Spoke machine

A technology of spokes and spoke wires, which is applied in the field of spoke machines, can solve problems such as the inability to adjust the stroke of the hammering slider, increase the volume of the whole machine by supporting the frame, and spiral scratches on the steel wires, so as to facilitate production and quality management, and effectively It is beneficial to the intact rate and the effect of reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

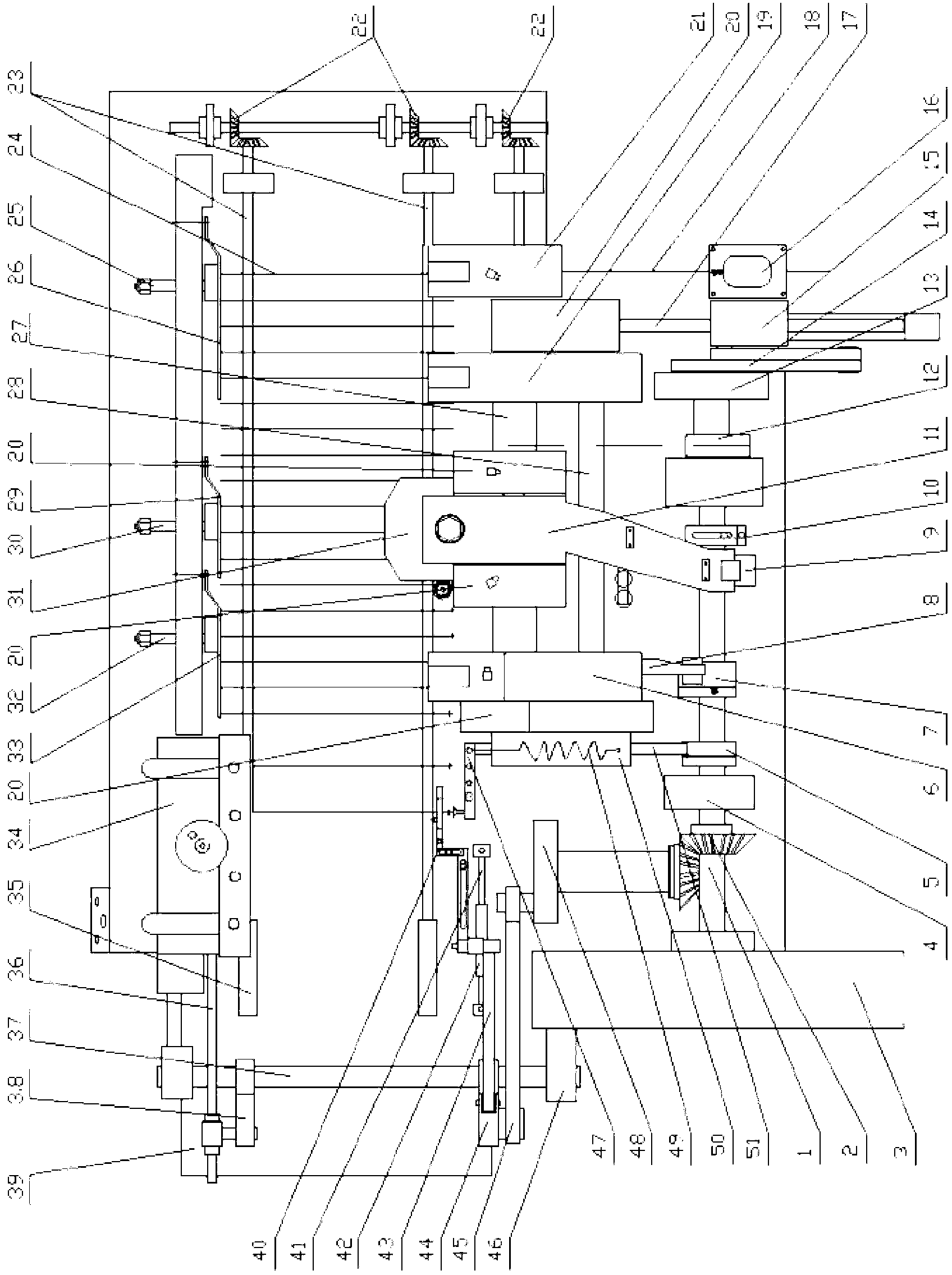

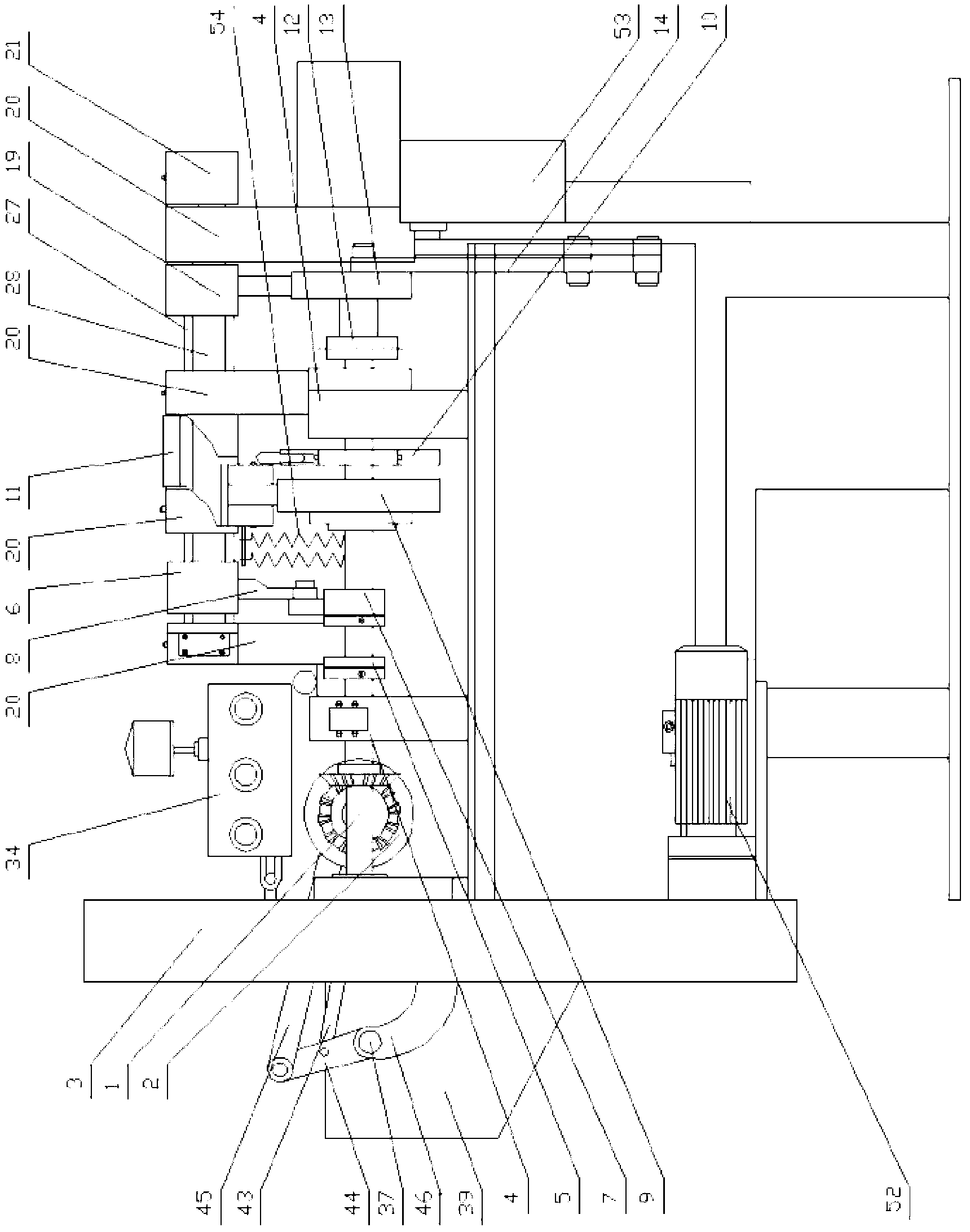

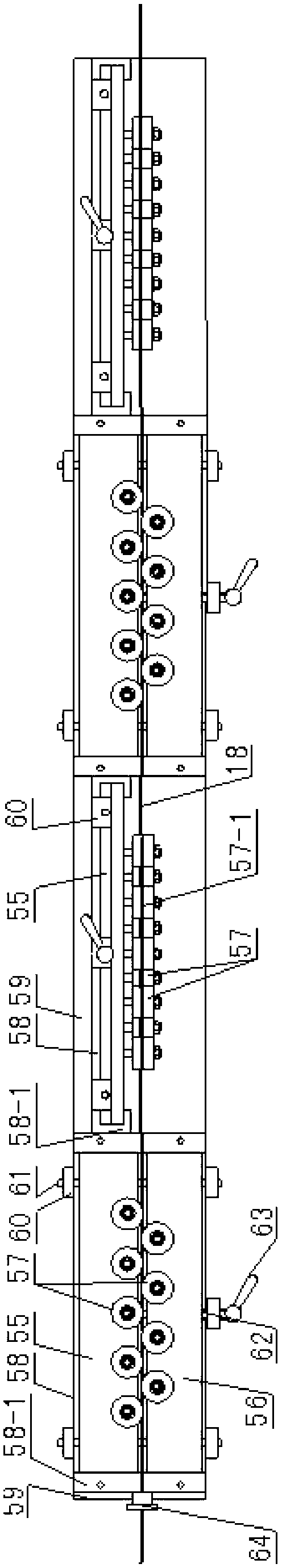

[0031] The spoke machine is equipped with a power mechanism, a spoke wire straightening mechanism, a spoke wire traction mechanism, a spoke blank material parallel screw rod conveying mechanism, a first and a second cutting mechanism, a pier cap mechanism, a bending mechanism, a thread rolling mechanism and a lubricating mechanism .

[0032] Such as figure 1 , 2 In the shown embodiment, the power mechanism is provided with a motor 52 and a speed reducer thereof and a belt transmission mechanism connected to the shield 3 of the speed reducer, and the driven pulley of the belt transmission mechanism has a power output supported by its wheel shaft and the shaft seat 4 The main shafts 1 are connected, and the power output main shaft 1 is sequentially provided with: the bevel gear pair 2 and the spoke positioning cam 5 transmitted to the thread rolling mechanism; the ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com