Plate material cutting device

A cutting device and plate technology, applied in electrostatic, metal processing, electrical components, etc., can solve the problems of uneven stacking of plates, failure to cut the cutting surface, and poor static removal effect, saving space and reducing defective products. efficiency, avoid the effect of plate cutting failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

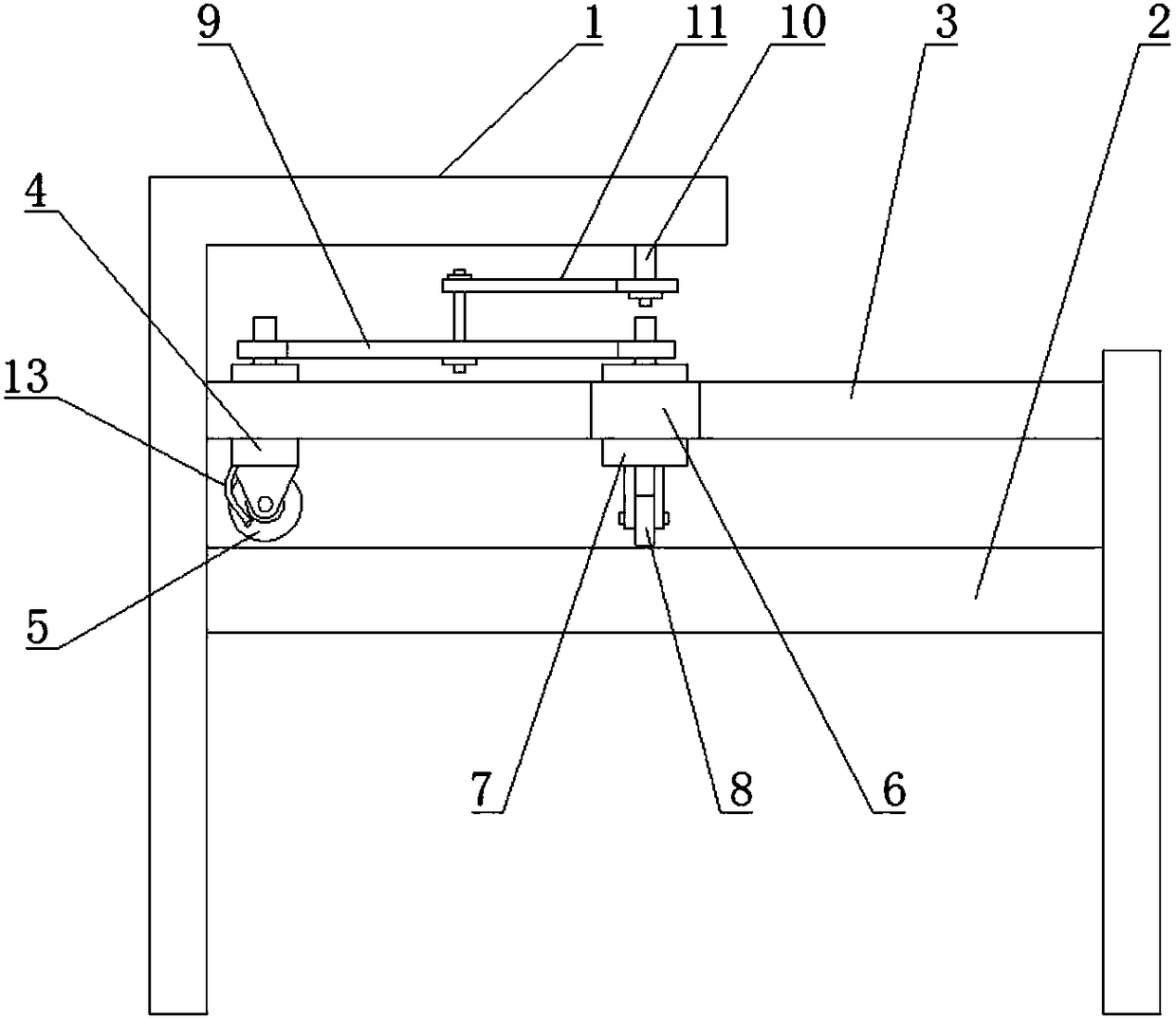

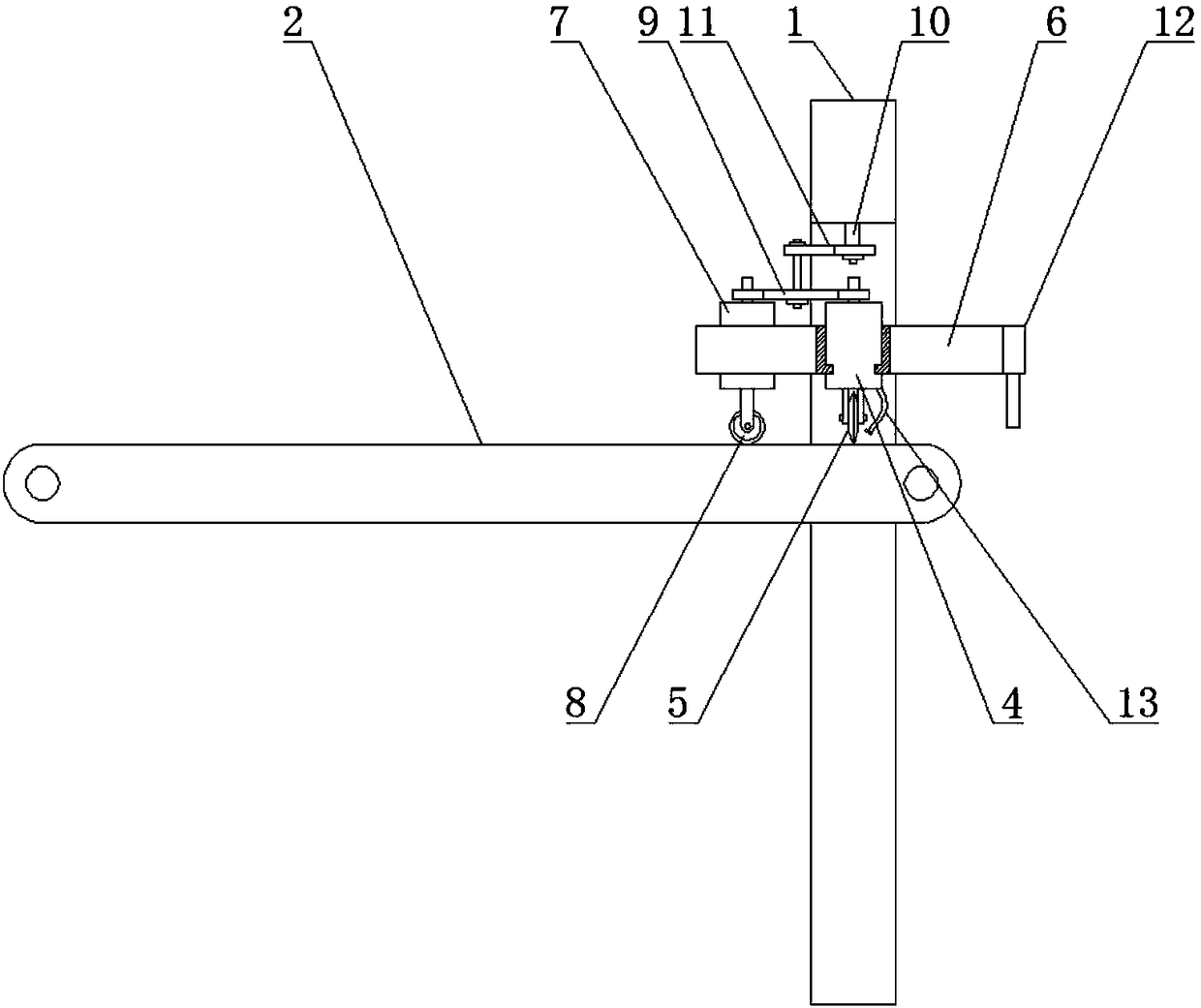

[0032] A plate material cutting device, comprising a bracket 1, an intermittent conveyor belt 2 is arranged on the bracket 1, a guide rail 3 is arranged on the bracket 1, a slider 4 is arranged inside the guide rail 3, and the slider 4 can move along the direction of the guide rail 3 in the guide rail 3 The axis reciprocates, the bottom of the slider 4 is provided with a cutter 5, the support 1 is also provided with a second guide rail 6 perpendicular to the guide rail 3, and the second guide rail 6 is provided with a second slide block 7, the second slide block 7 can be The second guide rail 6 reciprocates along the axis of the second guide rail 6 , and the bottom of the second slider 7 is provided with a metal roller 8 , which is connected with the plate.

[0033]In this embodiment, the cutting knife 5 does not move up and down periodically, but does a reciprocating linear motion in the direction perpendicular to the conveying line of the gap conveyor belt 2. The movement of ...

Embodiment 2

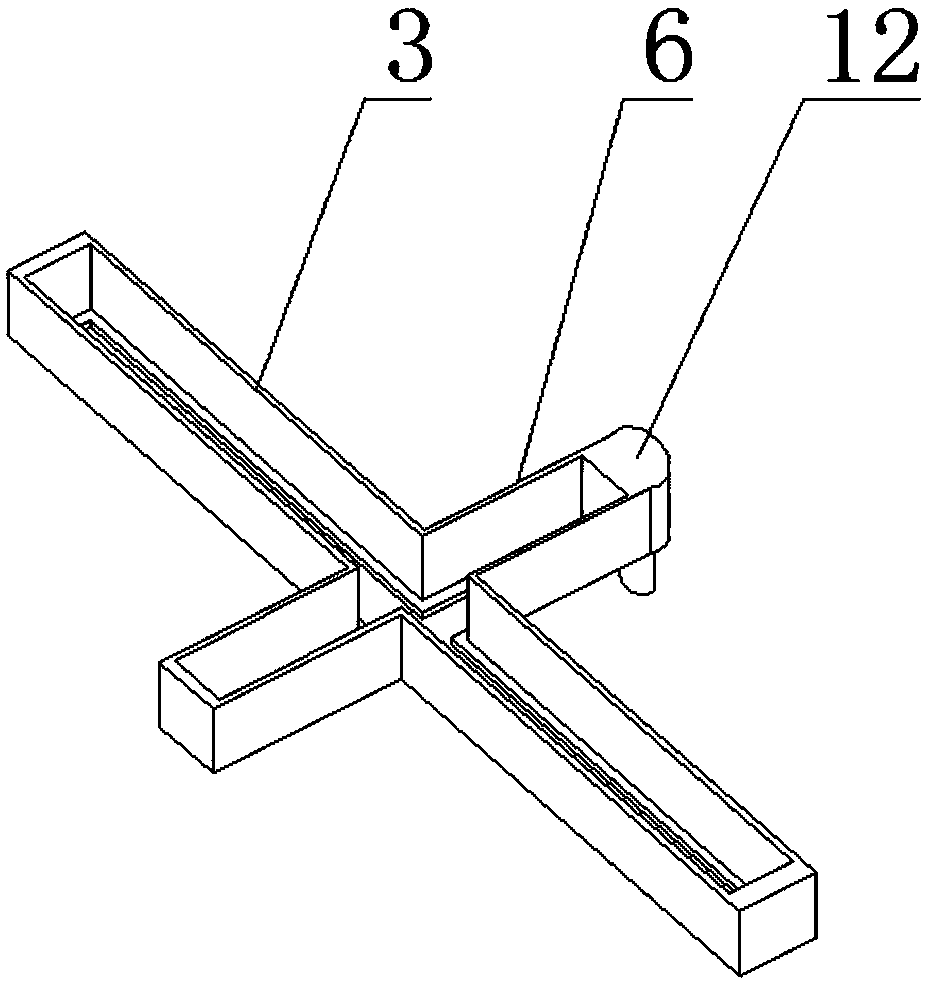

[0035] On the basis of Embodiment 1, in order to save space and reduce volume, the axis of the guide rail 3 and the axis of the second guide rail 7 are in the same plane, and the guide rail 3 and the second guide rail 7 together form a cross guide rail, which is convenient for the slider 4 and the second guide rail. Two slide blocks 7 linkage.

Embodiment 3

[0037] On the basis of Embodiment 1, it also includes a connecting rod 9, one end of the connecting rod 9 is hinged with the slider 4, and the other end of the connecting rod 9 is hinged with the second slider 7; The hinged shaft 10 is sleeved with a crank 11 , and the end of the crank 11 is hinged to the middle part of the connecting rod 9 .

[0038] In this embodiment, it is set so that an ellipse structure is formed between the slider 4 and the second slider 7, so that the slider 4 and the second slider 6 are linked in the cross guide rail, which simplifies the power mechanism required by the device , so that the mechanism of the device is simpler, the actions are more coordinated, and the degree of integration is high, and there is no need to set up a separate control structure to control the movement of the slider 4 and the second slider 7 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com