Fused salt system for molybdenum or molybdenum alloy binary co-penetration, composite catalyst and application

A molten salt system and molybdenum alloy technology, applied in the field of molybdenum or molybdenum alloy, can solve the problems of low binary co-infiltration rate, thin infiltration layer thickness, poor oxidation resistance of molybdenum or molybdenum alloy, etc. Good oxidation resistance at high temperature and the effect of resisting high temperature oxidation corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

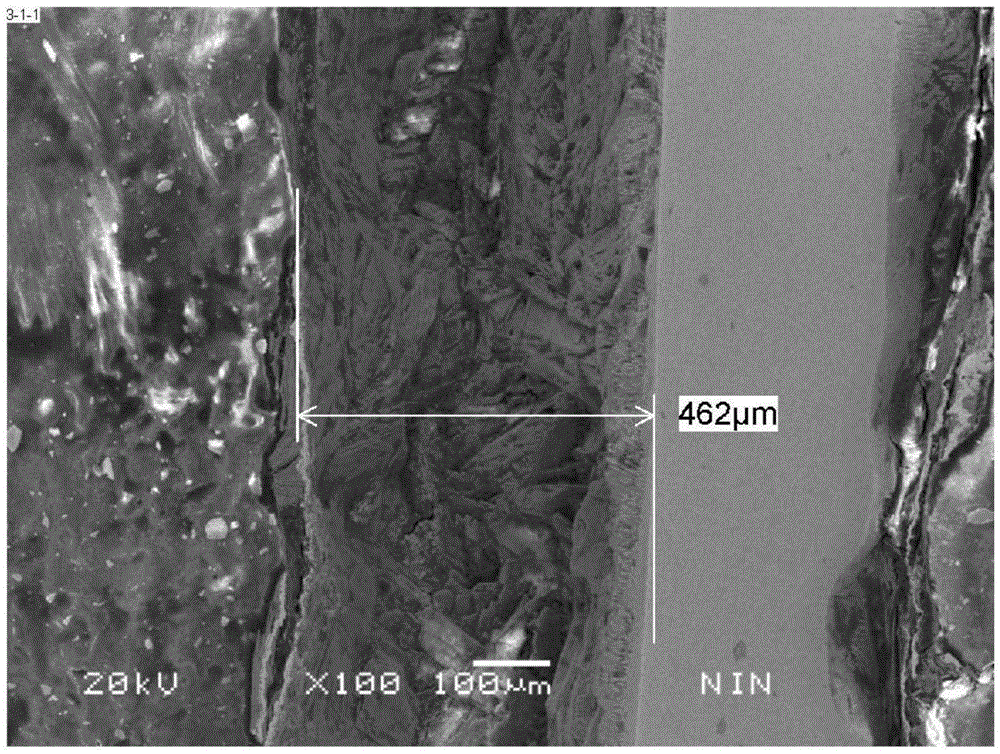

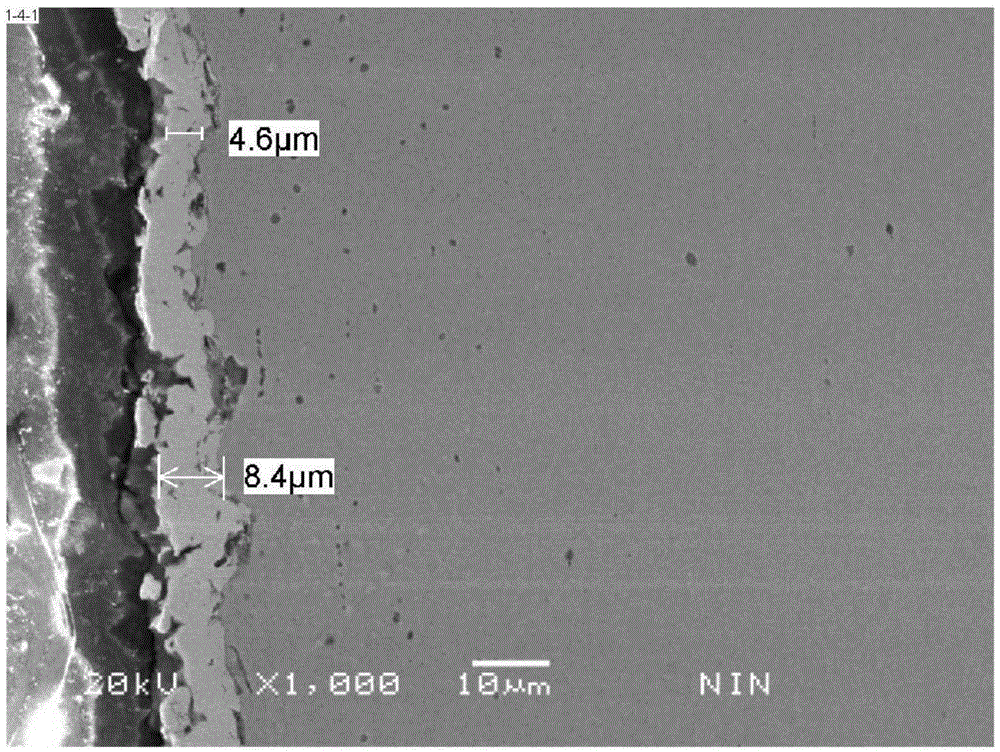

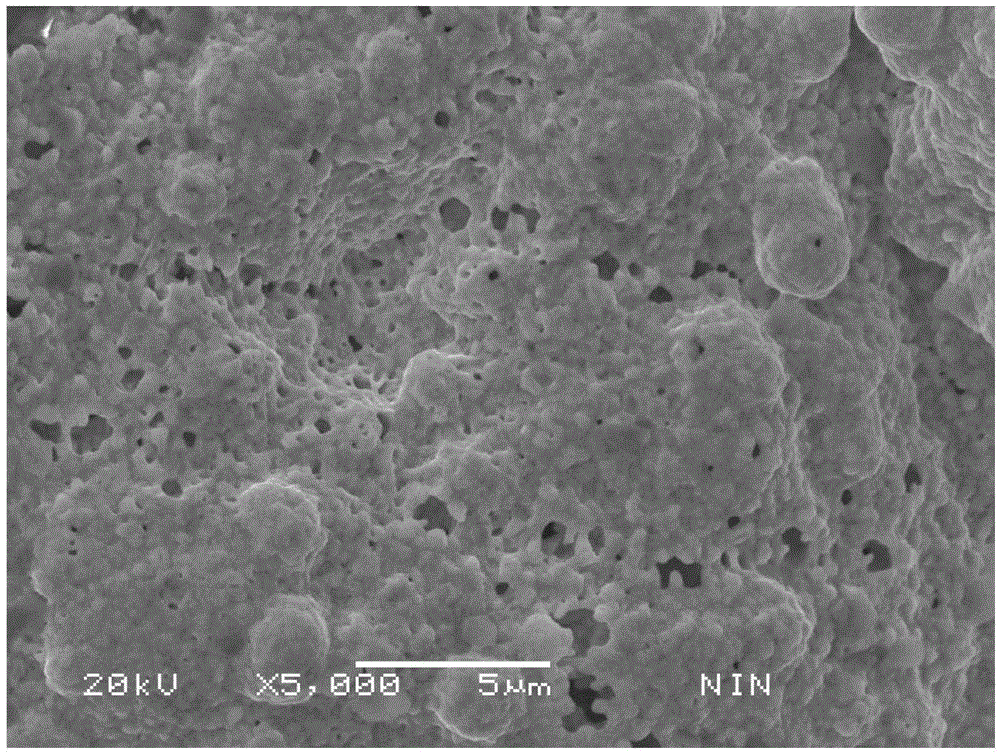

[0040] This embodiment provides a molybdenum or molybdenum alloy binary co-infiltration molten salt system and composite catalyst, as shown in Table 1 of the formula milk, the molybdenum or molybdenum alloy binary co-infiltration molten salt system of this embodiment is used The application of electrochemical binary co-infiltration to prepare the rare earth metal-boron binary co-infiltration layer on the surface of molybdenum or molybdenum alloy, the specific process includes the following steps:

[0041] Step 1, preparing molybdenum matrix or master alloy matrix:

[0042] Put molybdenum or molybdenum alloy in 20wt% NaOH solution, boil alkali to remove grease, wash with water after ultrasonic cleaning; then place in 30wt% HCl solution and heat to 90°C, keep for 1h to pickle and decontaminate; then place The surface is etched in a 10wt% hydrofluoric acid solution at a temperature of 80° C. until a uniform pockmark is formed on the surface. After taking it out, it is washed with...

Embodiment 2

[0051] This embodiment provides a molybdenum or molybdenum alloy binary co-infiltration molten salt system and composite catalyst, as shown in Table 1 of the formula milk, the molybdenum or molybdenum alloy binary co-infiltration molten salt system of this embodiment is used For the application of electrochemical binary co-infiltration to prepare the rare earth metal-boron binary co-infiltration layer on the surface of molybdenum or molybdenum alloy, the specific process is the same as in Example 1, and the specific conditions are shown in Table 1. The difference is that the molybdenum substrate is selected in this embodiment. The material is pure molybdenum rod matrix.

Embodiment 3

[0055] This embodiment provides a molybdenum or molybdenum alloy binary co-infiltration molten salt system and composite catalyst, as shown in Table 1 of the formula milk, the molybdenum or molybdenum alloy binary co-infiltration molten salt system of this embodiment is used For the application of electrochemical binary co-infiltration to prepare the rare earth metal-boron binary co-infiltration layer on the surface of molybdenum or molybdenum alloy, the specific process is the same as in Example 1, and the specific conditions are shown in Table 1. The difference is that the molybdenum alloy substrate is selected in this embodiment. The material of the alloy matrix is a plate of Mo-Ti alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com