A method for vacuum scattering and joining-up carbon-carbon composite material

A carbon composite material and vacuum diffusion technology, applied in the field of carbon/carbon composite material welding, can solve the problems of poor joint performance, large metal deformation and high connection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

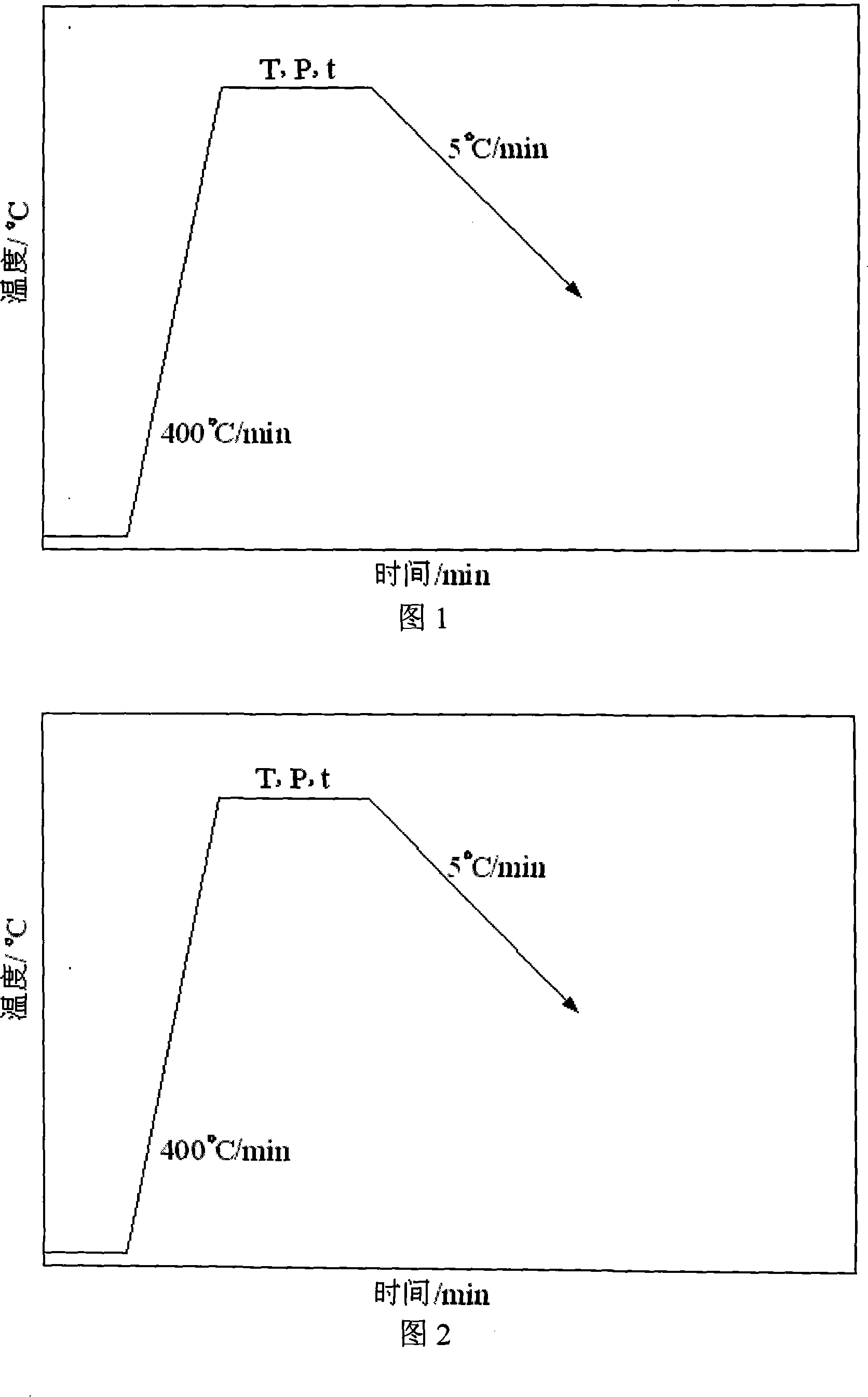

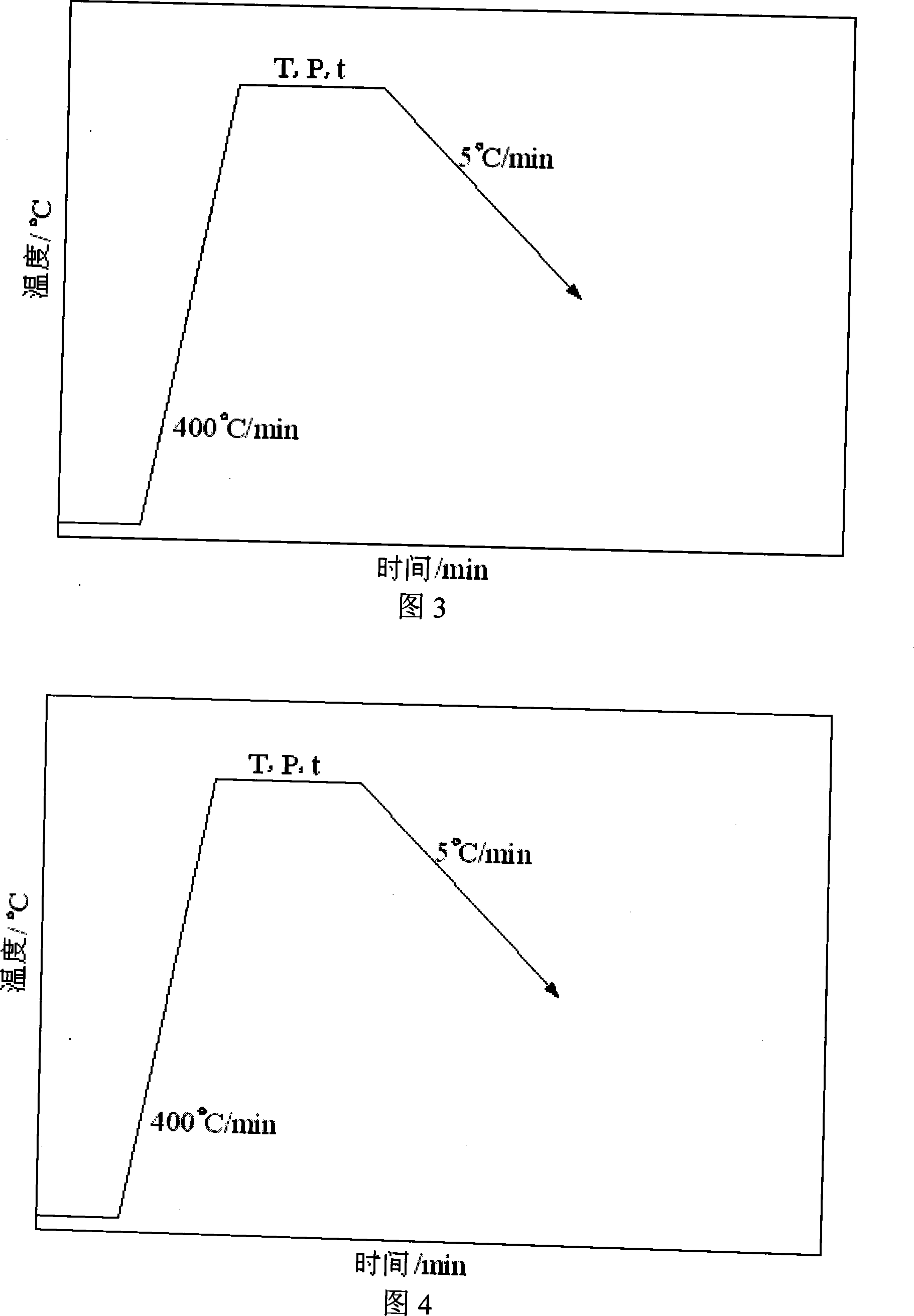

[0008] Specific Embodiment 1: In this embodiment, a method for vacuum diffusion bonding carbon / carbon composite materials is implemented according to the following steps: 1. Clean the surface of the base metal before diffusion bonding; 2. Place the diffusion intermediate layer evenly on the base material to be welded The connection surface of the material; the middle layer of the diffusion connection is a hydrogenated titanium or titanium alloy foil, and the thickness of the diffusion connection middle layer is 30-100 μm; 3. Place the clamped weldment in a vacuum diffusion welding machine for heating. Vacuum degree is 1.33×10 -3 ~4.0×10 -3 Diffusion connection is carried out under Pa vacuum condition; 4. After welding, the weldment is depressurized when the original vacuum condition drops to 100°C, and the weldment is taken out when the temperature is lowered to room temperature.

[0009] In this implementation method, the diffusion bonding process parameters should adopt the...

specific Embodiment approach 2

[0010] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the surface of the parent material is cleaned by physical cleaning, chemical cleaning or first physical cleaning followed by chemical cleaning; the physical cleaning is followed by 400 # 、500 # 、600 # , 800 # and 1000 # The metallographic sandpaper is polished step by step; the chemical cleaning is to prepare the corresponding corrosion solution according to the difference of the base metal to remove the adsorption layer, impurities or oxide film on the surface of the base metal, and then wipe the surface of the base metal to be welded with acetone or remove the base metal The materials were cleaned ultrasonically in acetone solution. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the thickness of the diffusion-connected intermediate layer in step 2 is 30-80 μm. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com