High-hardness nano-composite coating as well as preparation method and application thereof

A nano-composite coating, high hardness technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the problem of poor wear resistance of TiC and TiCN coatings, poor corrosion and wear resistance of coatings, hard The quality coating process is complex and other problems, to achieve excellent corrosion resistance, low cost, and improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

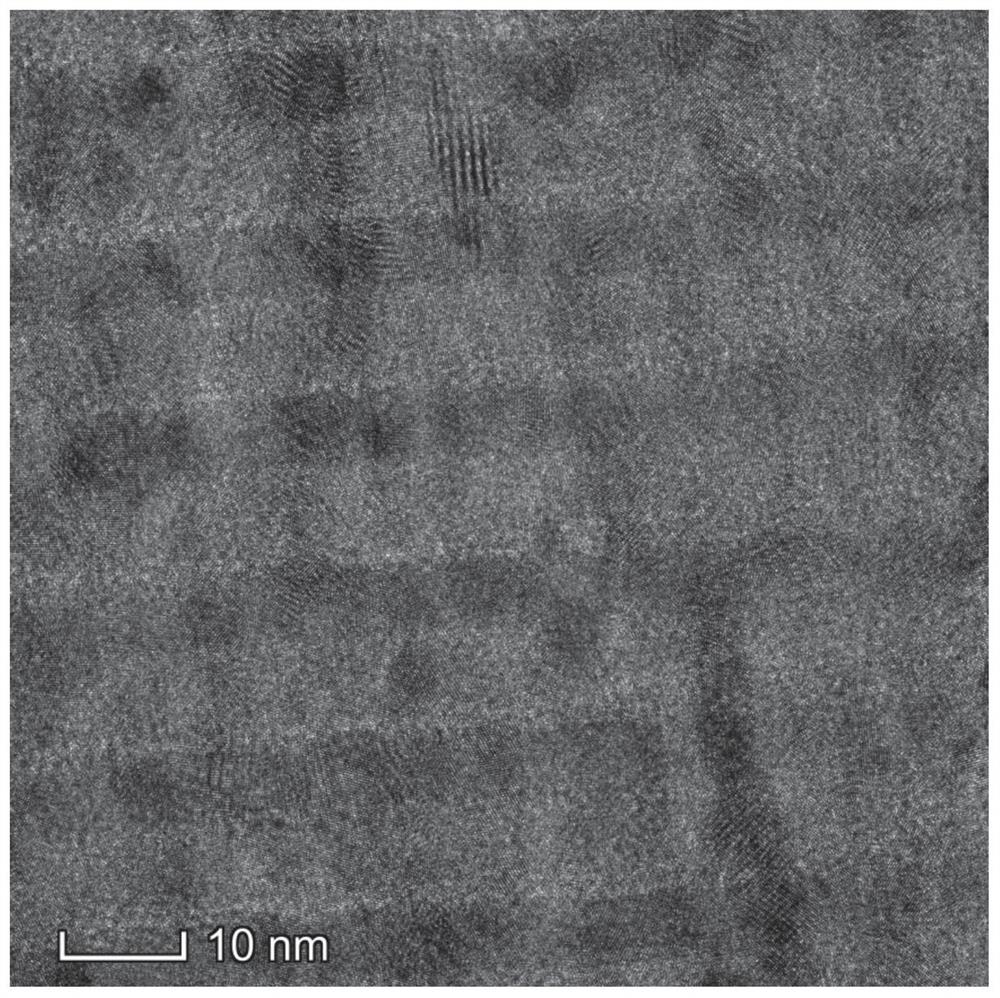

[0038] Another aspect of the embodiments of the present invention also provides the aforementioned method for preparing the high-hardness nanocomposite coating, which includes:

[0039] provide a substrate;

[0040] A transition layer and a TiAlCN layer are sequentially deposited on the surface of the substrate by adopting a multi-arc ion plating technology, thereby forming the high-hardness nanocomposite coating.

[0041] In some more specific embodiments, the method for depositing and forming the transition layer specifically includes:

[0042] Place the substrate in the reaction chamber, adopt multi-arc ion plating technology, use Ti target as the target material, and inert gas and nitrogen gas as the working gas, apply a negative bias voltage to the substrate, thereby depositing and forming the transition layer on the surface of the substrate, Among them, the target current of the Ti target is 60A-70A, the working temperature is 230-280°C, the negative bias voltage of the s...

Embodiment 1

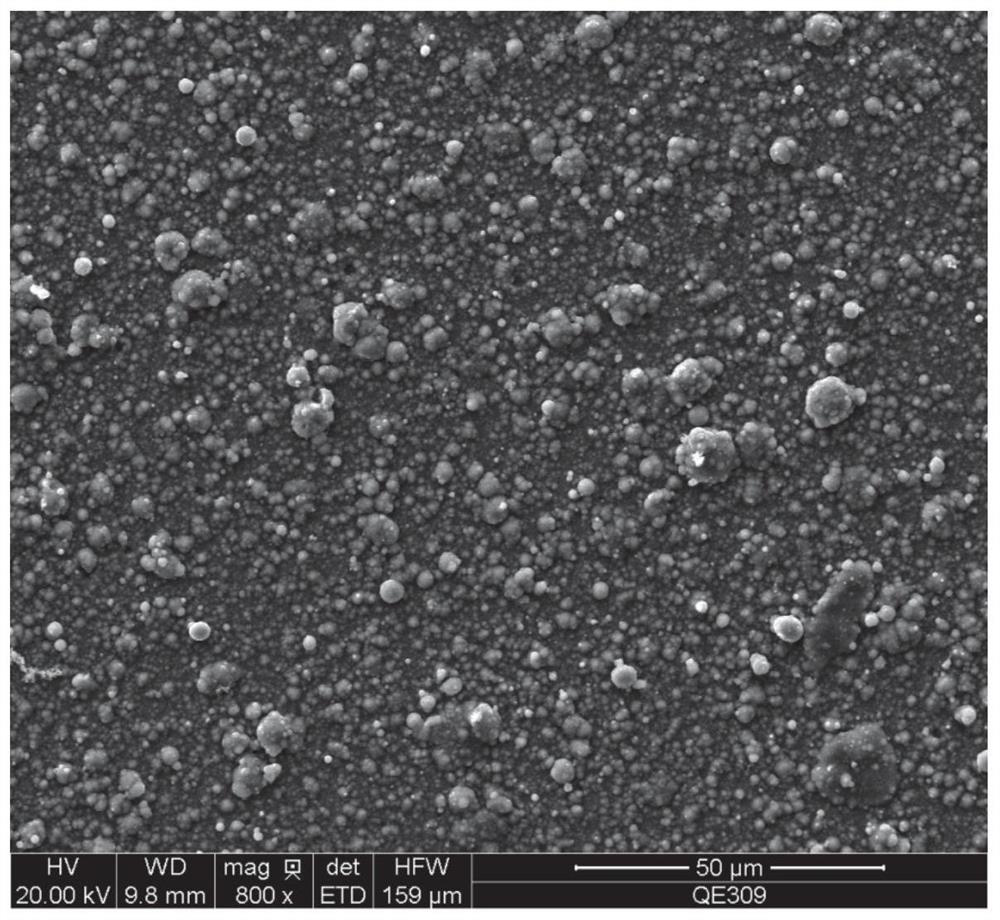

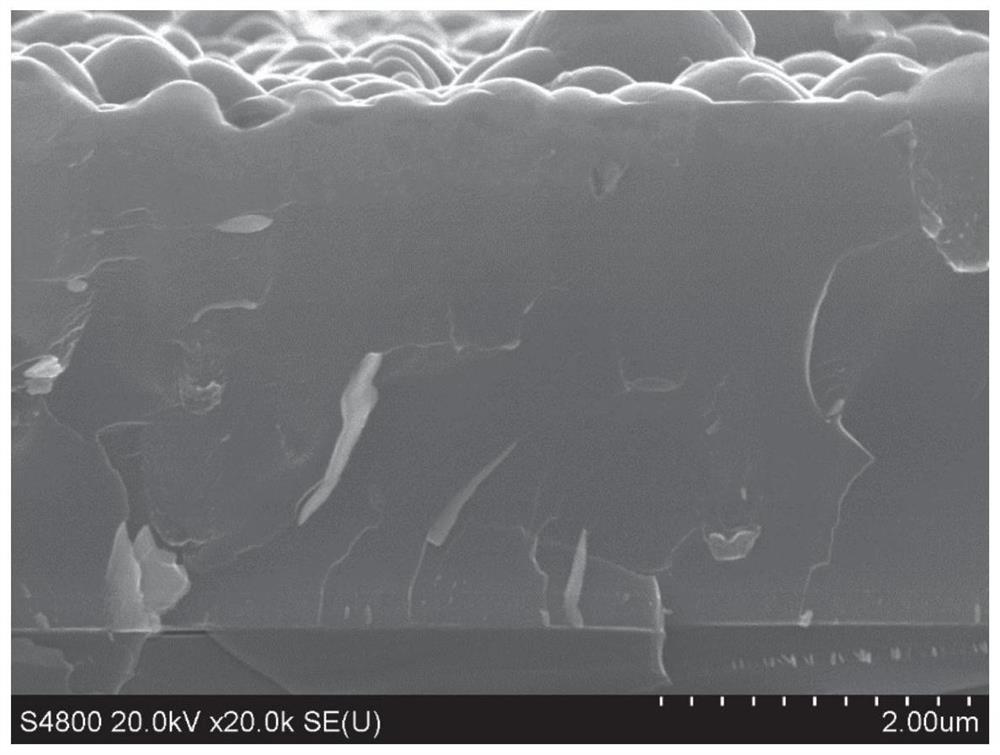

[0071] In this embodiment, the preparation method of depositing a high-hardness nanocomposite coating by adopting the method of multi-arc ion plating, wherein the thickness of the TiAlCN layer is about 3.4 μm, mainly includes the following steps:

[0072] (1) Firstly, the parts to be plated (or Ti6Al4V) are mechanically polished, and then ultrasonicated in petroleum ether, acetone, and absolute ethanol for 20 minutes, and then cleaned with N 2 blow dry;

[0073] (2) Install and fix the dried parts (or Ti6Al4V) into the turntable, and then vacuumize to 5×10 -5 Pa, during the vacuuming process, the chamber is heated at the same time, and the heating temperature is set to 250 °C;

[0074] (3) Target sputtering and etching cleaning of the sample, the target sputtering cleaning time is set to 2min, the substrate material is subjected to Ar ion etching, the time is set to 40min, and the Ar gas flow rate is set to 35sccm, PSE set to 200V;

[0075] (4) Deposition of high-hardness n...

Embodiment 2

[0078] In this embodiment, the preparation method of depositing a high-hardness nanocomposite coating by adopting the method of multi-arc ion plating, wherein the thickness of the TiAlCN layer is about 2.1 μm, mainly includes the following steps:

[0079] (1) Firstly, the parts to be plated (or 316 stainless steel) are mechanically polished, and then ultrasonicated in petroleum ether, acetone and absolute ethanol for 20 minutes, and then cleaned with N 2 blow dry;

[0080] (2) Install and fix the dried parts (or 316 stainless steel) into the turntable, and then vacuumize to 5×10 -5 Pa, during the vacuuming process, the chamber is heated at the same time, and the heating temperature is set to 250 °C;

[0081] (3) Target sputtering and etching cleaning of the sample, the target sputtering cleaning time is set to 2min, the substrate material is etched with Ar ions, the time is set to 30min, and the Ar gas flow rate is set to 30sccm, PSE set to 200V;

[0082] (4) Deposition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com