Shaft part on spiral track line contact surface

A technology for contacting surfaces and shaft parts. It is applied in the field of shaft parts. It can solve problems such as the difficulty in ensuring the correct fit of the guide post and the guide sleeve, the shift of the pressure center of the upper and lower molds, and the increase in the fit gap. It achieves a small gap and is easy to pull. Straight, small contact stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

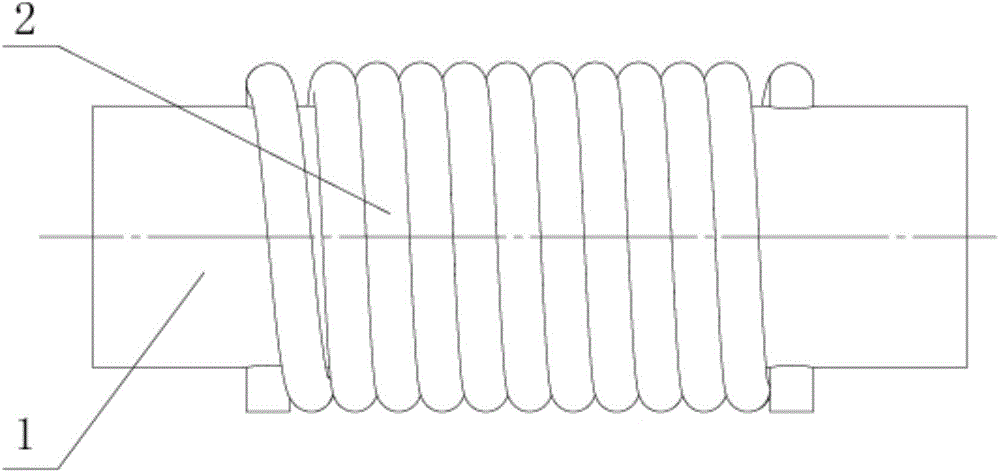

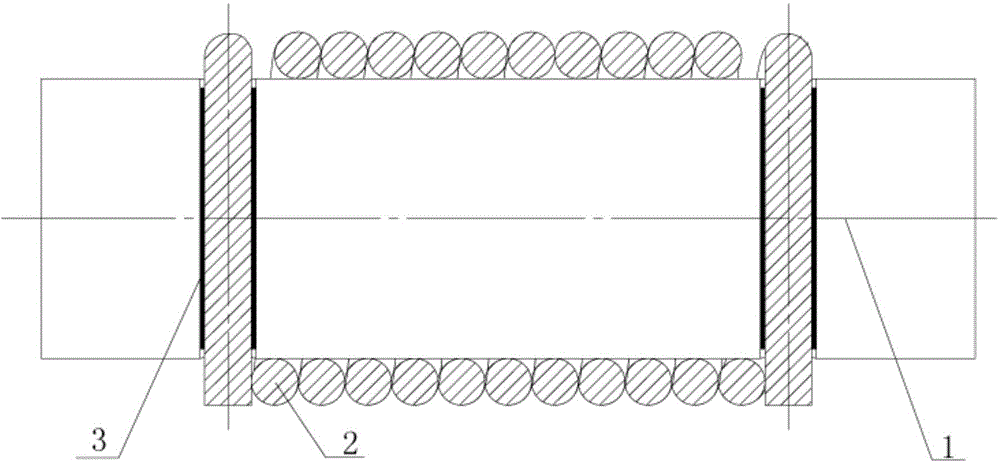

[0026] Such as figure 1 and figure 2 As shown, the shaft parts of the present invention that contact the surface of the helical track line, specifically the shaft whose surface is a helical track coating layer, include a shaft 1 and a helical track cylindrical part 2 fixed on the shaft 1, wherein , the spiral track cylindrical part 2 is spirally formed by winding the ribbon material on the shaft body of the shaft 1 along its axial direction. After forming, the outer surface of the spiral track cylindrical part 2 is the working surface of the shaft 1, and two ribbons The gap between the materials can hold the lubricant and loose particles, which greatly reduces wear and improves the service life of the parts. The two ends of the shaft 1 are respectively provided with a strip material installation hole, and the ribbon heads at the two ends of the spiral track cylindrical part 2 are respectively penetrated into the respective corresponding ribbon material installation holes, an...

Embodiment 2

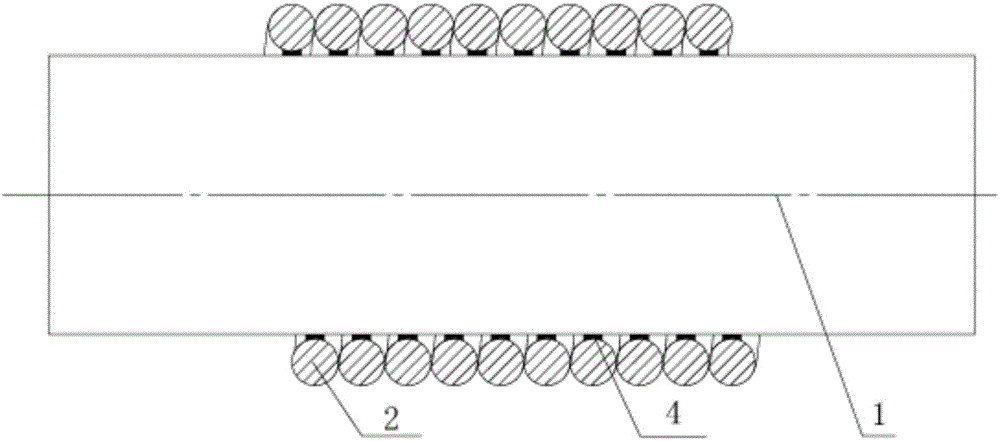

[0032] Such as image 3 As shown, the difference from embodiment 1 is that the two ends of the shaft 1 in this embodiment do not need to be provided with ribbon material installation holes, and the spiral track cylindrical part 2 is fixed by welding the ribbon material on the shaft 1 while winding it. 4 in the figure is solder.

Embodiment 3

[0034] Such as Figure 4 As shown, the difference from Example 2 is that the helical track cylindrical part 2 in this example is pasted and fixed on the shaft 1 by using a pasting material 5 (specifically, glass glue), and specifically, the pasting material 5 is first coated on the shaft 1. Material 5, and then tightly wind the ribbon material on the shaft 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com