Plasma spray coating on aluminum alloy base surface and preparation method thereof

A kind of aluminum alloy and plasma technology, applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of increasing process complexity, poor corrosion resistance, serious wear and damage, etc., achieve smooth shape, avoid Effect of over-oxidation, moderate pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

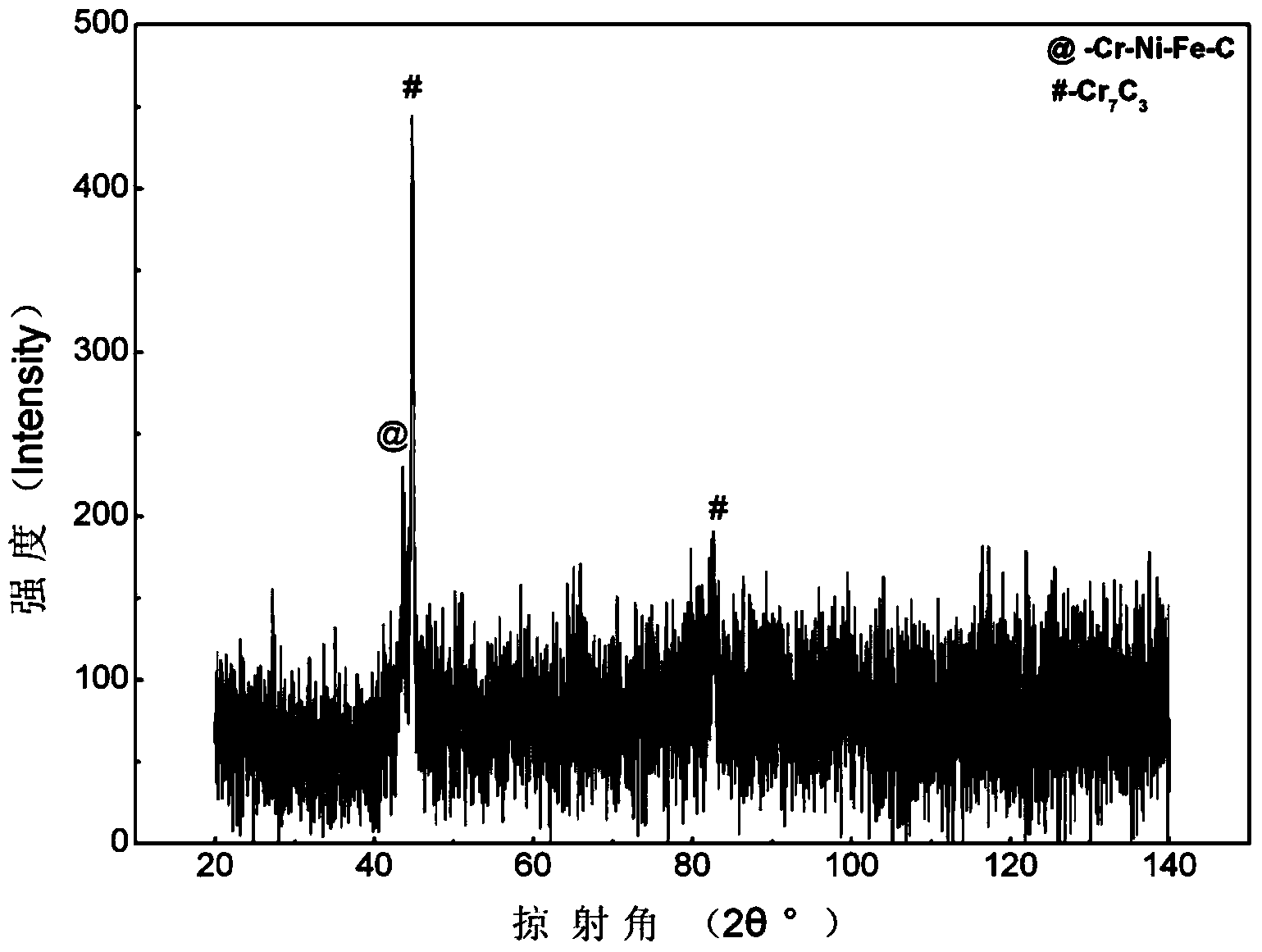

[0029] In this embodiment, the aluminum alloy substrate is an engine cylinder, and the surface of the inner wall of the cylinder is a plasma sprayed coating. The composition and content of the coating are as follows: 17.84% chromium, 8.45% nickel, 0.83% carbon, Silicon 3.12%, manganese 0.96%, the balance is iron; and, the austenite microstructure of the microstructure of the coating is dispersed with Cr 7 C 3 strengthening phase.

[0030] The preparation method of this coating is as follows:

[0031] (1) Machining and roughening the surface of the aluminum alloy substrate to form dovetail grooves with a width of 150 μm and a depth of about 100 μm are evenly distributed on the surface of the substrate, and then ultrasonic cleaning in acetone and ethanol for 20 minutes;

[0032] (2) According to the weight formula: 17.84% chromium, 8.45% nickel, 0.83% carbon, 3.12% silicon, 0.96% manganese, and the balance is iron to prepare chromium-iron-based alloy; then melt the alloy and p...

Embodiment 2

[0040] In this embodiment, the aluminum alloy substrate is an engine cylinder, and the surface of the inner wall of the cylinder is a plasma sprayed coating. The composition and content of the coating are as follows: 17.84% chromium, 8.45% nickel, 0.83% carbon, Silicon 3.12%, manganese 0.96%, the balance is iron; and, the microstructure of the coating is based on austenite, in which Cr 7 C 3 strengthening phase.

[0041] The preparation method of this coating is as follows:

[0042] (1) The surface of the aluminum alloy substrate is roughened by sandblasting, and then ultrasonically cleaned in acetone and ethanol for 15 minutes;

[0043] (2) According to the weight formula: 17.84% chromium, 8.45% nickel, 0.83% carbon, 3.12% silicon, 0.96% manganese, and the balance is iron to prepare a chromium-iron-based alloy; then melt the alloy and prepare it by gas atomization The chromium-iron-based alloy powder, so that the particle size of the chromium-iron-based alloy powder is -32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com