Method for screening short-cut nitrifying bacteria by using low-intensity ultrasonic waves and application thereof

A short-range nitrification and ultrasonic technology, which is applied in the direction of chemical instruments and methods, biochemical equipment and methods, bacteria, etc., can solve the problems of short-range nitrification system instability, and achieve the promotion of biological denitrification efficiency, reduction of environmental pollution, and energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

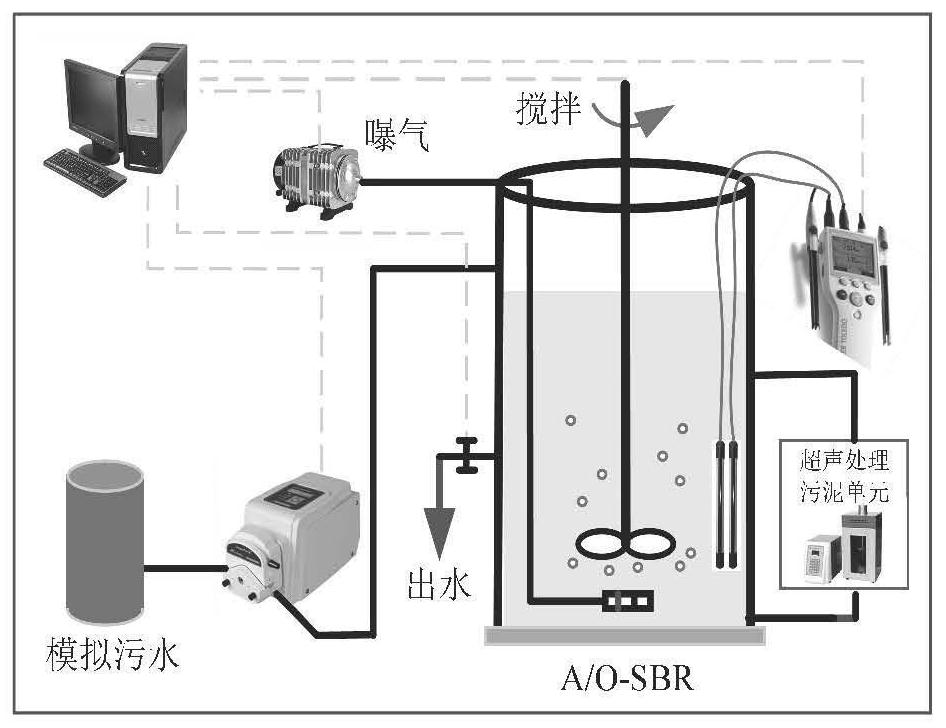

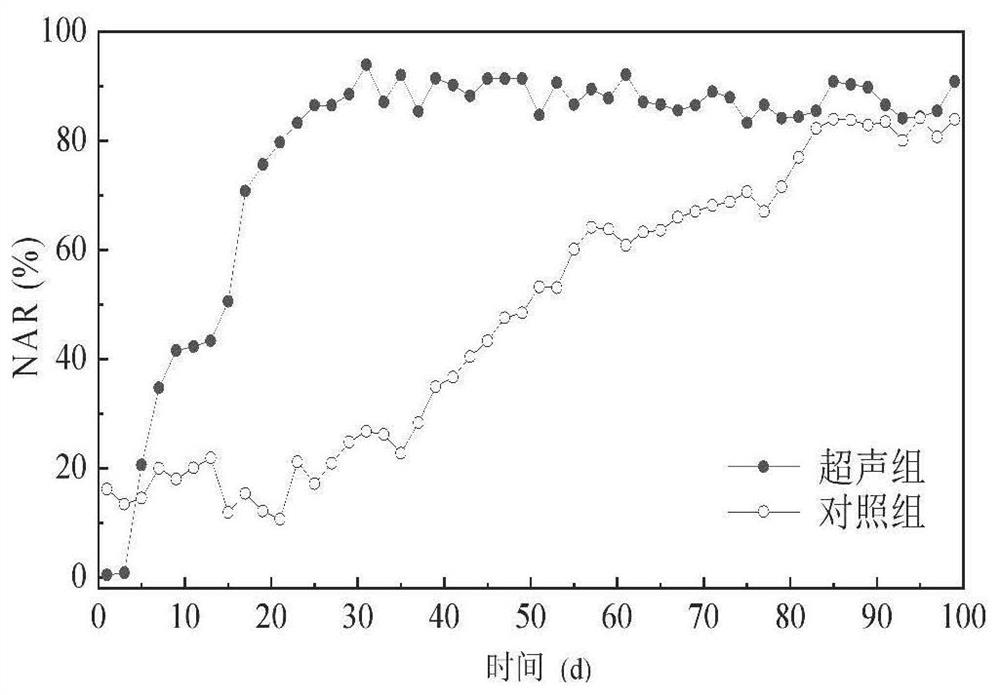

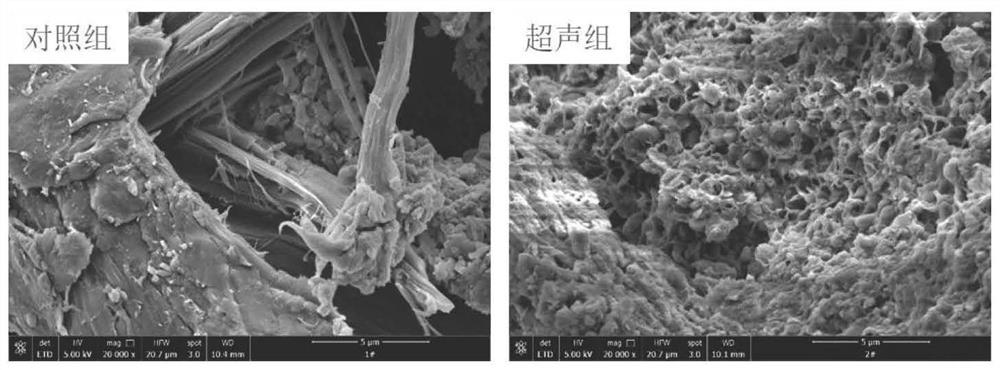

[0028] 1. Using SBR reactor, such as figure 1 As shown, it is divided into two SBR reactors, the control group and the ultrasonic group, the effective volume of each SBR is 5.0L, and the water exchange rate is 50%.

[0029] 2. Inoculation sludge: Activated sludge from a local sewage treatment plant, control the concentration of MLVSS in the reactor to 2200mg / L;

[0030] 3. Influent water quality: Influent COD, ammonia nitrogen, and total phosphorus are 150, 60, and 1.5 mg / L respectively. By adding NaHCO 3 Solution 600mg / L adjusts the pH in the reactor to be controlled at 8.0;

[0031] 4. Reactor operation mode: intermittent aeration operation mode is adopted, the total aeration time is 150min, divided into five aeration periods, the aeration time is 30min, and the aeration rate is 1.0-1.5L / min. stage ultrasonic irradiation;

[0032] 5. Reactor operating temperature: 18±3°C

[0033] 6. Ultrasonic sound energy density: use a sound energy density of 0.25W / mL to irradiate slud...

Embodiment 2

[0059] 1. Using SBR reactor, such as figure 1 shown. The test is divided into two SBR reactors, the control group and the ultrasonic group, each SBR has an effective volume of 5.0L and a water exchange rate of 50%.

[0060] 2. Inoculation sludge: Activated sludge from a local sewage treatment plant, control the concentration of MLVSS in the reactor to 2000mg / L;

[0061] 3. Influent water quality: Influent COD, ammonia nitrogen, and total phosphorus are 150, 60, and 1.5 mg / L respectively. By adding NaHCO 3 Solution (600mg / L) adjusts the pH in the reactor to be controlled at 7.5;

[0062] 4. Reactor operation mode: intermittent aeration operation mode is adopted, the total aeration time is 150min, divided into five aeration periods, the aeration time is 30min, and the aeration rate is 1.0-1.5L / min. stage ultrasonic irradiation;

[0063] 5. Reactor operating temperature: 25±3°C

[0064] 6. Ultrasonic sound energy density: 0.25W / mL;

[0065] 7. Ultrasonic irradiation time: 1...

Embodiment 3

[0077] 1. Using SBR reactor, such as Figure 6 Shown: The test is divided into two SBR reactors, the control group and the ultrasonic group, the effective volume of each SBR is 5.0L, and the water exchange rate is 60%.

[0078] 2. Inoculation sludge: Activated sludge from a local sewage treatment plant, control the reactor sludge concentration to 2500mg / L;

[0079] 3. Influent water quality: Influent COD, ammonia nitrogen, and total phosphorus are 120, 60, and 6mg / L respectively. By adding NaHCO 3 The solution adjusts the pH in the reactor to be controlled at 8.0;

[0080] 4. Reactor operation mode: the intermittent aeration operation mode is adopted, the total aeration time is 180min, divided into 6 aeration periods, the aeration time is 30min, and the aeration volume in the aerobic stage is 0.2-1.0L / min. Ultrasonic irradiation is carried out during the static stage of the reactor;

[0081] 5. Reactor operating temperature: 30±3°C

[0082] 6. Ultrasonic sound energy densi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com