A kind of graphene nanoribbon material and its preparation method and application

A nano-ribbon, graphene technology, applied in the direction of graphene nano-ribbon, graphene, nano-carbon, etc., can solve problems such as hindering lithium ion transmission, achieve lithium storage performance and lithium ion transmission rate improvement, increase specific surface area, The effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

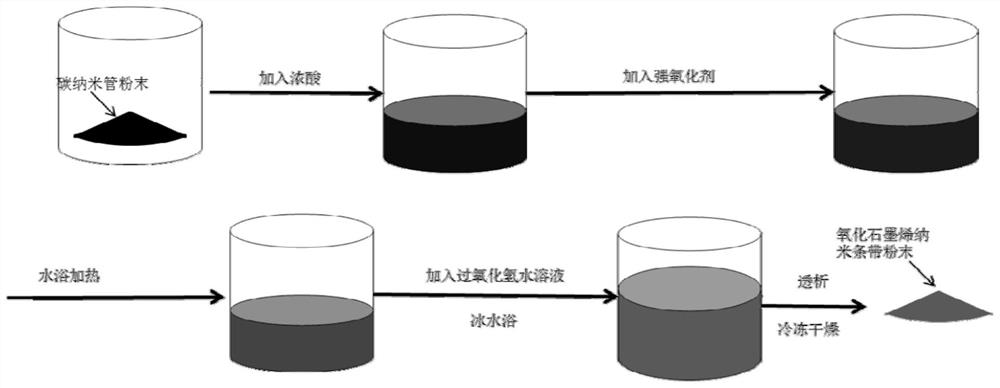

[0034] As an aspect of the technical solution of the present invention, what it relates to is a kind of preparation method of graphene nanoribbon material, and it comprises:

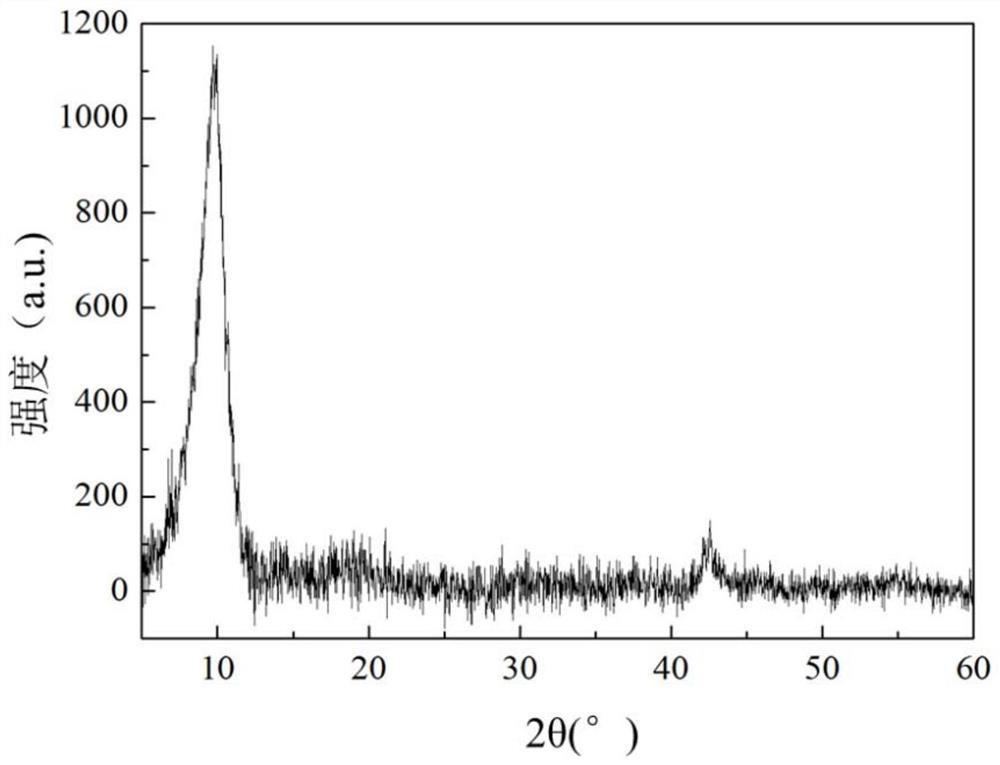

[0035] The carbon nanotubes are oxidized and stripped longitudinally by the Hummers method to form a graphene oxide nanoribbon solution;

[0036] Directional freeze-drying is performed on the graphene oxide nano-ribbon solution to obtain a structured and ordered flocculent graphene oxide nano-ribbon material.

[0037] In some embodiments, the preparation method includes: reacting a mixed reaction system comprising carbon nanotubes, concentrated sulfuric acid, phosphoric acid, and an oxidizing agent at 60-80° C. for 1-3 hours to form a graphene oxide nanoribbon solution.

[0038] Further, the preparation method specifically includes: adding carbon nanotubes into concentrated sulfuric acid and stirring for 1-3 hours, and then sequentially adding phosphoric acid and an oxidizing agent to form the mixed reac...

Embodiment 1

[0067] The preparation technology of graphene nano strip material in the present embodiment comprises the steps:

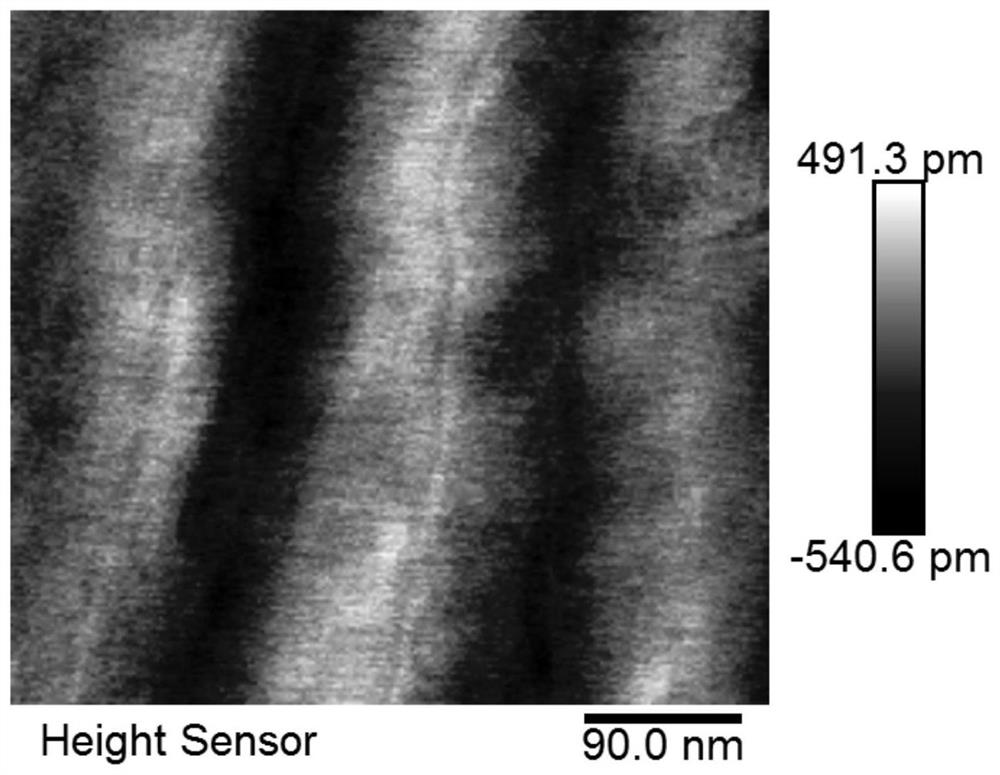

[0068] 1) Add 1 g of multi-walled carbon nanotubes (5-20 μm in length and 45 nm in average diameter) into 250 mL of concentrated sulfuric acid solution, stir at room temperature for 2 h; add 28 mL of phosphoric acid solution dropwise at a constant speed within 30 min, and add 6 g of potassium permanganate at 2 g / Add the mixed solution at a speed of h, and stir at room temperature for 1 hour; heat to 70°C and stir for 2 hours, then cool to room temperature naturally; slowly pour the mixed solution into 400 mL of 0.73% hydrogen peroxide solution in an ice-water bath, overnight; use 5 wt % hydrochloric acid solution for centrifugal washing and dialysis for 10 days.

[0069] 2) Sonicate the graphene oxide nanostrip solution obtained after dialysis for 1 hour, quickly immerse the 50mL needle tube with the built-in graphene oxide nanostrip solution in liquid nitrogen a...

Embodiment 2

[0072] The preparation technology of graphene nano strip material in the present embodiment comprises the steps:

[0073] 1) Add 1 g of multi-walled carbon nanotubes (5-20 μm in length and 45 nm in average diameter) into 250 mL of concentrated sulfuric acid solution, stir at room temperature for 2 h; add 28 mL of phosphoric acid solution dropwise at a constant speed within 30 min, and add 6 g of potassium permanganate at 2 g / Add the mixed solution at a speed of h, and stir at room temperature for 1 hour; heat to 70°C and stir for 2 hours, then cool to room temperature naturally; slowly pour the mixed solution into 400 mL of 0.73% hydrogen peroxide solution in an ice-water bath, overnight; use 5 wt % hydrochloric acid solution for centrifugal washing and dialysis for 10 days.

[0074] 2) Sonicate the graphene oxide nanostrip solution obtained after dialysis for 1 hour, and slowly immerse the 50mL needle tube with the built-in graphene oxide nanostrip solution in liquid nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com