Plasma melting coating iron-base amorphous nano-crystalline coat and preparing method thereof

A plasma cladding, amorphous and nanocrystalline technology, applied in coating, metal material coating process, etc., can solve the problems of high cost, poor bonding force between coating and substrate, etc., and achieve good thermal stability and excellent wear resistance Corrosion resistance and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The composition of multi-element alloy powder is calculated by weight percentage: C 0.5-3.0, B 2-5, Si 2-6, P 0.9-3.0, Mo 12.0-26.0, Ni 5.0-15.0, Cr 2.0-15.0, Re 0.8- 3.0, Fe balance, particle size range 106-180 microns. Prepare the coating on the A3 steel substrate by plasma cladding, the cladding process parameters are: use Ar as the protective and ionized gas, and the flow rate of the powder feeding argon gas is 0.2-0.8m 3 / h, the protective argon flow rate is 0.4-1.0m 3 / h, the ionized gas flow rate is 0.5-1.2m 3 / h, the current is 280-380A, and the scanning speed is 350-480mm / min.

Embodiment 2

[0020] The composition of multi-element alloy powder is calculated by weight percentage: C 0.5-3.0, B 0.5-1.0, Si 1-3.5, P 0.9-3.0, Mo 12.0-26.0, Ni 5.0-15.0, Cr 2.0-15.0, Re 0.8- 3.0, Fe balance, particle size range 106-180 microns. Prepare the coating on the A3 steel substrate by plasma cladding, the cladding process parameters are: use Ar as the protective and ionized gas, and the flow rate of the powder feeding argon gas is 0.2-0.8m 3 / h, the protective argon flow rate is 0.4-1.0m 3 / h, the ionized gas flow rate is 0.5-1.2m 3 / h, the current is 280-380A, and the scanning speed is 350-480mm / min.

Embodiment 3

[0022] The composition of multi-element alloy powder is calculated by weight percentage: C 0.5-3.0, B 0.5-1.0, P 1.0-2.0, Al 2.5-3.0, Mo 18.0-25.0, Ni 7.0-10.0, Cr 4.0-8.0, Zr 2.5- 3.0, Fe balance, particle size range 106-180 microns. Prepare the coating on the A3 steel substrate by plasma cladding, the cladding process parameters are: use Ar as the protective and ionized gas, and the flow rate of the powder feeding argon gas is 0.2-0.8m 3 / h, the protective argon flow rate is 0.4-1.0m 3 / h, the ionized gas flow rate is 0.5-1.2m 3 / h, the current is 280-380A, and the scanning speed is 350-480mm / min.

[0023] Select embodiment 1 to do coating analysis.

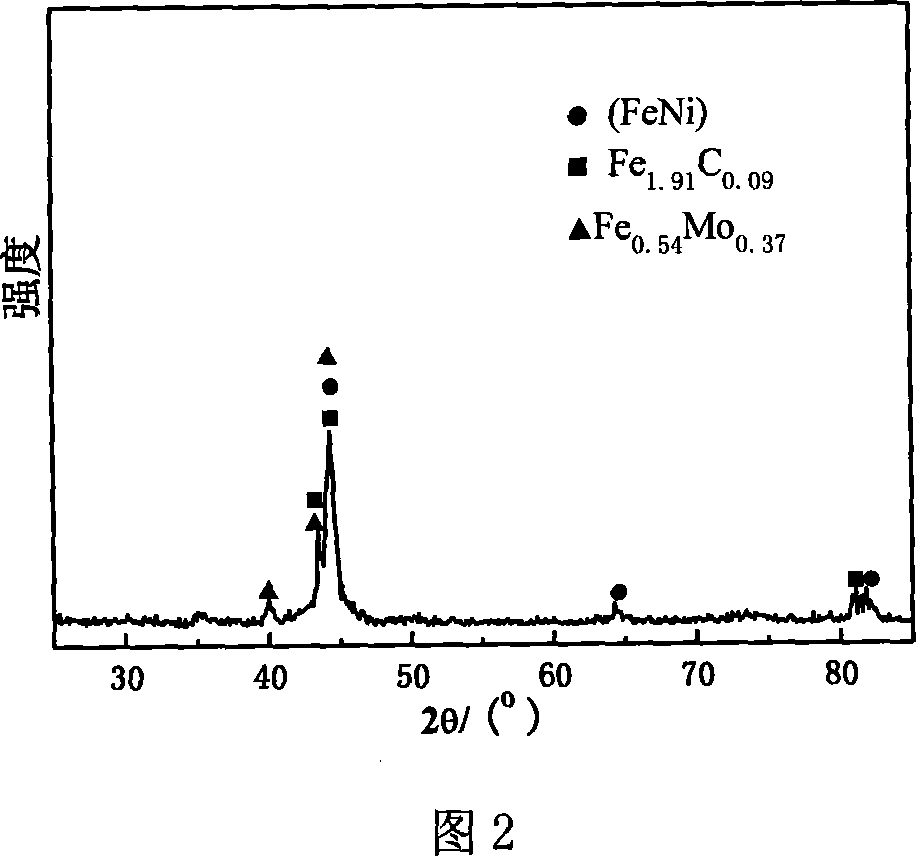

[0024] Crystal structure of the coating

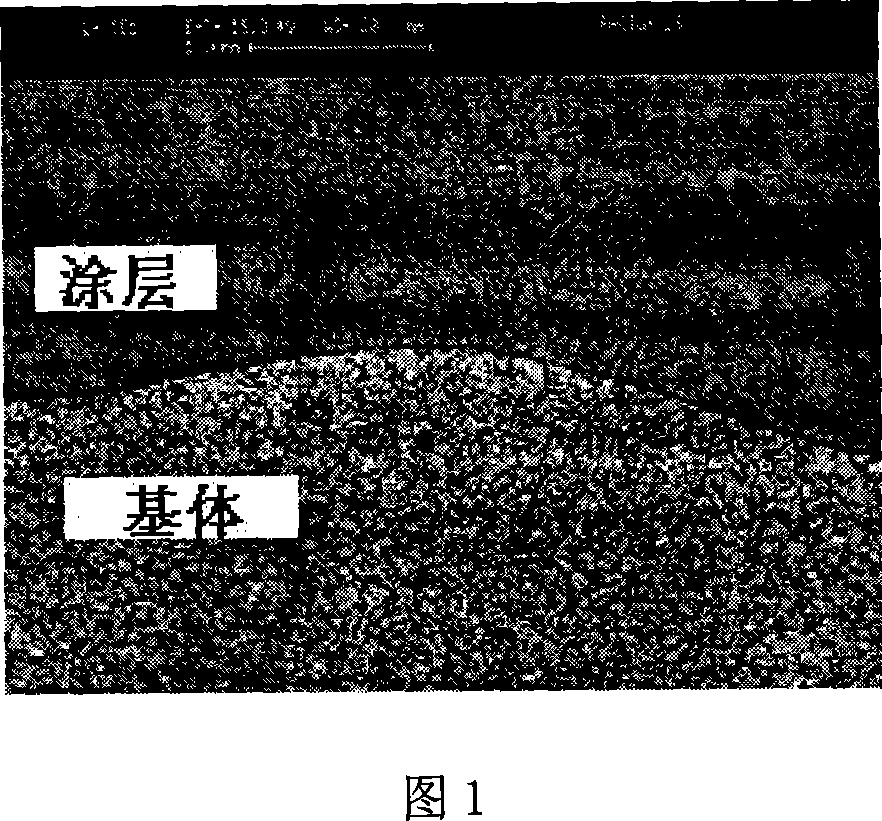

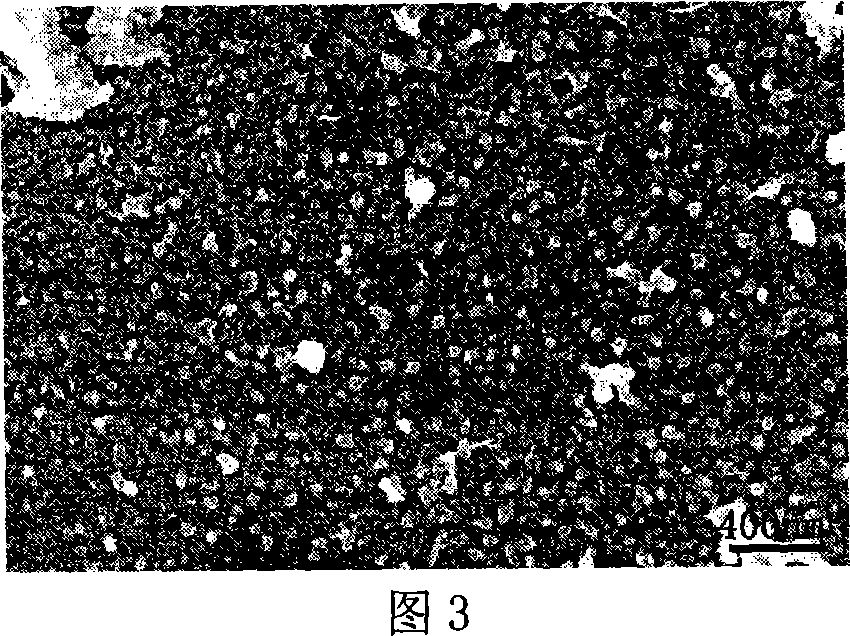

[0025] Figure 1 is a photo of the cross-sectional morphology of the plasma cladding iron-based coating. It can be seen that the coating has an overlapping morphology. The coating and the substrate are in good metallurgical bonding, and there are few defects such as cracks, pores, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com