Patents

Literature

64results about How to "Improve straightening quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

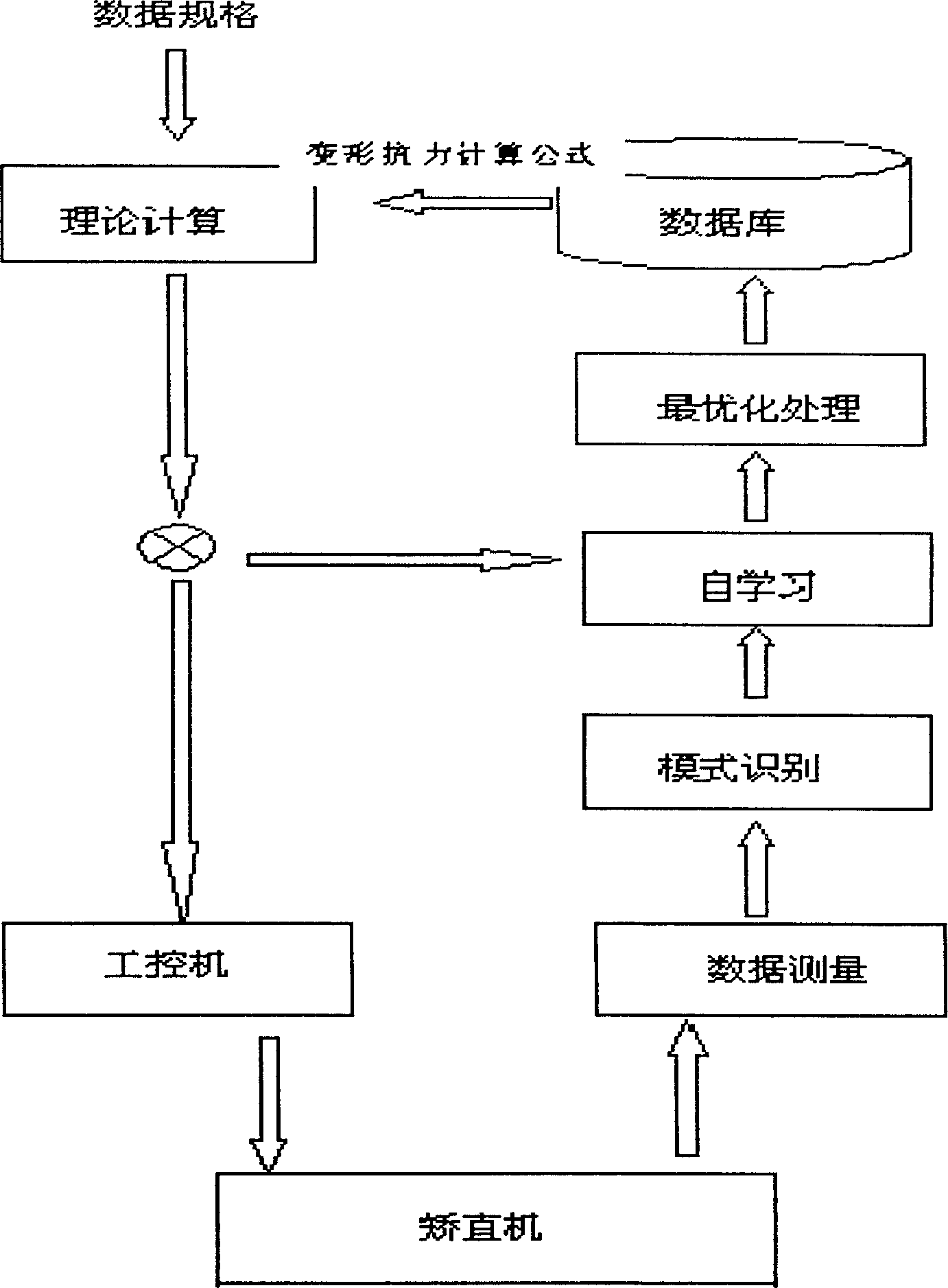

Automatic flattening process parameter optimization of metal plate band

InactiveCN1818913AImprove straightening qualityImprove straightening efficiencySpecial data processing applicationsEffect factorMetal sheet

The invention belongs to the metal sheet and strap straighten technology field, which is a technical parameter optimizing method of straightening the metal sheet and strap automatically. The existing technology is complexity during the process of the straighten of the sheet and strap, the effect factors of straightener such as bounce, abrasion and clearance of axletree etc, more wrap of the technical initialization between the theoretic calculation and factual operation that lead the request about the flat and straight of the production can not be satisfied. The invention is making the least optimizing process for the difference of the theoretic value and the fact measure value, that is correcting the undetermined variable in the theoretic calculating formulary of the straighten force - regressive coefficient a0, a1, a2, a3, a4, a5, a6, a7, that is the nearest value between the theoretic value and the fact measure value. The method of the invention can setup the technical parameter automatically, improve the quality and the efficiency of straighten, the online system base on the invention has successful apply on the 3500 millimeters thick sheet straightener, the average value of the measure straighten force is discrepance smaller +5% with the calculation value, the remnants curvature of the production is less than 1.5mm / m.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

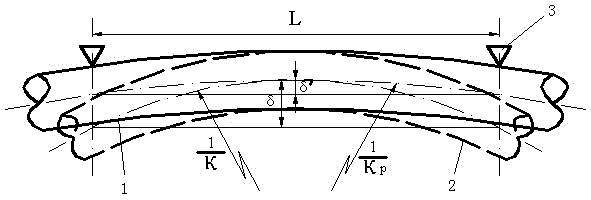

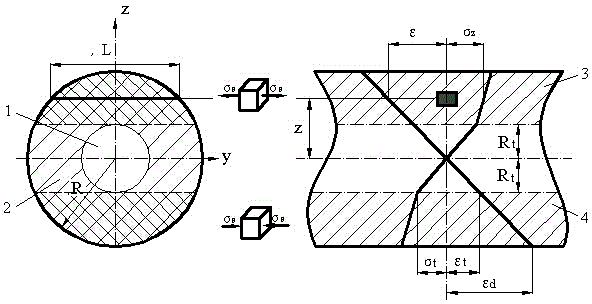

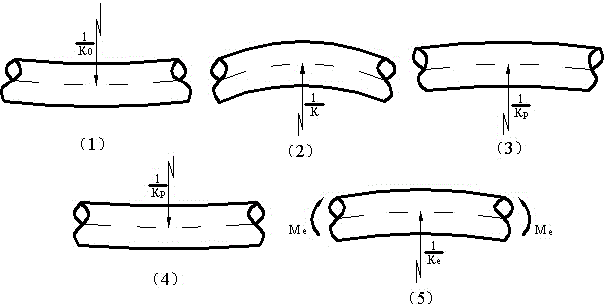

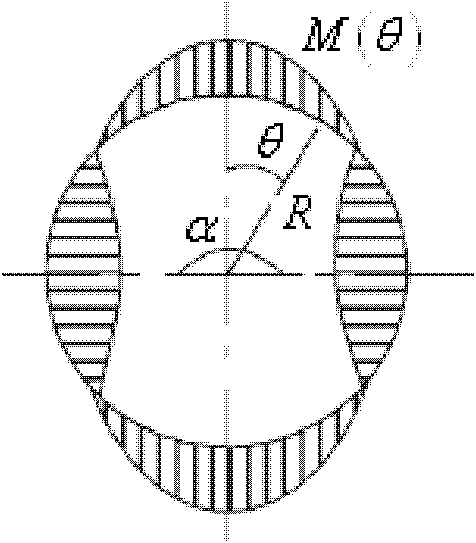

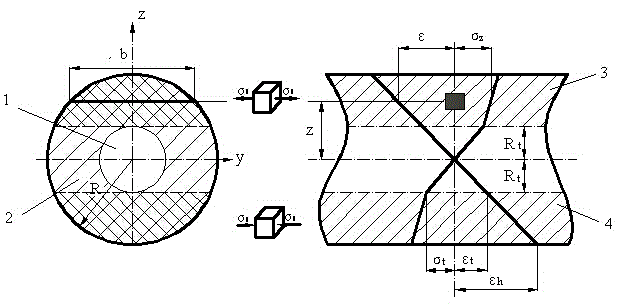

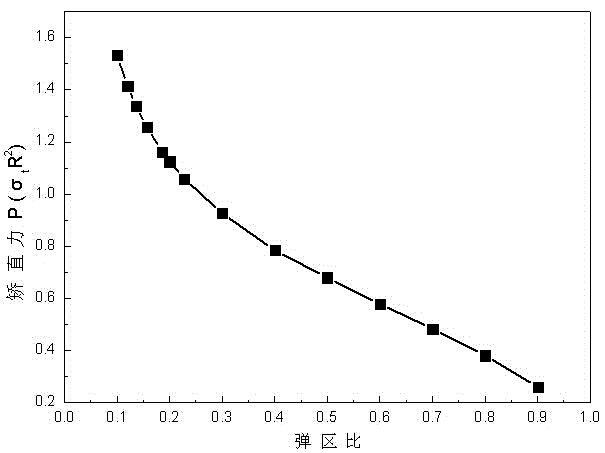

Model for predicting resilience of bar subjected to two roll straightening

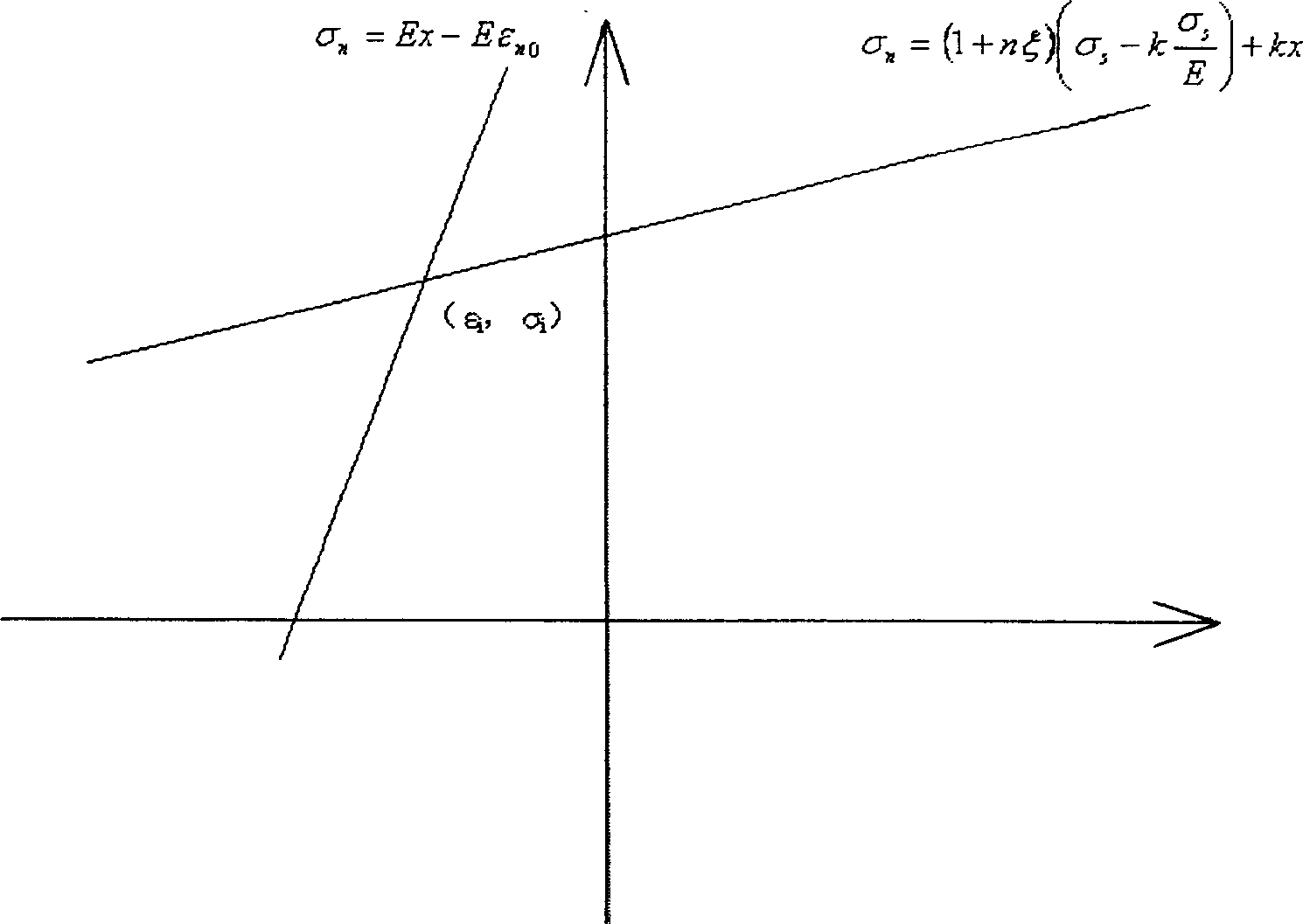

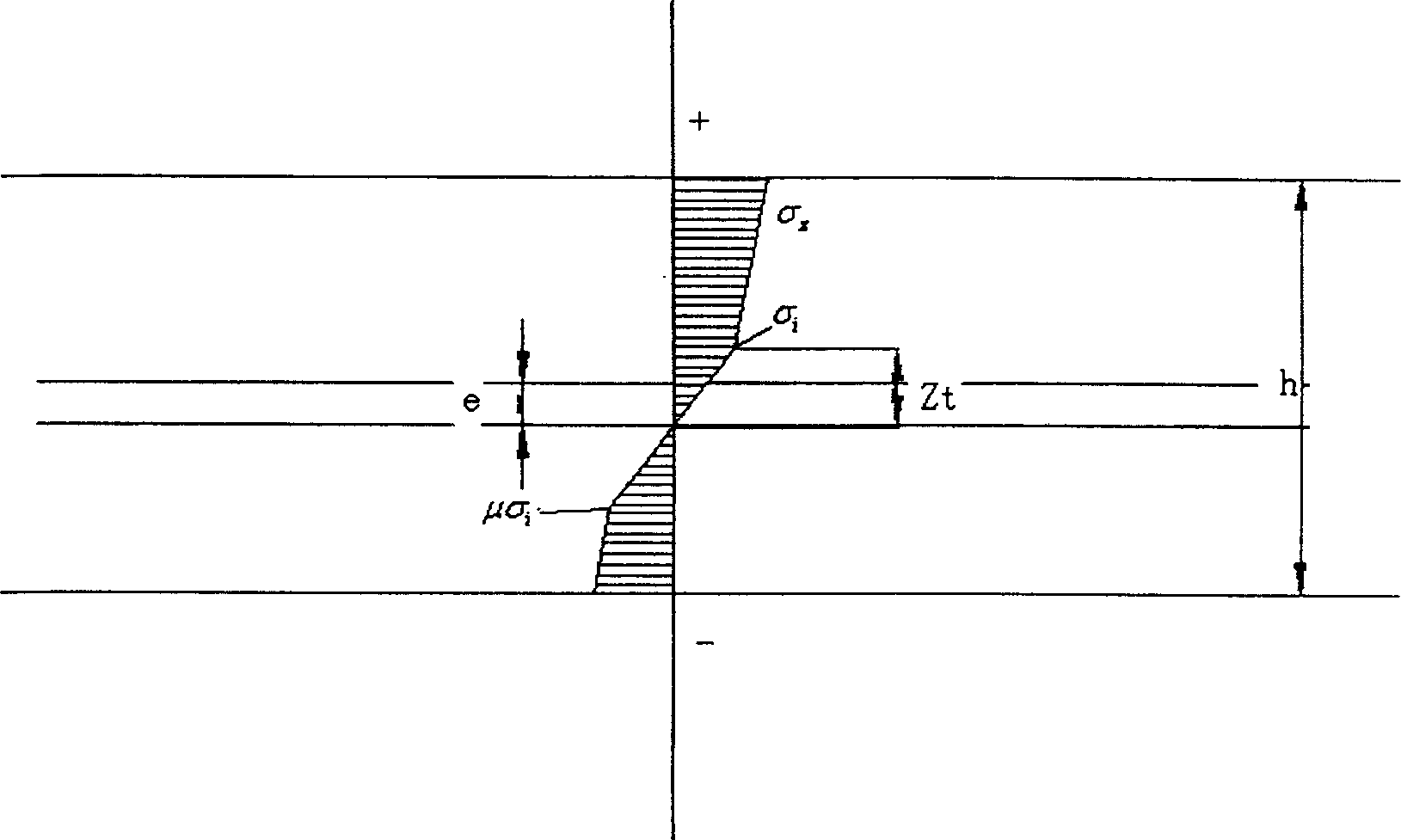

ActiveCN104866641AAccurately reflectAccurately describe the stress-strain relationshipSpecial data processing applicationsStress distributionTension compression

The invention relates to a method for predicting resilience of a bar subjected to two roll straightening, and belongs to the technical field of two-roll straightening machines. The method comprises the followings steps: firstly, determining the offset of a stress neutral layer when the rod is subjected to straightening; then, determining a deformation-hardening coefficient and tension-compression stress distribution according to different straightening processes and deformation characteristics of rods in different specifications; finally, determining the model for predicting rebound bending moment and straightening rebound deflection by combining a pure bending and rebound theory, wherein the rebound deflection delta is related to the following variables of R, sigma<t>, lambda, xi, psi, kappa, I, E, L, B, n, R0, Rw, P and tau; R represents a rod radius; sigma<t> represents the yield limit; lambda represents a hardening coefficient; xi represents an elastic region ratio; psi represents a neutral layer offset radius ratio; k represents an anti-bend rate; I represents rod section moment of inertia; E represents modulus of elasticity; L represents the distance between the two end points in three-point bending; B represents a plastic coefficient; n represents a hardening index; R0 represents an initial bending radius; Rw represents an anti-bend radius; P represents straightening force; tau represents a correction coefficient. According to the method, a straightening and deformation process can be truly reflected, and the straightening theory can be perfected; resilience in the straightening process can be accurately predicted, and bases for the roll shape design and process parameter establishment are provided.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

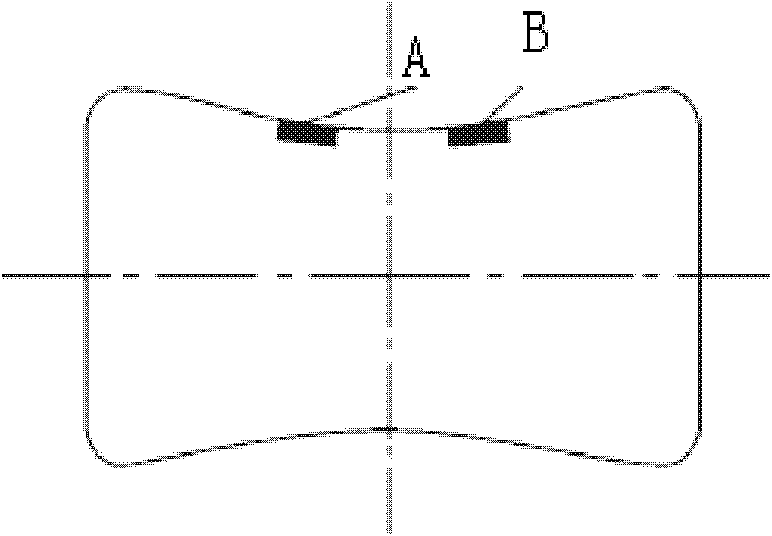

Method for realizing precision straightening of thin-wall seamless steel tubes by adopting six-roller straightener

InactiveCN101927278AReduce the number of squashesIncrease the number of squashesMechanical engineeringSteel tube

The invention discloses a method for realizing the precision straightening of thin-wall seamless steel tubes by adopting a six-roller straightener, aiming at providing a method for obtaining optimum technological parameters and producing thin-wall seamless steel tubes with high surface quality by calculating straightening press-down quantity and correcting press-down quantity, comparing the resultant force of straightening applied force and correcting applied force with and hertz contact force, and checking straightness accuracy and the diameter difference of long shafts and short shafts of an ellipse. The method comprises the following steps: confirming the press-down bending and straightening frequency and press-flat bending and correcting frequency; confirming the straightening press-down quantity, the straightening applied force, the correcting press-down quantity and the correcting applied force; working out the hertz contact force resulting in the sag deformation of the seamless steel tubes according to a hertz contact theory; comparing the hertz contact force with the resultant force of the straightening applied force and the correcting applied force; calculating straightness error according to the actual straightening press-down quantity from 1 to the last straightening; and calculating the corrected diameter difference of the long shafts of the ellipse and the diameter difference of the short shafts of the ellipse from 1 to the last correcting and comparing with a standard value.

Owner:TIANJIN UNIV OF COMMERCE

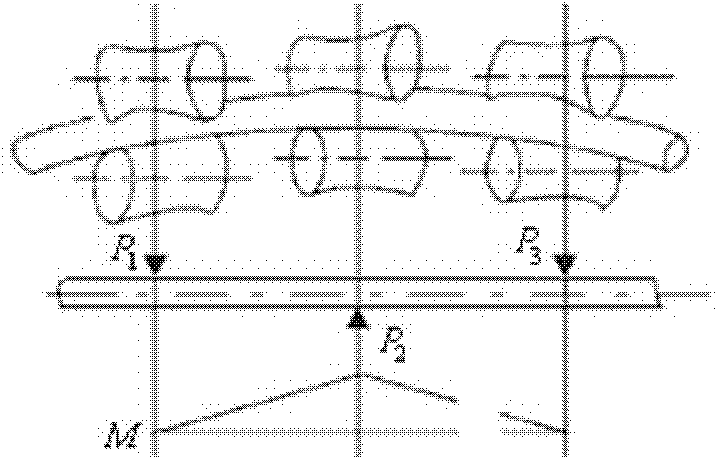

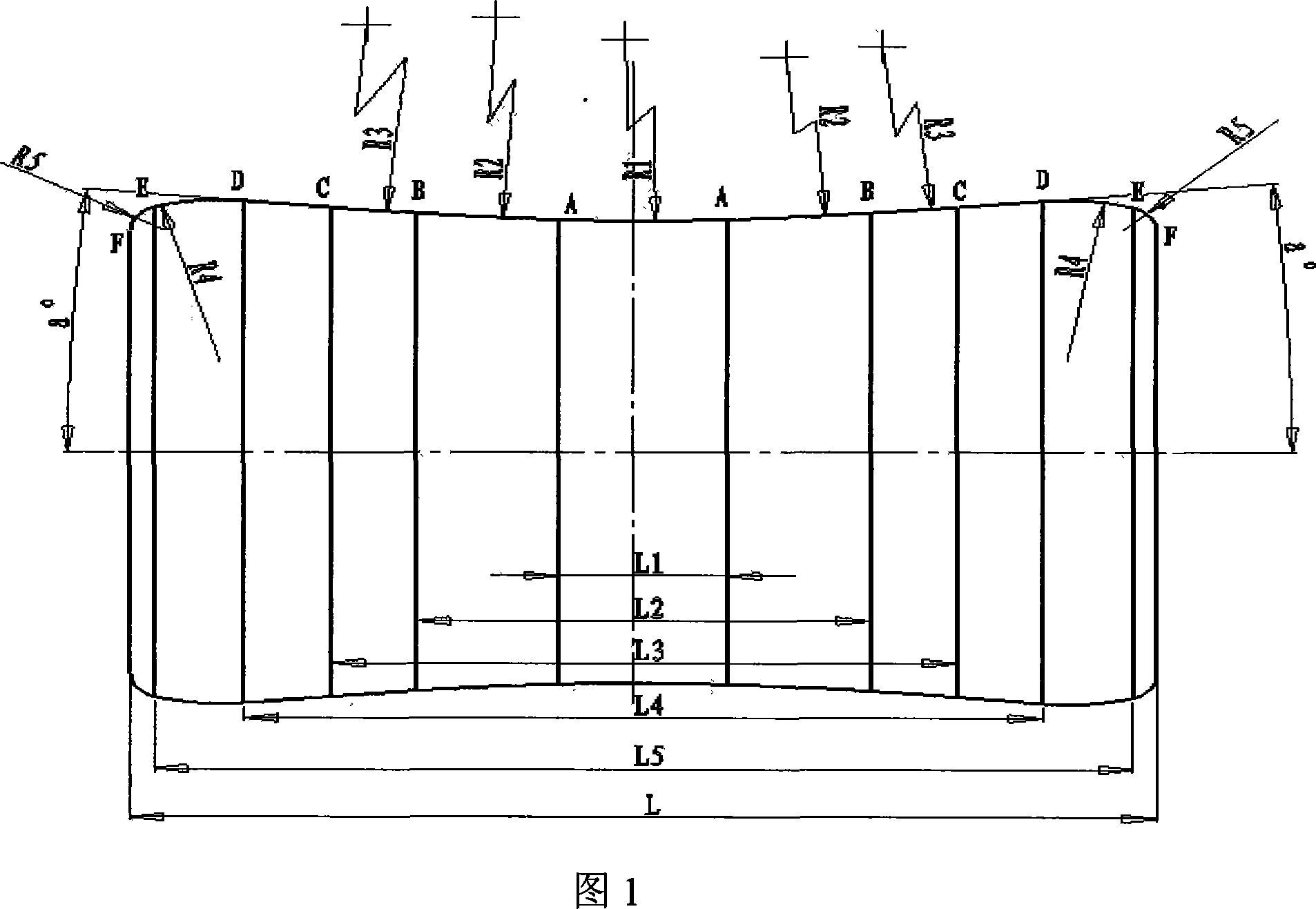

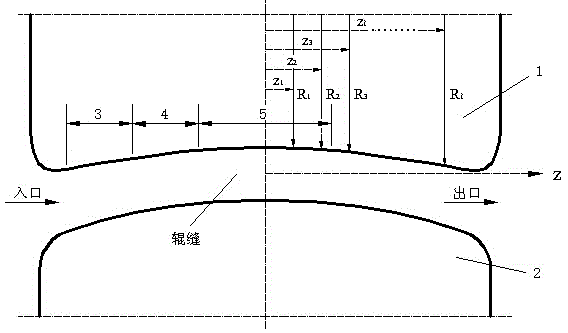

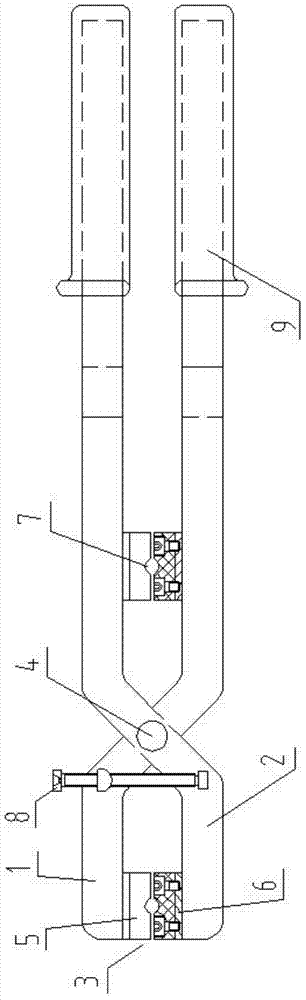

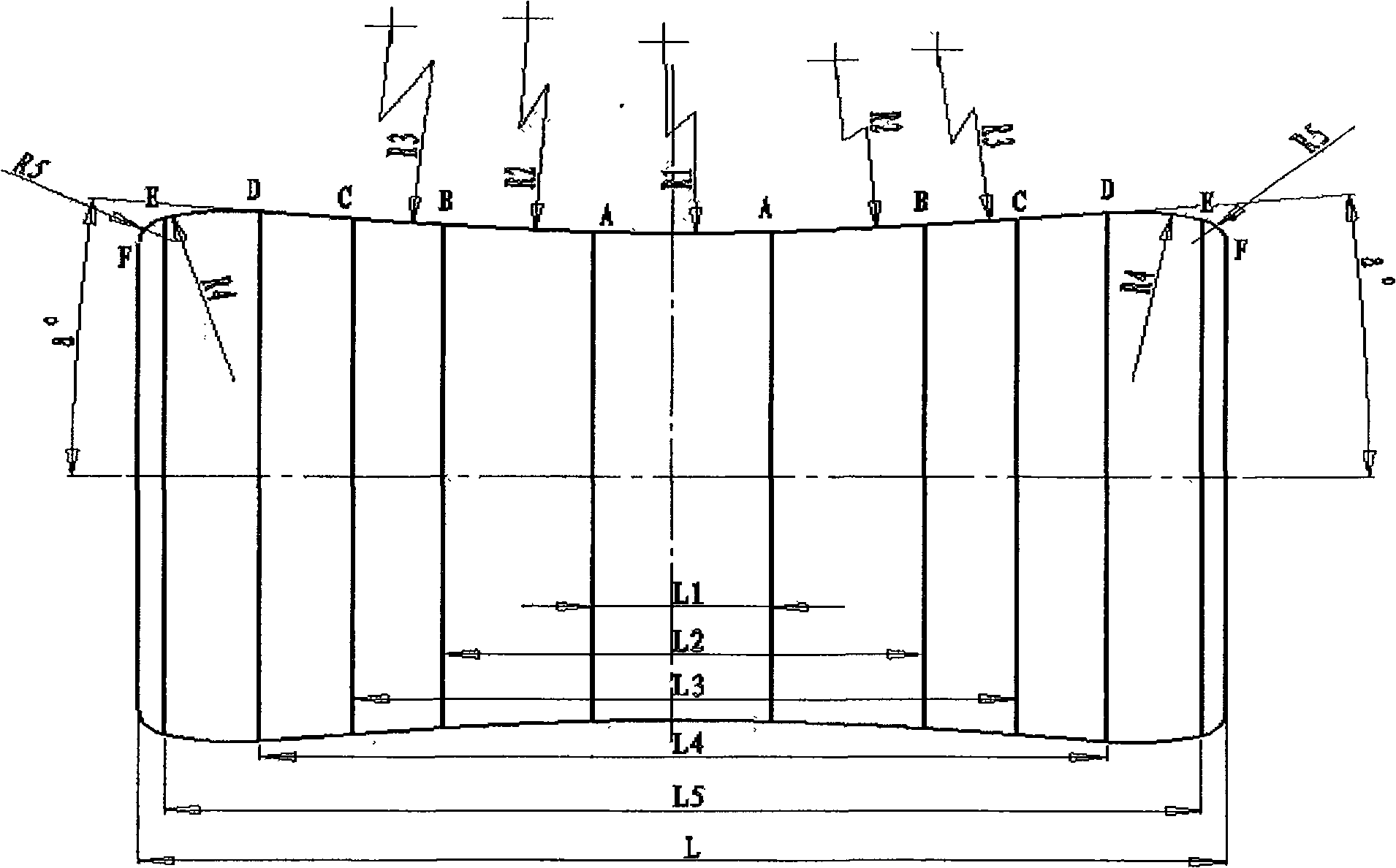

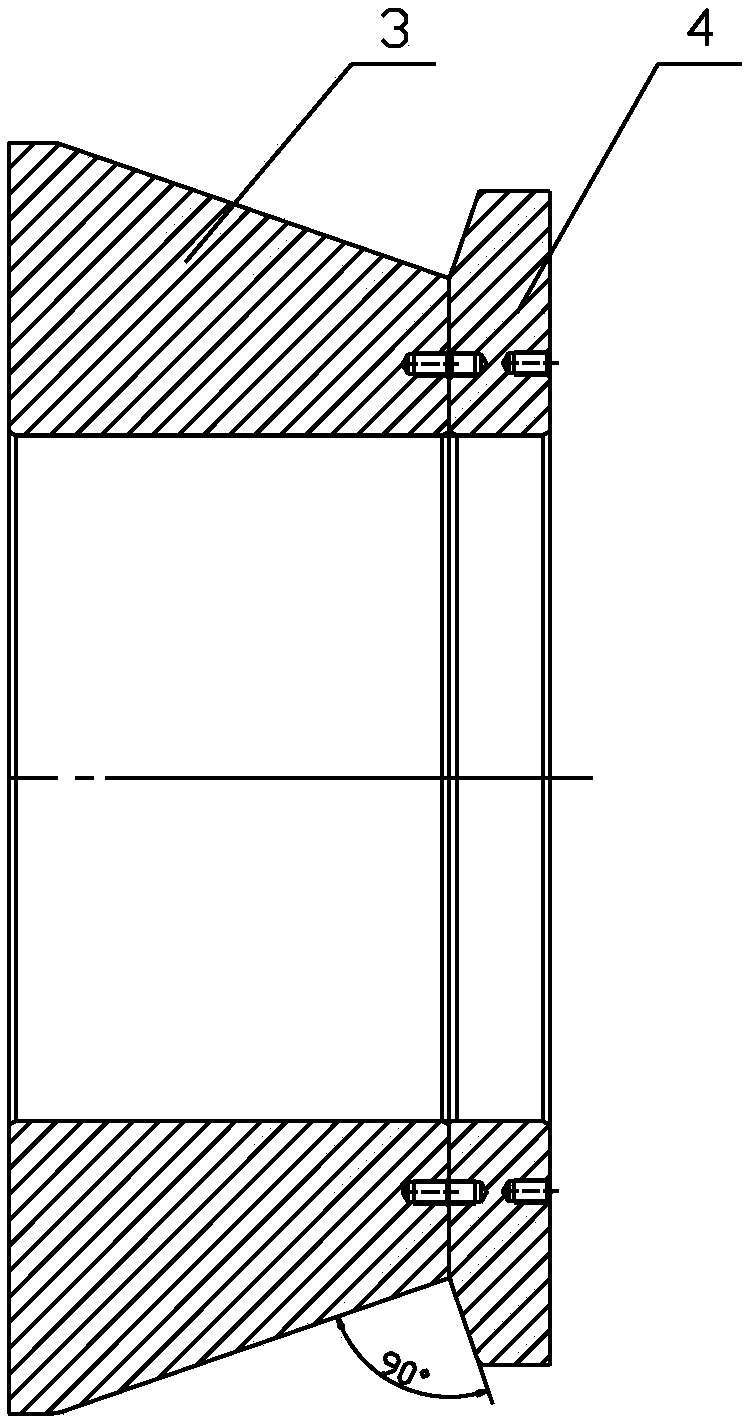

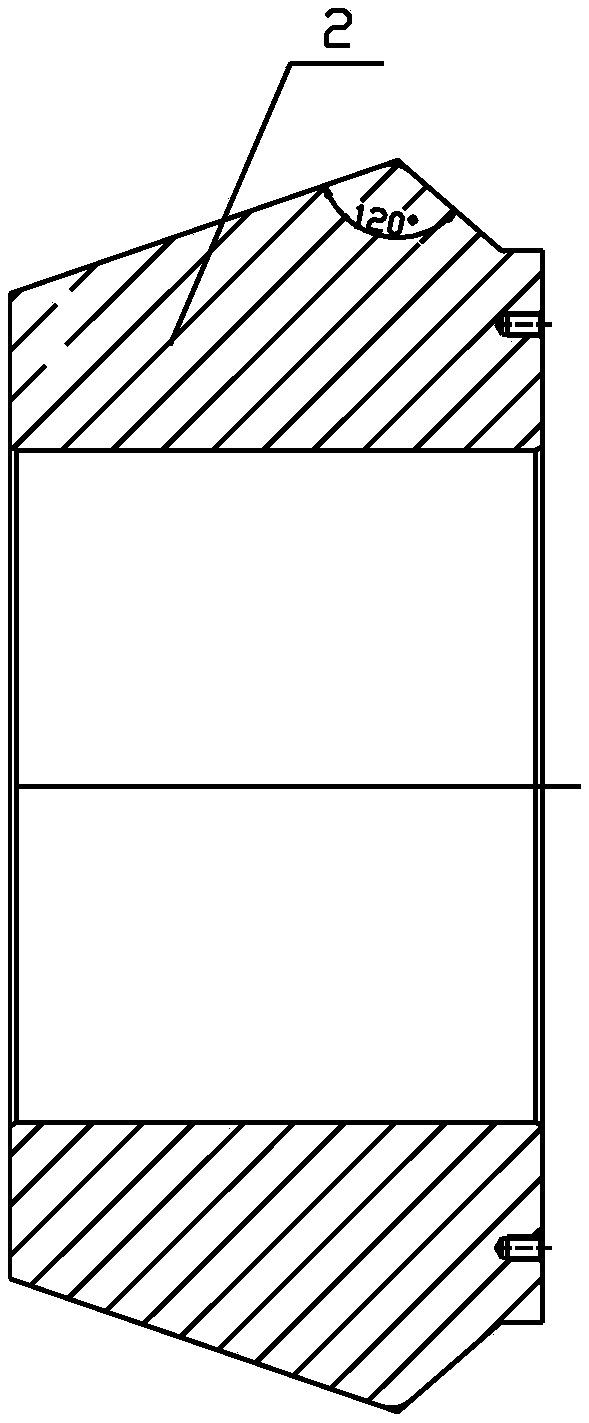

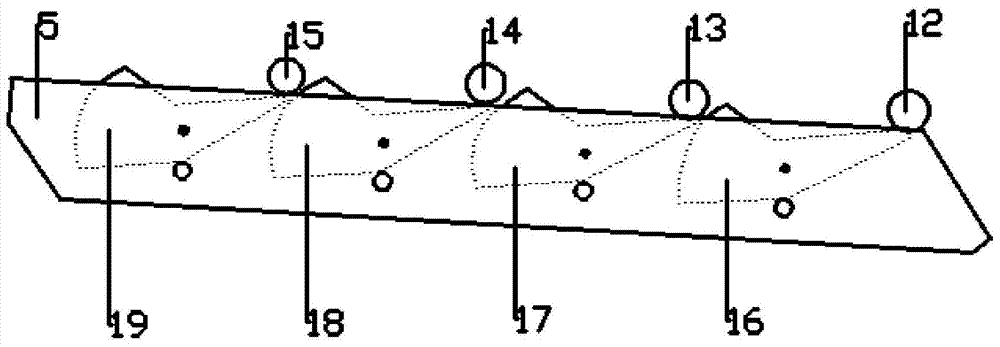

Pipe rod bar with major diameter double-roller unbender concave roller curve

InactiveCN101116882AOvercome limitationsEasy to processShaping toolsEngineeringMechanical engineering

The invention discloses a roll shape curve of the concave roll of a two-roll straightener of major diameter tube / bar materials. The invention is characterized in that: a roll shape symmetrical line is taken as the symmetry axis; the roll shape curve of the concave roll comprises three segments of a circular arc of unequal radial R1-R3, a segment of a virgule CD, a segment of a reversal circular arc R4 and a transitional circular arc R5; various segments of the circular arcs and the virgule are tangent on a straightening roll bus bar and are connected with each other smoothly; the radials of various segments of the circular arcs are calculated as follows: R1-R3=X1*dmin*pi*tg alpha max, R4=X2*dmin*pi*tg alpha max, R5=(20-50)mm; and the projected length in the horizontal direction with the radials of various segments of the circular arcs corresponding to the virgule is calculated as follows: L1-L5=Y*dmin*pi*tg alpha max. The invention has the advantages of easy manufacture, capacity of significantly improving the straightening quality and working efficiency of a product and significantly reducing whipping phenomenon at the same time, particularly adaptable for the straightening processing of major diameter tube / bar materials of phi100-200 mm.

Owner:YANSHAN UNIV

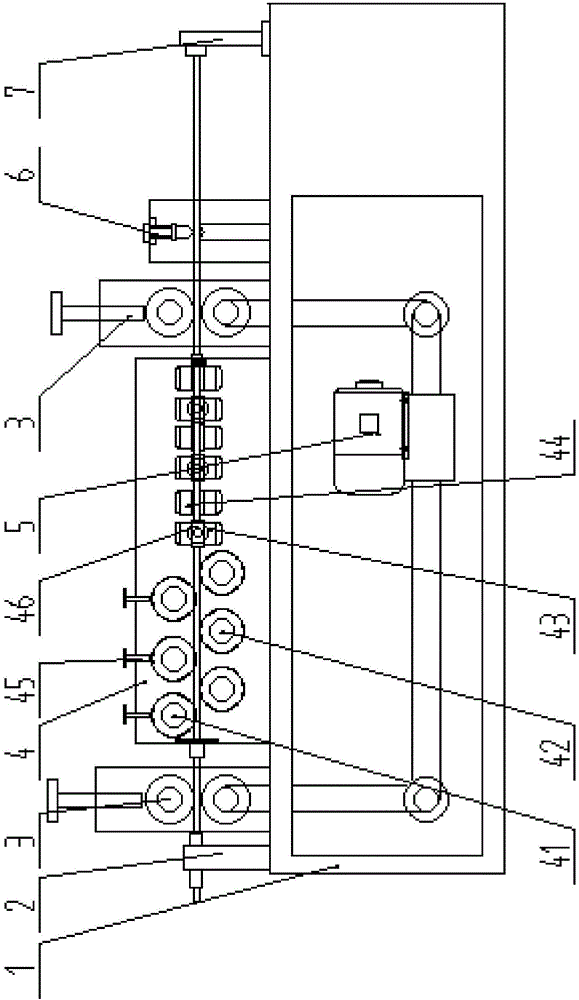

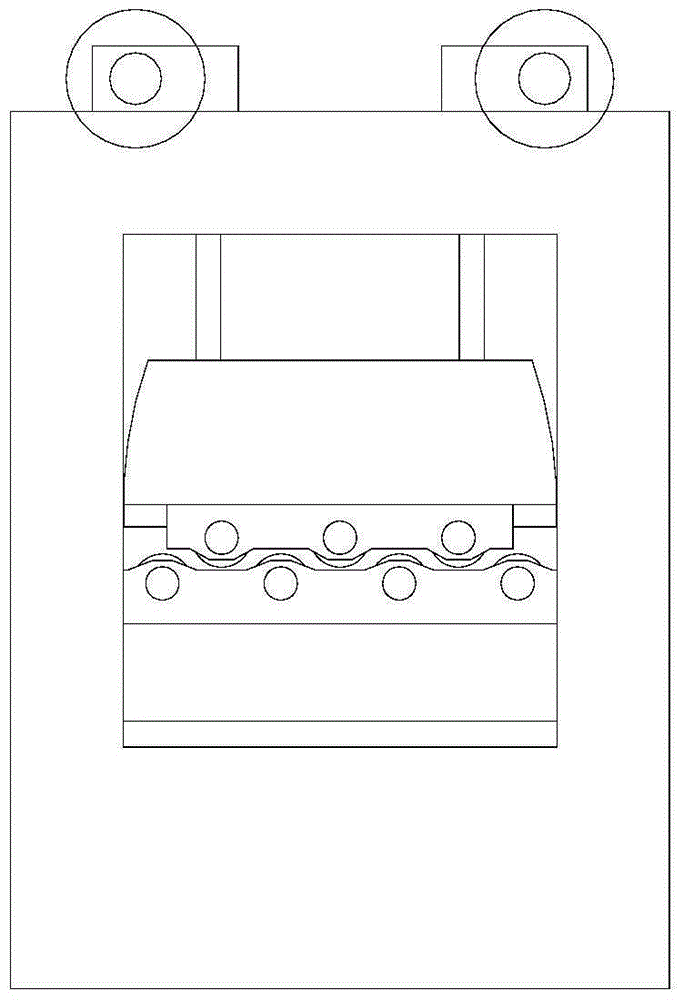

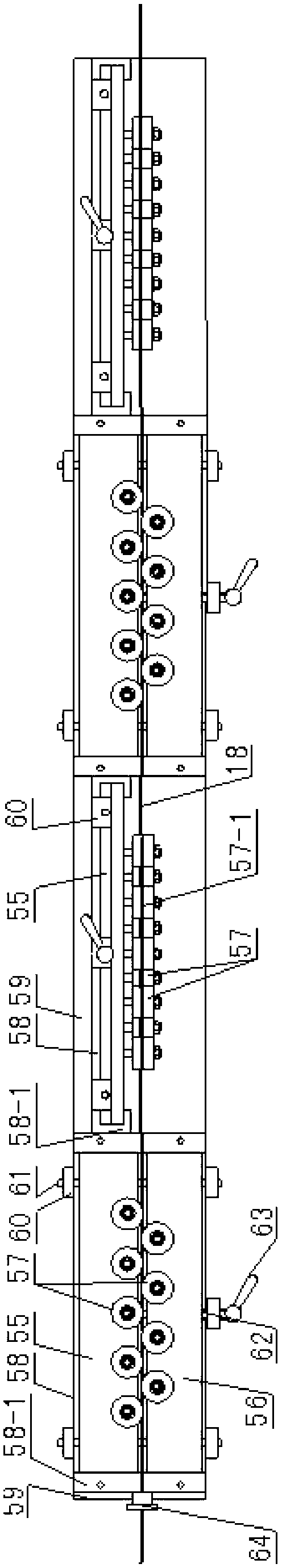

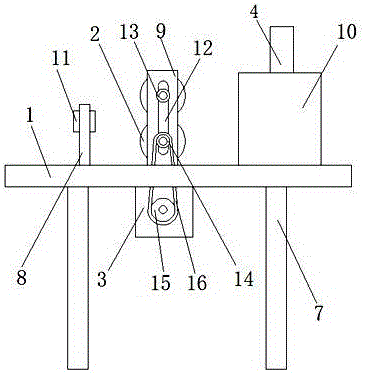

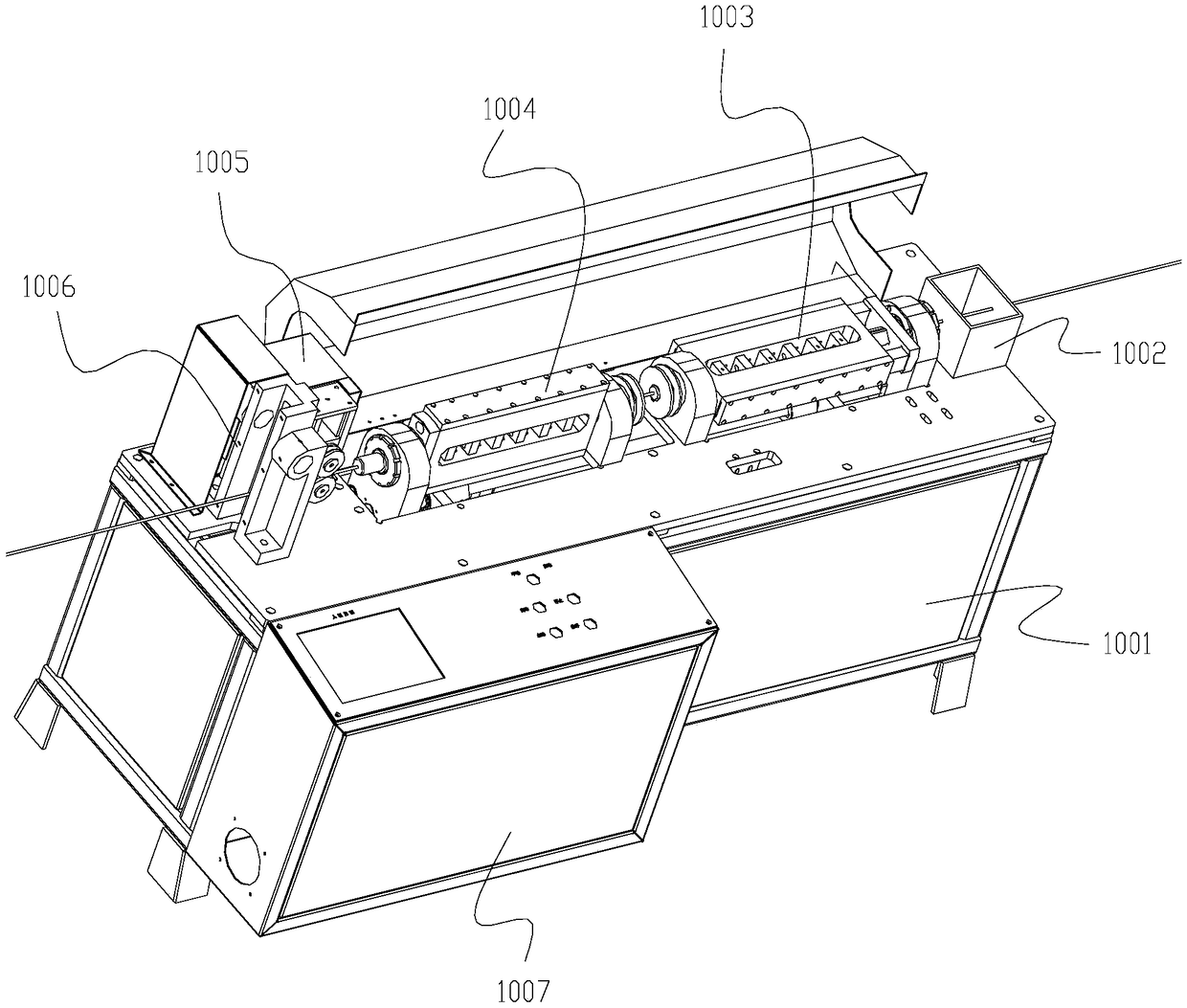

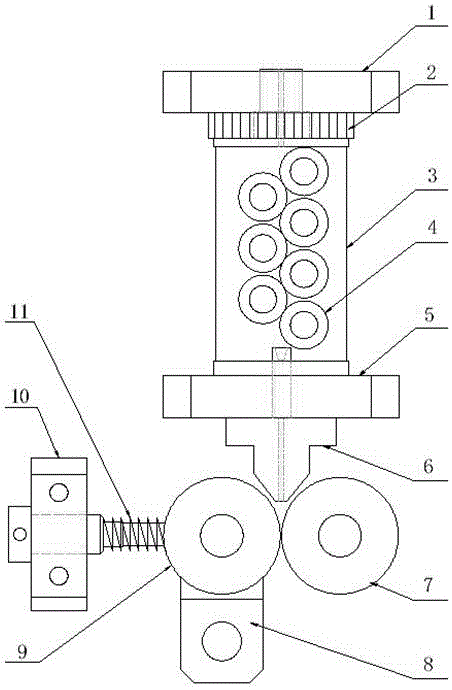

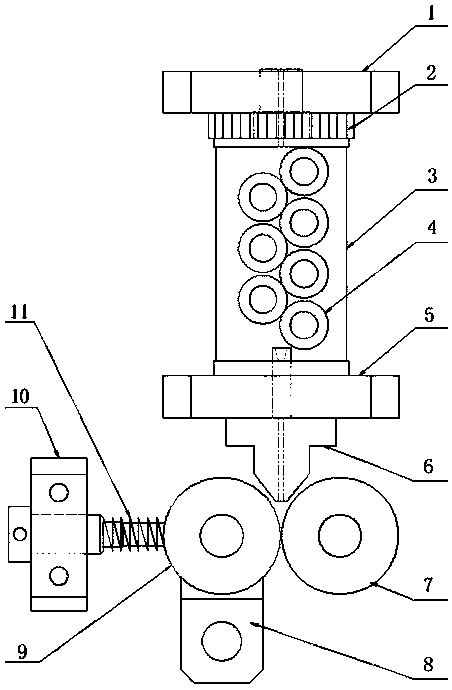

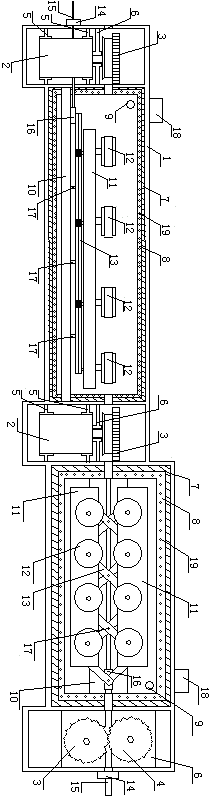

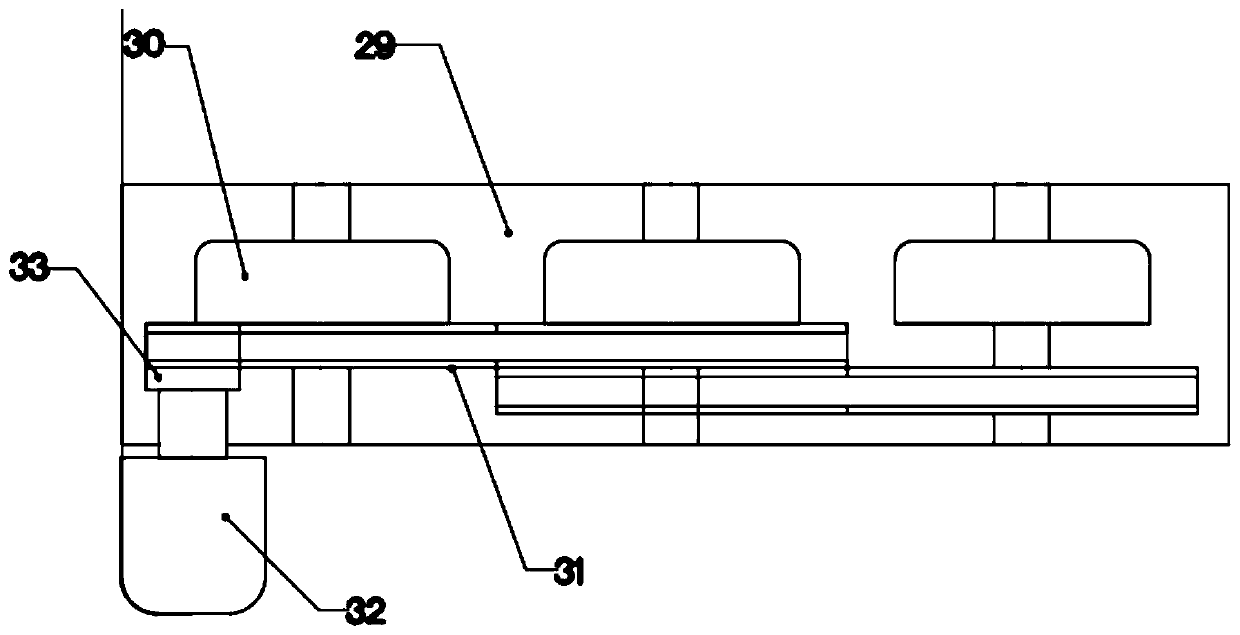

Automatic non-scratch steel wire straightening cutting-off machine

InactiveCN106513538ASimple structureSolve the problem that the flatness cannot meet the requirementsEngineeringPoint contact

The invention relates to the technical field of steel wire machining equipment, in particular to an automatic non-scratch steel wire straightening cutting-off machine. The straightening cutting-off machine comprises a guiding pipe, a steel wire feeding mechanism, a straightening mechanism and a cutting-off mechanism, all of which are sequentially arranged on a rack, and a transmission mechanism is arranged below the rack. The straightening mechanism straightens steel wires in the longitudinal direction and the transverse direction. The problems that according to an existing straightening cutting-off device, the surfaces of steel wires are scratched, and the straightness of the steel wires cannot meet the requirement are solved, and the steel wire straightening quality can be improved. Pressing wheels are U-shaped groove wheels, the groove wheels are matched with the to-be-machined steel wires in shape, the traditional line-face contact is changed into the point contact of the groove wheels and the steel wires, the contact face is small, and the surfaces of the steel wires are effectively prevented from being scratched. Straightening in the vertical direction is conducted through the upper pressing wheels and the lower pressing wheels, straightening of the steel wires in the transverse direction is conducted through the left pressing wheels and the right pressing wheels, straightening machining on the steel wires in all directions is achieved, meanwhile, the straightness of the steel wires is good, and the production technology requirement can be met.

Owner:云南灵瑞农业科技有限公司

Combined type straightening machine

The invention discloses a combined type straightening machine. The combined type straightening machine comprises at least three detachable straightening roll devices. Each straightening roll device is connected with a drive device. Every two adjacent straightening roll devices are movably connected and arranged in an up-down staggered mode. Plates or profiles are straightened by the straightening roll devices by penetrating through the straightening roll devices which are arranged in the up-down staggered mode. According to the combined type straightening machine, the straightening roll devices are movably connected and arranged in the up-down staggered mode, and compared with an existing straightening machine of a fixed structure, the roll number and the roll distance of the straightening machine can be changed by increasing or decreasing the number of the straightening roll devices according to needs without replacing the whole straightening machine. The weight of a machine frame of the straightening machine can be lowered, the size can be decreased, the rigidity can be improved, and the straightening technological requirement of the plates or profiles of different thicknesses can be met. Moreover, each straightening roll device is connected with the corresponding drive device, and the roll speed of each straightening roll device can be automatically adjusted, so that the plates or the profiles are better straightened.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

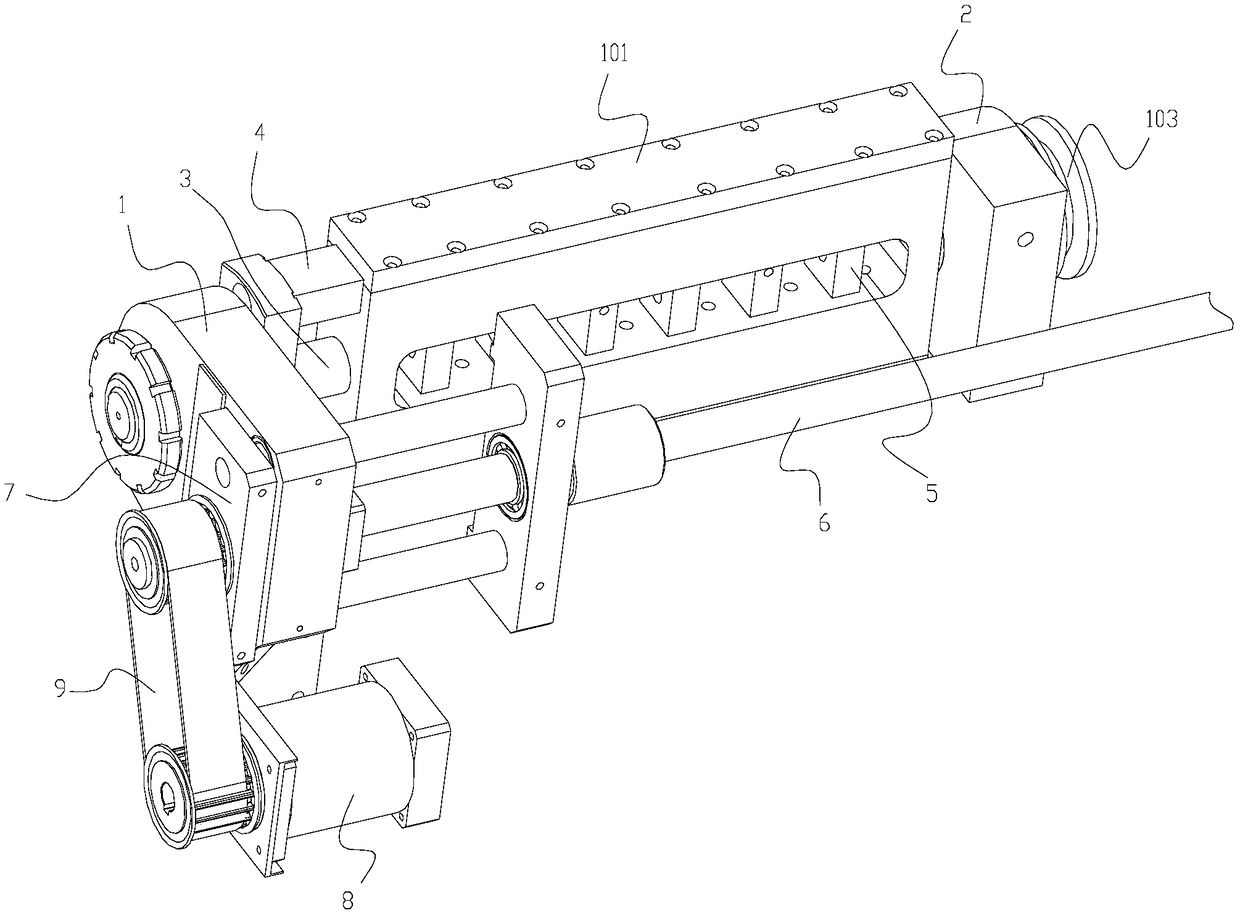

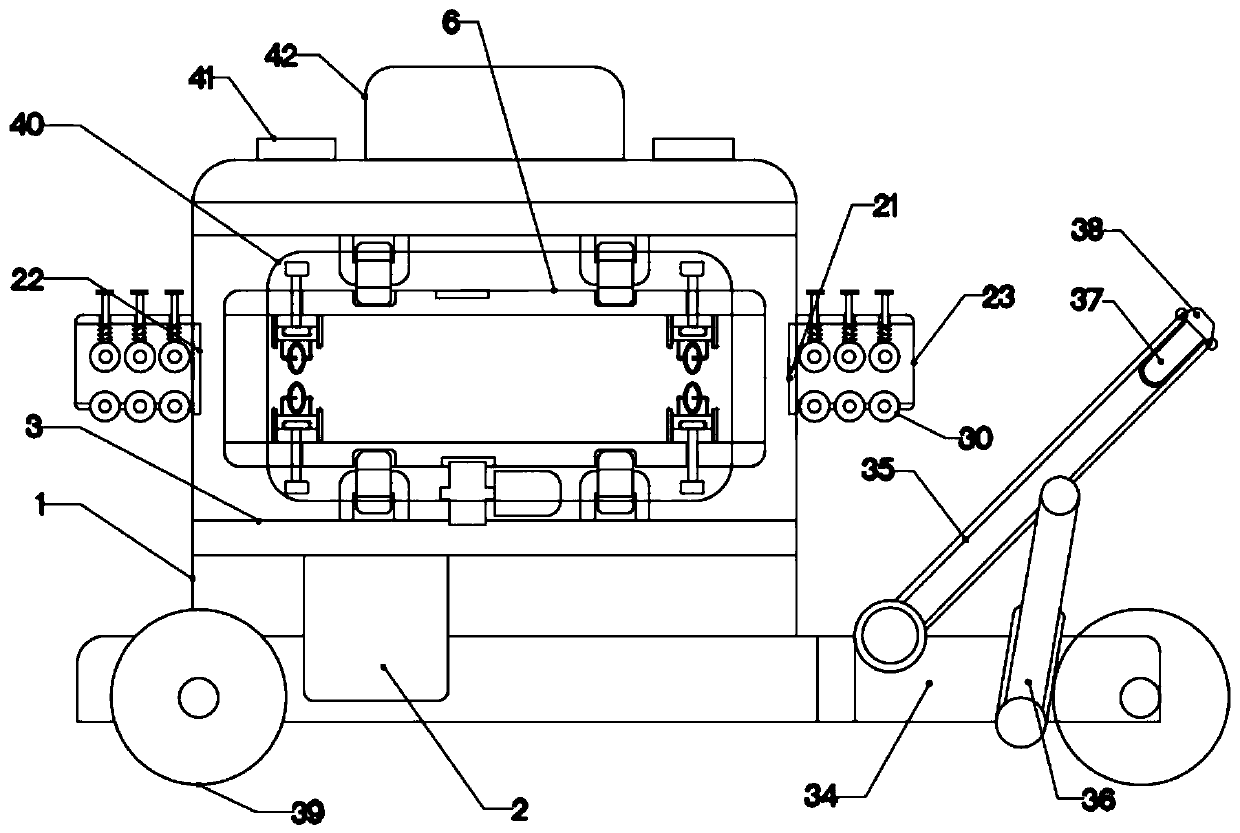

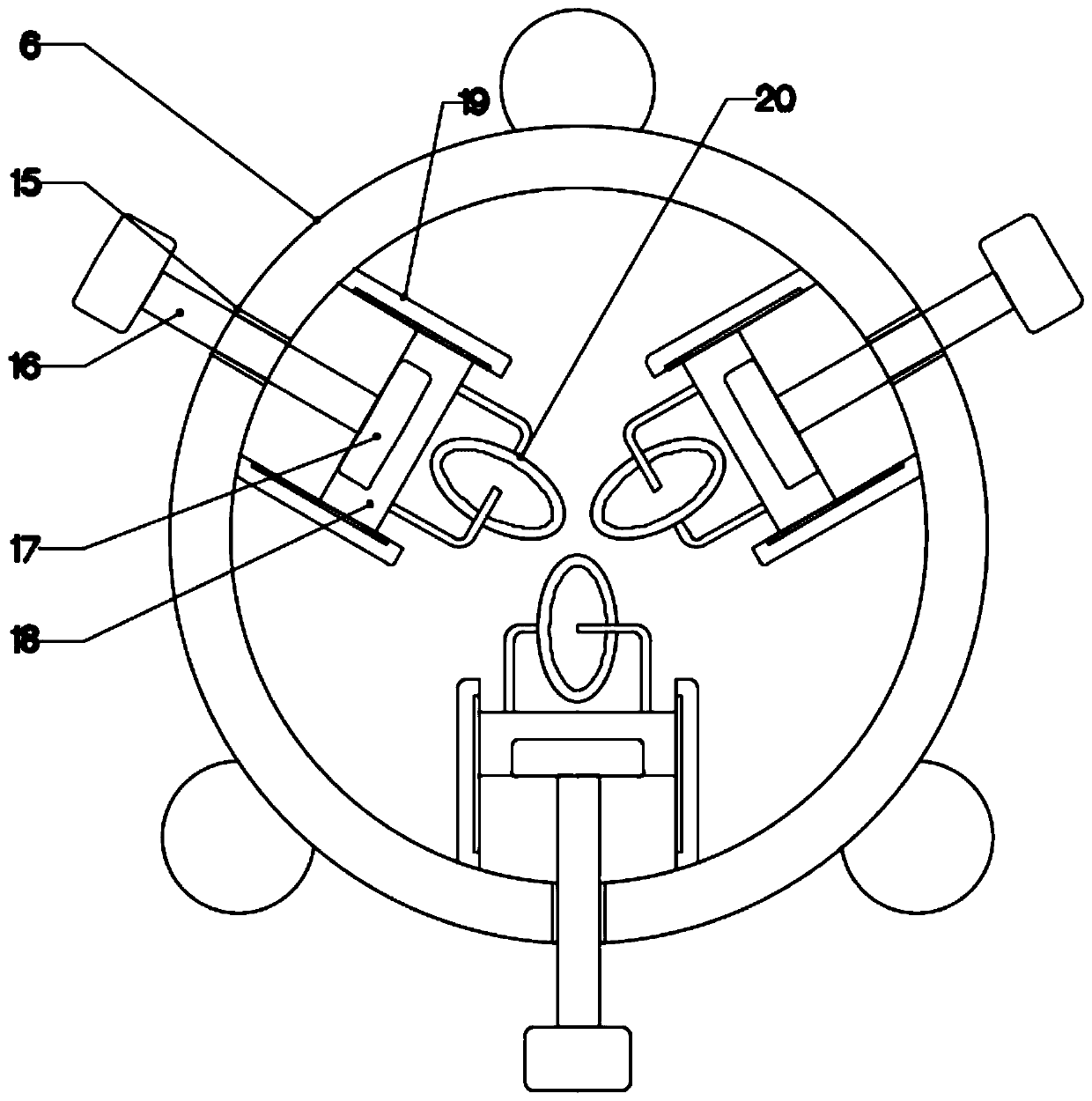

Spoke machine

ActiveCN103240605ASimple power mechanismSmall footprintOther manufacturing equipments/toolsSmall footprintSpoke

The invention provides a spoke machine which comprises a machine frame. The spoke machine is provided with a power mechanism, a spoke steel wire straightening mechanism, a spoke steel wire traction mechanism, a spoke blank parallel screw rod conveying mechanism, a first cutting-off mechanism, a second cutting-off mechanism, a pier cap mechanism, a bending mechanism, a wire rolling mechanism and a lubricating mechanism. Compared with existing spoke machines, the spoke machine has the outstanding advantages of being energy-saving, small in occupied area, low in operation noise, good in processing quality and high in production efficiency.

Owner:TIANJIN WANHUAVEHICLE COMPONENTS CO LTD

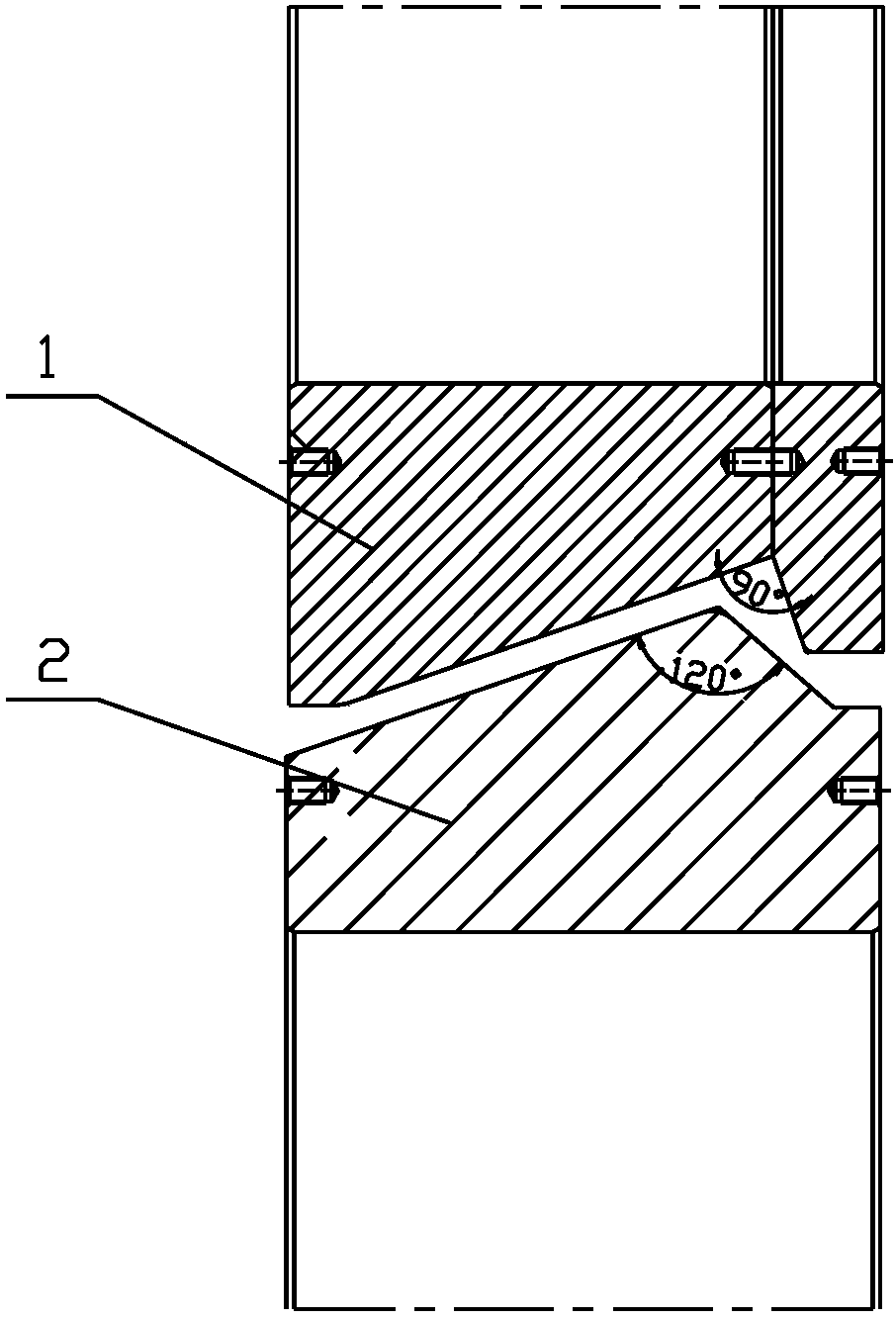

Method for designing roller shape of two-roller straightener concave roller

ActiveCN104615824AImprove straightening qualityMeet the requirements of high precision straighteningSpecial data processing applicationsClassical mechanicsEngineering

The invention relates to a method for designing a roller shape of a two-roller straightener concave roller and belongs to the technical field of two-roller straighteners. The method comprises the following steps that firstly, stress distribution of bar material straightening actual deformation is determined; secondly, a formula of a straightening reverse bending ratio is determined according to bar material straightening deformation characteristics; thirdly, on the basis, combining abrasion of straightening force on a roller face, residual stress and influence of an elastic core on hidden danger deflection, the reverse bending ratio of a roller lumbar segment is determined; finally, the reverse bending ratios of the roller lumbar segment and a roller thoracic segment are determined by a remnant curvature formula. The reverse bending ratios of all segments are related with the following variates : Cw = {delta, eta, sigma<t>, sigma<6> epsilon<t>}, wherein the delta is an elastic region ratio, the eta is a ratio of the maximum deformation stress to yield limit, the sigma<t> is the yield limit, and the sigma<6> epsilon<t> is the straightening maximum deformation stress corresponding to the <6> epsilon<t>. On the premise of ensuring the stable straightening quality, the straightening straightness accuracy of the bar materials is improved, the abrasion on the rollers is reduced, the import amount of foreign straightening rollers is reduced, and the enterprise cost is saved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

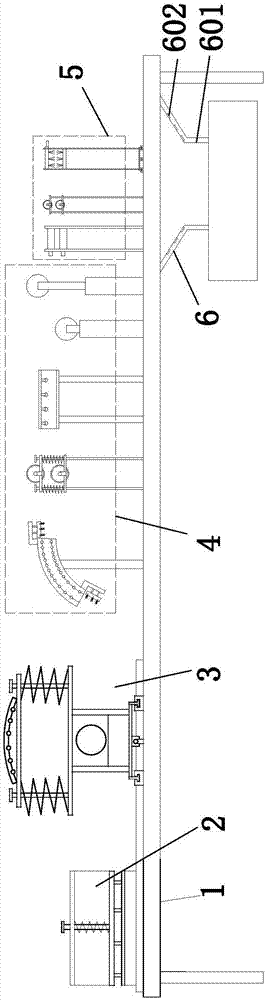

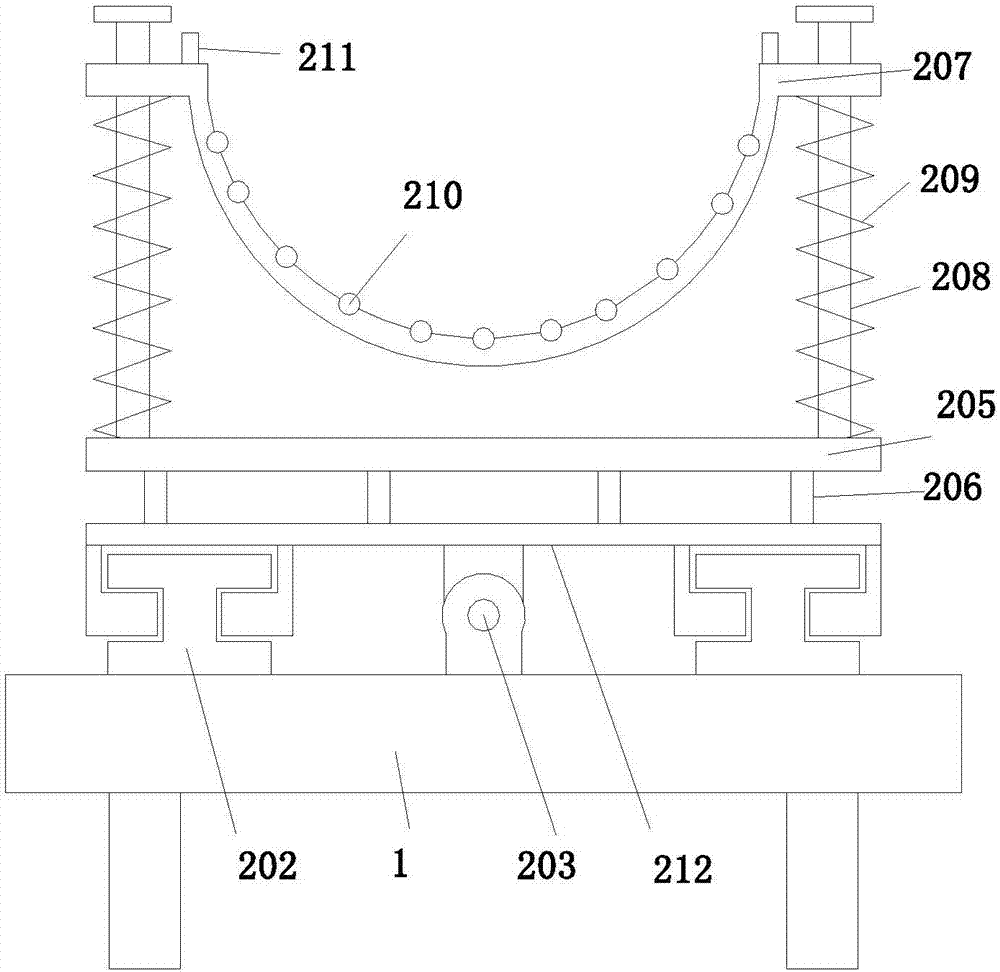

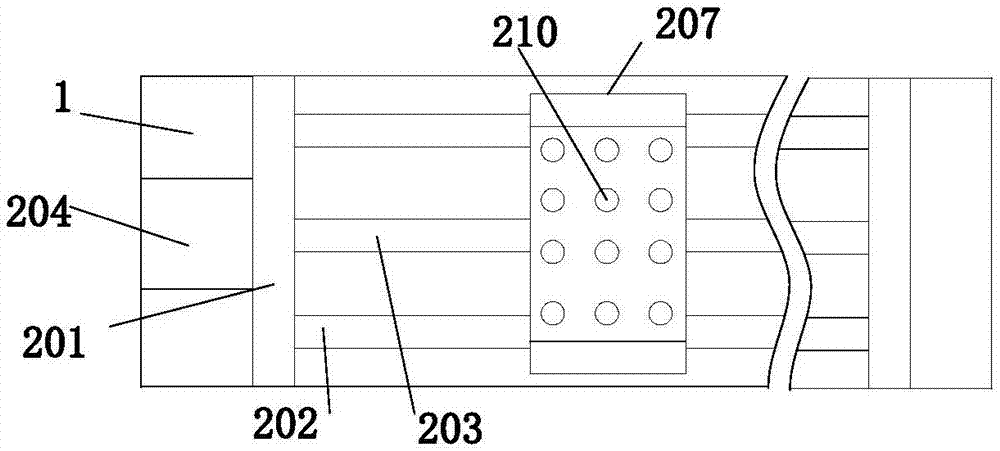

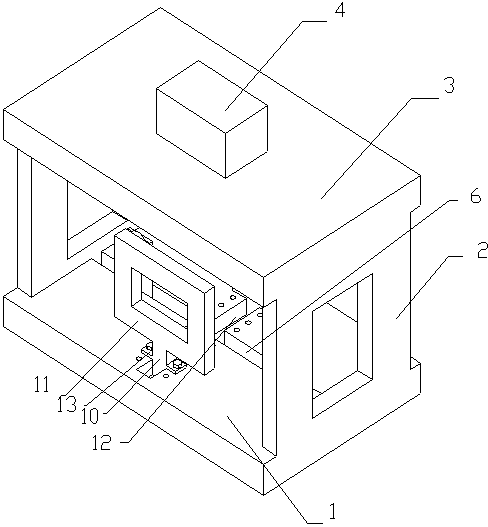

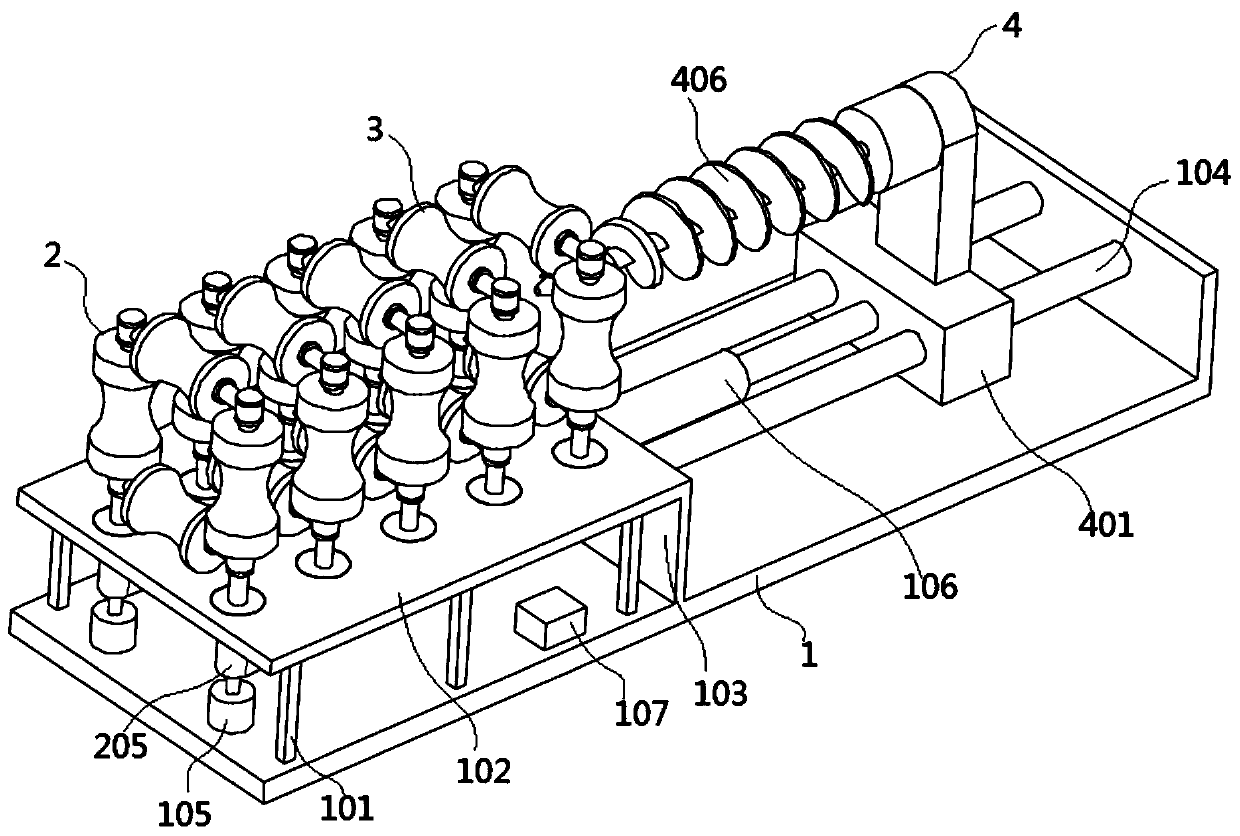

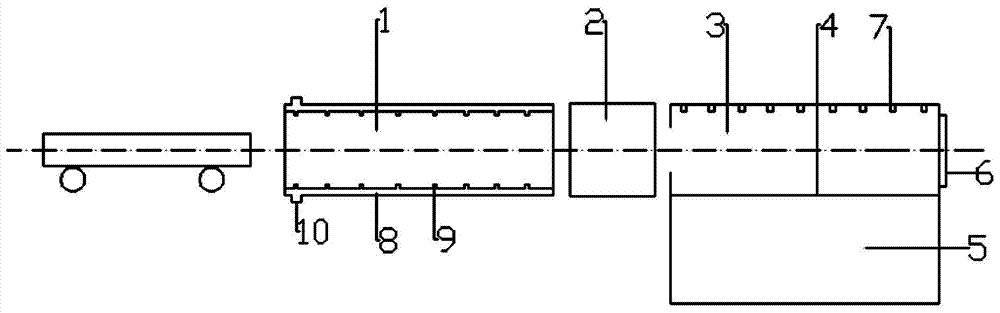

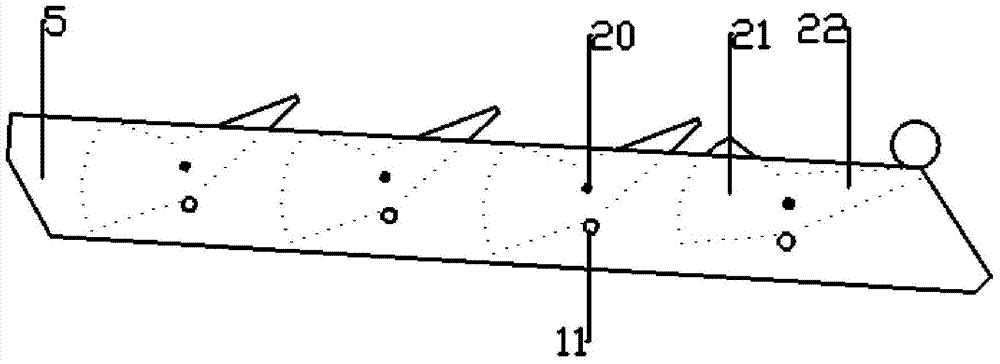

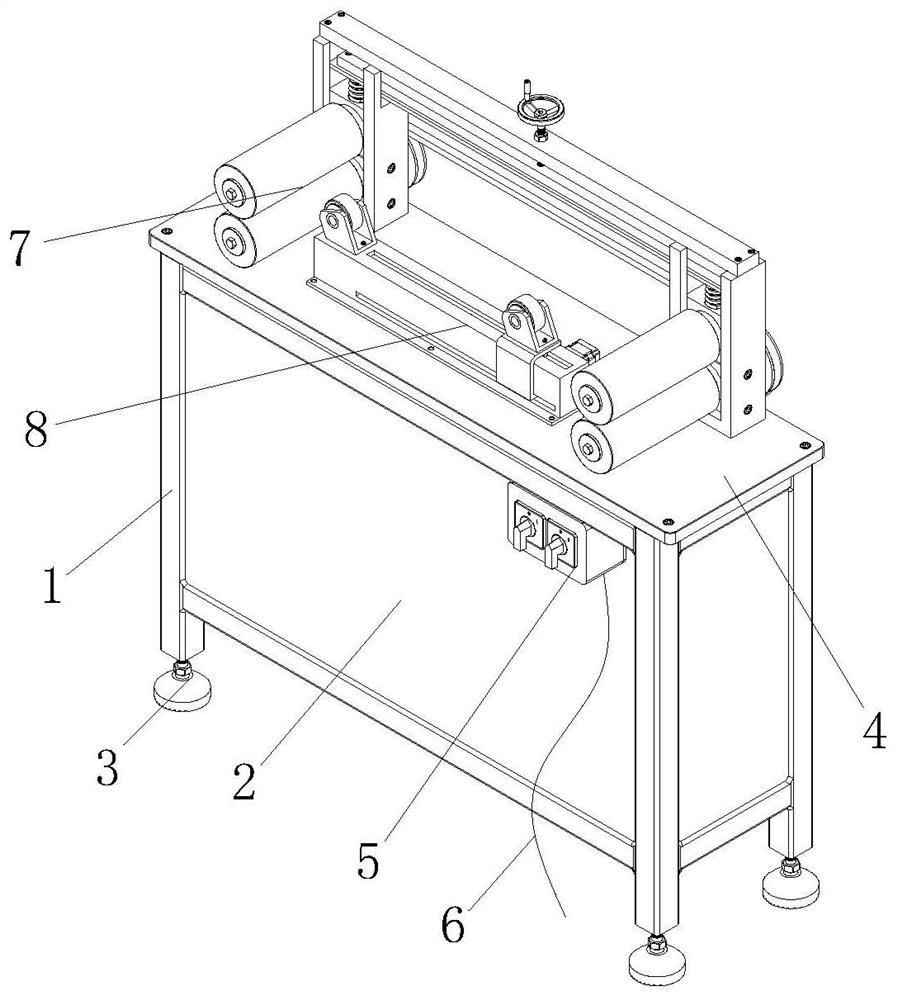

Automatic feeding device for lift guide rail bracket production

InactiveCN107335691AEasy to transportEasy to installGrinding machinesExtrusion cleaning devicesSurface cleaningWaste material

The invention discloses an automatic feeding device for lift guide rail bracket production. The automatic feeding device comprises a machine frame (1). A coiled steel conveying device (2), a coiled steel overturning device (3), a straightening device (4) and a coiled steel surface cleaning device (5) are sequentially arranged on the machine frame (1). A waste material recycling device (6) is arranged below the coiled steel surface cleaning device (5). The waste material recycling device (6) comprises a conical recycling hopper (601) fixed to the machine frame (1). The inner surface of the conical recycling hopper (601) is evenly provided with multiple electromagnets (602). The coiled steel conveying device (2) is connected with a controller (7). The controller (7) is connected with the coiled steel overturning device (3), the straightening device (4), the coiled steel surface cleaning device (5) and the waste material recycling device (6). The automatic feeding device has the advantages that coiled steel is convenient to convey, install and rotate, the labor intensity is lowered, the rust removal effect is improved, and the straightening effect is improved.

Owner:湖州南浔电梯配件配送中心有限公司

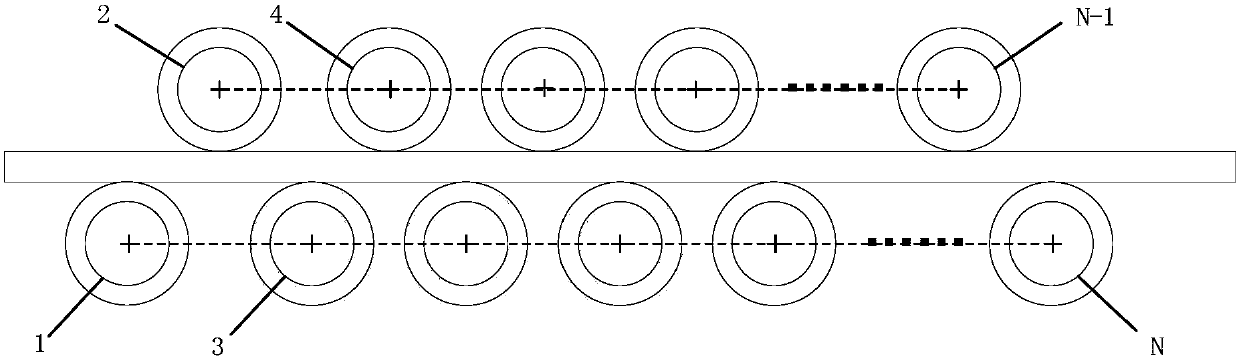

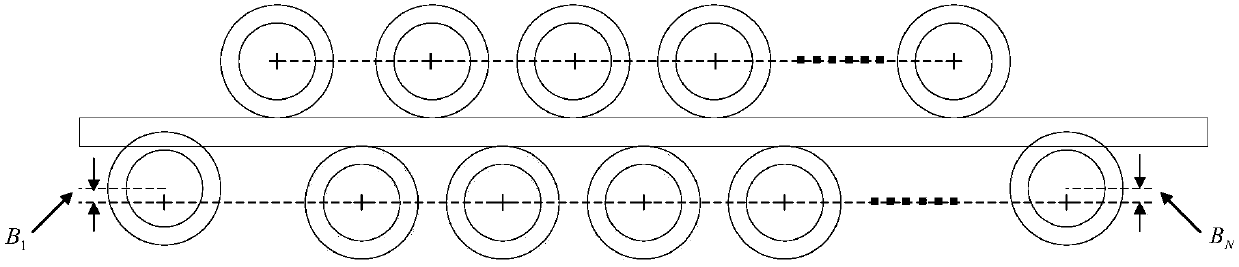

Process parameter setting method for roll straightening machine for small-batch multi-specification plate products

ActiveCN108500083AImprove straightening qualityReduce residual stressElastic modulusProcess engineering

The invention discloses a process parameter setting method for a roll straightening machine for small-batch multi-specification plate products, and belongs to the field of plate straightening. The process parameter setting method is characterized by comprising the following steps of 1. determining the temperature difference range of plates, and determining the material yield strength and the elasticity modulus at a temperature every a fixed value; 2. determining the thickness difference of the plates, that is, a standard thickness, the maximum thickness value and the minimum thickness value; 3. constructing a straightening process description space comprising S2, SN-1, B1 and BN, and traversing all available process combinations in the space; 4. when a group of S2, SN-1, B1 and BN is given, determining the position values of N straightening rolls according to a straightening equipment structure; 5. calculating the residual curvatures for the plates with specific materials and dimensions according to the related continuous bending algorithm for roll straightening; 6. with regard to fixed-point values in different temperature ranges and fixed points in different thickness ranges, obtaining different residual curvatures C under certain process of S2, SN-1, B1 and BN; 7. determining the maximum residual curvature C in the different residual curvatures C to be the residual curvatureCR under the straightening process; and 8. replacing the straightening process to obtain a new residual curvature CR, and taking the minimum value of all the residual curvatures CR as the optimal residual curvature CF, wherein the S2, SN-1, B1 and BN corresponding to the CF are the optimal process.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

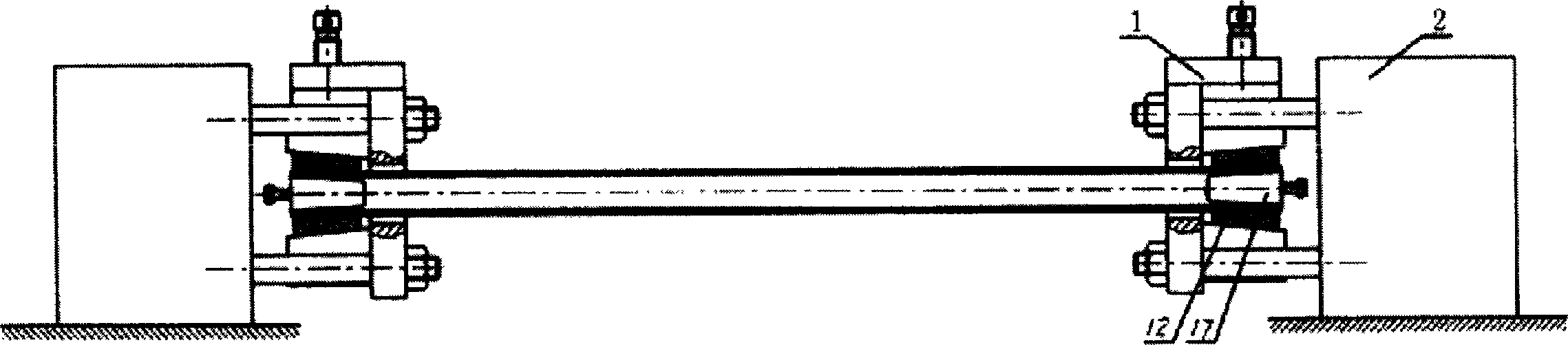

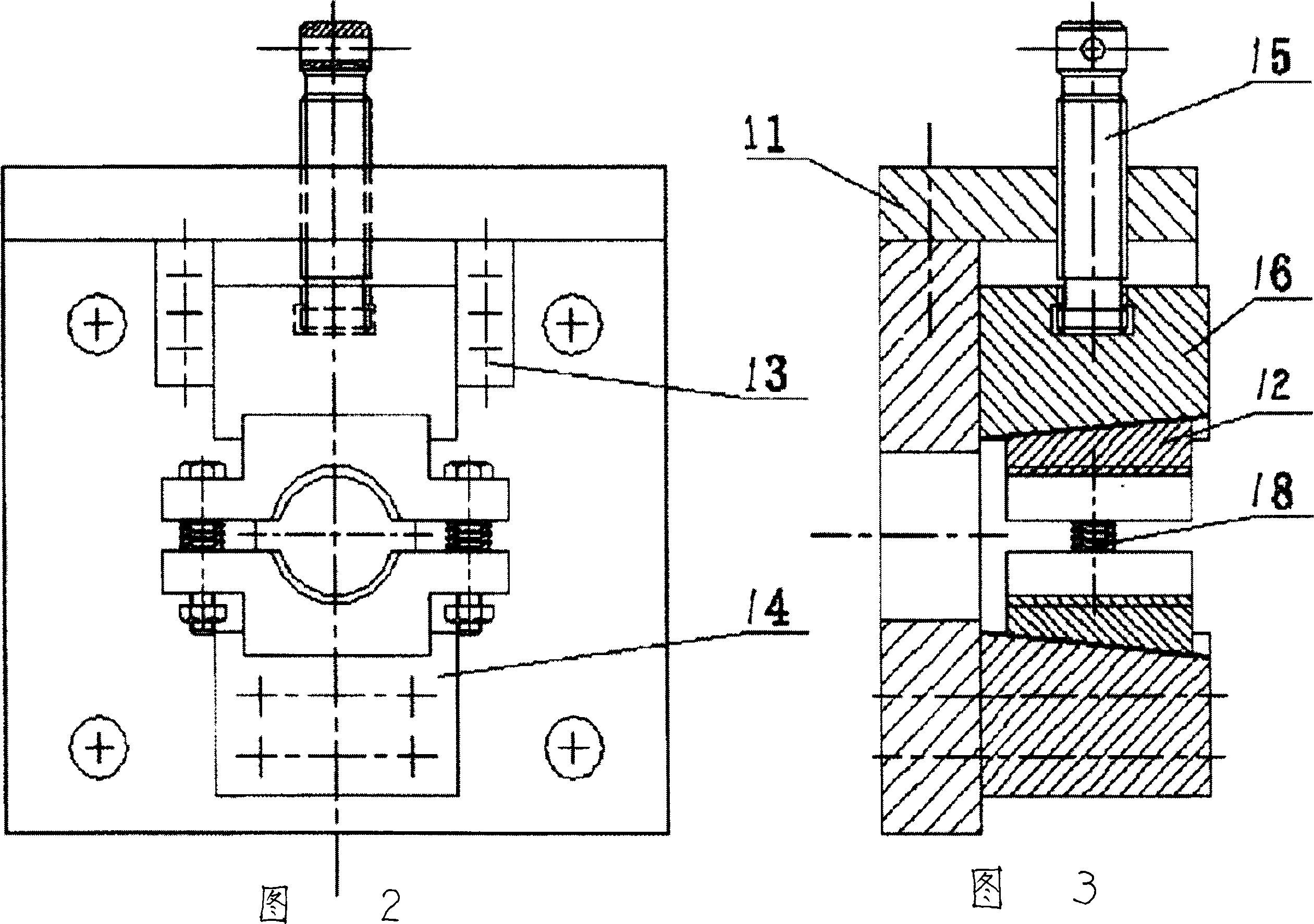

Aluminum alloy tubing straightening method and special fixture thereof

The invention provides an aluminum alloy pipe and tube alignment method which has the following characters: fixing the aluminum alloy pipe and tube on the coil winder by special tool to do lighten drawing to align the pipe and tube, improve the its strength of extension, rounding off the distorting parts of both extremities after aligning it. The special tool has the following characters: it is formed by frame, fixing bloke with clamp teeth, active block with clamp teeth, latch and baffle wall, wherein fixing bloke with clamp teeth is fixed on the frame; the active block with clamp teeth is fixed on the frame by latch and is opposed faced to fixing bloke with clamp teeth; baffle wall is used to stuff the extremities of aluminum alloy pipe and tube so that it can not be squeezed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

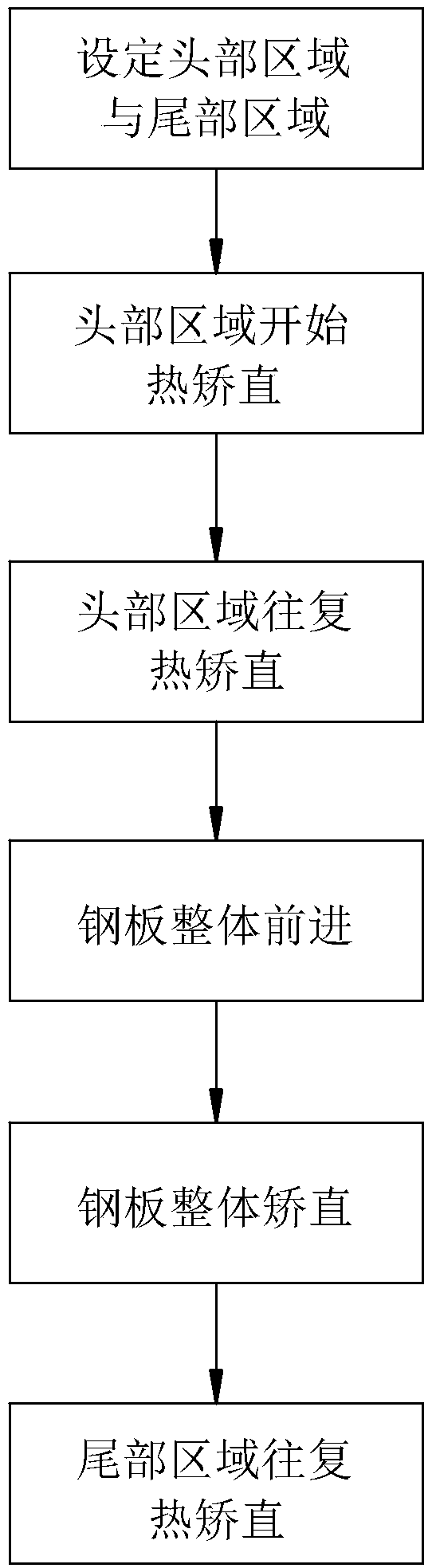

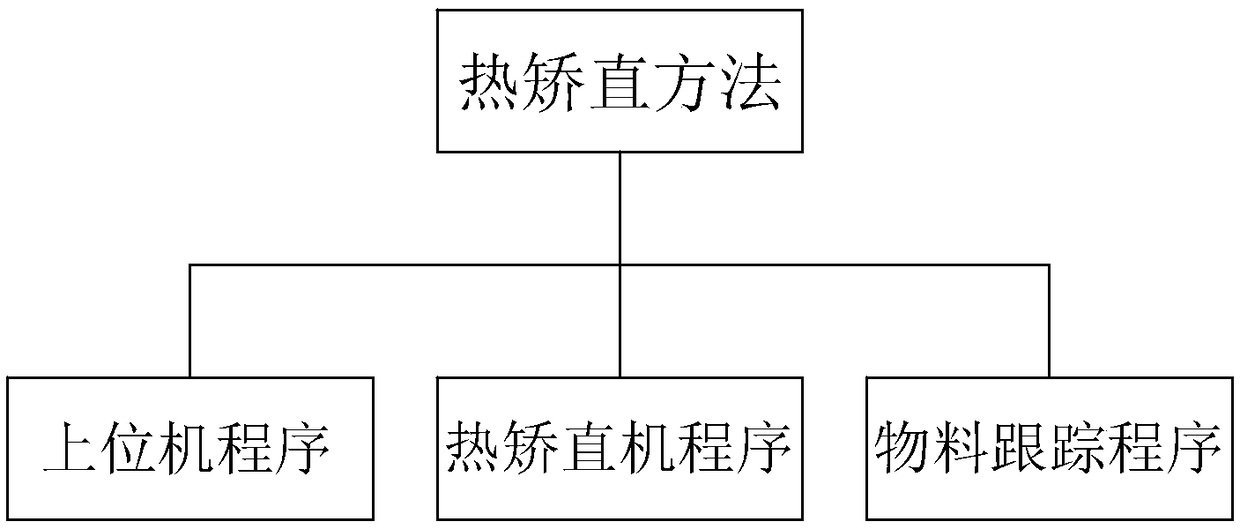

Roller type straightening technological parameter setting method for optimizing head and tail part straightening

ActiveCN108380700ASolve the problem of board shape defectsOptimizing process parameter setting methodGeometric CADSpecial data processing applicationsComputer scienceHead position

The invention discloses a roller type straightening technological parameter setting method for optimizing head and tail part straightening and belongs to the field of plate straightening. The roller type straightening technological parameter setting method is characterized by comprising the following steps: 1, constructing a straightening technology description space including S2, S<N-1>, B1 and BN; 2, given S2, S<N-1>, B1 and BN, calculating the rolling reduction of each roller; 3, calculating the compensation dosage K of bouncing; 4, wherein the middle rolling reduction of a straightened plate is equal to the theoretical calculating value, according to an edge roller, correcting (refer to the Specification) to obtain a residual curvature; 5, during the plate biting process, an upper roller system Sj2=S2+K...Sj10=S10, obtaining the rolling reduction of each roller, and correcting S2' and S<N-1>' to obtain the residual curvature of the plate head position; 6, during the plate tail drifting process, S'j2=S2...S'j10=S10+K, obtaining the rolling reduction of each roller, correcting S2' and S<N-1>', and calculating the residual curvature of the plate tail; 7, comparing the residual curvatures of the plate head, plate middle part and the plate tail, and taking the largest residual curvature as the quality evaluation residual curvature CR after plate straightening under the setting value of the technology; and 8, calculating to obtain CR in each technology, comparing all CR to obtain the smallest value, enabling the smallest value to be equal to CF and taking CF as the optimal residual curvature of the plate under the setting of all straightening technologies.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

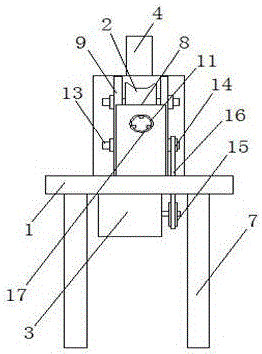

Universal type construction steel bar straightening and cutting machine and use method thereof

The invention discloses a universal type construction steel bar straightening and cutting machine which comprises an operation table, pressure rollers, a motor, a hydraulic cylinder, a cutter and a carrier block, and is characterized in that the operation table is arranged on brackets, and a locating plate, vertical plates and a supporting plate are arranged on the operation table; a transmission pipe is arranged on the locating plate; adjustment slots are formed in the vertical plates; the pressure rollers are arranged between the vertical plates through connection shafts; the motor is arranged on the operation table; the hydraulic cylinder is arranged on the supporting plate; the cutter is arranged on a connection rod through a connection block; and the carrier block is arranged on the operation table. According to the universal type construction steel bar straightening and cutting machine, the motor drives the pressure rollers to rotate to enable a steel bar to forward between the pressure rollers and straighten the steel bar; the pressure rollers are of structures capable of adjusting the position between the vertical plates; the universal type construction steel bar straightening and cutting machine can be applicable to the steel bars with different diameters; the universality of the steel bar straightening and cutting machine is improved; and the application range of the steel bar straightening and cutting machine is expanded.

Owner:芜湖瑞德机械科技有限公司

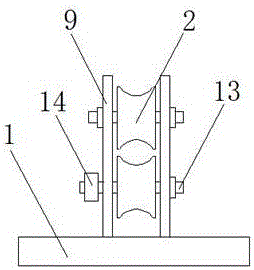

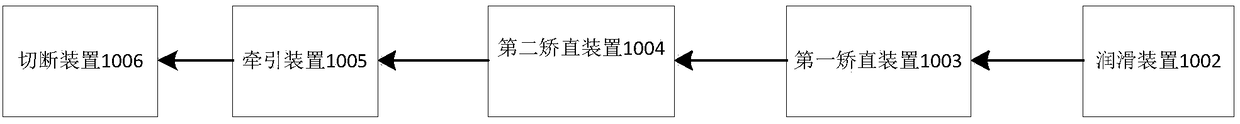

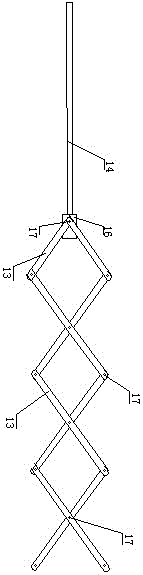

Steel wire straightening mechanism

The invention discloses a steel wire straightening mechanism. The steel wire straightening mechanism comprises a machine frame, a first straightening device, a second straightening device, a tractiondevice and a cutting device. The first straightening device, the second straightening device, the traction device and the cutting device are arranged on the machine frame in a straight line mode in sequence, and the first straightening device and the second straightening device are rotated in the opposite directions on the machine frame. The second straightening device comprises a left support, aright support, a central rotating shaft, a wedge block and sliding blocks. The left support is arranged at one end of the central rotating shaft, and the other end of the central rotating shaft is arranged on the right support. The central rotating shaft is provided with sliding holes, and the sliding blocks are arranged on the sliding holes. One end of the wedge block is arranged on the left support, and the other end of the wedge block abuts against the sliding blocks. The left support drives the wedge block to move back and forth in the axial direction of the central rotating shaft to enable the wedge block to drive the sliding blocks to slide up and down along the sliding holes. The steel wire straightening mechanism can solve the problem that a straightening machine in the prior art twists a steel wire in the straightening process and only adapts to the steel wire with a single bending degree and wire diameter.

Owner:ZHONGSHAN XINBAO PRECISION SCI & TECH

Straightening method of steel plate hot straightening machine

The invention relates to the field of metal sheet hot straightening technologies, in particular to a straightening method of a steel plate hot straightening machine. High efficiency and quality straightening of a medium steel plate is realized rapidly, and the production efficiency is not affected greatly when improving the quality. With the adoption of the straightening method, the head and the tail of the steel plate are independently subjected to three passes of straightening treatment, so that the defects of warping, bending and the like are overcome, the maximized straightening capabilityof the steel plate hot straightening machine is fully played, and the yield of the steel plate is improved, and the amendment rate is lowered.

Owner:SHANXIN SOFTWARE CO LTD

Bent pipe straightening device

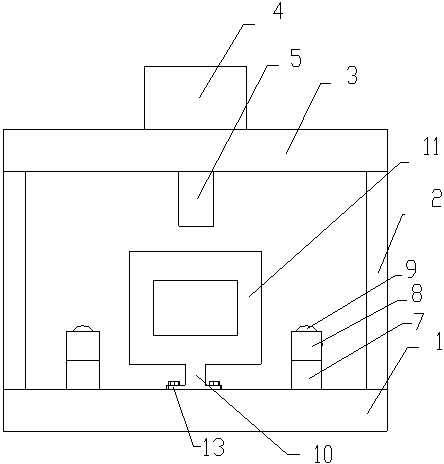

InactiveCN103639246AImprove straightening qualityImprove work efficiencyMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a bent pipe straightening device which comprises a base and a clamping device. Two supporting frames are symmetrically arranged on the base, a supporting platform is arranged above the supporting frames and fixedly connected with the two supporting frames, an oil cylinder is arranged on the supporting platform, a piston rod of the oil cylinder extends to the lower portion of the supporting platform, a sliding groove is horizontally formed in the base, two sliders are arranged in the sliding groove, supports are fixedly arranged on the sliders, carrier rollers are arranged on the supports, the clamping device comprises a moving block and a clamping plate, a clamping device mounting groove is vertically formed in the base, a group of threaded holes are further formed in the base and positioned in two sides of the clamping device mounting groove, the moving block is mounted in the clamping device mounting groove and positioned on two sides of the sliders, two side wing plates are welded on two sides of the moving block, the threaded holes are formed in the side wing plates, and the side wing plates are fixedly connected with the base through bolts. The bent pipe straightening device is high in working efficiency and bent pipe straightening quality.

Owner:JIANGYIN HAILU HIGH PRESSURE PIPE

Straightening plier for secondary cable core

InactiveCN104332249AEasy to useImprove efficiencyPliersCable/conductor manufactureEngineeringMechanical engineering

Owner:STATE GRID CORP OF CHINA +1

Metal wire straightener

The invention discloses a metal wire straightener and is intended to solve the problems that an existing straightener for metal wires is suitable for straightening a wire only in one direction, wire straightening quality is poor, straightening is performed nearly for the wires of only one type of material, changes in the material and quality of the wire may influence straightening quality, and the adaptability is poor. The metal wire straightener comprises a support part, an upper bearing block, an upper bearing arranged on the upper bearing block, a lower bearing block, a lower bearing arranged on the lower bearing block, a mounting seat, a straightening roll, a wire exit and a wire feeding mechanism mating with the wire exit. The defects of the prior art are overcome, and the novel metal wire straightener meeting the requirement for straightening metal wires of different materials and sizes and having good straightening quality is provided; the metal wire straightener is ingenious and reasonable in design, is highly adaptive, can provide optimal straightening quality for metal wires, and has good effective and promising market application prospect.

Owner:四川弘博新材科技股份有限公司

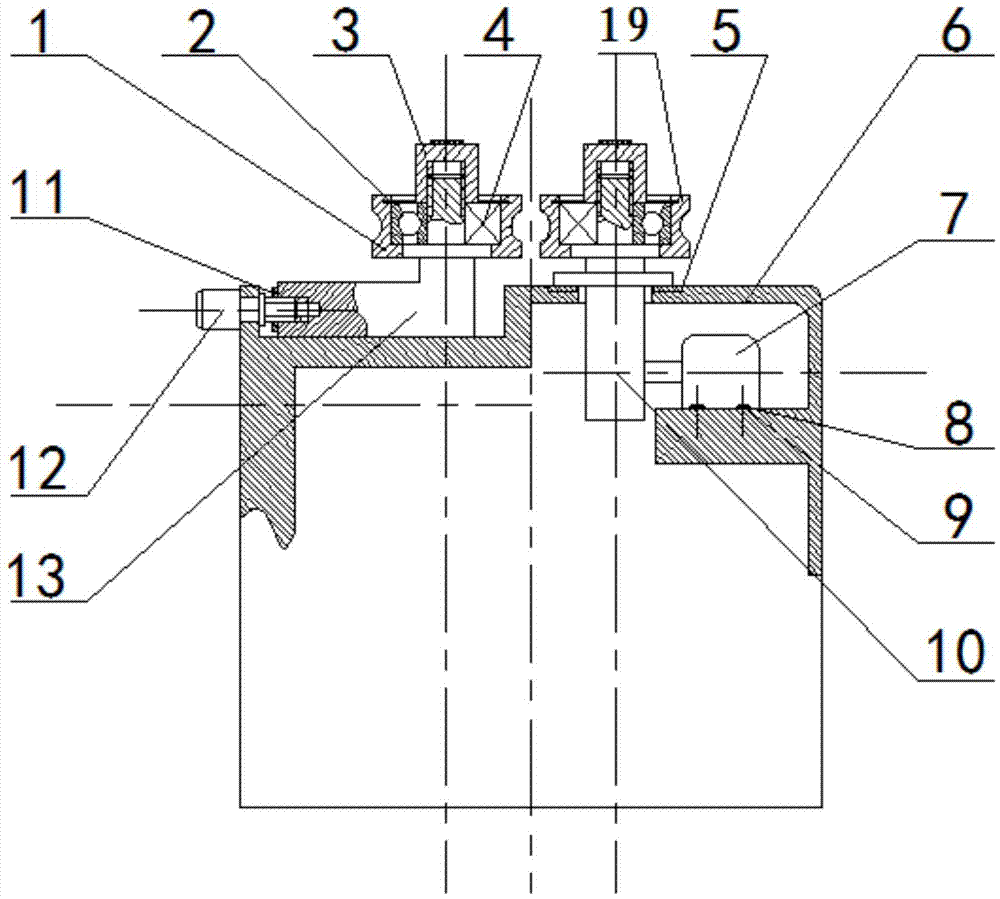

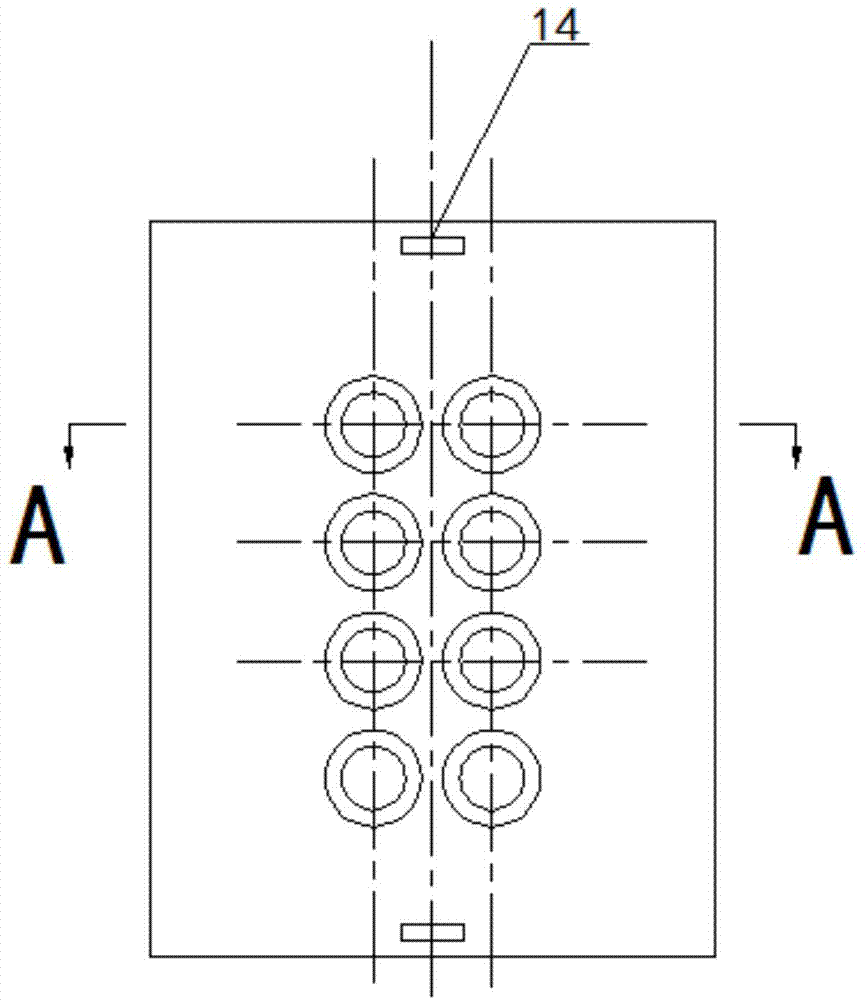

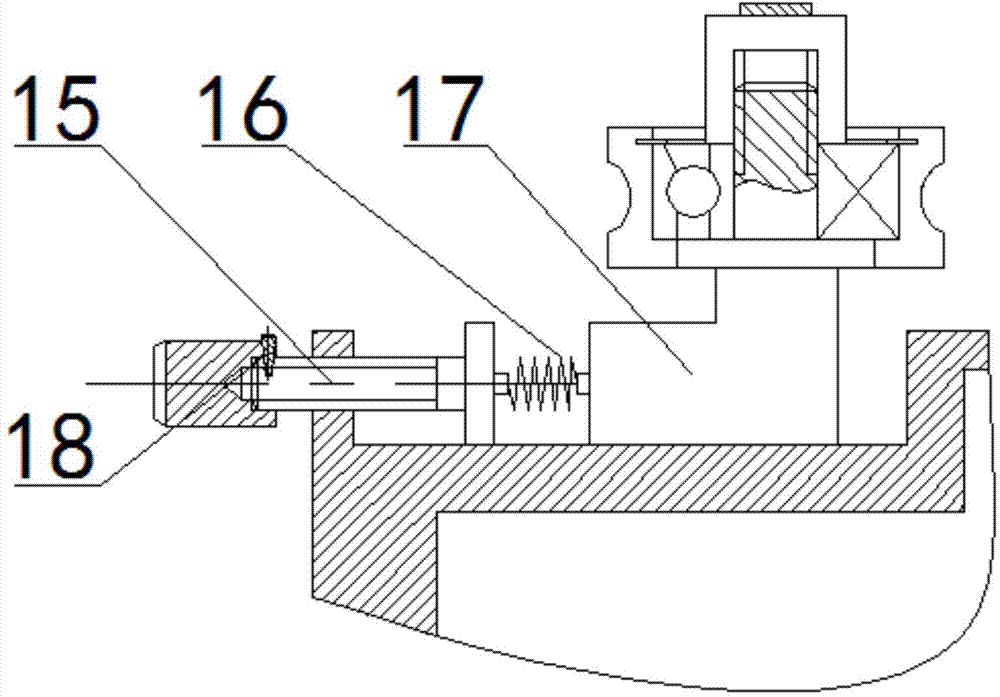

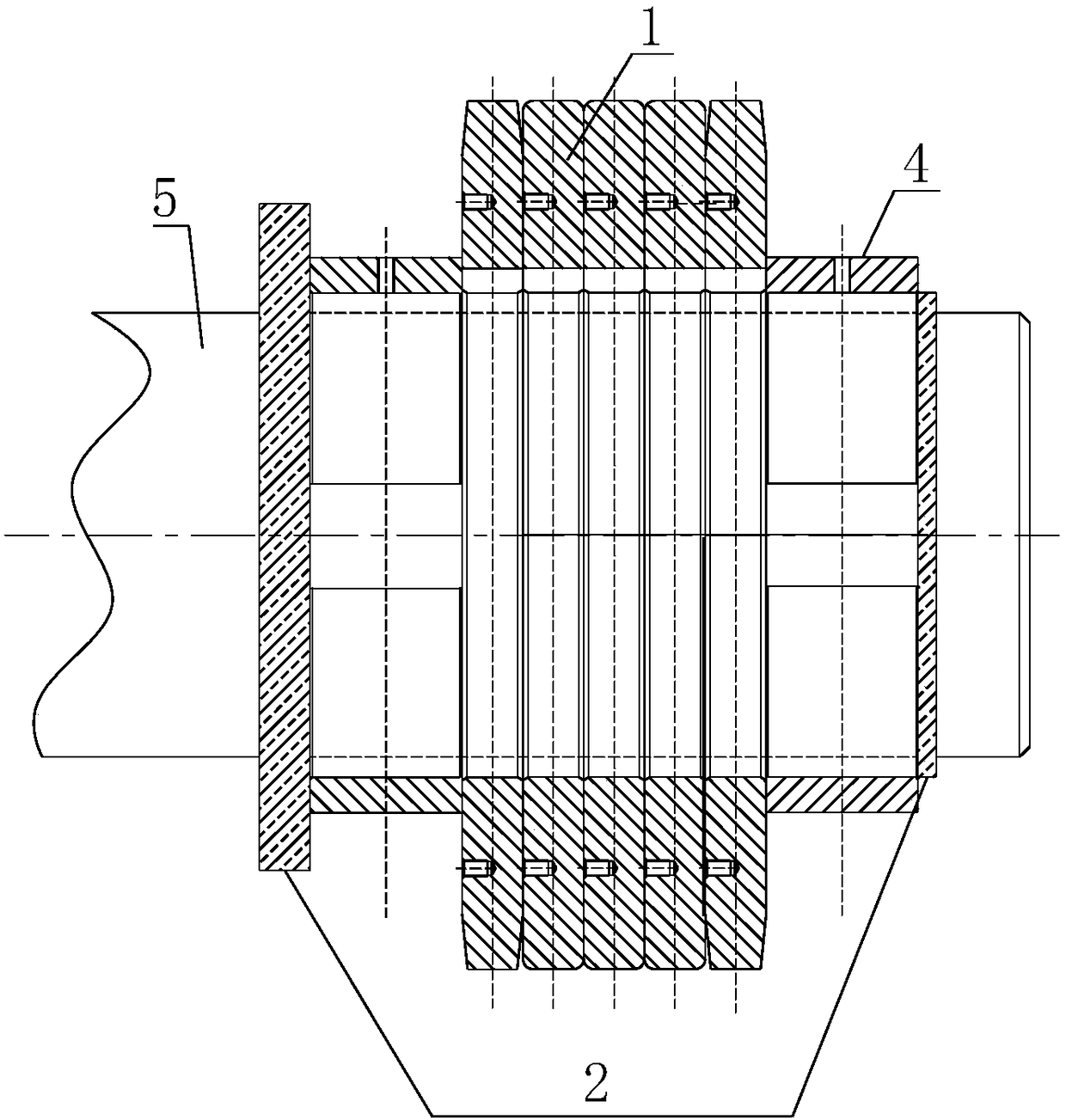

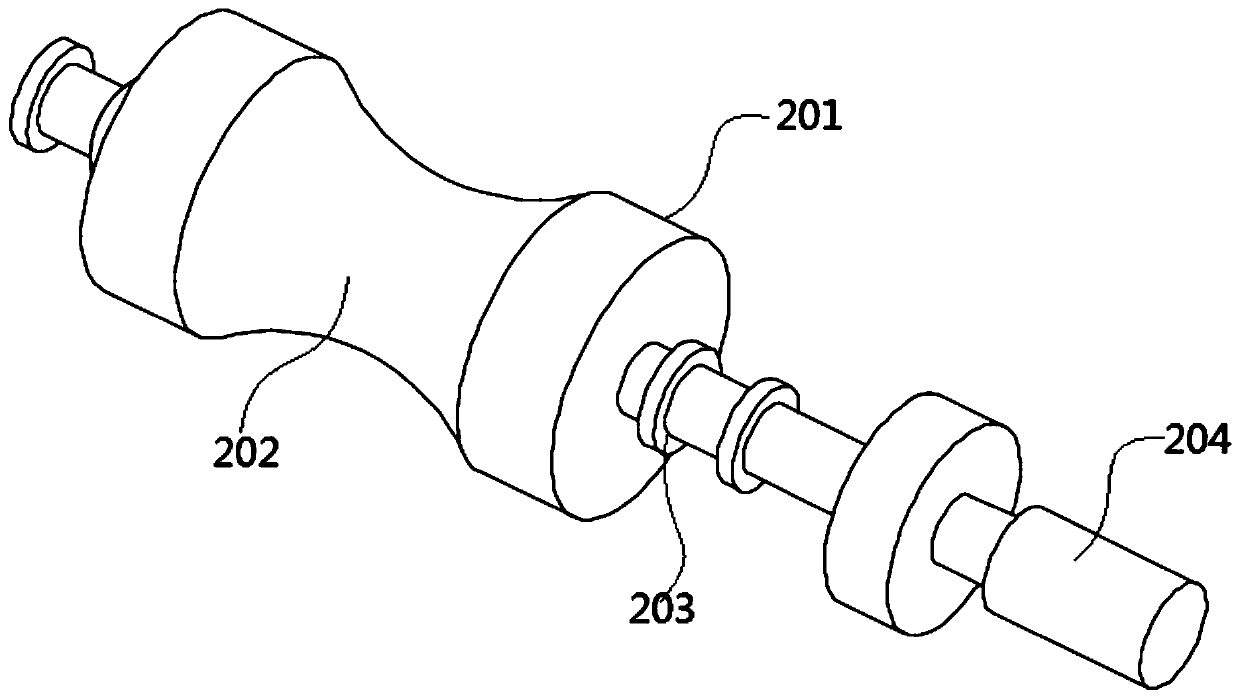

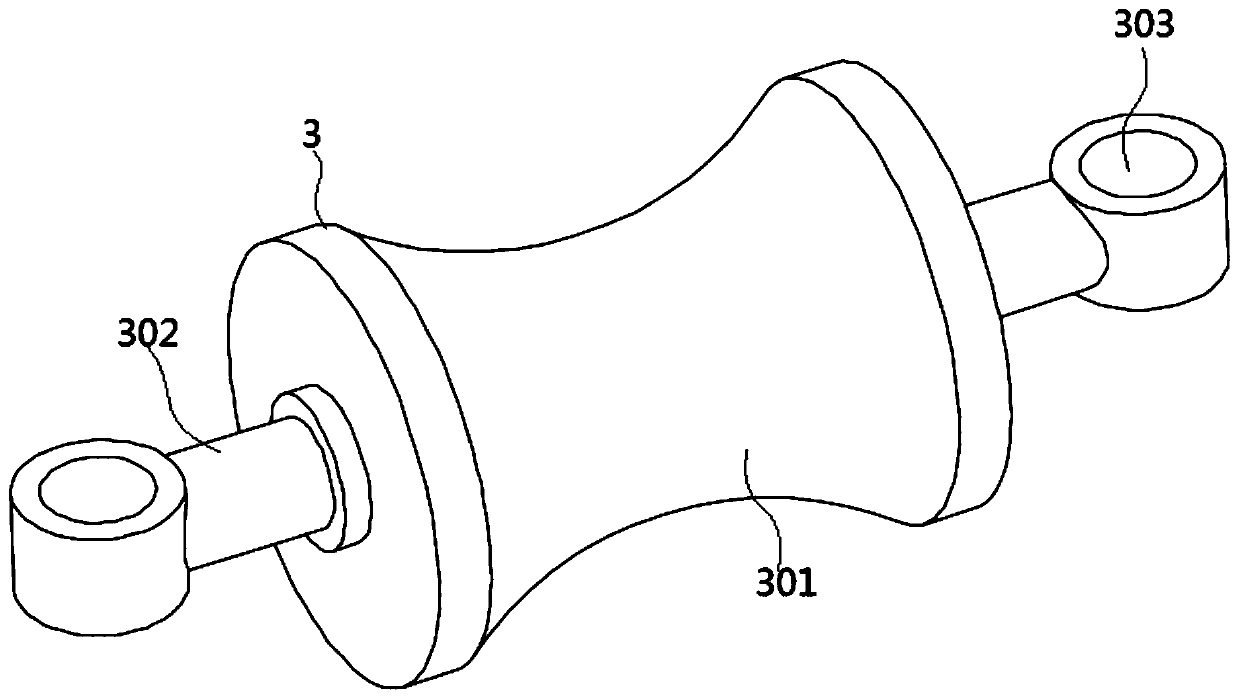

High-frequency vibration wire rod straightening device and using method thereof

The invention discloses a high-frequency vibration wire rod straightening device and a using method thereof. The high-frequency vibration wire rod straightening device comprises a casing and at least two groups of clamping devices, wherein each group of clamping devices comprises a first clamping unit and a second clamping unit. The first clamping unit comprises a first mold, a spring clamping ring, a bearing and a pressing end cover, the second clamping unit comprises a second mold, a spring clamping ring, a bearing and a pressing end cover, the first mold sleeves a distance adjusting shaft, the second mold sleeves a high-frequency vibration shaft, the lower portions of the first mold and the second mold are provided with bosses, the bearings, the spring clamping rings and the pressing end covers are sequentially arranged on the bosses, and the high-frequency vibration shaft is connected with a high-frequency vibration motor. The wire rod straightening is achieved by replacing the molds to straighten wire rods different in diameter and adjusting a distance between the centers of the molds to compensate mold abrasion. Most of stress of straightened materials is quickly eliminated through high-frequency vibration force, the wire rod straightening efficiency and quality are improved, straightening of wire rods different in material and diameter is achieved, and economic benefits of products is improved.

Owner:NANTONG HUALIANG FITNESS EQUIP CO LTD

Large-diameter thin-wall steel pipe straightening machine and its anti-deformation side roll device

The invention discloses a large-diameter thin-wall steel pipe strengthening machine and an anti-deforming side roller device thereof. The anti-deforming side roller device comprises a connecting bracket, a roller assembly, a movable support plate and a hydraulic cylinder, wherein the connecting bracket comprises a lug which is used for fixing the connecting bracket on the large-diameter thin-wall steel pipe strengthening machine; the hydraulic cylinder is arranged on the connecting bracket; the roller assembly is arranged on the first side face of the movable support plate; and a piston rod of the hydraulic cylinder is connected to the second side face of the movable support plate to drive the roller assembly to move along the horizontal direction. The device has the advantages of capability of greatly improving the strengthening quality of the steel pipe, compact structure, low cost, high exchangeability, small occupied space, low fault rate and easiness for maintenance.

Owner:TAIYUAN HEAVY IND

Combined box iron straightening roller

InactiveCN109013759ALow production costImprove straightening qualityEngineeringMechanical engineering

The invention relates to a combined box iron straightening roller. The combined box iron straightening roller comprises an upper roller and a lower roller; each of the upper and lower rollers comprises a roller sleeve, a plurality of roller rings, and a fastening washer, wherein each roller ring is of a circular ring structure, the roller rings and the roller sleeve are fixedly connected through the fastening washer, and gaskets are arranged between the roller rings. The combined box iron straightening roller has the advantages that the manufacturing cost of the straightening roller is reduced, and the straightening quality is improved; existing box iron has a total of 10 varieties, each variety contains 10 roller rings, but by adopting the combined straightening roller, the requirements can be met only by manufacturing one set of single-piece roller rings; meanwhile, if the local of the straightening roller is damaged, the corresponding roller ring can be replaced, and the maintenancecost is reduced; by increasing or decreasing the number of the roller rings, the straightening roller can adapt to box iron with multiple models; and the outer diameter of the roller rings arranged at the two ends of the upper roller are large, the position of the box iron can be limited during box iron straightening, the deviation is prevented, meanwhile, the two sides of the ox iron can be straightened once, and the straightening efficiency is improved.

Owner:ANGANG STEEL CO LTD

Device for straightening aluminum profile

InactiveCN110421022AImprove straightening qualityMeet the standard requirementsEngineeringMechanical engineering

The invention discloses a device for straightening an aluminum profile, and relates to the technical field of aluminum profile processing. The device for straightening the aluminum profile comprises abase, wherein a support rod is fixed to one surface of the base; a fixed seat is fixed to one end of the support rod; two driving guide roller groups are uniformly arranged on eachsurface array of the fixed seat; a driven roller is rotatably connected between every two driving guide roller groups; a connecting plate is fixed between the fixed seat and the base; a guide rod is fixed to one surfaceof the connecting plate; a repairing mechanism is in sliding fit to the circumferential side surface of the guide rod and comprises a moving table; a support pillar is rotatably connected to one surface of the moving table; a first servo motor is fixed to one side surface of the support pillar; a rotary shaft is fixed to one end of a rotary shaft of the first servo motor; and a spiral convex ringis fixed to the circumferential side surface of the rotary shaft. According to the device for straightening the aluminum profile provided by the invention, the first servo motor provides power to drive the rotary shaft to rotate, and the rotary shaft drives the spiral convex ring to eject out a concave pit of a straightened curved node, so that time and effort are saved, the straightening qualityof an aluminum pipe is improved, and the standard requirement of the aluminum pipe is met.

Owner:HENAN YUQIAN TECH TRANSFER CENT CO LTD

Pipe rod bar with major diameter double-roller unbender concave roller curve

The invention discloses a concave roll of a two-roller straightening machine for large-diameter pipe / rod. Reverse arc DE and a section of transition arc EF are composed, where the radius of arc AA is R1, the radius of arc AB is R2, the radius of arc BC is R3, the radius of arc DE is R4, and the radius of arc EF is R5. The circular arcs and oblique lines are tangent to the straightening roller generatrix and connected smoothly, wherein: the radius of each circular arc is: R1~R4=(X1~X4)×dmin×π×tgαmax; R5=(20~50) mm; the horizontal projection length corresponding to the radius of each segment of the arc and the oblique line is: L1~L5=(Y1~Y5)×dmin×π×tgαmax. The concave roll shape is easy to process and manufacture, can significantly improve product straightening quality and work efficiency, and can significantly reduce tailing phenomenon at the same time. The invention is particularly suitable for the straightening processing of large-diameter pipes / rods with a diameter of Φ100-200mm.

Owner:YANSHAN UNIV

A wire straightening machine

The invention discloses a metal wire straightener and is intended to solve the problems that an existing straightener for metal wires is suitable for straightening a wire only in one direction, wire straightening quality is poor, straightening is performed nearly for the wires of only one type of material, changes in the material and quality of the wire may influence straightening quality, and the adaptability is poor. The metal wire straightener comprises a support part, an upper bearing block, an upper bearing arranged on the upper bearing block, a lower bearing block, a lower bearing arranged on the lower bearing block, a mounting seat, a straightening roll, a wire exit and a wire feeding mechanism mating with the wire exit. The defects of the prior art are overcome, and the novel metal wire straightener meeting the requirement for straightening metal wires of different materials and sizes and having good straightening quality is provided; the metal wire straightener is ingenious and reasonable in design, is highly adaptive, can provide optimal straightening quality for metal wires, and has good effective and promising market application prospect.

Owner:四川弘博新材科技股份有限公司

Straightening method for flat-bulb steel and straightening roll

InactiveCN108296315ASolve the difficulty of feedingReduce labor intensityShaping toolsEngineeringAxial force

The invention relates to a straightening method for flat-bulb steel. The method comprises the steps that 1) 'oblique straightening method' is adopted as the straightening method for the flat-bulb steel for shipbuilding, that is, the flat-bulb steel obliquely enters into a straightening machine at an angle of 16 degrees to 25 degrees; 2) upper and lower straightening rolls of a hole pattern adjustsvertical bending, the side wall of the end face of the hole pattern adjusts horizontal bending, the upper straightening roll is a two-piece combination type, and the lower straightening roll is an integral type; 3) straightening pressures are sequentially decreased from an entrance direction of the straightening machine, and a depressed stroke is adjusted within a range of 4 millimeters to 15 millimeters. The straightening method for the flat-bulb steel has the advantages that the flat-bulb steel is straightened by a roll type straightening machine, a cross-sectional shape is rolled by combining with an oblique rolling method, and the straightening positions are a flat-bulb steel web plane and the outer side of a bulb. The combined upper straightening roll can effectively solve the problem that the side wall is broken due to excessive axial force, and thereby roll scrap is produced, the straightening roll consumption is greatly reduced, the straightening quality and output are remarkably improved, the oblique straightening method reduces the amount of vehicle repair and improves the utilization rate of the rolls.

Owner:ANGANG STEEL CO LTD

Feeding and discharging device of pipe straightener

InactiveCN103495668AReduce the temperaturePrevent disengagementShaping toolsMetal-working feeding devicesEngineering

The invention provides a feeding and discharging device of a pipe straightener. The feeding and discharging device comprises an inlet guide barrel, the straightener, an upper outlet guide barrel, an output roller way, and a table frame. The inlet guide barrel is located at the front end of the straightener. The upper inner wall and the lower inner wall of the inlet guide barrel are connected with mist spray water rows. The upper outlet guide barrel and the output roller way are located at the back end of the straightener. Baffles are arranged at the back end of the upper outlet guide barrel and the back end of the output roller way. The table frame is located at the lower end of the output roller way. More than one blower is arranged on the inner wall of the upper outlet guide barrel. Due to the further arrangement of the mist spray water rows and the blowers, the temperature of steel pipes in front of the straightener and the temperature of steel pipes behind the straightener are reduced, straightening quality is improved, and deformation after straightening is reduced. The baffles prevent straightened steel pipes from coming off the roller way. A spiral roller is adopted for the output roller way and enables the straightened steel pipes to go straightly on the output roller way and deviate toward the table frame at the same time, so that production efficiency is improved, and the effects of saving energy and reducing consumption are achieved. A tumbler type baffle mechanism is simple in structure, light in weight, and capable of separating steel pipes one by one, so that friction collisions caused at rolling time of the steel pipes are avoided.

Owner:天津腾飞钢管有限公司

Adjustable bent steel strip straightening machine

InactiveCN105728499AChange structural stressAvoid replacementShaping toolsMetal-working feeding devicesEngineeringStructural stress

The invention relates to an adjustable bending steel bar straightening machine, comprising a steel bar conveying system and a bending straightening system. Straightening unit, the unit connection sequence from left to right is horizontal conveying unit, horizontal straightening unit, horizontal conveying unit, vertical straightening unit and vertical conveying unit; the present invention can correct the bent steel bar in all directions through the horizontal straightening unit and the vertical straightening unit; The heating wire of the bending correction system provides heat to promote the temperature of the steel bar to change the internal structural stress of the steel bar, so that the steel bar becomes straight and no longer bends after correction; the shear difference, distance adjustment nut and distance adjustment screw of the bending correction system can be used. Adjust the gap of the straightening wheel to avoid the ordinary replacement of the straightening wheel; the straightening is comprehensive, the work efficiency is high, the adjustment is convenient, the straightening quality is improved, and the product quality is improved.

Owner:LIUZHOU ZHENGLING VEHICLE IND ACCESSORIES CO LTD

Knitted fabric straightening device for textile mill

InactiveCN112877971AImprove efficiencyQuality improvementStretchingTextile millStructural engineering

The invention discloses a knitted fabric straightening device for a textile mill. The knitted fabric straightening device comprises supporting legs, a case, bottom feet, a workbench, a controller, a power line, a bidirectional straightening device and an auxiliary pushing device. Trough arrangement of the bidirectional straightening device, under the driving of a first motor, a synchronous transmission mechanism synchronously drives a left straightening mechanism and a right straightening mechanism to work after carrying out synchronous transmission, so that fabric can be secondarily straightened by the left straightening mechanism and the right straightening mechanism in one process, and therefore, the straightening efficiency and quality are greatly improved; and an auxiliary pushing device is arranged, and after a first pushing wheel and a second pushing wheel are matched with each other, the fabric passing through the left straightening mechanism and the right straightening mechanism is pushed in an auxiliary mode, so that the fabric is better conveyed, the fabric is kept parallel, a pulling force borne by the fabric during straightening is reduced, and thus the straightening quality is improved.

Owner:泉州泉港华誉工业设计有限公司

Municipal engineering cable straightening device

The invention discloses a municipal engineering cable straightening device. The municipal engineering cable straightening device comprises a rectangular box body, wherein a wire roller supporting device is arranged on one side of the rectangular box body, a controller is arranged on the side surface of the rectangular box body, a rotary cable straightening device is arranged on the inner surface of the rectangular box body, cable anti-skid driving devices are arranged on the two sides of the rectangular box body, and the rotary cable straightening device is used for carrying out rotary extrusion on cables through a plurality of roller wheels so as to achieve the purpose of straightening; the cable anti-skid driving devices apply force to the cables through a plurality of driving wheels, sothat the anti-skid function is achieved. The municipal engineering cable straightening device has the beneficial effects of being simple and convenient to operate and high in practicability.

Owner:程荧

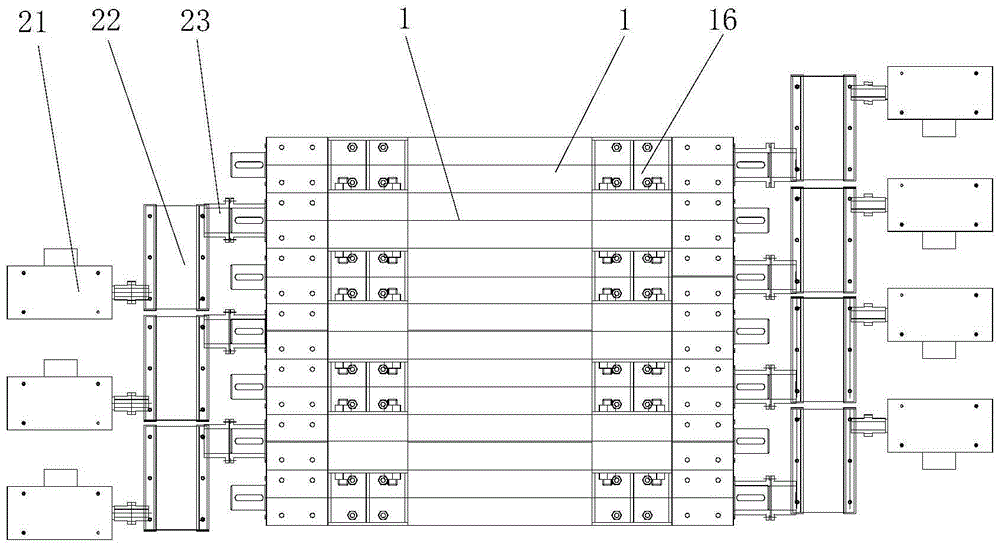

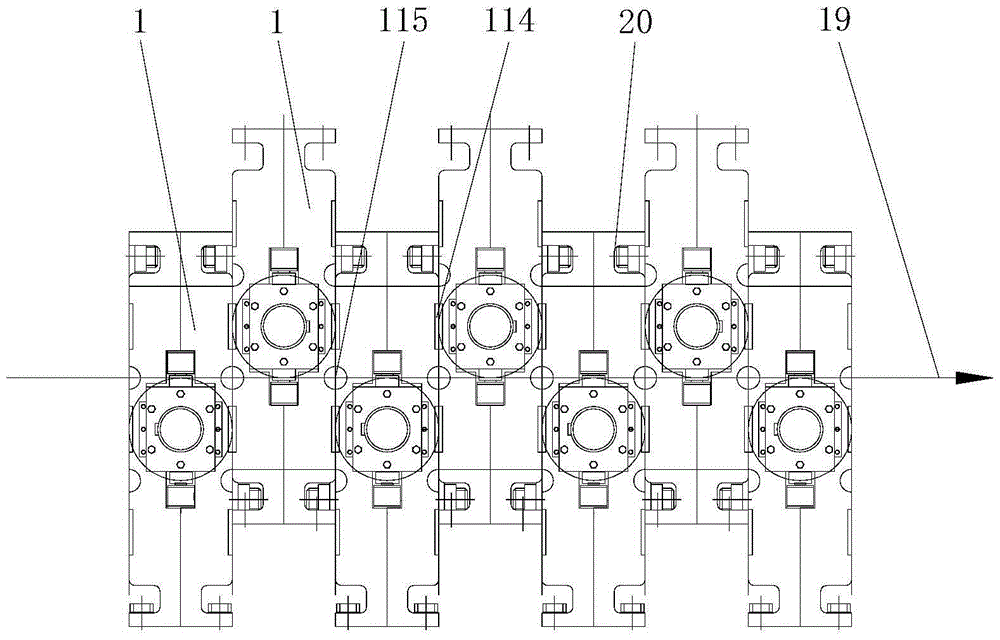

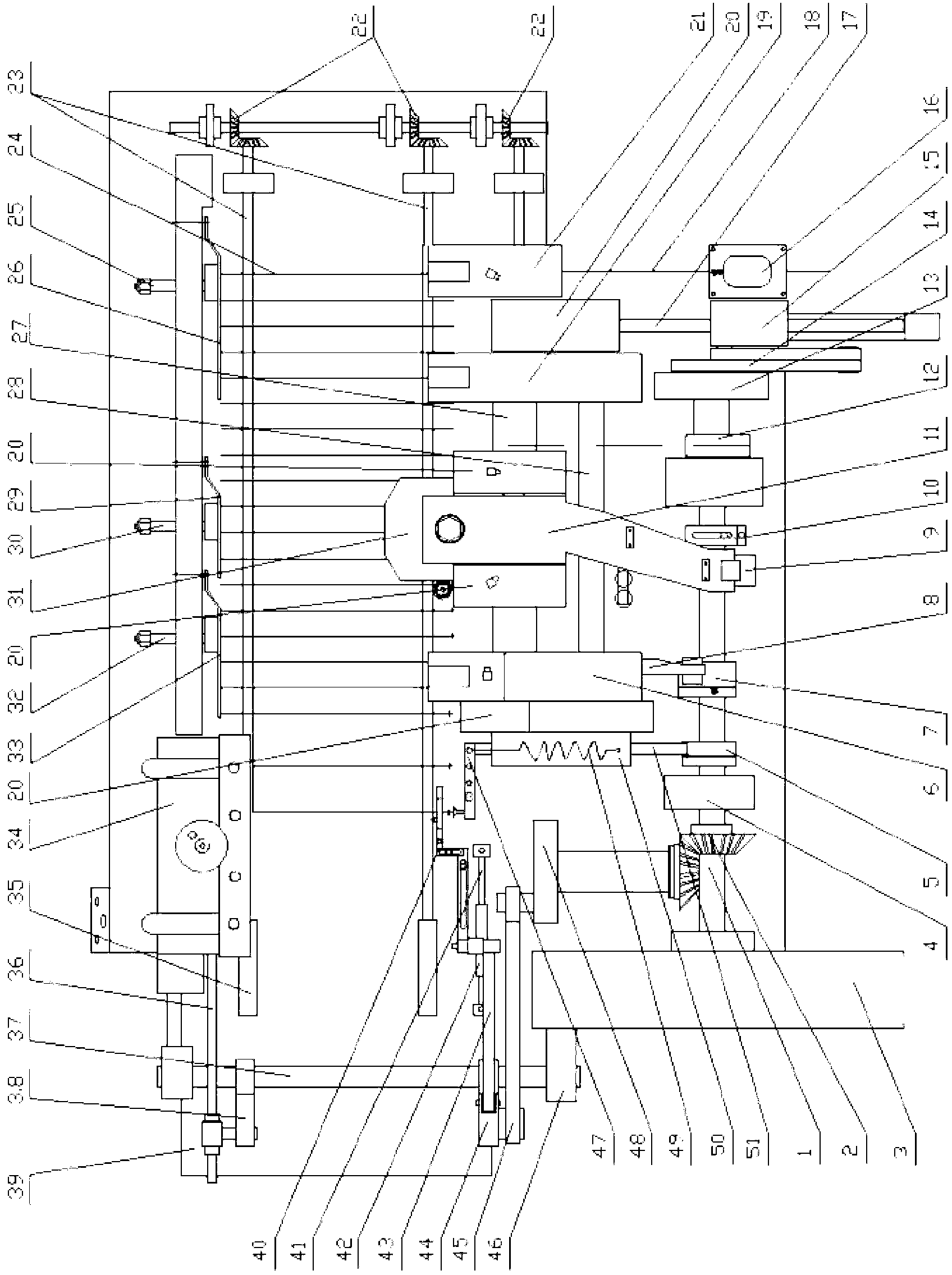

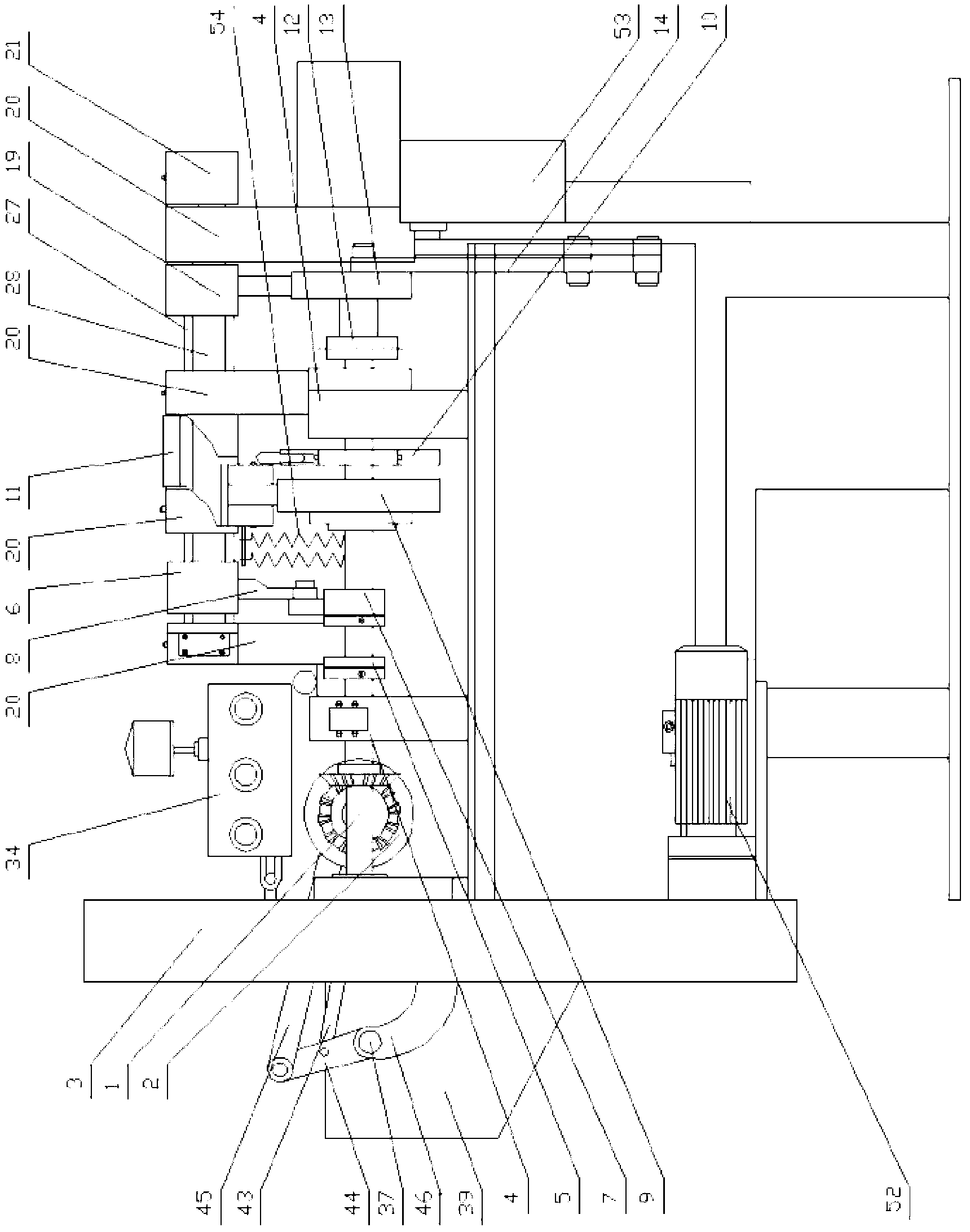

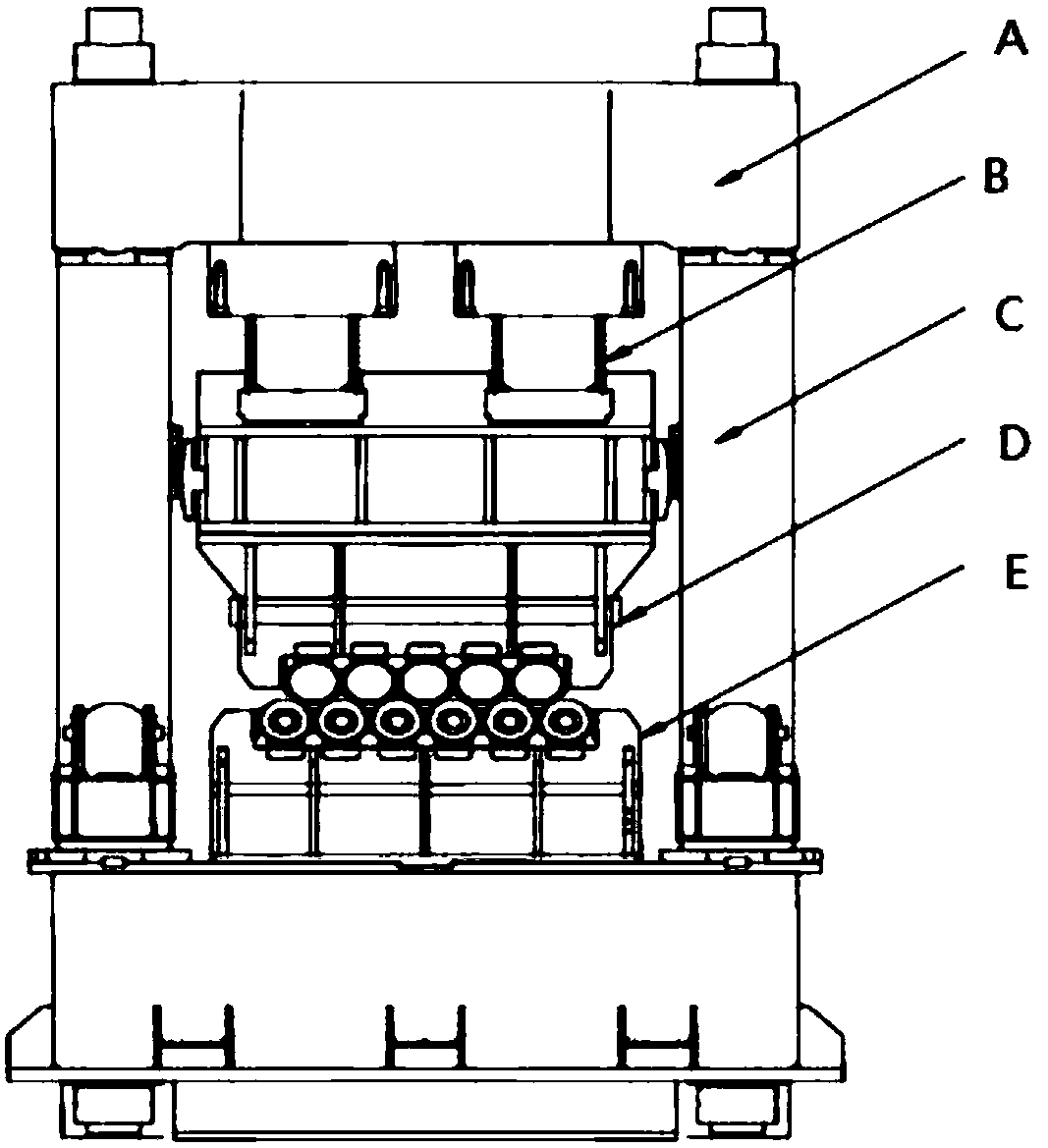

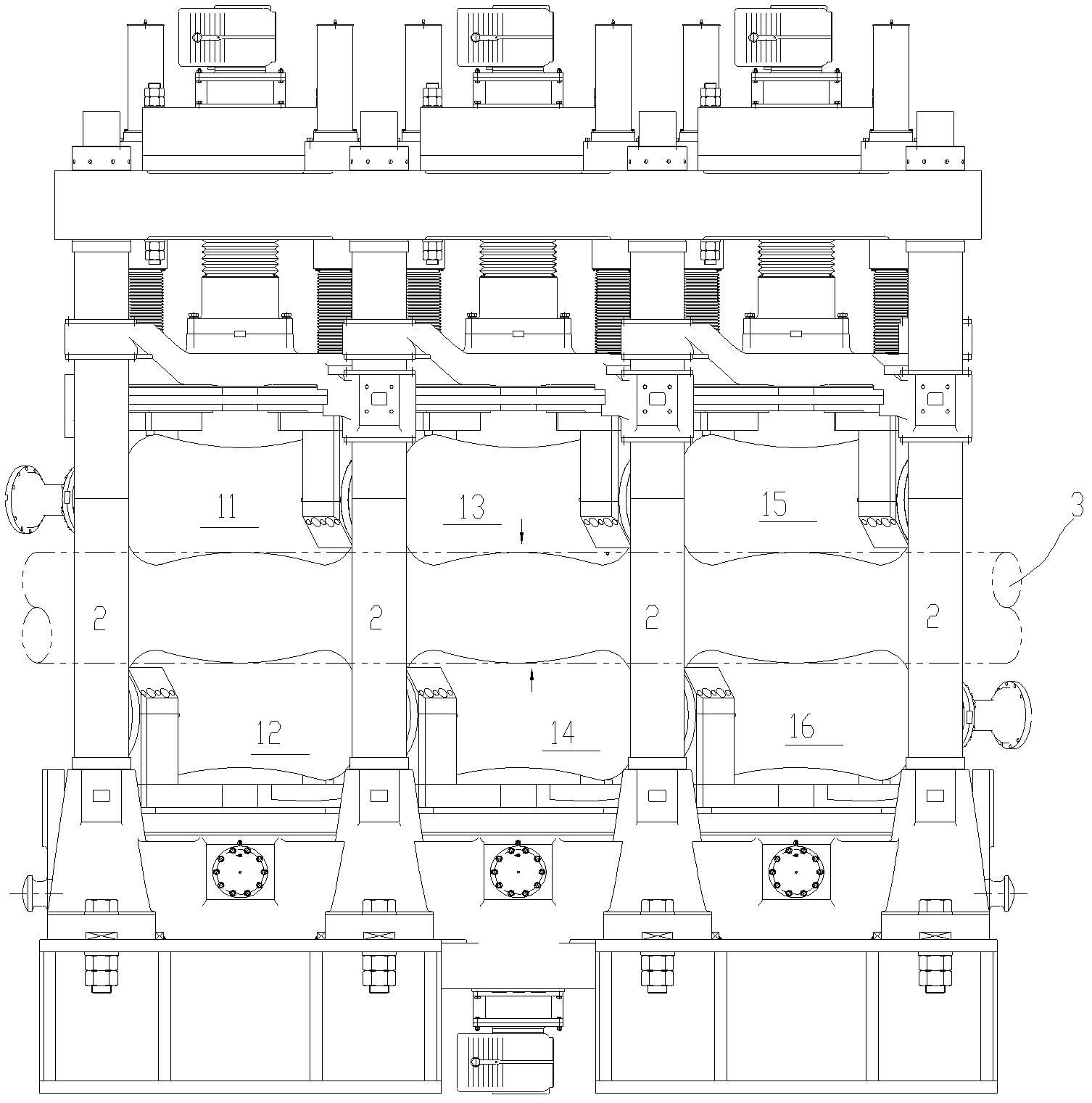

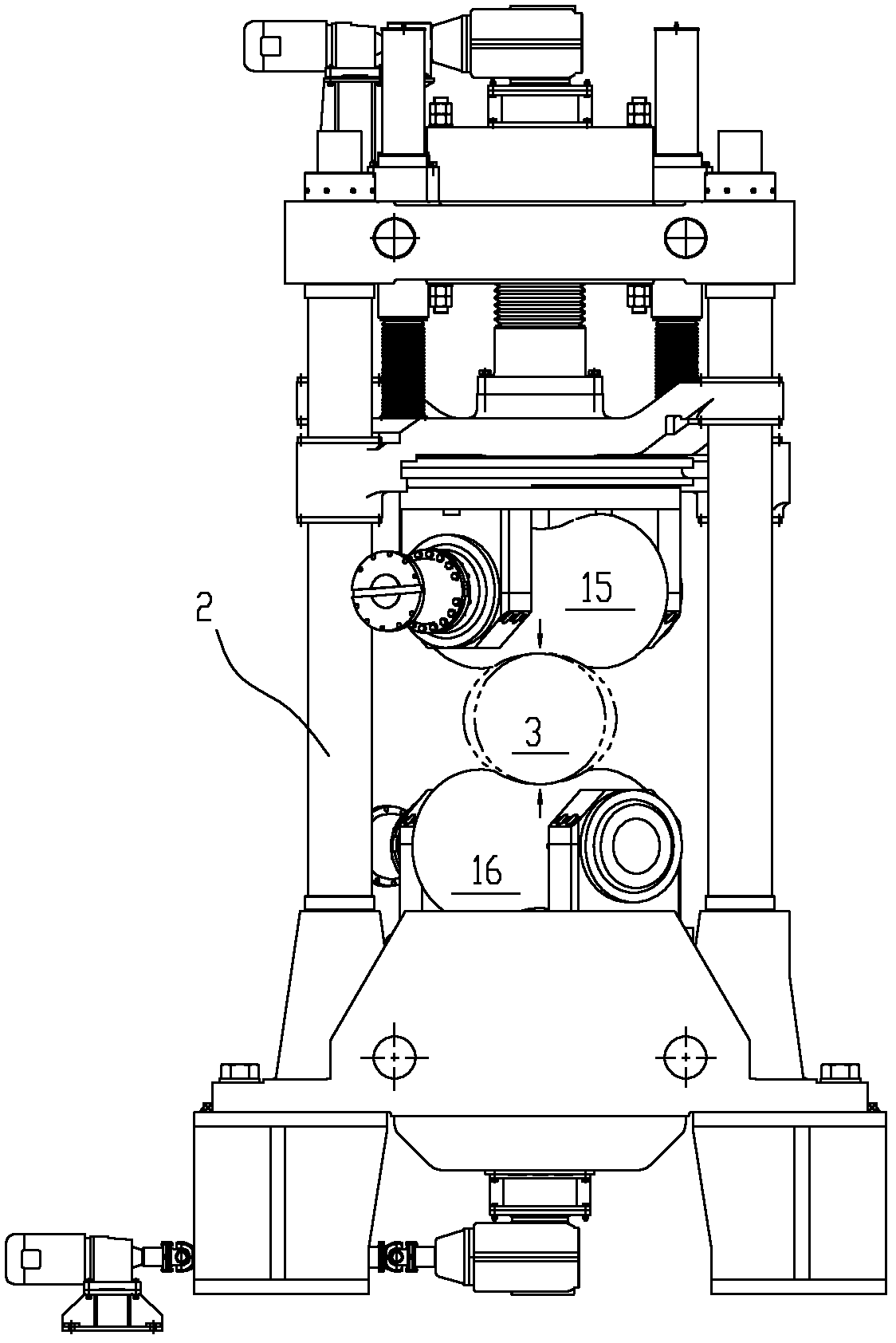

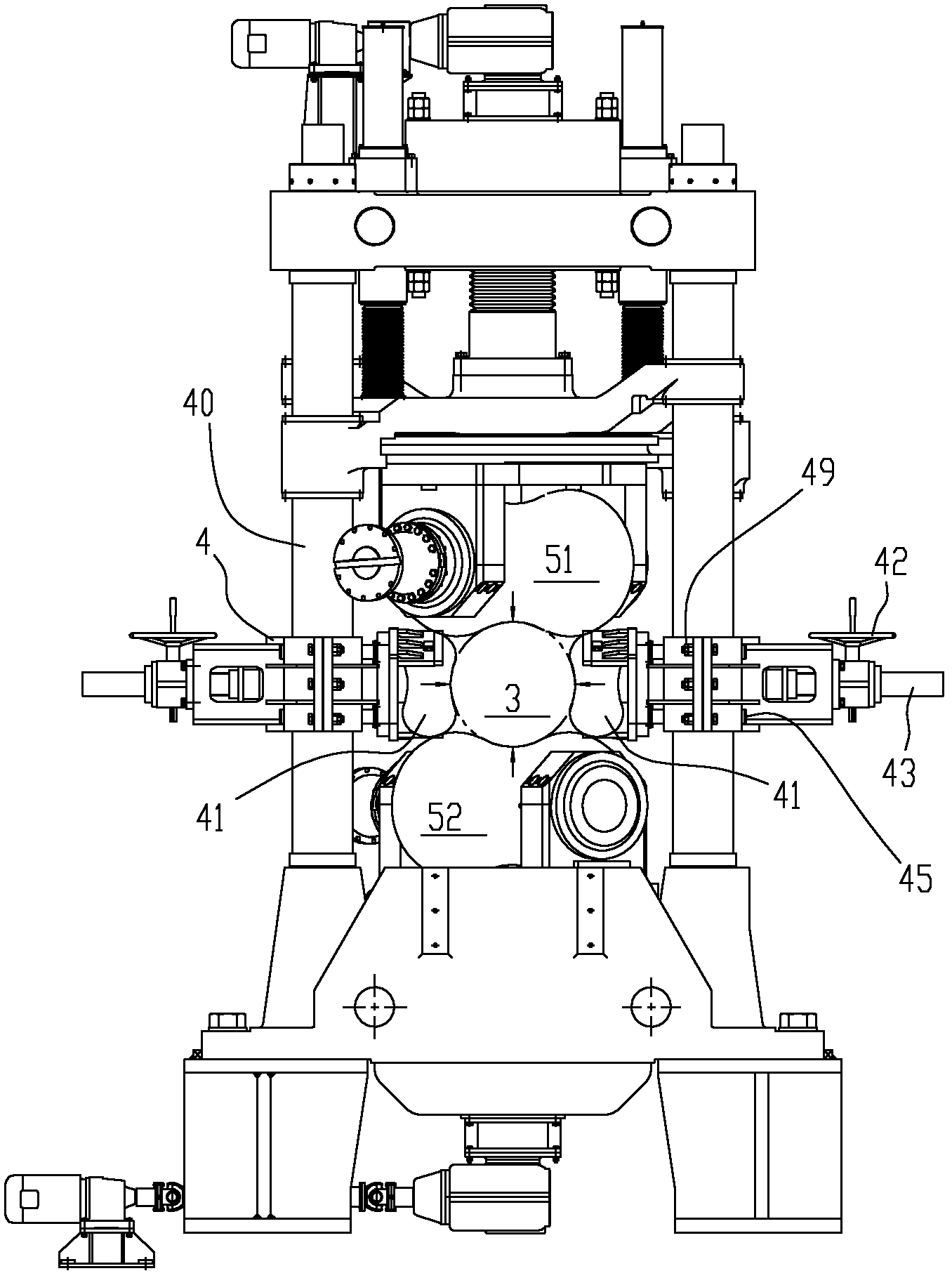

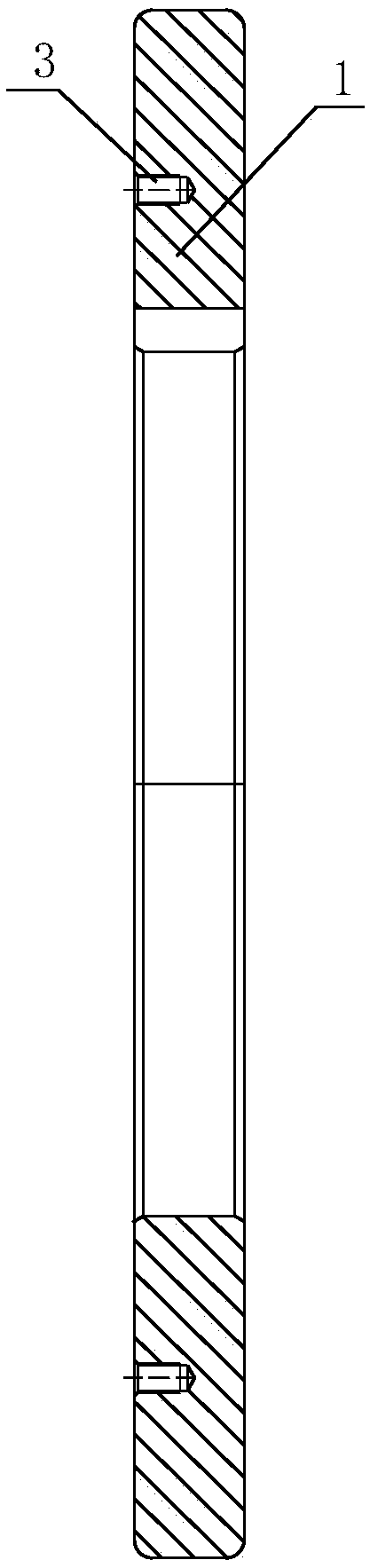

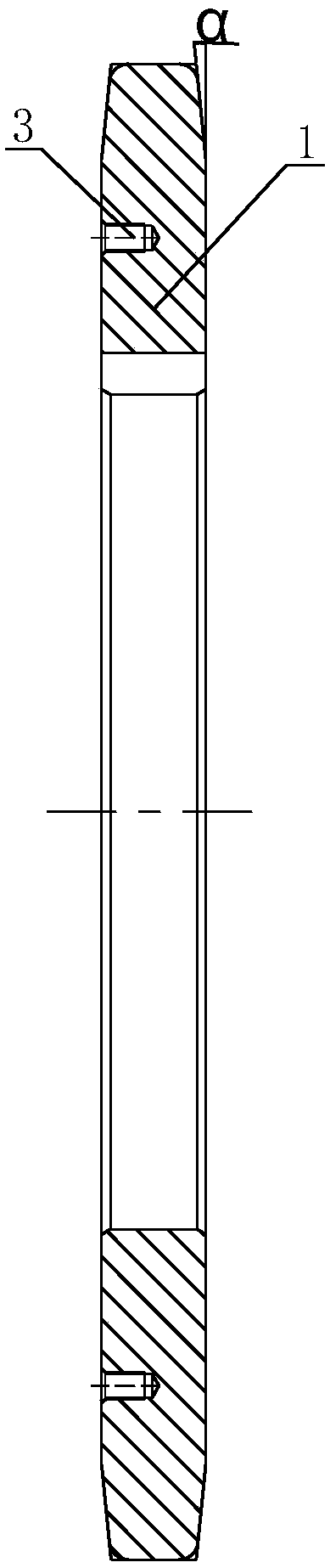

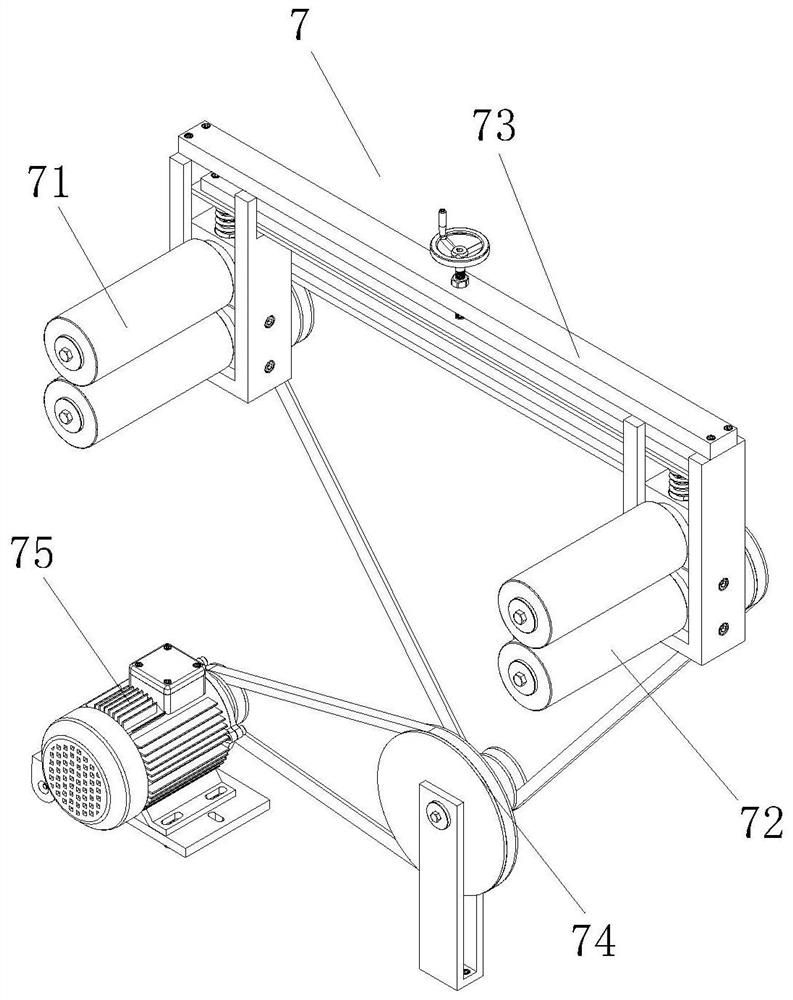

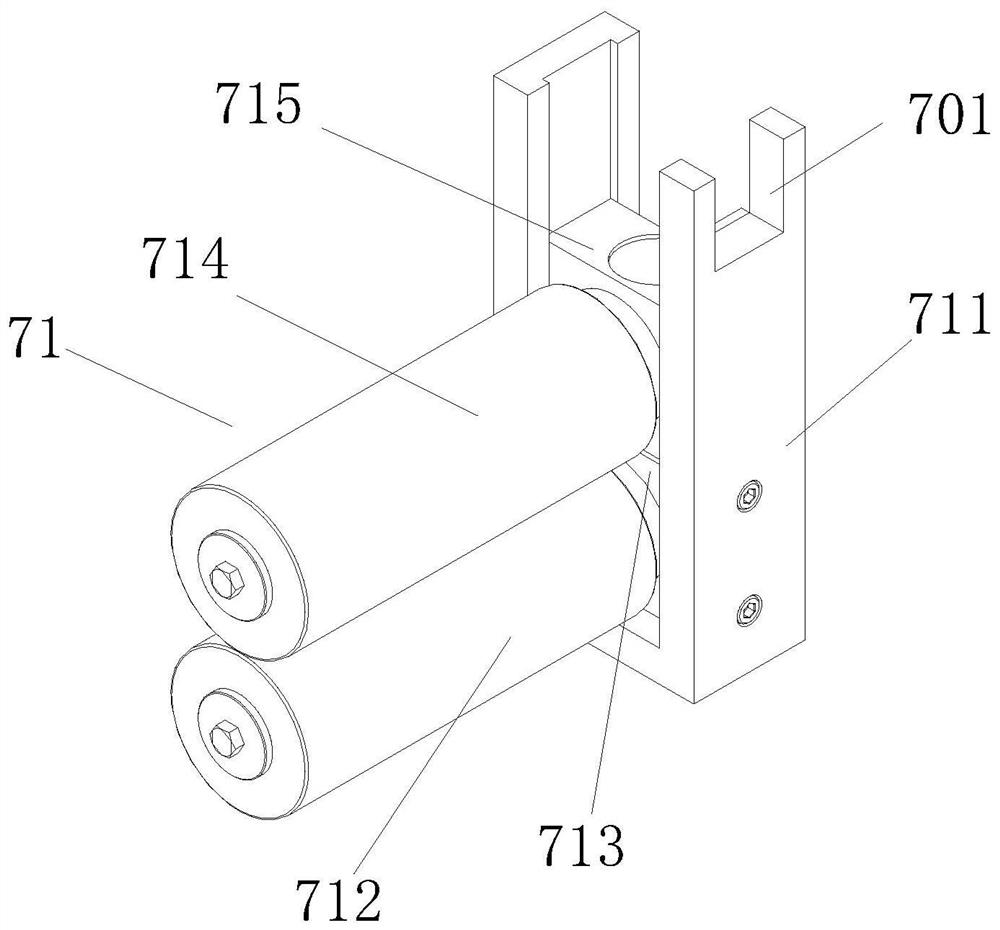

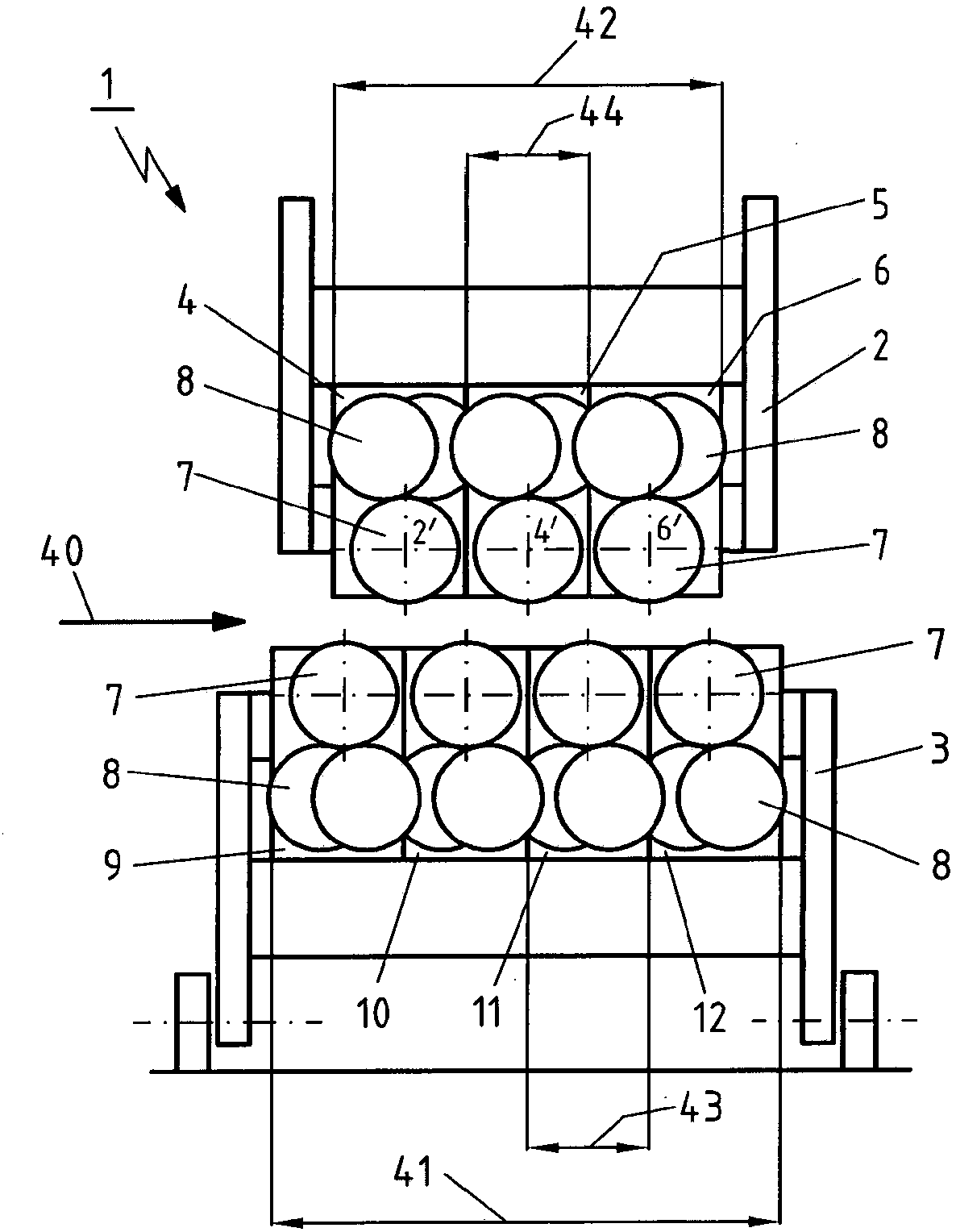

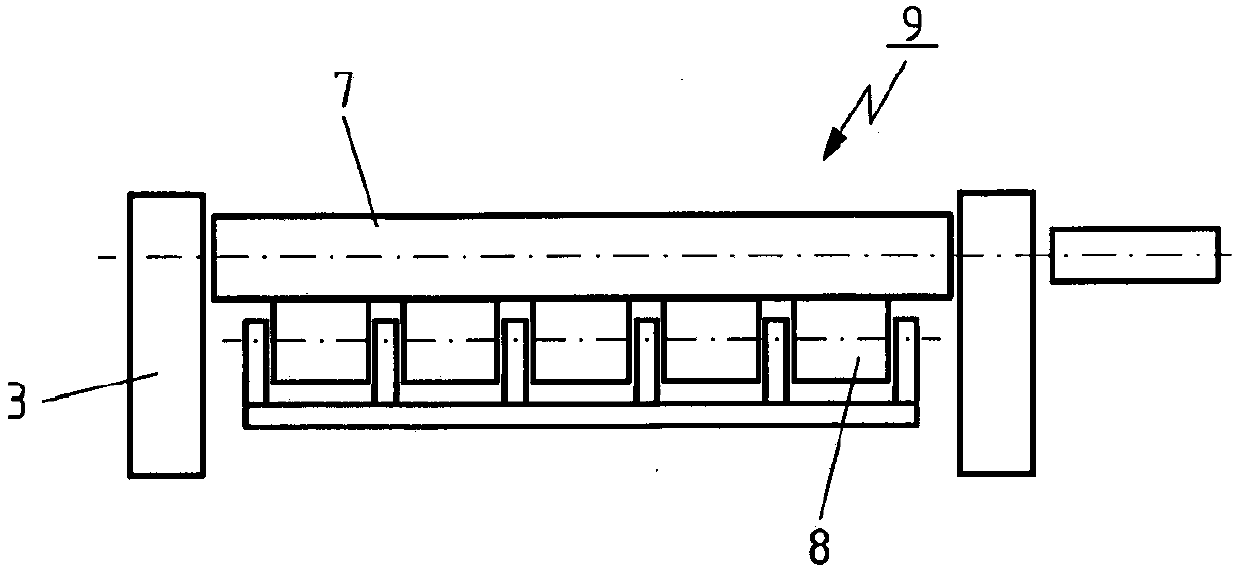

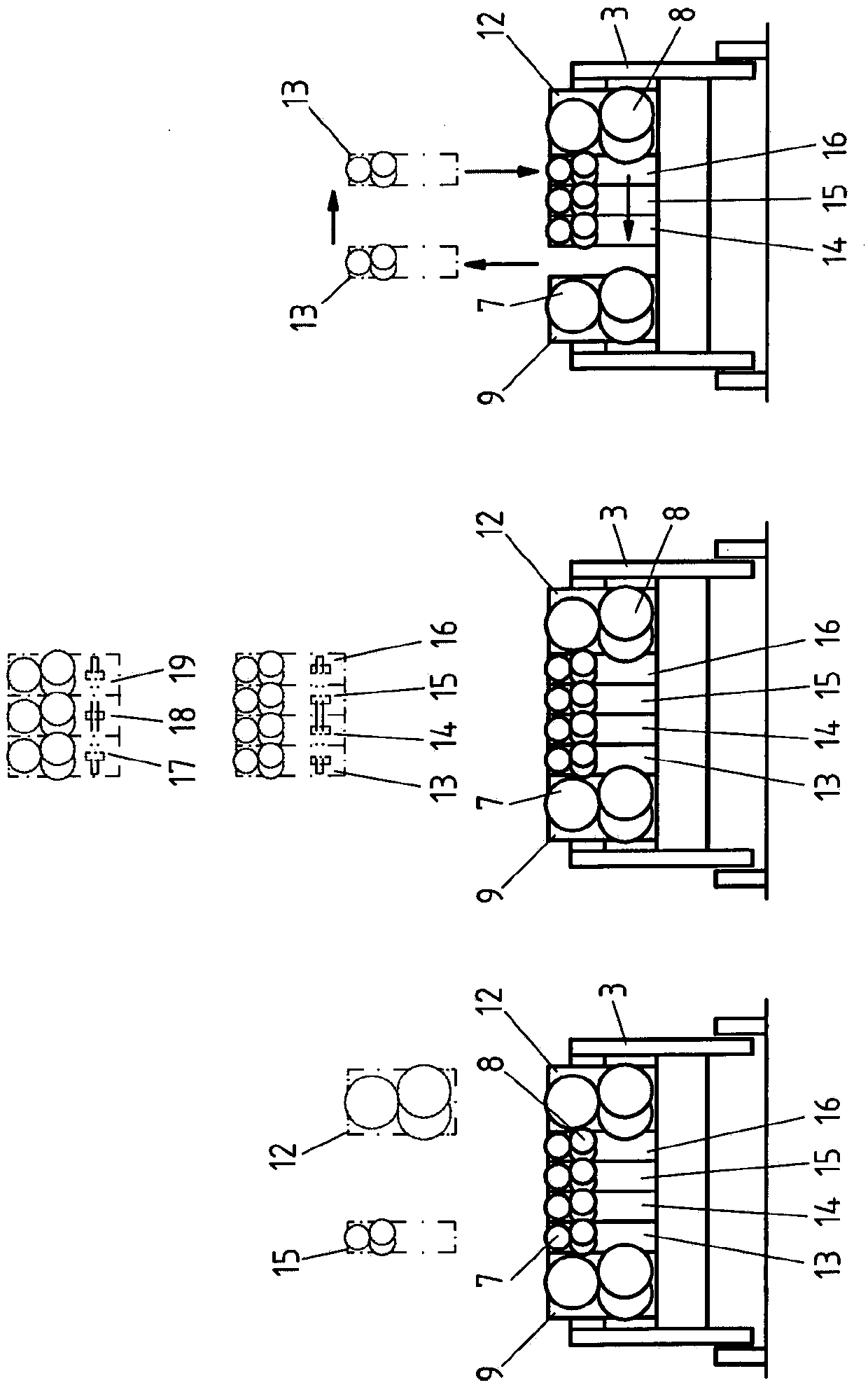

Straightening machine with a modular interchangeable casette system

ActiveCN107921502ASuitable designExpand the straightening rangeShaping toolsMetal rolling stand detailsModularityEngineering

The invention relates to a straightening machine (1) having an allocated straightening roll drive (31) comprising a top bearing frame (2) and a bottom bearing frame (3), in which a plurality of straightening rolls (7) and supporting rolls (8) are held in a cassette-like manner and arranged in an interchangeable manner, a solution is to be created that provides an improved adaptability of a straightening machine to different straightening requirements and straightening areas. This is achieved in that all the straightening rolls (7) and supporting rolls (8) respectively arranged in the top and / or bottom bearing frame (2, 3) are distributed into several straightening roll segments (4-6, 9-30) that are modularly adapted to one another and each configured in the form of an interchangeable cassette, wherein each straightening roll segment (4-6, 9-30) comprises at least one layer of supporting rolls (8) and at least one allocated straightening roll (7).

Owner:SMS GRP GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com