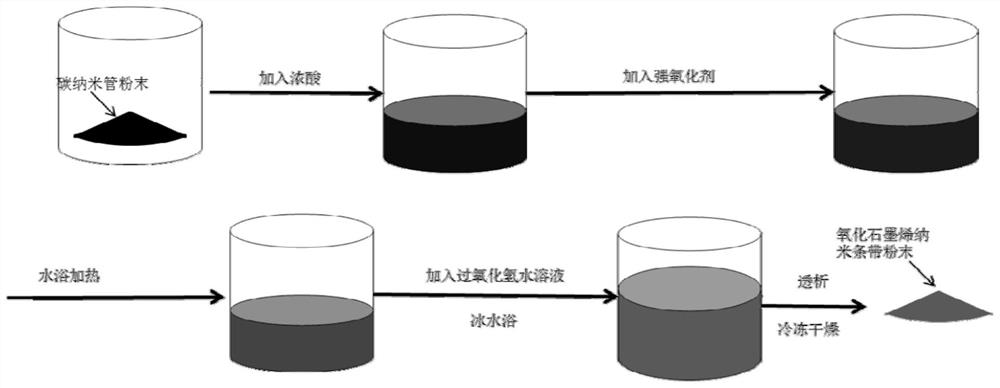

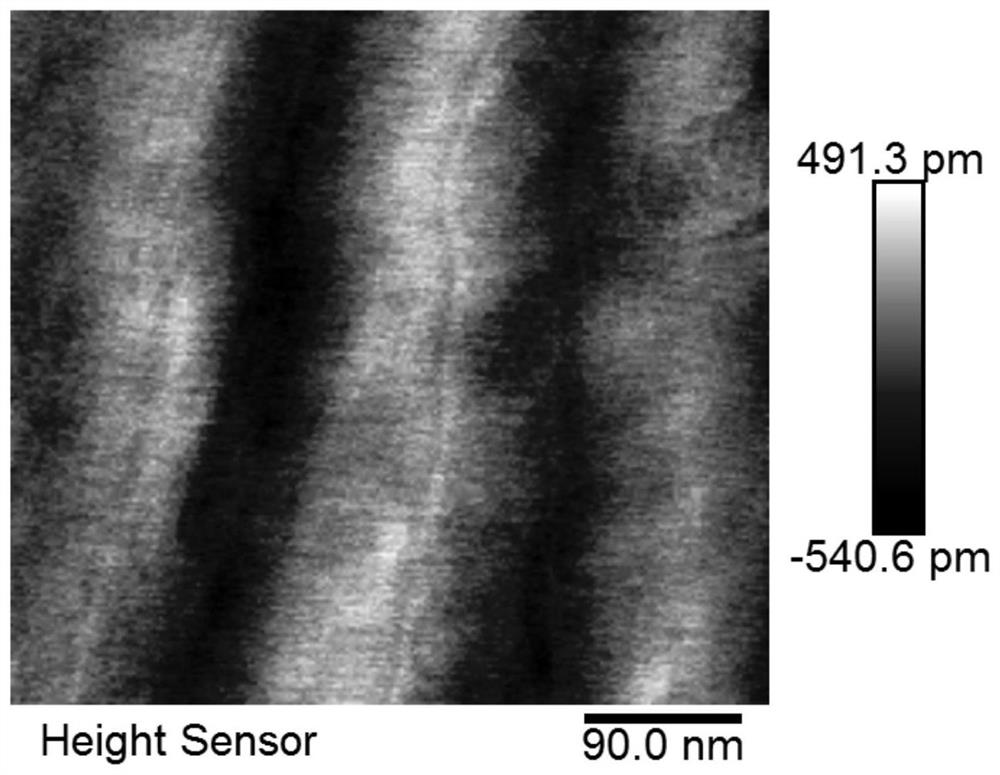

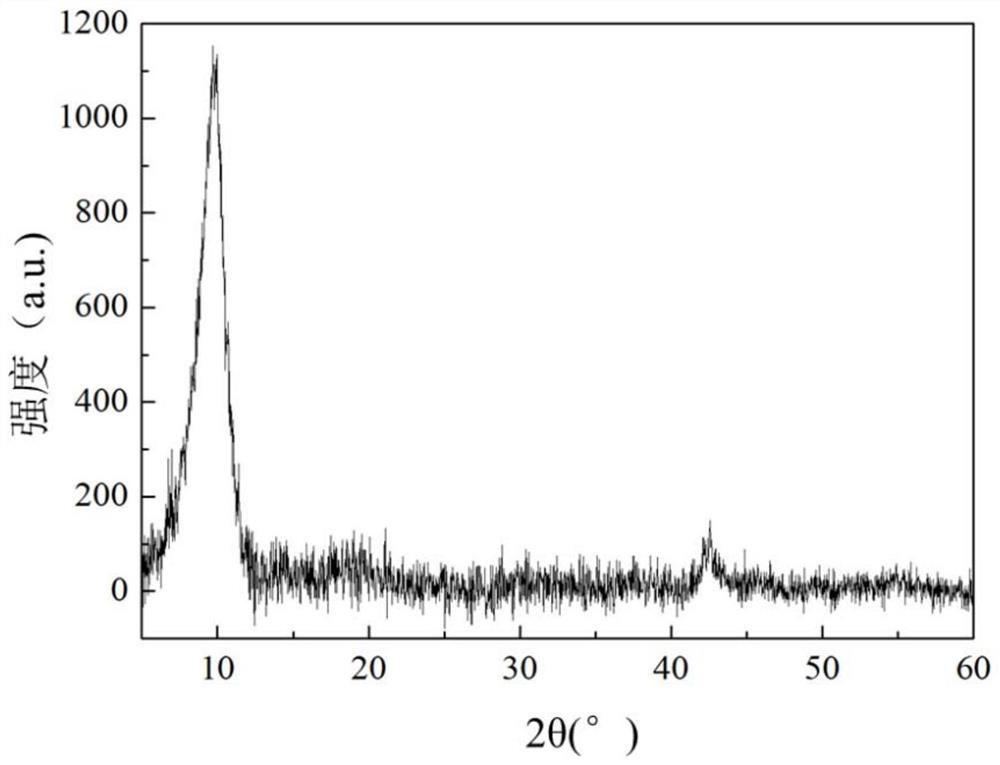

A kind of graphene nanoribbon material and its preparation method and application

ActiveCN110078060BSimple processImprove conductivityCell electrodesSecondary cellsFreeze-dryingGraphene nanoribbons

The invention discloses a graphene nano strip material, a preparation method and application thereof. The preparation method comprises: using the Hummers method to longitudinally oxidize and strip the carbon nanotubes to form a graphene oxide nanostrip solution; to perform directional freeze-drying on the graphene oxide nanostrip solution to obtain a flocculent oxidized carbon nanotube with an ordered structure. Graphene nanoribbon materials. The process of the present invention is simple, and the obtained graphene nano strip material has a three-dimensional porous structure, a large specific surface area and a large amount of oxygen-containing functional groups that are beneficial to lithium storage, and the lithium ion battery negative electrode prepared from this material has a high specific capacity (500 ‑650mAh / g), superior electrochemical performance and good rate performance, it is an ideal battery anode material.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

A kind of silicon-based composite negative electrode material for lithium ion battery

ActiveCN104241621BAlleviate volume changesEvenly dispersedCell electrodesSecondary cellsSodium-ion batteryOxygen

The invention relates to a silicon-based composite negative electrode material for a lithium ion battery, wherein a silicon-containing material with the size of less than 0.3 [mu]m is dispersed uniformly in a porous silicon oxygen carbon skeleton. The invention also provides a method for preparing the composite negative electrode material, wherein the method includes the steps: dispersing the silicon-containing material in a liquid organo-siloxane monomer, successively adding an ethanol-water acidic solution, a curing agent and an amorphous carbon source precursor solution into the dispersion liquid, and carrying out heat preservation to make the mixed solution cured; carrying out high temperature calcination on the precursor after curing in a protective atmosphere, to obtain a bulk silicon-based composite material; and crushing the bulk silicon-based composite material by ball milling to obtain the silicon-based lithium ion battery negative electrode material having various different particle sizes. The silicon-containing material in the silicon-based composite negative electrode material is firmly and evenly distributed in the porous silicon oxygen carbon skeleton, and the structure can effectively bear a volume effect brought by embedding and stripping of lithium and has the characteristics of adjustable charge / discharge specific capacity and high electrochemical cycle stability.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com