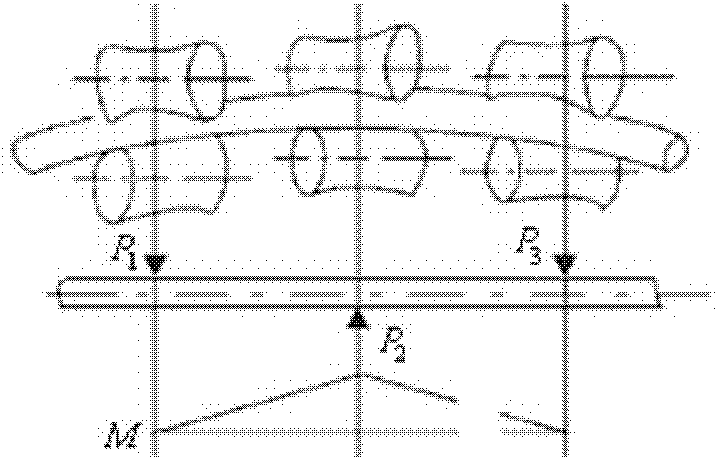

Method for realizing precision straightening of thin-wall seamless steel tubes by adopting six-roller straightener

A seamless steel pipe straightening technology, applied in the field of precision straightening of thin-walled seamless steel pipe, can solve problems such as excessive reduction, spiral indentation on the steel pipe surface, and low pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Basic parameters of seamless steel pipe straightening mill:

[0074] Straightening roll length is 660mm

[0075] Straightening roll diameter is 480mm

[0076] Straightening temperature 500℃

[0077] Straightening speed 10-72m / min

[0078] Material of seamless steel pipe: 29CrMo44V

[0079] The mechanical performance index is σ E =36.92Mpa, E=21920Mpa

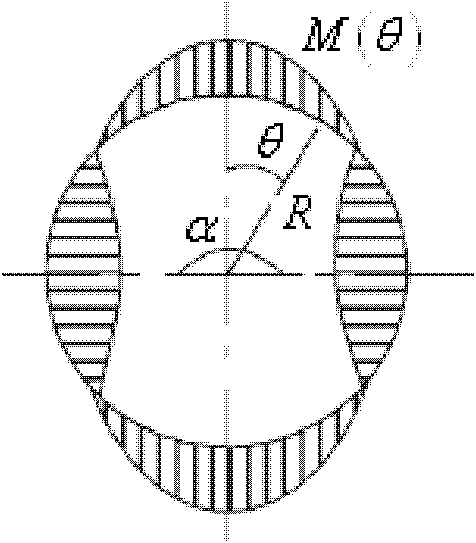

[0080] The dimensions and specifications of the steel pipes are respectively outer diameter d=273.05mm and wall thickness t=10.16mm.

[0081] The specific implementation process is as Figure 4 As shown, the specific description is as follows.

[0082] First enter the raw data.

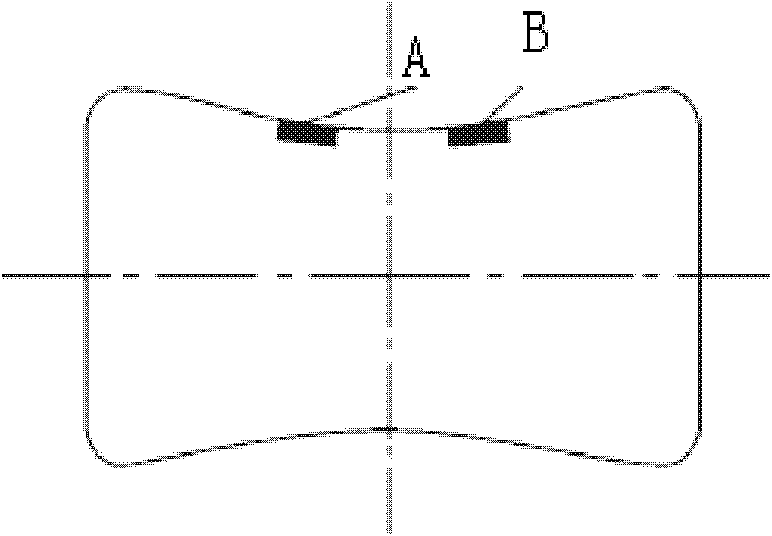

[0083] (1) steel pipe straightening or correction process

[0084] After the pipe enters the straightening roller, it is subjected to the pressure of the contacting roller for a certain length to produce bending and flattening deformation at the same time. Bending and straightening makes the pipe bend and deform under the rolling action ...

Embodiment 2

[0163] Basic parameters of seamless steel pipe straightening mill:

[0164] Length of straightening roll L=660mm

[0165] Straightening roll diameter D = 480mm

[0166] Straightening temperature 500℃

[0167] Straightening speed 10-72m / min

[0168] Material of seamless steel pipe: 29CrMo44V

[0169] The mechanical performance index is σ E =36.92Mpa, E=21920Mpa

[0170]The dimensions and specifications of the steel pipes are respectively d=219.08mm and t=6.71mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com