Patents

Literature

121results about How to "Good wear resistance and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

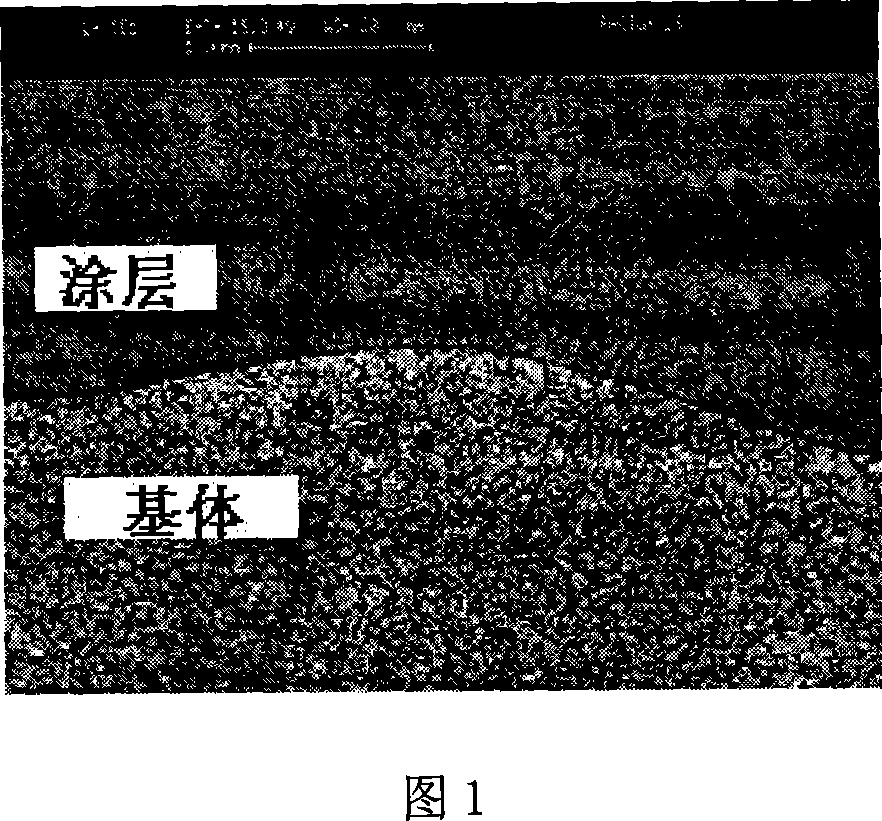

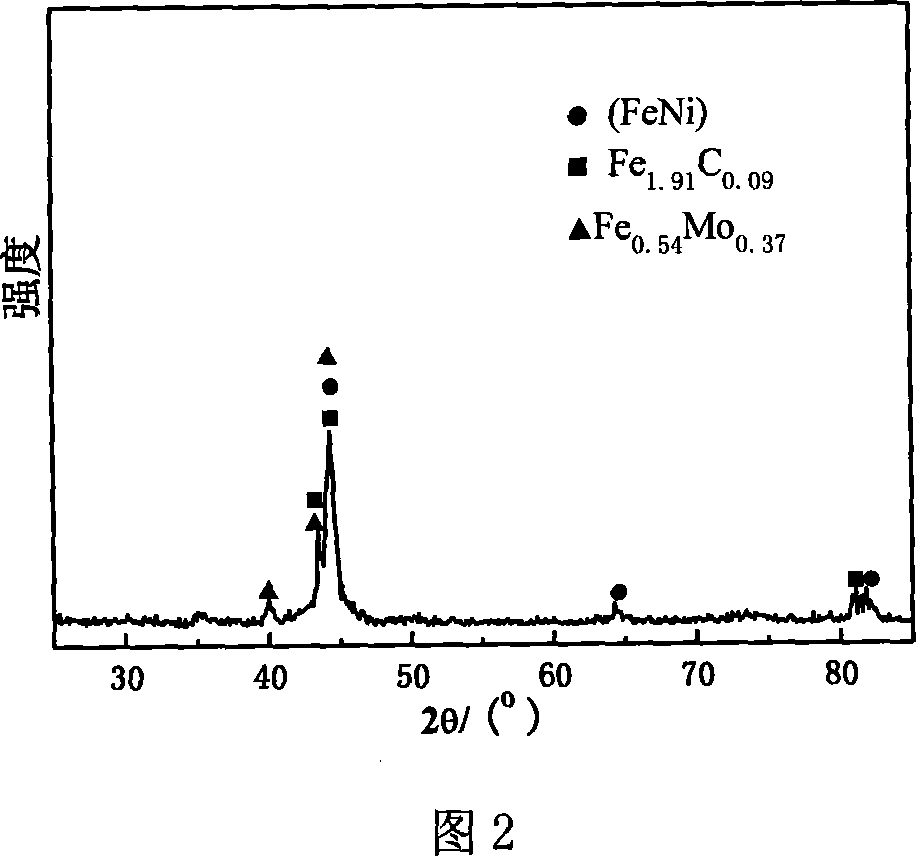

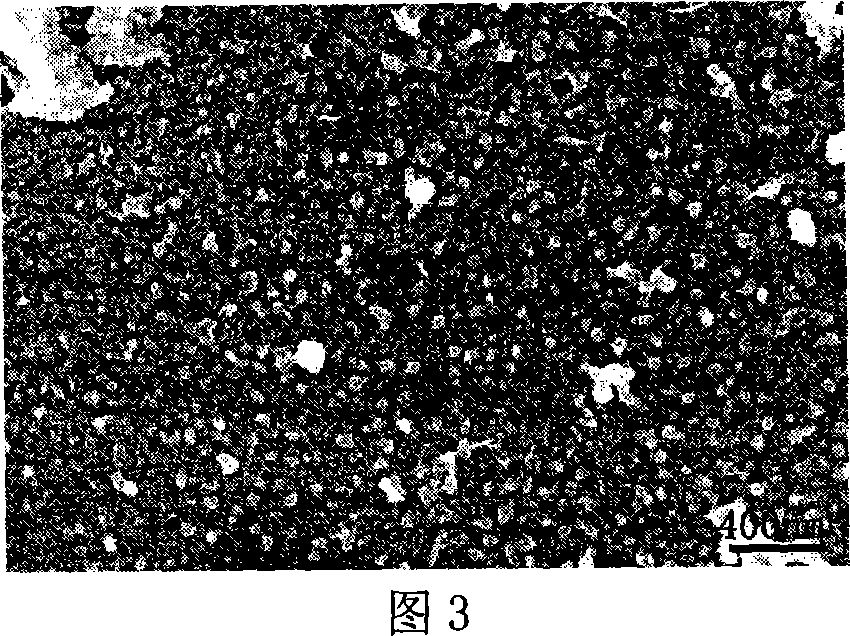

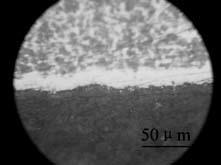

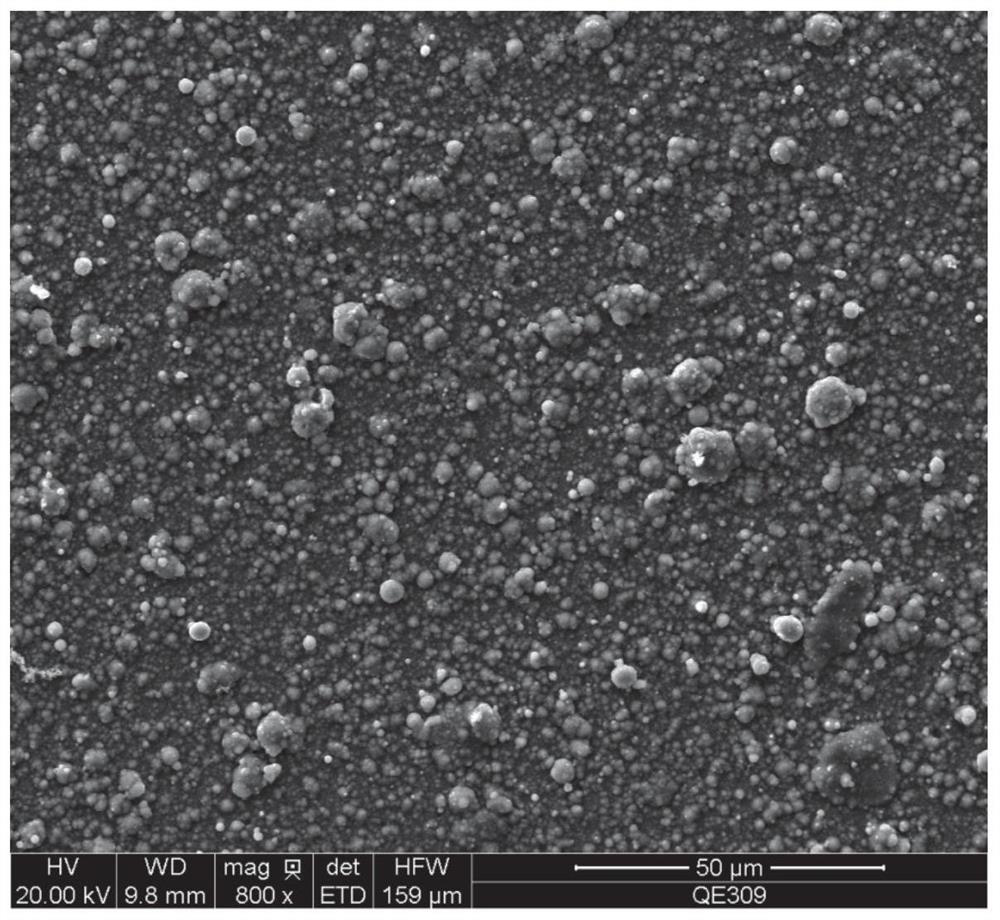

Plasma melting coating iron-base amorphous nano-crystalline coat and preparing method thereof

InactiveCN101033543AGood wear resistance and corrosion resistanceImprove thermal stabilityMetallic material coating processesCrystal structureNanostructure

This invention relates to plasma cladding Fe base non-crystal nanometer crystal foating and its preparation method, in which, the cladding material includes the following components in weight percentages: C 0.5-3.0, B 2-5, Si 2-6, P 0.9-3.0, Mo 12.0-26.0, Ni 5.0-15.0, Cr 2.0-15.0, Re 0.8-3.0 and Fe for the rest the size is 106-180mum. The preparation method includes: cladding plasma on an A3 steel base to prepare a coating in the following technical parameters: Ar is the protection and ionization gas, the Ar flow for transmitting powder is 0.2-0.8m3 / h, the protection flow is 0.4-1.0m3 / h, the ionization gas flow is 0.5-1.2m3 / h, the current is 280-380A and the scan speed is 350-480mm / min. Advantage: a non-crystal nanometer crystal compound coating containing either a non-crystal structure or a nanometer structure is prepared having excellent performance of wear resistance and anti-corrosion.

Owner:UNIV OF SCI & TECH BEIJING

Anti-icing coating for ultra-high voltage power transmission line and preparation method thereof

The invention discloses an anti-icing coating for an ultra-high voltage power transmission line. The coating includes the following raw materials by weight: 50-60 parts of silicon fluorine resin, 6-10 parts of diamond like carbon, 2-3 parts of carbon nanotube, 5-8 parts of nano TiO2, 8-12 parts of nano SiO2, 0.3-1 part of a dispersant, 0.5-1 part of an antifoaming agent, 0.3-1 part of a leveling agent, 1-3 parts of an anticorrosive and bactericidal agent, and 20-30 parts of a solvent. The anti-icing coating for ultra-high voltage power transmission line has contact angle with water reaching 135-165 DEG C, also has good heating effect, the average temperature rise of 9.5-16 DEG C, very high hardness, excellent adhesion performance, acid and alkali resistance and wear resistance.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

Nitriding salt for low-temperature salt-bath nitriding

InactiveCN102220552AApplicable temperature range reducedGood wear resistance and corrosion resistanceSolid state diffusion coatingRadiochemistryNitriding

The invention discloses a nitriding salt for low-temperature salt-bath nitriding, which comprises the following components in percentage by weight: 45 to 55 percent of CO(NH2)2, 5 to 15 percent of K2CO3, 3 to 15 percent of Na2CO3, 3 to 15 percent of Li2CO3, 5 to 15 percent of NaCl and 5 to 15 percent of KCl. When the nitriding salt is used, the temperature for common salt-bath nitriding is lowered, and the use temperature range of the conventional nitriding salts is raised. In addition, the nitriding salt also has the advantages that: the deformation of a process workpiece is small; the equipment is simple; environment-friendly operation is realized; and the like.

Owner:SICHUAN UNIV

Nitride salt for low temperature salt bath nitriding of stainless steel

InactiveCN102220553AApplicable temperature range reducedGood wear resistance and corrosion resistanceSolid state diffusion coatingAustenitic stainless steelNitriding

The invention discloses nitride salt for low temperature salt bath nitriding of austenitic stainless steel. The nitride salt consists of the following components in percentage by weight: 1%-55% of KCNO, 1%-55% of NaCNO, 35%-15% of K2CO, 33%-15% of Na2CO, 33%-15% of Li2CO, 5%-15% of NaCl, 5%-15% of KCl and 40.1%-2% of Na2SO. In the invention, the temperature of the common salt bath nitriding is lowered and the using temperature of the currently known nitride salt is enlarged. In addition, the nitride salt has the advantages that the deformation of the processed workpiece is very small, the equipment is simple, the pollution-free work is realized and the like.

Owner:SICHUAN UNIV

Two-phase stainless steel

InactiveCN1412337AStrong acid and alkali corrosion resistanceImprove wear resistance and corrosion resistanceAcid corrosionStress corrosion cracking

The composition of biphase stainless steel is formed from (wt%) 0.01-0.12% of C, 4.0-8.0 % of Mn, 12.0-25.0% of Cr, 0.20-1.5% of Al, 0.5-3.0% of Ni, 0.4-3.0% of Mo, Cu is greater than or equal to 1.0%, 0.2-2.5% of Si, 0.05-0.3% of N, 0.02-0.05% of Re, S is greater than of equal to 0.03%, P is greater than or equal to 0.035% and the rest is Fe. Said biphase stainless steel can resist alkali corrosion, resist acid corrosion, specially it can resist stress corrosion cracking under the condition of resisting chlorine ion and in oxidative acid medium, can resist seam currosion and resist cavity corrosion, and its strength is high and toughness is good, etc.

Owner:陈才金

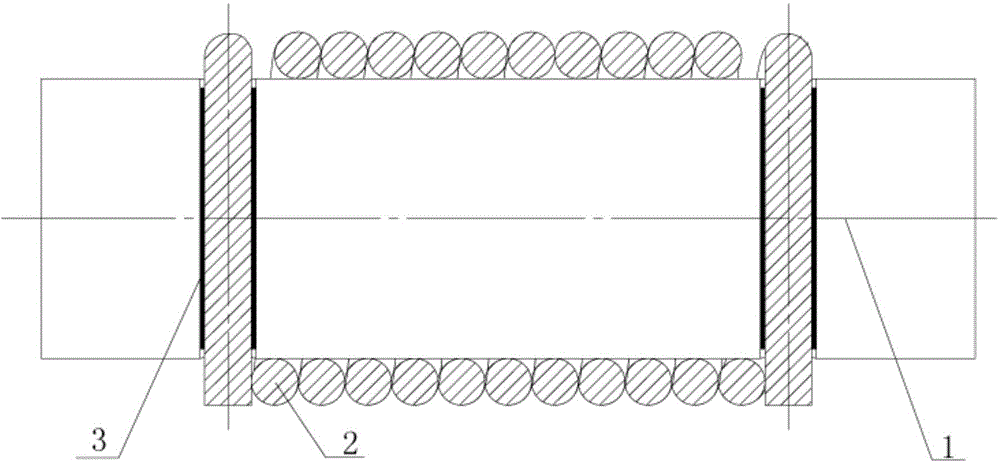

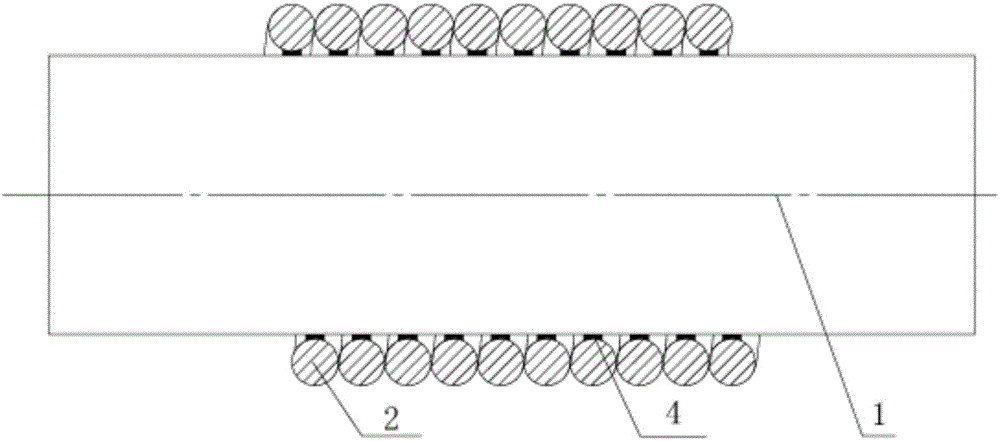

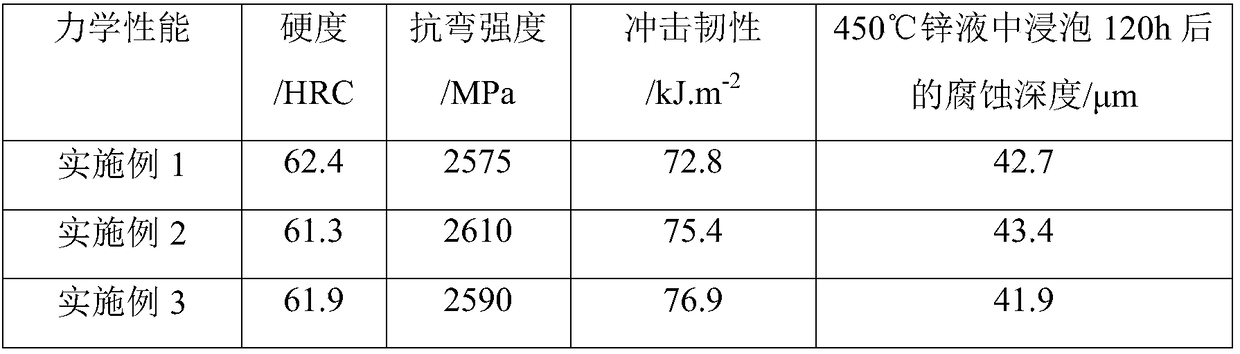

Preparation method of high-boron and wear-resistant alloy

ActiveCN104195362AHigh hardnessGood resistance to zinc liquid corrosion and wearMetallic material coating processesIron powderWear resistant

The invention discloses a preparation method of a high-boron and wear-resistant alloy, belonging to the technical field of molten zinc corrosion wear materials. The preparation method comprises the steps of uniformly mixing 45-50% of boron and iron powder, 14-16% of chromium iron powder, 3-5% of molybdenum iron powder, 4-4.6% of pure nickel powder, 1.5-2.5% of WC powder and 25-30% of pure iron powder which are within the particle size range of 140-200 meshes; and carrying out laser cladding on a stainless steel base material by using a fiber laser and a synchronous powder feeding method to obtain a high-boron and wear-resistant alloy laser cladding layer, the surface of which has no cracks, inclusions and air holes and is smooth.

Owner:BEIJING UNIV OF TECH

Biphase stainless steel

InactiveCN101429629AStrong acid and alkali corrosion resistanceHigh strengthChemical compositionSodium thiocyanate

The invention relates to a two phase stainless steel, which comprises the following chemical components in weight percent: 0 to 0.12 percent of C, 4.0 to 8.0 percent of Mn, 12.0 to 25.0 percent of Cr, 0.20 to 1.5 percent of Al, 0.5 to 3.0 percent of Ni, 0.4 to 3.0 percent of Mo, 0 to 1.0 percent of Cu, 0.2 to 2.5 percent of Si, 0.05 to 0.3 percent of N, 0.02 to 0.05 percent of Re, less than or equal to 0.03 percent of S, less than or equal to 0.035 percent of P, and the balance being Fe. The two phase stainless steel has the advantages of high strength, good toughness, excellent wear resistance and corrosion resistance, in particular the superiorities of stress corrosion cracking resistance, complete corrosion resistance, intergranular corrosion resistance, and pitting corrosion resistance and vacuole corrosion resistance in sea water in solutions such as strong base (such as NaOH), chlor-alkali (NH4Cl), oxidizing acid (such as HNO3), sodium thiocyanate, phosphate solution, good hot and cold processability, and low cost.

Owner:顾贤良

Preparation method of strengthened coating

InactiveCN103103521AImprove compactnessGood wear resistance and corrosion resistanceMetallic material coating processesBound propertyMaterials science

The invention discloses a preparation method of a strengthened coating. The preparation method comprises the following steps of: S1, preparing a first self-fluxing alloy powder coating on the surface of a substrate, wherein the first self-fluxing alloy powder coating comprises nickel-based alloy powder and / or iron-based alloy powder; S2, preparing a mixed powder coating on the surface of the first self-fluxing alloy powder coating obtained in the step S1, wherein the mixed powder coating comprises mixed powder, and the mixed powder comprises tungsten powder, titanium powder and graphite powder; S3, preparing a second self-fluxing alloy powder coating on the surface of the mixed powder coating obtained in the step S2, wherein the second self-fluxing alloy powder coating comprises nickel-based alloy powder and / or iron-based alloy powder; and S4, putting a product obtained in the step 3 in an induction field, centrifuging the product and preparing the strengthened coating on the surface of the substrate by adopting a self-propagating-centrifuge method under inductive heating. The strengthened coating prepared by using the preparation method is better in compactness, stronger in wear resistance and corrosion resistance and better in binding property between the coating and the substrate; and the preparation method is simple in process and low in cost and has a wide application prospect.

Owner:KING STRONG MATERIAL ENG LTD

3D printing method for ceramic-based nickel alloy composite material

ActiveCN105256160AHigh strengthImprove toughnessAdditive manufacturing apparatusMicrometerBiocompatibility Testing

A 3D printing method for a ceramic-based nickel alloy composite material is characterized in that ZrO2 ceramic powder and Ni-based alloy powder which are evenly mixed according to a proportion are put into a metal 3D printing work chamber, printing is conducted on the conditions that power is 100-400 W, the scanning speed is 200-600 mm / s, the diameter of light spots is 30-60 micrometers, the scanning interval is 40-70 micrometers and the oxygen concentration of the work chamber is smaller than 50 ppm, and a product obtained through 3D printing is annealed under the protection of N2 gas at the temperature of 800-890 DEG C for 8-12 hours. The biocompatibility of the material of the product obtained through the printing and a human body is good; the structure is compact and controllable; the mechanical property is good, the product has good corrosion and abrasion resistance, and is short in production period and low in manufacturing cost; the whole strength of the formed product can be adjusted by changing the proportion of Ni60 alloy in a base material.

Owner:GUANGDONG INST OF NEW MATERIALS

Diamond-like composite coating and preparation method thereof

ActiveCN106756820AReduce internal stressImprove toughnessVacuum evaporation coatingSputtering coatingInternal stressToughness

The invention discloses a diamond-like composite coating, a preparation method thereof and an abrasion-resistant component containing the diamond-like composite coating. The diamond-like composite coating comprises a transitional metal layer combined to the surface of a substrate and further comprises transitional metal boride layers and diamond-like layers, and the transitional metal boride layers and the diamond-like layers are sequentially combined to the surface of the transitional metal layer in the extension direction from the substrate to the transitional metal layer; the transitional metal boride layers and the diamond-like layers are combined by being alternately stacked at least one time, and the outermost layer is one transitional metal boride layer. Sufficient relief of internal stress of the diamond-like composite coating can be achieved, and the overall toughness, abrasion resistance and corrosion resistance of the diamond-like composite coating are improved. As for the preparation method, complex preparation processes are avoided, performance stability of the deposited diamond-like composite coating is ensured, and the preparation cost of the diamond-like composite coating is effectively reduced.

Owner:SHENZHEN INST OF ADVANCED TECH

3D printing method of ceramic titanium alloy composite biological implanting product

InactiveCN105728722AHigh strengthImprove toughnessAdditive manufacturing apparatusIncreasing energy efficiencyBiocompatibility TestingAlloy composite

A 3D printing method of a ceramic titanium alloy composite biological implanting product is characterized in that ceramic powder ZrO2, Al2O3 or ZrO2 / Al2O3 and titanium alloy powder which are evenly mixed according to the proportion are placed in a metal 3D printing work chamber, and printing is carried out under the conditions that power ranges from 200 W to 500 W, the scanning speed ranges from 200 mm / s to 600 mm / s, the spot diameter ranges from 30 micrometers to 60 micrometers, the scanning gap ranges from 40 micrometers to 70 micrometers and the working chamber oxygen concentration is smaller than 50 ppm; and the product obtained through 3D printing is subject to isostatic pressing or solid solution treatment under the Ar gas protection and at the temperature ranging from 950 DEG C to 1050 DEG C, and time ranges from 1.5 h to 4 h. The printed product material is good in biocompatibility with the human body, compact and controllable in texture, adaptive in mechanical property, short in production period and low in manufacturing cost and has the excellent corrosion-resisting wear-resisting performance, and the whole strength of the forming product can be adjusted by changing the proportion of a titanium alloy in a base body material.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

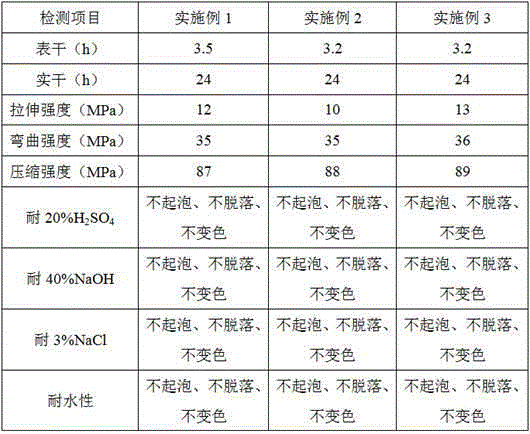

Solvent-free epoxy self-leveling terrace

ActiveCN105238225AEasy constructionShorten drying timeAnti-corrosive paintsEpoxy resin coatingsPolymer scienceSolvent free

The invention discloses a solvent-free epoxy self-leveling terrace. E-54 epoxy resin, phenyl glycidyl ether, a defoaming agent and alicyclic amine serve as raw materials to be prepared into a prime coating layer; E-54 epoxy resin, butyl glycidyl ether, allyl glycidyl ether, a defoaming agent, allyl glycidyl ether, a thixotropic agent and talcum powder serve as raw materials to be prepared into a leveling layer; E-54 epoxy resin, diglycidyl ether, phenyl glycidyl ether, alicyclic amine, elastic polyurethane, talcum powder, heavy calcium carbonate powder, quartz sand, a wetting dispersant, a flatting agent, a deforming agent, color paste and a thixotropic agent serve as raw materials to be prepared into a top coating layer. After the prime coating layer, the leveling layer and the top coating layer are coated separately, the prepared solvent-free epoxy self-leveling terrace has the advantages of being easy and convenient to construct, short in drying time, high in compressive strength, good in wearproof and anti-corrosion performance and the like, can be stored for a long time and has the good application prospect.

Owner:FUZHOU ROYAL FLOOR

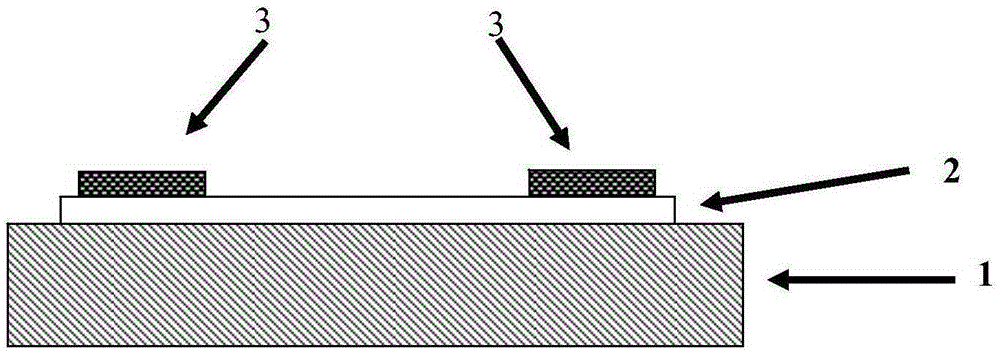

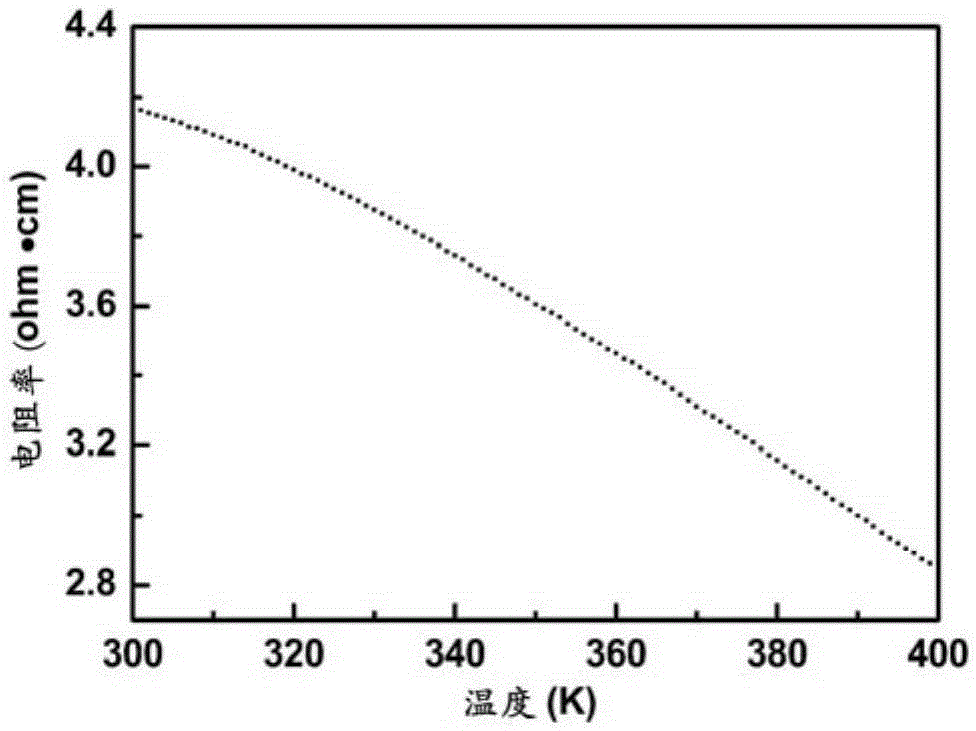

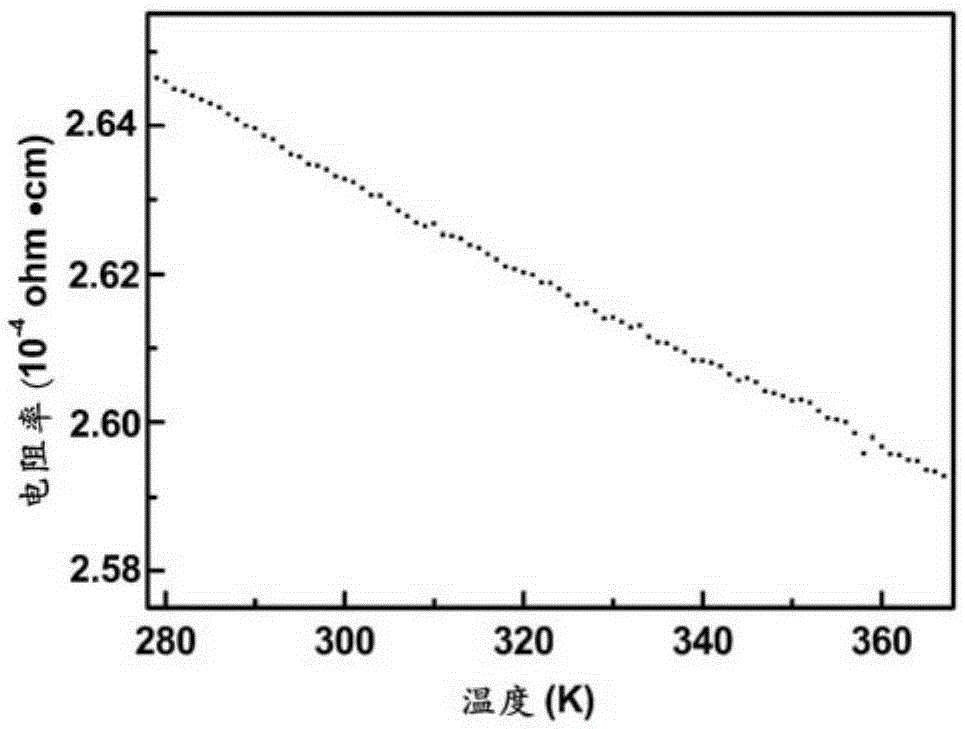

Metal-doped amorphous carbon film temperature-sensing element and preparation method therefor

ActiveCN105241569AHigh sensitivityHigh TCR valueThermometers using electric/magnetic elementsVacuum evaporation coatingTemperature senseTribology

The invention provides a metal-doped amorphous carbon film temperature-sensing element. The element consists of a base body, a metal-doped amorphous carbon film, and an electrode. The metal-doped amorphous carbon film is located on the surface of the base body, and the electrode is located on the surface of the metal-doped amorphous carbon film. Compared with a conventional temperature-sensing element, the element has an adjustable TCR value and resistivity, can have a high TCR value and excellent mechanical performance and frictional performance at the same time, and can achieve the application in a severe environment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Impact modified polyvinyl chloride cable material

InactiveCN104861352AImprove impact resistanceEasy to processPlastic/resin/waxes insulatorsCarbon fibersModified carbon

The invention discloses an impact modified polyvinyl chloride cable material. The impact modified polyvinyl chloride cable material comprises, by mass, 40-65% of polyvinyl chloride resin, 10-15% of PET resin, 5-8% of modified carbon fiber, 2-4% of nanometer silica, 3-5% of butadiene-acrylonitrile rubber powder, 2-5% of ACR, 1-4% of TPEE, 4-6% of DEHP, 0.5-1.5% of a calcium and zinc stabilizer, 0.5-1% of calcium stearate, 0.5-2% of an anti-ageing agent, 0.1-0.5% of an antioxidant and 6-8% of melamine cyanurate, wherein the modified carbon fiber is a short cut polyacrylonitrile carbon fiber with the surface subjected to oxidation pretreatment and gamma-aminopropyltrimethoxysilane coupling agent activation treatment The impact modified polyvinyl chloride cable material has the advantages of excellent low temperature impact resistance and processability, good fire retardation property, strong ageing resistance and excellent wear and corrosion resistance.

Owner:殷培花

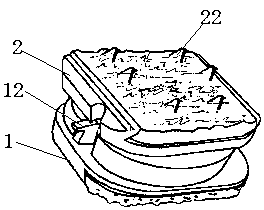

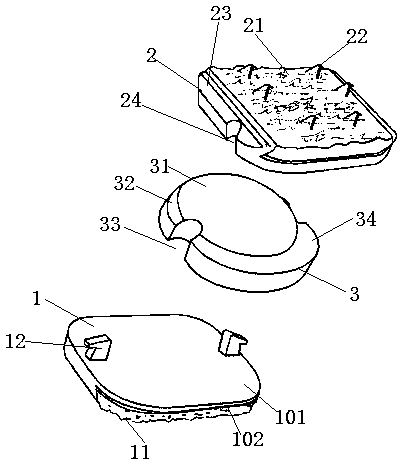

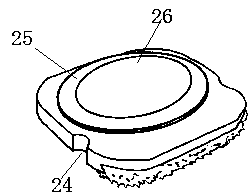

3D (three-dimensional) printing artificial cervical disc prosthesis

PendingCN108095863APreserve integritySimplify the implantation processAdditive manufacturing apparatusSpinal implantsLamina terminalisProsthesis

The invention discloses a 3D (three-dimensional) printing artificial cervical disc prosthesis which comprises a prosthesis upper end plate, a prosthesis lower end plate and a prosthesis nucleus pulposus. The prosthesis nucleus pulposus is arranged between the prosthesis upper end plate and the prosthesis lower end plate, the prosthesis upper end plate, the prosthesis lower end plate and the prosthesis nucleus pulposus are connected in a mutually matched manner, a first microporous surface is arranged on the upper surface of the prosthesis upper end plate, first inverted teeth are distributed on the first microporous surface, a second microporous surface is arranged on the lower surface of the prosthesis lower end plate, and second inverted teeth are distributed on the second microporous surface. The prosthesis nucleus pulposus comprises an elliptical base. The prosthesis has the advantages that the prosthesis is designed by reverse technology, design is completely bionic design, three-dimensional anatomic forms of the prosthesis end plates are completely fitted with those of vertebral end plates, grinding of the upper end plate and the lower end plate is almost omitted when the prosthesis is implanted, and completeness of the vertebral end plates is retained. The prosthesis can be rapidly manufactured by 3D printing technology, an implanting process can be simplified in practical application, surgical time is shortened, and surgical safety is improved.

Owner:XIAN HONGHUI HOSPITAL

Anticorrosion anti-sulfur wear-resistant oil pipe laser cladding coating preparation process

InactiveCN105586588AIntensity has no effectGuaranteed StrengthMetallic material coating processesMelting tankHeat-affected zone

The present invention discloses an anticorrosion anti-sulfur wear-resistant oil pipe laser cladding coating preparation process. According to the preparation process, a 5000 W cross-flow CO2 laser is used, and the work platform is a digital control laser processing machine; nickel-based alloy powder is automatically conveyed into a laser cladding pool by using a coaxial or paraxial powder conveying device, and a uniform and compact anticorrosion anti-sulfur wear-resistant laser cladding coating with a thickness of 3-6 mm is formed on the processed surface; and a laser surface cladding process is used, the heat-affected zone is small and the strength of the oil pipe is not affected during the cladding process, and the nickel-based alloy with characteristics of good corrosion resistance and high strength is used, such that the oil pipe achieves excellent corrosion resistance and excellent wear resistance while the strength of the oil pipe is ensured. According to the present invention, corrosion resistance, sulfur resistance and wear resistance of the oil pipe are reinforced, the service life of the oil pipe is prolonged, and the long-term problem in the application fields of the oil pipes and the oil pipe corrosion in the petroleum exploration, the oil, gas and water well production operation and construction, and maintenance is solved.

Owner:HUBEI XINCHEN AUTOMATION EQUIP

Wear-resisting and corrosion-resisting alloy casting for mechanical arm and preparation method thereof

The invention provides a wear-resisting and corrosion-resisting alloy casting for a mechanical arm and a preparation method thereof. The wear-resisting and corrosion-resisting alloy casting is prepared from the following components in percentage by mass: 0.4 percent to 0.6 percent of C, 1.2 percent to 1.4 percent of Si, 0.9 percent to 1.2 percent of Mn, 0.3 percent to 0.35 percent of W, 18 percent to 20 percent of Cr, 3.5 percent to 5 percent of Ni, 0.025 percent to 0.03 percent of B, 0.3 percent to 0.5 percent of Mg, 0 to 1.5 percent of Cu, 0 to 0.4 percent of Zn, 0.05 percent to 0.2 percent of rare earth oxide, 0.005 percent to 0.01 percent of N, less than or equal to 0.02 percent of P, less than or equal to 0.02 percent of S and the balance of Fe; the wear-resisting and corrosion-resisting alloy casting is prepared through the steps of hot melting, oxygen removing and degassing, inoculating, hot rolling, quenching, annealing and the like; the prepared alloy casting has excellent wear-resisting and corrosion-resisting performances and high strength and high rigidity; the anti-oxidization performance and the anti-deformation performance are also remarkably improved and the service life is greatly prolonged.

Owner:安徽臣诺机器人科技有限公司

Laser-cladding coating preparation process of corrosion-resistant, sulfur-resistant and wear-resistant tubing coupling

ActiveCN104032301AIntensity has no effectGuaranteed StrengthMetallic material coating processesMelting tankNumerical control

The invention discloses a laser-cladding coating preparation process of a corrosion-resistant, sulfur-resistant and wear-resistant tubing coupling. A 5000 W cross-flow CO2 laser is used; a working platform is a numerical control laser machine; a coaxial or paraxial powder feeding device is used for automatically feeding nickel-based alloy powder into a laser molten pool; and a corrosion-resistant, sulfur-resistant and wear-resistant laser-cladding coating with uniformity and compactness is formed on a processing surface, and is 3-6 mm thick. A laser surface cladding process is adopted; in the cladding process, a heat-affected zone is small, and no influence is generated on the strength of the coupling; and nickel-based alloy with good corrosion resistance and high strength is adopted, so that the coupling obtains excellent corrosion resistance and wear resistance while the strength of the coupling is guaranteed. The preparation process intensifies the corrosion resistance, sulfur resistance and wear resistance of the tubing coupling, prolongs the service life of the tubing coupling, and solves a difficulty unsolved for a long time in the corrosion-resistant application field of an oil tube and the tubing coupling in the oil exploitation and the production operation and maintenance of oil, gas and water wells in our country.

Owner:江苏点金激光科技有限公司

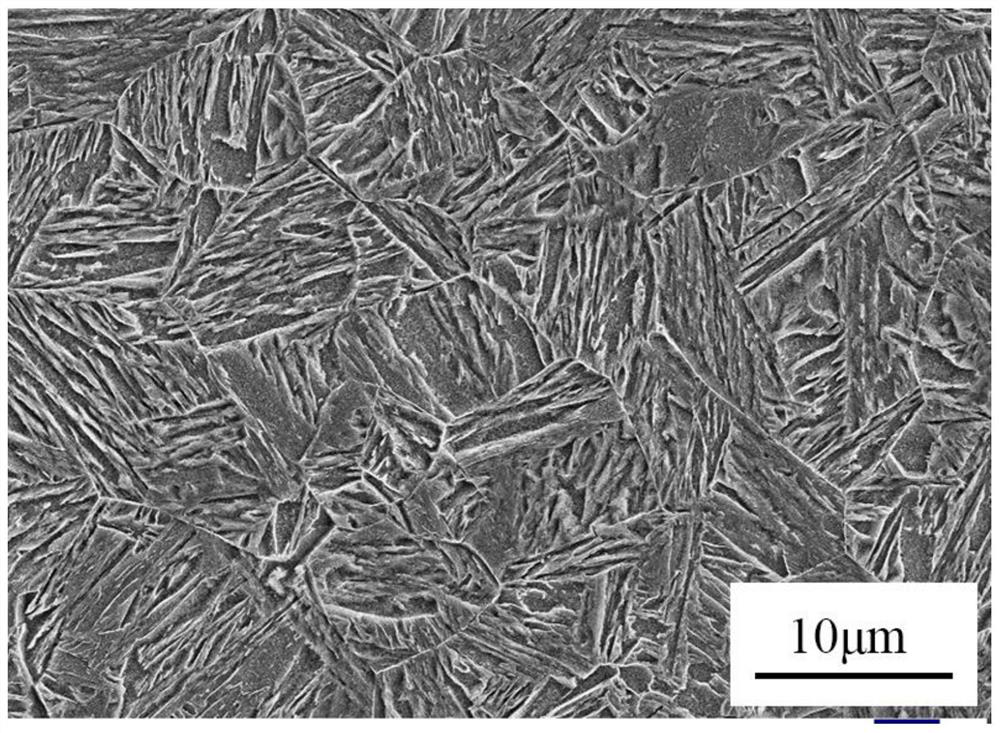

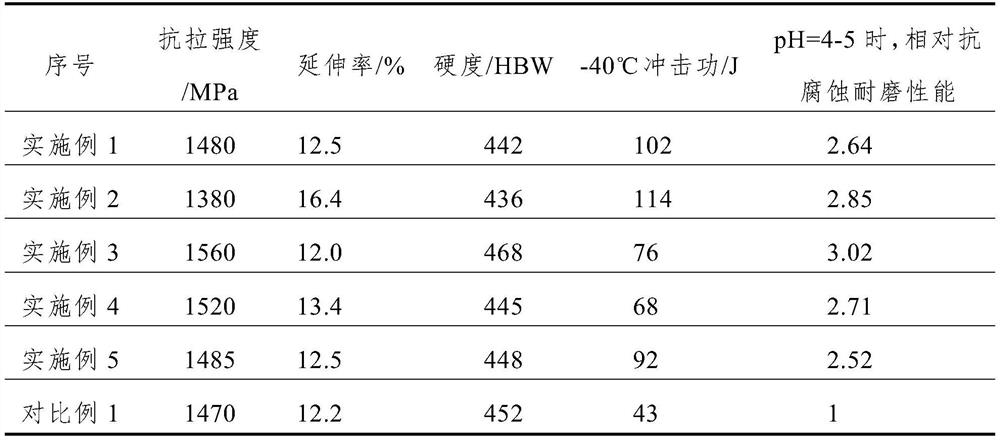

Corrosion-resistant wear-resistant steel plate and preparation method thereof

InactiveCN112159934AExcellent resistance to corrosion and wearGood wear resistance and corrosion resistanceBrinellingPapermaking

The invention relates to a corrosion-resistant wear-resistant steel plate and a preparation method thereof. The corrosion-resistant wear-resistant steel plate comprises the following chemical components in percentage by mass: 0.14-0.22% of C, 0.10-1.00% of Si, 0.1-1.0% of Mn, less than 0.015% of P, less than 0.005% of S, 3.00-6.00% of Cr, 0.00-1.50% of Ni, 0.00-0.80% of Mo, 0.02-0.06% of Als, 0.0008-0.005% of B, 0.0015-0.0040% of Ca and the balance of Fe and inevitable impurity elements, wherein Ca / S> / =1, and the volume fraction of a lath martensite structure in the steel plate is larger thanor equal to 95%. The novel steel plate with excellent corrosion and wear resistance in an acid environment is prepared through an alloy component design and the combination of a heat treatment process, the corrosion and wear resistance of the novel steel plate is 2.5-3.0 times that of existing Brinell hardness martensite wear-resistant steel under the acid working condition with a pH value of 4-5,the corrosion-resistant wear-resistant steel plate can be widely applied to manufacturing of equipment for garbage storage and transportation, papermaking and chemical engineering, ore sand transportation, coal mining and transportation and the like.

Owner:NORTHEASTERN UNIV

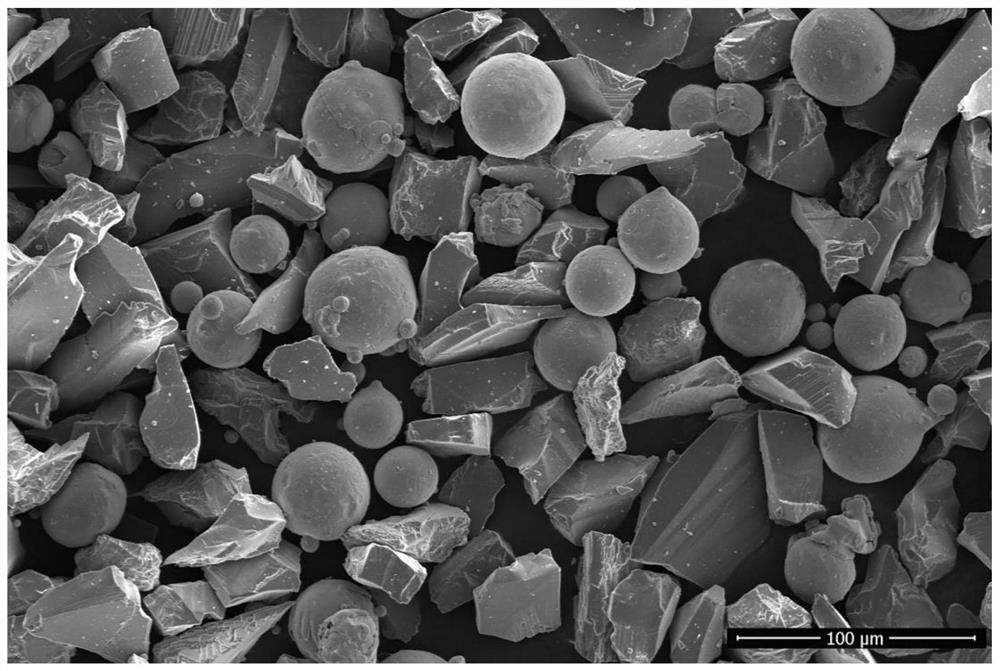

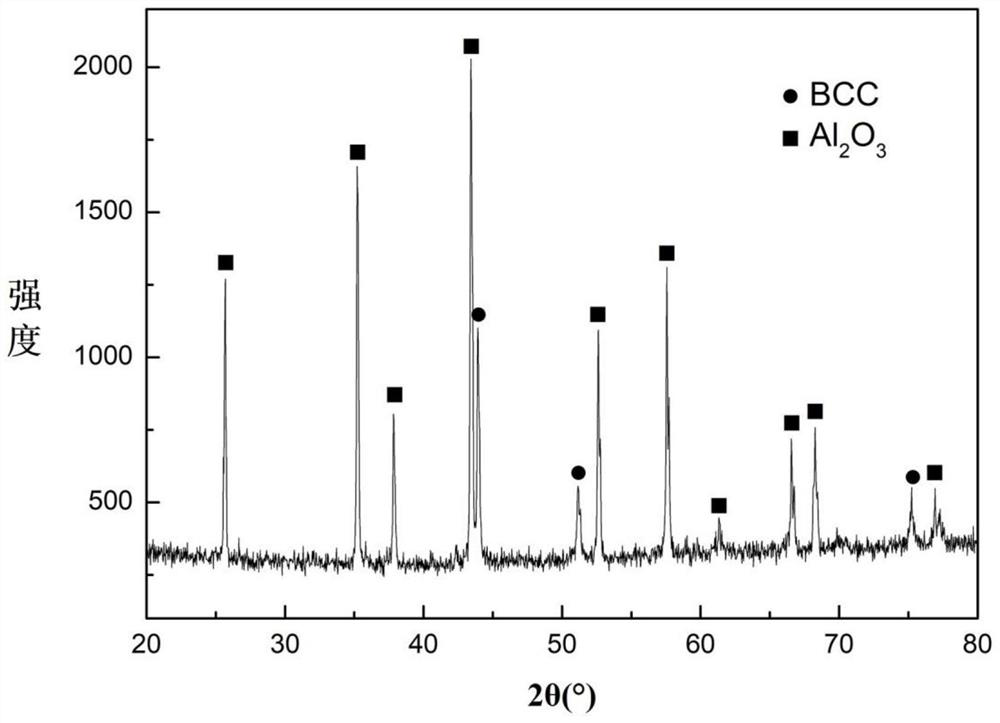

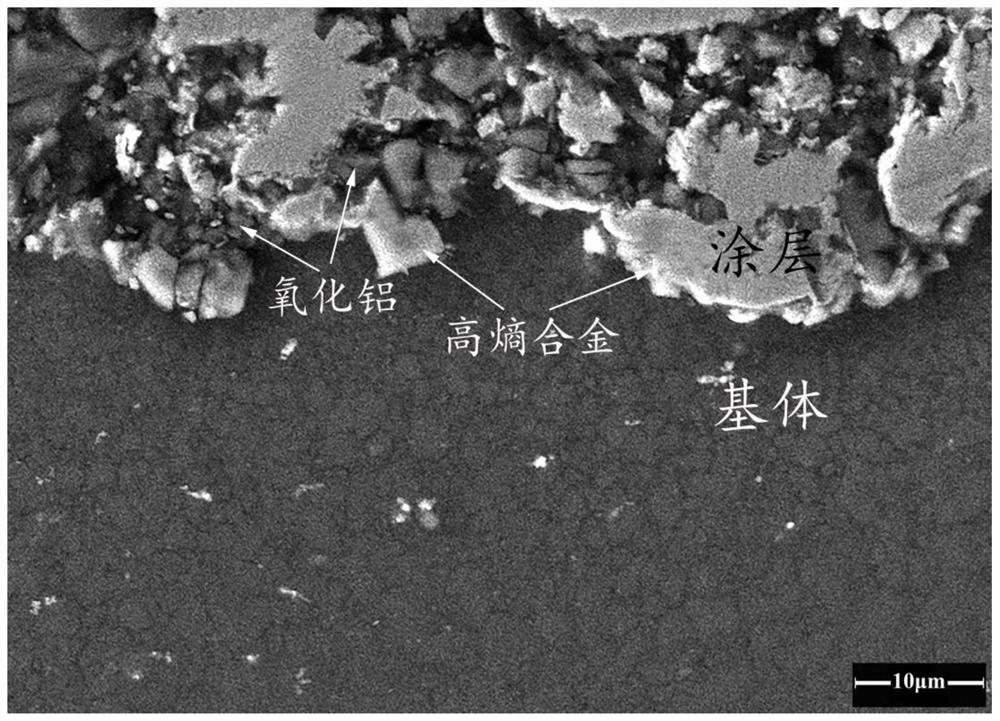

Preparation method of low-cost light-weight high-entropy alloy/aluminum oxide composite coating on surface of magnesium alloy

ActiveCN113445041AImprove plasticityGuaranteed Deposit BondingPressure inorganic powder coatingHigh volume manufacturingHigh entropy alloys

The invention provides a preparation method of a low-cost light-weight high-entropy alloy / aluminum oxide composite coating on the surface of a magnesium alloy. A high-entropy alloy is a CoCrFeNi alloy, alloy powder is prepared by gas atomization, the magnesium alloy is a magnesium alloy with different grade, and the high-entropy alloy powder is mixed with aluminum oxide particles by a mechanical method; and cold spraying gas is nitrogen, the distance between a base body and a spray gun is 10-25 cm, the moving speed of the spray gun is 50-250 mm / min, the powder feeding rate is 100-300 g / min, the carrier gas temperature is 400-600 DEG C, the carrier gas pressure is 2-5 MPa, and the spraying angle is 80-90 degrees. According to the preparation method of the low-cost light-weight high-entropy alloy / aluminum oxide composite coating on the surface of the magnesium alloy, the advantages of the high-entropy alloy and aluminum oxide are crossed and fused to the surface of the magnesium alloy, and the obtained composite coating is low in density, low in cost and excellent in corrosion resistance and wear resistance; and the preparation method is simple and convenient in process, suitable for mass production and suitable for protection and remanufacturing of magnesium alloy parts in the fields of automobile manufacturing, aerospace, rail transit and the like.

Owner:SHANDONG UNIV OF TECH

Method for preparing intermetallic compound powder cored filament material for electric arc spraying

The preparation process of intermetallic compound filament with powder core for arc spraying includes the following steps: mixing aluminum powder of granularity 38-44 micron and purity not lower than 99.5 % and iron (nickel ) powder of granularity 53-61 micron and purity not lower than 99.5 % in the atom ratio of 1 to 1; pressing the mixture in a hydraulic press into blank and painting the surface with one thin graphite layer; self-spreading reaction in a vacuum combustor to obtain loose intermetallic compound block; crushing, grinding, sieving to obtain 200-325 mesh granularity powder material and drying; and making Fe (Ni)-Al compound filament with powder core. The present invention has good spraying performance, good coating layer performance, high performance / cost ratio, wide use temperature range, simple technological process and low power consumption.

Owner:SHANDONG UNIV OF SCI & TECH

Wear-resistant and corrosion-resistant aluminum alloy drill rod preparation method and prepared aluminum alloy drill rod

ActiveCN106835233AHigh bonding strengthImprove impact toughnessAnodisationDrilling rodsWear resistantVolumetric Mass Density

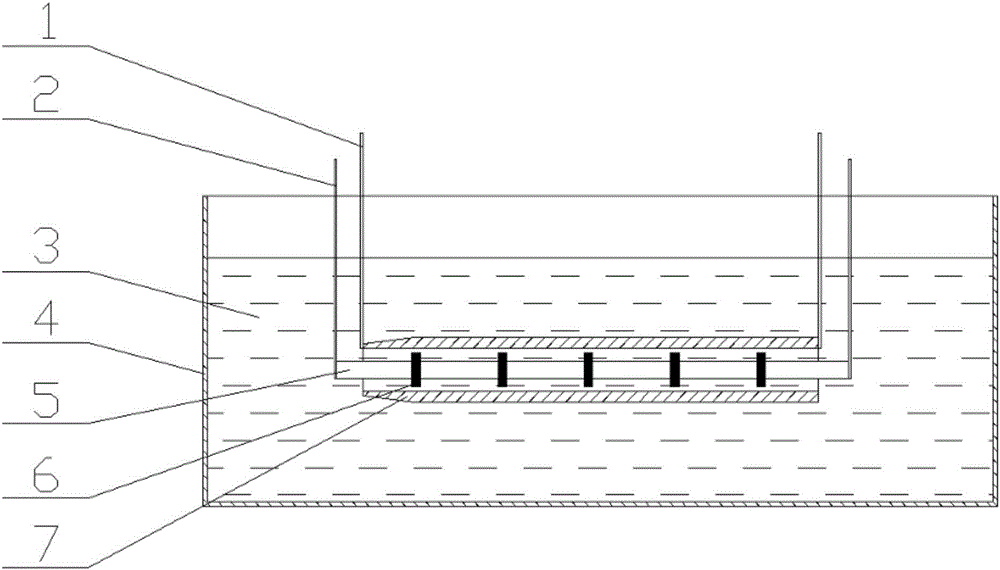

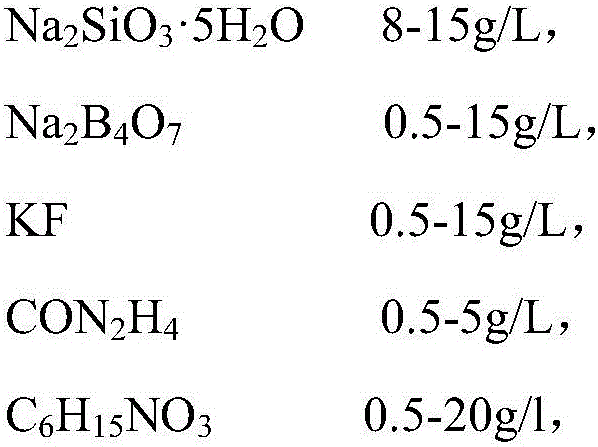

The invention relates to a wear-resistant and corrosion-resistant aluminum alloy drill rod preparation method which comprises the following steps: a drill rod is hoisted to a deionized aqueous solution in a stainless steel tank: 8-15 g / L of Na2SiO3.5H2O, 0.5-15 g / L of Na2B4O7, 0.5-15 g / L of KF, 0.5-5 g / L of CON2H4, 0.5-20 g / L of C6H15NO3 and 0.5-3 g / L of KOH; the drill rod is electrically connected with a positive electrode of a power supply, and a negative electrode is electrically connected with a stainless steel auxiliary cathode (5) and the stainless steel tank (4); a plurality of fluorine rubber rings (6) are uniformly distributed and sheathed on the stainless steel auxiliary cathode; the power supply is subjected to constant voltage control, the positive current density is 2-15 A / dm<2>, and when the positive voltage rises to 410-430 V, the negative voltage is loaded, so that the negative current density is 1-8 A / dm<2>; when the positive voltage rises to 500-540 V, the power supply is disconnected; after being taken out and cleaned, the drill rod is subjected to sealing treatment. The drill rod is wear-resistant, corrosion-resistant and long in service life.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

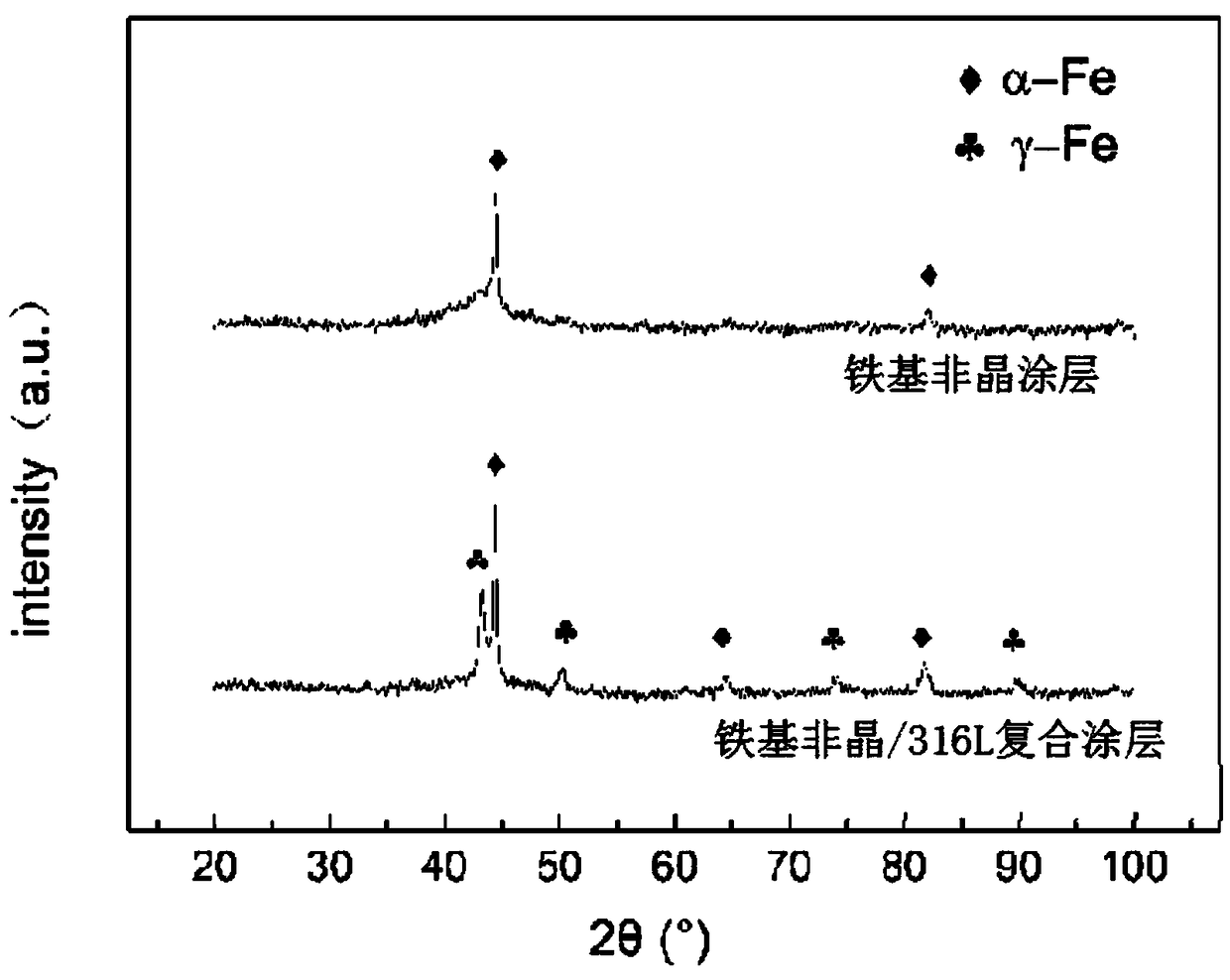

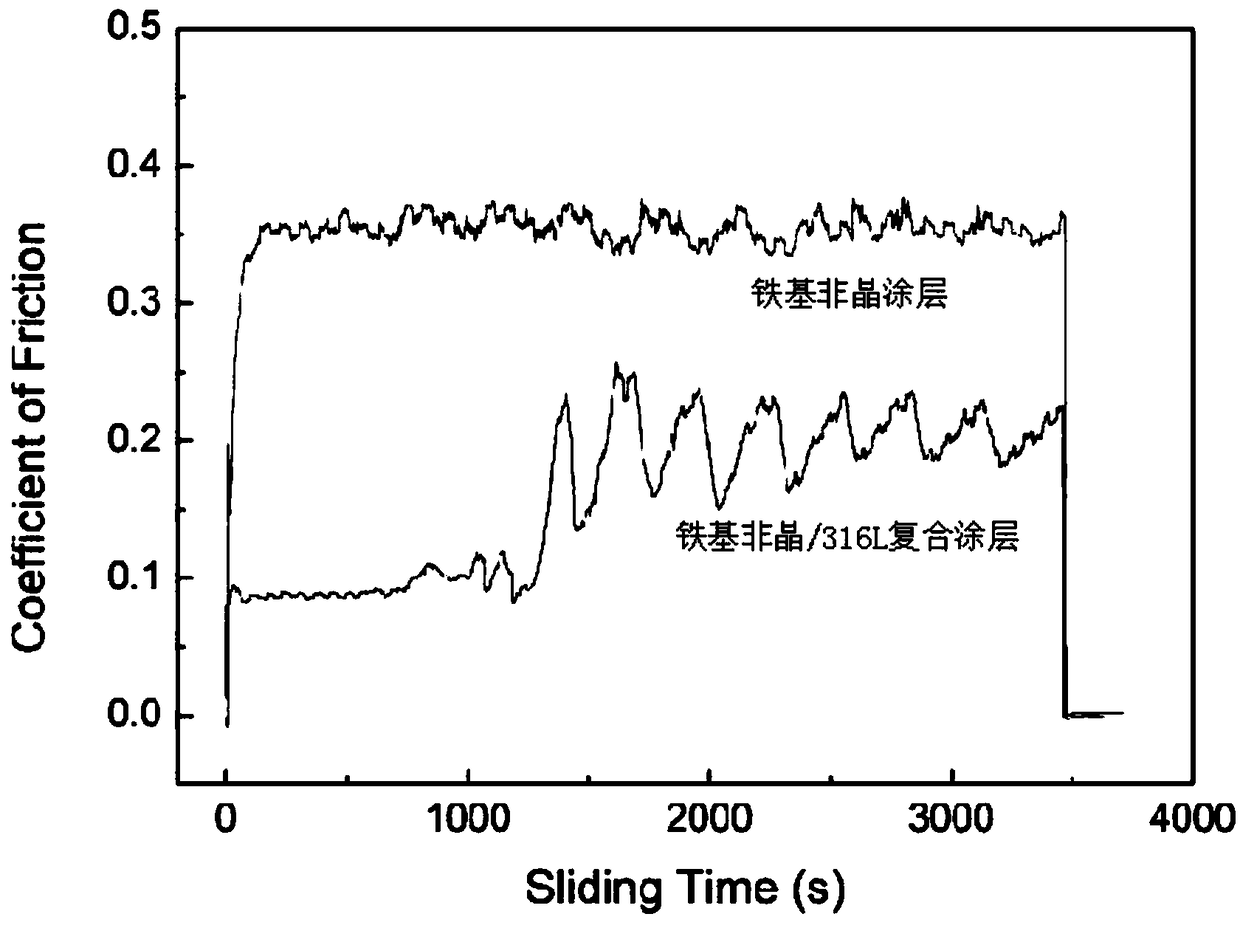

Preparation method of metallic coating applied to corrosive environment

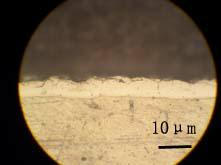

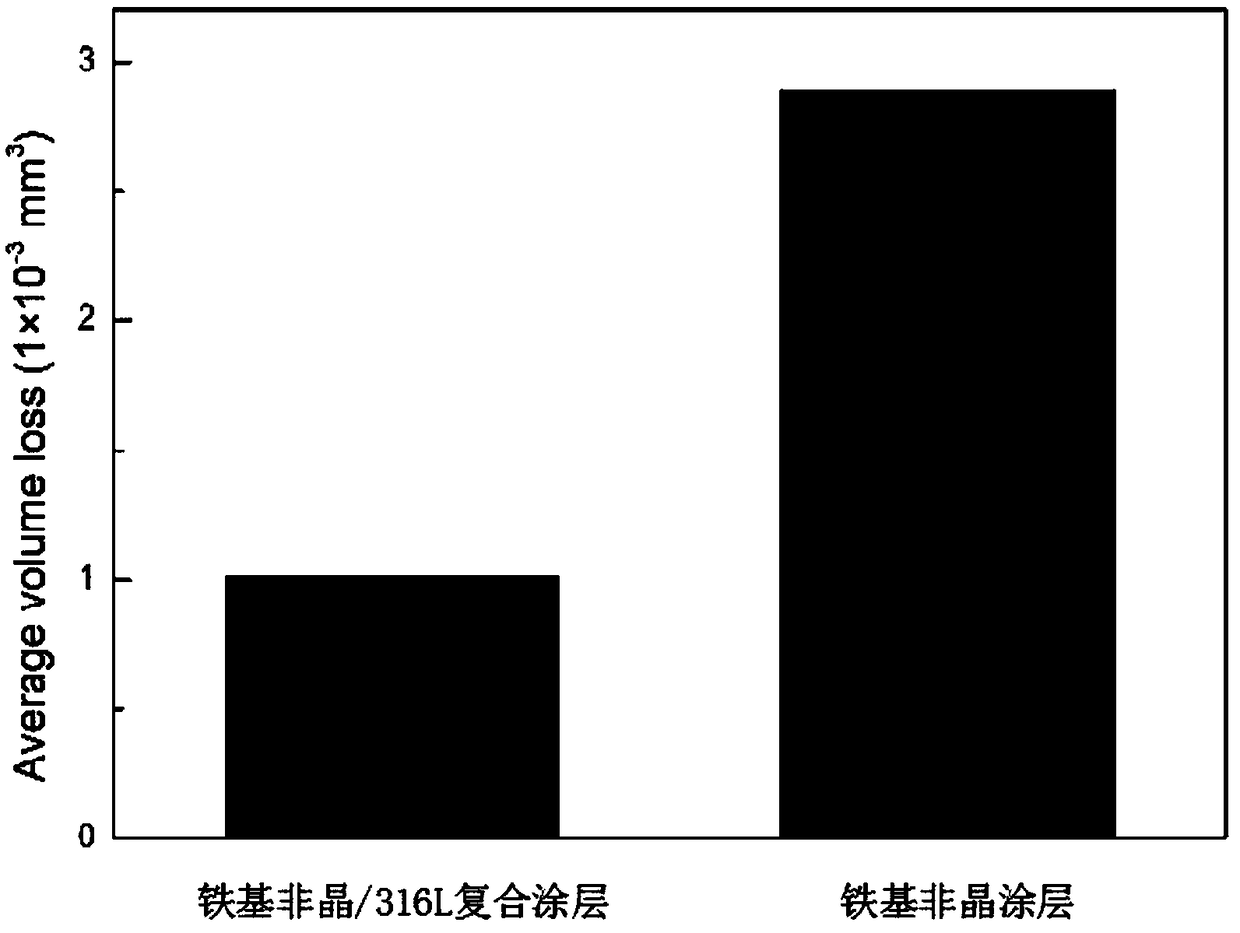

ActiveCN109082659AImprove wear resistanceGood wear resistance and corrosion resistanceMetallic material coating processesMetal coatingHigh density

The invention discloses a preparation method of a metallic coating applied to a corrosive environment. The preparation method includes the steps of coating a metal base with preset powder and drying uniformly; melting to clad the preset powder on the metal base through laser to achieve metallurgical bonding between the metal base and preset powder; repeating to coat the metal base with one layer of preset powder, cladding a second layer through the laser to obtain an amorphous / metallic composite coating, and performing characterization. Stainless steel and a thin layer of amorphous powder aremolten mutually to obtain the multi-phase structural composite coating by high-density energy of the laser according to the laser cladding technology; the composite coating has anti-friction performance, wear resistance and corrosion resistance much excellent than those of iron-based amorphous coating and the stainless steel base.

Owner:HOHAI UNIV CHANGZHOU

Metallized plating solution and method for metallizing surface of magnesium alloy product

InactiveCN104032287AImprove corrosion resistanceThere will be no shedding phenomenonLiquid/solution decomposition chemical coatingSuperimposed coating processElectrolysisCopper plating

The invention discloses a metallized plating solution and a method for metallizing the surface of a magnesium alloy product. Every one littler of metallized plating solution comprises 15g of nickel sulfate, 25g of sodium hypophosphite, 20mL of 20% sodium hydroxide and 3g of lithium fluoride, wherein the solvent is water. The method for metallizing the surface of the magnesium alloy product comprises the following steps: degreasing; acid washing; acid activating; alkaline activating; chemical nickel-plating; electrolyzing and activating; and copper plating and chrome brightening. The metallized plating solution disclosed by the invention has the beneficial effects that the coating made from the metallized plating solution has high wear resistant and corrosion resistant performances and particularly has an extremely strong adhesive to a matrix; if even the product is broken, falling of the plating layer is further avoided; the plated part obtained by the method provided by the invention has the advantages of bright surface luster and color, very high surface quality and excellent wear resistant and corrosion resistant performances; the plated part still can maintain a very high adhesive force under a high impact.

Owner:董武祥

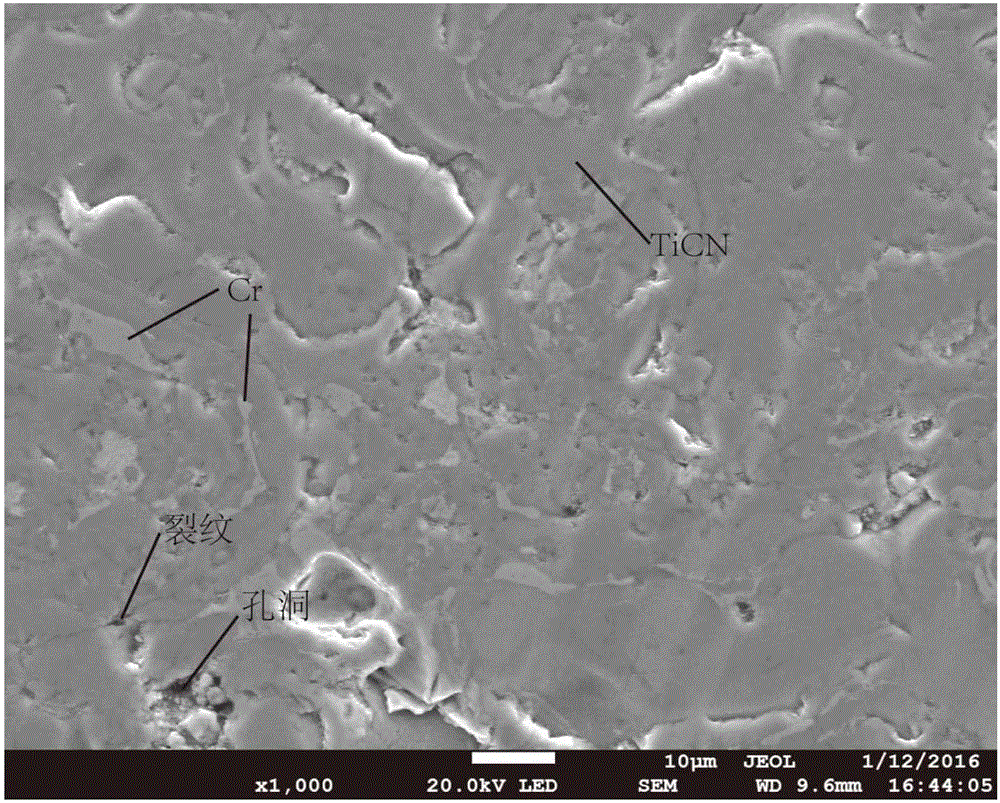

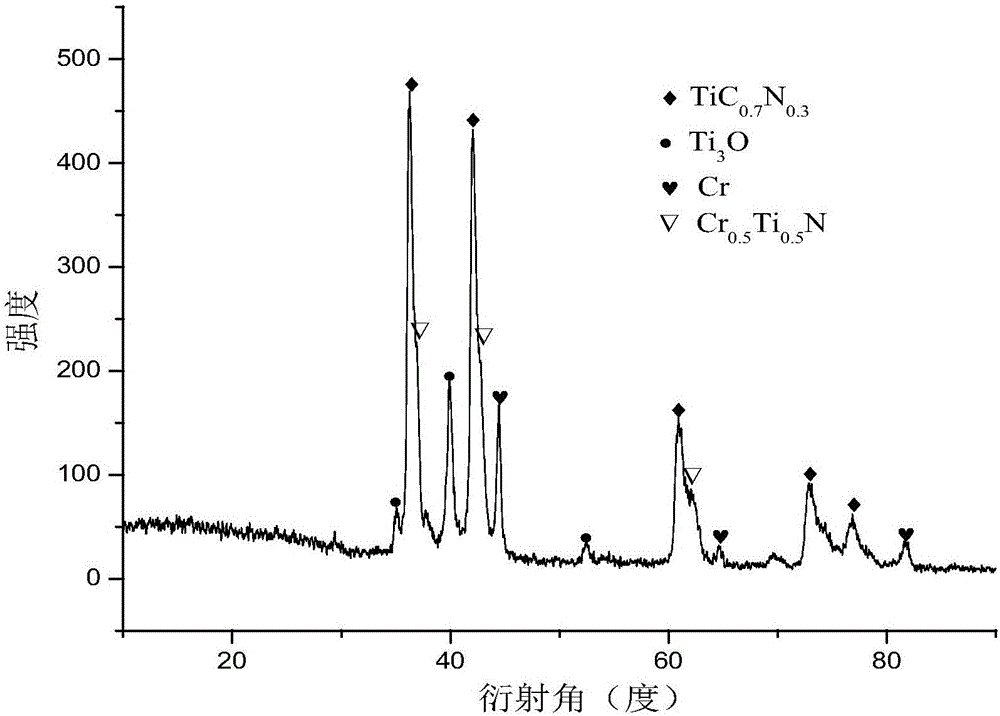

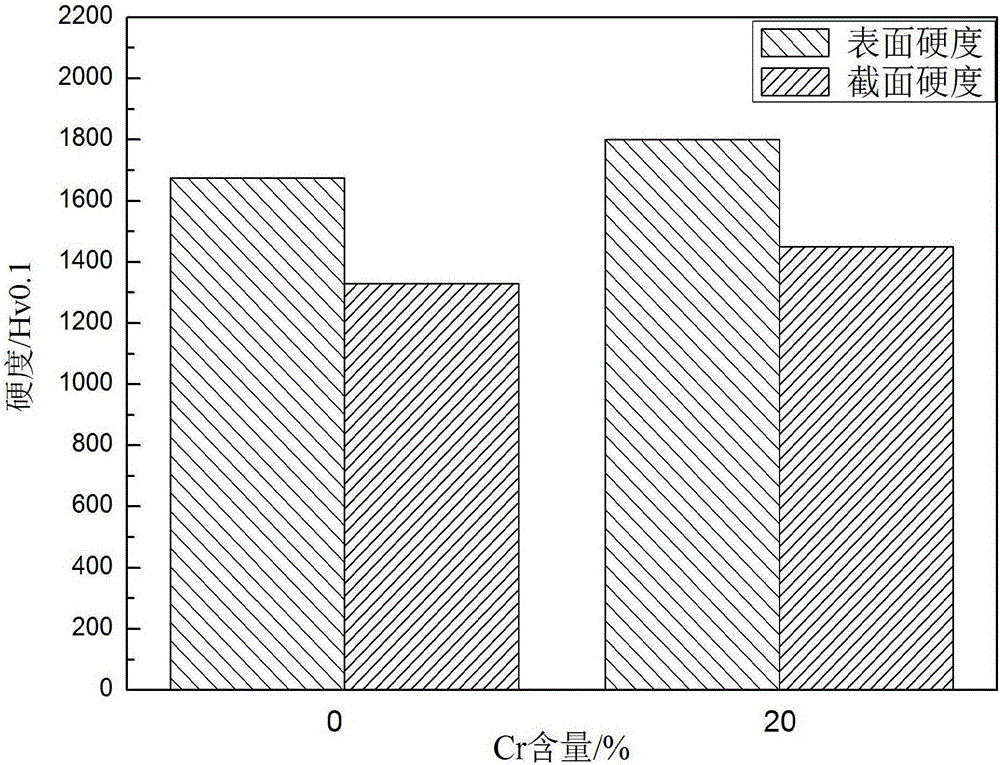

Preparation method of Cr-containing TiCN-based composite coating

The invention discloses a preparation method of a Cr-containing TiCN-based composite coating. The method comprises the steps of step 1, carrying out roughening treatment on the surface of a matrix sample; step 2, mechanically mixing Ti / C composite powder with Cr powder to obtain original feeding composite powder; step 3, spraying Ni-Al self-fluxing alloy powder on the surface of a matrix in advance to obtain a bottom layer of which the thickness is 90 to 120 <mu>m, wherein the weight percent of Al in the Ni-Al self-fluxing alloy powder is 10 wt%; and step 4, spraying the original feeding composite powder on the surface of the bottom layer to obtain a TiCN-Cr metal-based ceramic composite coating of which the thickness is 300 to 500 <mu>m. The plasma spraying TiCN-Cr metal-based ceramic composite coating provided by the invention has relatively high hardness and good abrasion resistance and corrosion resistance, is suitable for working under abrasive and corrosive environment conditions like the fields of machinery manufacturing of cutting tools, drills and molds, automobile manufacturing and aerospace, and has quite wide application prospect.

Owner:HEBEI UNIV OF TECH

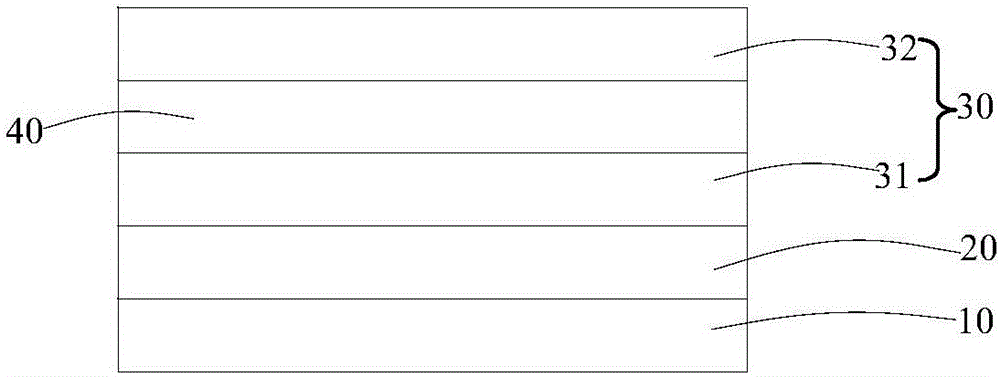

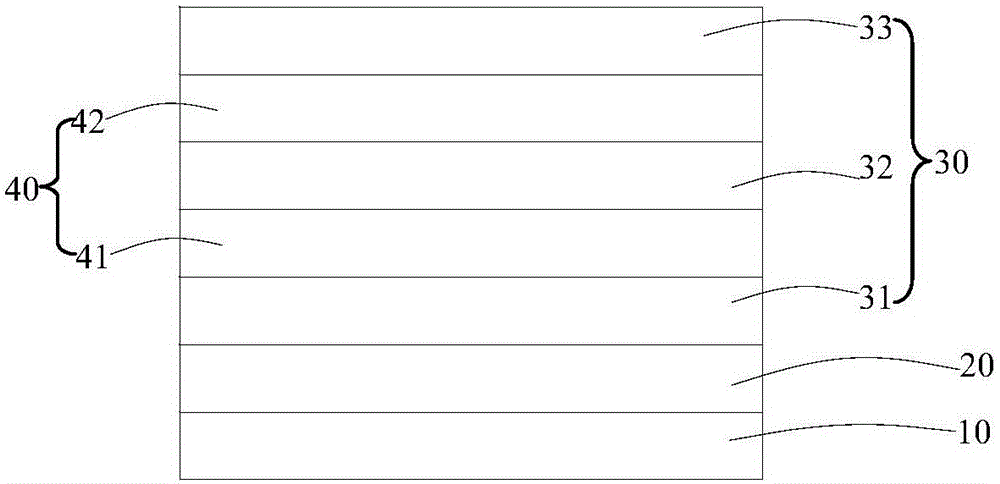

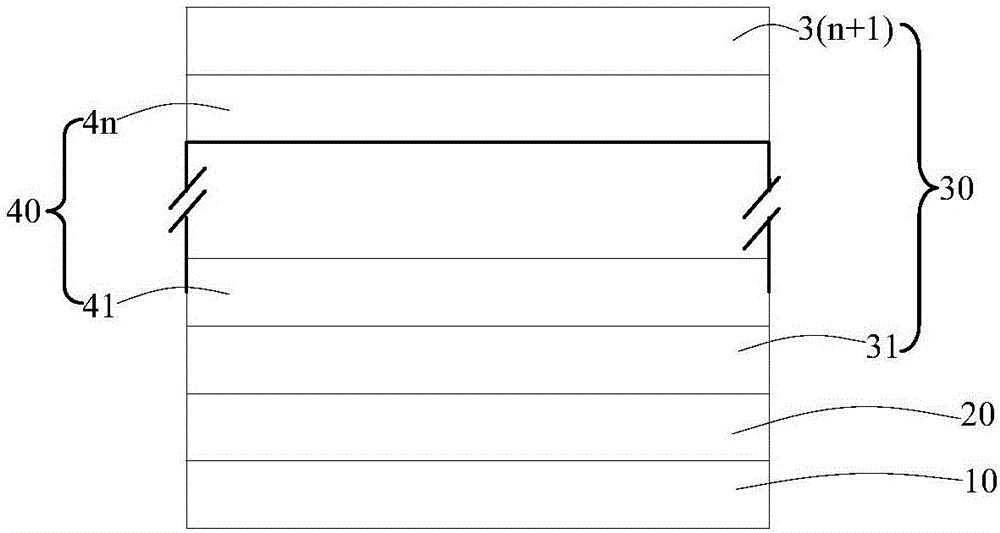

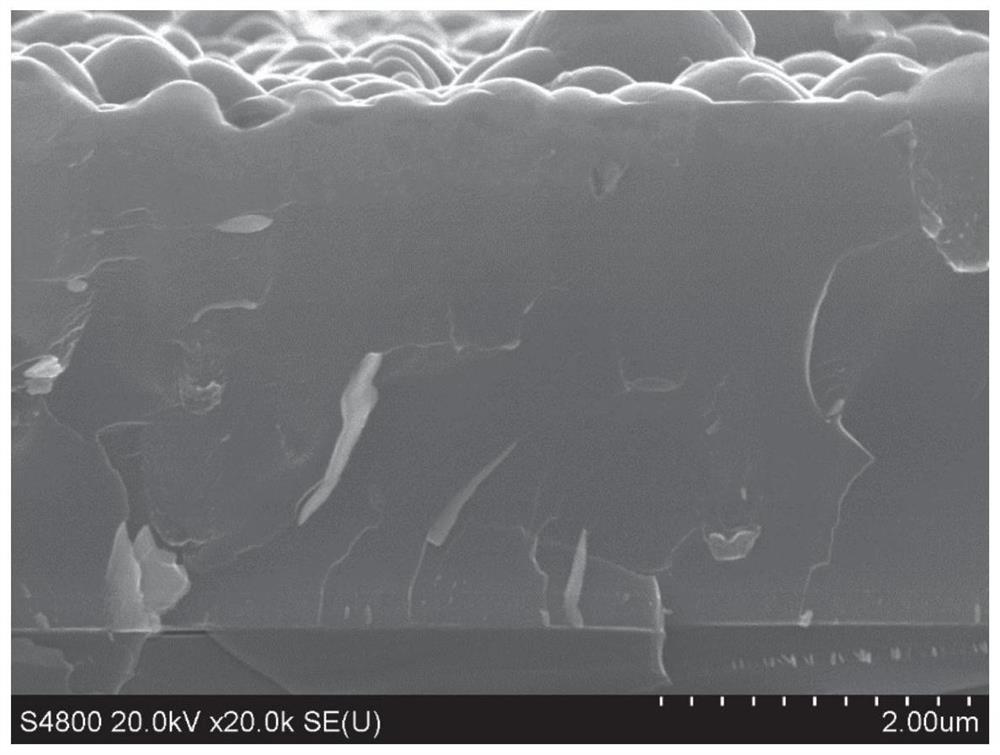

Preparation method for double-layer high-strength corrosion-resistant iron-based amorphous composite coating

InactiveCN106835132AStrong wear and corrosion resistanceImprove bindingMolten spray coatingSuperimposed coating processCorrosion resistantMetallic Nickel

The invention discloses a preparation method of a double-layer high-strength corrosion-resistant iron-based amorphous composite coating, which belongs to the technical field of amorphous coating preparation. In the present invention, the mixed iron-based powder is melted and plasma sprayed on the surface of the stainless steel plate to form an amorphous coating with a high degree of crystallization, and then a corrosion-resistant coating is formed by nickel plating, and then it is laser clad to form an amorphous coating. The coating, through the intermediate layer with high crystallinity, delays the secondary crystallization degree of the mixed alloy during laser cladding, and effectively enhances the mechanical strength of the crystal. The double-layer wear-resistant and corrosion-resistant iron-based amorphous composite coating prepared by the present invention has excellent Wear-resistant and corrosion-resistant properties have great potential in the application of surface coating materials, and the double-layer wear-resistant and corrosion-resistant iron-based amorphous composite coating prepared by the present invention has a high degree of bonding between the coating and the substrate, and has a wide range of application prospects and use value.

Owner:仇颖莹

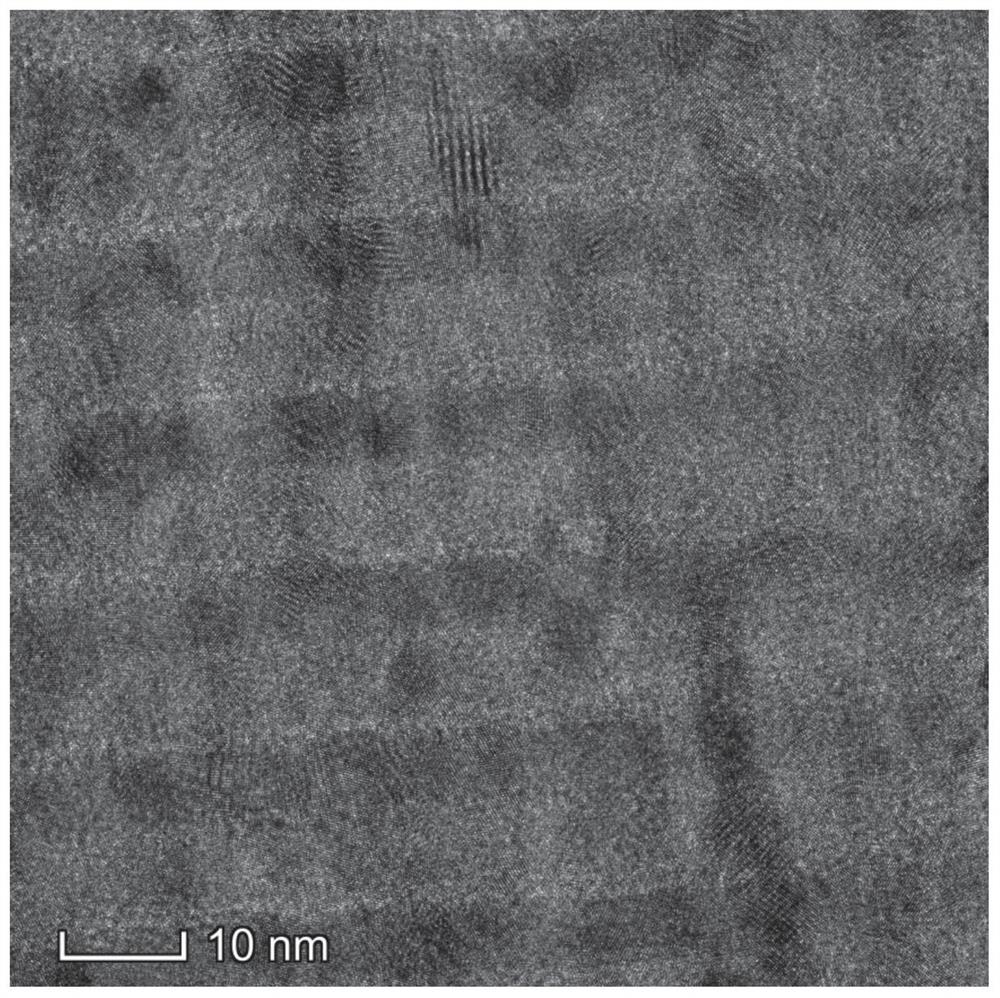

High-hardness nano-composite coating as well as preparation method and application thereof

ActiveCN113046703AHigh hardnessGrowth inhibitionVacuum evaporation coatingSputtering coatingAmorphous phaseWear resistance

The invention discloses a high-hardness nano-composite coating as well as a preparation method and application thereof. The high-hardness nano-composite coating comprises a transition layer and a TiAlCN layer which are sequentially formed on the surface of a base body, the phase structure of the TiAlCN layer comprises a hard nano-metal phase and an amorphous phase, the amorphous phase is evenly distributed in the hard nano-metal phase, the hard nano-metal phase comprises any one or a combination of two or more of a Ti (C, N) phase, a TiN phase, a TiC phase and an AlN phase, and the amorphous phase comprises an amorphous carbon phase. The high-hardness nano-composite coating prepared by the method has high hardness and high toughness, has excellent corrosion and wear resistance in an atmospheric environment and a seawater environment, and can effectively prolong the service life of the base body; and meanwhile, the coating has a huge potential application prospect in surface protection of equipment such as marine parts and cutters.

Owner:KUNMING UNIV OF SCI & TECH +1

Method for preparing intermetallic compound powder cored filament material for electric arc spraying

The preparation process of intermetallic compound filament with powder core for arc spraying includes the following steps: mixing aluminum powder of granularity 38-44 micron and purity not lower than 99.5 % and iron (nickel ) powder of granularity 53-61 micron and purity not lower than 99.5 % in the atom ratio of 1 to 1; pressing the mixture in a hydraulic press into blank and painting the surface with one thin graphite layer; self-spreading reaction in a vacuum combustor to obtain loose intermetallic compound block; crushing, grinding, sieving to obtain 200-325 mesh granularity powder material and drying; and making Fe (Ni)-Al compound filament with powder core. The present invention has good spraying performance, good coating layer performance, high performance / cost ratio, wide use temperature range, simple technological process and low power consumption.

Owner:SHANDONG UNIV OF SCI & TECH

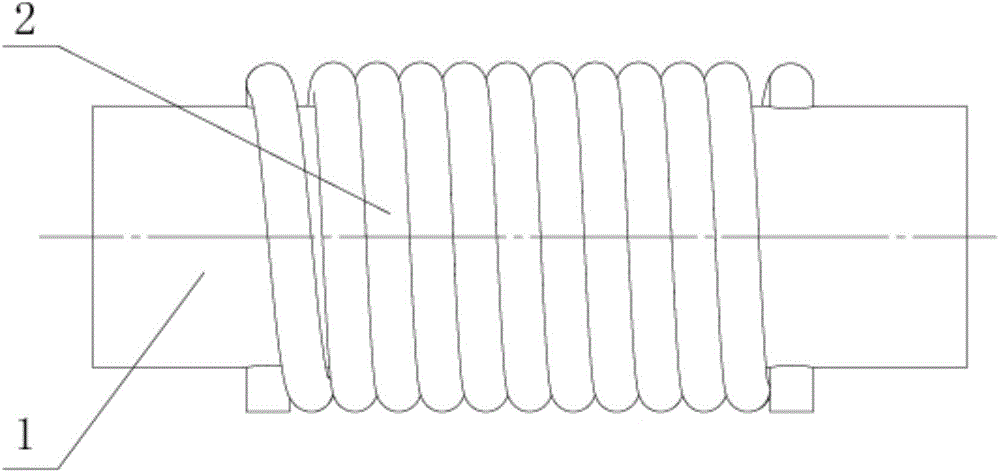

Shaft part on spiral track line contact surface

InactiveCN104832528AReduce contact stressImprove bearing capacityShaftsFree particleBearing capacity

The present invention discloses a shaft part on the spiral track line contact surface. The shaft part comprises a shaft and a spiral track cylindrical member fixed on the shaft, wherein ribbon materials are wound on the shaft body and are subjected to spiral forming along the axis direction to form the spiral track cylindrical member, the outer surface of the spiral track cylindrical member is the working surface of the shaft after the forming, and the gap exists between the two ribbon materials and can accommodate lubricating oil and free particles. The shaft part of the present invention has characteristics of long service, large bearing capacity, and low maintenance cost.

Owner:SOUTH CHINA UNIV OF TECH

Chromium-aluminum alloying Fe-B alloy resisting corrosive wear of zinc liquid and manufacturing method of chromium-aluminum alloying Fe-B alloy

ActiveCN108220804ASimple preparation processReduce manufacturing costChemical compositionMolten steel

The invention relates to a chromium-aluminum alloying Fe-B alloy resisting corrosive wear of zinc liquid and a manufacturing method of the chromium-aluminum alloying Fe-B alloy, which belongs to the technical field of corrosion wear. An electric furnace is used for mixing, heating and melting waste steel, ferrochrome, ferromolybdenum and carburant to form molten steel, the chemical composition andmass percent of the molten steel in the furnace are controlled at: 18.53 to 19.28 percent of Cr, 2.26 to 2.41 percent of Mo, 0.59 to 0.66 percent of C, less than 0.65 percent of Si, less than 0.48 percent of Mn, less than 0.04 percent of P, less than 0.03 percent of S, and the balance of Fe, the temperature of the molten steel is heated to 1603 to 1619 DEG C, pure aluminum and ferroboron are successively added, (Ti,Nb)C particles are poured along with the metal molten liquid in the metal molten liquid pouring process, and finally the mixture is poured and casted to obtain the chromium-aluminum alloying Fe-B alloy. The chromium-aluminum alloying Fe-B alloy has good zinc liquid corrosive wear resistance.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com