A kind of composite solid electrolyte and its preparation method and application

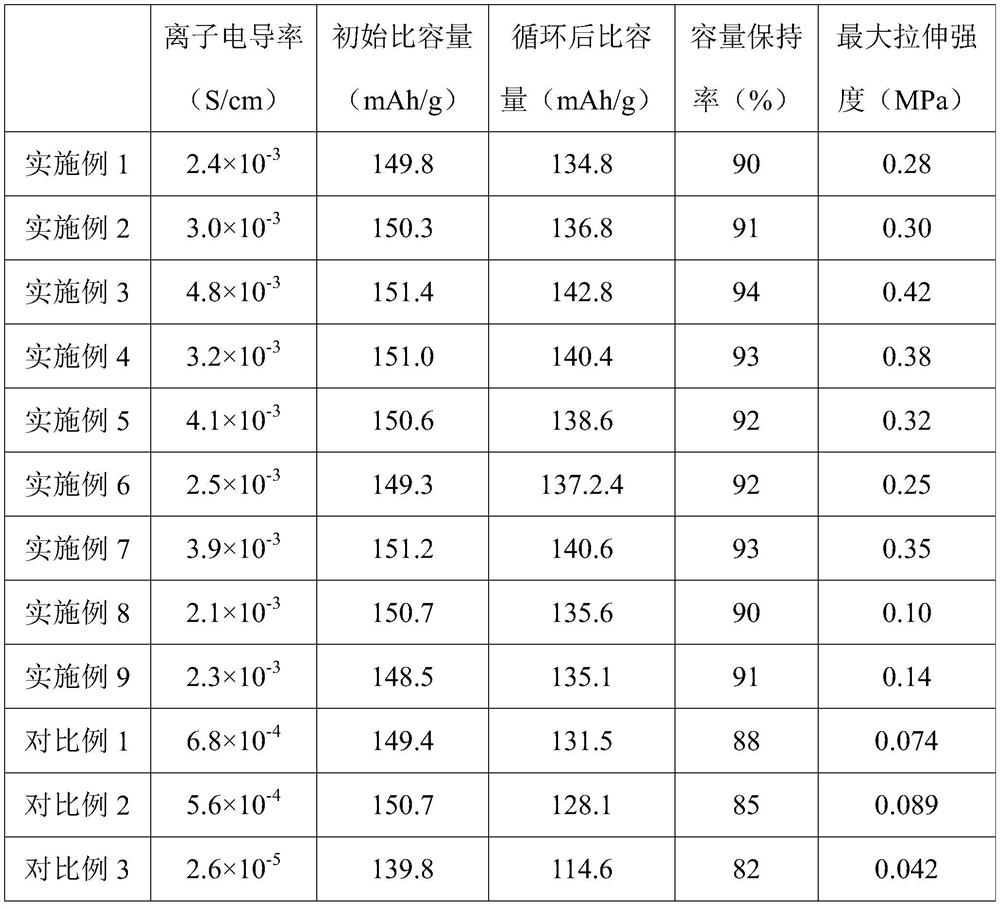

A technology of solid electrolytes and composites, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of limited performance improvement of solid electrolytes, achieve excellent lithium ion transmission performance, cycle stability, good compatibility, The effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment provides a composite solid electrolyte, which consists of the following components according to parts by weight: 50 parts of polyethylene oxide (purchased from Shanghai McLean Biochemical Technology Co., Ltd., trade name 68441-17-8), lithium 10 parts of salt (LiClO with a mass ratio of 1:1:1 4 , LiPF 6 and LiAsF 6 ), 5 parts of plasticizer (succinonitrile) and 10 parts of 2D flake inorganic matter (the mass ratio of MXene to AlOOH is 1:0.15).

[0066] The preparation method of the above-mentioned composite solid electrolyte comprises the following steps:

[0067] (1) Synthesis of MXene-AlOOH: Al(NO) with a molar ratio of 18:1 3 ) 3 ·9H 2 O and urea were dissolved in water respectively, and the two were mixed after magnetic stirring uniformly. 3 ) 3 ·9H 2 The concentration of O was 0.5 mmol / L, and then MXene (Nb with a mass ratio of 1:1 was added) 2 C and Nb 4 C 3 ), where Al(NO 3 ) 3 ·9H 2 The mass ratio of O to MXene was 0.94:1, ultrasonic...

Embodiment 2

[0070] This embodiment provides a composite solid-state electrolyte, which consists of the following components according to parts by weight: 55 parts of polyethylene oxide (purchased from Shanghai McLean Biochemical Technology Co., Ltd., trade name 68441-17-8), lithium 15 parts of salt (LiBF with a mass ratio of 2:1:1:2:1 4 , LiFSI, LiBC 4 O 8 , LiN (CF 3 SO 2 ) 2 and LiBF 2 C 2 O 4 ), 8 parts of plasticizer (polyethylene glycol, purchased from Shanghai McLean Biochemical Technology Co., Ltd., trade name 25322-68-3) and 15 parts of 2D flaky inorganic substances (the mass ratio of MXene to AlOOH is 1:3 ).

[0071] The preparation method of the above-mentioned composite solid electrolyte comprises the following steps:

[0072] (1) AlCl with a molar ratio of 22:1 3 and urea were dissolved in water respectively, and the two were mixed after magnetic stirring, and the prepared AlCl 3 The concentration of the 2 C. Ti 3 CN, Ta 4 C 3 and V 2 C), wherein, AlCl 3 The m...

Embodiment 3

[0075] This embodiment provides a composite solid electrolyte, which consists of the following components according to parts by weight: 50 parts of polyethylene oxide (purchased from Shanghai McLean Biochemical Technology Co., Ltd., trade name 68441-17-8), lithium 20 parts of salt (LiTFSI), 10 parts of plasticizer (succinonitrile) and 20 parts of 2D flake inorganic matter (the mass ratio of MXene to AlOOH is 1:0.25).

[0076] The preparation method of the above-mentioned composite solid electrolyte comprises the following steps:

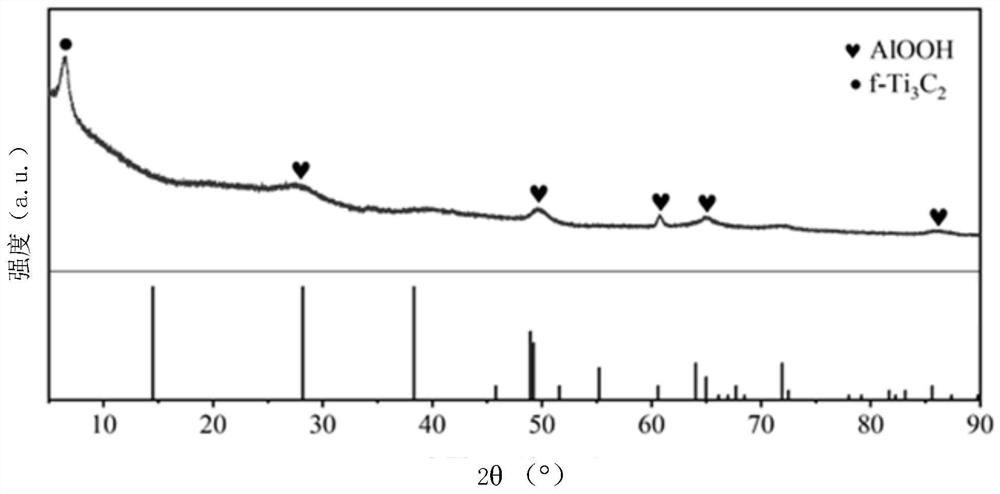

[0077] (1) Synthesis of MXene-AlOOH: Al with a molar ratio of 20:1 2 (SO 4 ) 3 ·18H 2 O and urea were dissolved in water respectively, and the two were mixed after magnetic stirring. 2 (SO 4 ) 3 ·18H 2 The concentration of O was 1 mmol / L, and then MXene (f-Ti 3 C 2 , few-layer titanium carbide, purchased from Shandong Xiyan New Material Technology Co., Ltd.), in which Al 2 (SO 4 ) 3 ·18H 2 The mass ratio of O to MXene was 1.39:1, ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com