Patents

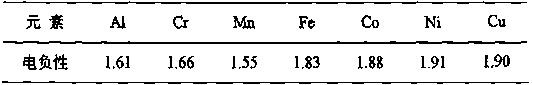

Literature

43results about How to "Reduced activation energy for diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

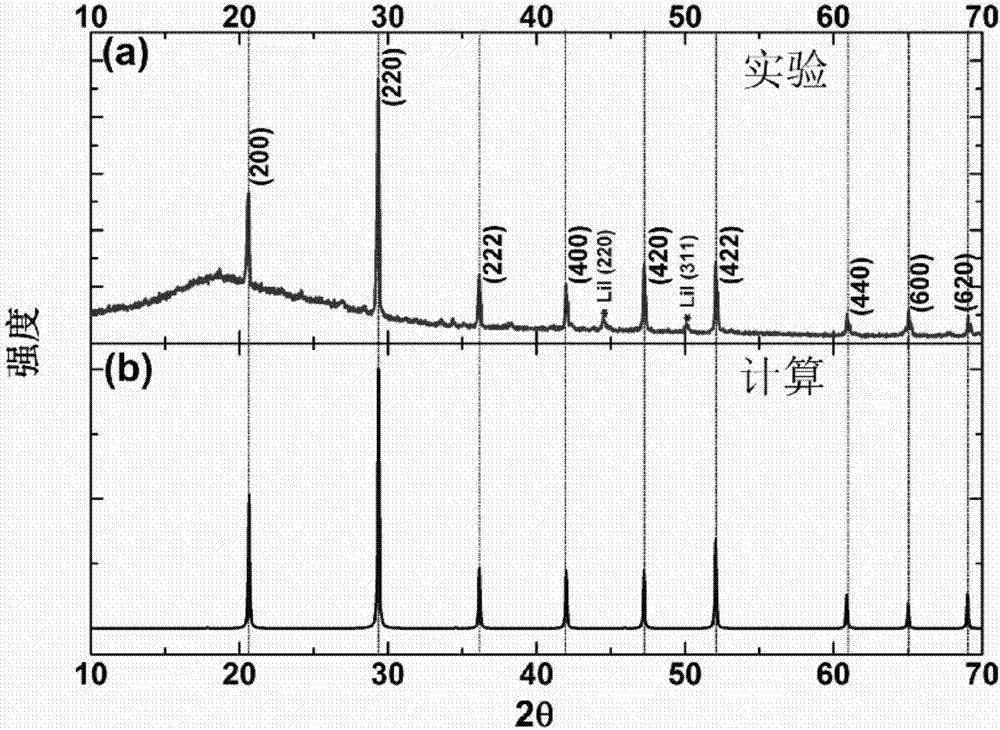

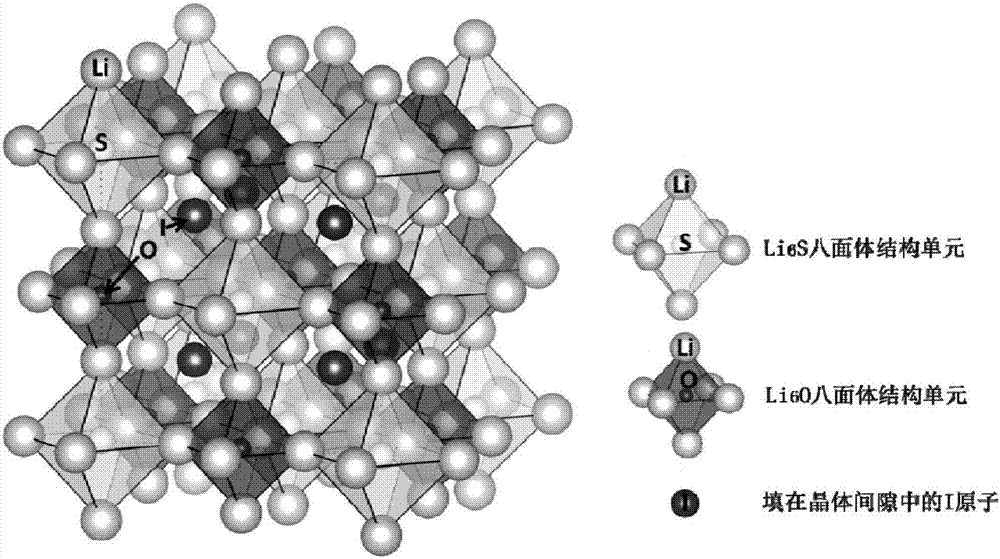

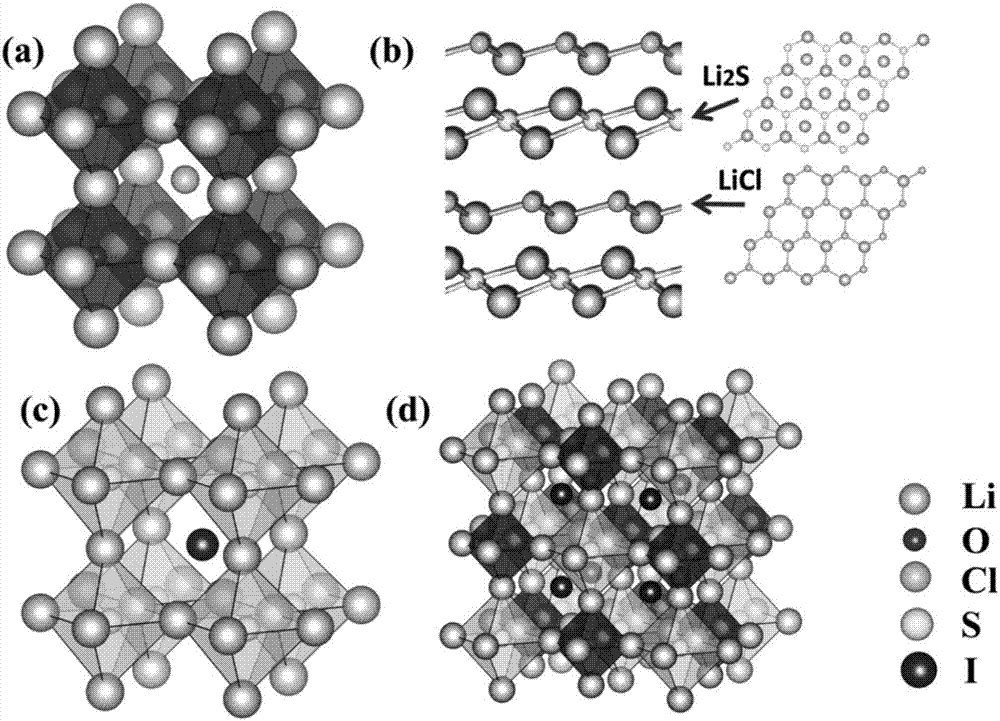

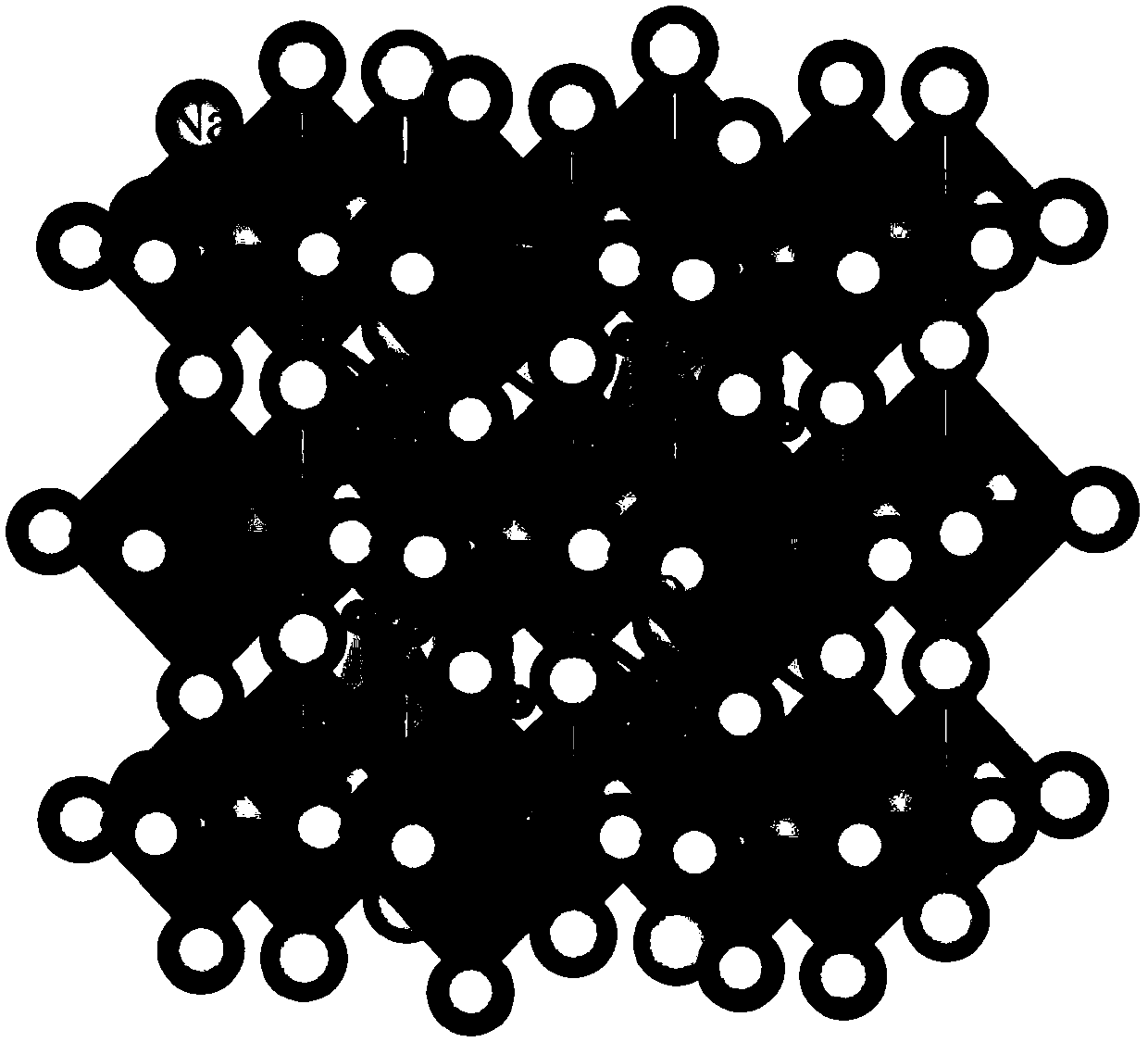

Lithium ion solid electrolyte and preparation method and application thereof

ActiveCN107425218AExcellent lithium ion conductivityHigh thermodynamic stabilityCell electrodesSecondary cellsHalogenPhysical chemistry

The invention relates to a lithium ion solid electrolyte and a preparation method application thereof, and belongs to the technical field of a lithium ion battery. The lithium ion solid electrolyte has the chemical formula shown as follows: Li<3+a>MA<m>B<n>Y<1-b>, wherein a is more than or equal to -0.25 but less than or equal to 0.25, b is more than or equal to 0 but less than or equal to 0.5, m is more than or equal to 0 but less than or equal to 1.25, n is more than or equal to 0 but less than or equal to 1.25, M is one of Ca, Ba, Mg, Al and Ti, A and B are separately selected from one of O, S, Se, Te, N, P, Si, C, Sb, Bi, F, Cl, Br and I, and Y is one of halogen, minus monovalent ionic group or vacancy. The lithium ion solid electrolyte has a stable structure and favorable lithium ion transmission performance and has favorable electrochemical performance and safety performance when used as a solid electrolyte of the lithium ion battery.

Owner:ZHENGZHOU NEW CENTURY MATERIALS GENOME INST CO LTD

Method for vacuum scattering intermetallic compound for coupling TiAL

InactiveCN101176946AImprove diffusion abilityGood removal effectNon-electric welding apparatusBeta phaseThermal deformation

The invention relates to a TiAl-intermetallic-compound vacuum diffusing connection method, belonging to the TiAl-intermetallic-compound welding field, which overcomes the technical drawbacks of high temperature of diffusing connection and high pressure of diffusing connection in the prior TiAl-intermetallic-compound diffusing connection technology. The invention adopts hydrogenated titanium or titanium alloy chaff as the interface layer of diffusing connection. Ti3Al+TiAl dual phase (Alpha2+Gamma) organ can be formed under the temperature of diffusing connection titanium, which facilitates the formation of high-intensity connector lug of TiAl-intermetallic-compound diffusing connection. And hydrogen makes the flow stress of thermal deformation of titanium or titanium alloy decrease and the thermal plasticity increase, so that hydrogenated titanium or titanium alloy is prone to deform under high temperature. Meanwhile,, the self-diffusing capacity of hydrogen in titanium or titanium alloy and the diffusing capacity of solute are enhanced, more particularly, in Beta phase the capacities are more enhanced, so that hydrogen can accelerate the diffusing of the alloy elements, reduce the atomic combination energy and the diffusing activation energy, promote the diffusing coordinated deformation capacity, and the reliable diffusing connection of connector lug of TiAl-intermetallic-compound can be realized under comparatively low temperature.

Owner:HARBIN INST OF TECH

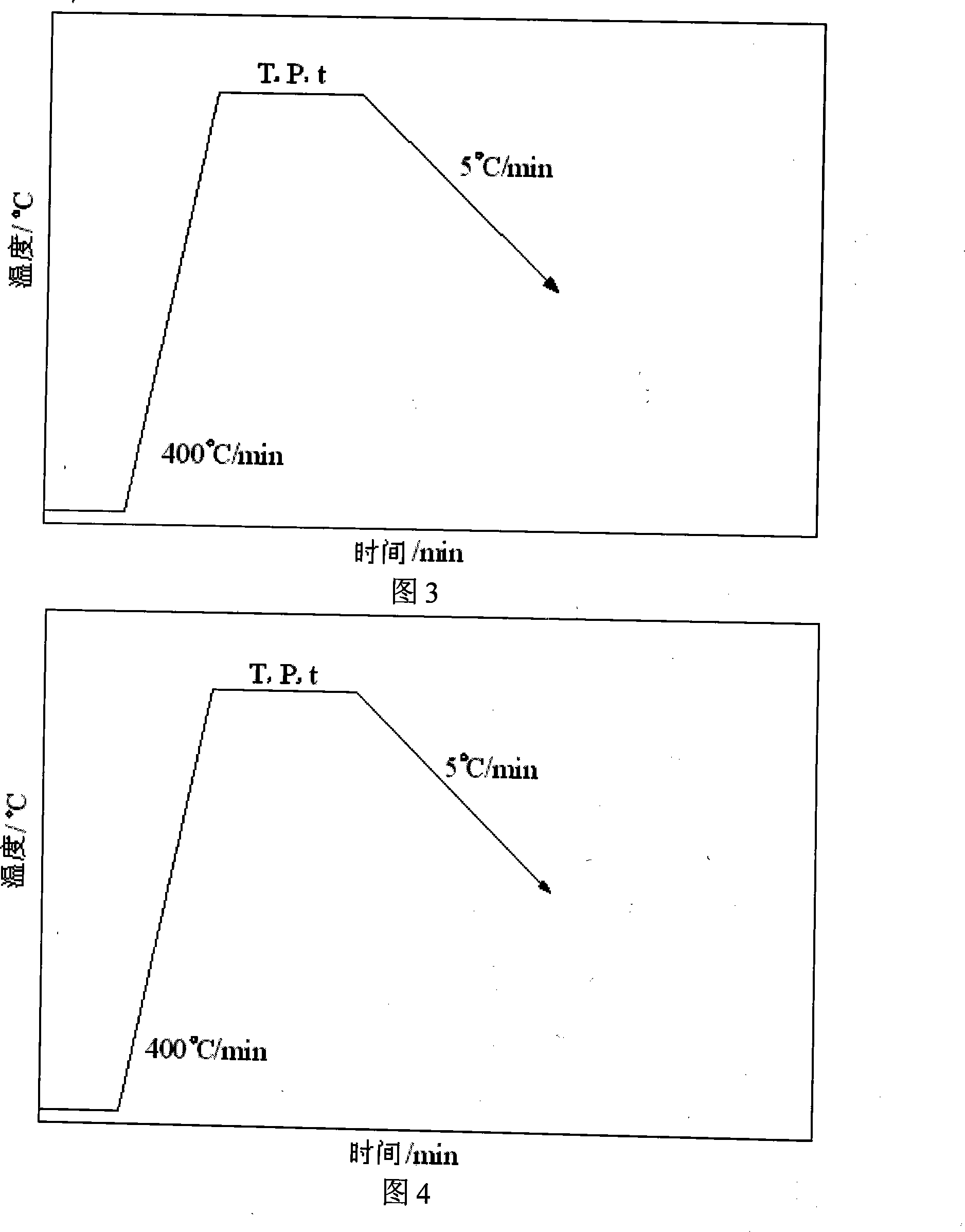

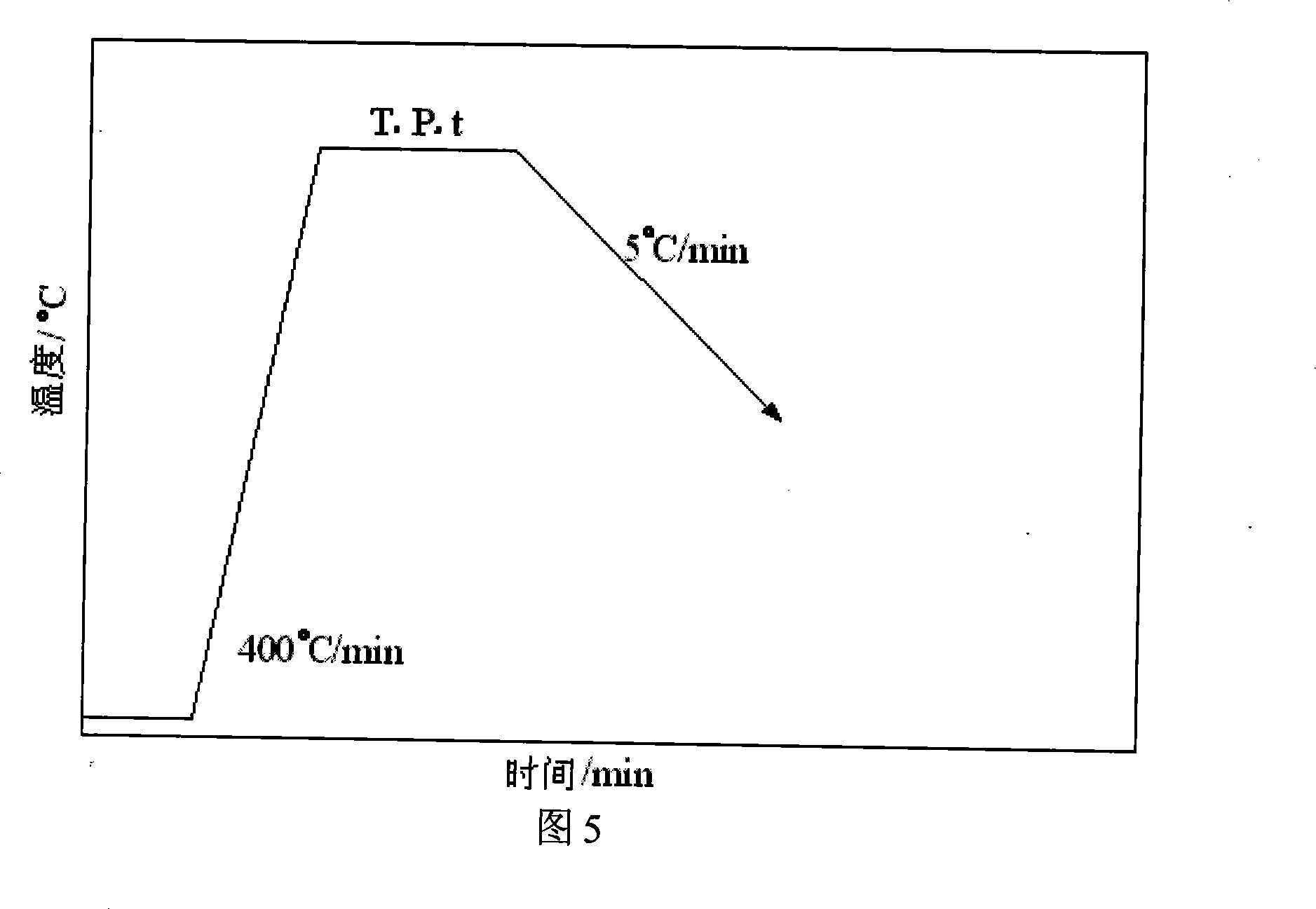

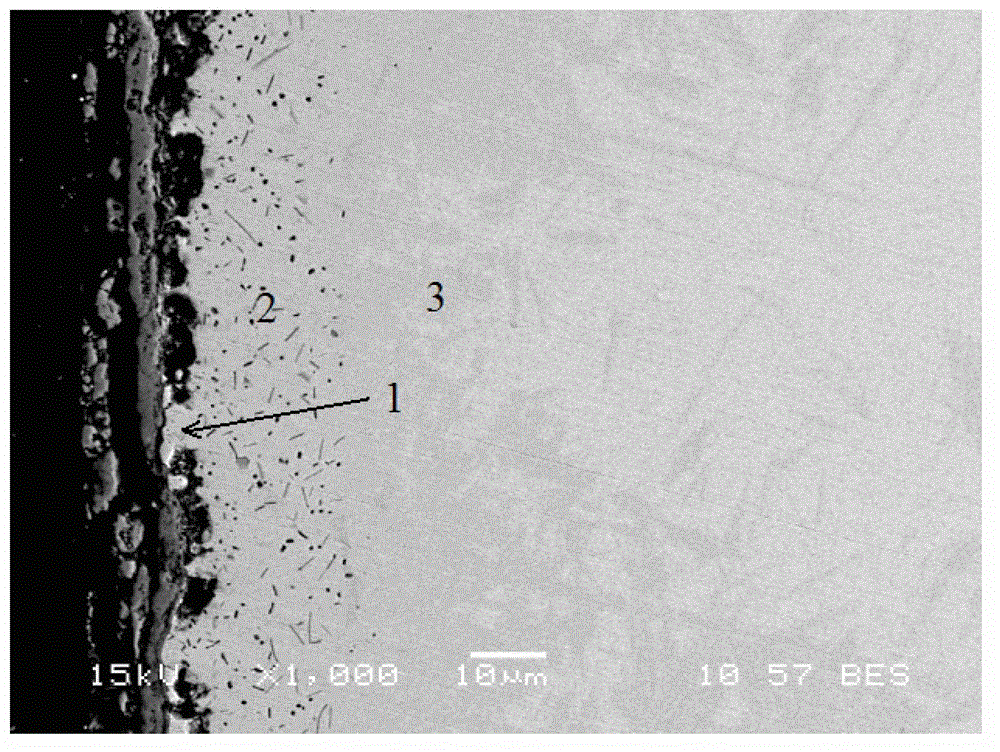

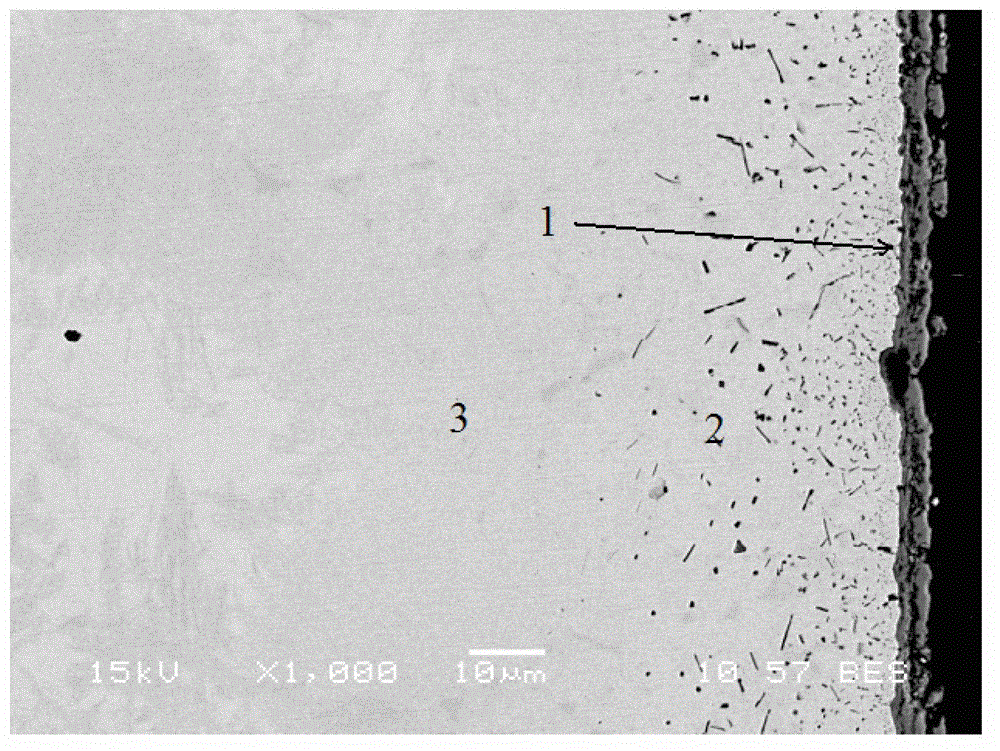

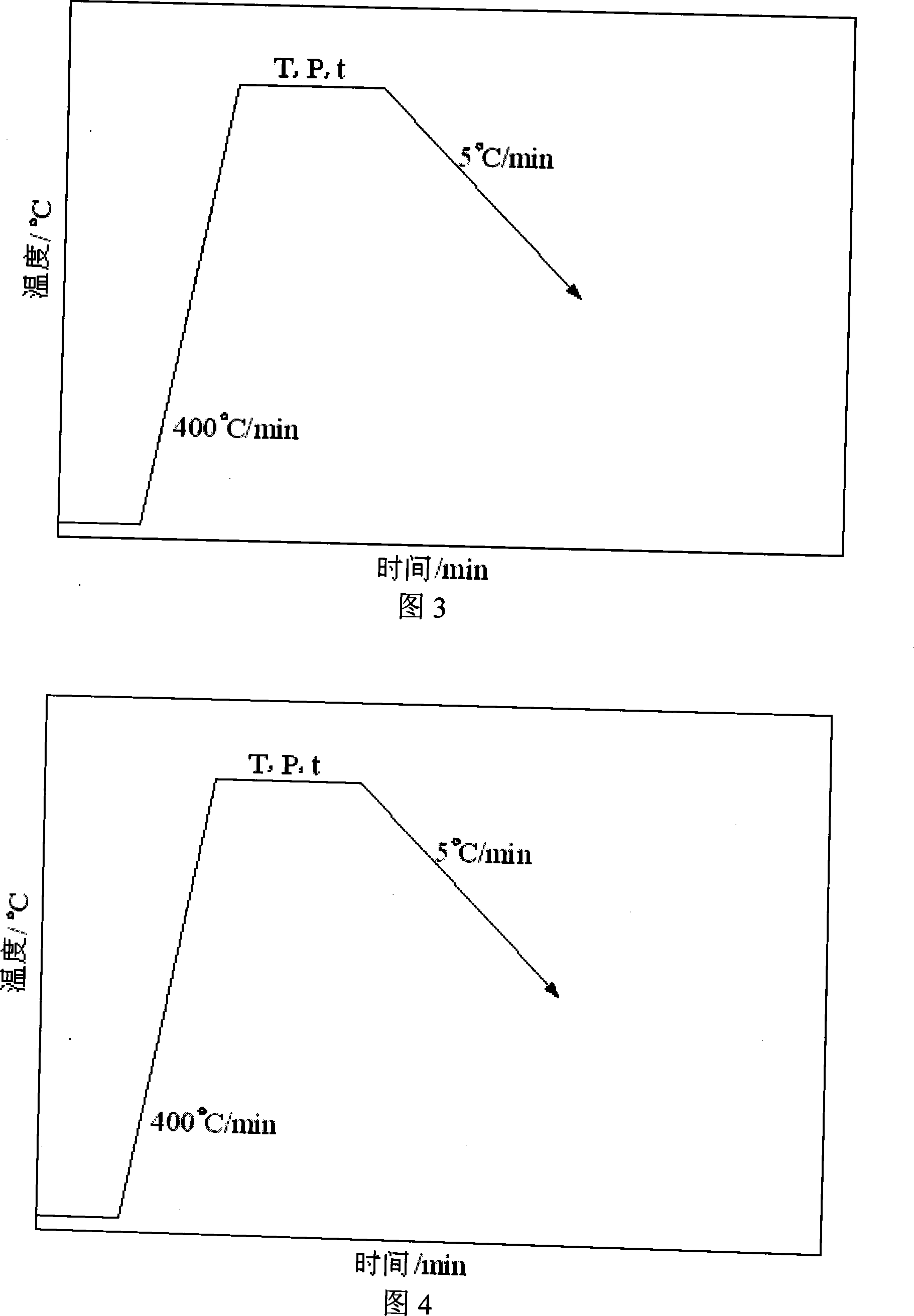

Method for carrying out anatonosis by adopting laser plasma impact wave in chemical heat treatment process

InactiveCN102978628AReduced activation energy for diffusionImprove diffusion efficiencyCorrosion resistantMaterials science

The invention relates to a method for carrying out anatonosis by adopting laser plasma impact waves in a chemical heat treatment process. According to the method, induction to generate plasma impact waves are generated by induction with high-power short-pulse laser, act on materials and are combined with chemical heat treatment, thereby improving the surface property of metal materials and members and enhancing the oxidation resistance, abrasion resistance and corrosion resistance of the metal material and the members, wherein the chemical heat treatment can be alumetizing, carburization, nitridation, aluminum-chromium penetration and the like. The method disclosed by the invention has the beneficial effects that the temperature of the chemical heat treatment in order to obtain identical penetration layer depth, the temperature of the chemical heat treatment can be obviously reduced, and the treatment time is shortened, thereby reducing the deformation of workpieces.

Owner:AIR FORCE UNIV PLA

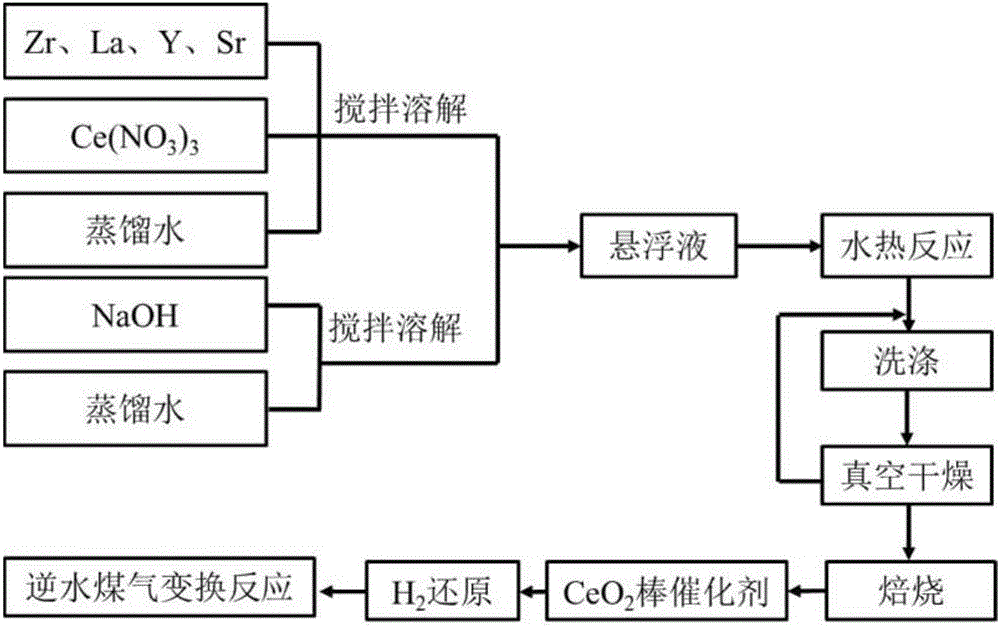

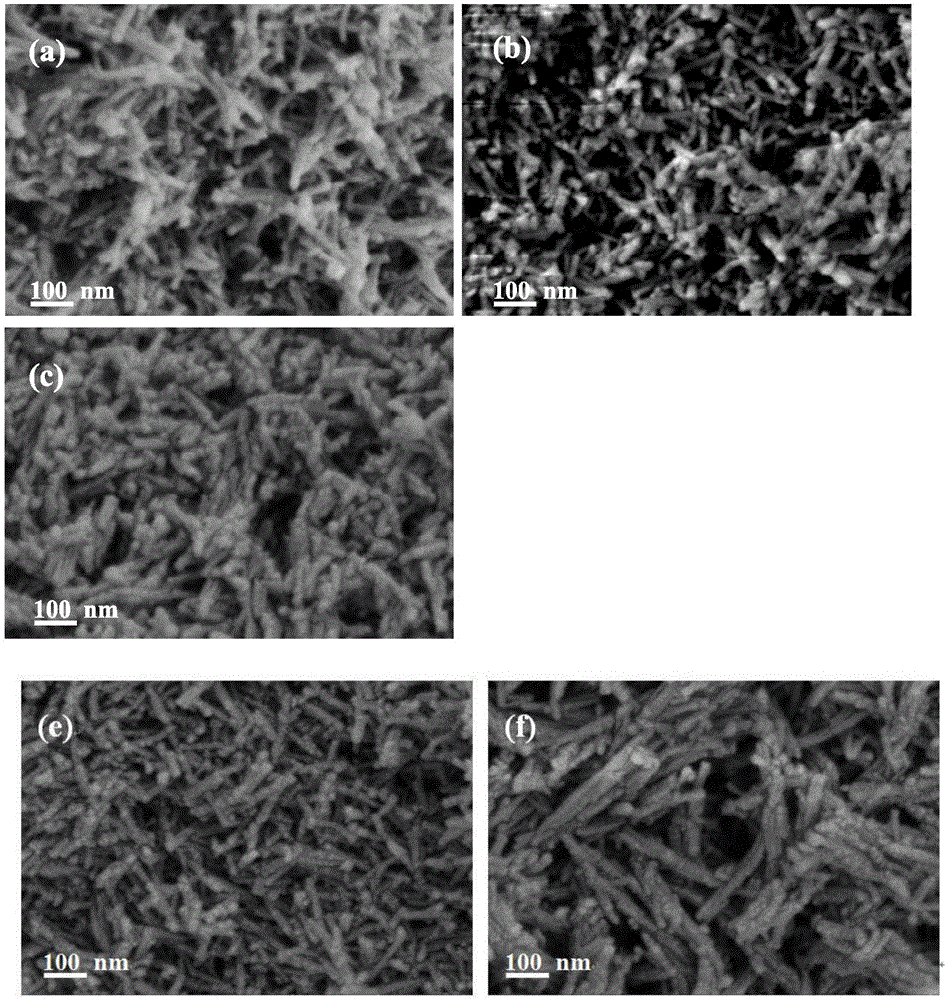

Modified CeO2 nanorod-doped catalyst and application thereof

ActiveCN106492778AMaximize the catalytic effectGood conversion response performanceCombustible gas catalytic treatmentMetal/metal-oxides/metal-hydroxide catalystsWater-gas shift reactionHydrothermal synthesis

The invention discloses a modified CeO2 nanorod-doped catalyst and application thereof. The catalyst is composed of CeO2 nanorod and modified metallic element which is doped thereon by in-situ hydrothermal synthesis. The CeO2 nanorod is exposed to (110) and (100) crystal faces. The modified metallic element is Zr, La, Y or Sr. As different morphologies of nano-CeO2 are exposed to different crystal faces, different surface characteristics and catalytic characteristics will be shown. Reverse water gas shift reaction of CeO2 nanorod exposed to the (110) and (100) crystal faces is the best. With the rod-like nano-CeO2, catalytic action of the catalyst can be performed to the greatest extent.

Owner:HUAQIAO UNIVERSITY

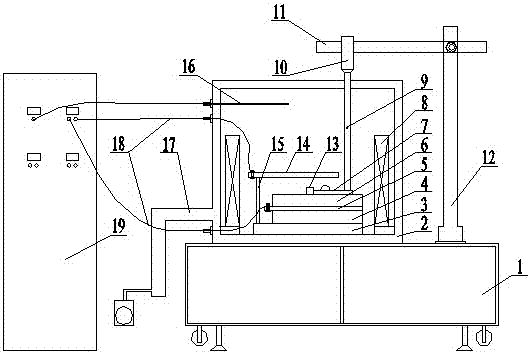

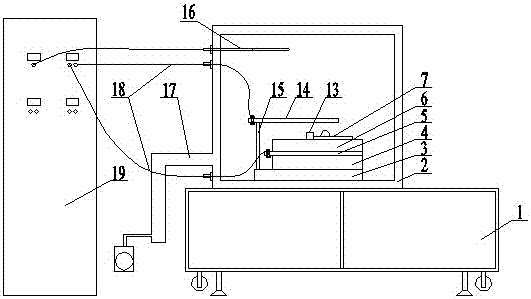

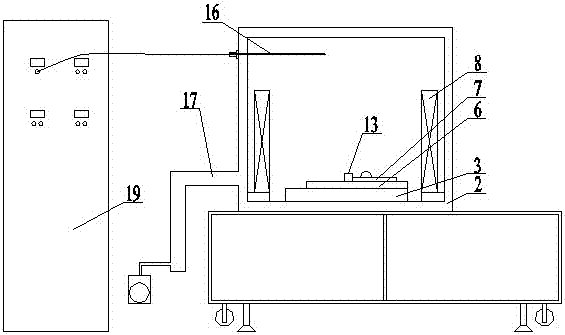

Material wettability improvement device and method based on multi-field coupling

ActiveCN107052494AImprove wettabilityWay to overcomeMuffle furnacesPreparing sample for investigationEngineeringMechanical engineering

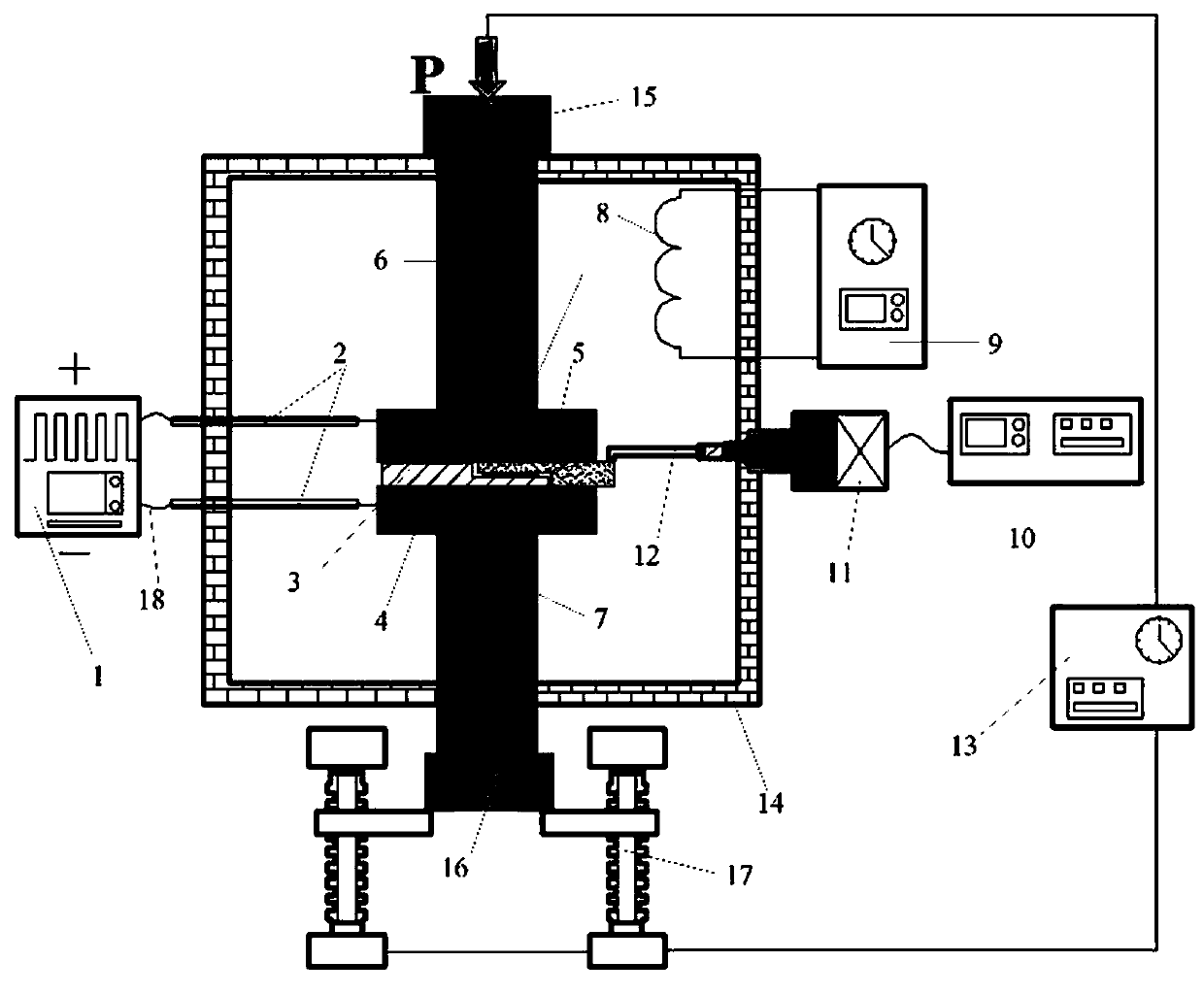

The invention provides a material wettability improvement device and method based on multi-field coupling. The material wettability improvement device comprises an operation platform, a vacuum furnace stored on the operation platform, a high-voltage power supply control box, an ultrasonic auxiliary device, an electric field auxiliary device and a magnetic field auxiliary device. A rack on one side of the vacuum furnace is provided with a guide rail stand column. The upper end of the guide rail stand column is provided with a movable cross beam. An ultrasonic transducer is fixed to the cross beam. An ultrasonic variable-pressure rod stretches into the vacuum furnace through a corrugated pipe. The electric field auxiliary device is arranged below the ultrasonic variable-pressure rod. A sample is stored on an insulating ceramic plate and positioned through a stop block. The inner side of the vacuum furnace is further provided with a magnetic field power coil which generates a variable magnetic field after being applied with current. By adoption of the material wettability improvement device and method, the sample can be wetted under mutual assistance of an ultrasonic vibration load, an electric field and the magnetic field, and the problems that existing additionally arranged auxiliary equipment is simplex in applying mode, the ultrasonic applying mode is large in power loss, and simplex assistance is unobvious in sample wettability improvement effect are solved.

Owner:HENAN UNIV OF SCI & TECH

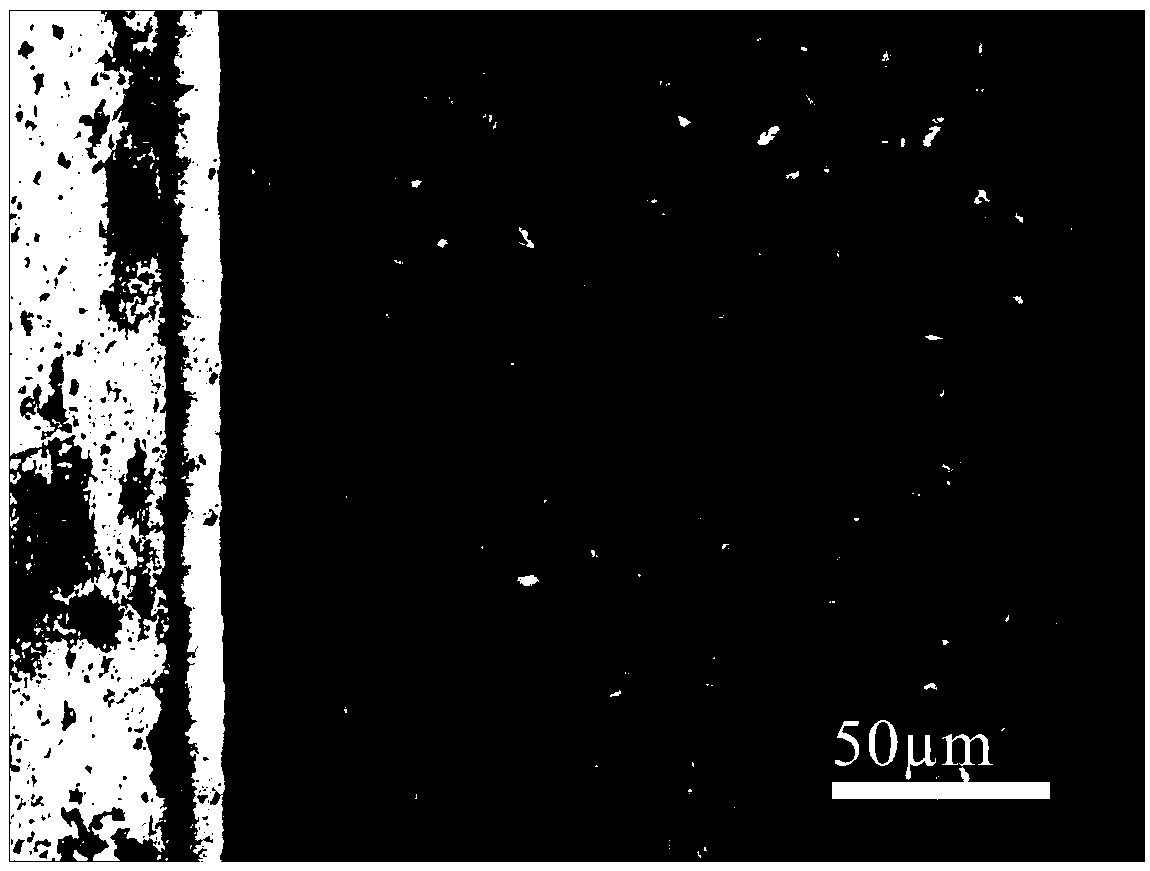

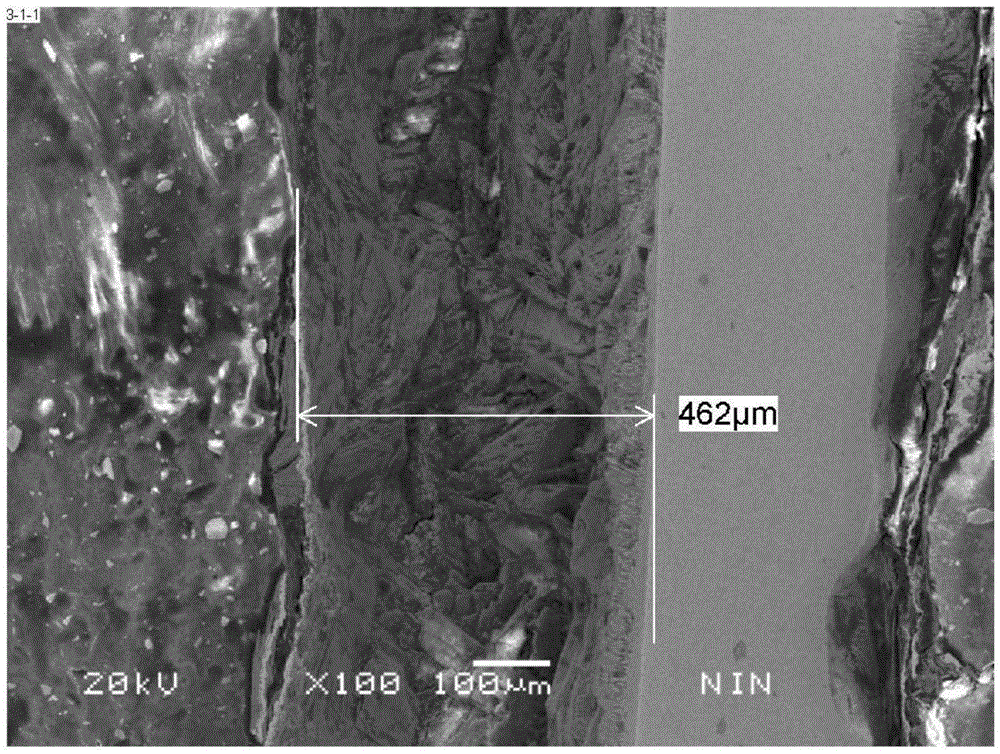

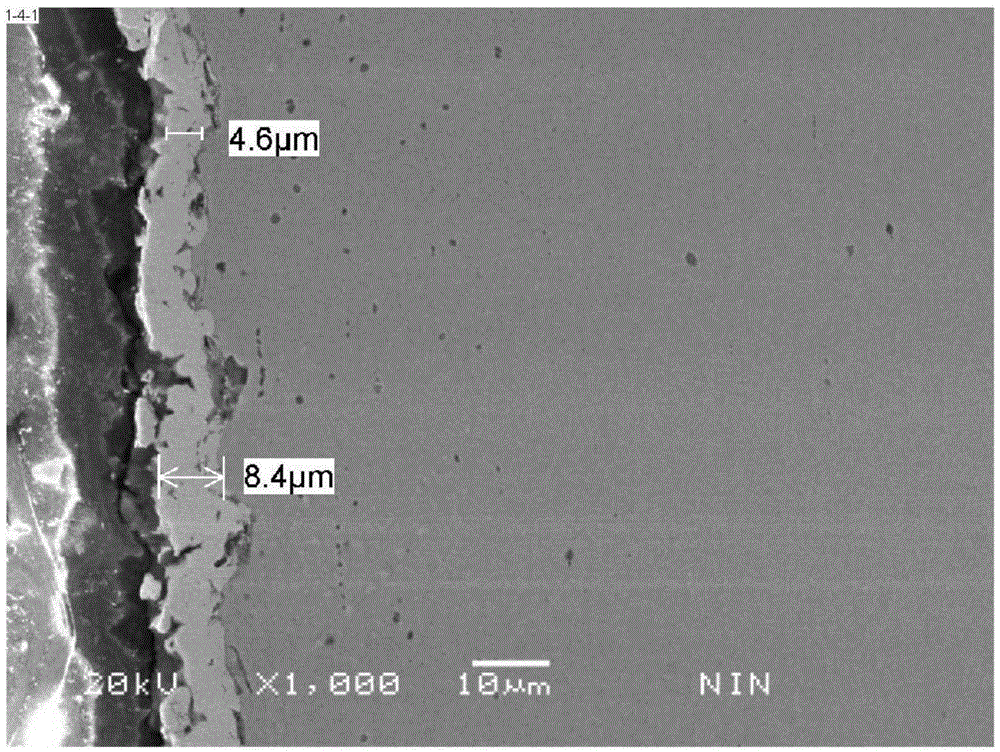

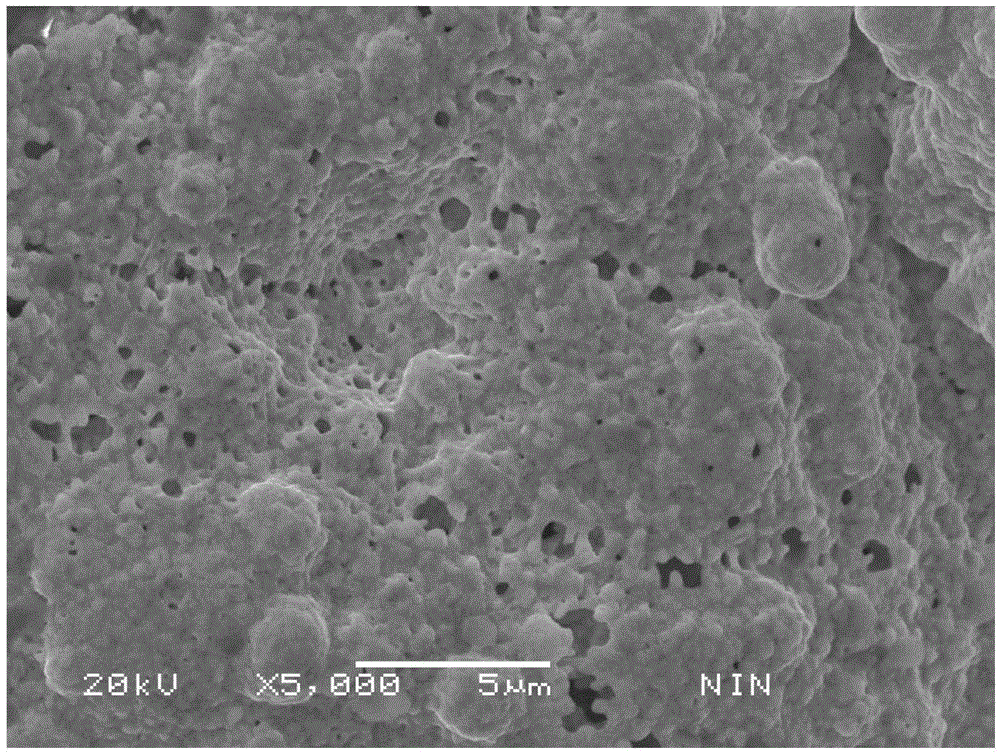

Laser shock technology for improving ion nitriding efficiency

InactiveCN108441625AIncrease infiltration concentrationImprove the unevenness of the seepage layerSolid state diffusion coatingDislocationIon

The invention relates to a laser shock technology for improving the ion nitriding efficiency. The technology comprises the following steps: processing and cutting raw steel to form a sample; quenchingand tempering the sample, polishing the sample, ultrasonically cleaning the polished sample in an organic solvent, and drying the cleaned sample; clamping the sample to a laser shock peening test platform, and performing laser shock treatment on the surface; and placing the sample in an ion nitriding furnace, performing ion nitriding treatment, and performing furnace cooling to room temperature.The technology has the following advantages: laser shock treatment causes plastic deformation of the surface layer of a material to form high density dislocations, refine crystal grains and even generate nanocrystals, so diffusion channels are provided for nitrogen atom diffusion, and the diffusion activation energy is reduced, thereby the technology significantly increases the nitriding efficiency, and has the advantages of high efficiency and energy saving.

Owner:CHANGZHOU UNIV

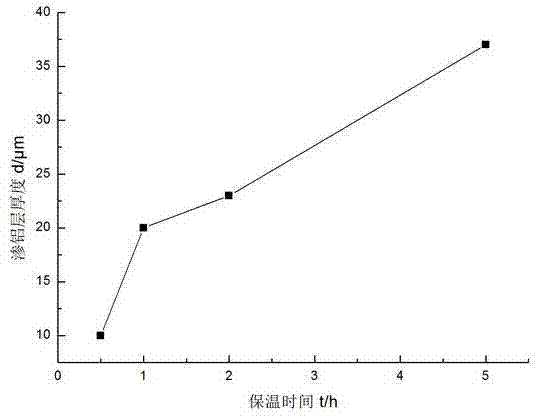

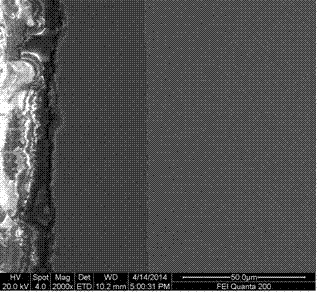

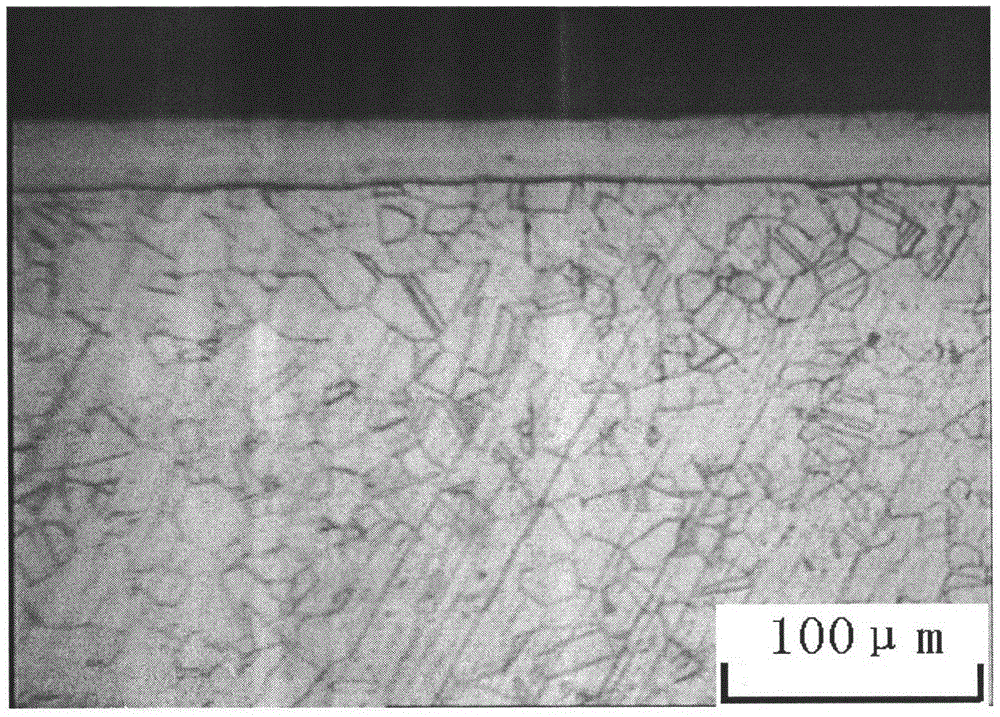

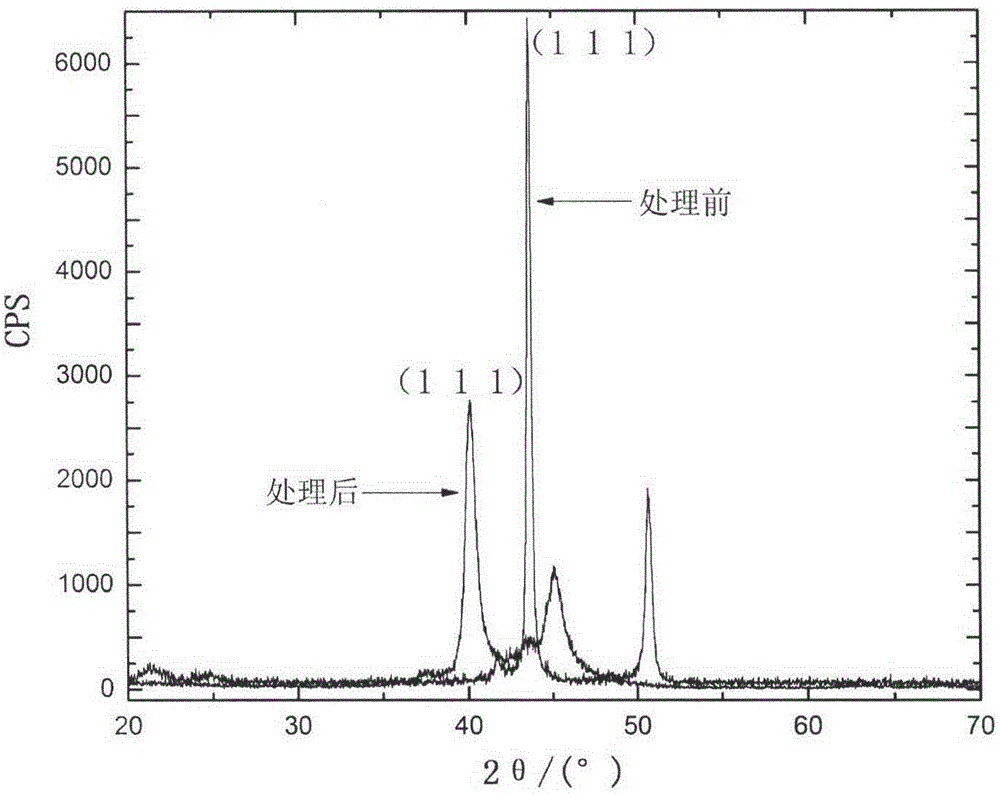

Low-temperature oil casing steel surface pack cementation aluminizing technique

InactiveCN101775575AAvoid problemsLower activation energySolid state diffusion coatingAl powderSurface layer

The invention relates to a metal surface aluminizing technique, in particular to a low-temperature oil casing steel surface pack cementation aluminizing technique. The invention at least solves the following problems that: the complex change of the variety and content of aluminizing agent in the aluminizing technique needs to be reduced by changing aluminizing agent, the property stability can hardly be controlled, and the cost is high. The adopted technical scheme is as follows: the low-temperature oil casing steel surface pack cementation aluminizing technique sequentially includes the following steps that: the surface nanocrystallization of an oil casing steel sample: a SNC-2 metal surface nanocrystallization tester is utilized to nanocrystallize the surface of the oil casing steel sample in order to obtain a nano-structured surface layer with the thickness of 50Mu m to 90Mu m; the aluminization of the surface-nanocrystallized oil casing steel sample: aluminizing process parameters are as follows: the aluminizing temperature is 380 DEG C to 500 DEG C, and the aluminizing time is 6 hours to 10 hours; and the composition and content of the aluminizing agent are as follows: Al powder as metal source, Zn powder, NH4CL as activating agent and Al2O3 as filler. The aluminizing temperature is low; the variety of aluminizing agent is simple, the content can be easily controlled, and the process stability is high; and the effect is good.

Owner:XI'AN PETROLEUM UNIVERSITY

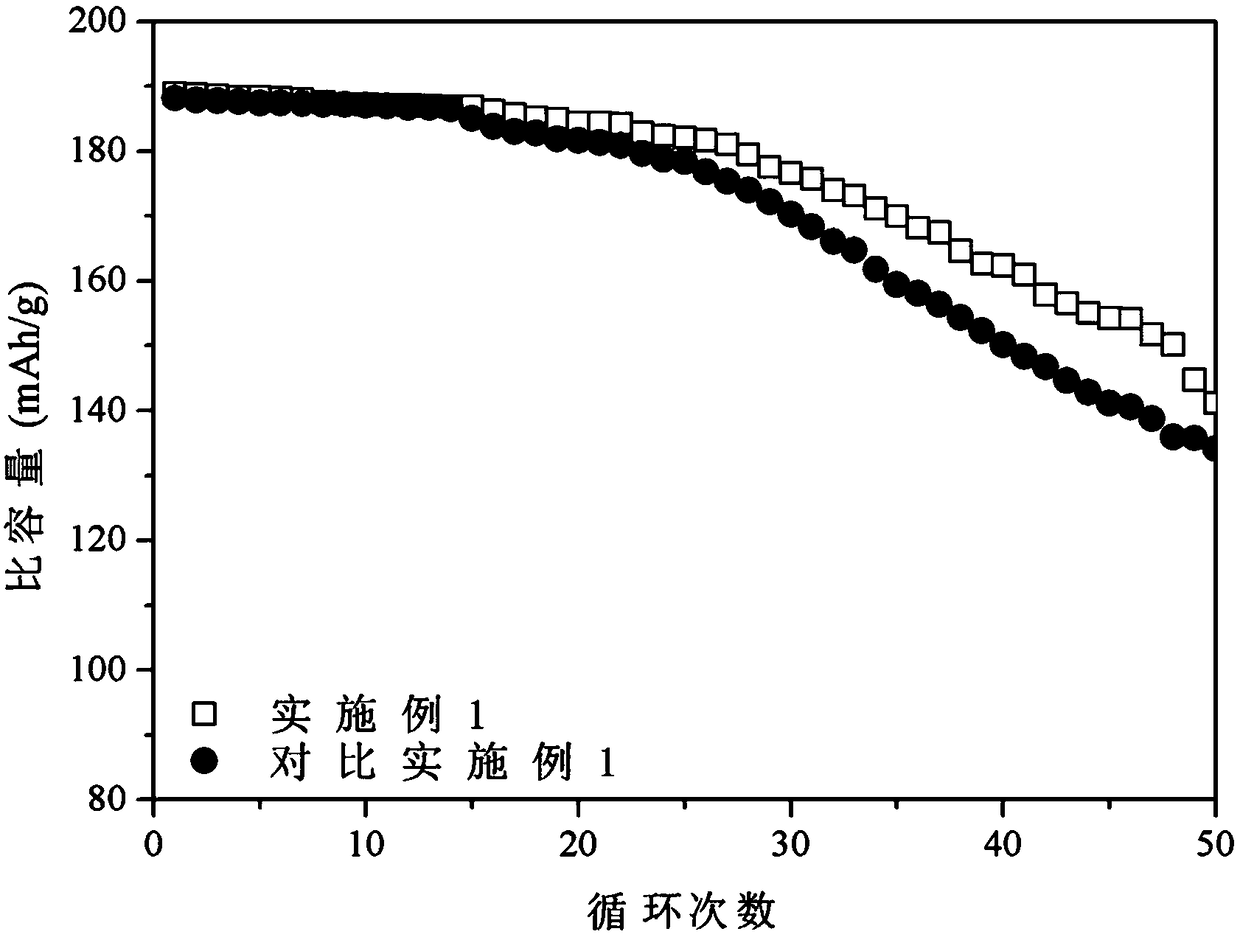

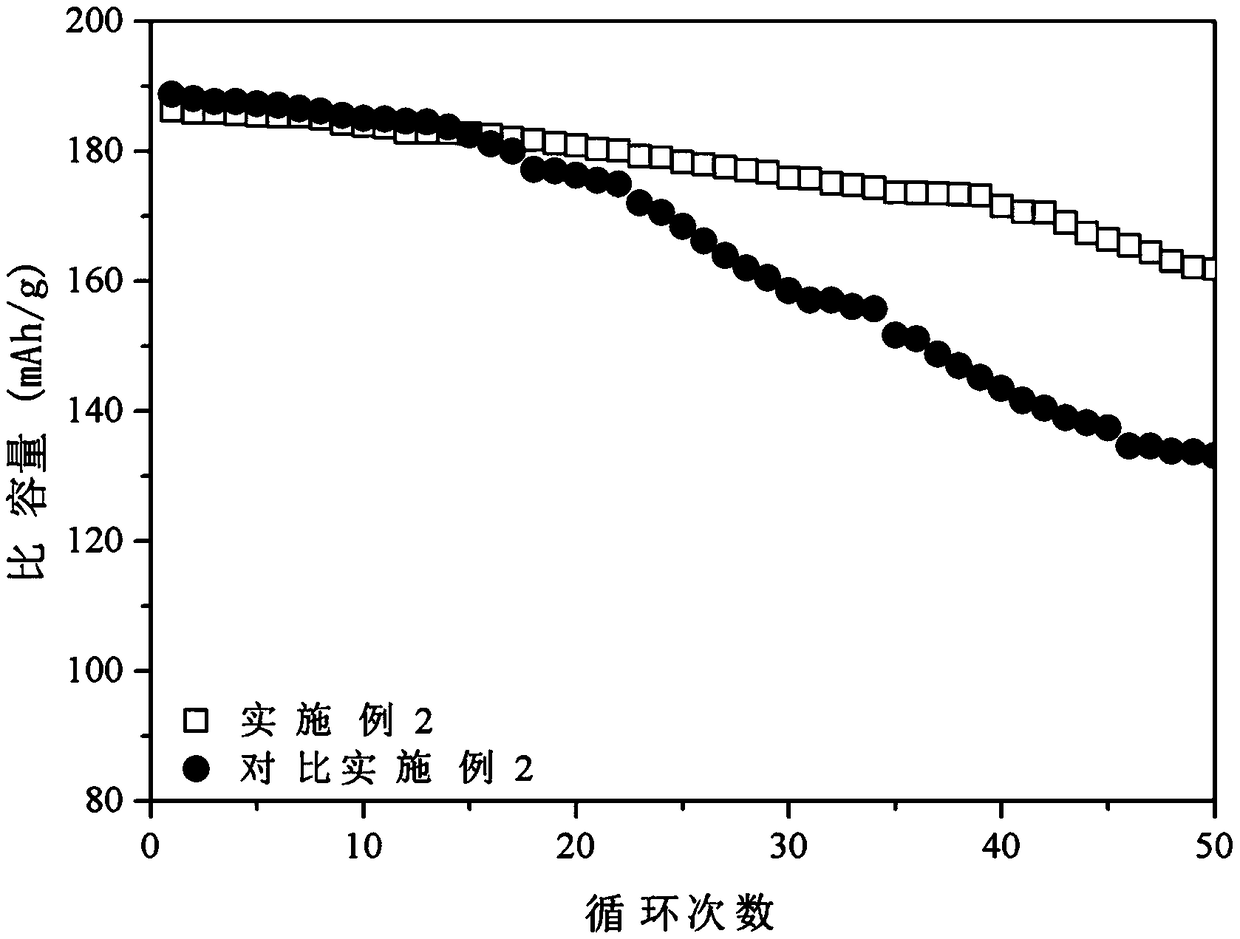

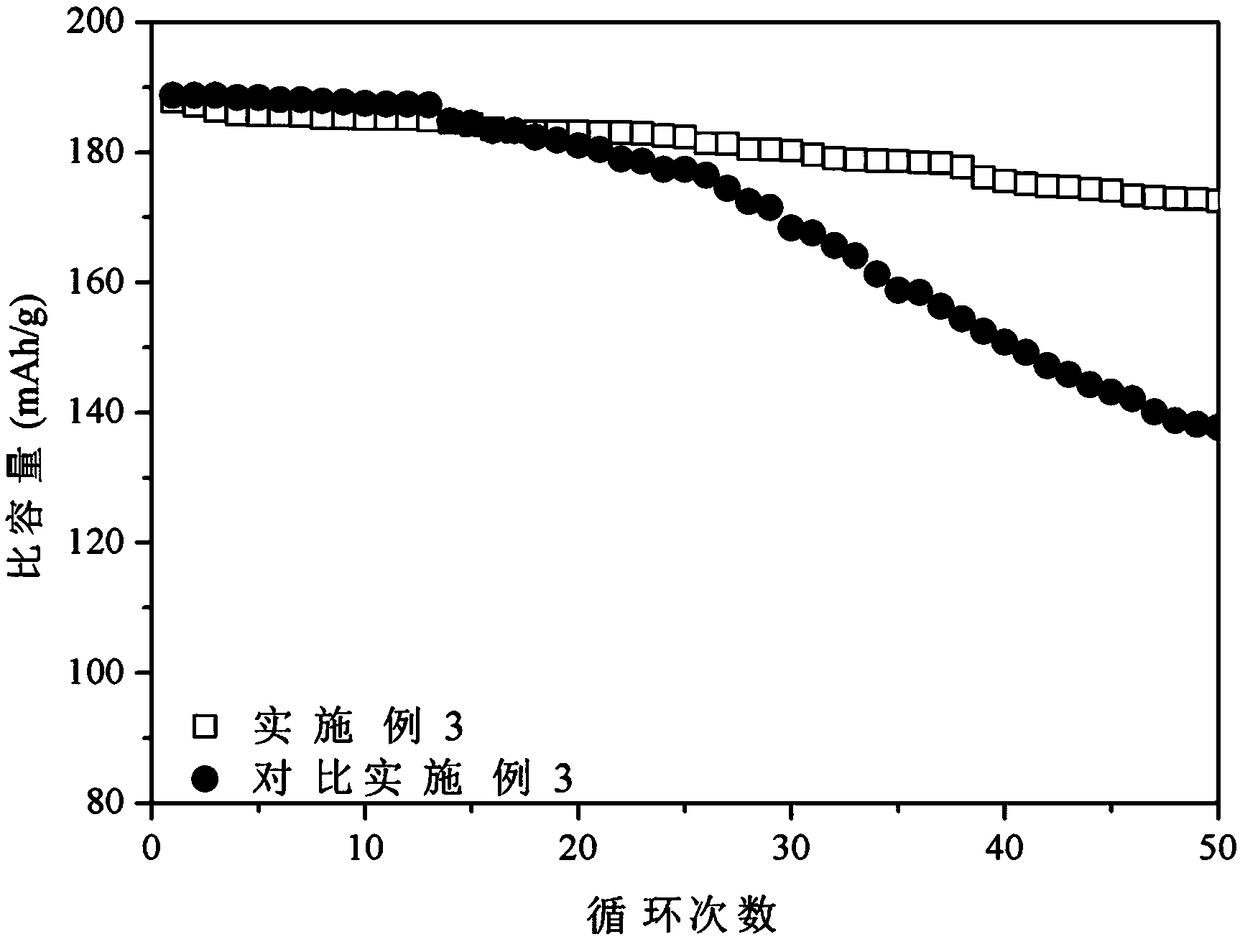

Nickel-cobalt lithium aluminate material coated with sodium-based oxidizing agent and preparation method thereof

ActiveCN108695506AFacilitate de-intercalationReduced activation energy for diffusionCell electrodesSecondary cellsLithium aluminateSodium antimonate

The invention discloses a nickel-cobalt lithium aluminate material coated with a sodium-based oxidizing agent and a preparation method thereof. According to the method, the surface of the nickel-cobalt lithium aluminate material is coated with a layer of sodium-based oxidizing agent, the sodium-based oxidizing agent is one or more of sodium peroxide, sodium bismuthate and sodium antimonate and hasstrong oxidability, in the sintering process, the oxidizing agent is partially diffused into crystal nuclei of the material, the oxidation of Ni<2+> is promoted, the lithium-nickel synchysis is reduced, a coating layer with a proper thickness is formed on the surface of the material by other part of the oxidizing agent, the material is prevented from being corroded by electrolyte in the chargingand discharging processes, and the cycling stability of the material is improved.

Owner:SHAANXI COAL & CHEM TECH INST

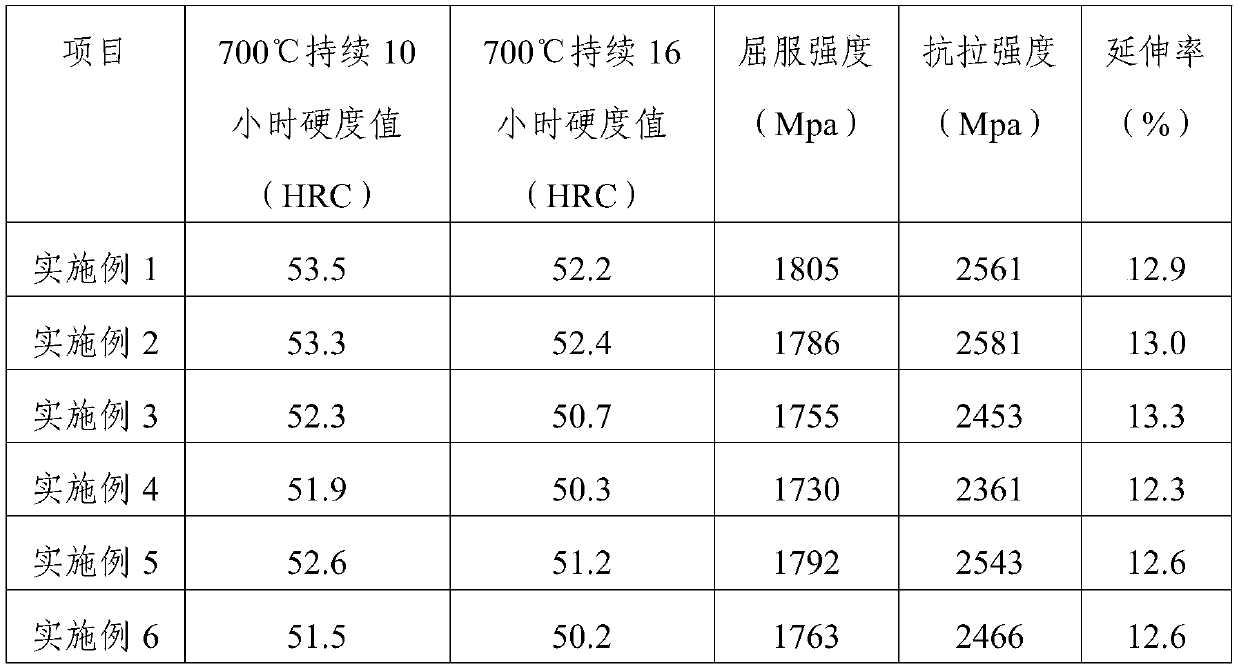

Manufacturing process of hot work die steel for high performance die-casting die

InactiveCN111057933ATissue uniform refinementHigh strengthSolid state diffusion coatingFurnace typesTemperingManufacturing technology

The invention provides a manufacturing process of hot work die steel for a high performance die-casting die and relates to the technical field of die steel. The manufacturing process of the hot work die steel comprises the following steps of (1) smelting; (2) high-temperature homogenization treatment; (3) forging; (4) annealing treatment; (5) quenching and tempering treatment; (6) nitriding treatment; and (7) tempering treatment. The hot work die steel is prepared from the following components in percent by weight: 0.33-0.46% of C, 1.5-2.3% of Si, 0.32-0.45% of Mn, 1.6-2.3% of Mo, 2.6-3.6% ofW, 0.16-0.27% of Nb, 2.8-3.7% of Cr, 0.21-0.53% of Sr, 0.16-0.31% of Ti, 0.05-0.09% of Ce, less than or equal to 0.003% of S, less than or equal to 0.03% of P and the balance Fe. The hot work die steel prepared by the manufacturing process has relatively high surface hardness and wear resistance, relatively good impact toughness and excellent fatigue resistance and strength, so that the service life of the hot work die steel for the die-casting die is prolonged effectively.

Owner:宁波海琰伟业金属制品有限公司

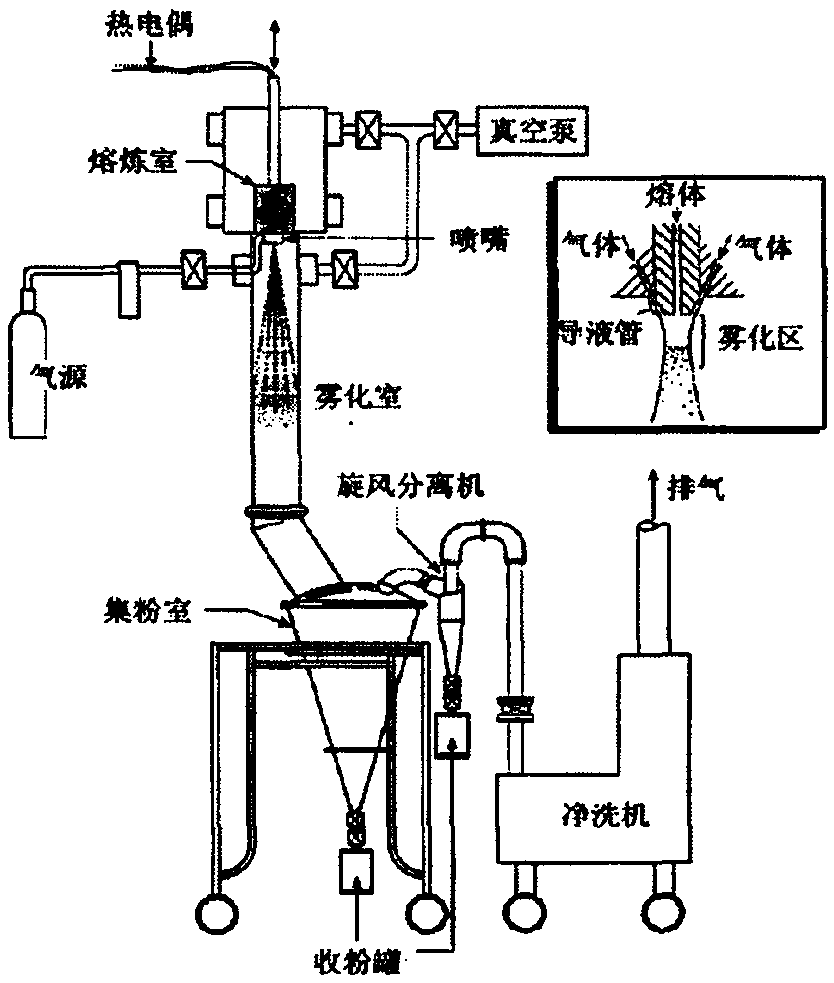

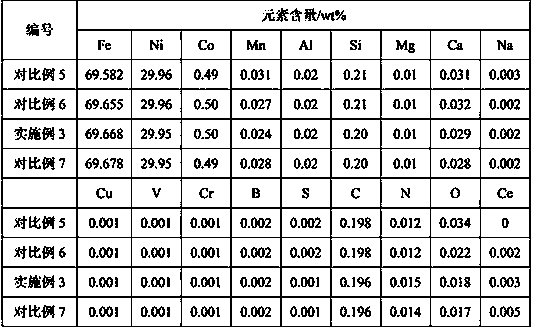

Accelerant for gem grade colorless diamond and preparation method thereof

InactiveCN109225238ASmall tissueUniform compositionUltra-high pressure processesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementNitrogen

The invention belongs to the technical field of artificial diamonds and in particular relates to an accelerant for a gem grade colorless diamond and a preparation method thereof. The accelerant for the gem grade colorless diamond is powdery and is prepared from the following raw materials in percent by weight: 60-80% of Fe, 25-35% of Ni, greater than 0 but less than or equal to 1% of Co, greater than 0 but less than or equal to 0.5% of Si and greater than 0 but less than or equal to 0.8% of rare earth elements. The preparation method of the accelerant comprises the following steps: 1) meltingand mixing the raw materials; 2) carrying out gas atomization to prepare powder; 3) carrying out primary pressing; 4) carrying out vacuum treatment; and 5) carrying out secondary pressing. The accelerant used for prepare the colorless diamond is easy to produce, stable in structure of the diamond, good in catalytic effect, high in nitrogen removal effect, high in rate of finished products and highin practicality, and the product quality is ensured.

Owner:ZHONGNAN DIAMOND CO LTD

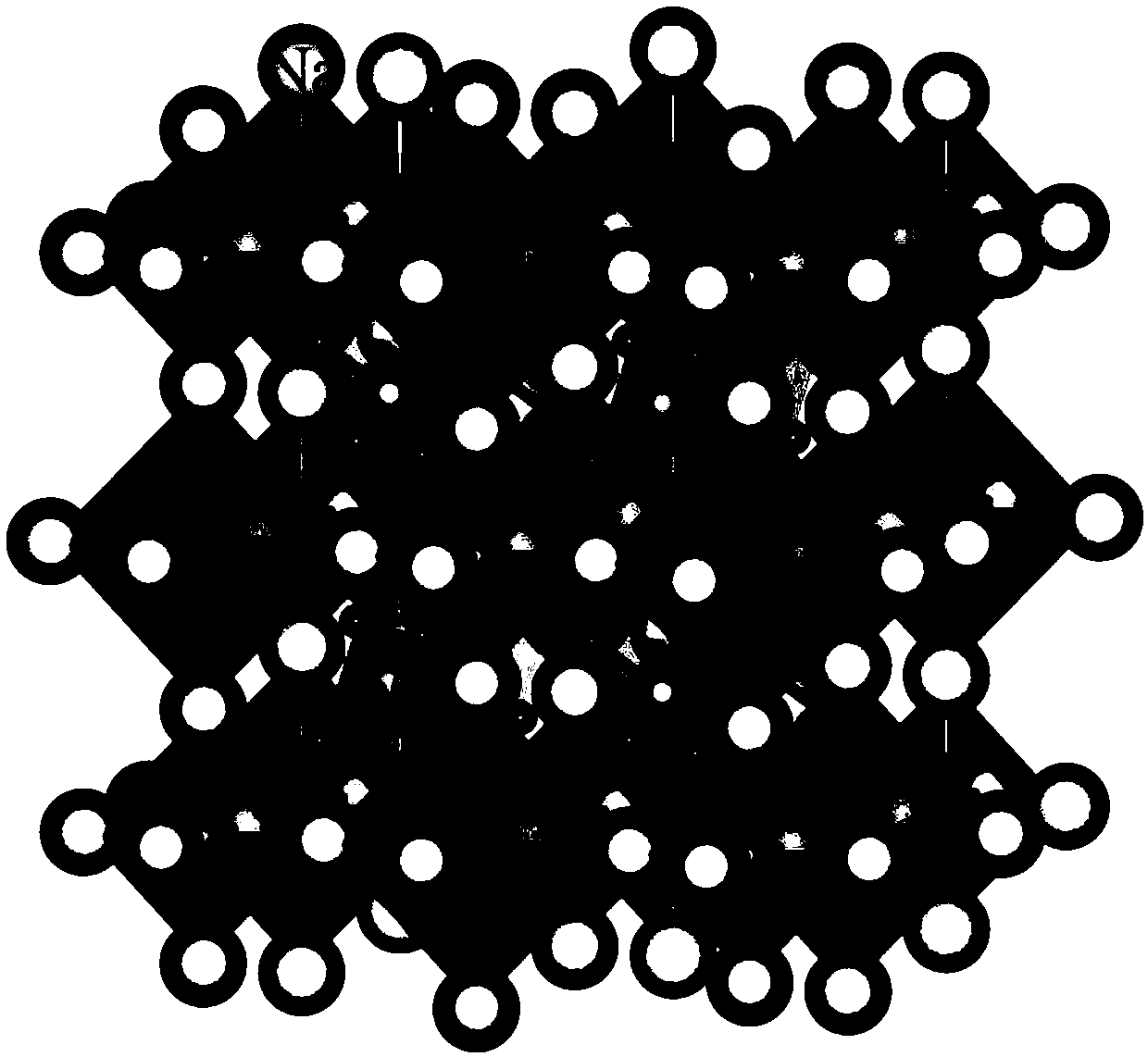

Sodium ion solid electrolyte and preparation method thereof

ActiveCN109687017AExcellent metal ion conductivityHigh thermodynamic stabilityFinal product manufactureElectrolyte accumulators manufactureHigh sodiumChemical composition

The invention relates to a sodium ion solid electrolyte and a preparation method thereof and belongs to the technical field of metal ion batteries. The chemical composition of the sodium ion solid electrolyte is NaaLibR(3-a-b) / 2ApB1-pXmY1-m, wherein R is selected from metal ions of +2 valence, A and B are independently selected from one of SO42- and SeO42-, X and Y are independently selected fromone of monovalent chloride ions and fluoride ions, , 2.45 <= a <= 3, 0 <= b <= 0.45, 0 <= (3-a-b) / 2 <= 0.05, 0 <= p <= 1, and 0 <= m <= 1. The sodium ion solid electrolyte has excellent sodium ion conductivity and thermodynamic stability, has three-dimensional equivalent ultrafast ion transmission capacity, lower diffusion activation energy and higher sodium ion conductivity, and a sodium ion battery electrode has good electrochemical compatibility.

Owner:ZHENGZHOU NEW CENTURY MATERIALS GENOME INST CO LTD

Method for quickly preparing aluminum-iron alloy coating on surface of metal material

InactiveCN104726820AAchieving mechanical energy assisted aluminizingImprove temperature uniformitySolid state diffusion coatingMechanical energyAlloy coating

The invention discloses a method for quickly preparing an aluminum-iron alloy coating on the surface of a metal material. According to the method, compound powder, medium balls and a to-be-treated workpiece are put into a sealed roller, and the sealed roller is put into an aluminized furnace for heating at the same time. The roller is connected with a turntable at one side by virtue of a flange, and then is connected with a gear motor by virtue of a bearing, and the gear motor rotates at different speeds to provide different rotating speeds for the roller. The surface of the to-be-treated workpiece is subjected to impact and friction by using the rolling of the medium balls and the compound powder in the sealed roller, and by virtue of the combination of heat energy, mechanical impact and mechanical friction, a sufficient quantity of spare spaces required by atomic diffusion are generated on the surface of the workpiece, and a mechanical energy aided diffusion aluminum alloy coating is formed at 400-600 DEG C. The method disclosed by the invention has the advantages that compared with the conventional metal process, the activation energy of diffusion and the diffusing permeation temperature are reduced, the diffusing permeation time is shortened, the production efficiency is improved, and the energy conservation and consumption reduction are significant.

Owner:NANCHANG HANGKONG UNIVERSITY

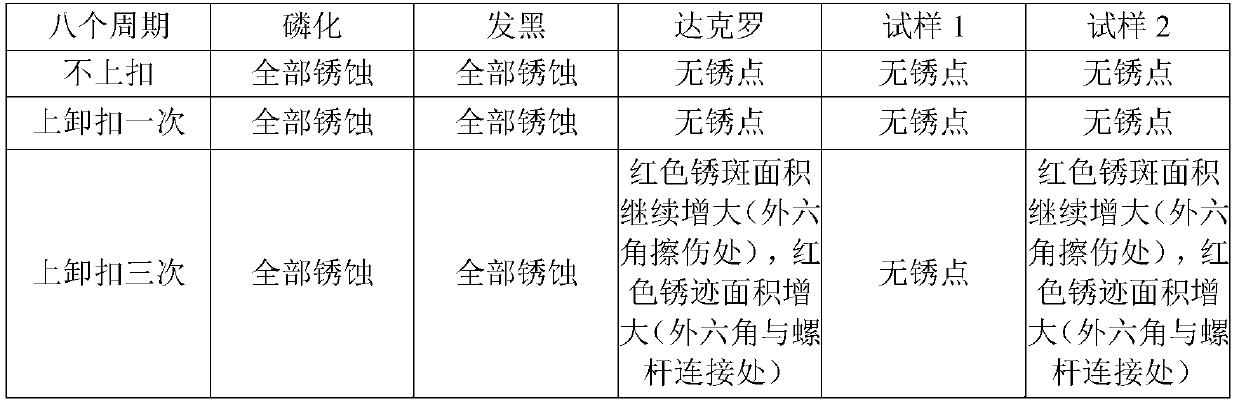

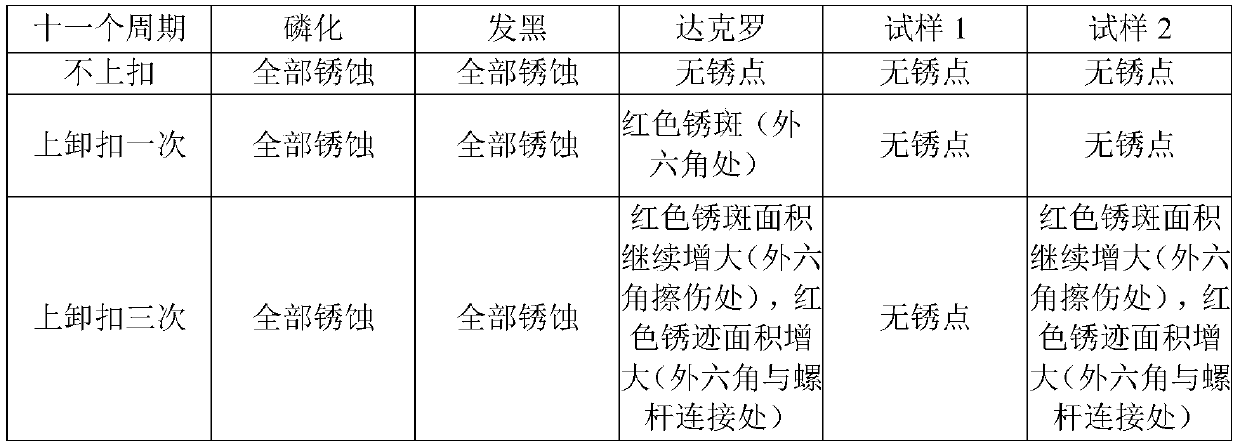

Surface treatment method capable of preventing high-strength bolt from corrosion and thread gluing

ActiveCN108239740ALow melting pointImprove liquiditySolid state diffusion coatingOxygen ionsLanthanum

The invention discloses a surface treatment method capable of preventing a high-strength bolt from corrosion and thread gluing. According to the surface treatment method, a carbon nitrogen lanthanum yttrium ion seeping agent, a lanthanum yttrium activation seeping agent and an oxygen ion seeping agent are utilized to seep non-metallic elements and trace metal elements into the surface of a high-strength bolt substrate so as to form a compound layer and a metal oxidation layer, so that a wearing layer is formed on the surface of the high-strength bolt substrate, the service life of the high-strength bolt is greatly prolonged, the corrosion resistance of the high-strength bolt is also improved; and the high-strength bolt has high mechanical property, and the precision of the high-strength bolt is not affected by the surface treatment. The seeping agents are low in melting point and high in stability; and the ions are cooperated with each other, so that the seeping effect can be effectively ensured to ensure the product quality.

Owner:湖南红宇智能制造有限公司

A method for vacuum scattering and joining-up carbon-carbon composite material

InactiveCN101161397AThermal deformation flow stress dropImprove thermoplasticityNon-electric welding apparatusCarbon compositesShape change

A vacuum diffusion connecting carbon / carbon composite material method belongs to the welding field of the carbon / carbon composite material. The present invention settles the problems of high jointing temperature, large metal deformation of the partial part of joint and inferior joint capability in the existing diffusion connecting carbon / carbon composite material. The invention comprises the following steps: 1. doing cleaning to the surface of the base metal; 2. homogeneously parking the diffusion middle layer to the connecting surface of the base metal to be welded; 4. reducing temperature then the welded component which is connected well is obtained. The diffusion connecting carbon / carbon composite material of the invention is reduced by 100 to 300 DEG C, the shear strength of the diffusion connecting between the carbon / carbon composite material and the carbon / carbon composite material or the carbon / carbon composite material to other metal material is increased by 20 to 220 percent, and the metal at the joint has no evident shape change.

Owner:HARBIN INST OF TECH

Fused salt system for molybdenum or molybdenum alloy binary co-penetration, composite catalyst and application

ActiveCN105385989AGood high temperature oxidation resistanceGood compatibilitySolid state diffusion coatingElectrolysisThiourea

The invention provides a fused salt system for molybdenum or molybdenum alloy binary co-penetration, a composite catalyst and application. The fused salt system comprises 10% to 20% of borax, 0.9% to 1.2% of penetration-catalyzing activating agent rare earth metal, 2% to 6% of the composite catalyst and the balance fused salt. The mass ratio of thiourea and nickel chloride in the composite catalyst is 1:(0.8-1.25). The fused salt system for molybdenum or molybdenum alloy binary co-penetration is used for application of electrochemical binary co-penetration for manufacturing a rare earth metal-boron binary co-penetrated layer on the surface of molybdenum or molybdenum alloy. The molybdenum or molybdenum alloy manufactured through the fused salt system or provided with the binary co-penetrated layer is good in high-temperature oxidation resistance and can resist high-temperature oxidation corrosion. The composite catalyst is added to achieve the overall electrolysis effect, compared with a method that alloy is obtained through single rare earth penetration catalysis, the compatibility of the La-B binary co-penetrated layer manufactured through the method and a molybdenum or molybdenum alloy base body is good, and the La-B binary co-penetrated layer is not prone to cracking or falling. The use temperature of the molybdenum or molybdenum alloy with the surface subjected to binary co-penetration treatment can reach 1500 DEG C.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method for rare-earth metal-molybdenum binary diffusion coating on surface of kovar alloy

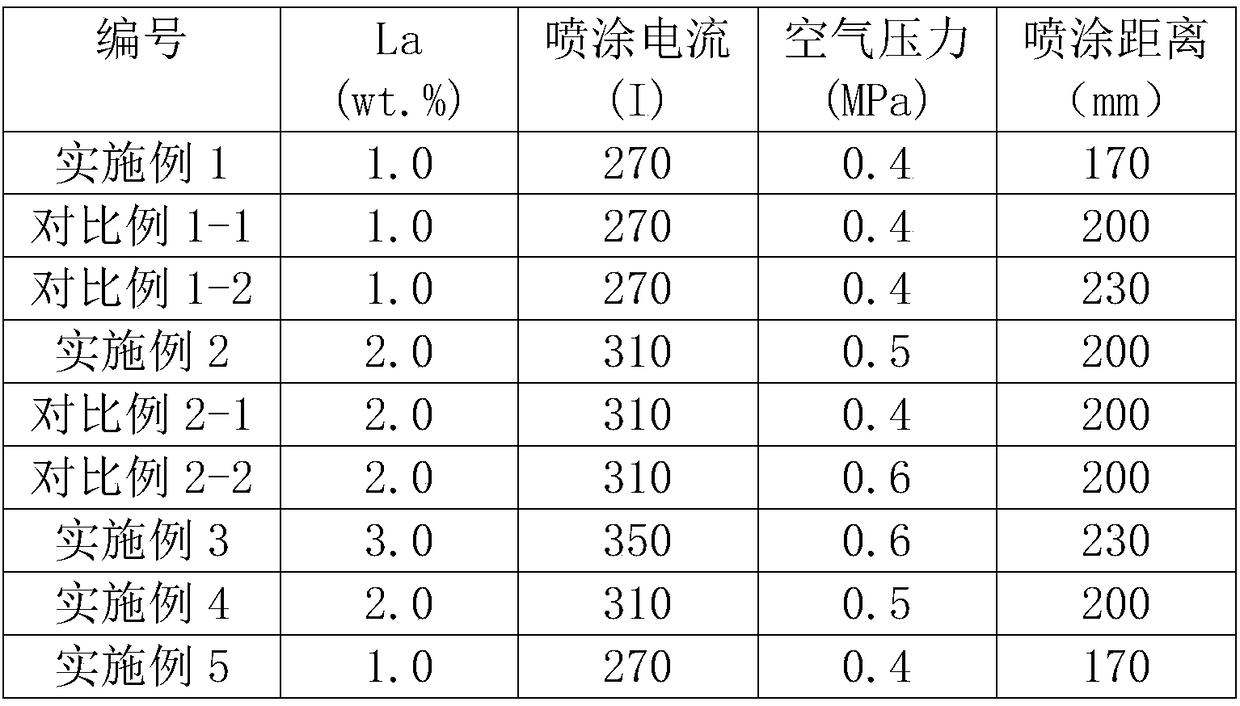

PendingCN109487198AComprehensive performance is good and stableGood effectMolten spray coatingSolid state diffusion coatingSpace environmentRare earth

The invention provides a preparation method for a rare-earth metal-molybdenum binary diffusion coating on the surface of a kovar alloy. The method comprises the following steps that the uniform and compact rare-earth metal-molybdenum binary diffusion coating is formed on the surface of the kovar alloy by adopting a supersonic plasma spraying technology. The kovar alloy is subjected to combined oilremoval, pickling and activating, a supersonic plasma spraying method is adopted to prepare the rare-earth metal-molybdenum binary diffusion coating, and a post-treatment procedure is conducted on the diffusion coating. The obtained kovar alloy rare-earth metal-molybdenum binary diffusion coating is good in binding force and fine and smooth in appearance, can tolerate an atomic oxygen impact testand a high-low temperature impact test in a low-orbit space environment, and meets the requirements of comprehensive performance such as tensile strength. Experiments and tests prove the feasibilityof the process. According to the method, the supersonic plasma spraying technology is adopted to prepare the rare-earth metal-molybdenum binary diffusion coating on the surface of the kovar alloy, andthe method has the technical advantages that the process is simple, the cost is low, the zero pollution is realized, and the comprehensive effect of the coating is remarkable.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

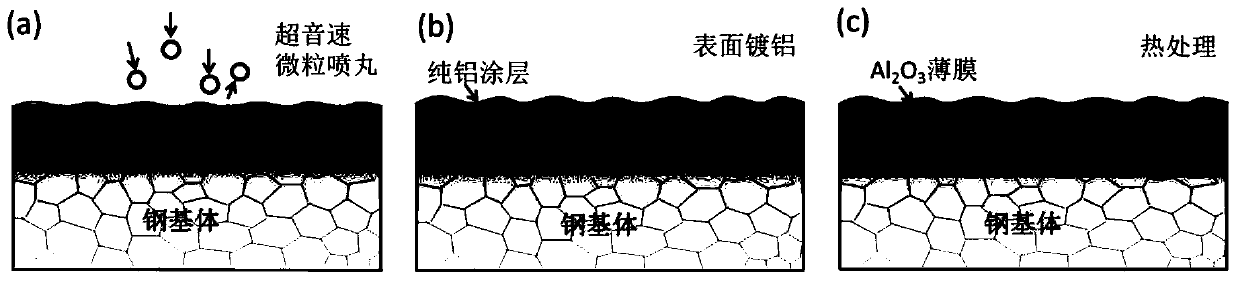

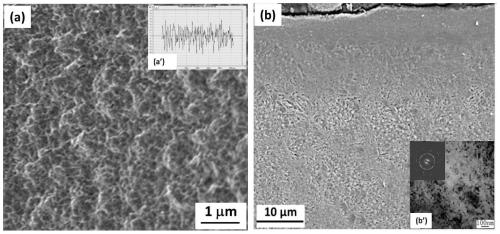

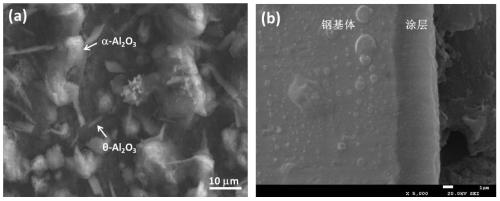

Fe-al/al for fusion reactor tritium breeding cladding 2 o 3 Tritium blocking coating and preparation method thereof

ActiveCN106048519BEnhanced resistance to peelingReduce contentVacuum evaporation coatingSputtering coatingDiffusion layerMaterials science

The invention discloses Fe-Al / Al for fusion reactor tritium breeding cladding 2 o 3 Tritium-blocking coating and preparation method thereof, coating of the present invention is formed by Fe-Al diffusion layer and its surface in situ oxidation-generated Al 2 o 3 film composition. The nano-grain boundary on the side of the steel matrix in the Fe-Al diffusion layer of the present invention can become a channel for Al atoms to diffuse to the inside of the steel matrix; during diffusion annealing, the Al atoms diffuse rapidly along the nano-grain boundary to the inside of the steel matrix, which will greatly reduce the The content of Al element in the coating and the interface can inhibit the high aluminum compound (Fe 2 Al 5 , FeAl 3 , FeAl 2 etc.); in the coating, the formation of low-aluminum compounds (FeAl) reduces the composition gradient of Fe and Al elements and inhibits the generation of Kirkendall voids.

Owner:SICHUAN UNIV

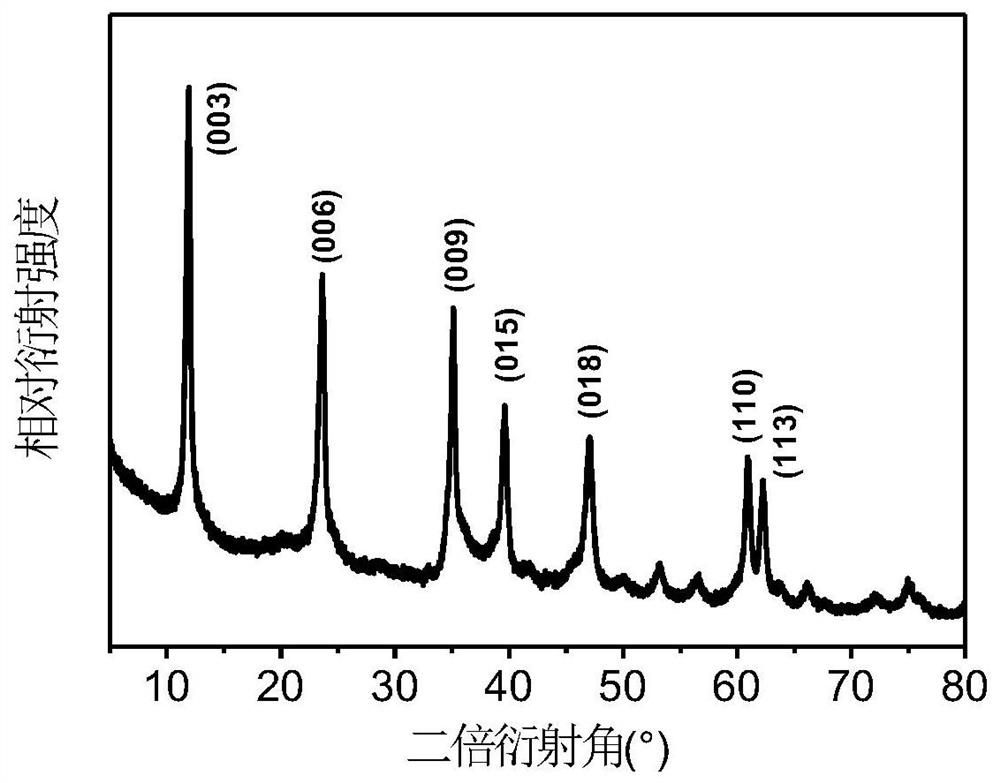

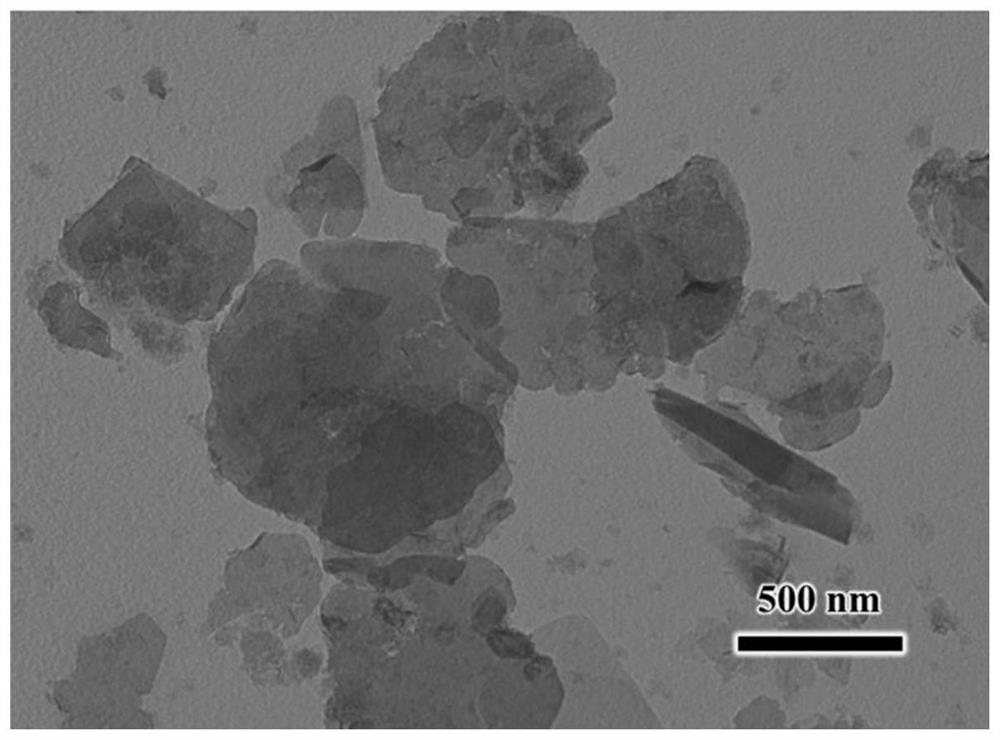

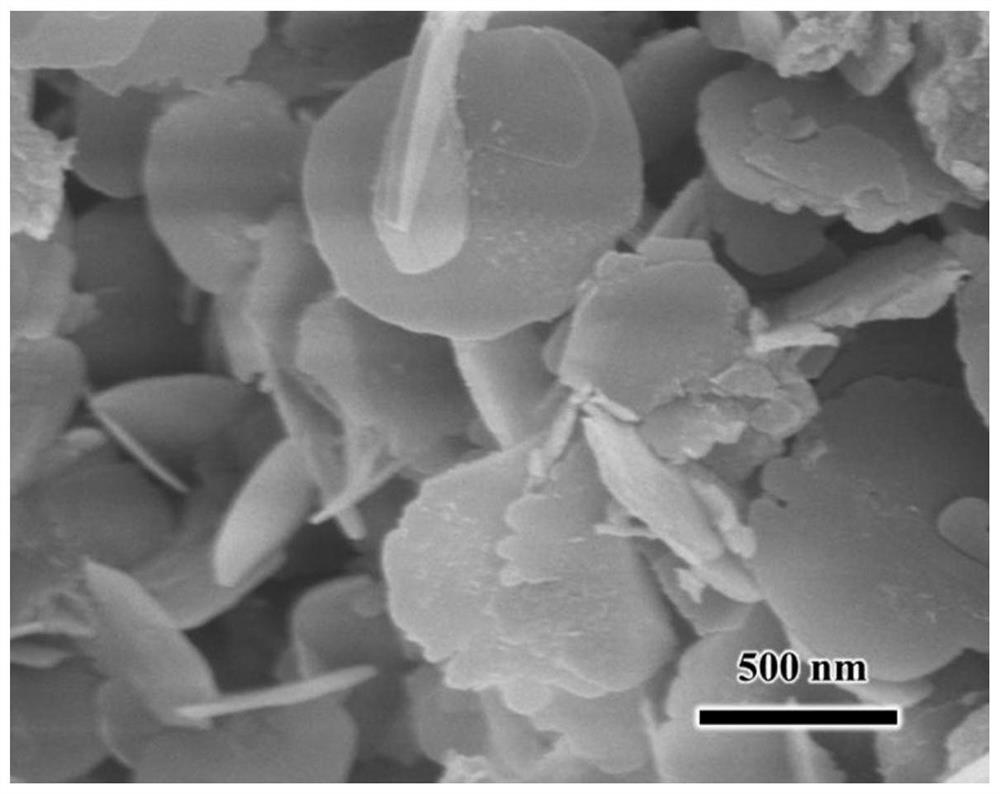

Preparation method of silicon-containing layered double hydroxide

ActiveCN113023730AGood crystallinityImprove dispersionAluminium compoundsNanotechnologyFire retardantCrystallinity

The invention provides a preparation method of a silicon-containing layered double-metal hydroxide, the preparation method comprises the following steps: mixing a divalent metal ion hydroxide and a trivalent metal ion hydroxide, and carrying out ball milling to obtain a hydroxide mixture; then dispersing the obtained hydroxide mixture in a solvent to obtain hydroxide mixture dispersion liquid; adding SiCl4 into the hydroxide mixture dispersion liquid, fully stirring to obtain a suspension liquid, and then standing and aging; and after the reaction is finished, filtering, washing and drying to obtain silicon-containing layered double-metal hydroxide powder. The method disclosed by the invention is mild in experimental condition, simple to operate, low in energy consumption, less in sewage discharge, high in yield, easy to industrialize and the like. The prepared product has high specific surface area and crystallinity, and has great application value in the fields of catalysis, energy storage, flame retardants, composite materials and the like.

Owner:SHANDONG UNIV

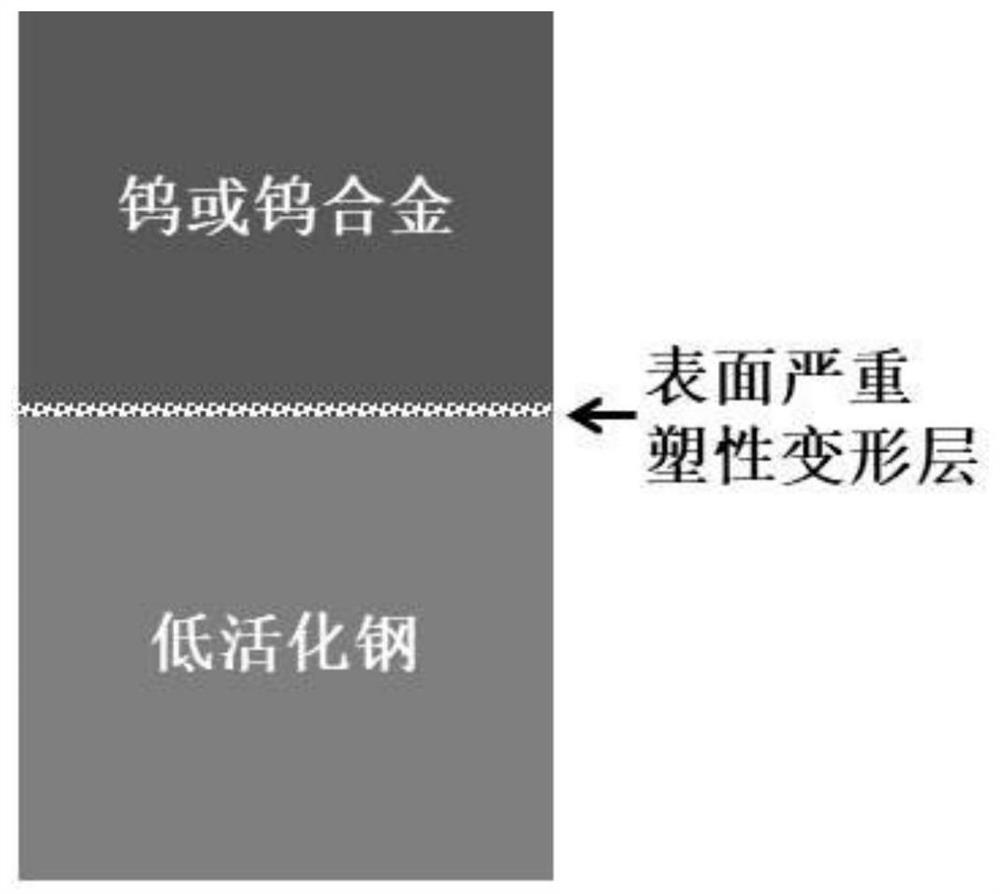

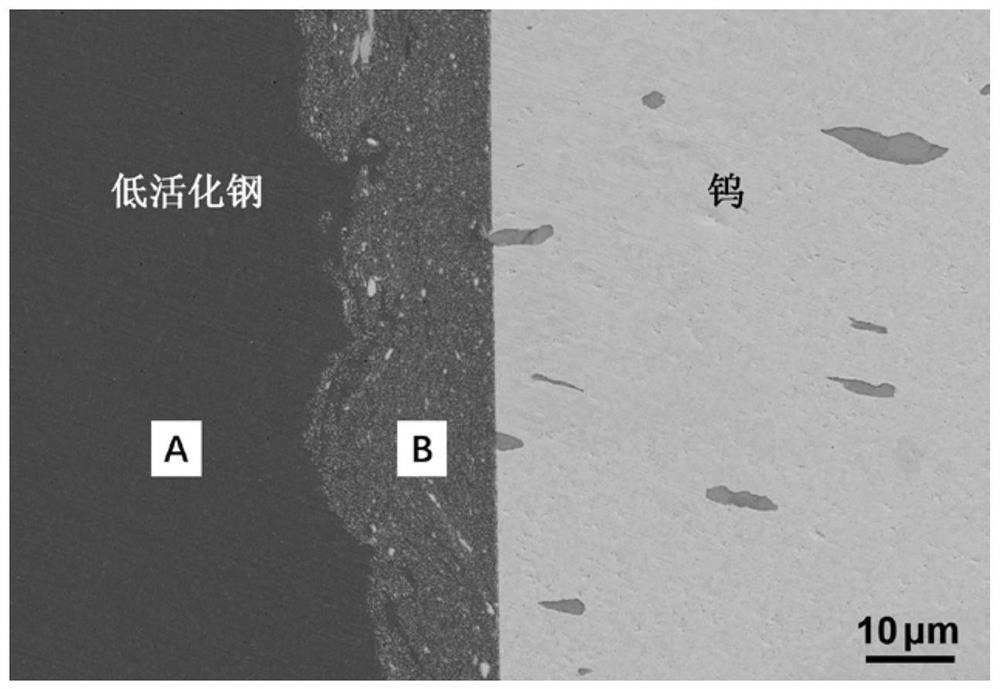

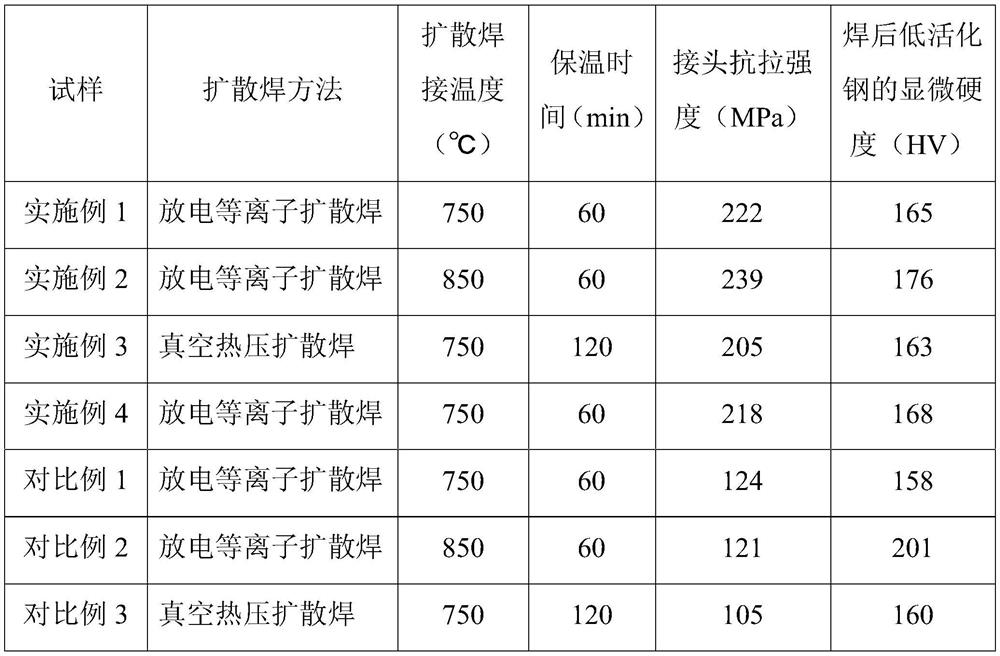

Method for low-temperature diffusion welding of tungsten and low-activation steel

PendingCN113600997AAvoid damageIncrease the diffusion coefficientNon-electric welding apparatusTemperingMetallurgy

The invention discloses a method for low-temperature diffusion welding of tungsten and low-activation steel. The method comprises the following steps: carrying out surface severe plastic deformation treatment on the low-activation steel to refine the grain sizes of the surface and near surface of the low-activation steel to nanoscale to obtain surface structure modified low-activation steel; and tungsten and the surface structure modified low-activation steel are welded through a diffusion welding method. By means of the method, high-strength connection of tungsten and the low-activation steel can be achieved near the tempering temperature of the low-activation steel, the excellent tensile strength of a connector is guaranteed, meanwhile damage to the mechanical property of a low-activation steel body in the existing diffusion welding process is reduced, and an obtained tungsten and low-activation steel connecting piece can be used at high temperature.

Owner:HEFEI UNIV OF TECH

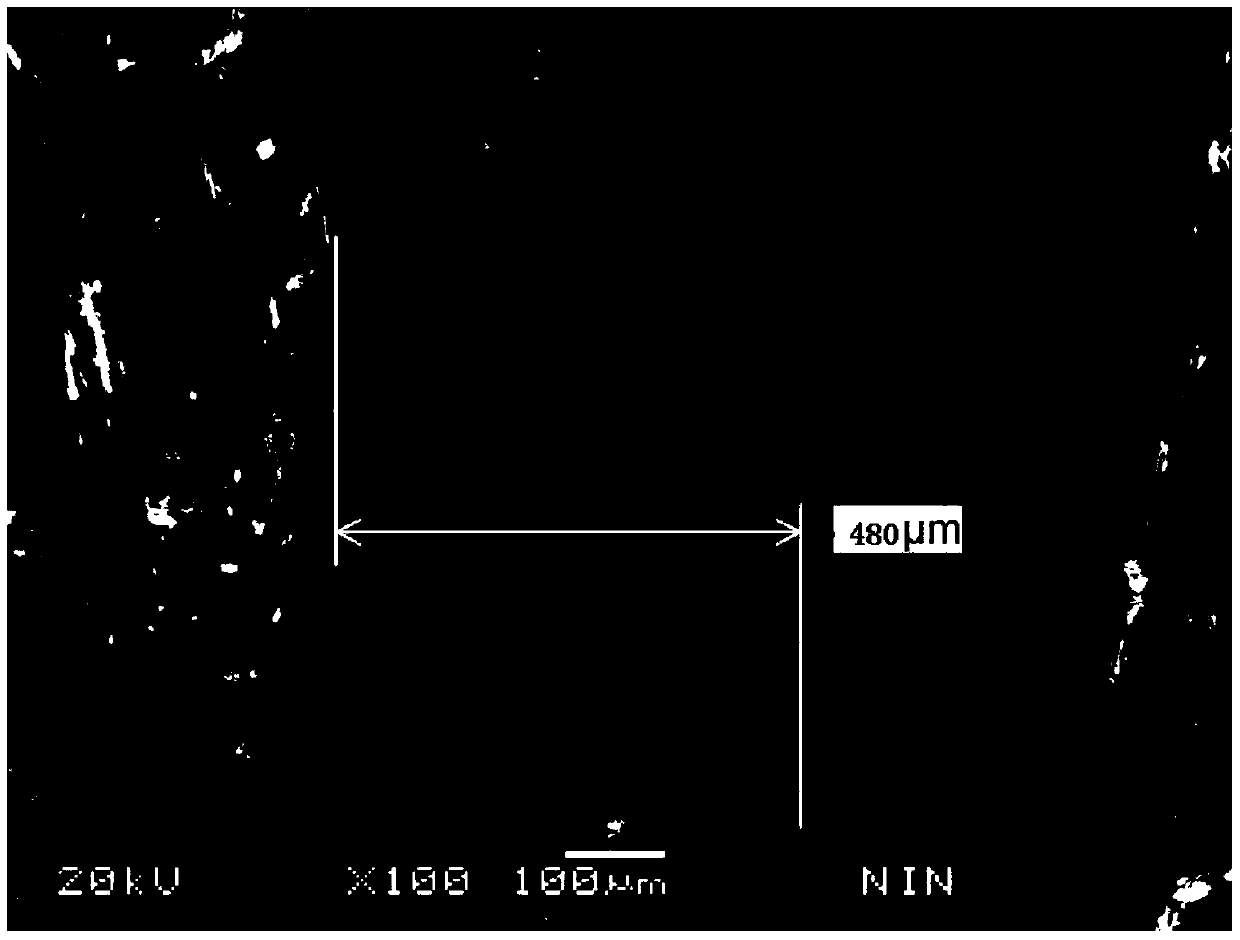

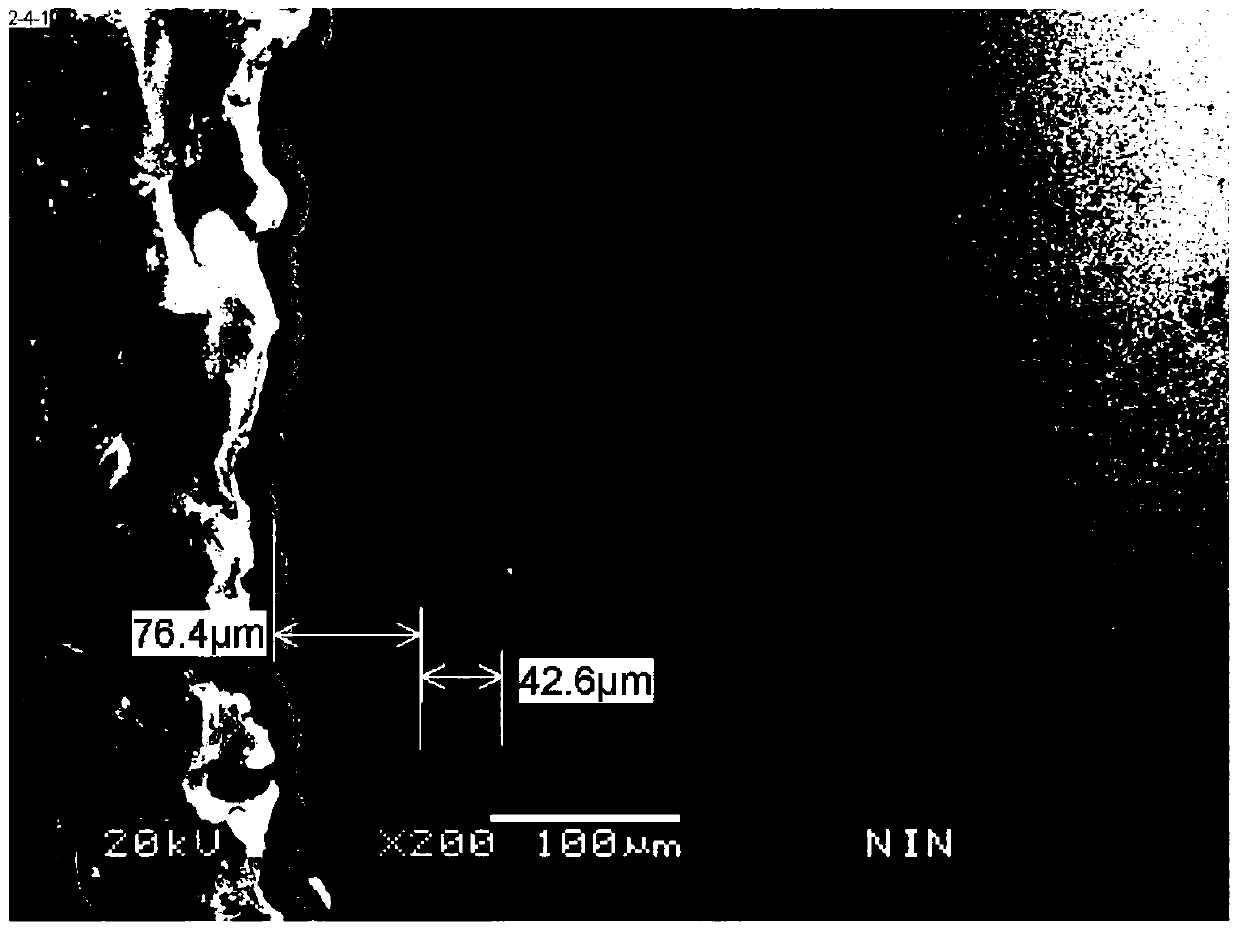

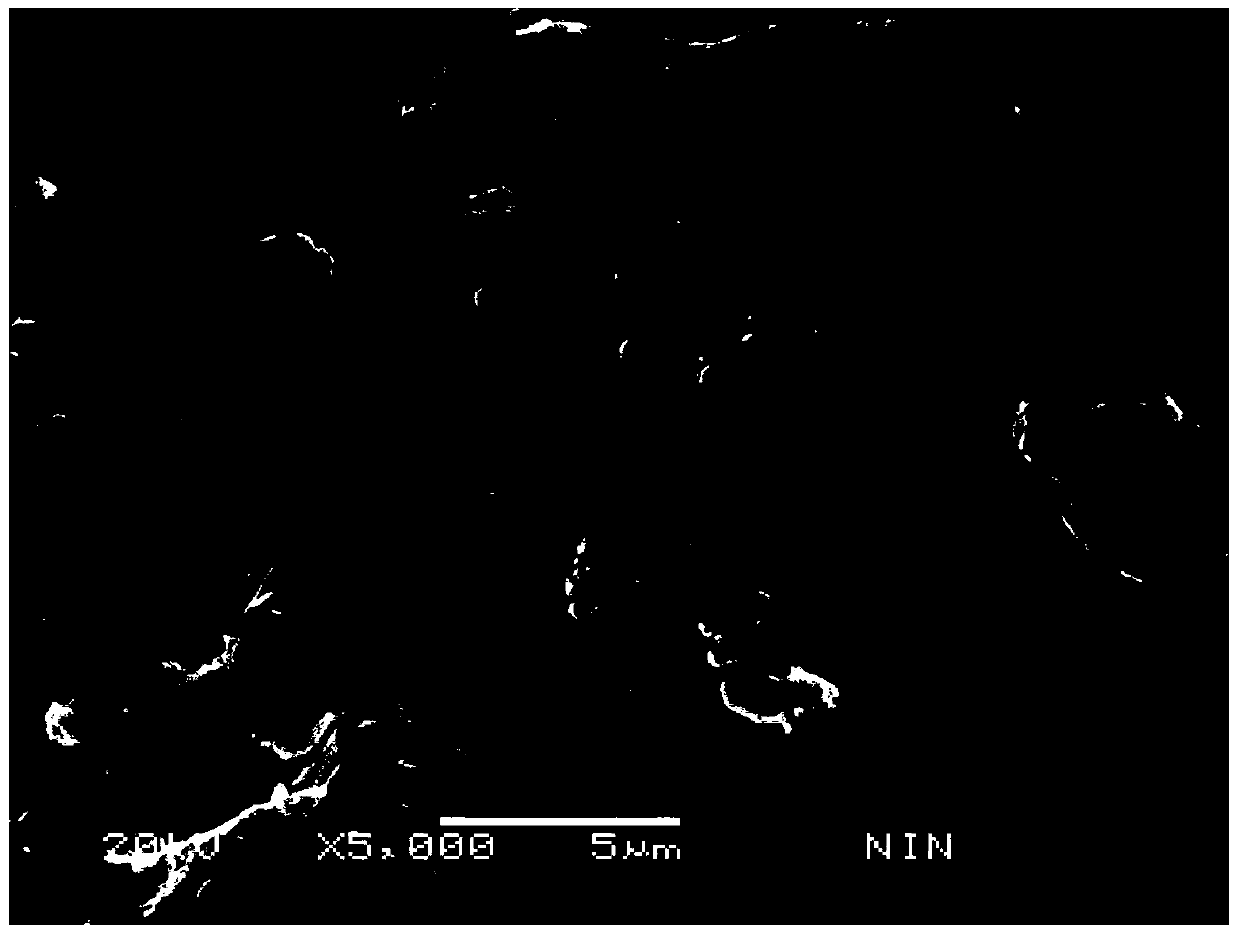

Method for preparing iron-based material and zinc system alloy mechanically-bonded modified layer

InactiveCN109628875AReduced activation energy for diffusionLower diffusion temperatureSolid state diffusion coatingMechanical propertyPeening

The invention relates to a method for preparing an iron-based material and zinc system alloy mechanically-bonded modified layer. The method comprises the steps that an iron-based material is subjectedto shot blasting treatment; a zinc foil material is attached to the surface of the cleared iron-based material; the iron-based material with the attached zinc foil material is heated; the heated material is subjected to shot blasting treatment; and the material with the attached zinc foil material is subjected to shot blasting treatment again, and thus the modified layer is formed. According to the method for preparing the iron-based material and zinc system alloy mechanically-bonded modified layer, the corrosion-resistant capability of the metal material in atmosphere, water, hydrogen sulfide and certain organic media can be improved, and the surface of a product can obtain hardness and abrasion resistance which are higher than the hardness and the abrasion resistance of electrogalvanizing and hot galvanizing; the treatment temperature is low, thus the mechanical property of the iron-based material can be kept, and the deformation amount of the iron-based material is very small; anda zinc impregnation layer and a matrix are subjected to metallurgical bonding, thus the zinc impregnation layer is quite difficult to peel off, the potential difference between the zinc impregnation layer and iron is smaller than the potential difference between zinc and iron, and the modified layer has a better protection effect when serving as an anodic protection layer.

Owner:TONGJI UNIV

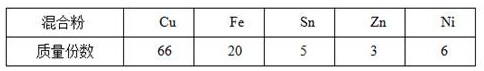

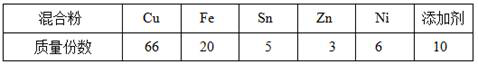

Copper-based pre-alloyed powder additive for diamond tool and preparation method thereof

Owner:HENAN INST OF ENG

A kind of aluminosilicate glass and its preparation method and application

ActiveCN111499192BSimple processSuitable for industrial productionGlass furnace apparatusDetails for portable computersMolten statePotassium nitrate

The invention relates to an aluminosilicate glass and a preparation method and application thereof. The preparation method comprises the following steps: taking corresponding glass raw materials according to the set content of each component of the aluminosilicate glass and mixing them uniformly, wherein the glass The raw material contains Al(PO 3 ) 3 powder; carry out high temperature melting, clarification, leakage forming and annealing of the uniformly mixed raw materials to obtain aluminosilicate glass; preheat the tempered molten salt to a molten state, wherein the tempered molten salt includes potassium nitrate, sodium nitrate, phosphoric acid Potassium and potassium carbonate; the prepared glass is immersed in molten tempered molten salt, and chemically tempered to obtain a strengthened aluminosilicate glass. In the preparation method of the aluminosilicate glass of the present invention, by adding potassium phosphate and potassium carbonate to the molten salt, a better strengthening effect can be achieved and the service life of the molten salt can be ensured.

Owner:CHINA BUILDING MATERIALS ACAD

A kind of preparation method of molybdenum or molybdenum alloy surface rare earth metal-boron binary co-infiltration layer

ActiveCN105385988BGood high temperature oxidation resistanceNot easy to fall offSolid state diffusion coatingRare-earth elementTime range

The invention provides a method for preparing a rare earth metal-boron binary co-infiltration layer on the surface of molybdenum or molybdenum alloys, wherein the molten salt system is first pretreated before electrochemical binary co-infiltration, and the pretreatment process is as follows: : Put the molten salt system into the sealed seepage tank, pressurize and keep warm in the seep tank, the pressurized pressure is 0.3-0.7MPa, the keep-warm temperature is 100°C-300°C, and the pressurization time is 0.5-1h. The molybdenum or molybdenum alloy with binary co-infiltration layer prepared by the method of the present invention has good high temperature oxidation resistance and can resist high temperature oxidation corrosion; the La-B binary co-infiltration layer prepared by the method is compatible with molybdenum or molybdenum alloy substrate Good capacity, not easy to crack, not easy to fall off. The service temperature of molybdenum or molybdenum alloy after surface binary co-infiltration treatment can reach 1500 ℃.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

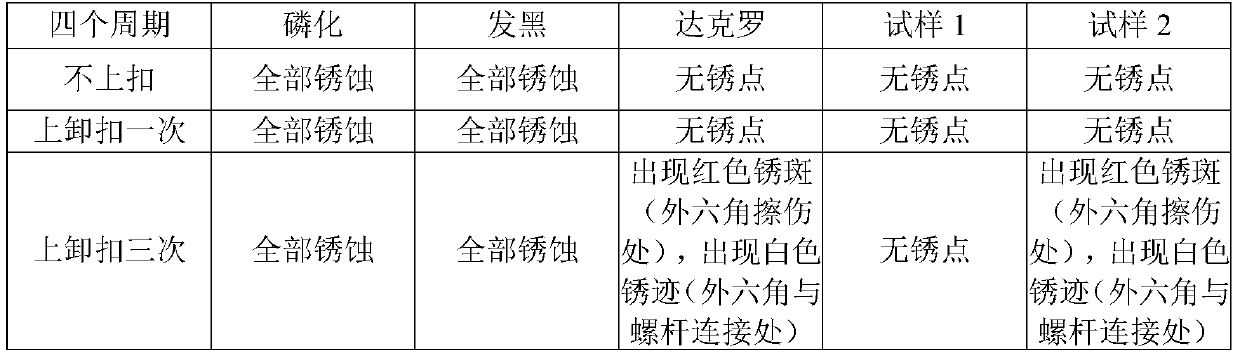

A surface treatment method for preventing high-strength bolts from corroding and sticking

ActiveCN108239740BHigh hardnessAccelerated corrosionSolid state diffusion coatingMinor metalsOxygen ions

The invention discloses a surface treatment method capable of preventing a high-strength bolt from corrosion and thread gluing. According to the surface treatment method, a carbon nitrogen lanthanum yttrium ion seeping agent, a lanthanum yttrium activation seeping agent and an oxygen ion seeping agent are utilized to seep non-metallic elements and trace metal elements into the surface of a high-strength bolt substrate so as to form a compound layer and a metal oxidation layer, so that a wearing layer is formed on the surface of the high-strength bolt substrate, the service life of the high-strength bolt is greatly prolonged, the corrosion resistance of the high-strength bolt is also improved; and the high-strength bolt has high mechanical property, and the precision of the high-strength bolt is not affected by the surface treatment. The seeping agents are low in melting point and high in stability; and the ions are cooperated with each other, so that the seeping effect can be effectively ensured to ensure the product quality.

Owner:湖南红宇智能制造有限公司

Salt-bath hardening treatment method for obtaining supersaturated solid solution from stainless steel surface

InactiveCN104060216AStrong reduction potentialLower salt bath melting pointSolid state diffusion coatingHydrogen fluorideCryogenic hardening

The invention discloses a salt-bath hardening treatment method for obtaining a supersaturated solid solution from a stainless steel surface, belonging to the field of surface treatment of stainless steel. The stainless steel is soaked and activated by using a 5V01.% HF (Hydrogen Fluoride) water solution and subjected to salt-bath hardening treatment for 8-10 hours below the temperature of 480 DEG C; the salt bath contains CNO<->, the mass concentration is controlled to be 50%-55%, and the salt bath also contains K2CO3, N2CO3, CO(NH2), Li2CO3 and other trace elements. As the salt bath adopted by the method disclosed by the invention has low melting point and good liquidity at a low temperature and the CNO<-> in the salt bath has relatively high reduction potential, the stainless steel is subjected to activation treatment and low-temperature hardening treatment below the critical temperature, and active nitrogen atoms have direct contact with the base body, thus a supersaturated solid solution hardened layer can be obtained, the hardened layer has an S-phase structural characteristic, the surface hardness of the hardened layer is three times the hardness of the base body; and the supersaturated solid solution hardened layer has higher corrosion resistance than austenitic stainless steel before the hardening treatment.

Owner:JIANGSU HAINA MECHANICAL & ELECTRIC EQUIP GRP +1

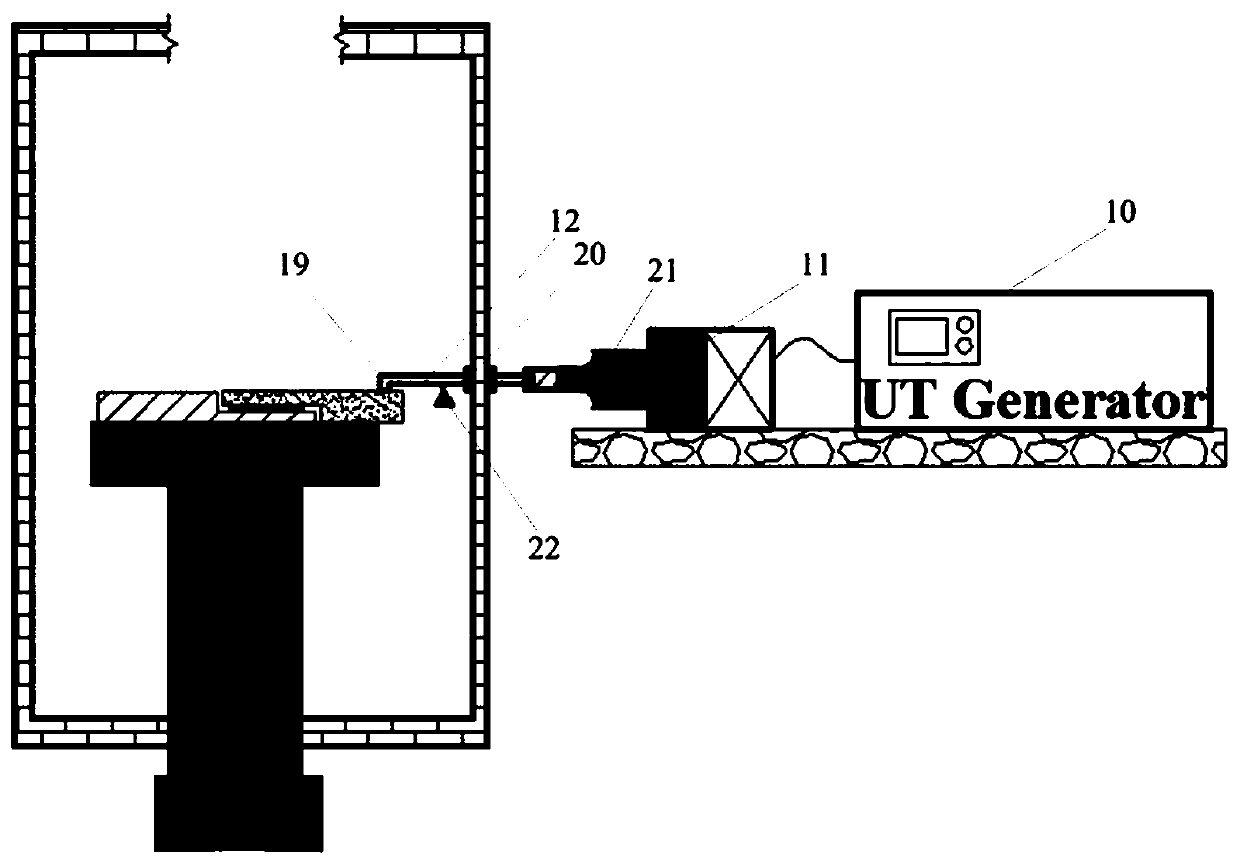

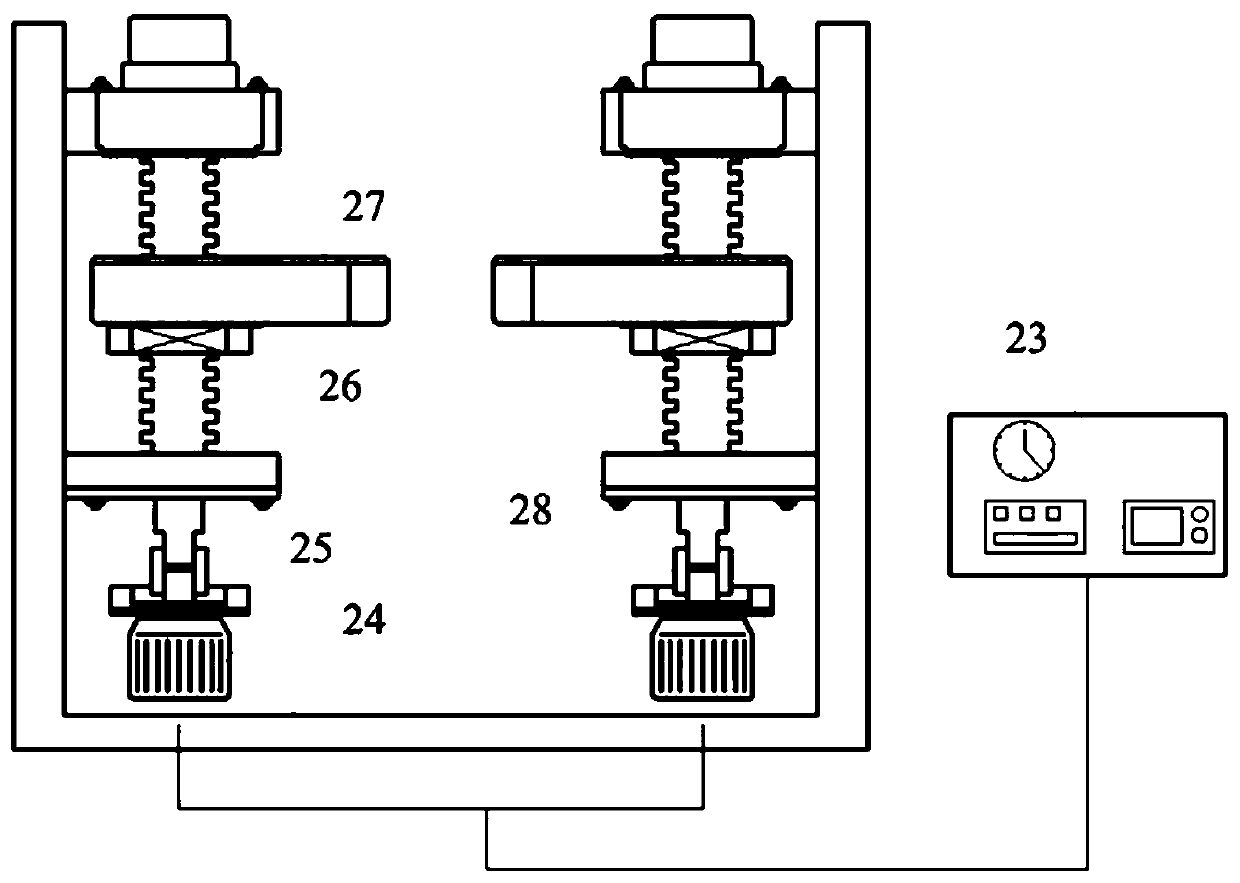

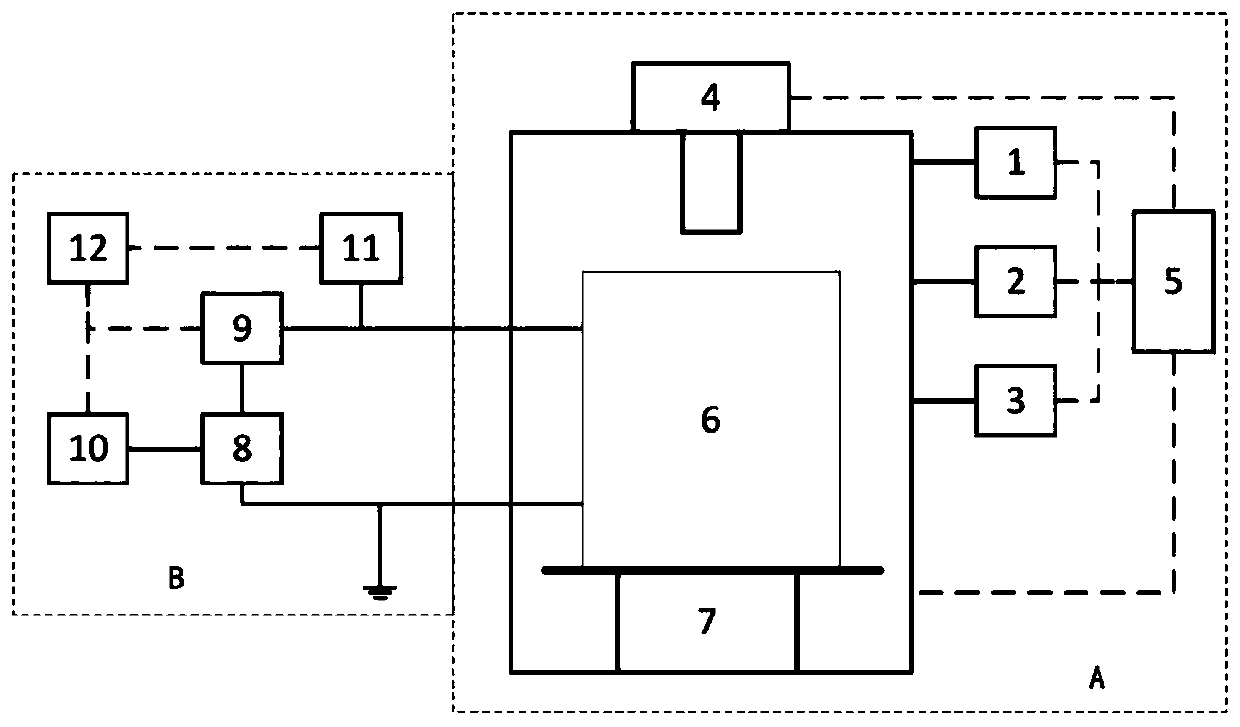

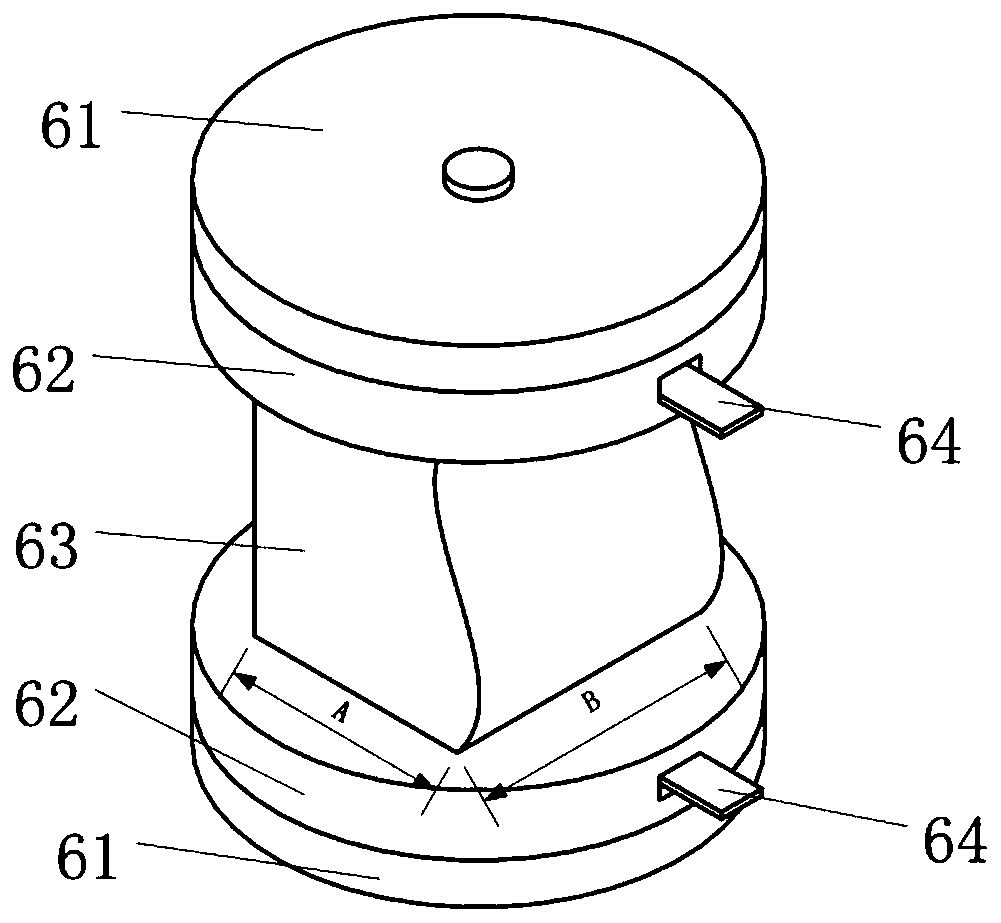

Pulse electric field and ultrasonic field assisted metal matrix composite sintering synchronous joining method and device

ActiveCN108890114BSevere thermal expansion effectChange growth characteristicsCharge treatment typeFurnace typesElectrical resistance and conductanceSurface oxidation

The invention relates to a method and device for sintering synchronous connection of metal matrix composite materials assisted by pulsed electric field and ultrasonic field, and discloses a method for connecting a magnesium (or copper) matrix composite material containing a high volume fraction reinforcing phase to stainless steel while sintering. The devices involved in this method include: a closed heating furnace, a pulse current loading system, an ultrasonic load applying system, a pressure and lifting system, and auxiliary devices such as sealed insulating tubes. The significant advantage of adopting the present invention is that the sintering of the metal matrix composite material and the connection of different materials are carried out simultaneously; the pulse current flows through the experimental material, causing interface resistance heat and plasma discharge heat, and the sintering and connection interface temperature rises and cools quickly, reducing external radiation heat, reduce the residual stress of the joint; use the coupling effect of pulsed electric field-ultrasonic field-pressure field to break the oxide film on the surface of the reinforcement phase, realize sintering under atmospheric conditions, reduce the activation energy of atomic diffusion, promote the interface metallurgical reaction, and control the particle shape and size , refine the interface grains, improve the quality and stability of the joint, and is conducive to the preparation of metal matrix composites / alloy joints with high comprehensive performance.

Owner:李纲

A device and method for repairing cracks in hot work dies

The invention relates to a hot working die crack repairing device and method and belongs to the field of die crack repairing. The device includes a high temperature diffusion system, a pulse current generation system and a die fixture tool. Crack gaps are reduced or even pressed through high temperature pressurization, and cracks are healed through tissue creeping and elemental diffusion. At the same time, auxiliary current can effectively detect generation expansion positions of the cracks, energy is controllably injected for healing microcracks, and an excellent crack repair quality and a high success rate can be obtained through appropriate vacuum diffusion process parameters. The repairing method can be used as a novel approach to repairing hot working die cracks and prolonging the service life of the device, and the device and method have high applicability, environmental protection and economic performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

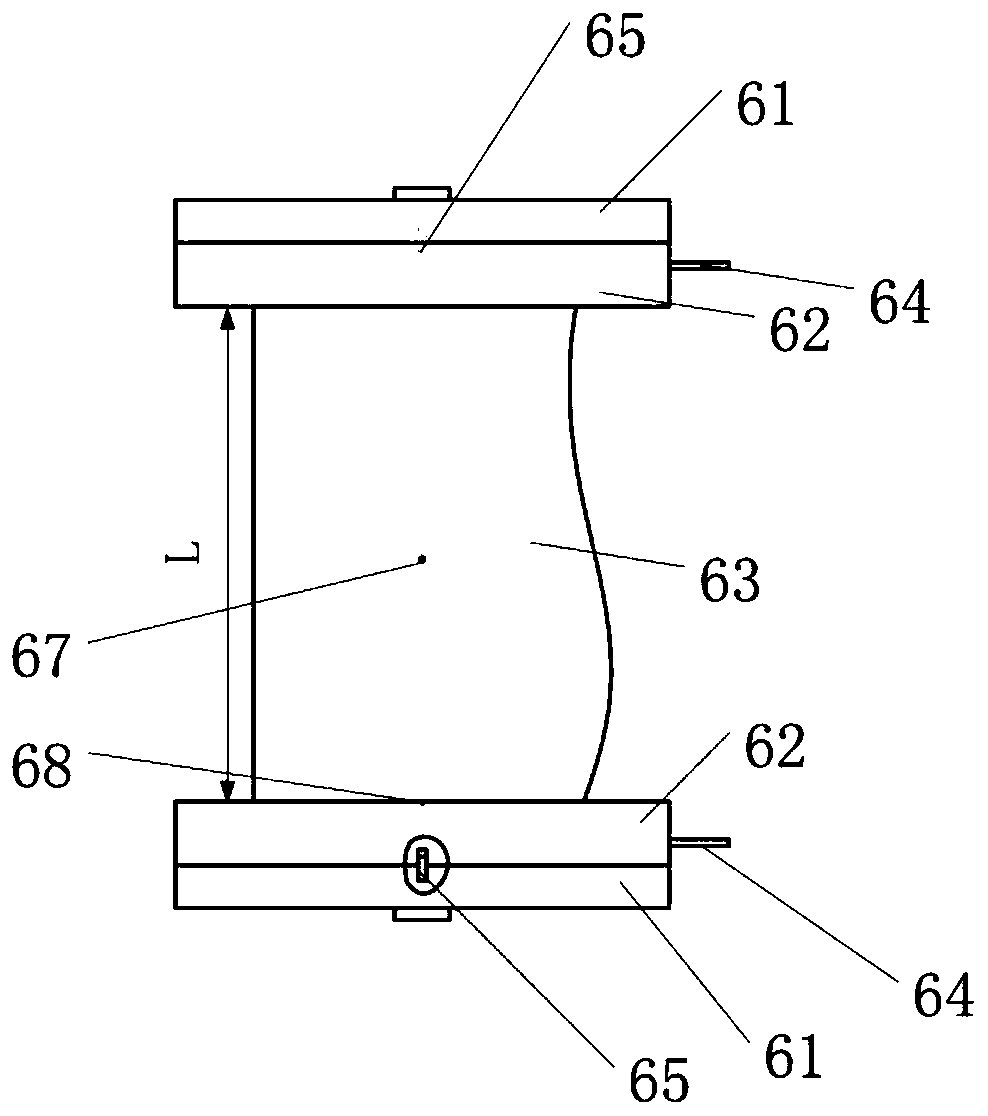

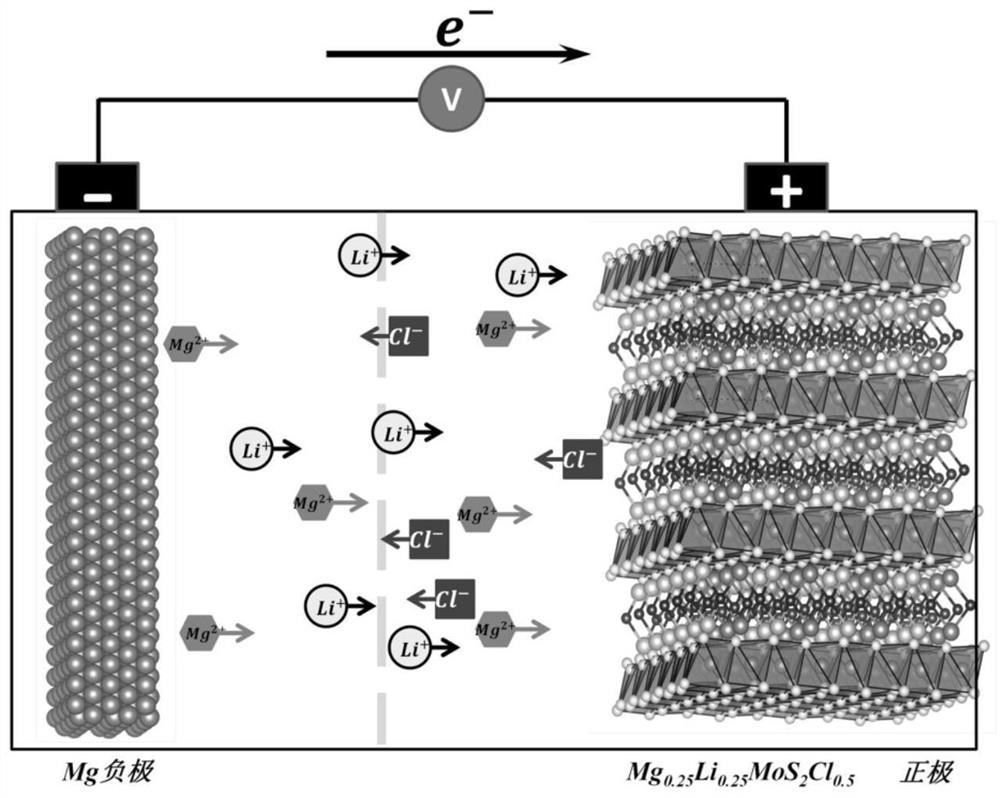

A kind of magnesium ion battery material and preparation method thereof, magnesium ion battery composite material and preparation method thereof

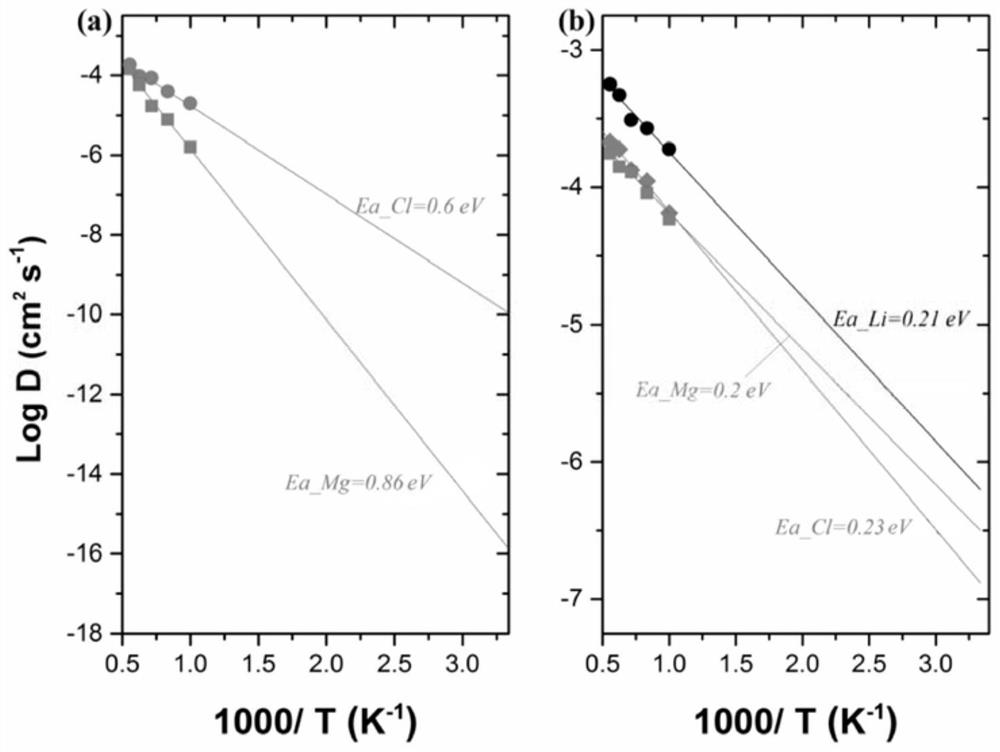

ActiveCN108682834BHigh thermodynamic stabilityUltrafast ion transport capabilityCell electrodesMetallic electrodeMg2 ions

The invention relates to a magnesium ion battery material, a preparation method of the magnesium ion battery material, a magnesium ion battery composite material and a preparation method of the magnesium ion battery composite material, and belongs to the technical field of a magnesium ion battery. The magnesium ion battery material has the chemical formula of MgaAbMo1-mXmS2YnZc, wherein the a is greater than or equal to 0 but smaller than or equal to 1; the A is one kind of materials from Li and Na; the b is greater than or equal to 0 but smaller than or equal to 1; the X is one or several kinds of materials from Ti, Sn, V, Fe, Nb, Zn, Cu, W, Ni and Co; the m is greater than or equal to 0 but smaller than or equal to 0.15; the Y is one or several kinds of materials from O, C, N, S, Se andTe; the n is greater than or equal to 0 but smaller than or equal to 0.10; the Z is halogen; the c is greater than or equal to 0 but smaller than or equal to 1. The magnesium ion battery material provided by the invention has good magnesium ion electric conduction performance and thermal mechanical stability; the diffusion activation energy is low; the current carrier electric conductivity is high; in addition, good electrochemical compatibility is realized with the metal Mg electrodes.

Owner:ZHENGZHOU NEW CENTURY MATERIALS GENOME INST CO LTD

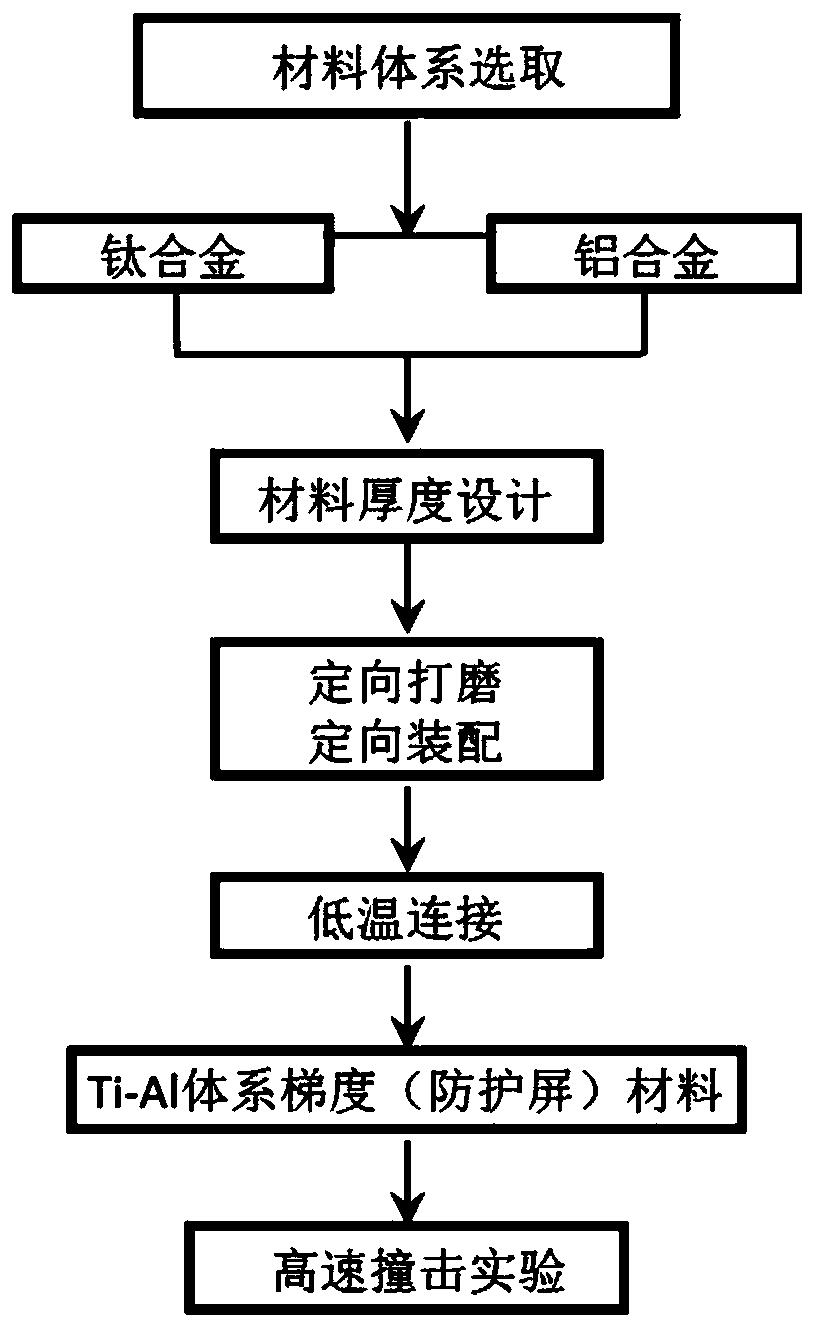

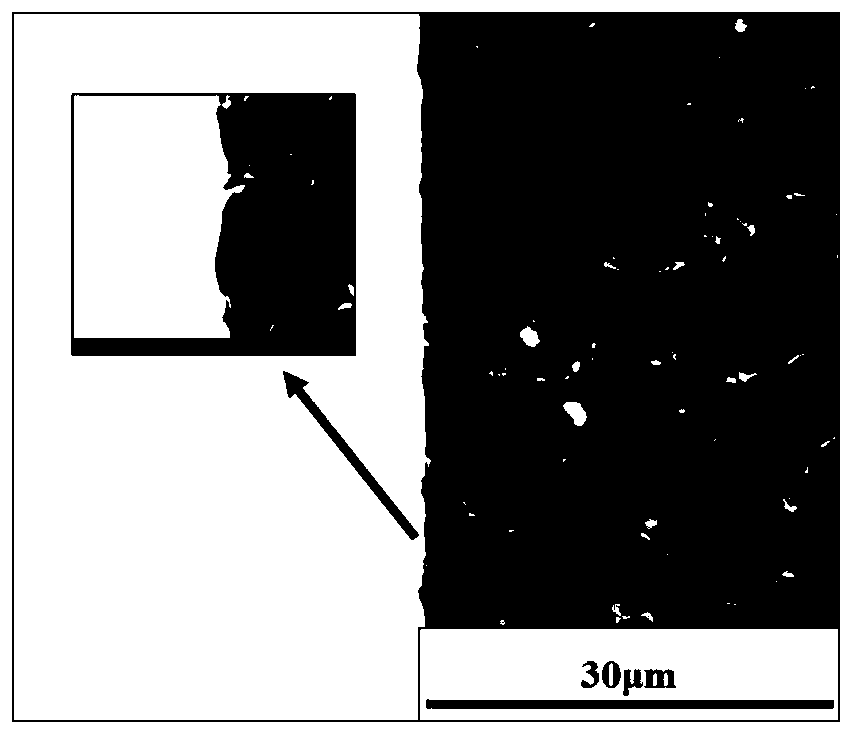

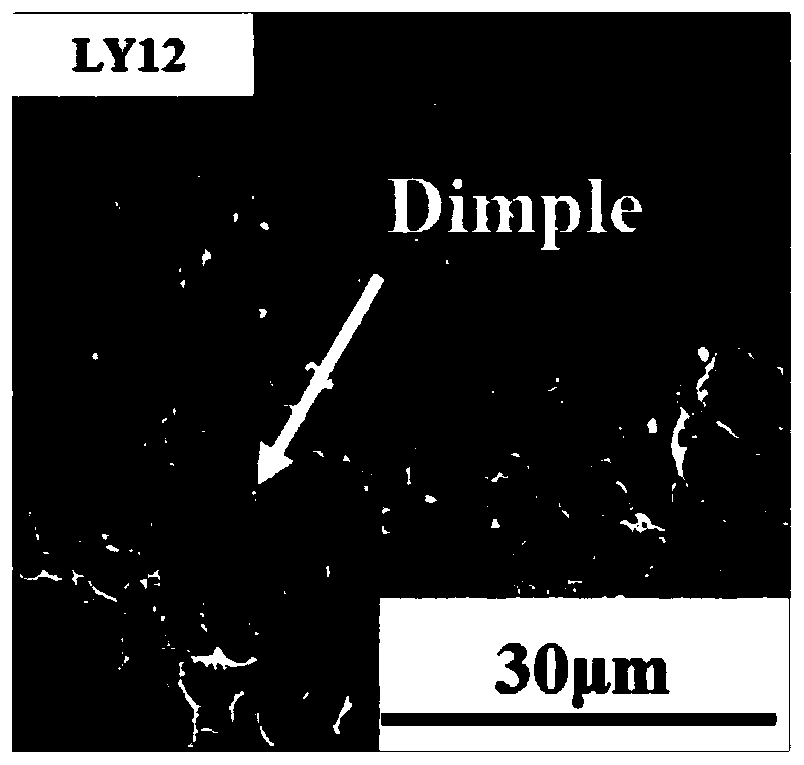

A kind of preparation method of ti-al system gradient protective screen material

ActiveCN108098270BFacilitate contact areaFirmly connectedNon-electric welding apparatusVolumetric Mass DensityTitanium alloy

The invention discloses a preparation method for a Ti-Al system gradient protective screen material, and the preparation method improves sample connecting performance through a method of improving anatom contact area at a diffusion welding physical contact stage. The preparation method specifically comprises the following steps of: (1) selecting and designing a gradient protective screen body system; (2) performing orientated grinding treatment on the surface of a to-be-connected Ti / Al system sample; (3) performing oriented assembly on the Ti / Al system to-be-welded sample; and (4) performinglow-temperature connection on the Ti / Al system sample. The preparation method can realize low-temperature high-strength connection between the titanium alloy and the aluminum alloy; the prepared Ti-Algradient material is good in welding joint combination, is simple and convenient to operate and is small in control difficulty in comparison with a conventional welding joint, is low in preparation temperature, is low in cost, is free of an intermetallic compound, is small in joint residual stress and is extremely good in performance; and the Ti-Al system gradient protective screen material has shear strength of 128 MPa, and is used as a gradient protective screen which is novel and reasonable in structural design in comparison with a conventional protective screen, is small in density and isgood in protective effect.

Owner:WUHAN UNIV OF TECH

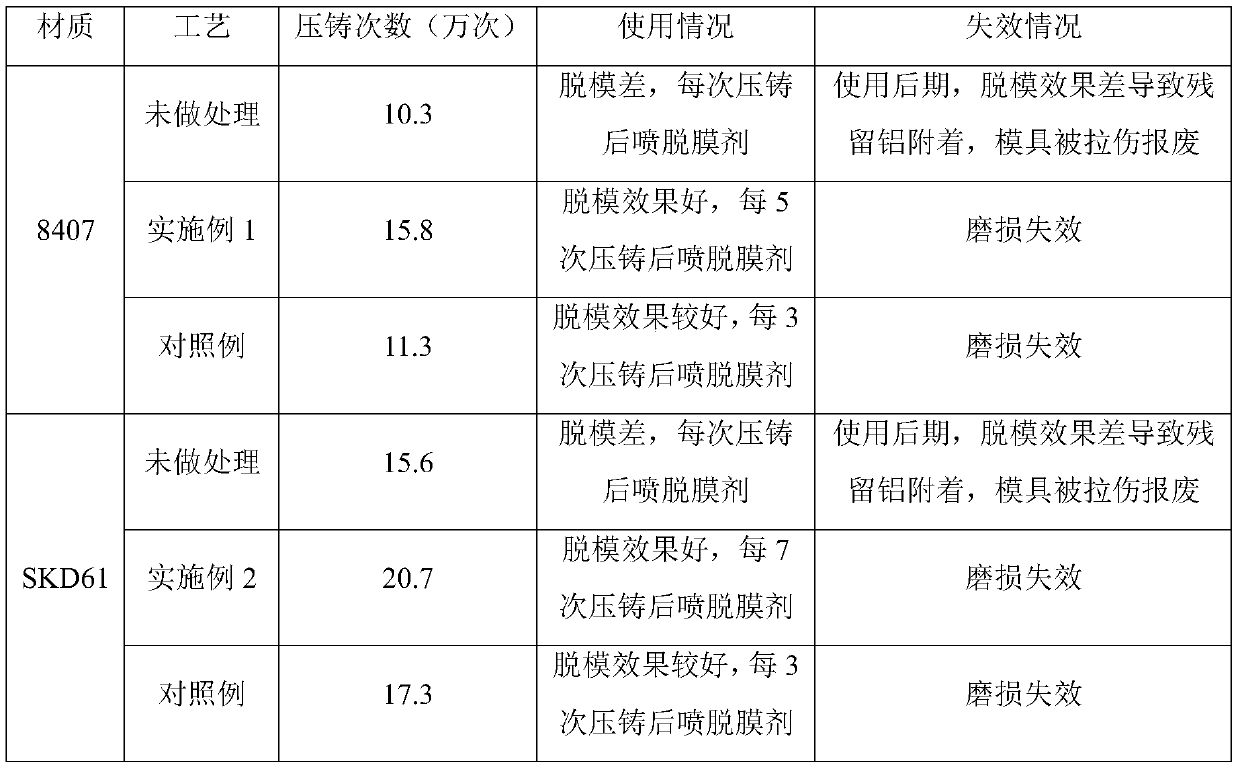

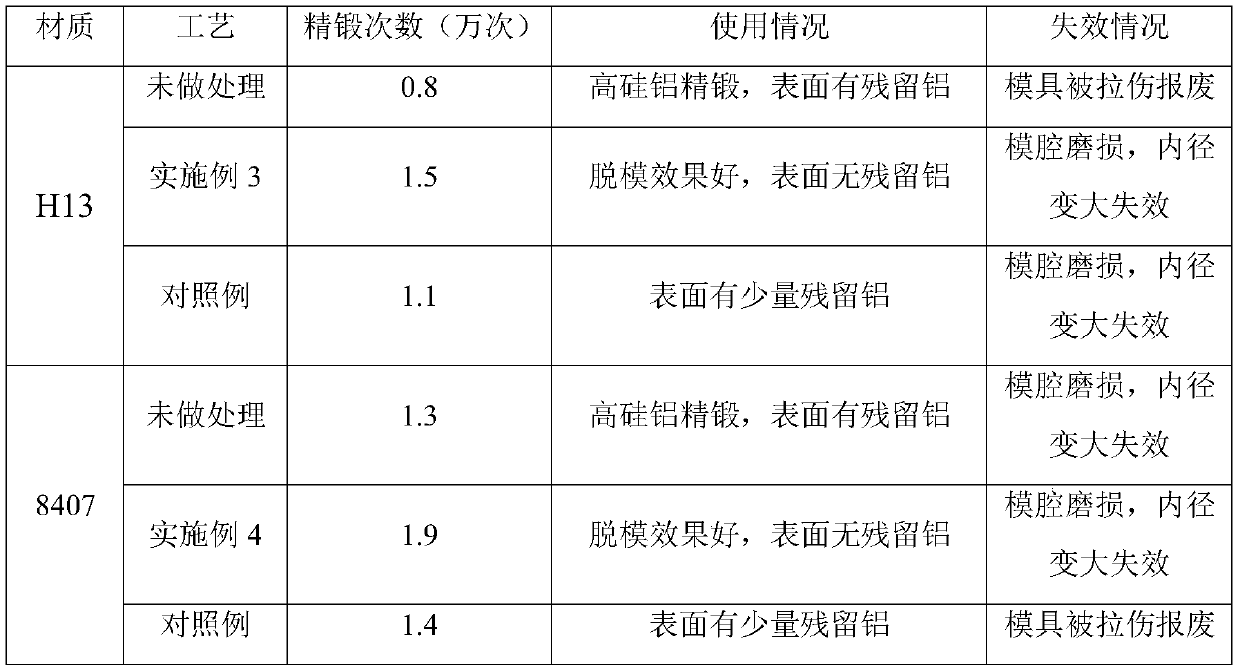

A processing method for improving aluminum die casting and precision forging dies

ActiveCN108239741BImprove wear resistanceDeep diffusionMetal-working apparatusSolid state diffusion coatingOxygen ionsLanthanum

The invention discloses a machining method for improving an aluminum pressure casting and precision forging die. According to the method, a carbon, nitrogen, lanthanum and yttrium permeability agent,a lanthanum and yttrium excitation permeability agent and an oxygen ion permeability agent are used, a non-metallic element and a trace metal element permeate the surface of a die base body, a carbon,nitrogen, lanthanum and yttrium diffusion layer and an oxygen ion diffusion layer are formed, the service life of the die is greatly prolonged, the treated die has the good mechanical property, and the die accuracy is not influenced by surface treatment. A permeable layer element distribution gradient of the die is gentle, a compound layer is not formed, the overall die surface stress distribution is even, and die surface peeling, layering and the like are avoided. According to the machining method, the permeability agent melting points are low, mobility is good, the permeable layer quality is more even and stable, treatment can be carried out at lower temperature, the diffusion efficiency of carbon, nitrogen, lanthanum and yttrium ions in the base body can be improved, and the activationenergy of diffusion is reduced.

Owner:湖南红宇智能制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com