Pulse electric field and ultrasonic field assisted metal matrix composite sintering synchronous joining method and device

A pulsed electric field, composite material technology, applied in metal processing equipment, charge, electric furnace heating, etc., can solve the problems of oxide film blockage on the surface of materials, high difficulty of interfacial atom diffusion, and large physical and chemical differences of heterogeneous materials, etc., to increase the number of and uniform distribution, ensure the quality of sintering and connection, and improve the effect of growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

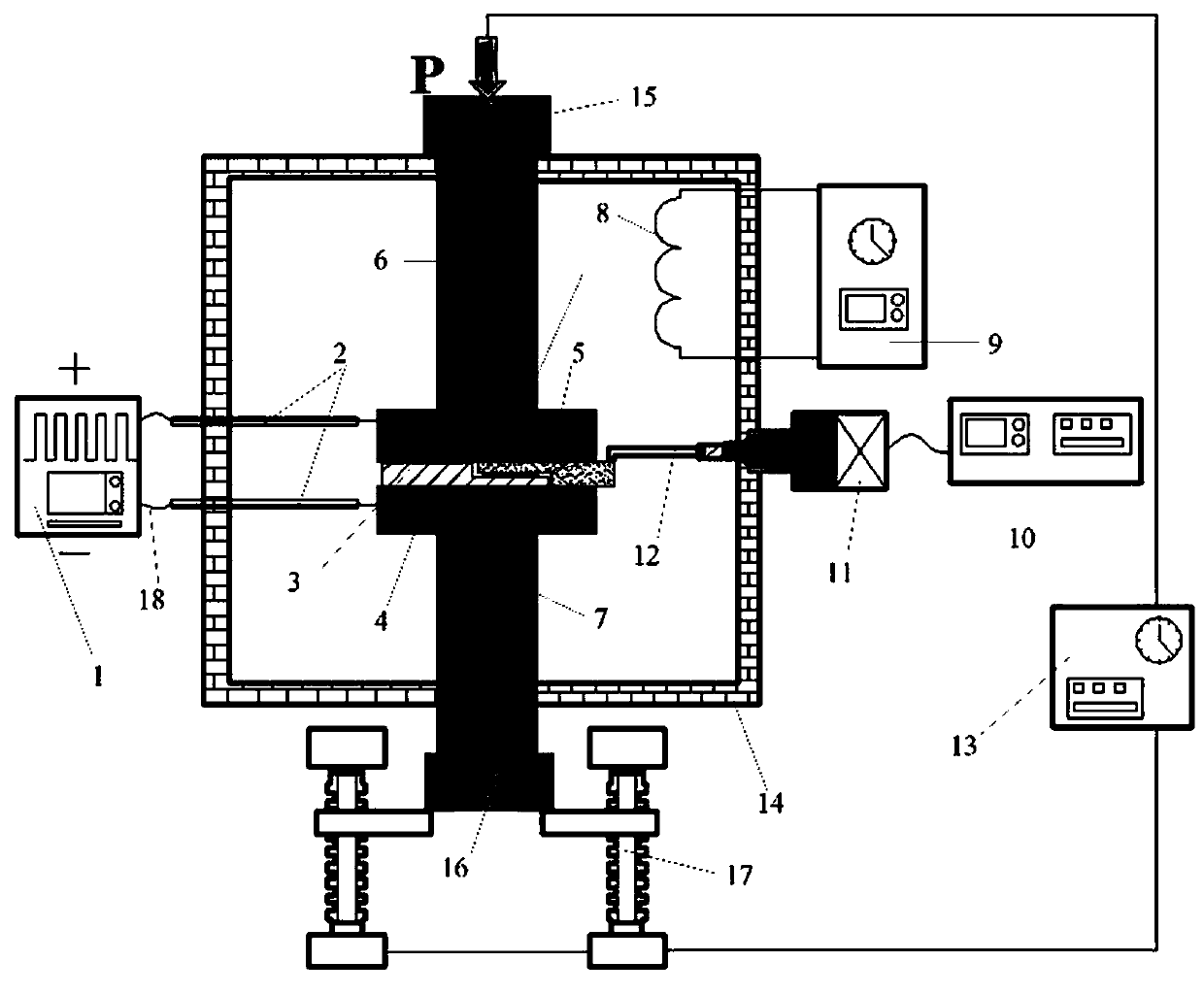

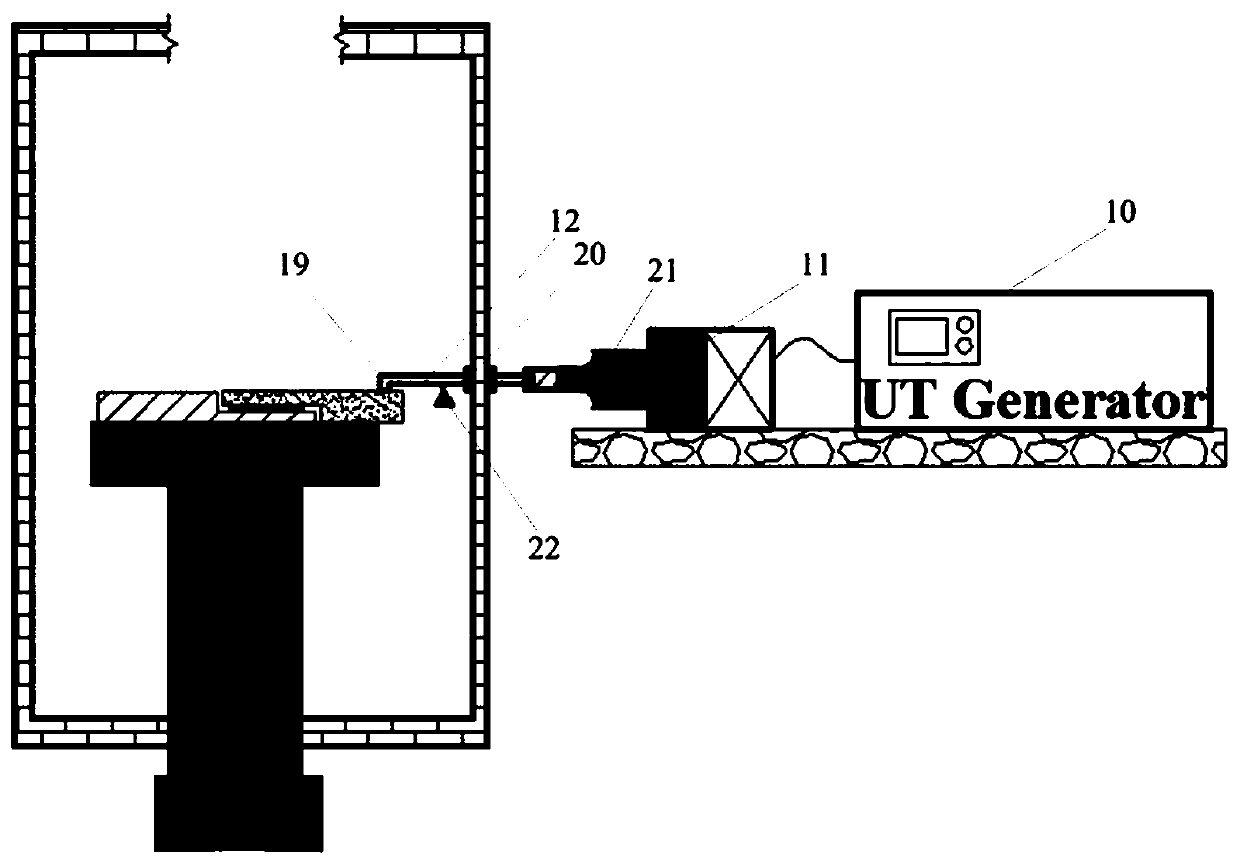

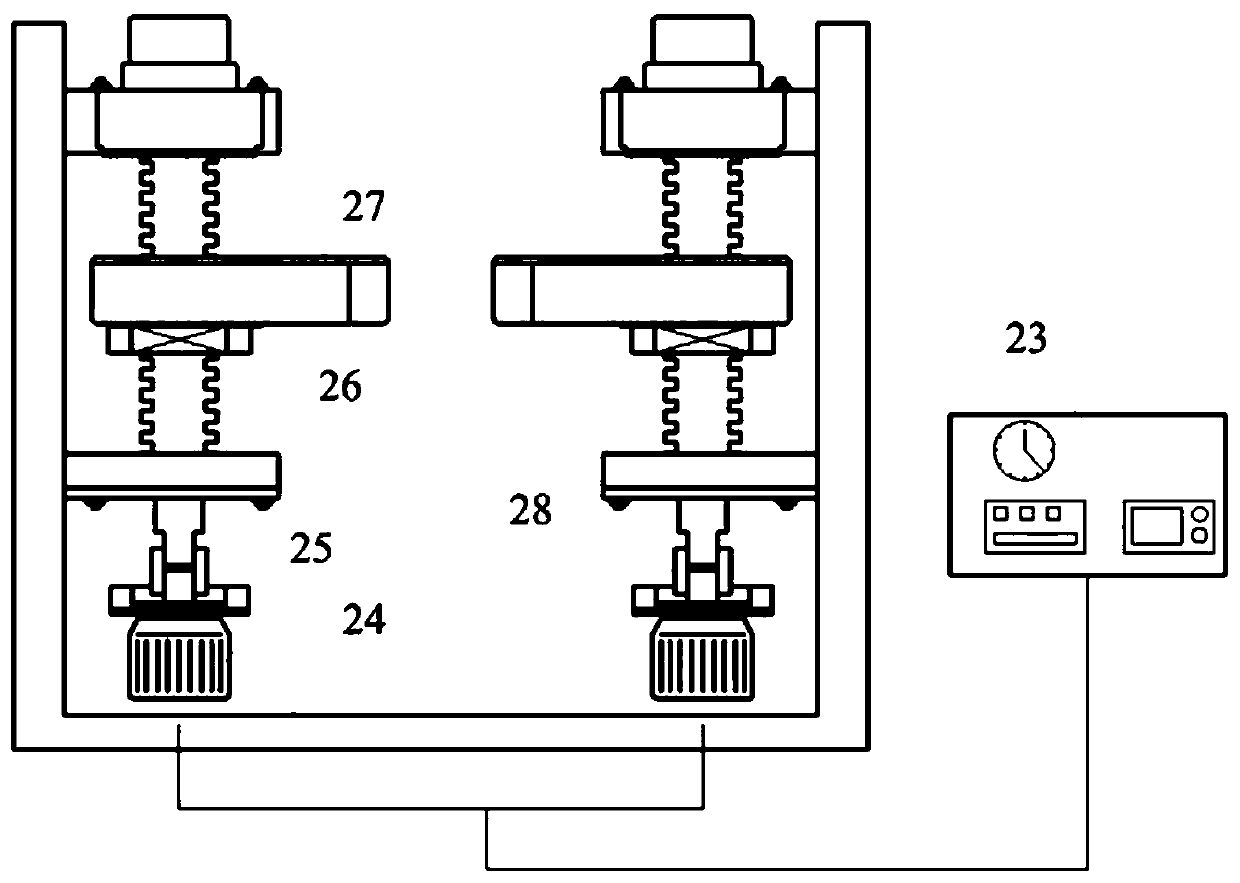

Method used

Image

Examples

preparation example Construction

[0047] A. Preparation of experimental materials:

[0048] Material: Micron-level magnesium alloy or copper alloy powder is selected as the matrix material, and the micron-level (≤20μm) reinforcement phase (such as SiC ceramic particles) is used. Firstly, a certain proportion of the reinforcement phase particles and the matrix material are subjected to high-energy ball milling by high-energy ball milling. The rotation speed of the ball mill is 1200~1500rpm, the ball milling time is 6~10h, the reinforcement and the base material are mixed evenly, the mixed powder is sintered in a vacuum sintering furnace, and the pre-sintered block is prepared under a pressure of 2~3MPa. The intermediate layer alloy is formed into a thin sheet.

[0049] Use a diamond grinding disc to polish the surface of the pre-sintered block and the alloy to be welded flat and smooth, and then polish it with a 0.5 μm diamond polishing machine until the interface is bright and smooth, and clean the surface of ...

Embodiment 1

[0060] Pulsed current-ultrasonic composite assisted sintering of SiC magnesium matrix composites and simultaneous diffusion bonding of 316L stainless steel plates.

[0061] 1. Preparation of experimental materials

[0062] a. The base material to be welded is high volume fraction SiC magnesium-based powder pre-sintered billet and 316L stainless steel plate, cut into a cuboid of 8×15×30mm, and processed into a stepped lap structure, and polished with 800#~1200# sandpaper The surface of the base metal to be welded is ultrasonically cleaned in acetone and dried for later use. The pre-sintered billet is sintered synchronously during the diffusion welding process, in which the volume fraction of SiC reinforcement phase is 10%~50%, the average diameter of SiC powder is 100nm, and the metal matrix is AZ61 magnesium alloy powder;

[0063] b. Cut the middle layer Ag-21Cu-4.5Ti (Ag content 74.5%, Cu content 21%, Ti content 4.5%) alloy into 8×8×0.3mm thin slices, ultrasonic cleaning i...

Embodiment 2

[0073] Pulsed current-ultrasonic composite assisted sintering of B4C copper matrix composites with simultaneous diffusion bonding of Ti-6Al-4V alloys.

[0074] 1. Preparation of experimental materials

[0075] a. The base metal to be welded has a high volume fraction B 4 C copper-based powder pre-sintered compact and Ti-6Al-4V (Ti content 90%, Al content 6%, V content 4%) alloy plate, cut into 8 × 15 × 30mm cuboid, and use 800 # ~1200 # Grind the surface of the base metal to be welded with sandpaper, ultrasonically clean it in acetone, and dry it for later use. The pre-sintered body is sintered synchronously during the diffusion welding process, where B 4 The volume fraction of C reinforcement phase is 10%~50%, B 4 The average diameter of the C powder is 100nm, and the Cu powder is an aerosolized spherical powder;

[0076] b. Cut the Al-12Si (88% Al content, 12% Si content) amorphous alloy in the middle layer into thin slices of 8×8×0.3 mm, ultrasonically clean them in ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com