Nickel-based high temperature alloy, preparation method thereof as well as application thereof in spark plug electrode

A nickel-based high-temperature alloy and spark plug technology, which is applied in the direction of spark plugs, circuits, electrical components, etc., can solve the problems of increased ignition energy and easy ablation of the central electrode, so as to improve stability, reduce holes, and promote rapid formation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of nickel-based superalloy (7# alloy):

[0038] The material is composed of the following weight percentages: C0.05%, Cr20%, W8%, Mo6%, Ti2%, Al2%, B0.005%, Zr0.04%, Fe0.8%, Nb2%, Y0.4 %, Ni58.705%.

[0039] According to the above composition, the raw materials were smelted in a vacuum arc melting furnace, shaped, and subjected to solution treatment, kept at 1200°C for 4 hours, and air-cooled; then subjected to aging treatment, kept at 800°C for 10 hours, and air-cooled.

[0040] Preparation of comparative nickel-based superalloys:

[0041] The preparation method is the same as that of nickel-based superalloy, and the composition of each material is shown in Table 1 (1#~6#).

[0042] Table 1 Chemical composition (wt%) of nickel-based superalloy materials

[0043]

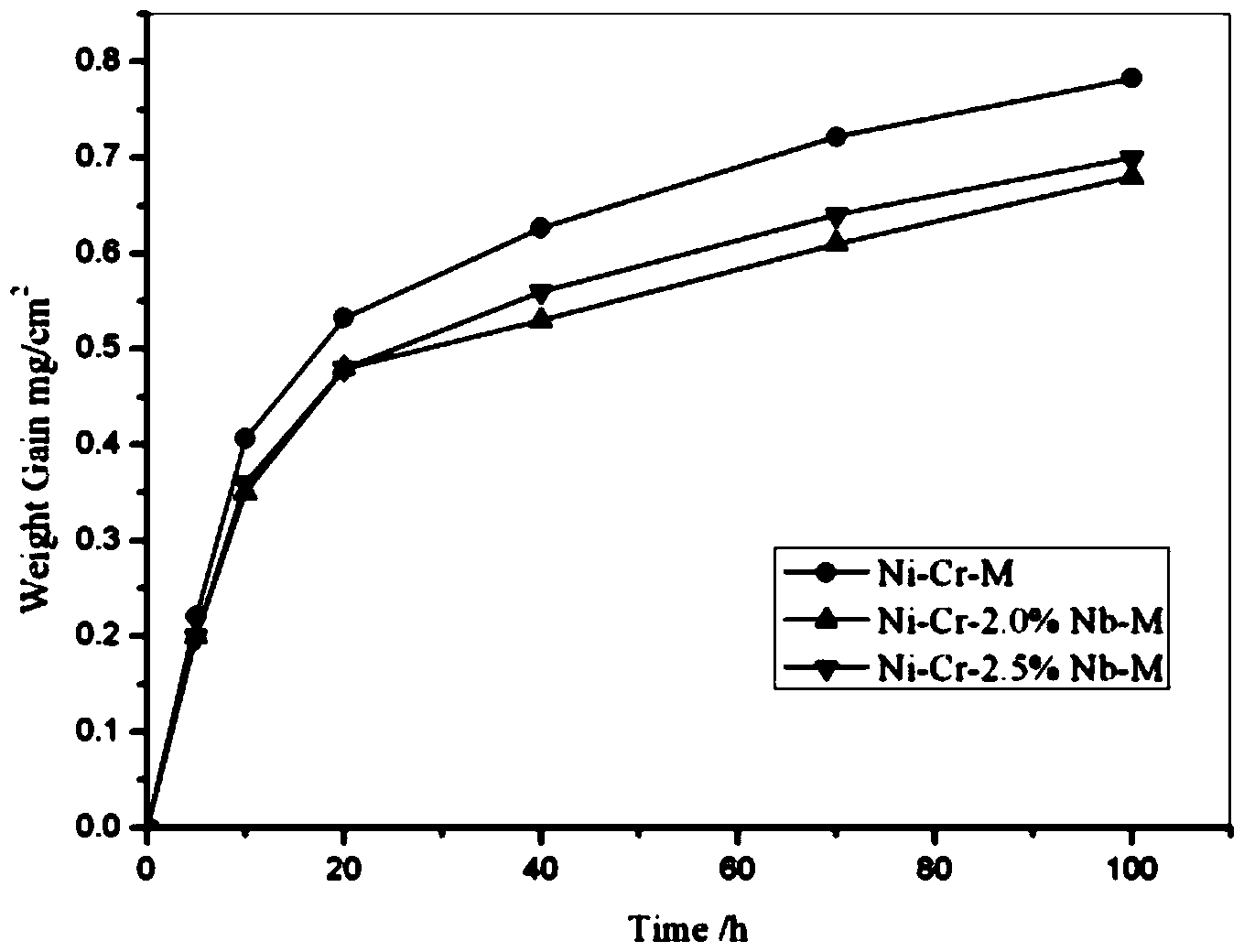

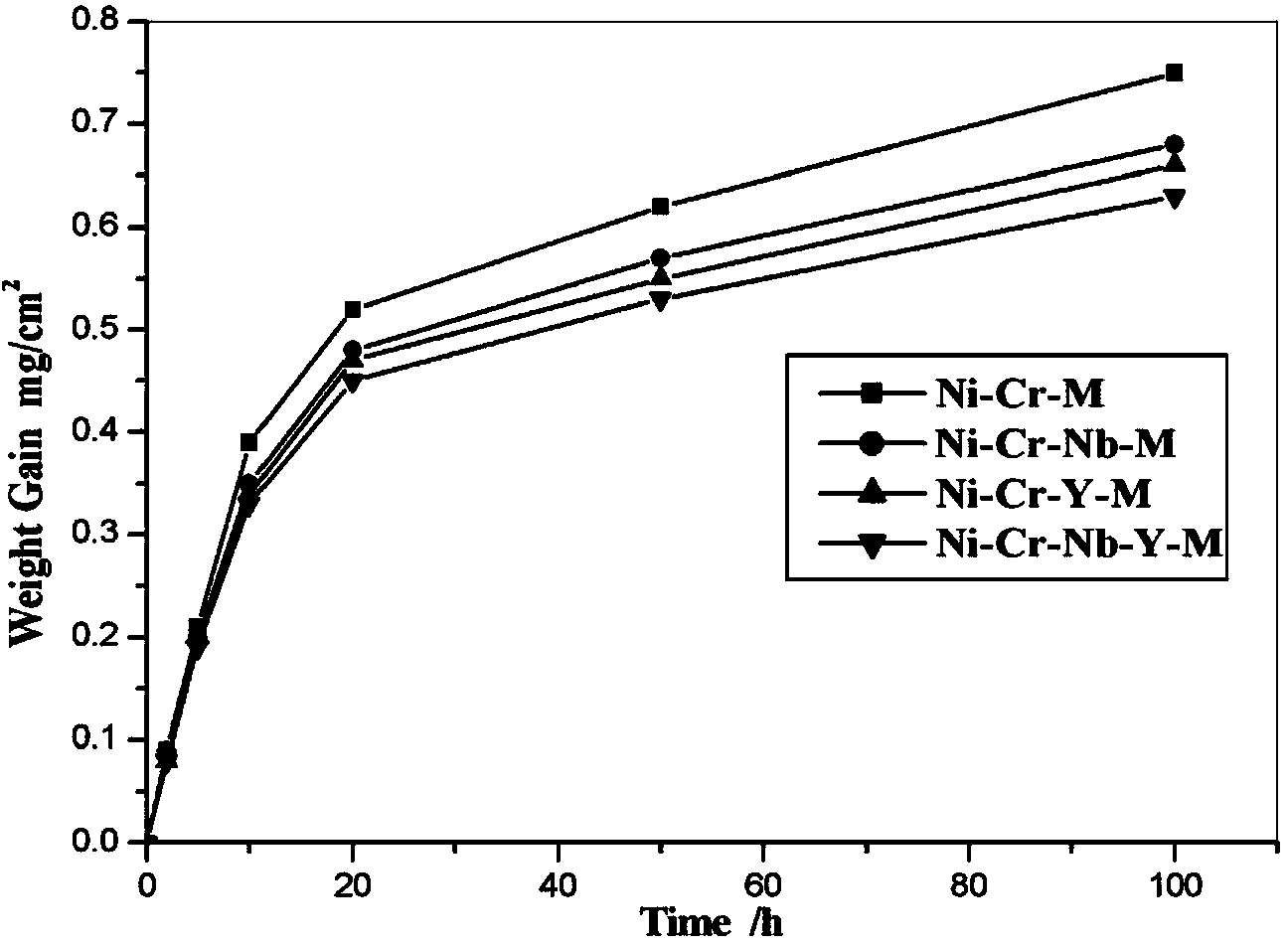

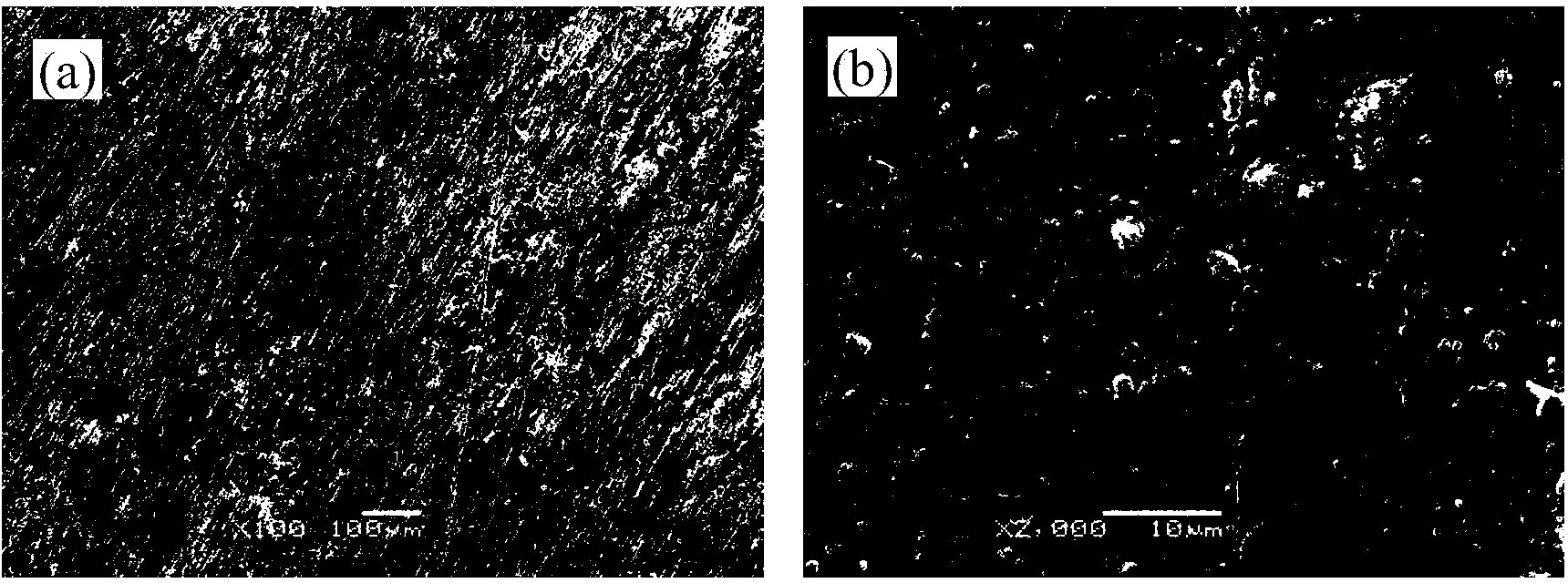

[0044] The as-cast microstructure of nickel-based alloys, from Figure 11 It can be seen that the alloy structure is dendritic, and the primary trunk and the secondary and tertiary trunks a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com