Patents

Literature

245results about How to "Avoid fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

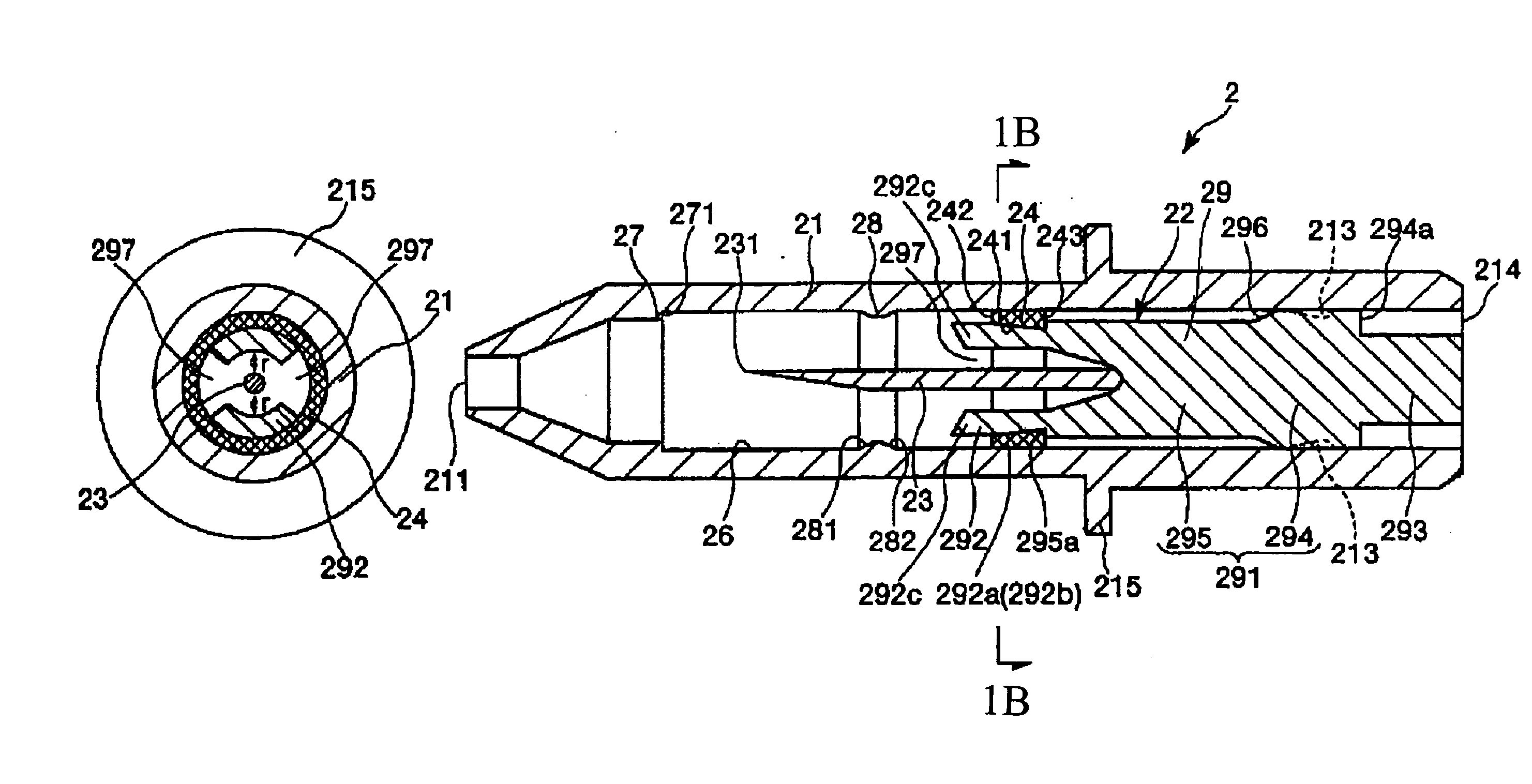

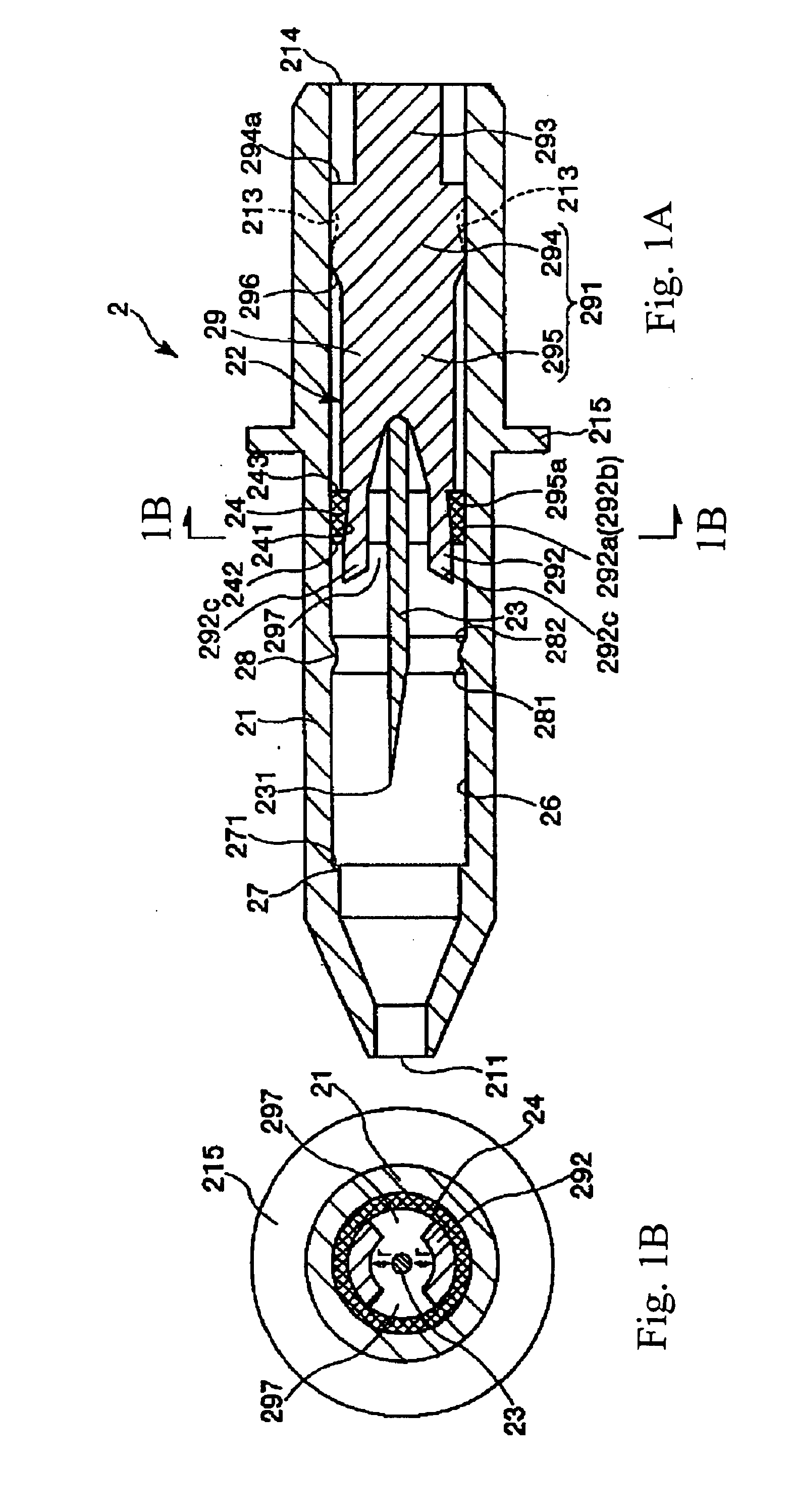

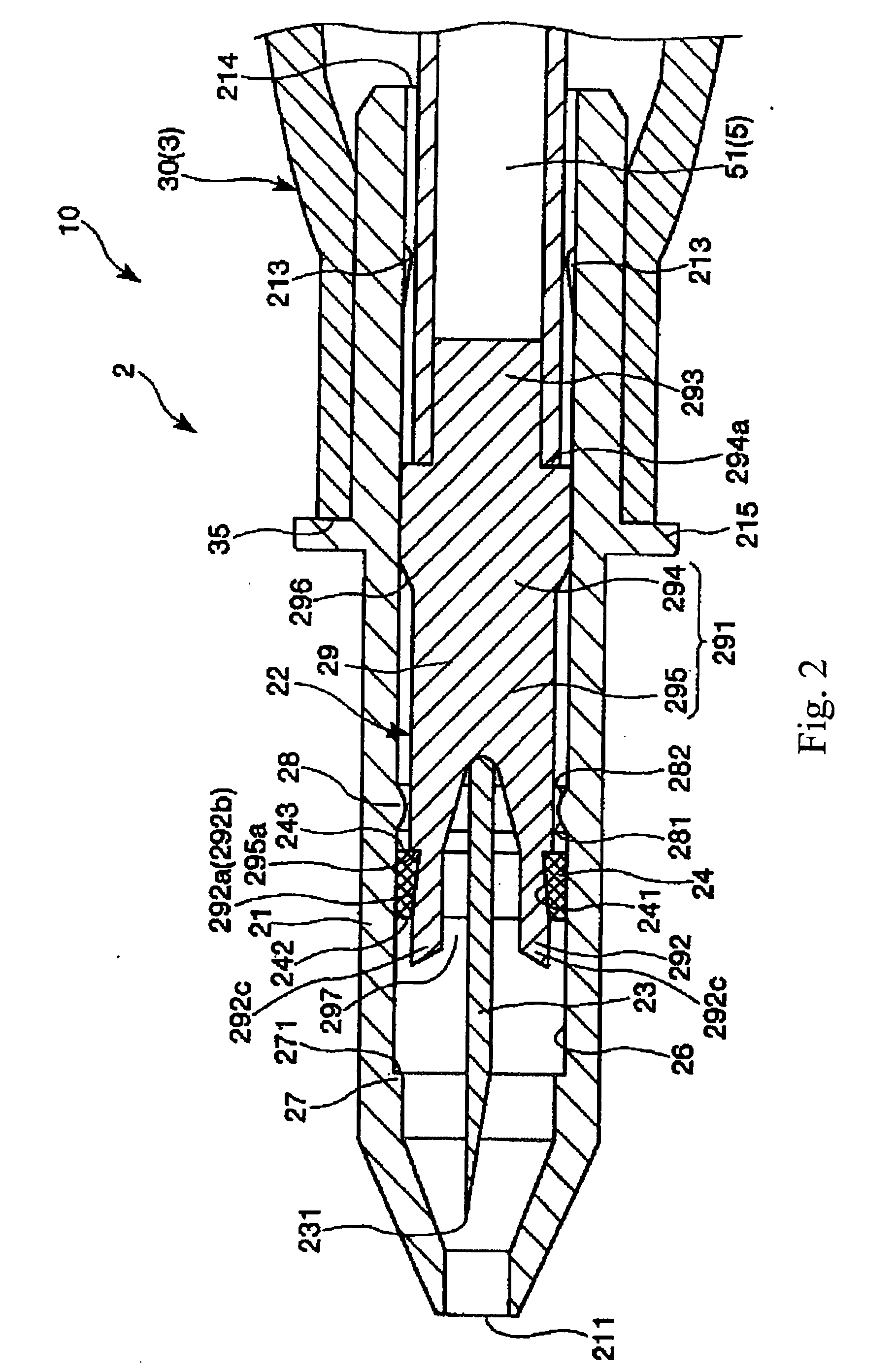

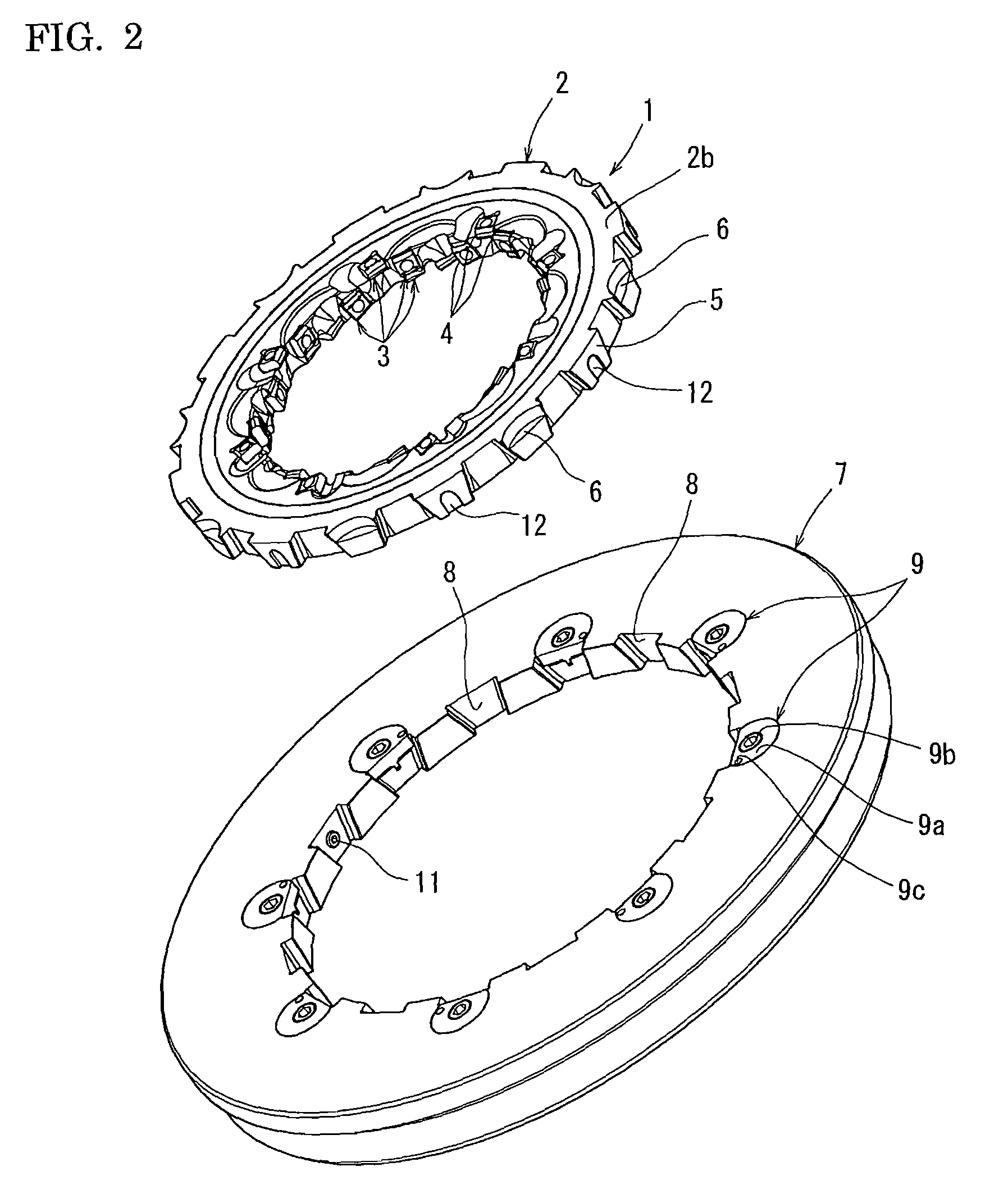

Lancet Instrument

A lancet instrument detachably fitted to a lancing apparatus, comprising a lancet having a lancet body with a sharp lancet tip at its tip, a lancet hub fixed to the lancet body so that the lancet tip is exposed, and an elastic deformation part extended from the lancet hub in the tip direction and elastically deformable so that the distance thereof from the lancet body can be changed, a ring-like member fitted to the outer periphery of the elastic deformation part and releasable in the tip direction by changing the distance between the elastic deformation part and the lancet body, and a casing having a ring-like member contact part storing the lancet so as to be movable in the longitudinal direction and formed in the inner peripheral part thereof so that the ring-like member is brought into contact therewith and stopped to move in the tip direction and a tip opening through which the lancet tip can be projected. The lancet instrument thus obtained is so formed that the projection of the lancet tip through the tip opening of the casing is blocked by moving the ring-like member released from the elastic deformation part in the tip direction between the tip of the elastic deformation part and the ring-like member contact part to restrict the movement of the lancet.

Owner:TERUMO KK

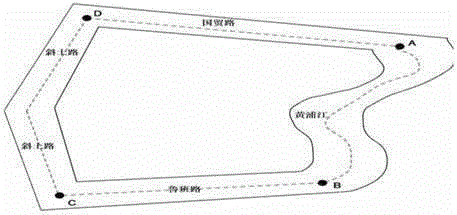

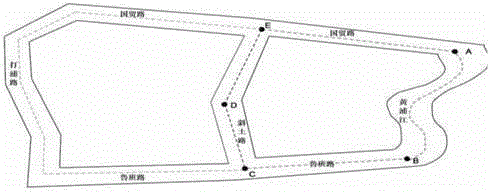

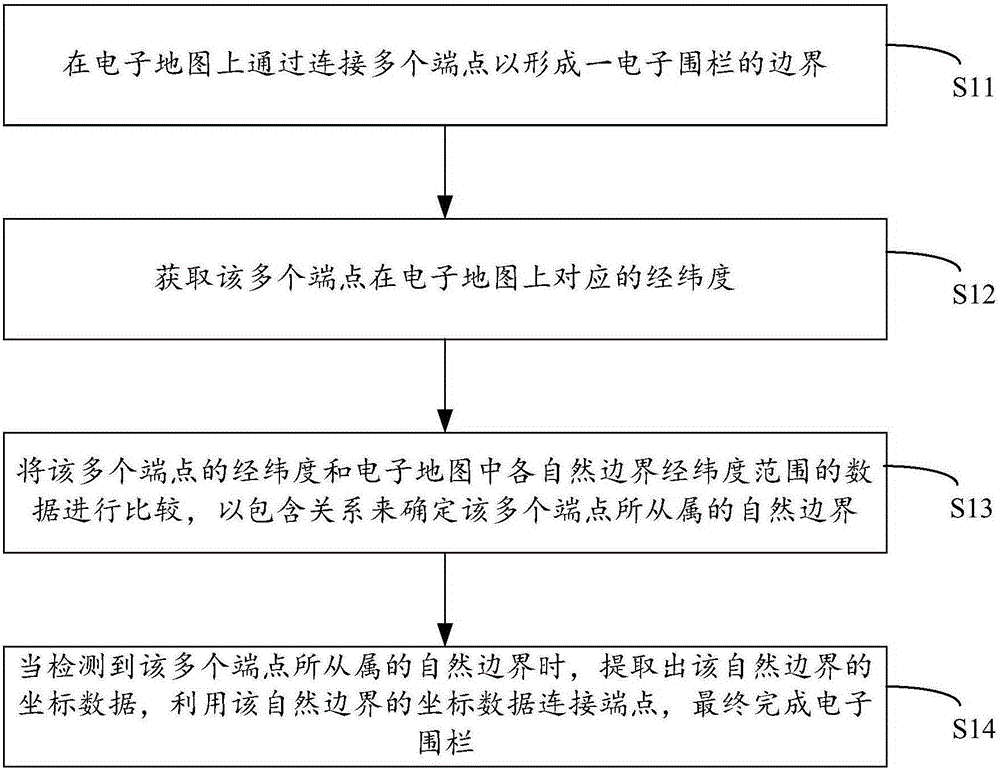

Polygon accurate drawing method based on electronic map and application method thereof

InactiveCN106652756APrecise delineationAvoid overlapping bordersMaps/plans/chartsData connectionInclusion relation

The invention discloses a polygon accurate drawing method based on an electronic map and an application method thereof. Problems that based on the electronic map, during drawing of a single covering, rivers, roads, and fuzzy boundaries cannot be discriminated accurately, and during the drawing of a plurality of polygon coverings, the adjacent boundaries are easy to overlap and are not superposed are solved. The technical scheme provided by the invention is characterized in that by connecting a plurality of endpoints, a boundary of an electronic fence is formed on the electronic map; the corresponding longitudes and the corresponding latitudes of the plurality of endpoints in the electronic map are acquired; the longitudes and the latitudes of the plurality of endpoints are compared with the data of the longitude and latitude ranges of the natural boundaries of the electronic map, and the natural boundaries of the plurality of endpoints are determined by an inclusion relation; when the natural boundaries of the plurality of endpoints are detected, the coordinate data of the natural boundaries is extracted, and the endpoints are connected by using the coordinate data of the natural boundaries, the electronic fence is finally completed.

Owner:YTO EXPRESS CO LTD

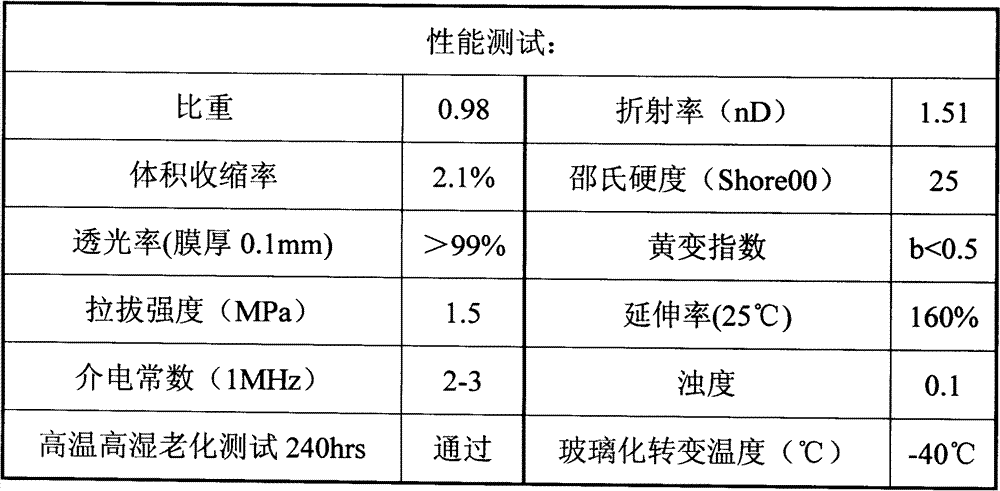

Ultraviolet curable resin composition and application thereof

ActiveCN102766428AGood liquidityNot crushableLayered productsPolyureas/polyurethane adhesivesPrepolymerPhotoinitiator

The invention discloses an ultraviolet curable resin composition, which comprises the following components by weight: 50-90 parts of ultraviolent sensitive prepolymer resin, 10-50 parts of active diluent monomer, 5-20 part of olefin modified resin, 1-20 parts of ultraviolent free radical photoinitiator and 1-2 parts of functional auxiliary agent. The ultraviolet curable resin composition prepared by the invention is better in mobility, more excellent in optical performance and bonding strength, lower in Shore hardness, and small in impedance corrosion for ITO (indium tin oxide), can be widely applied to plane or curved surface bonding of the transparent materials in the optical field, such as a touch screen, and is capable of effectively inhibiting unevenness display of laminated bodies caused by an internal stress and an external stress and stripping of cured resin; and furthermore, the operating process is simpler, reworking is easier and the product yield is high.

Owner:PANYU NANSHA YAN TIN CHEM

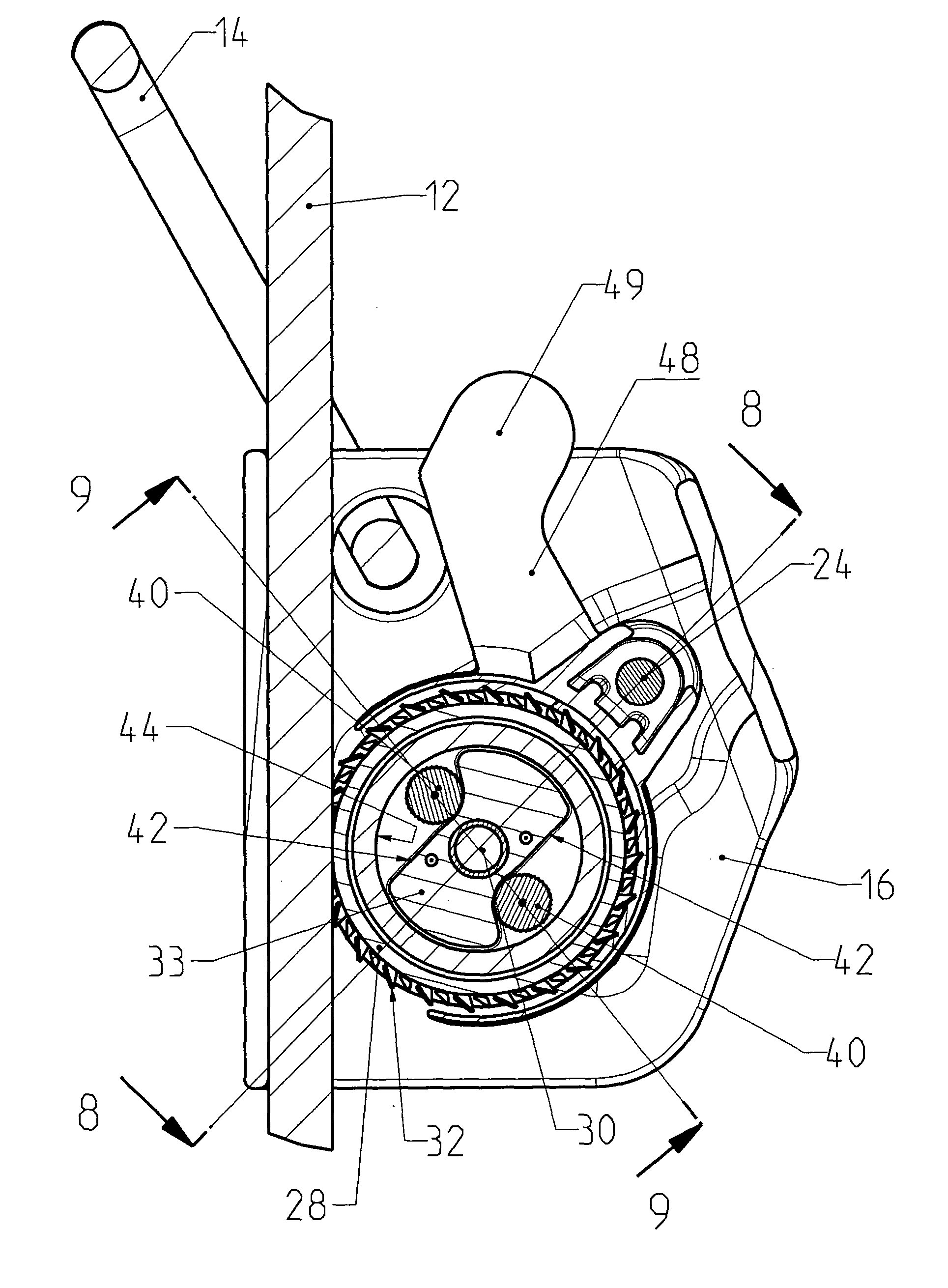

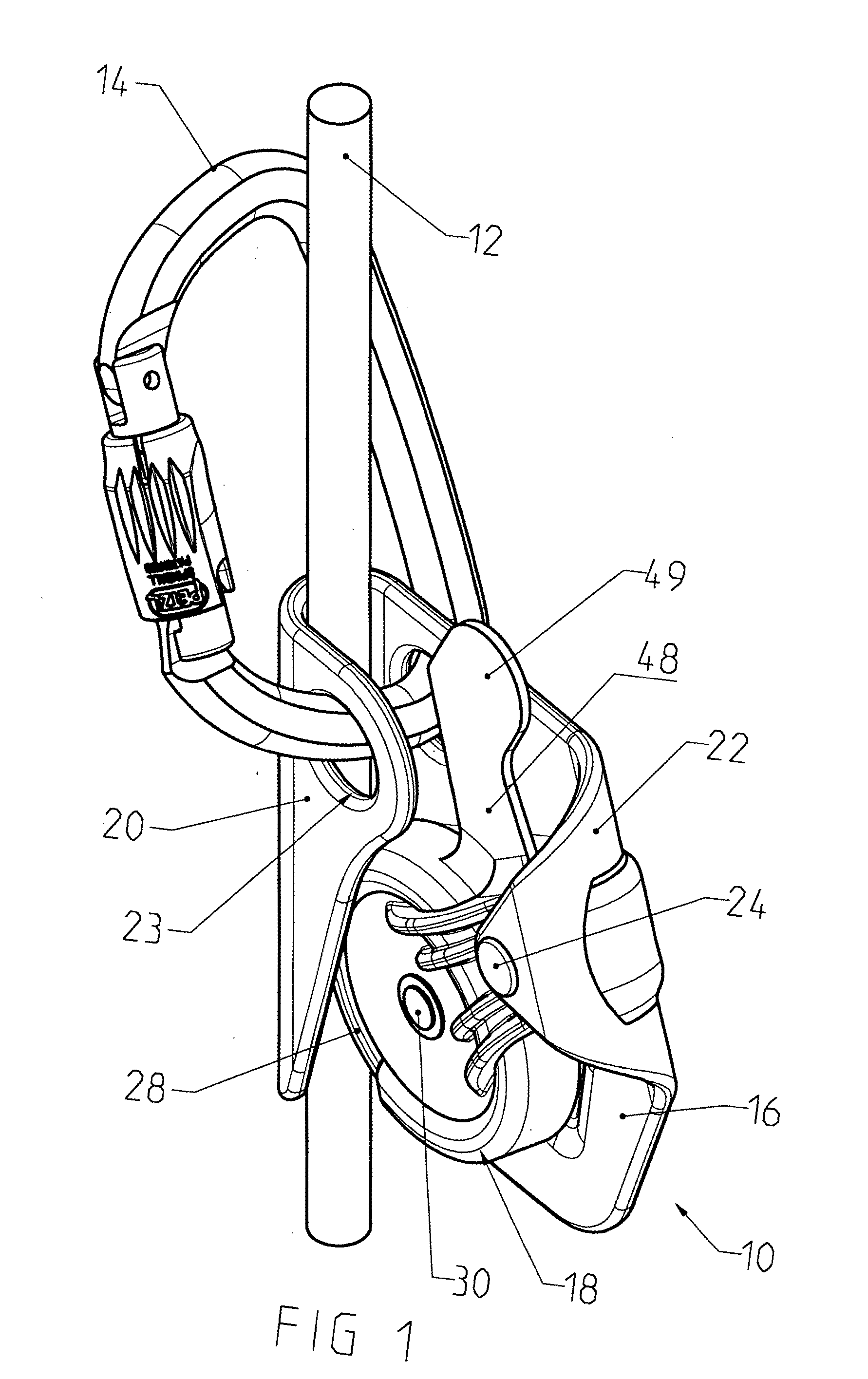

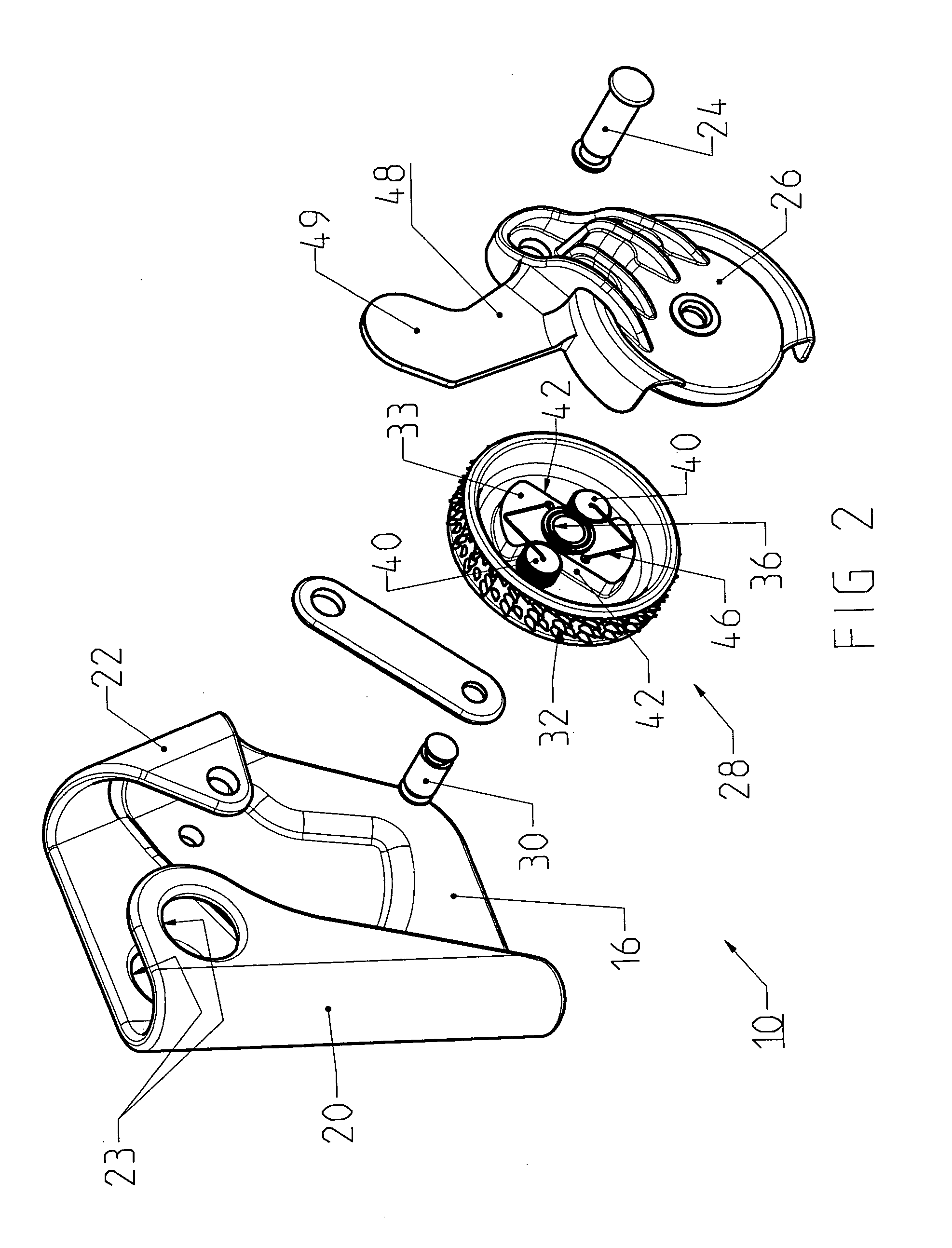

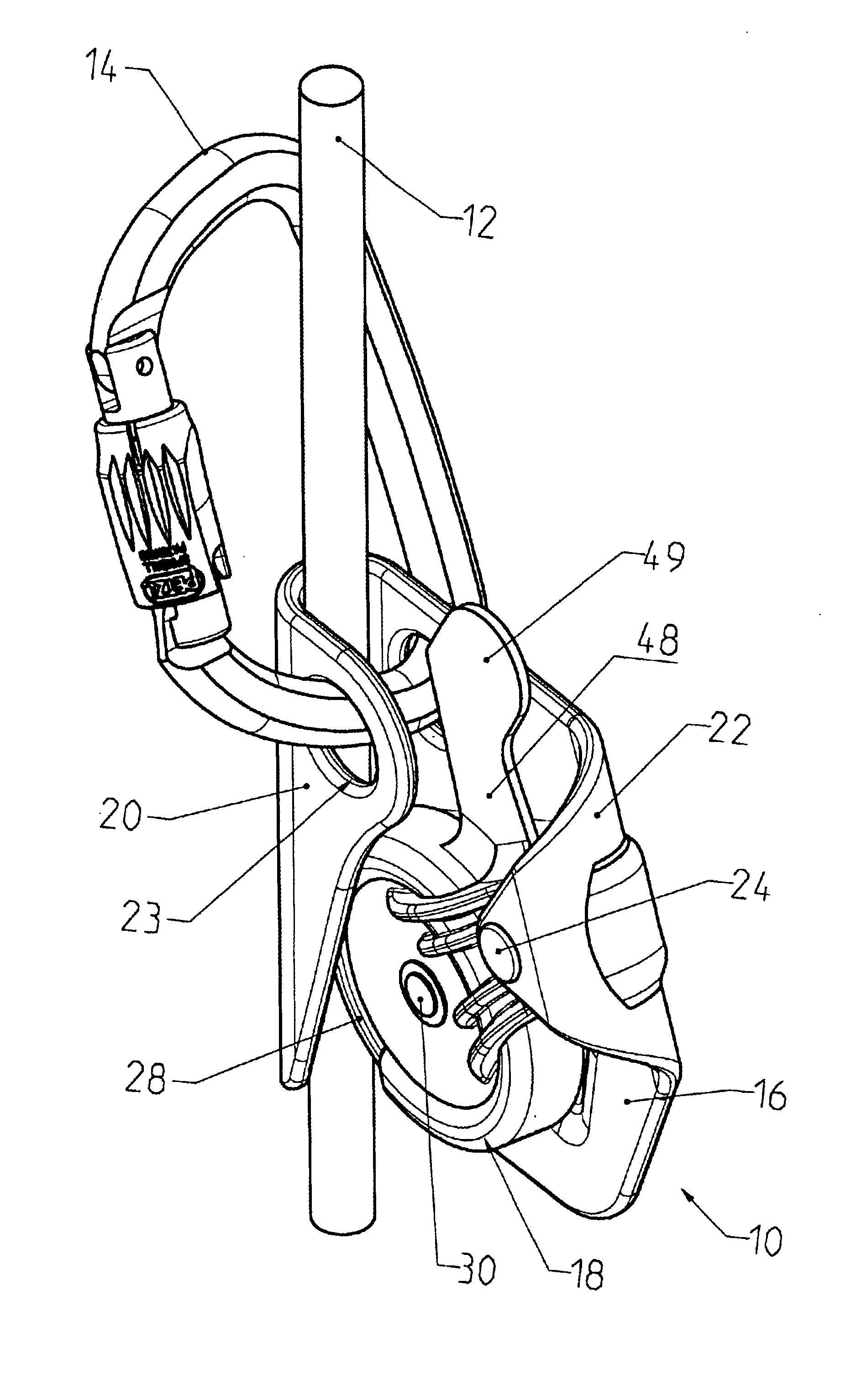

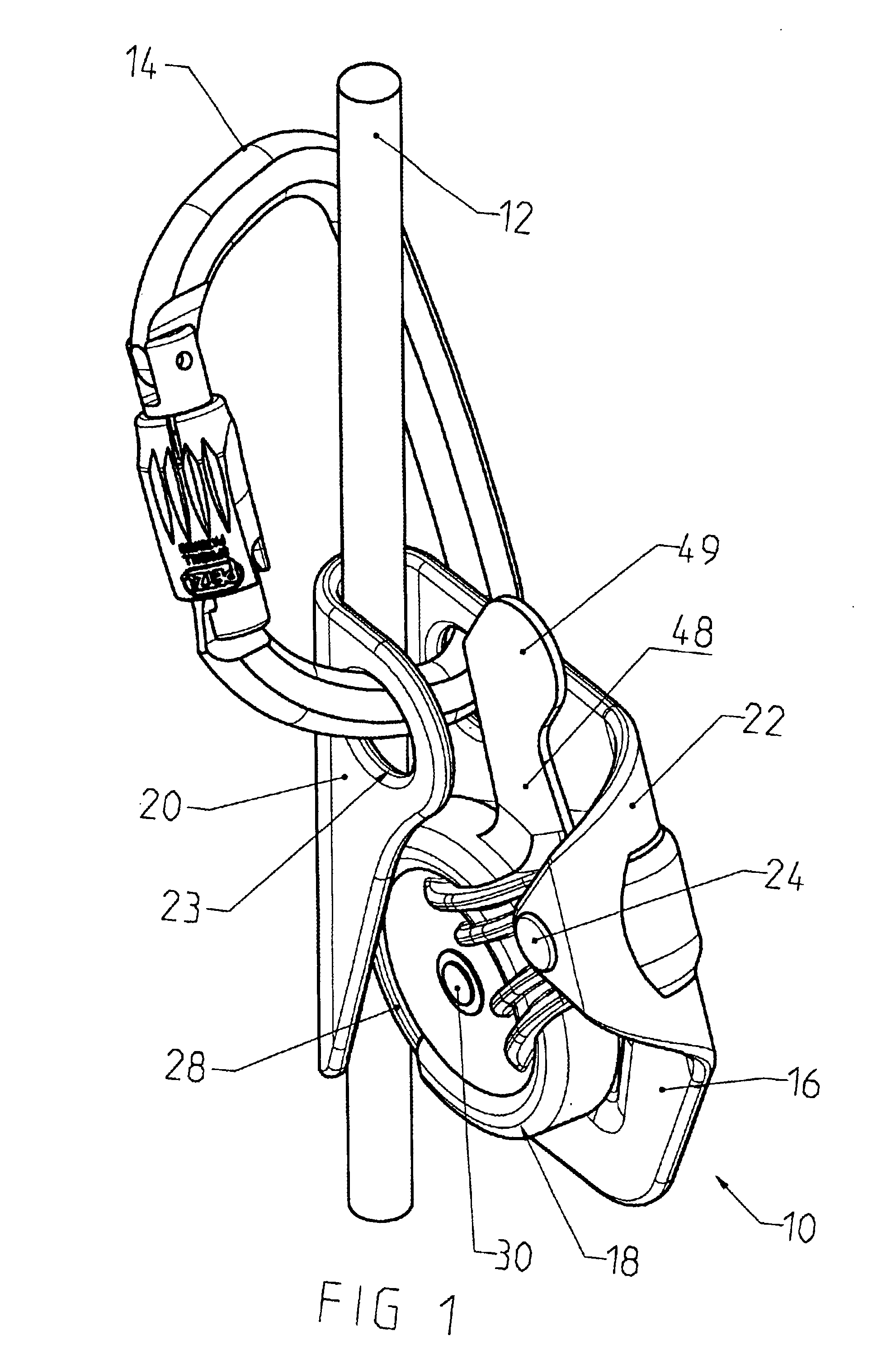

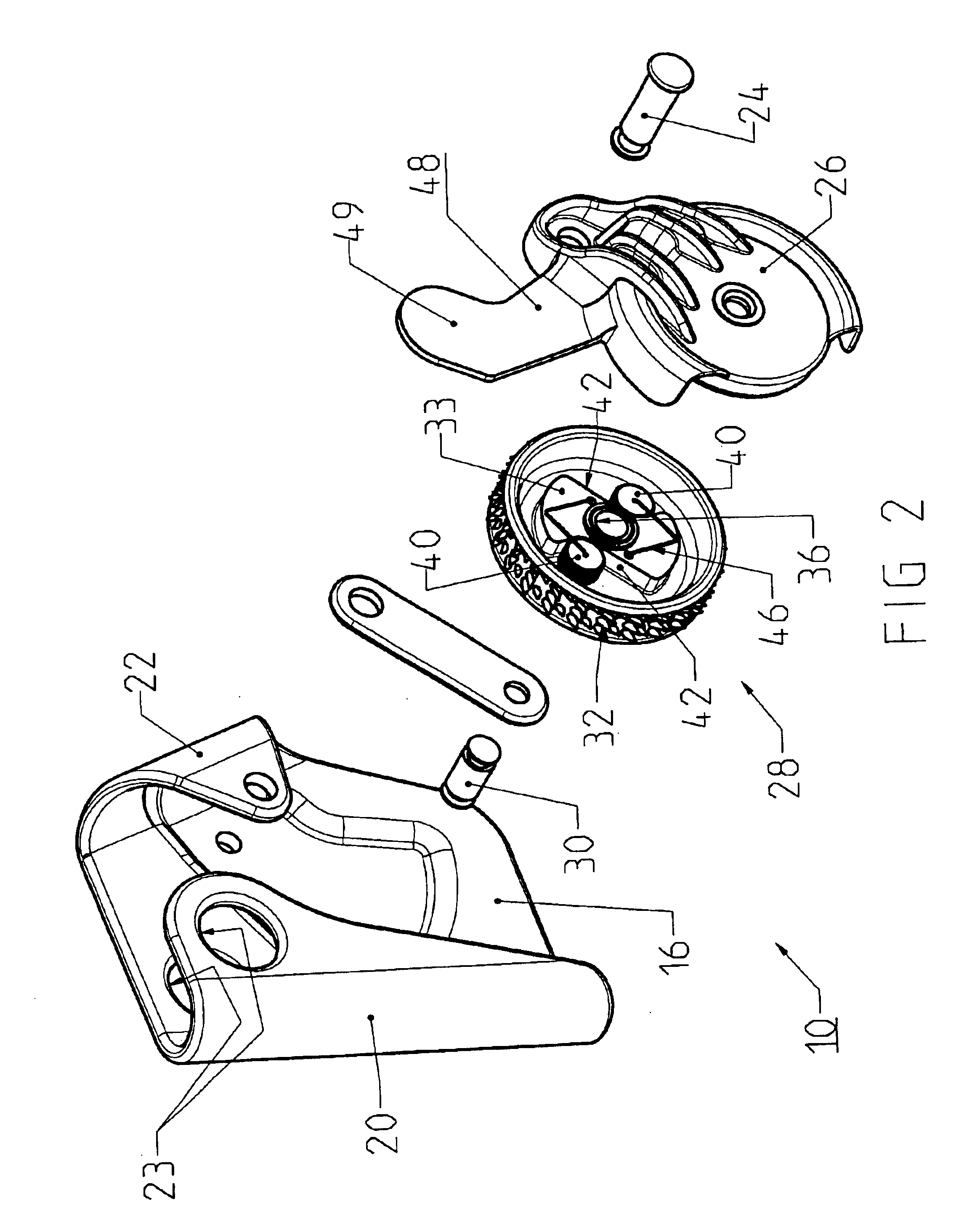

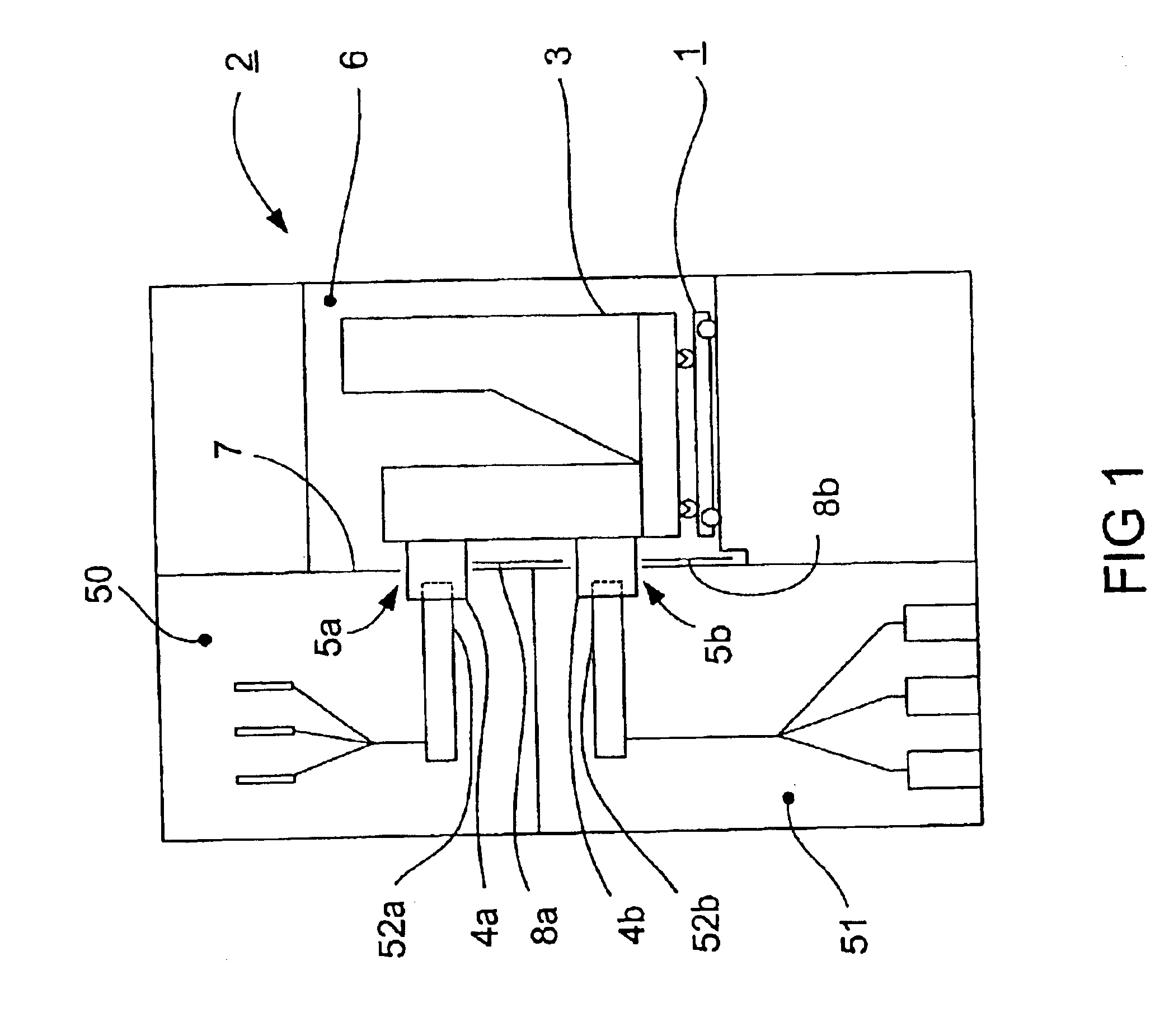

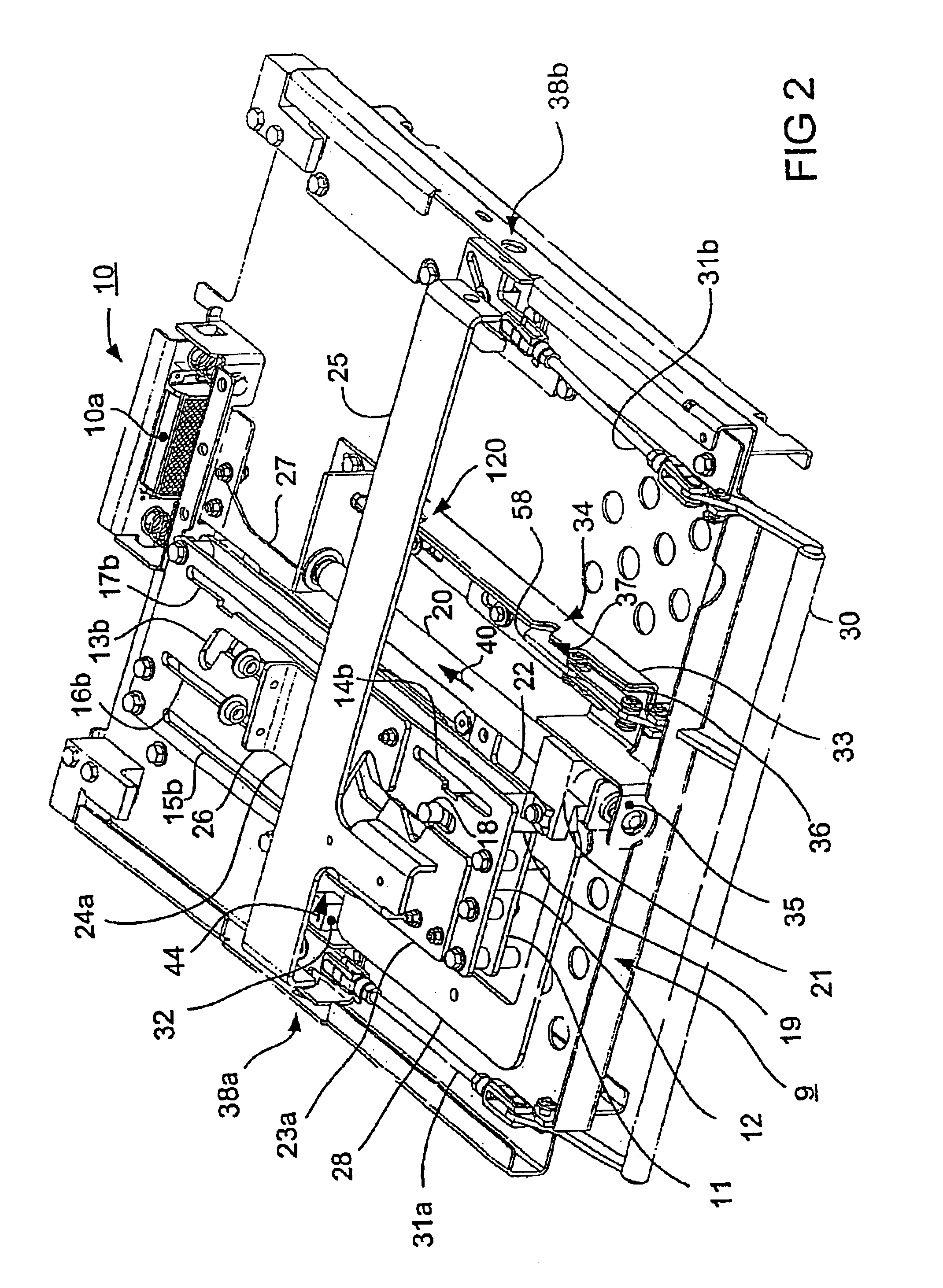

Fall arrest device for a fixed rope

ActiveUS20040020727A1Maximum safetyTravel can be limitedSafety beltsFilament handlingCentrifugal clutch

A follower fall arrest device used with a fixed safety rope is equipped with a securing system comprising a support arm articulated on a first spindle between an active locking and an inactive unlocking position, a roller in the form of a cylindrical wheel mounted rotating free on a second spindle securedly attached to the support arm, and a centrifugal clutch mechanism arranged between a drive member of the roller and the support arm so as to occupy a disengaged position or an engaged position. The peripheral surface of the roller is equipped with a plurality of studs presenting a predetermined angle of incline so as to cause rotation of the roller in the descending direction, and sliding on the rope in the ascending direction. The body comprises a straight U-shaped channel for passage of the rope, said channel having holes for passage of the attachment means.

Owner:ZEDEL CORP

Fall arrest device for a fixed rope

InactiveUS6793046B2Maximum safetyTravel can be limitedSafety beltsFilament handlingCentrifugal clutchEngineering

A follower fall arrest device used with a fixed safety rope is equipped with a securing system comprising a support arm articulated on a first spindle between an active locking and an inactive unlocking position, a roller in the form of a cylindrical wheel mounted rotating free on a second spindle securedly attached to the support arm, and a centrifugal clutch mechanism arranged between a drive member of the roller and the support arm so as to occupy a disengaged position or an engaged position. The peripheral surface of the roller is equipped with a plurality of studs presenting a predetermined angle of incline so as to cause rotation of the roller in the descending direction, and sliding on the rope in the ascending direction. The body comprises a straight U-shaped channel for passage of the rope, said channel having holes for passage of the attachment means.

Owner:ZEDEL CORP

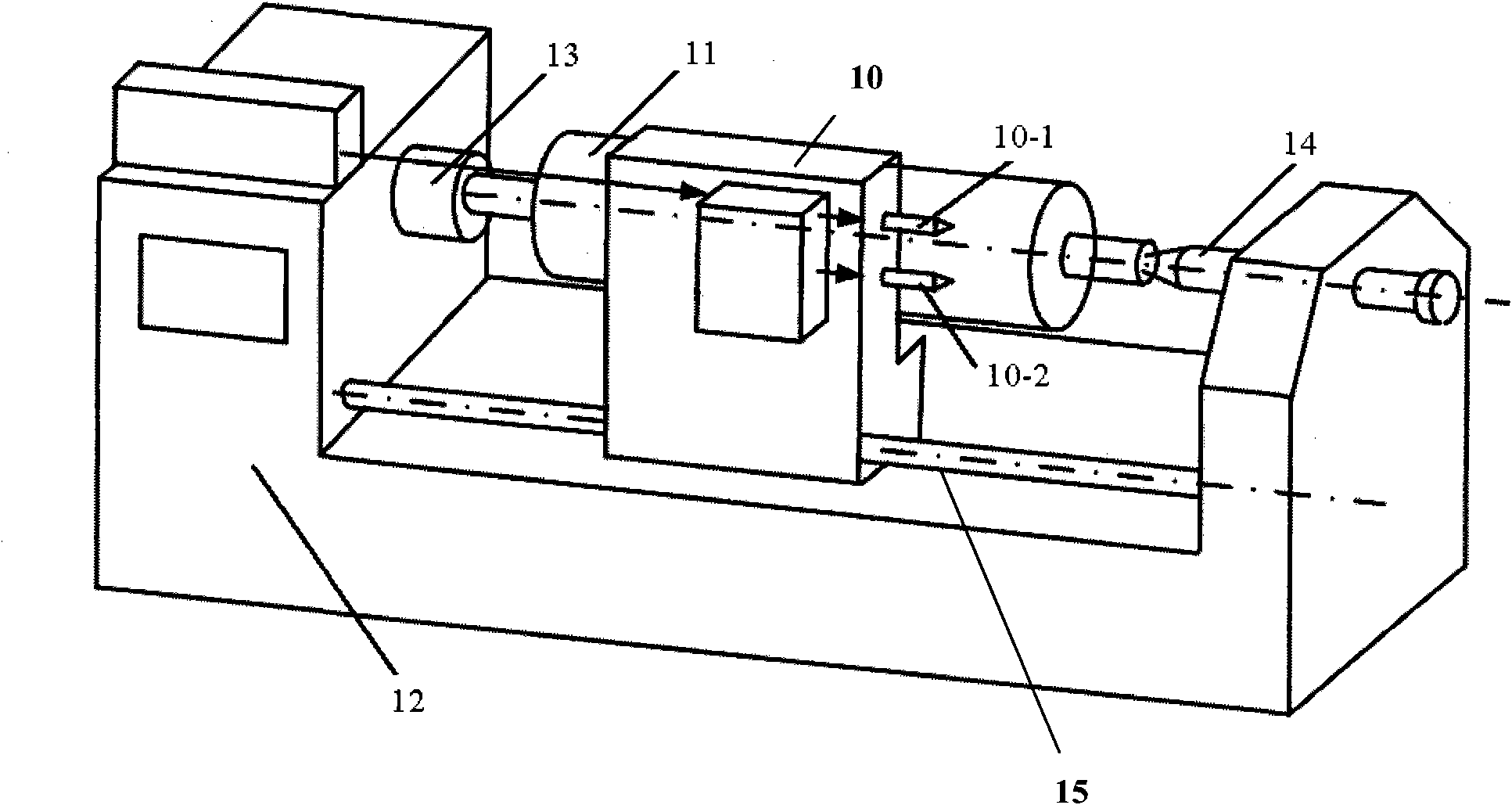

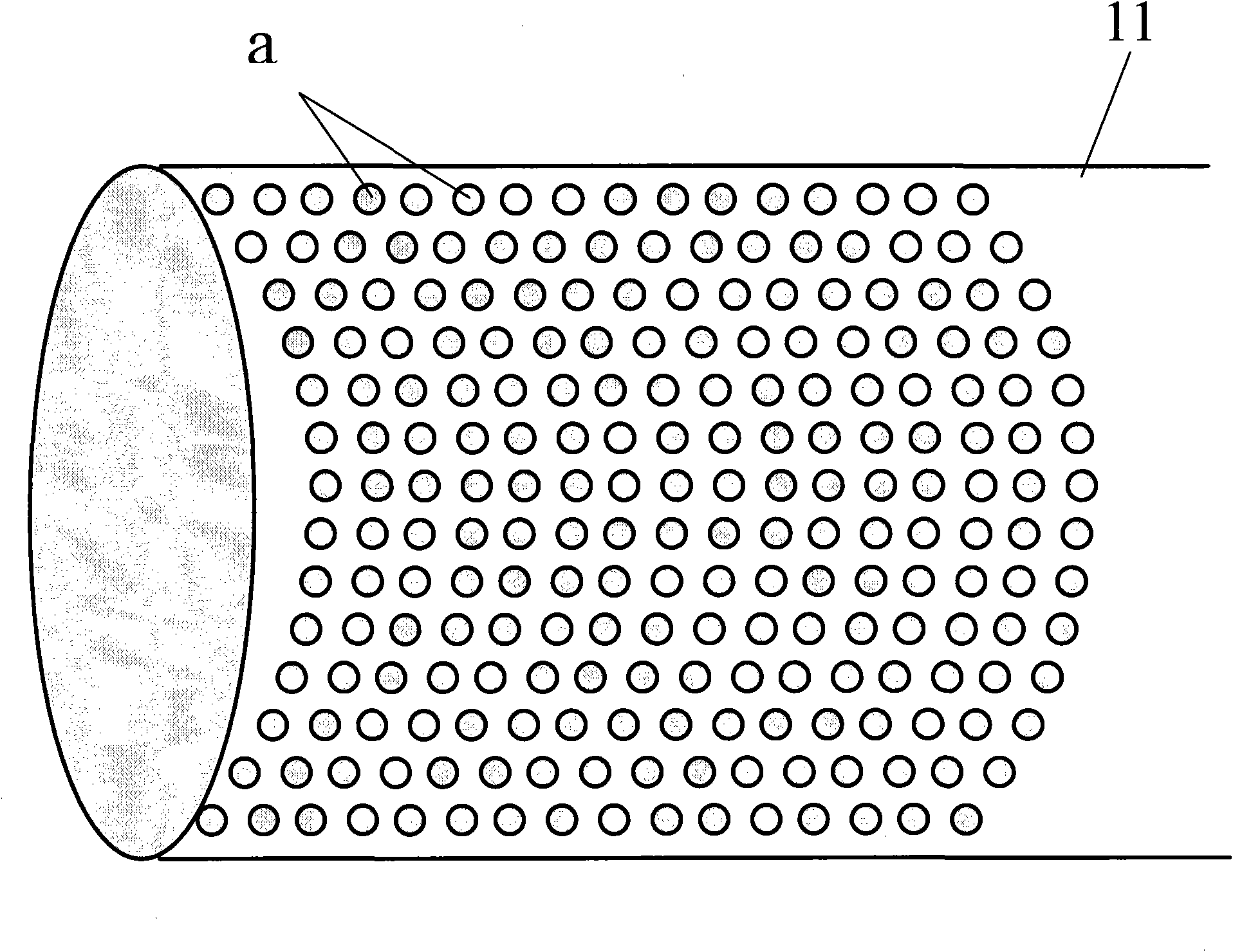

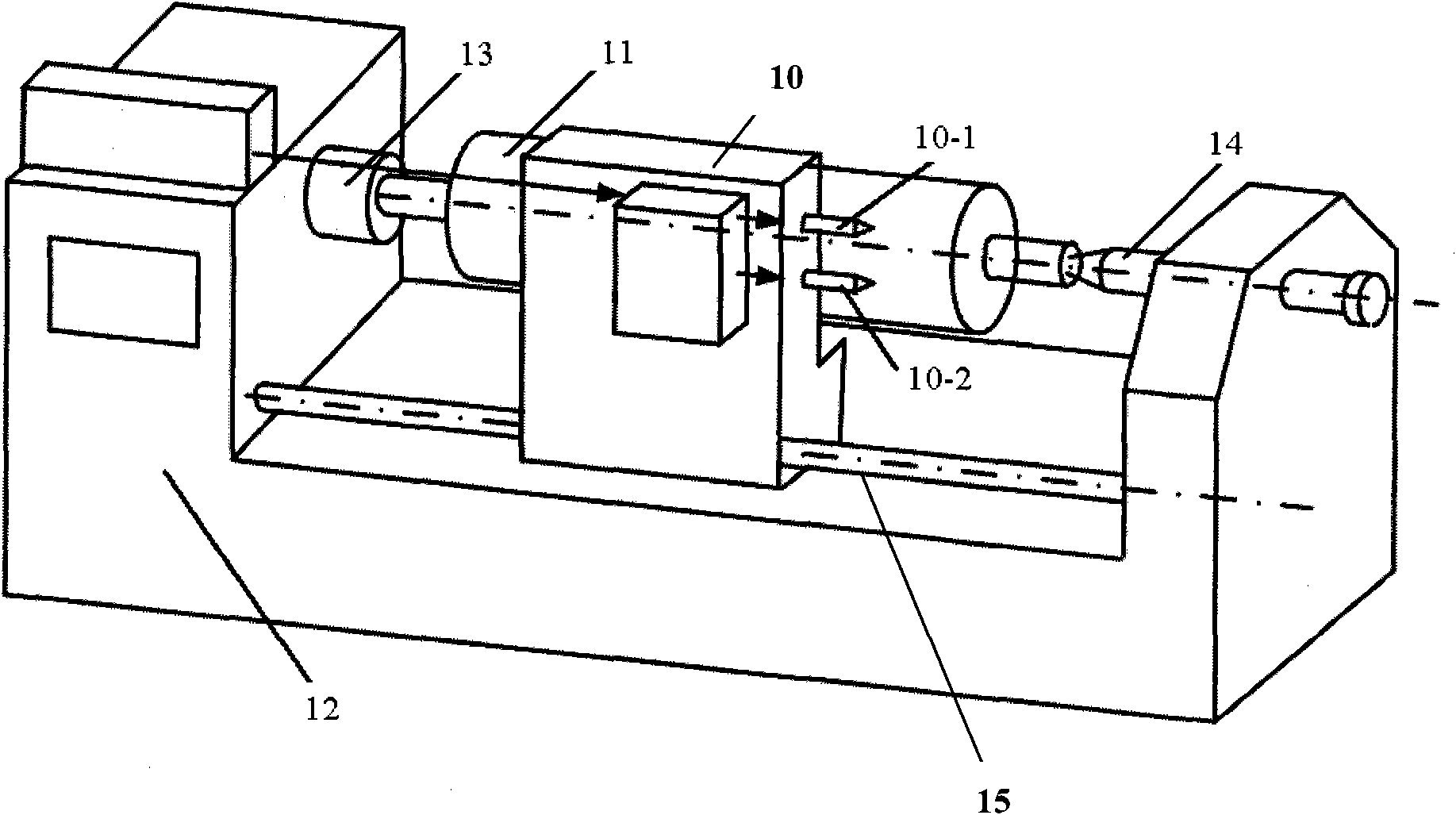

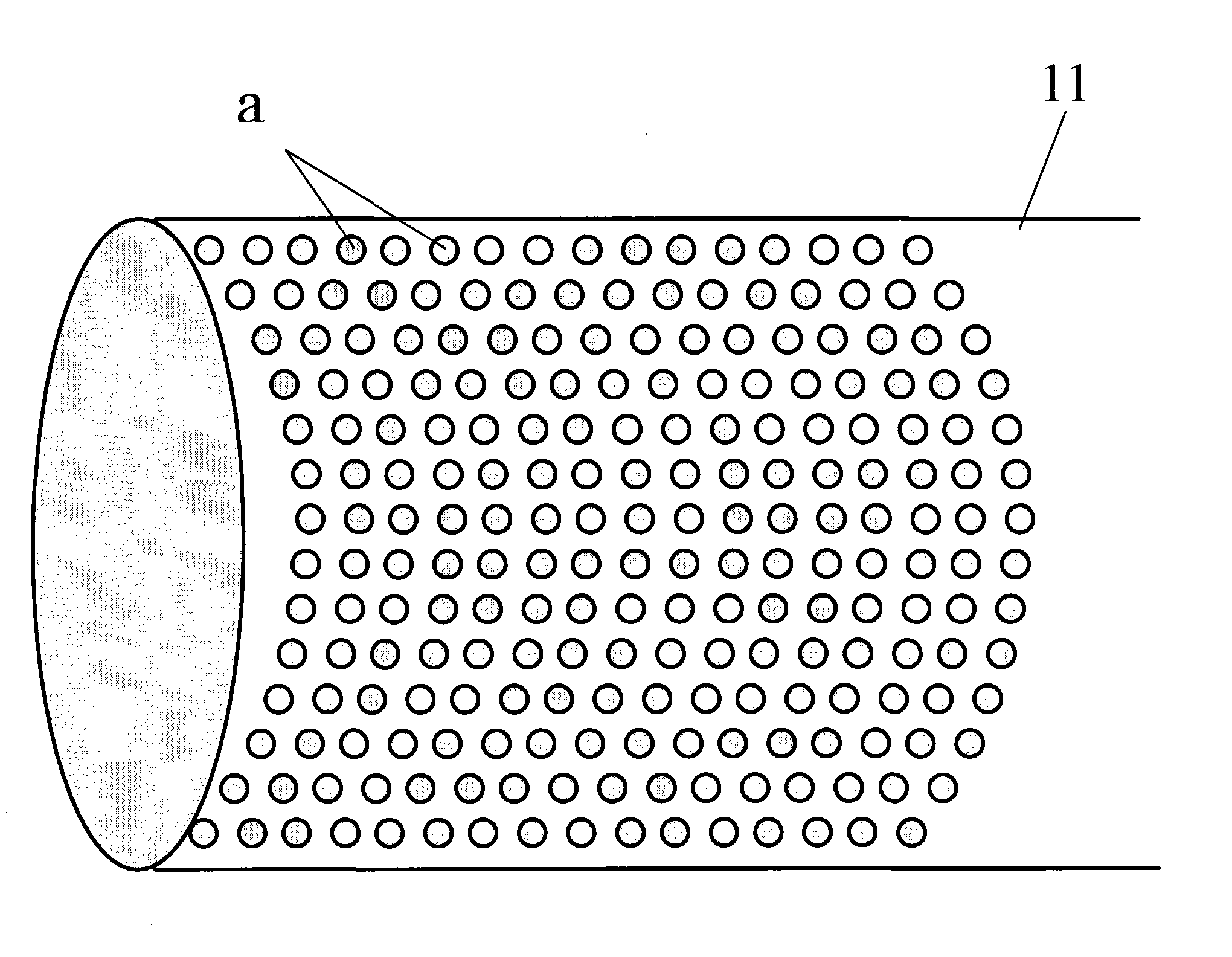

Laser texturing processing method on surface of roller

InactiveCN101642778AImprove rolling qualityImprove wear resistanceRolling equipment maintainenceLaser beam welding apparatusHelical lineSheet steel

The invention discloses a laser texturing processing method on the surface of a roller, comprising the following steps: leading the roller to rotate with uniform velocity along self axes; simultaneously, leading a laser texturing head to move with uniform velocity along the axial direction of the roller; and periodically transmitting laser beam to the surface of the roller and forming texturing spots on the surface of the roller. The method is characterized in that by accelerating the moving speed V of the laser texturing head along the axial direction of the roller, the texturing spots are distributed along the high inclination-angle helical line with the thread pitch of delta being equal to 2-200mm on the roller. As the roller has no smooth straight line between the two rows of the texturing spots on the circumference of the surface of the roller, when rolling a steel plate, the roller and the steel plate can prevent from jointing at those parts, the iron slag grains can be absorbedby texturing concave holes crisscross distributed on the peripheral direction of the roller, scratch can not be produced on the length direction of the steel plate, and the iron slag grains can not fray and break the texturing spots, thereby greatly improving the rolling quality of the steel plate and the wearing resistance of the roller, and prolonging the service life of the roller.

Owner:苏州市博海激光科技有限公司

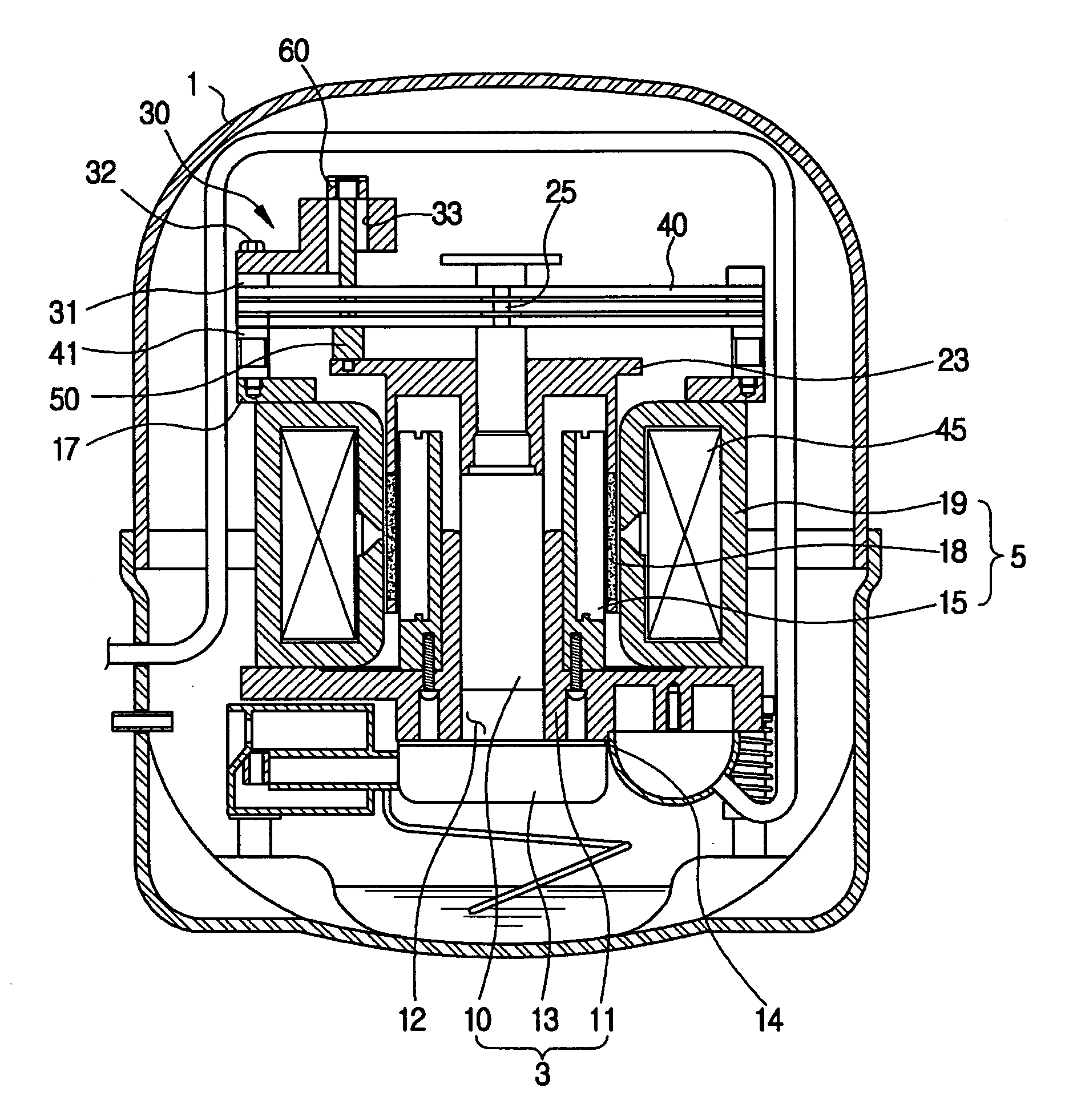

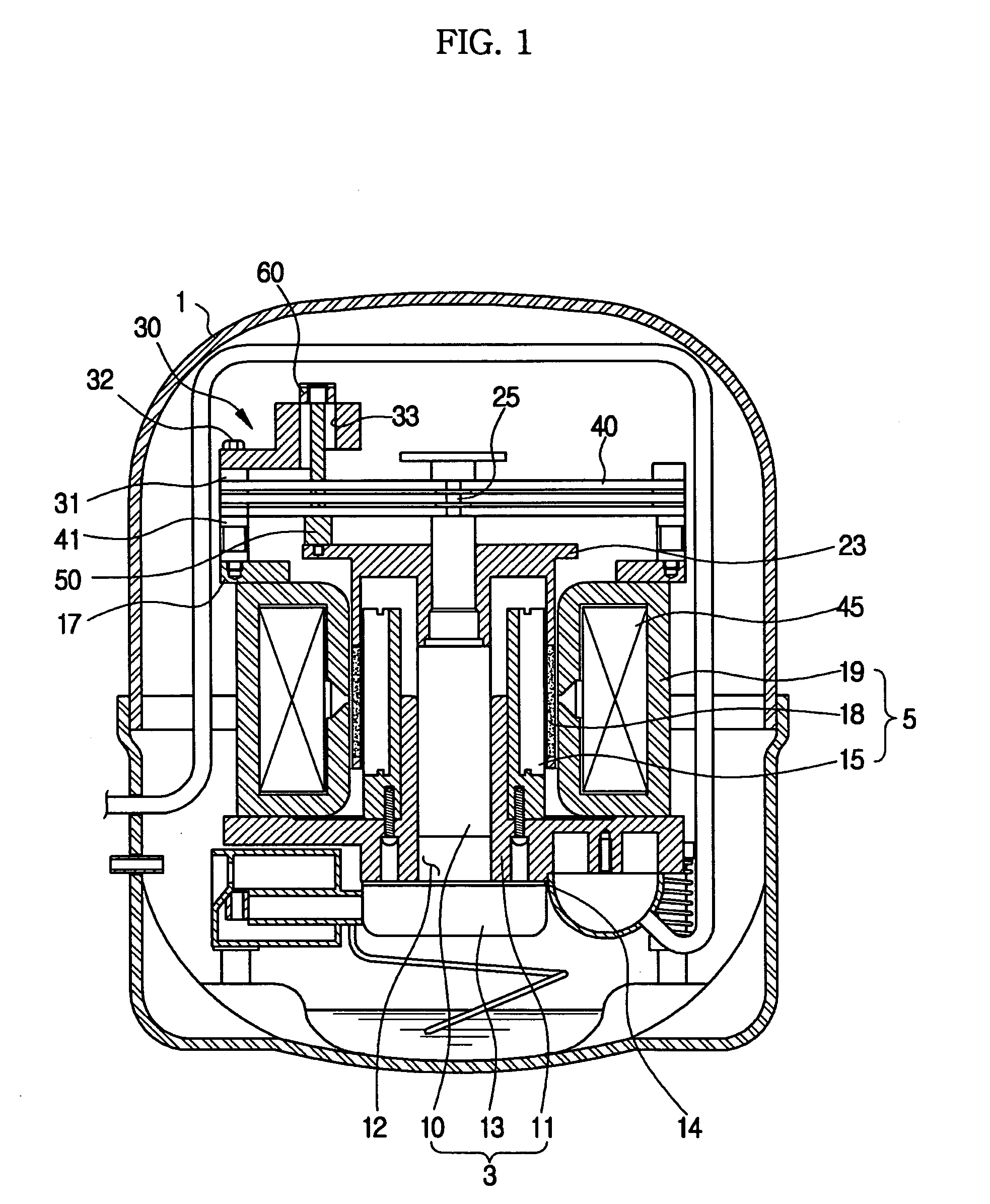

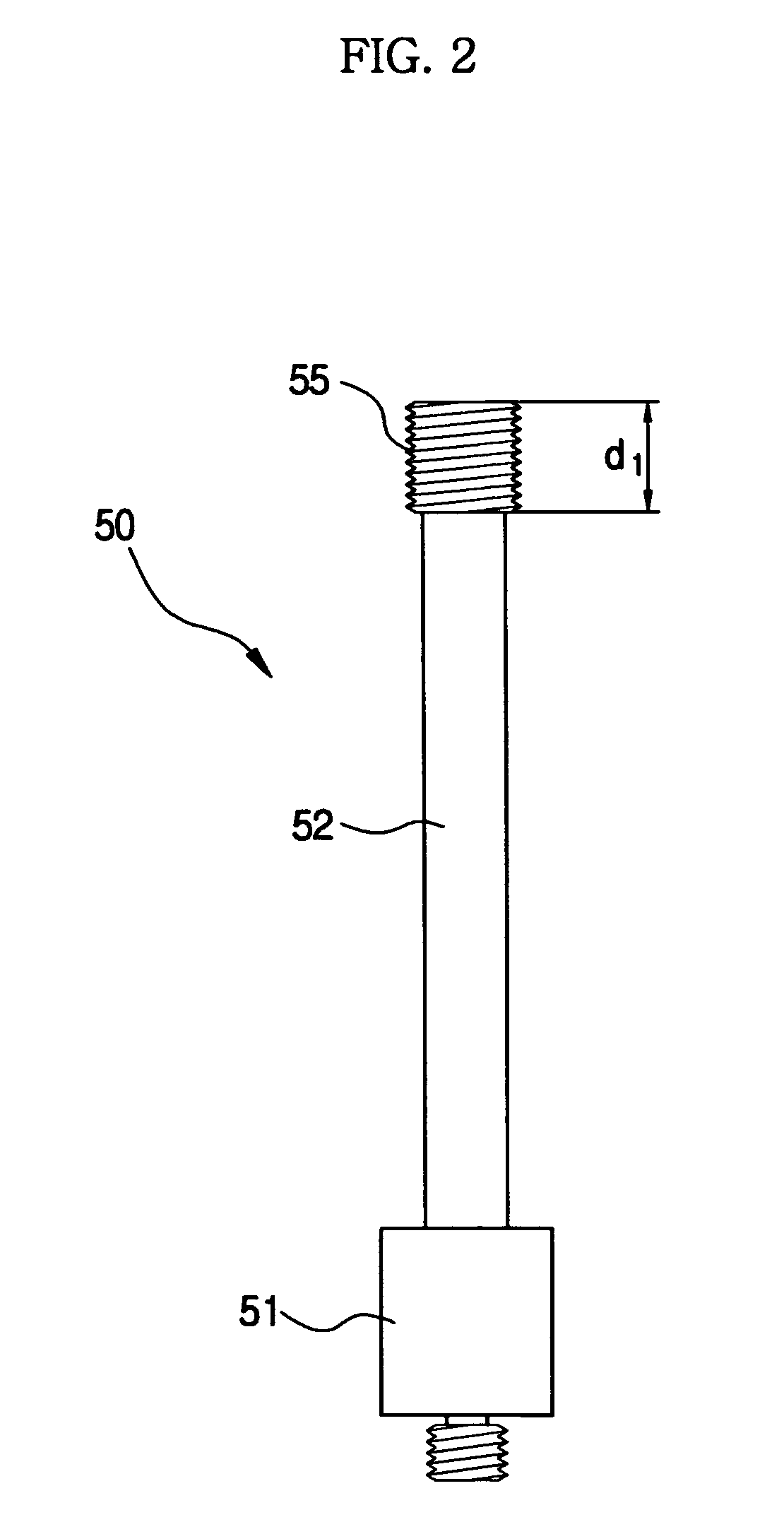

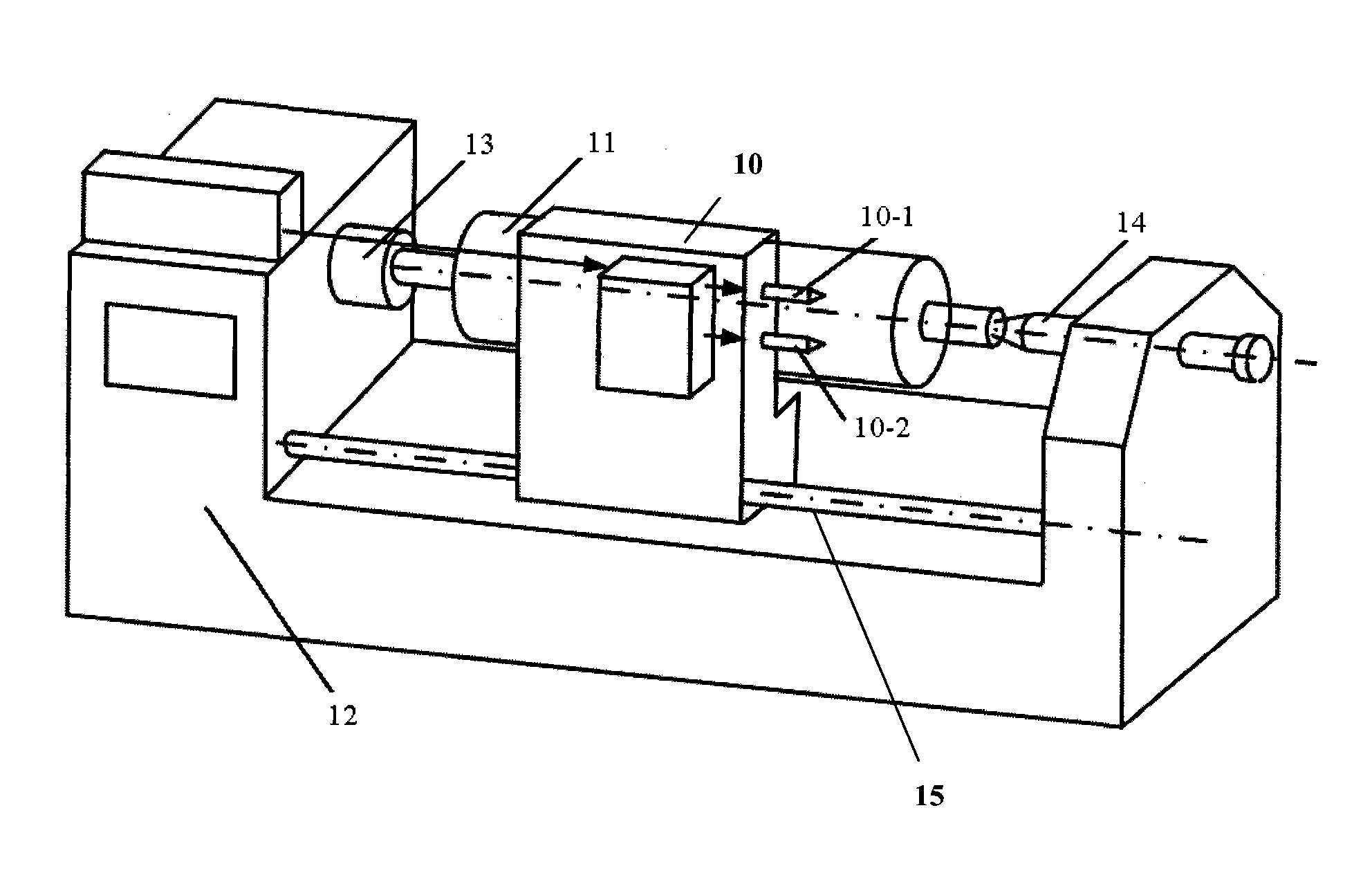

Linear compressor with sensor

InactiveUS20050260086A1Improve productivityReduce manufacturing costEngine fuctionsWorking fluid for enginesProduction rateLinear compressor

Disclosed herein is a linear compressor having a sensor for detecting the position of a piston. The linear compressor has a position-detecting unit for detecting the position of a piston. The position-detecting unit comprises a sensor core mounted such that the sensor core can be moved along with the piston and the position of the sensor core can be adjusted, and a sensor having a detection hole formed therein for detecting the position of the sensor core disposed in the detection hole. The sensor is fixed to a fixing frame. The sensor core is engaged with a core-supporting member in such a manner that the height of the sensor core can be adjusted without using washers for adjusting the height of the sensor, whereby productivity is improved and manufacturing costs are reduced.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

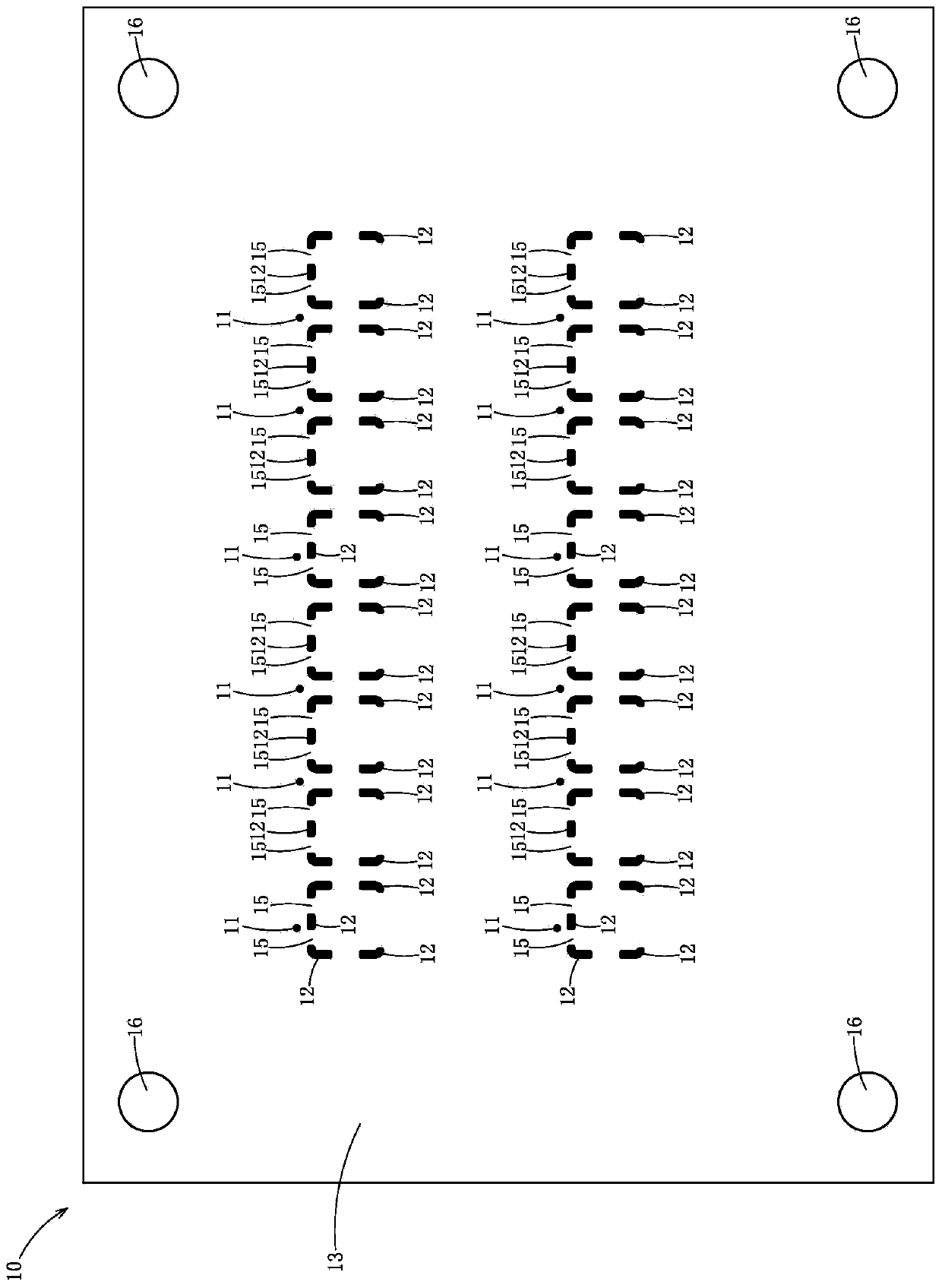

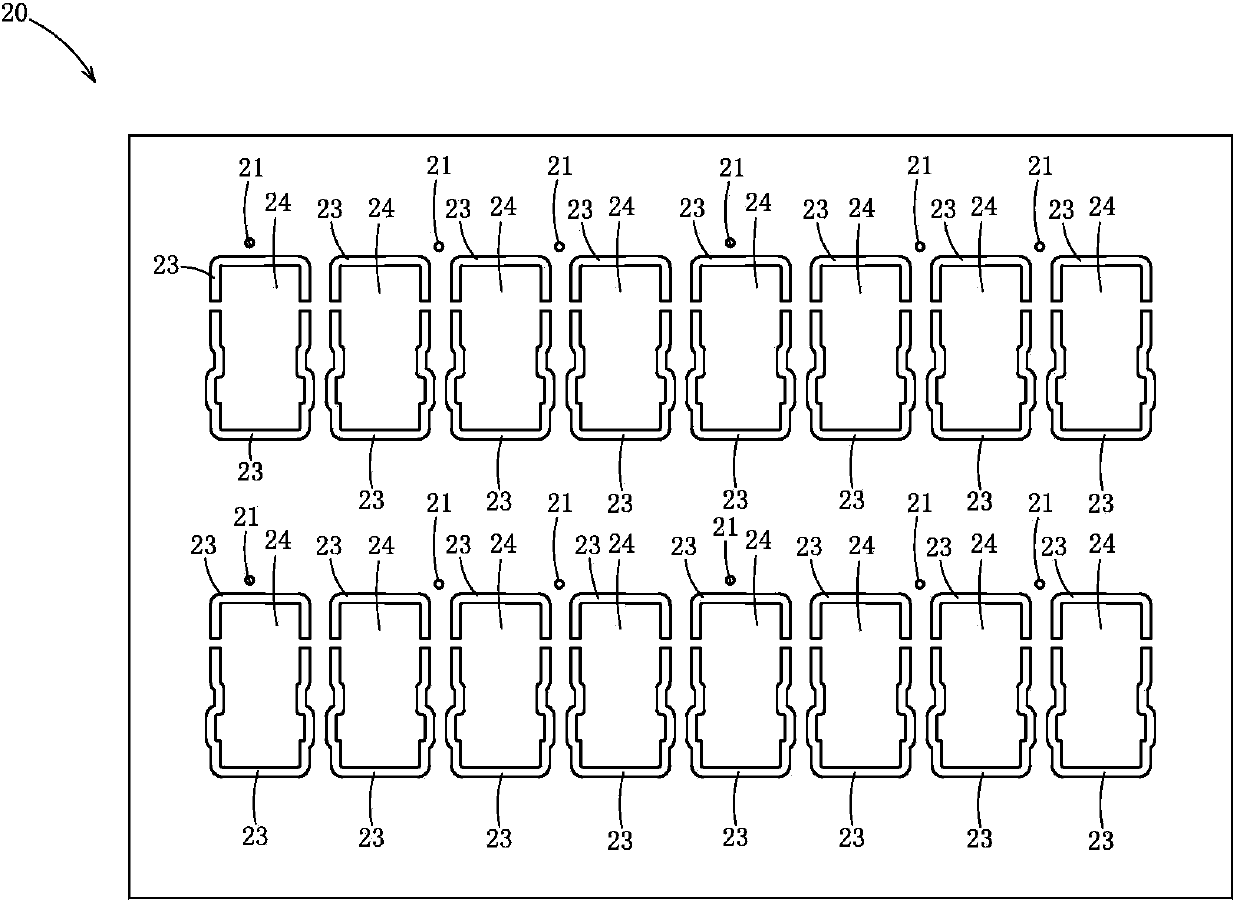

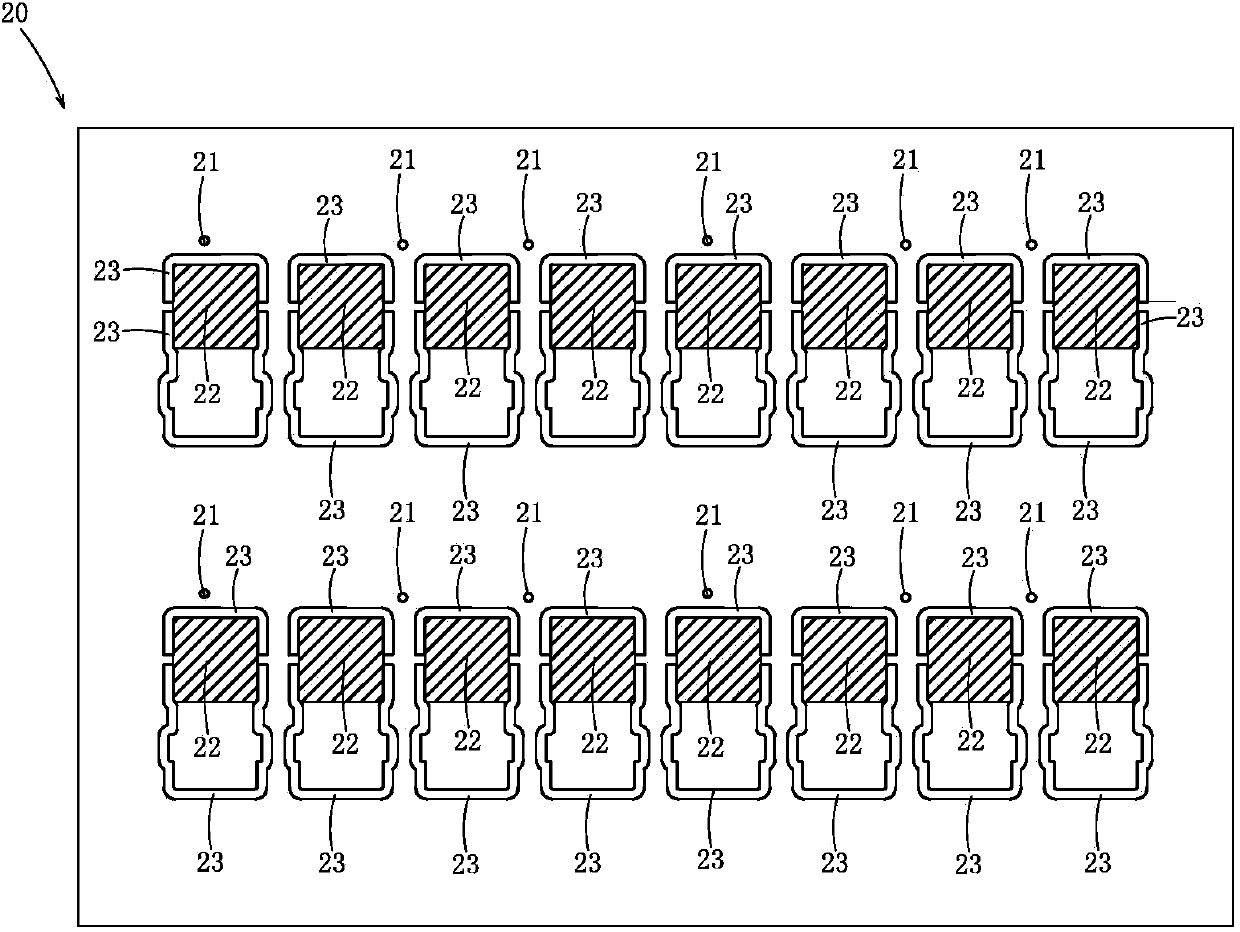

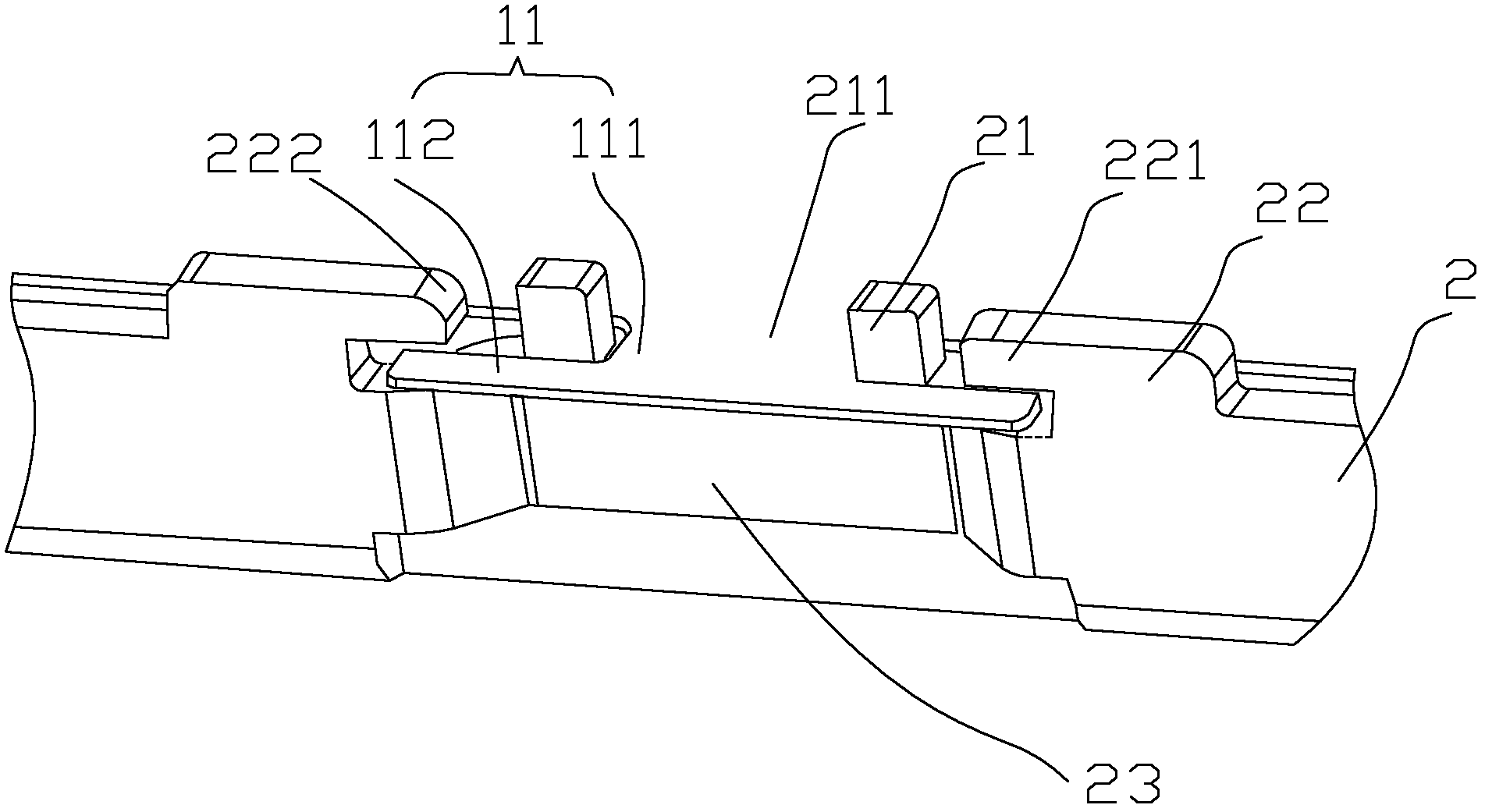

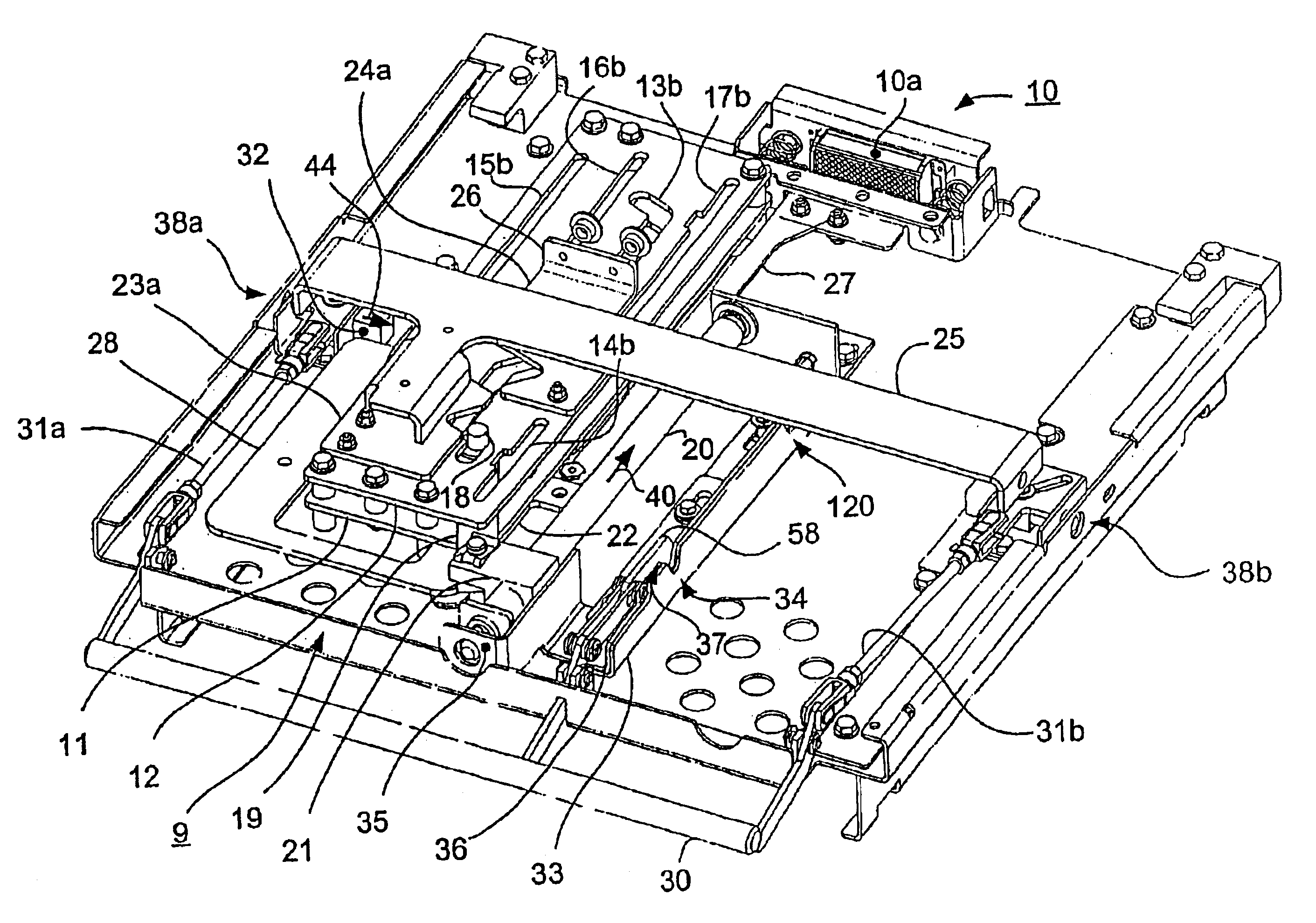

Attaching method of steel sheet enhancing sheets of flexible circuit board, jigs of flexible circuit board, and strip attaching steel sheets of flexible circuit board

ActiveCN103731991AAdvantages of bonding methodAvoid fitPrinted circuit detailsPrinted circuit manufactureFlexible circuitsEngineering

The invention discloses an attaching method of steel sheet enhancing sheets of a flexible circuit board, jigs of the flexible circuit board, and strip attaching steel sheets of the flexible circuit board. The method includes the first step of arranging pure glue, covering enhancing sheet attaching positions located on the upper portion inside all regions surrounded by all grooves, on all rows of grooves of the flexible circuit board, the second step of enabling position fixing stop dogs corresponding to the jigs to be sleeved with all the rows of grooves of the flexible circuit board, and enabling upper positioning pins to be sleeved with first positioning holes above all the rows of grooves, the third step of attaching the steel sheet enhancing sheets of the strip attaching steel sheets corresponding to all the rows of grooves to the pure glue in the enhancing sheet attaching positions, and enabling each positioning pin to be sleeved with the corresponding strip attaching steel sheet through a second positioning hole of a connecting rib, the fourth step of placing the jigs into a false attaching machine along with the flexible circuit board and the strip attaching steel sheets to be pressed in advance, pressing the pure glue through a hot press after pressing is conducted through the false attaching machine in advance, and enabling all the steel sheet enhancing sheets to be attached to the enhancing sheet attaching positions of the flexible circuit board, and the fifth step of stripping all the connecting ribs of the strip attaching steel sheets from the steel sheet enhancing sheets on the connecting ribs. According to the method, the multiple enhancing sheets can be simultaneously attached, the attaching efficiency is improved, and the operation is convenient.

Owner:SHENZHEN HUALIN CIRCUIT TECH

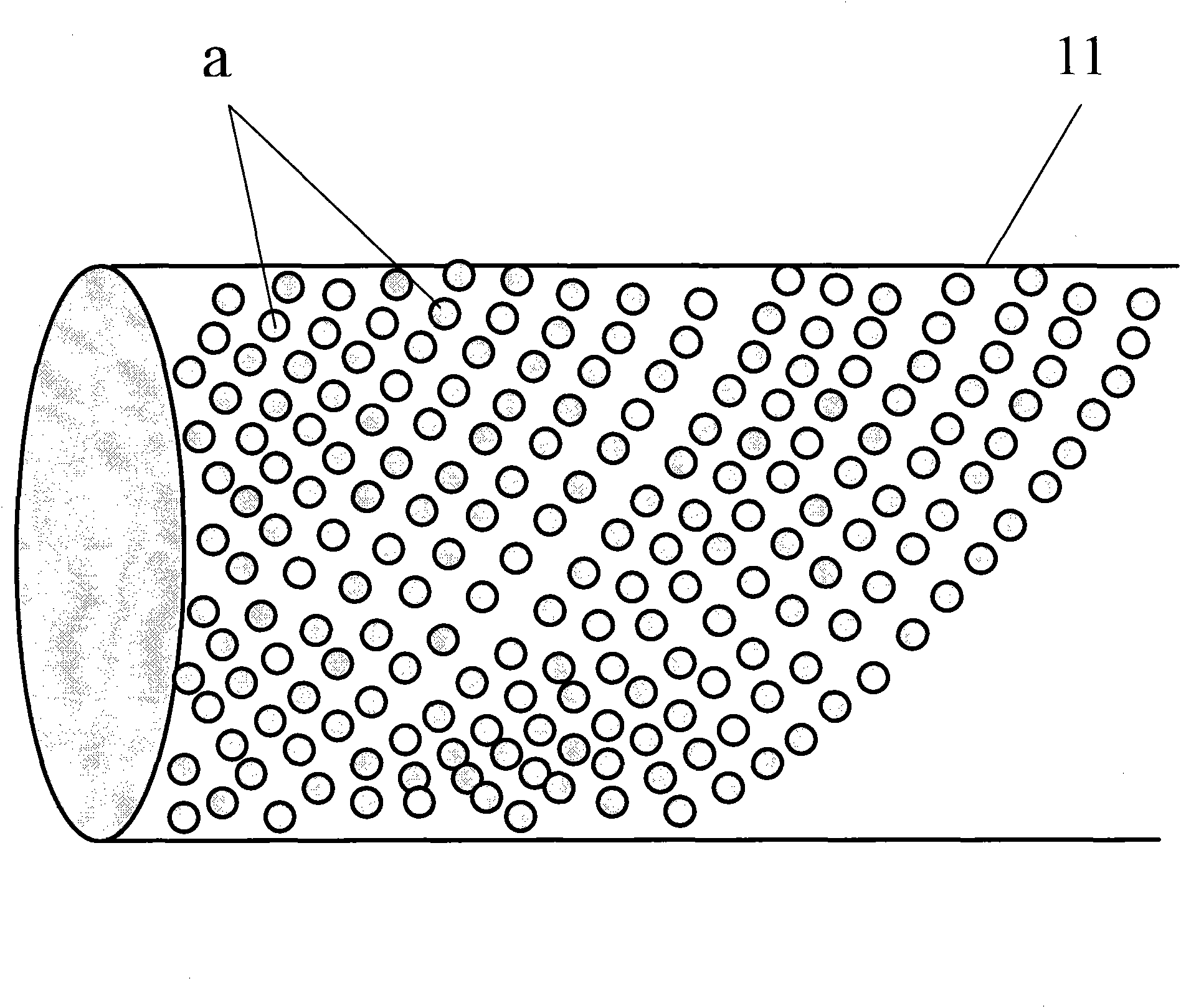

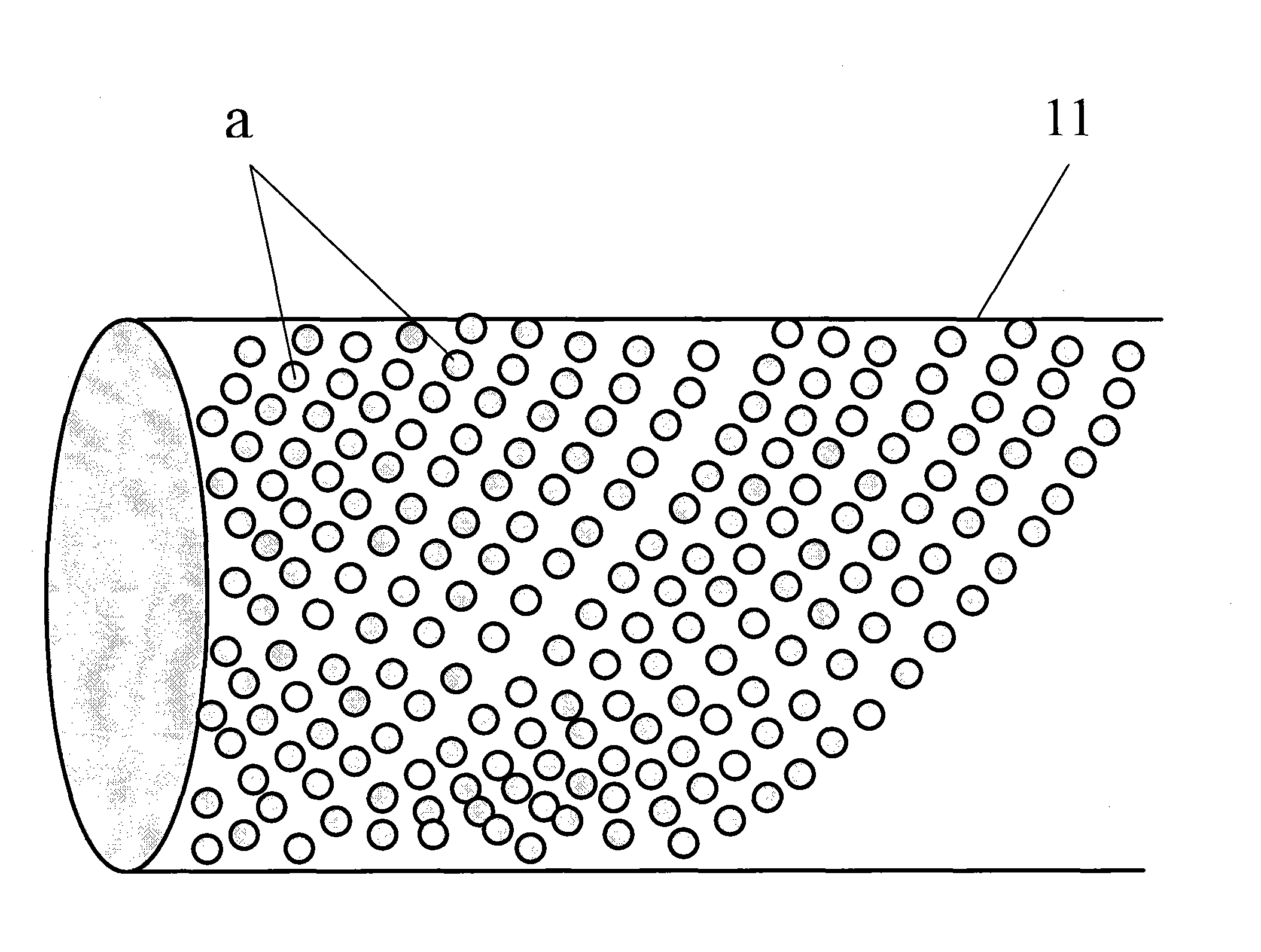

Laser texturing processing method on surface of roller

InactiveCN101642849AImprove rolling qualityImprove wear resistanceLaser beam welding apparatusSheet steelSlag

The invention discloses a laser texturing processing method on the surface of a roller, comprising the following steps: leading the roller to rotate with uniform velocity along self axes; leading a laser texturing head to move with uniform velocity along the axial direction of the roller; and periodically transmitting laser beam to the surface of the roller and forming texturing spots on the surface of the roller. The method is characterized by leading focal light spots to randomly swing with low amplitude from left and right at a preset spiral line so as to produce the irregularly distributedtexturing spots on the surface of the roller. As the roller has no smooth straight line between the two rows of the texturing spots on the circumference of the surface of the roller, when rolling a steel plate, the roller and the steel plate can prevent from jointing at those parts, the iron slag grains can be absorbed by texturing concave holes crisscross distributed on the peripheral directionof the roller, scratch can not be produced on the length direction of the steel plate, and the iron slag grains can not fray and break the texturing spots, thereby greatly improving the rolling quality of the steel plate and the wearing resistance of the roller, and prolonging the service life of the roller.

Owner:苏州市博海激光科技有限公司

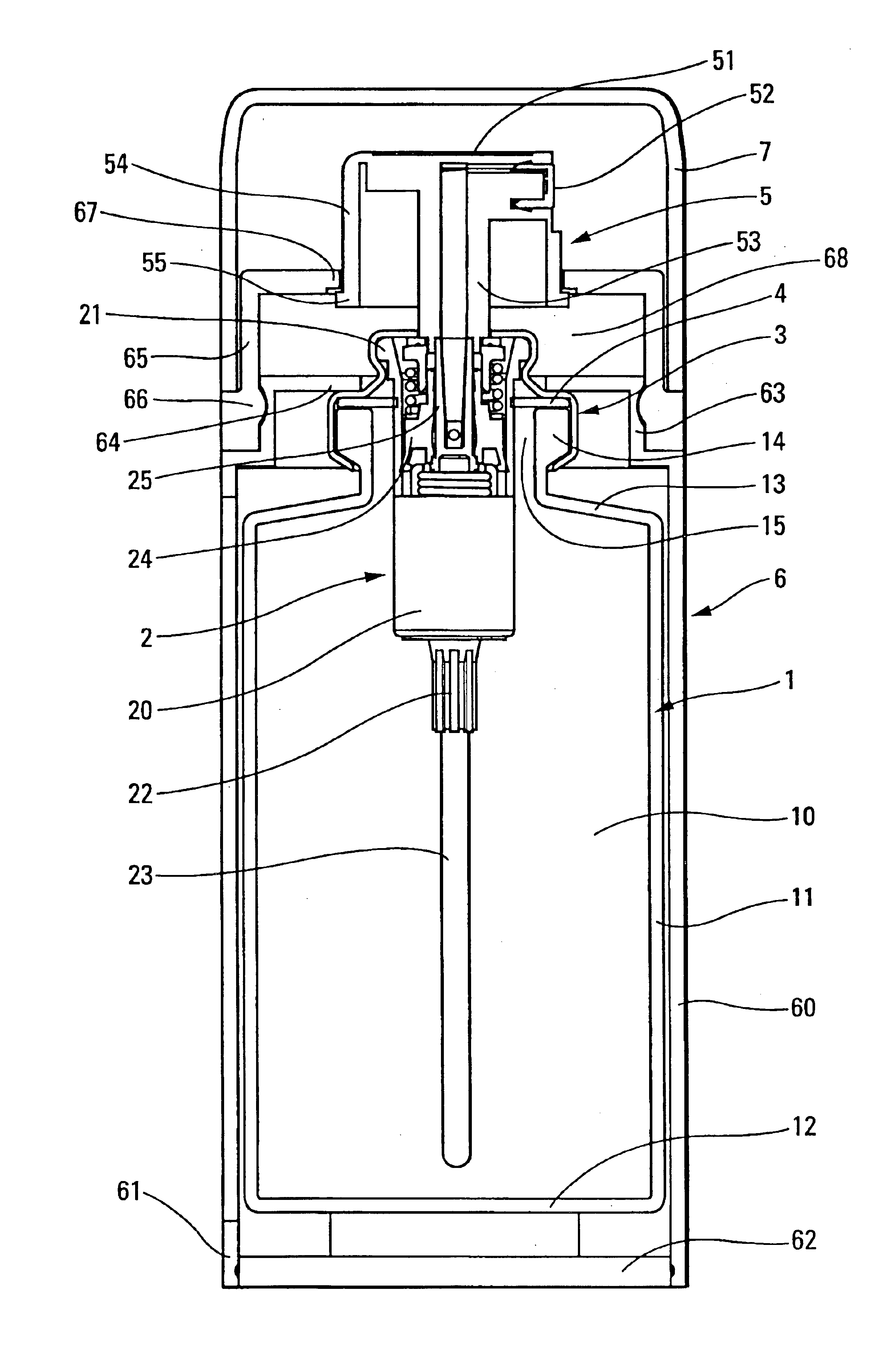

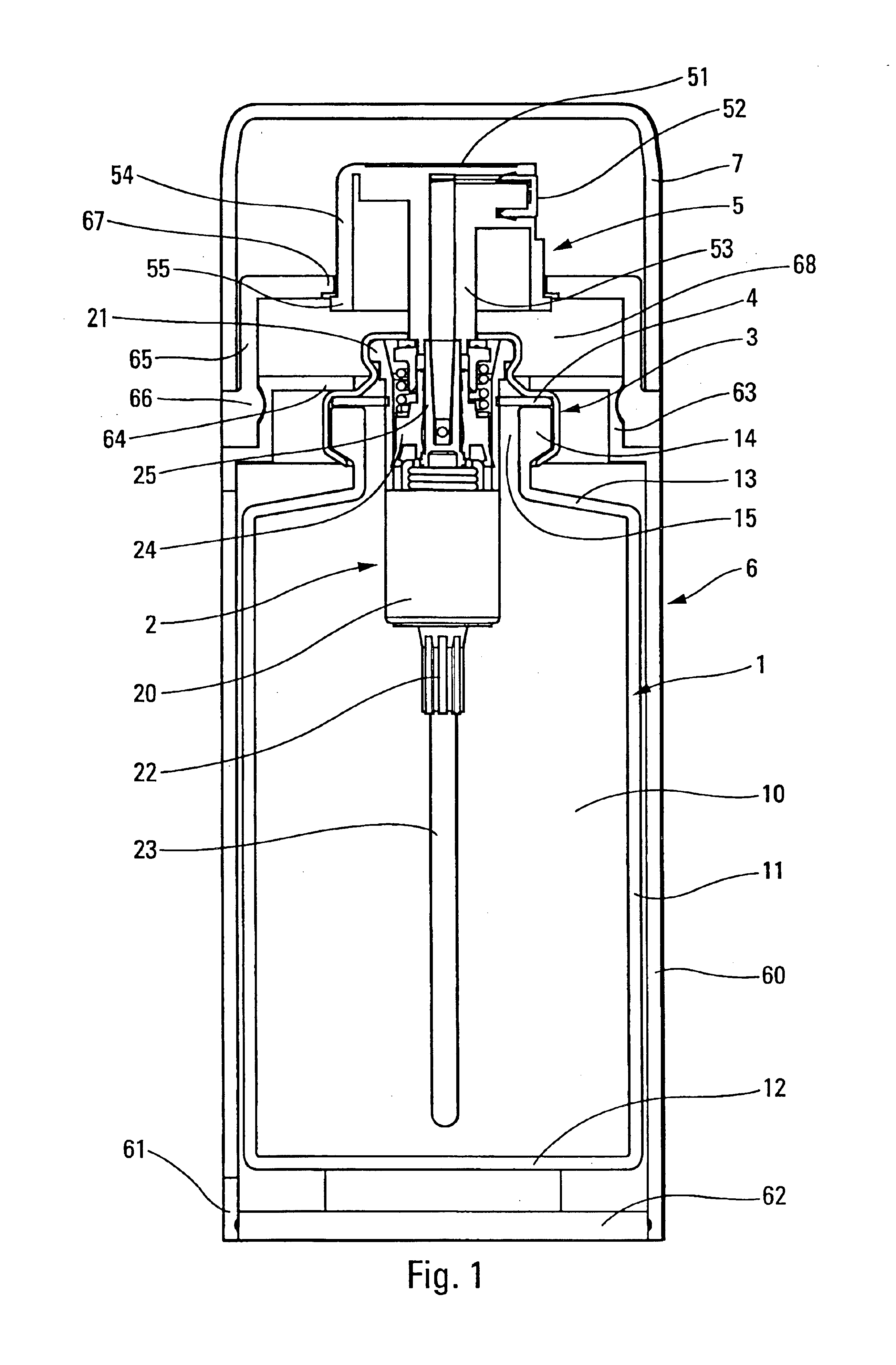

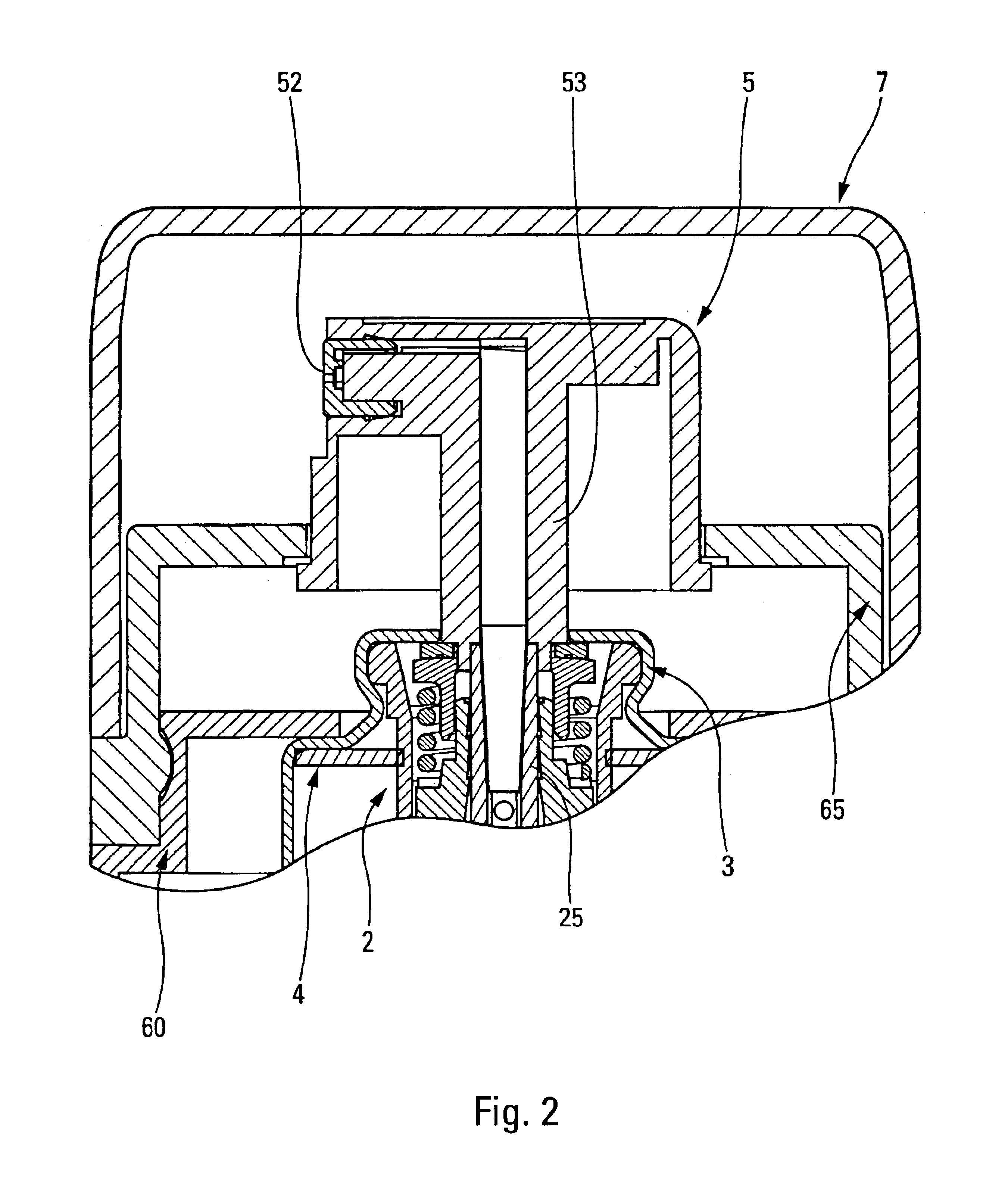

Fluid dispenser

A fluid dispenser, including: a receptacle defining a fluid reservoir and an opening; a dispensing member fitted in the opening of the receptacle, and provided with an actuating rod, and a pusher serving to be fitted to the actuating rod of the dispensing member. A trim shell is provided in which an assembly made up of the receptacle and of its dispensing member is adapted to be held in removable manner, and in that the pusher is held captive by the trim shell so that the actuating rod can be connected to the pusher only when inside the trim shell.

Owner:VALOIS SA

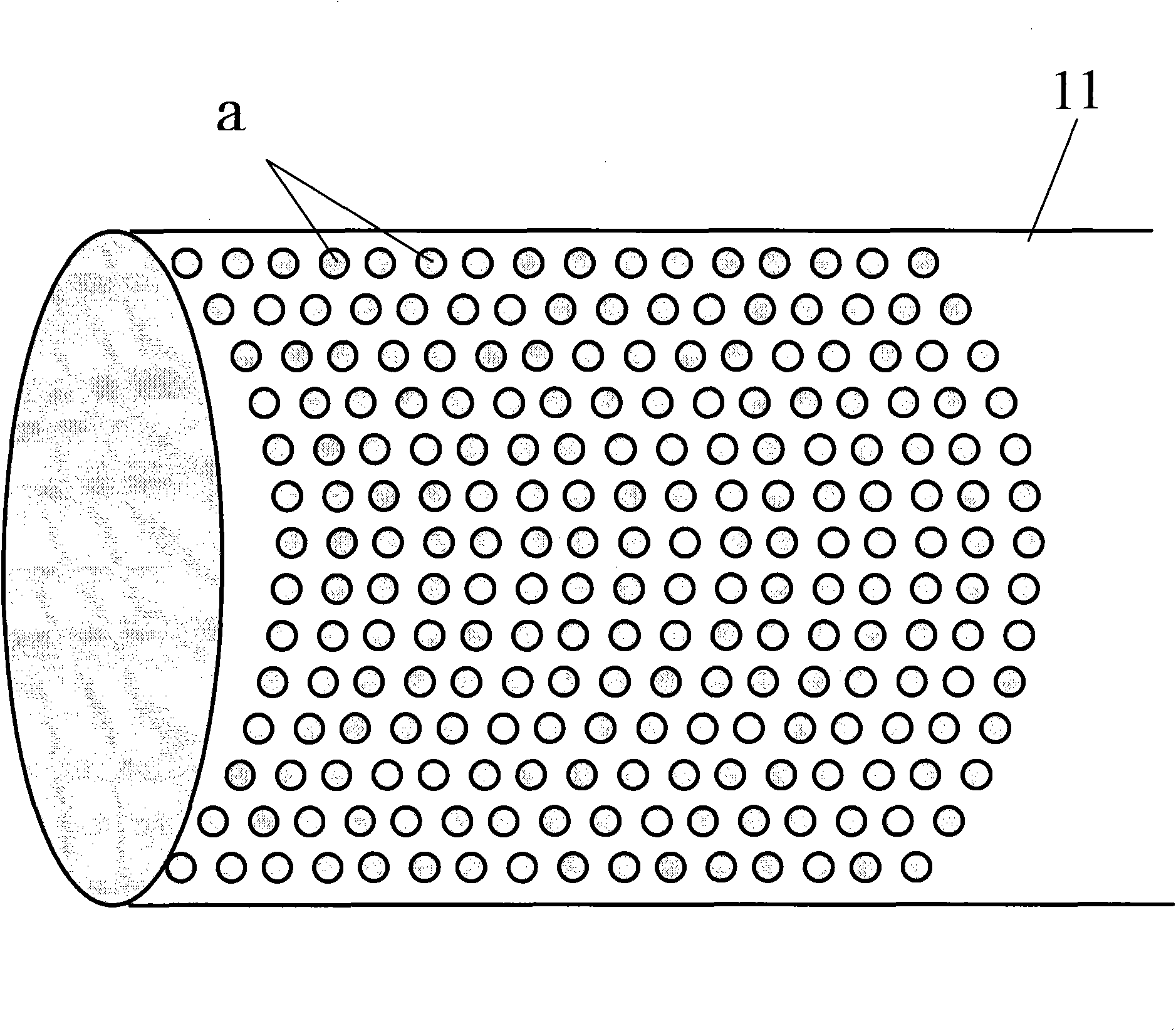

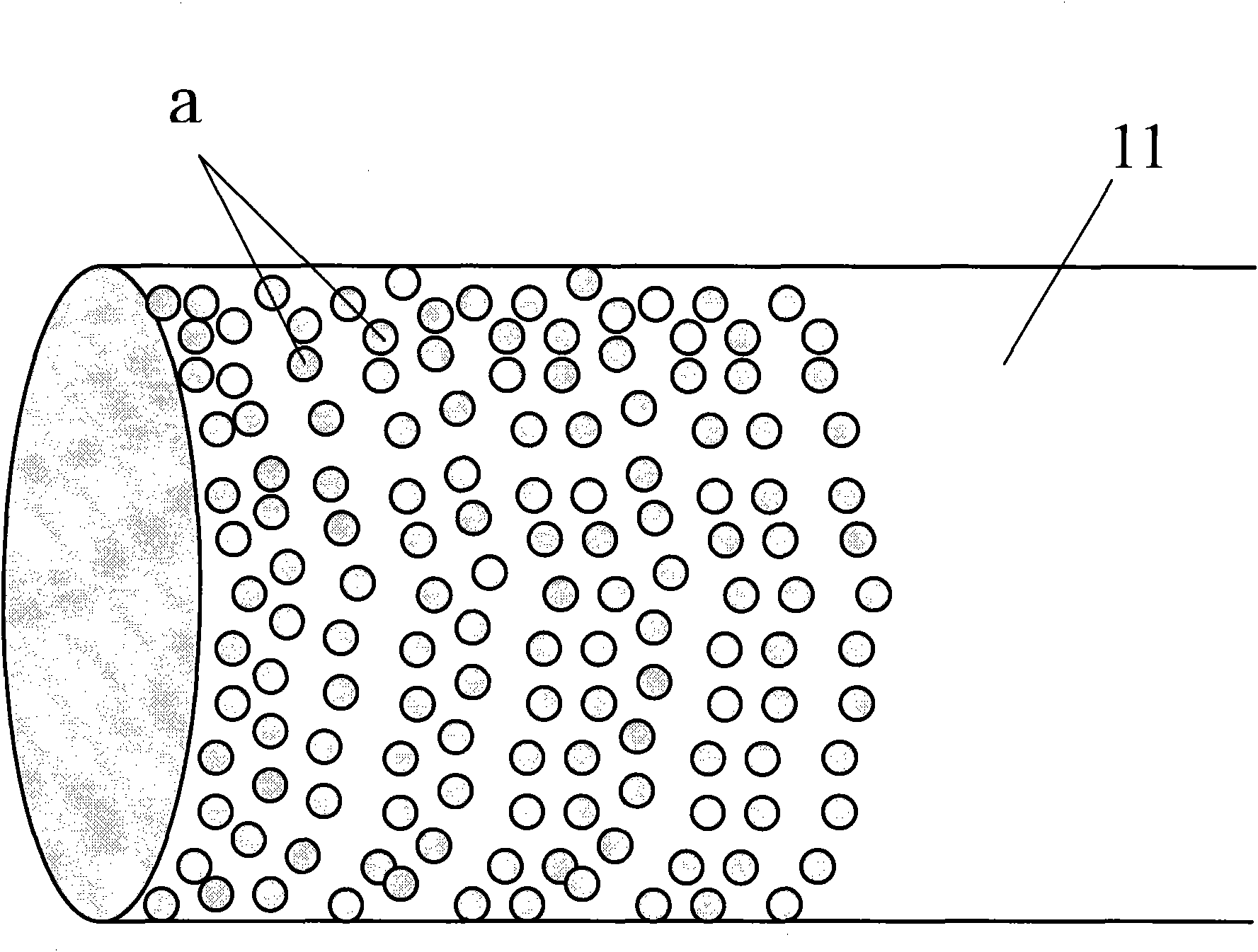

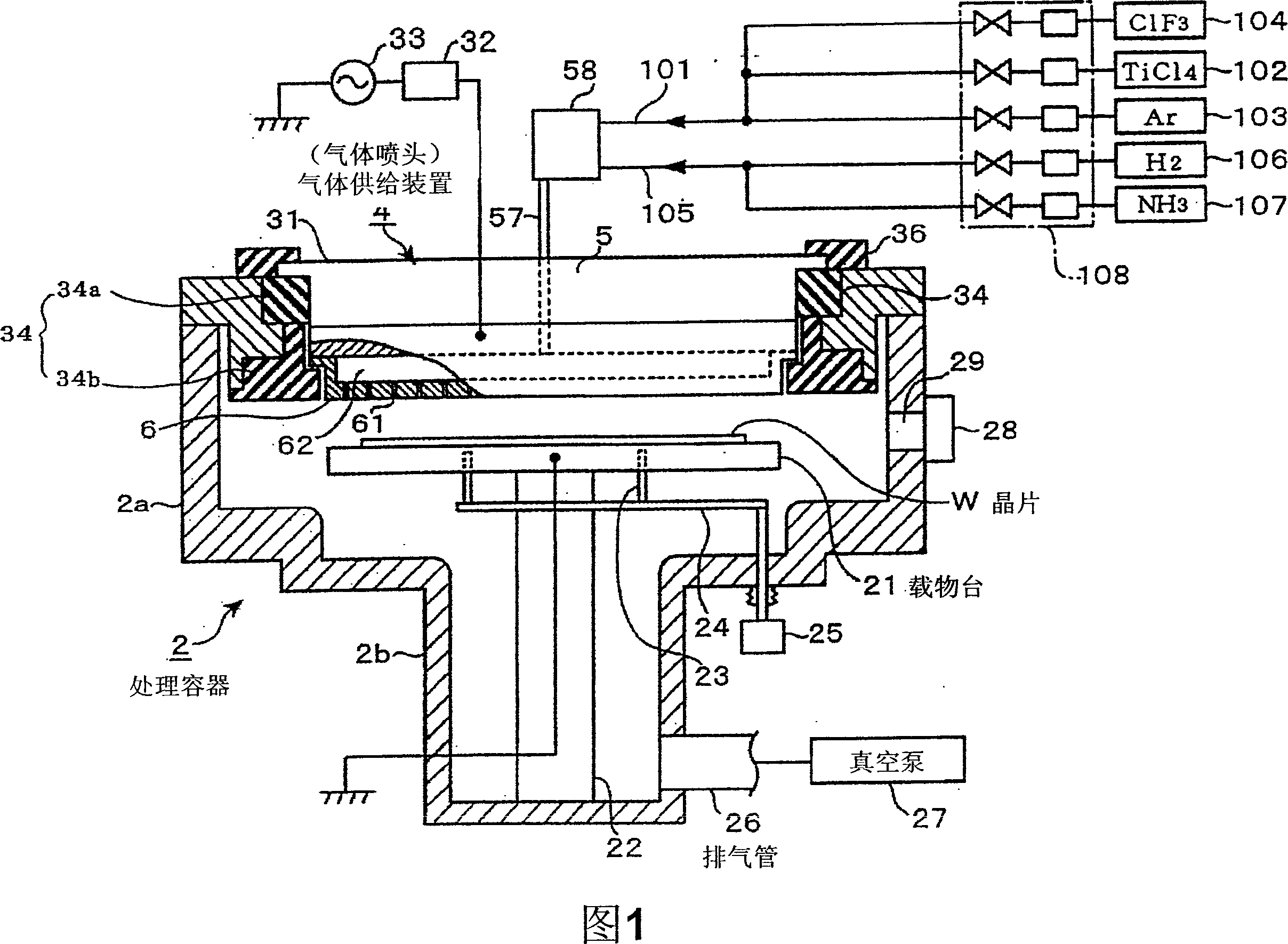

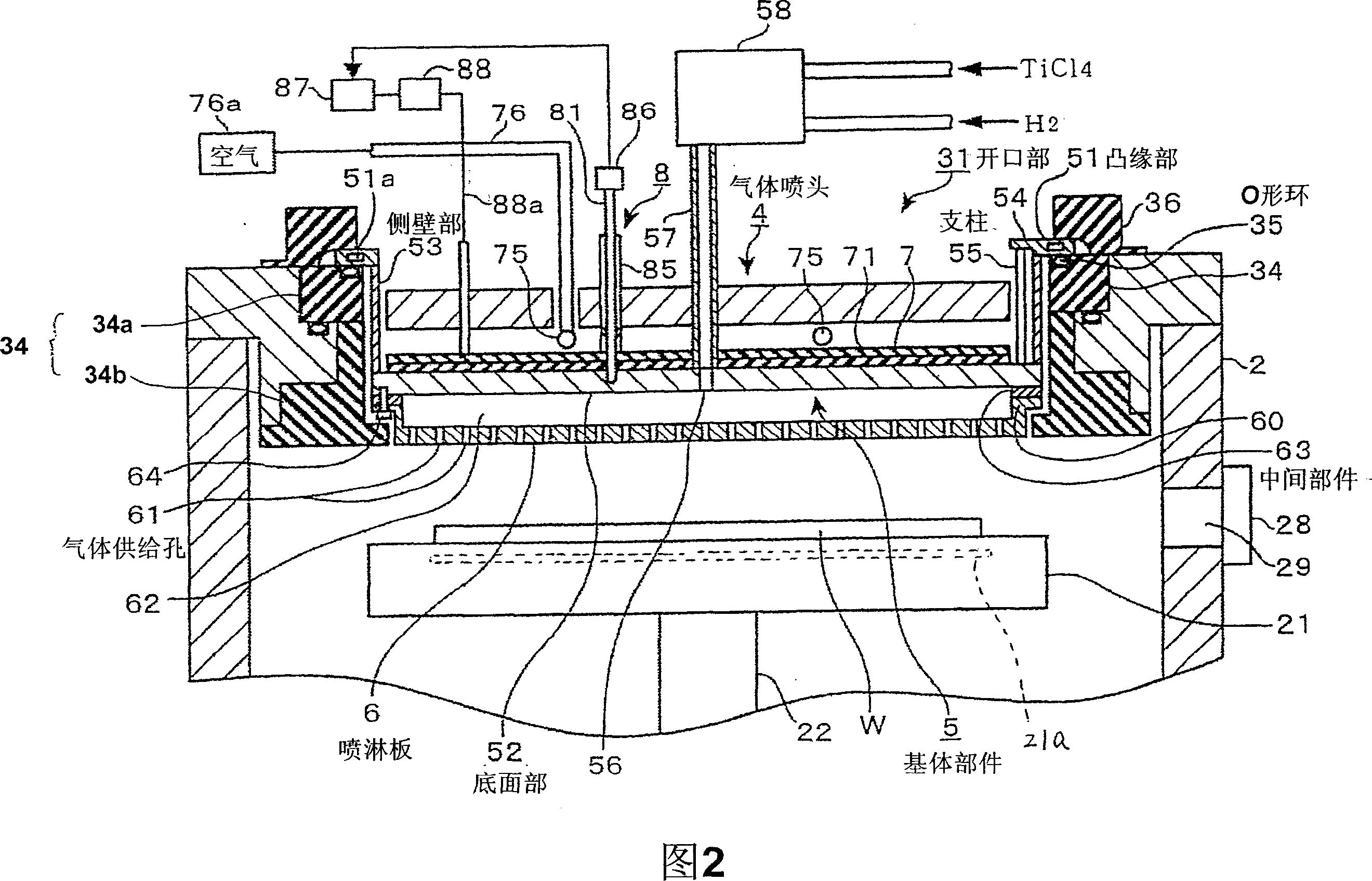

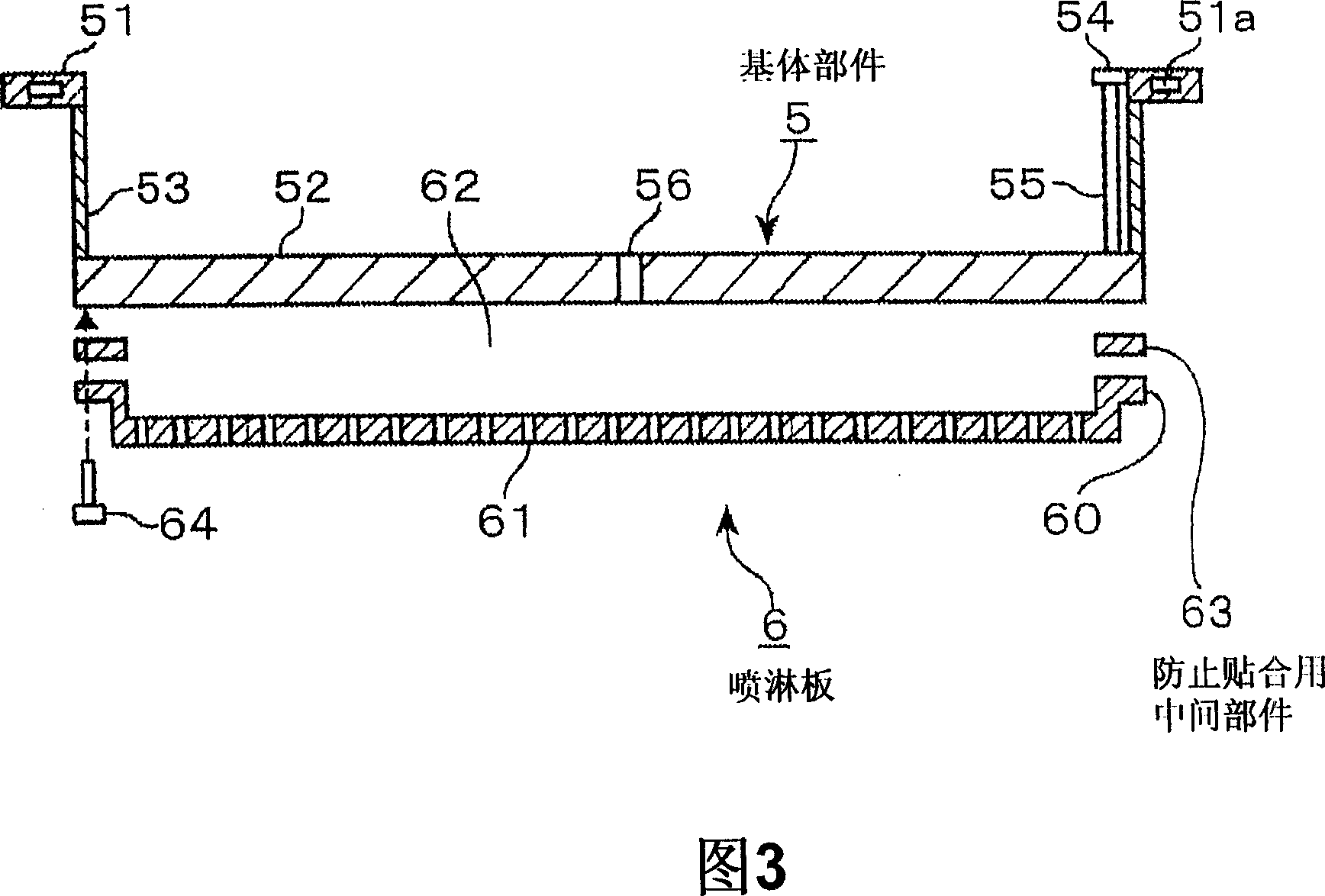

Gas supplying unit and substrate processing apparatus

ActiveCN1958170AAvoid fitPromote decompositionElectric discharge tubesVacuum evaporation coatingEngineeringProcess engineering

The invention relates to a gas supplying unit to be arranged to hermetically fit in an opening formed at a ceiling part of a processing container for conducting a process to a substrate. The gas supplying unit includes a plurality of nickel members. A large number of gas-supplying holes is formed at a lower surface of the gas supplying unit, a process gas is adapted to be supplied from the large number of gas-supplying holes into the processing container, and the plurality of nickel members is fixed to each other via an intermediate member for preventing sticking made of a material different from nickel.

Owner:TOKYO ELECTRON LTD

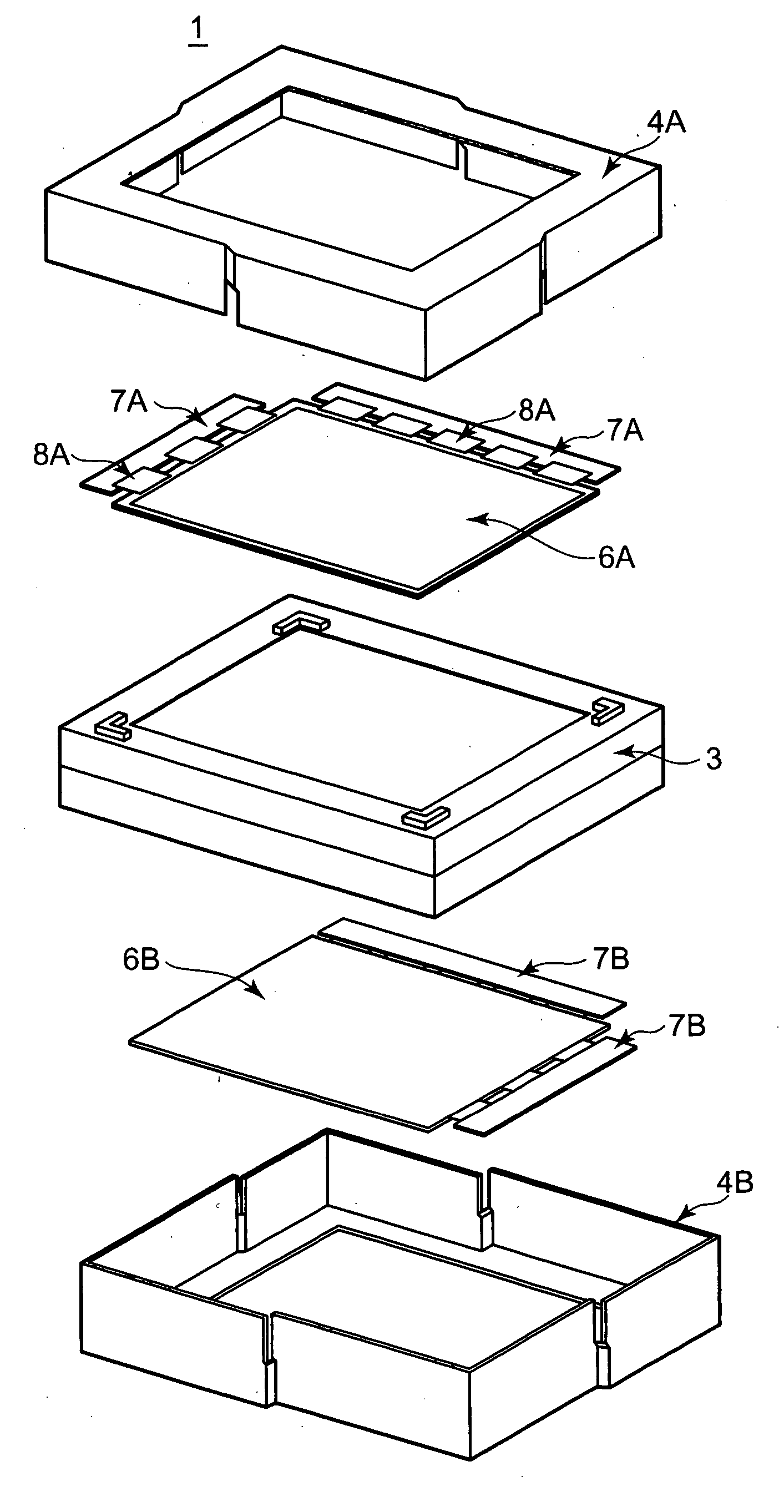

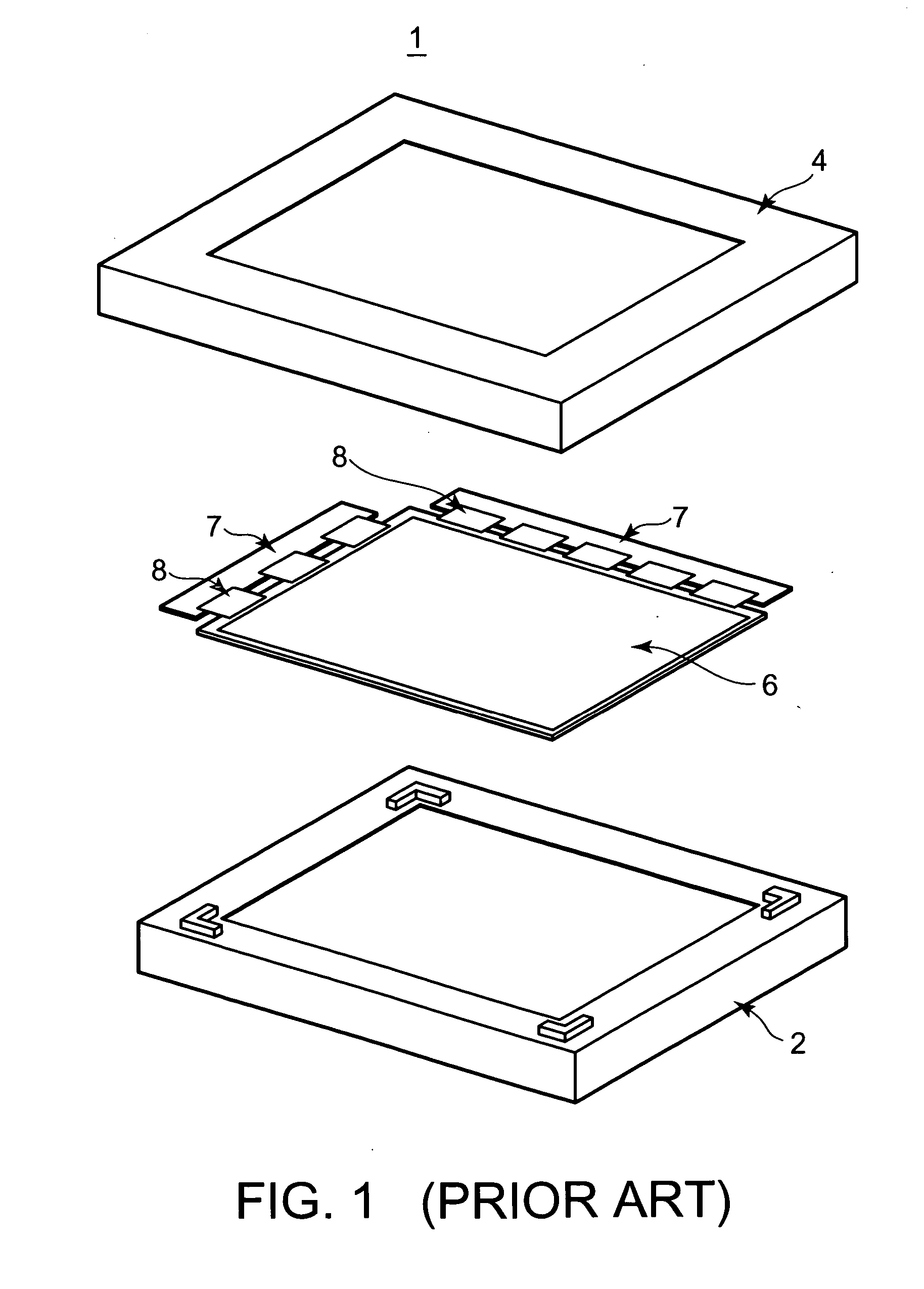

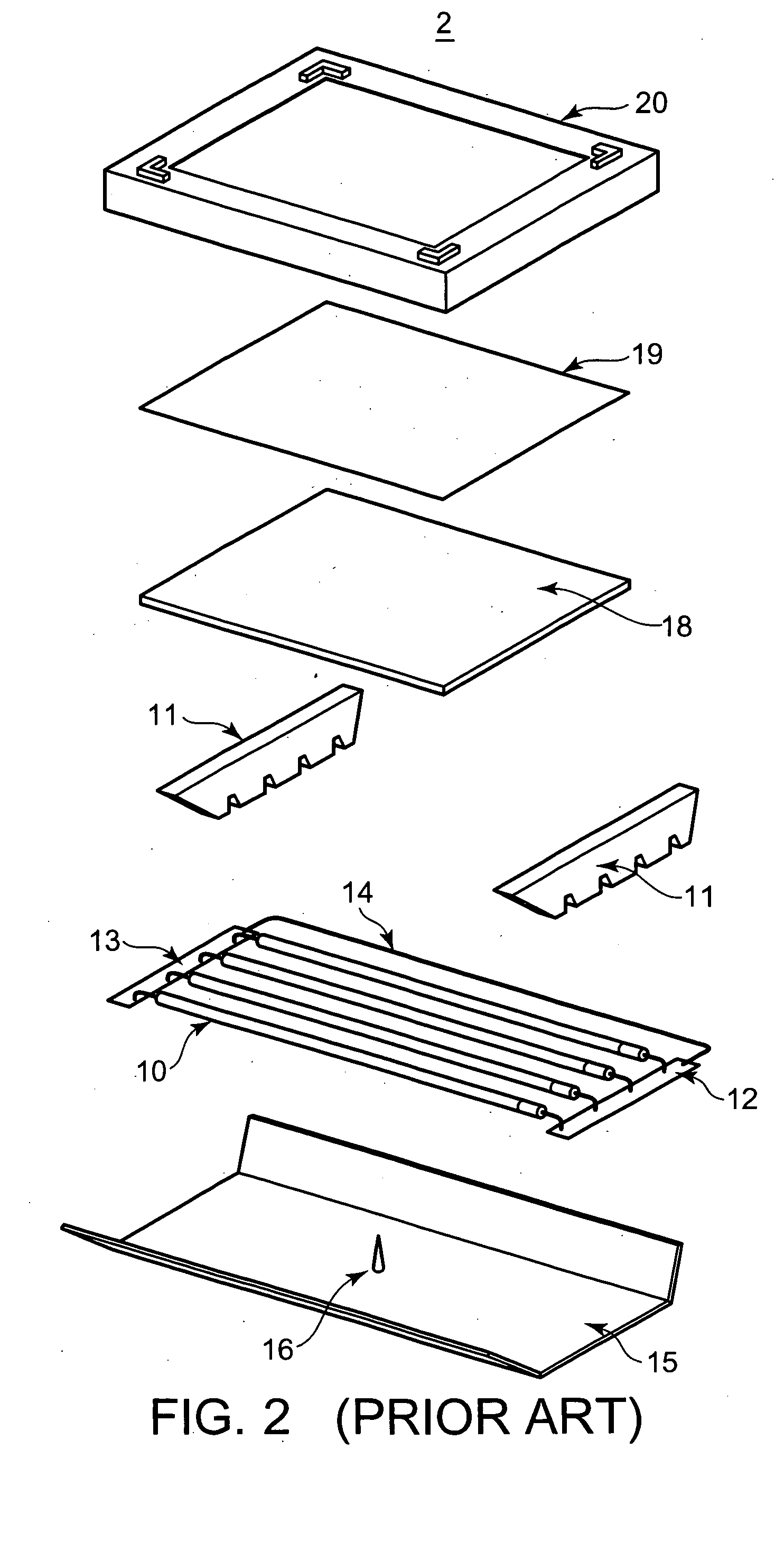

Housing and display device provided with the housing

ActiveUS20050151895A1High strengthStrong and stable structureNon-linear opticsIdentification meansLiquid-crystal displayDisplay device

A housing for holding and fixing components of a liquid crystal display device is composed of a pair of frame members each having the same shape. Four sides of the side face of each frame member are formed such that an outer face section positioned at the outer side when combined and an inner face section positioned at the inner side when combined are stepped to each other, and a cut section is formed between the outer face section and the inner face section. The side face section of the frame member of the housing is formed to be stepped as described above, so that the strength and assembling property are enhanced, thereby being capable of preventing deterioration in display quality caused by the displacement of the position and space of the components.

Owner:NEC LCD TECH CORP

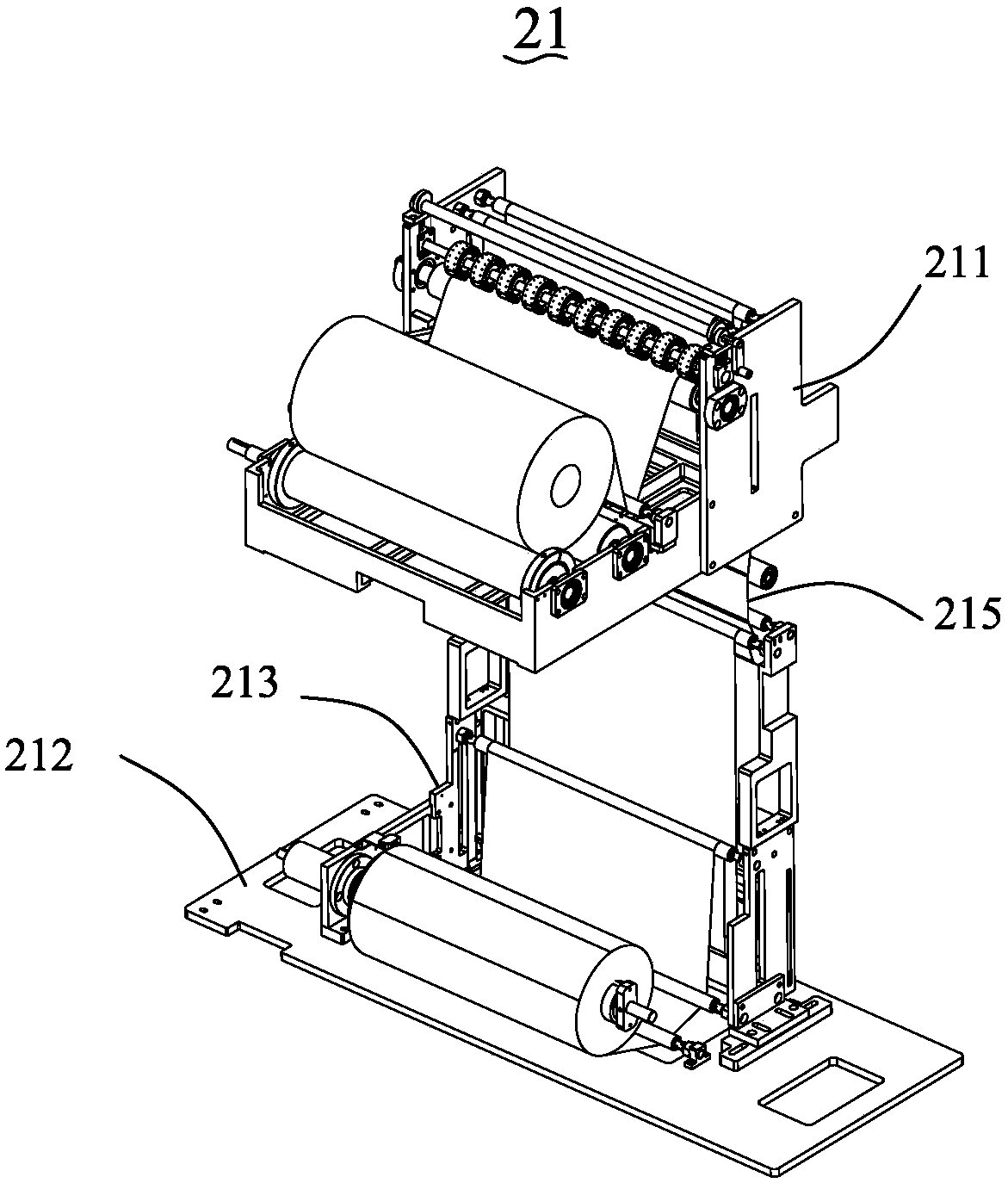

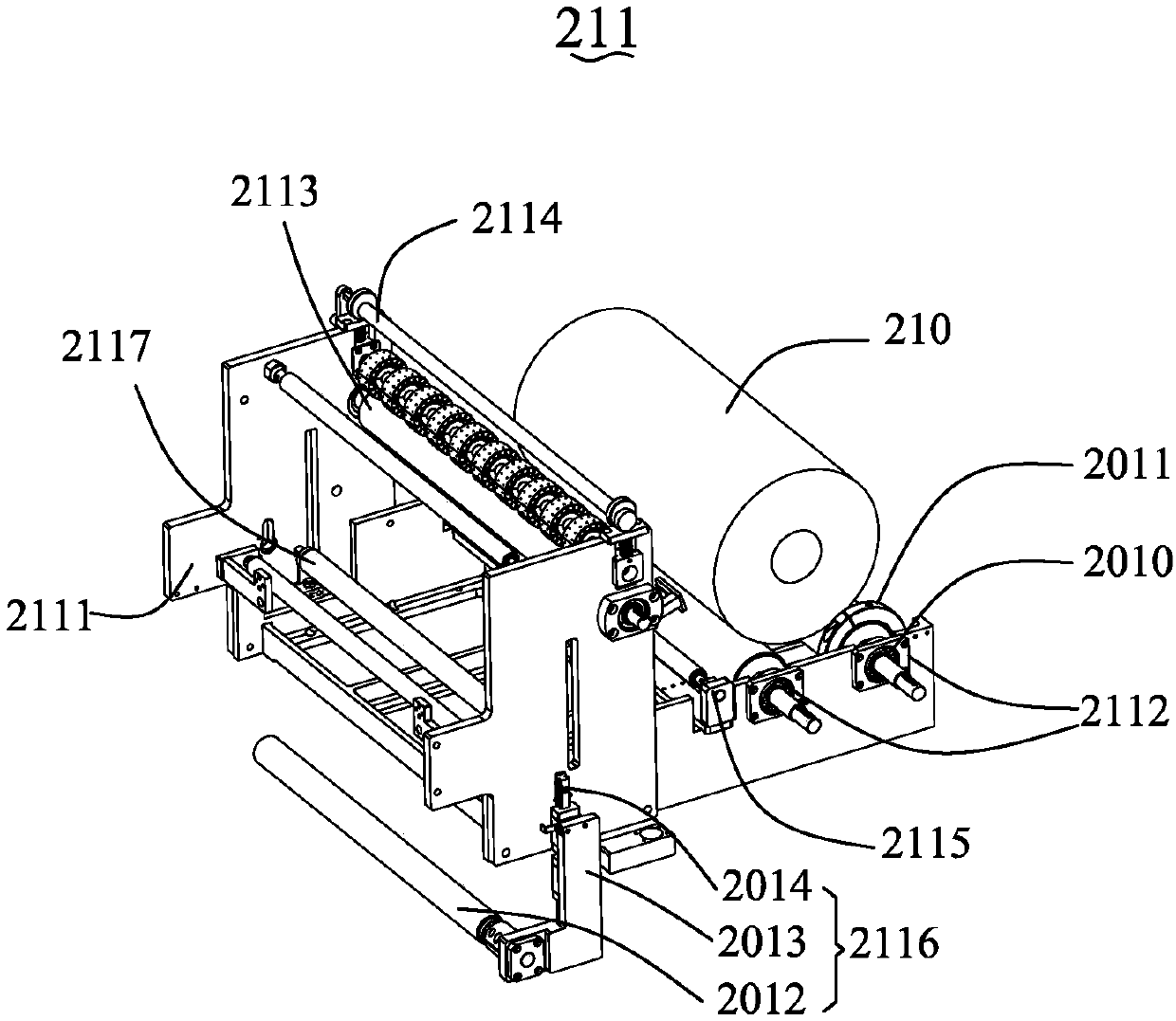

Packaging paper feeding mechanism

ActiveCN103407821AImprove general performancePrevent deviationArticle deliveryWebs handlingPulp and paper industryAntistatic device

The invention relates to a packaging paper feeding mechanism which comprises a roller way delivering unit and a blowing guide unit. A paper thickness adjusting device is connected with the roller way delivering unit and arranged above the roller way delivering unit, the output end of the roller way delivering unit is connected with the input end of the blowing guide unit, and the blowing guide unit is provided with an antistatic device. A blowing pipe is arranged above a guide plate of the packaging paper feeding mechanism adopting the structure, even if paper is thin, the paper can still be moved along the blowing direction and the guide plate, the situation that the paper hikes up or is stuck does not occur, the antistatic device prevents adhesion of the paper and the guide plate, the paper thickness adjusting device is arranged above a driven roller, and accordingly the paper feeding mechanism can adapt to paper of different thickness and is good in universality. In addition, the packaging paper feeding mechanism can be automatically adjusted through a spring and a cylinder, manual operation is not needed, and the problem of paper deflection caused by the manual operation is prevented.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

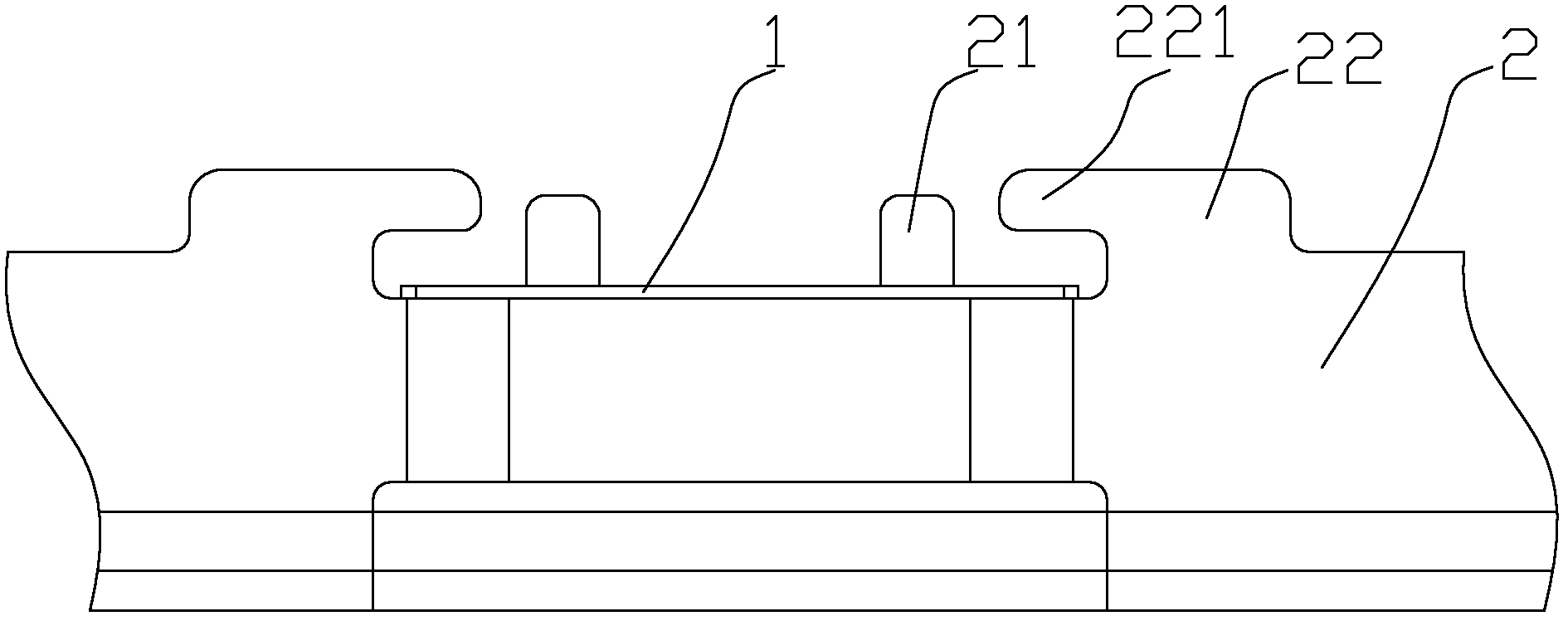

Backlight module and liquid crystal display device using the backlight module

InactiveCN102606954AEasy to installReduce the chance of bending deformationNon-linear opticsLight fasteningsLiquid-crystal displayBackplane

The invention relates to a backlight module and a liquid crystal display device using the backlight module. The backlight module includes a back plate and an optical film arranged on the back plate, wherein a lug for location is arranged on the optical film, and includes a root part and an expansion part extending outwards; the width of the expansion part is larger than that of the root part; a first bump is arranged on the sidewall of the back plate; an opening is formed on the first bump; the root part of the lug of the optical film is accommodated in the opening; a second bump is arranged on the sidewall of the back plate and includes an extension part; and the expansion part of the lug of the optical film is accommodated below the extension part of the second bump. By arranging the second bump on the back plate, the extension part of the second bump can prevent the lug of the optical film from moving in a direction vertical to the plane of the optical film; the second bump can be arranged at a low cost; and the optical film is simple in installation and can save time and effort.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Locking device

InactiveUS6864444B2Low mobilityAvoid fitSwitchgear with withdrawable carriageContact operating partsJoystickEngineering

A locking device of an electrical switch which can be moved between a disconnected position and an operating position with the switching states of the electrical switch. A first strip has a control contour which extends in a first direction and has a ramp which interacts with a control rod which can be moved in certain states of the electrical switch.

Owner:SIEMENS AG

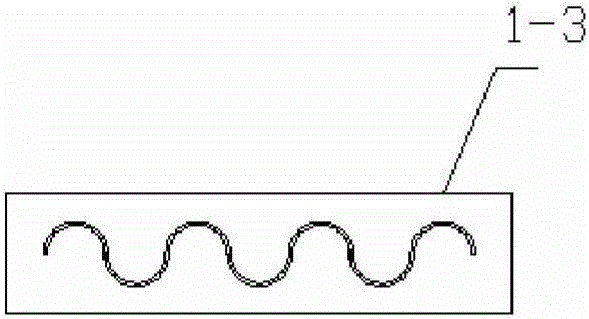

Plate-shaped corrugated membrane diaphragm having uniform aperture and preparation method thereof

The invention relates to a plate-shaped corrugated membrane diaphragm having uniform aperture and a preparation method thereof, which belong to the technical field of sewage processing. According to the invention, a plate-shaped membrane having a corrugated shape is employed, and the method comprises a high-energy radiation etching step, a PET extrusion moulding step and a marking radiation pore-forming step; the PET extrusion moulding step employs a PET extrusion form to form a heterotype diaphragm, a nuclear track membrane moulding technology step is used on the heterotype diaphragm for completing the moulding of the aperture; and the plate-shaped corrugated membrane diaphragm having uniform aperture is prepared. The plate-shaped corrugated membrane diaphragm having uniform aperture has the advantages that PET extrusion moulding and the marking radiation pore-forming technology are combined, the corrugated plate-shaped membrane is obtained through PET extrusion, diaphragm applying while operation can be effectively prevented, the hydrophilic performance of a PET material is stronger than that of PVDF, good aperture uniformity can be guaranteed by the radiation pore-forming technology, and better effect of the plate-shaped corrugated membrane can be obtained through a plurality of effects.

Owner:BEIJING ORIGIN WATER FILM TECH

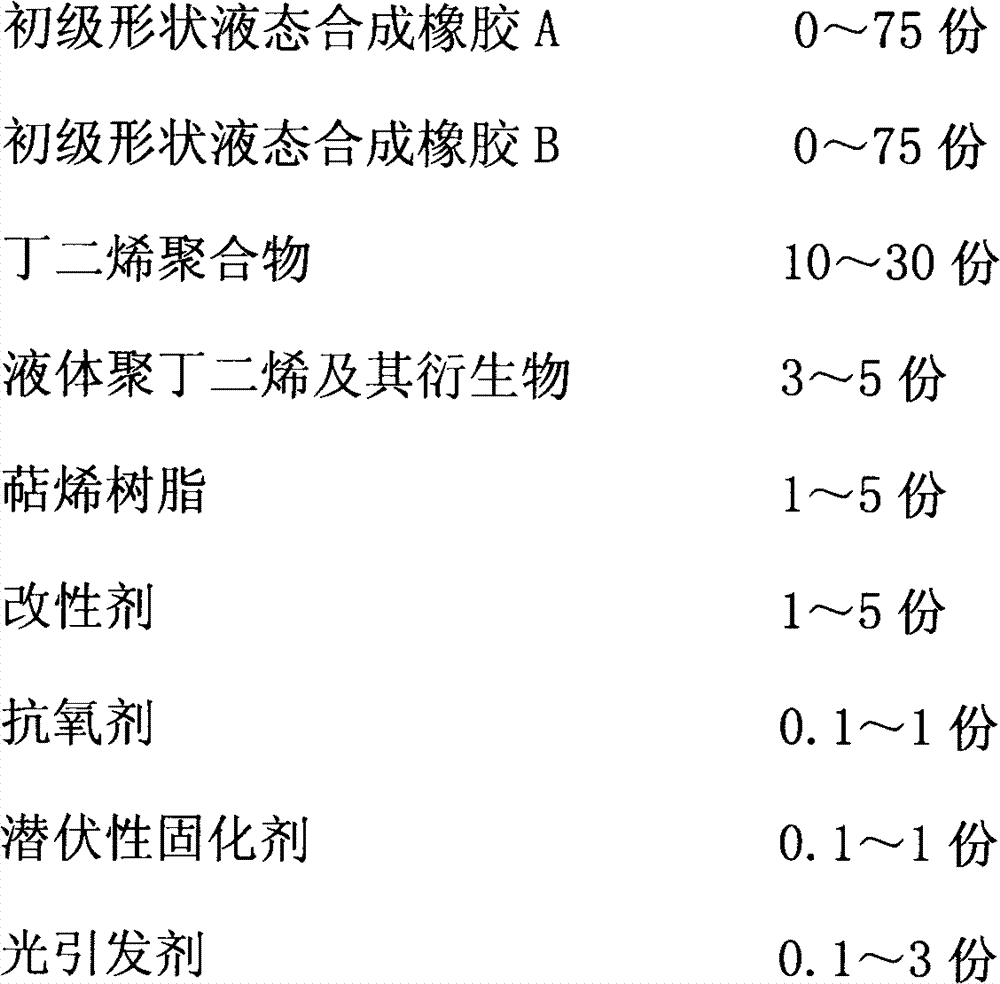

Liquid optical clear adhesive for liquid crystal display touch screen and preparation method thereof

InactiveCN102732183AGood softness and ductilityImprove adhesion strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to a liquid optical clear adhesive (LOCA) for a liquid crystal display (LCD) touch screen and a preparation method thereof. The adhesive comprises 0-75 weight parts of liquid synthetic rubber A or B in primary forms, 10-30 weight parts of butadiene polymer, 3-5 weight parts of liquid polybutadiene and its derivative, 1-5 weight parts of terpene resin, 1-5 weight parts of modifier, 0.1-1 weight parts of antioxidant, 0.1-1 weight parts of latent curing agent, and 0.1-3 weight parts of photoinitiator, wherein the A is maleated isoprene telomer with the molecular weight being between 12000-18000, the B is maleated isoprene telomere with the molecular weight being between 32000-38000, and A and B are not 0 weight part simultaneously. The preparation method comprises the steps of mixing and dissolving, filtering, conducting vacuum pumping, etc. The LOCA of the invention has high bonding strength, high light transmittance, good ductility, small cure shrinkage, and yellowing resistance, and the preparation method is simple and green. The invention has a wide scope of application.

Owner:烟台伟昌电子材料有限公司

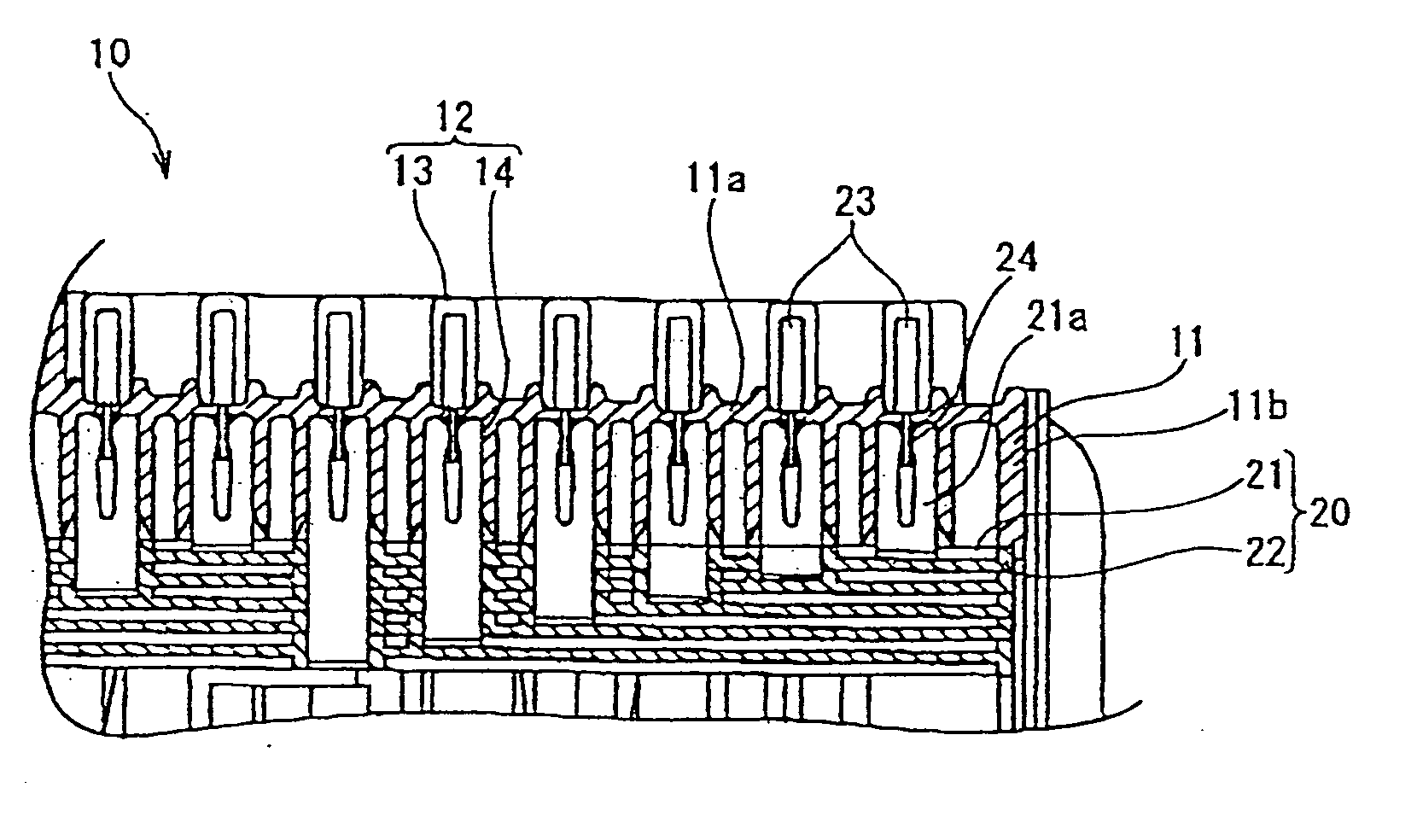

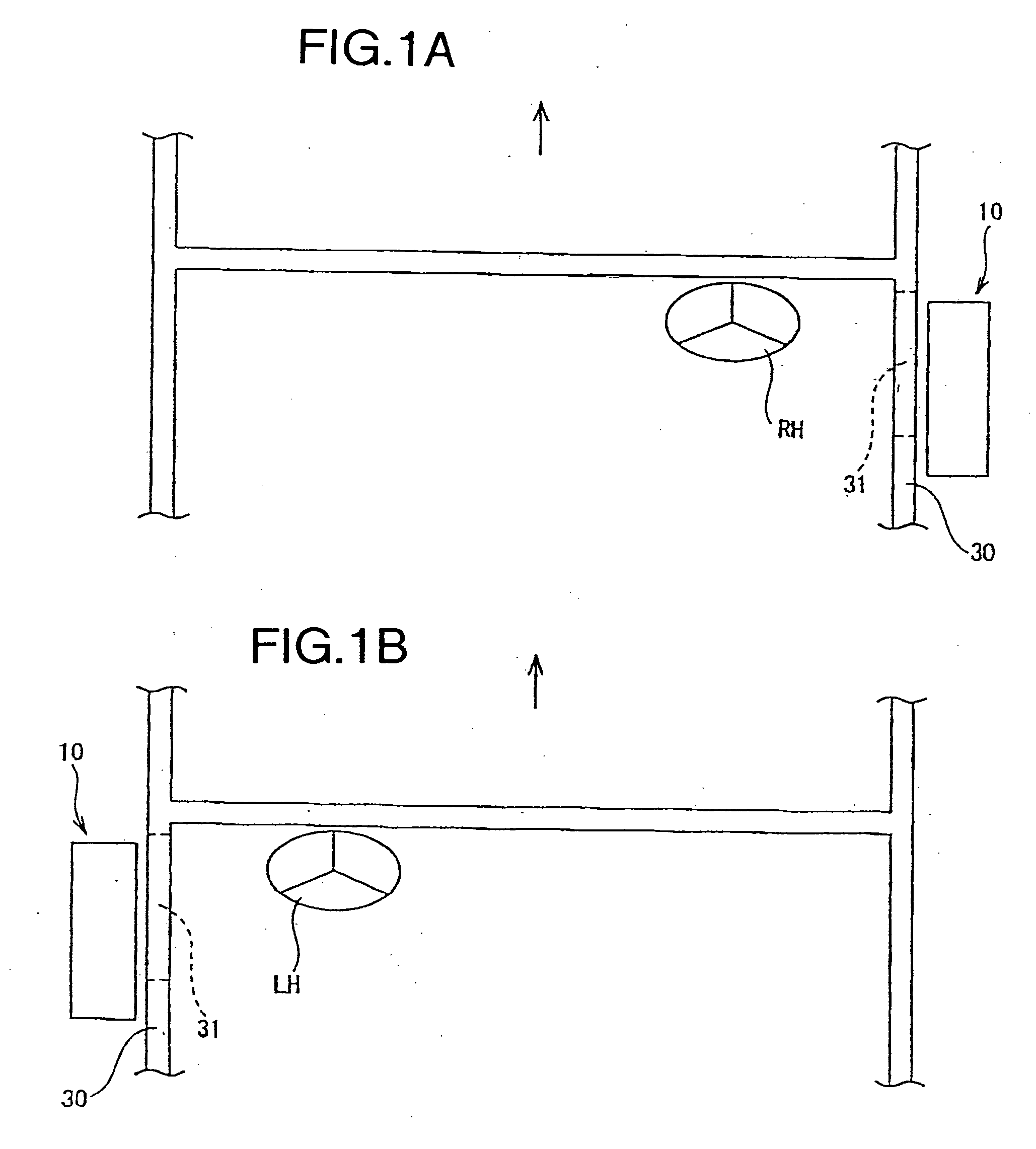

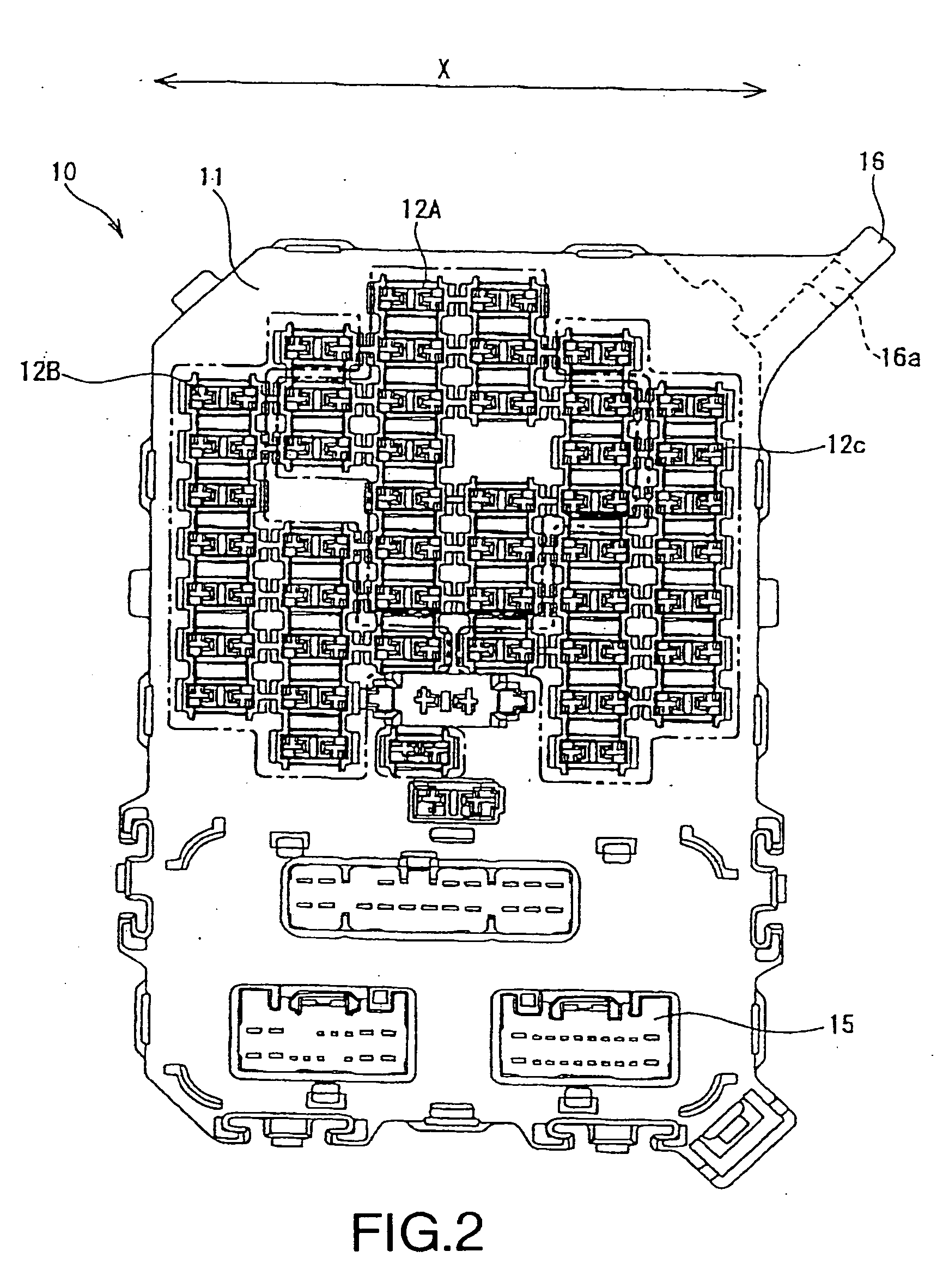

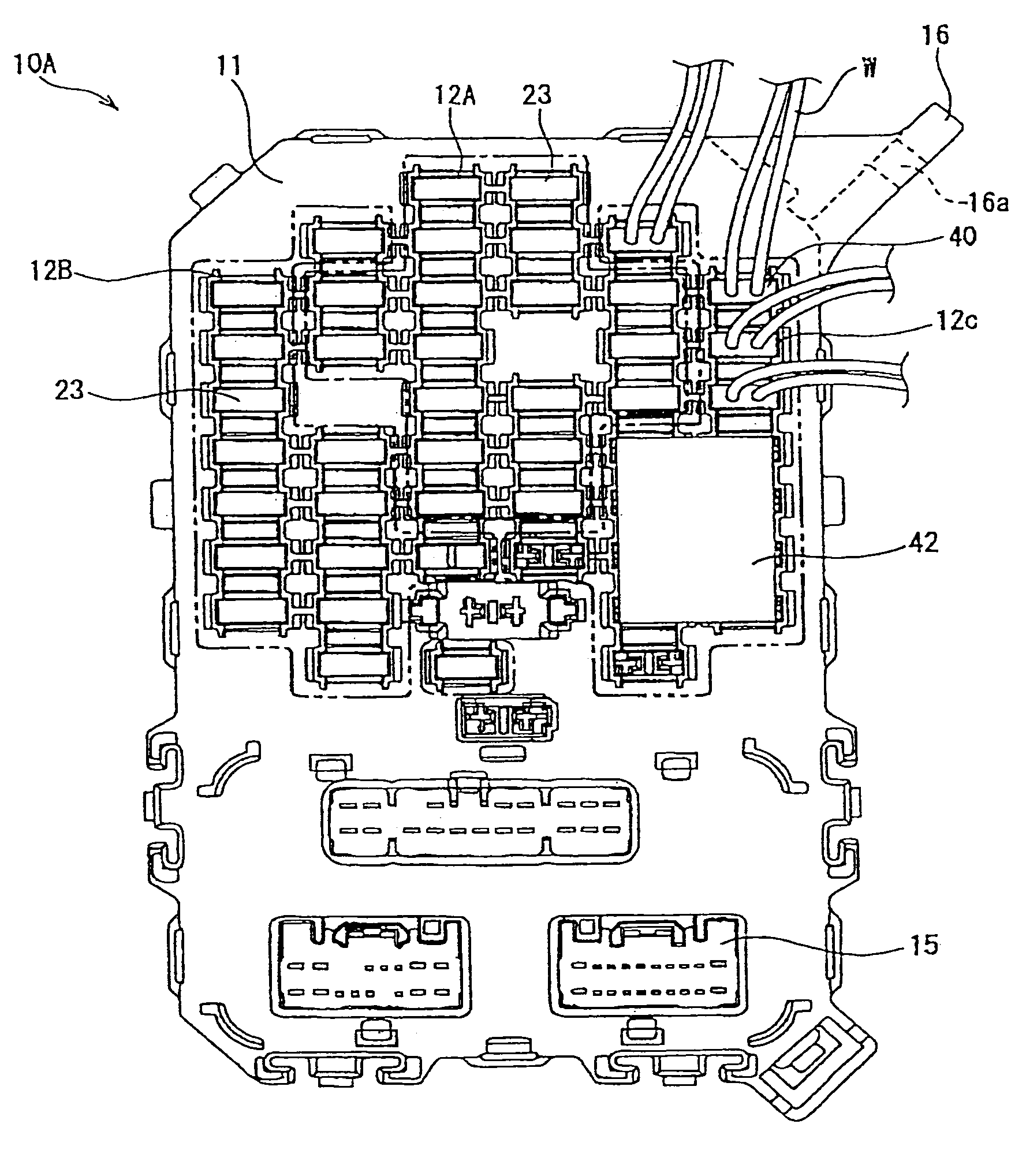

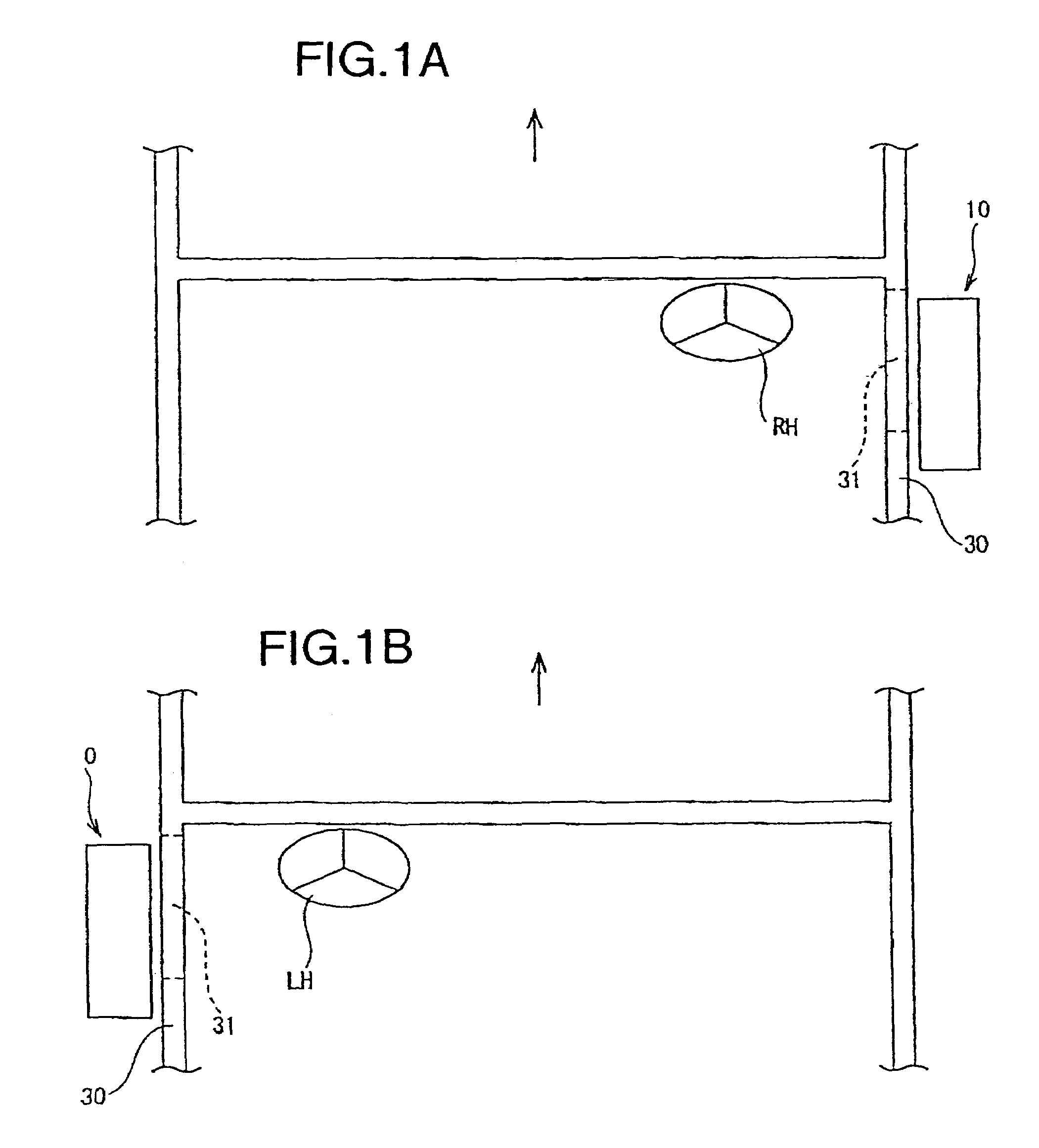

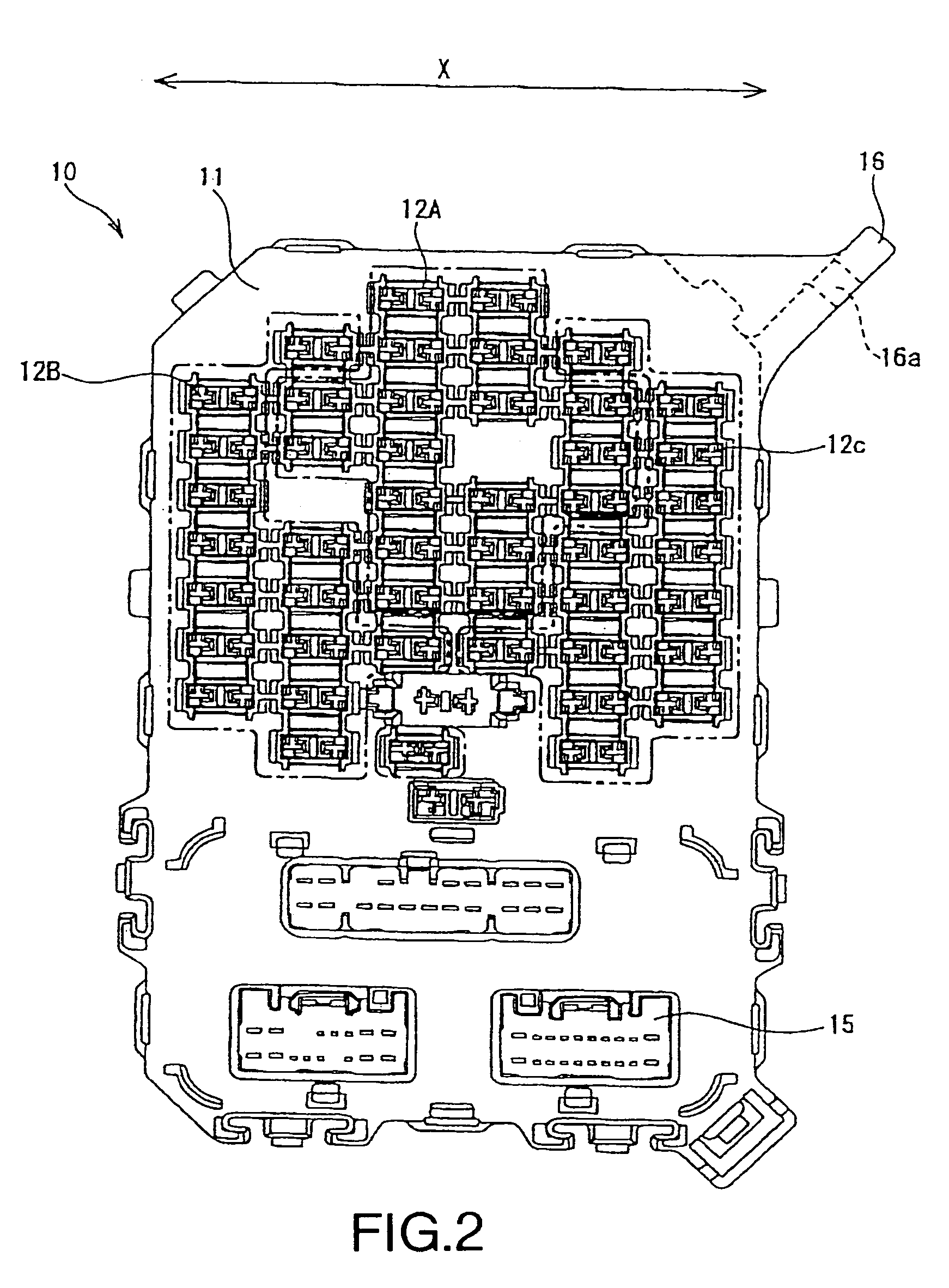

Electric junction box for a vehicle

InactiveUS20060046536A1Easy to useReduce in quantityVehicle connectorsElectrically conductive connectionsEngineeringJunction box

An electric junction box for use in either a right hand drive vehicle or a left hand drive vehicle. Fuse replacements of the electric junction box are performed through a fuse-replacement opening provided on the vehicle-body side. The electric junction box includes a plurality of fuse-connecting units provided on the case of the electric junction box. The plurality of fuse-connecting units include shared fuse-connecting units located in a middle region among the plurality of fuse-connecting units, fuse-connecting units for a right hand drive vehicle and fuse-connecting units for a left hand drive vehicle. The shared fuse-connecting units aligned with the fuse-replacement opening whether the electric junction box is installed in a right hand drive vehicle or a left hand drive vehicle.

Owner:SUMITOMO WIRING SYST LTD

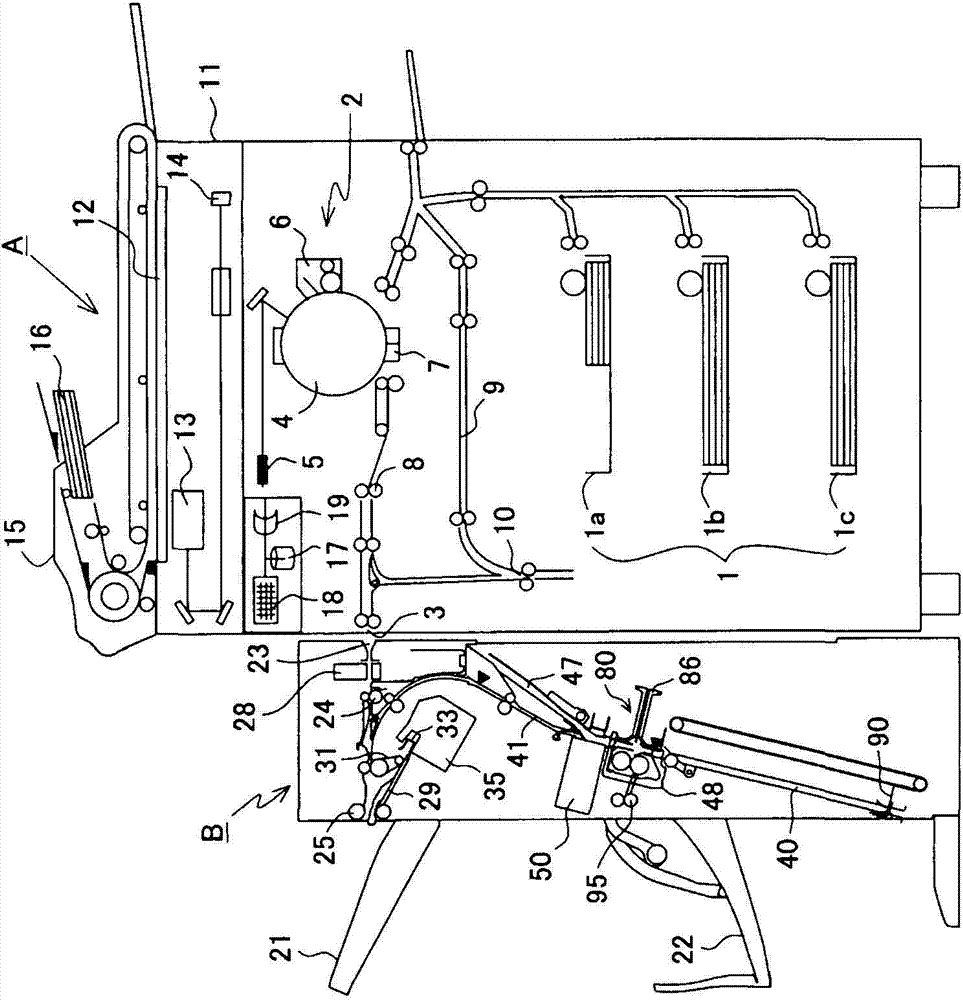

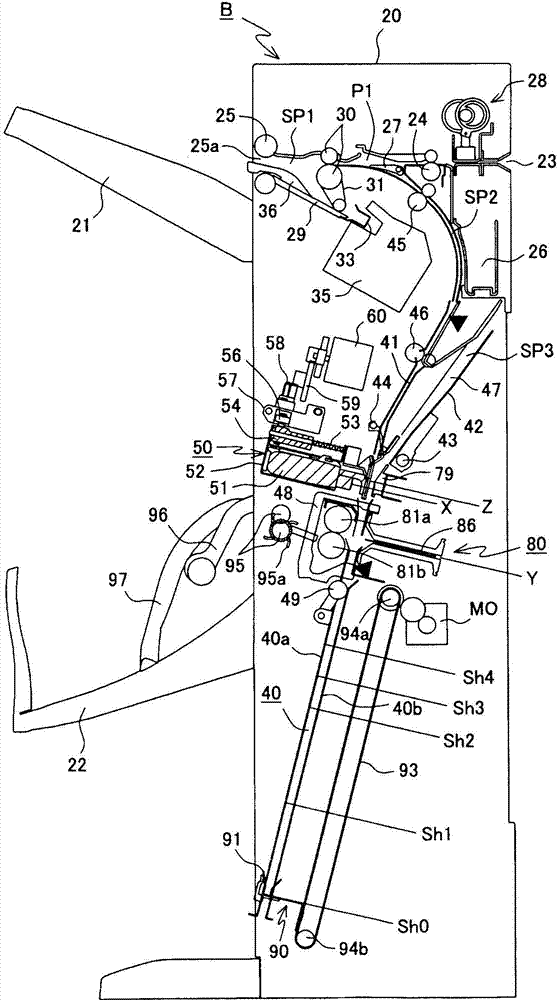

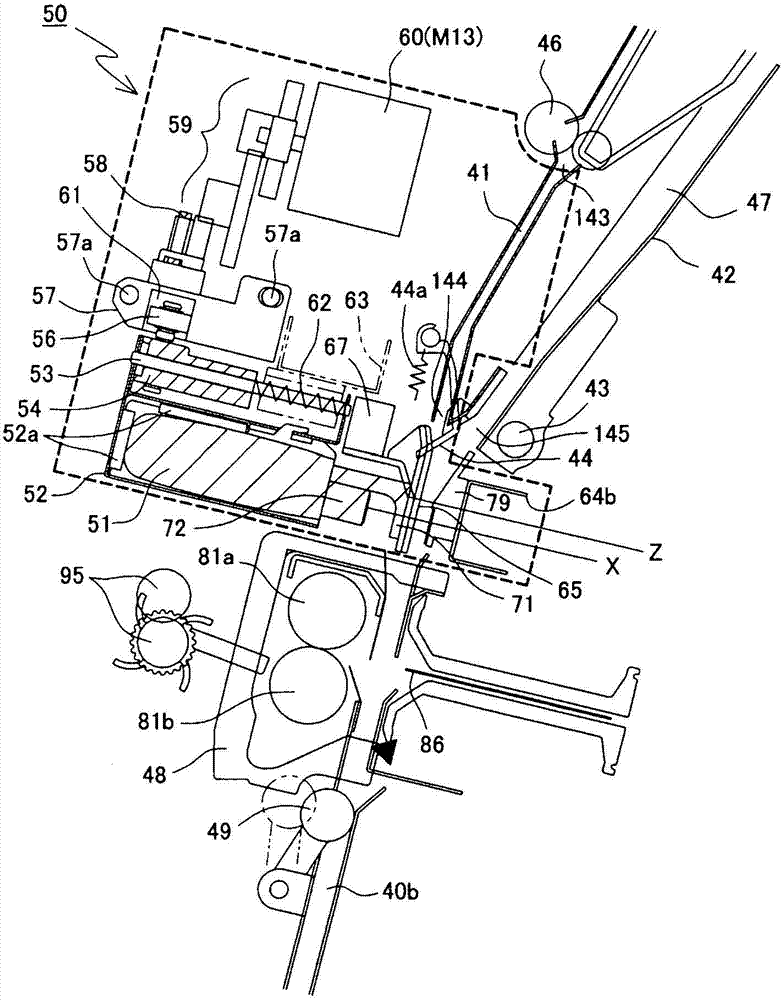

Sheet Processing Device, Image Forming Device Provided With The Same, And Sheet Bonding Method

Provided is a sheet processing device including a carry-in path along which the paper sheet is carried in and a retreat path that branches off from the carry-in path, along which at least a part of the paper sheet stored in a stacker section is retreated in a direction opposite to a sheet conveying direction. A bonding means is disposed at a merging point between the carry-in path and retreat path. An adhesive-applied position of a preceding paper sheet is retreated to the retreat path when a next paper sheet is carried in to the stacker section, then the next paper sheet is moved to a bonding position for adhesive application. The above operations are sequentially repeated to generate a paper sheet bundle. Thus, a paper sheet bundle can be generated by bonding the paper sheets using an adhesive, so that it is possible to reduce stress to be applied to the paper sheet as compared to a case where the paper sheet bundle is bound with a metallic staple or by deforming the paper sheets themselves. Further, it is possible to comparatively reduce movement of the paper sheet applied with the adhesive to prevent the adhesive from being adhered to a portion other than the paper sheet, thereby preventing the paper sheets from being bonded to each other at a position other than a predetermined position. As a result, there can be provided a sheet processing device, that is rather small and can bond the paper sheets at a predetermined position.

Owner:COPYER

Electric junction box for a vehicle

InactiveUS7168962B2Reduce in quantityAvoid huge wasteVehicle connectorsElectrically conductive connectionsElectricityEmbedded system

Owner:SUMITOMO WIRING SYST LTD

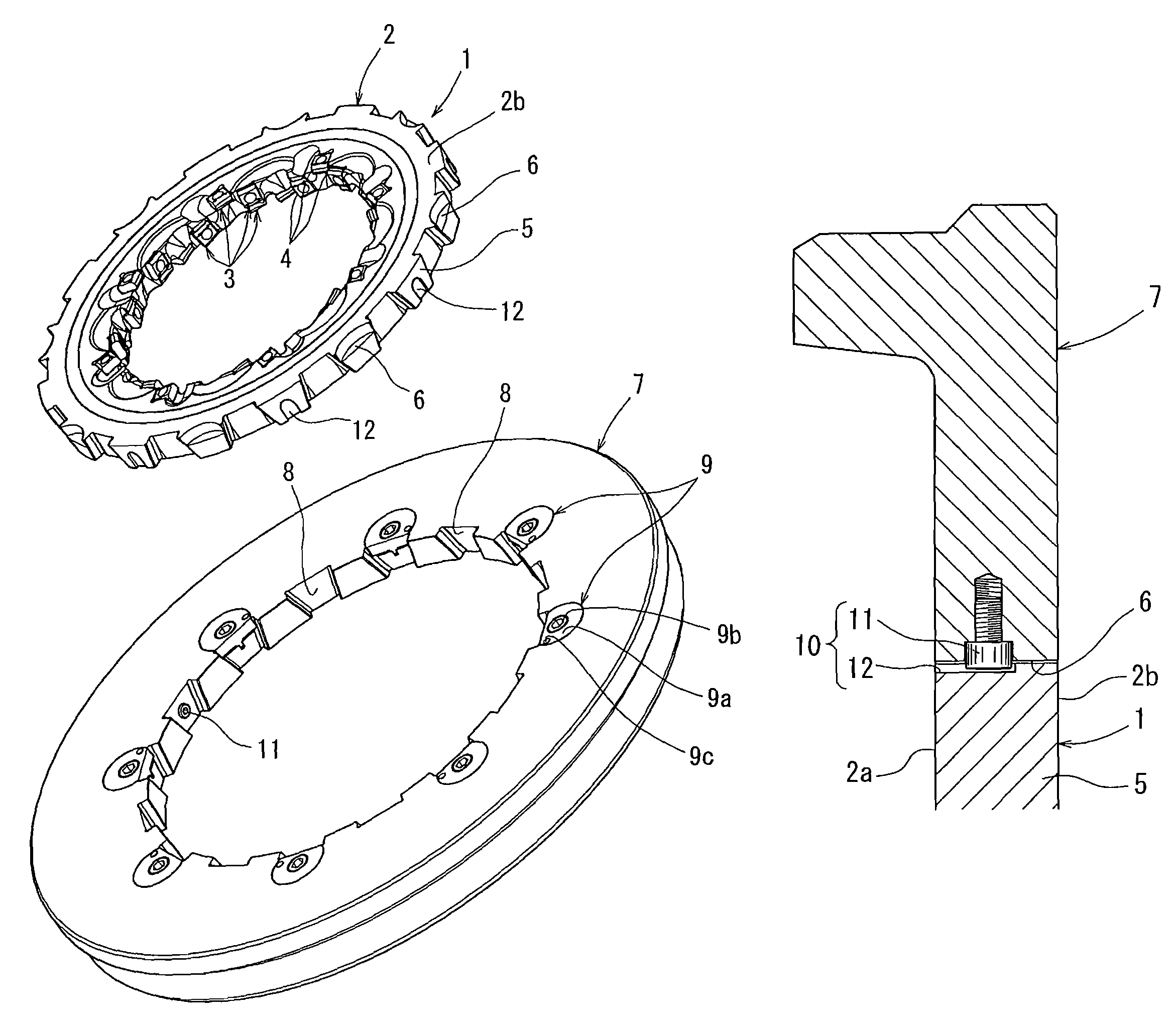

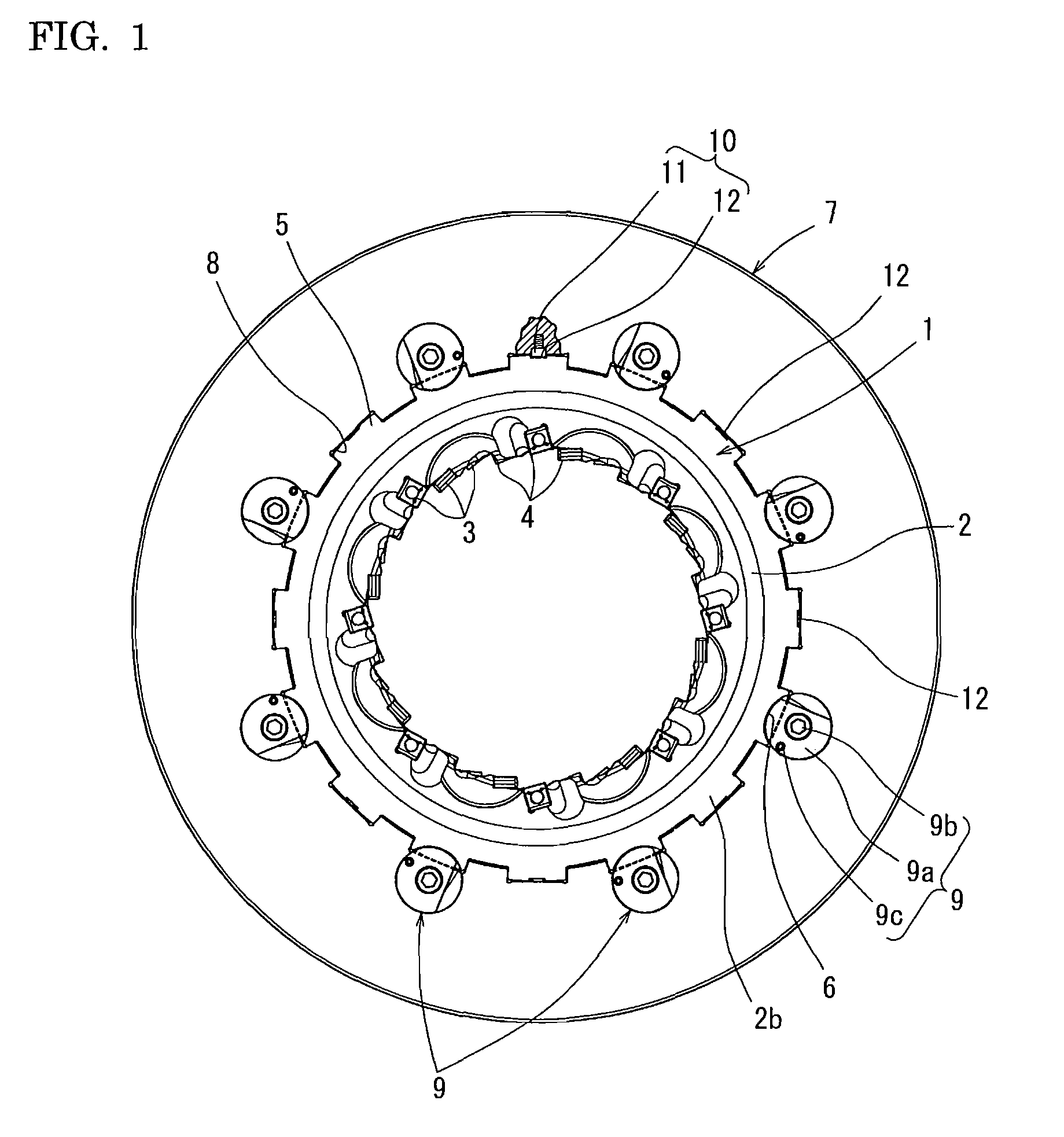

Pin milling cutter

ActiveUS7544020B2Avoid mistakesDisadvantageous in of costLathesMilling cuttersMilling cutterError prevention

The present invention provides a pin milling cutter formed by combining a cutter and an adapter to prevent errors in attaching a cutter to the adapter even when the cutter is similar but of a different type and even if the engagement section between the cutter and the adapter are the same. A mounting error prevention mechanism is provided on a main cutter unit and an adapter to prevent an erroneous combination of a cutter and adapter from fitting together normally. The mounting error prevention mechanism includes: a projection and a cavity corresponding to the main cutter unit and the adapter and providing a tapered fit; and a projection and a corresponding groove. The projection can be inserted into the groove only when the cutter and the adapter are combined correctly.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

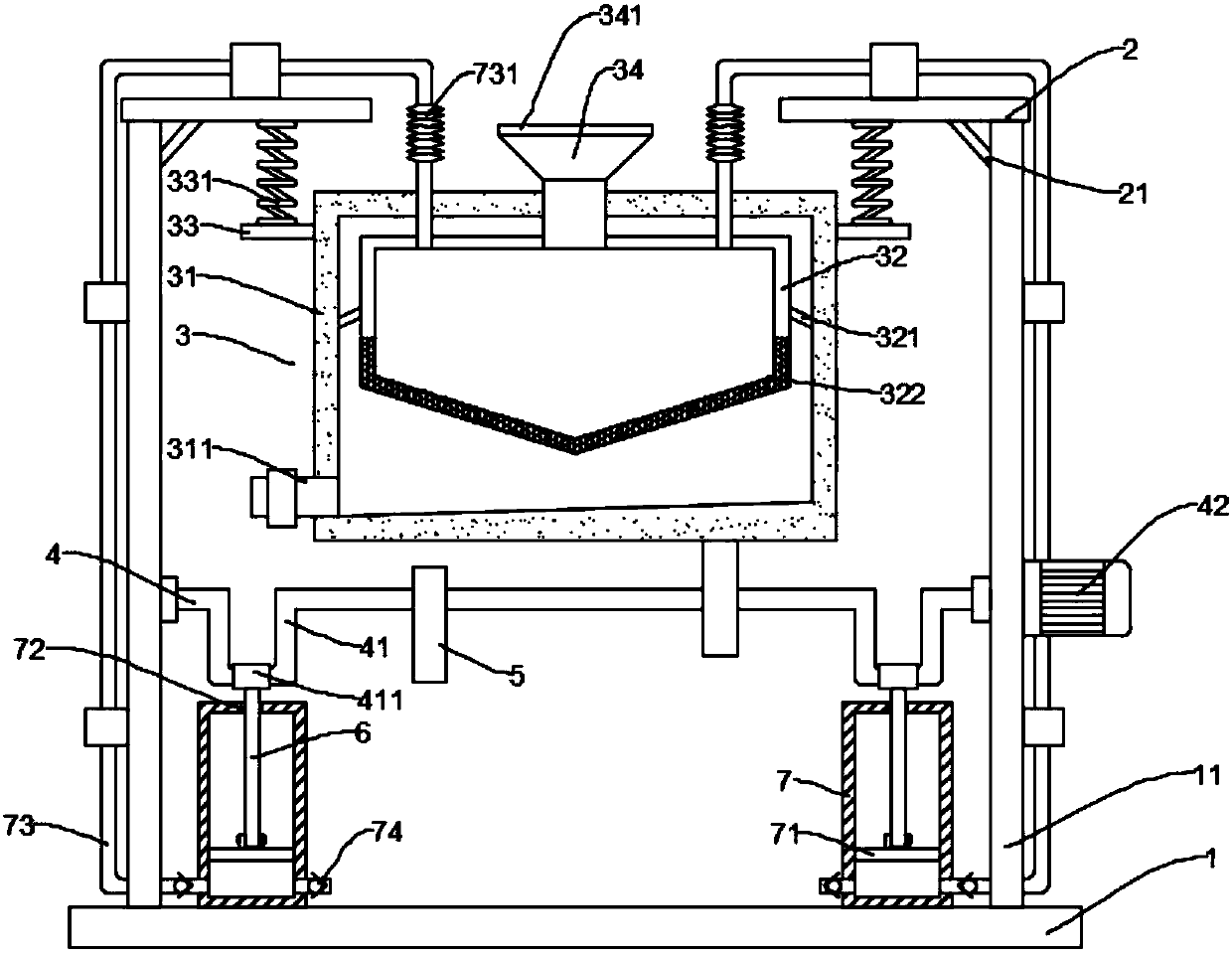

High-effective traditional Chinese medicine liquid residue filtering device having structure of inner and outer boxes

InactiveCN107823948ASpeed up filteringGuaranteed normal fermentationMoving filtering element filtersFiltrationEngineering

The invention discloses a high-effective traditional Chinese medicine liquid residue filtering device having a structure of inner and outer boxes. The device includes: a pedestal, a residue filteringbox, a rotary shaft and two cylinder bodies. Two vertical frames are symmetrically fixed to the left and right sides of the top of the pedestal. A top board is connected to the tops of the vertical frames. The residue filtering box is arranged between the two vertical frames. Horizontal plates are fixed symmetrically to the left and the right sides of the residue filtering box and are located below the top board and connected to the top board through springs. The rotary shaft is rotatably connected between the two vertical frames and is arranged at a position below the residue filtering box. Amotor driving the rotary shaft to rotate is arranged at the right side thereof. Two cams are fixed to the periphery of a shaft body on the middle part of the rotary shaft respectively at the left andthe right side. Cranks are symmetrically disposed at the left and the right side of the rotary shaft. The cylinder bodies are fixed at positions, which are under the cranks, on the pedestal. The device has compact structure and is easy to use, can effectively accelerate filtration of the medicine liquid and improve residue removal efficiency, and brings convenience to decoction operation of the traditional Chinese medicines.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

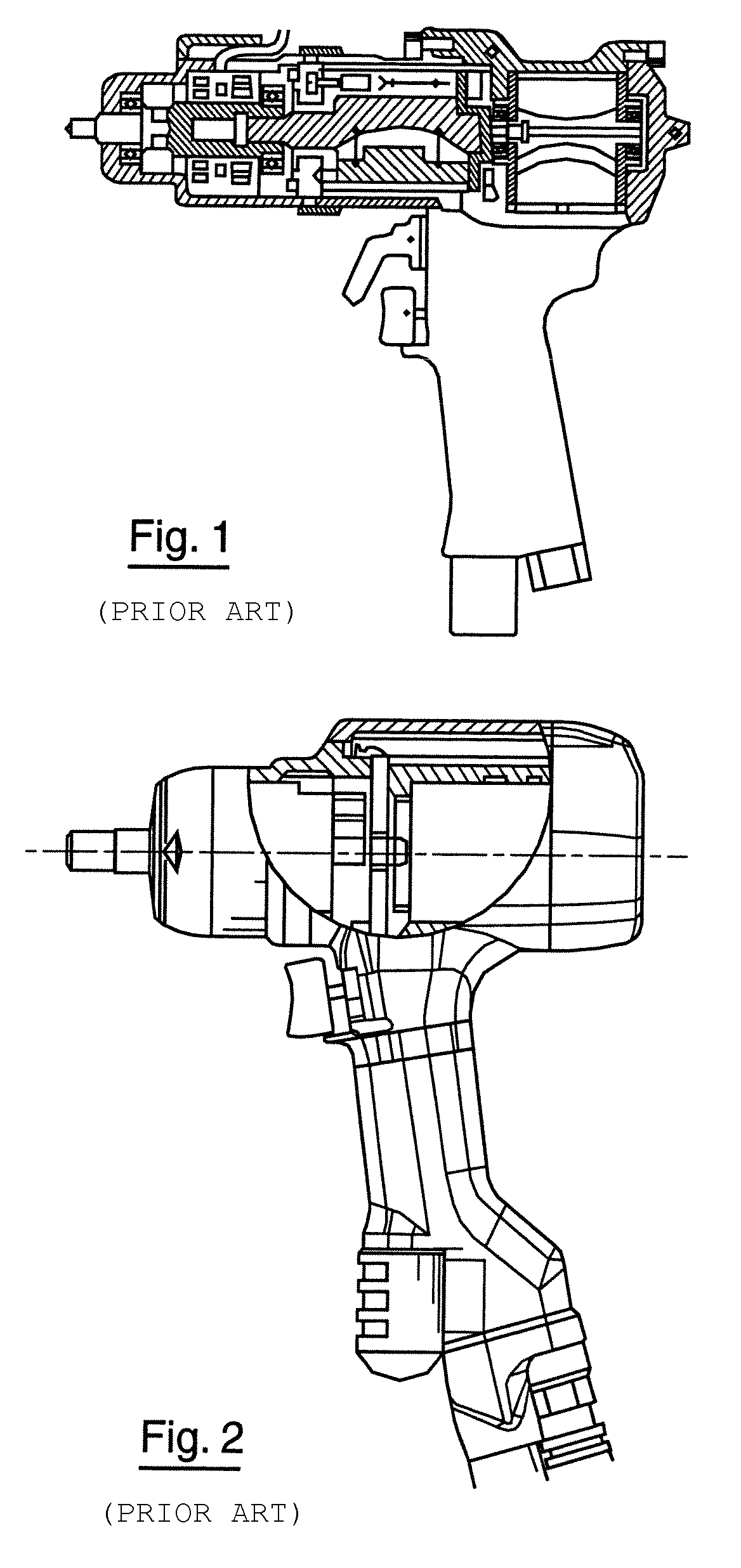

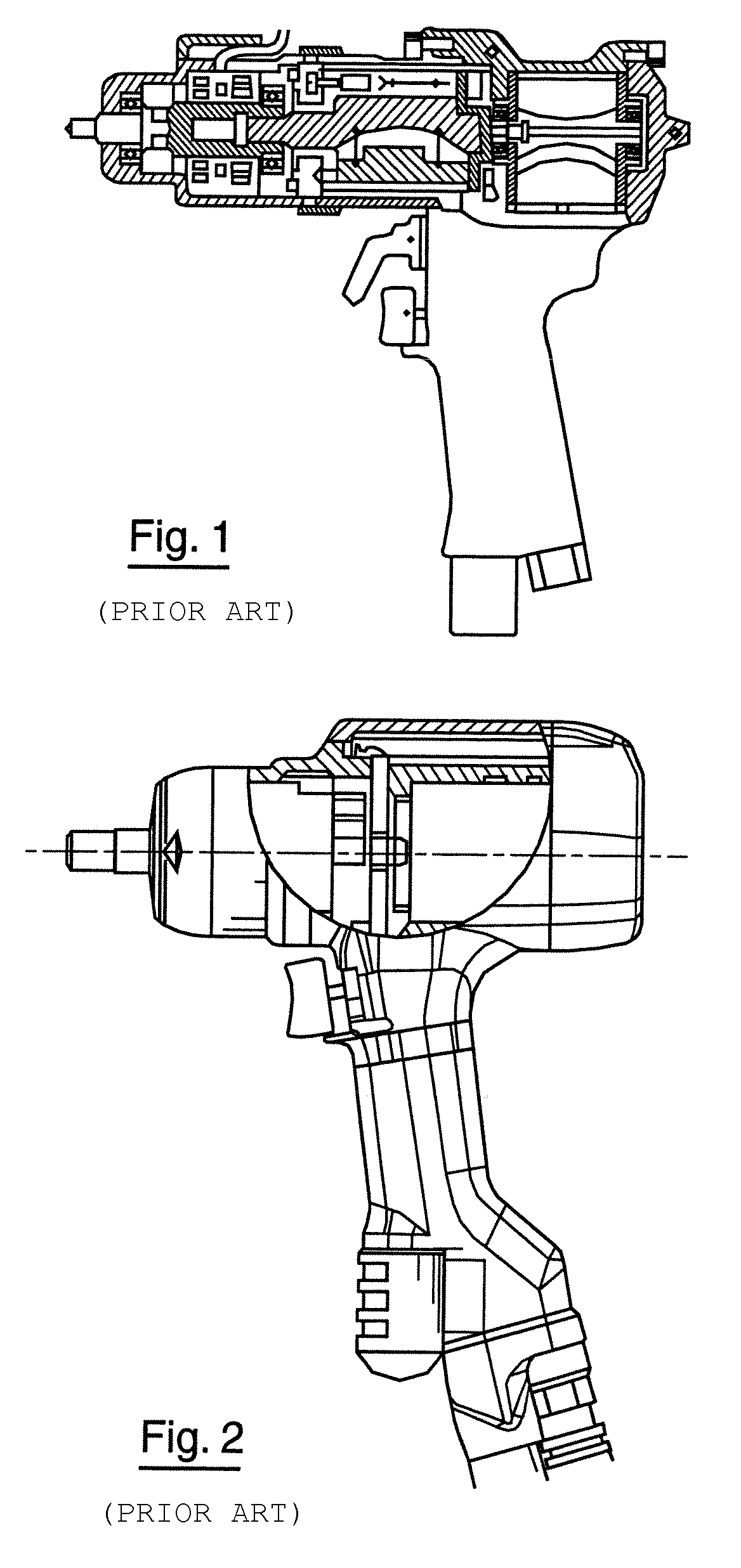

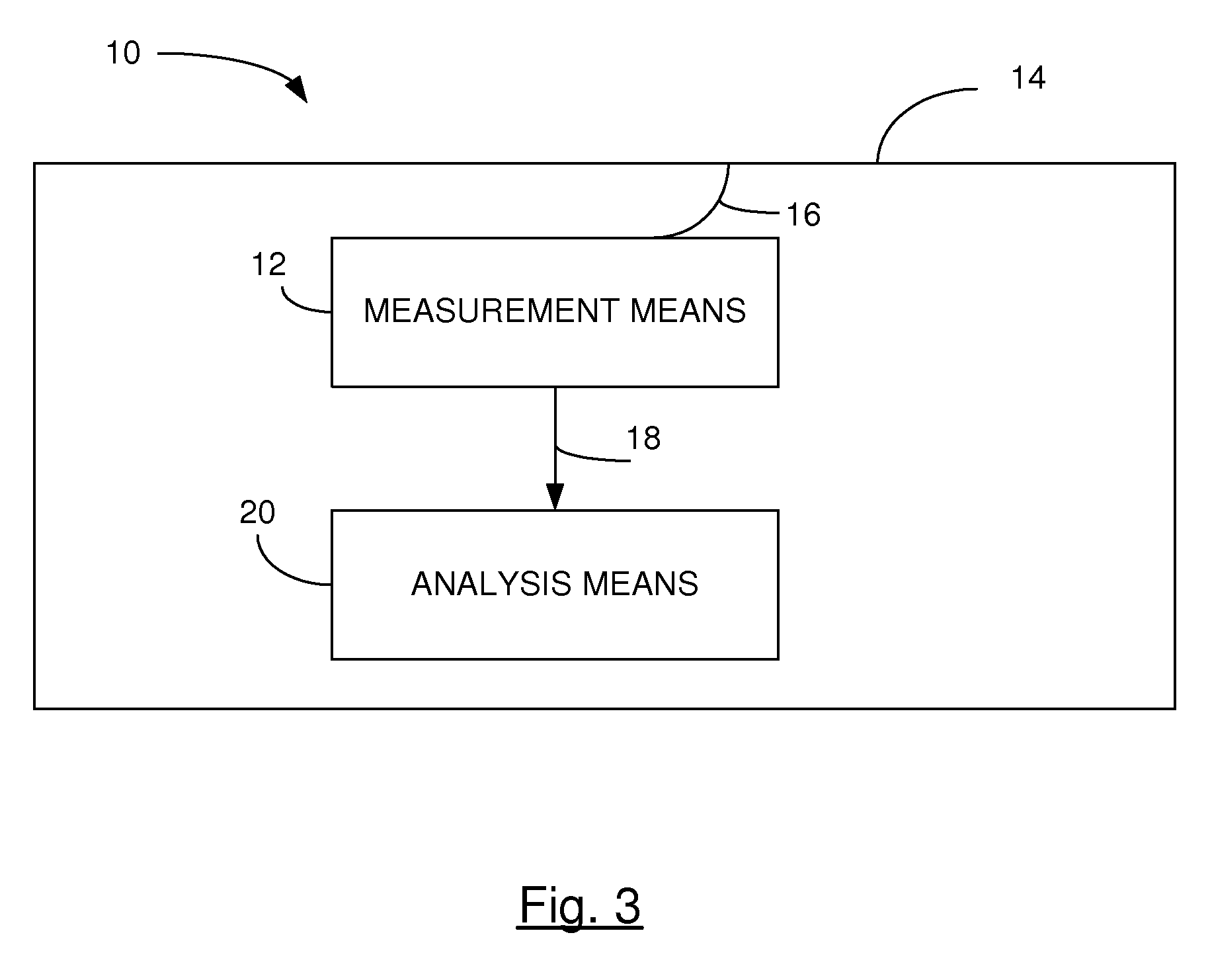

Discontinuous tightening wrench comprising means for measuring dynamic events caused by this tightening on the casing of the wrench

InactiveUS7987919B2Avoid fitEasy to handleMeasurement of torque/twisting force while tighteningDerricks/mastsWrenchClutch

The invention relates to a discontinuous clamping wrench, of the type comprising a motor and a pulse clutch integrated in a casing, characterised in that it comprises measurement means of dynamic phenomena induced by said clamping on said casing, with a view to correlating said measurement with a clamping level.

Owner:ETAB GEORRENAULT

Discontinous tightening wrench comprising means for measuring dynamic events caused by this tightening on the casing of the wrench

InactiveUS20090114411A1Avoid fitEasy to handleMeasurement of torque/twisting force while tighteningDerricks/mastsElectric machineWrench

The invention relates to a discontinuous clamping wrench, of the type comprising a motor and a pulse clutch integrated in a casing, characterised in that it comprises measurement means of dynamic phenomena induced by said clamping on said casing, with a view to correlating said measurement with a clamping level.

Owner:ETAB GEORRENAULT

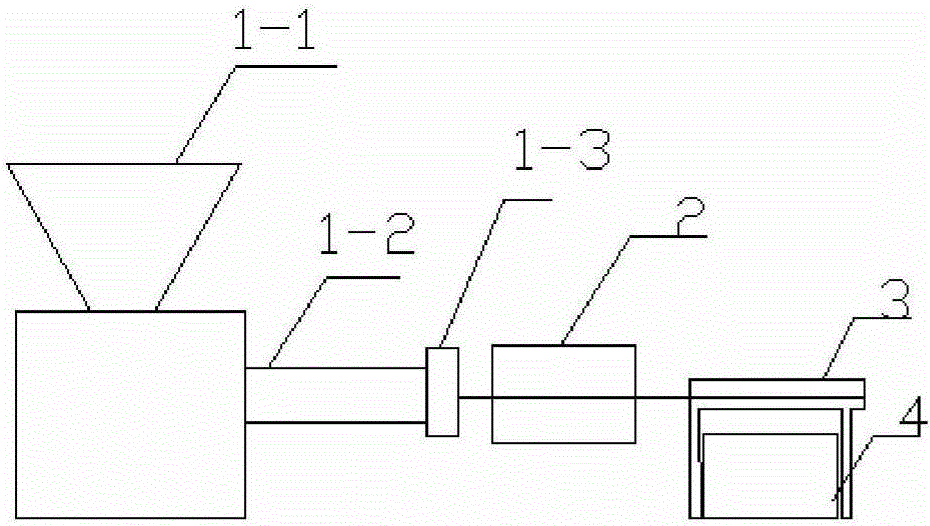

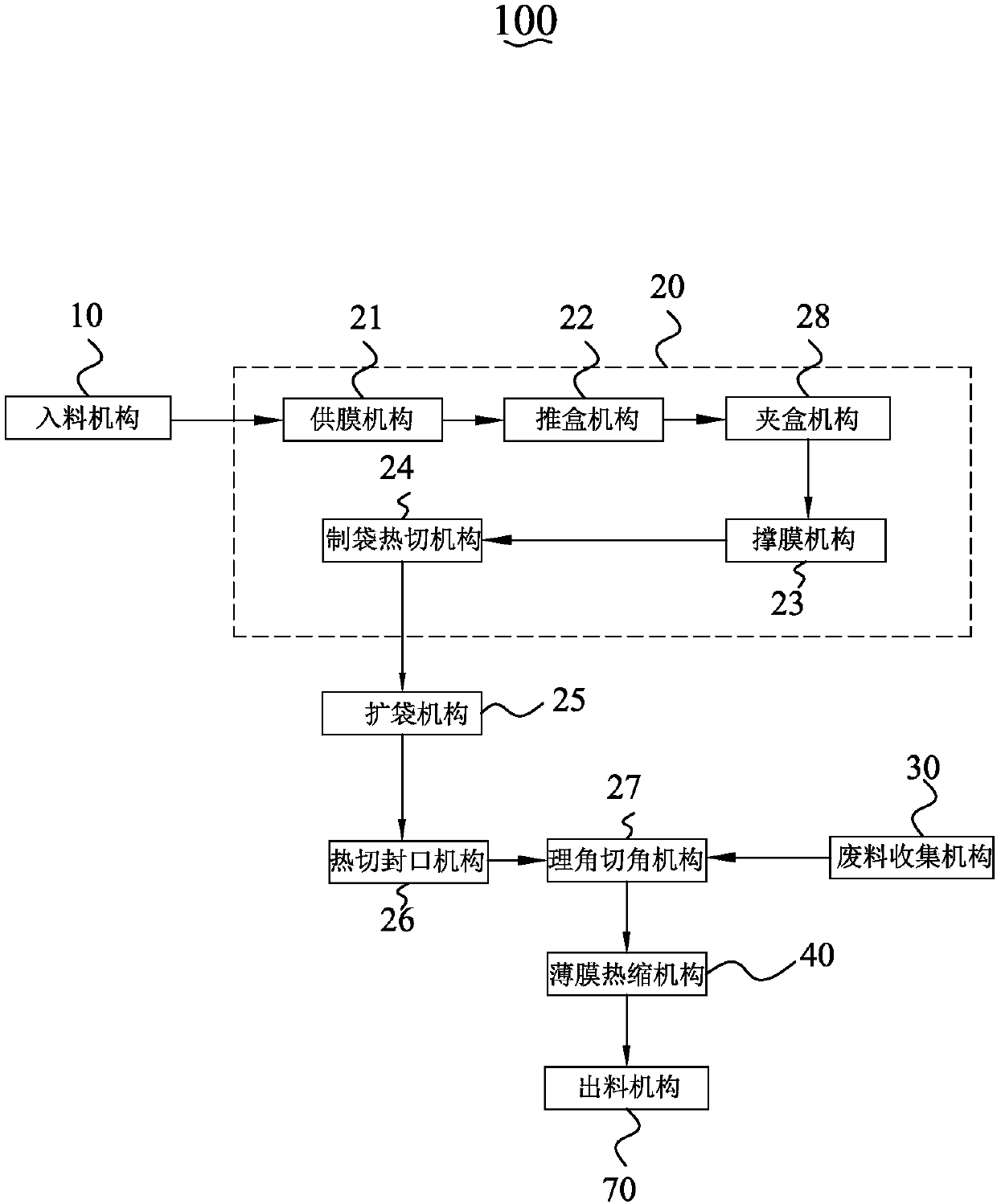

Film packing machine and process

ActiveCN109515801AAvoid fitFit tightlyWrappers shrinkageConveyor wrappingEngineeringPackaging machine

The invention provides a film packing machine used for packing a square packing box. The film packing machine comprises a feeding mechanism, a bag making packing mechanism and a hot-cutting sealing mechanism which are sequentially arranged; the bag making packing mechanism comprises a film supplying mechanism, a box pushing mechanism, a film supporting mechanism and a bag making hot-cutting mechanism; the film supplying mechanism provides an open film and defines a feeding inlet, and the square packing box is conveyed to the feeding inlet through the feeding mechanism; the box pushing mechanism pushes the packing box to the feeding inlet to enable two of three adjacent openings of the film to be located on the two opposite sides of the packing box; the film supporting mechanism enters theopenings located in the two opposite sides of the packing box and moves to open the film on the two opposite sides of the openings; the bag making hot-cutting mechanism conducts hot-cutting sealing onthe other opening of the film, and the film is made into a packing bag with openings in the two opposite sides; and the hot-cutting sealing mechanism conducts hot sealing on the openings in the two opposite sides of the packing bag, so that the six surfaces of the packing box are wrapped with the film. The invention further provides a film packing process.

Owner:SHENZHEN FUYUNDI TECH

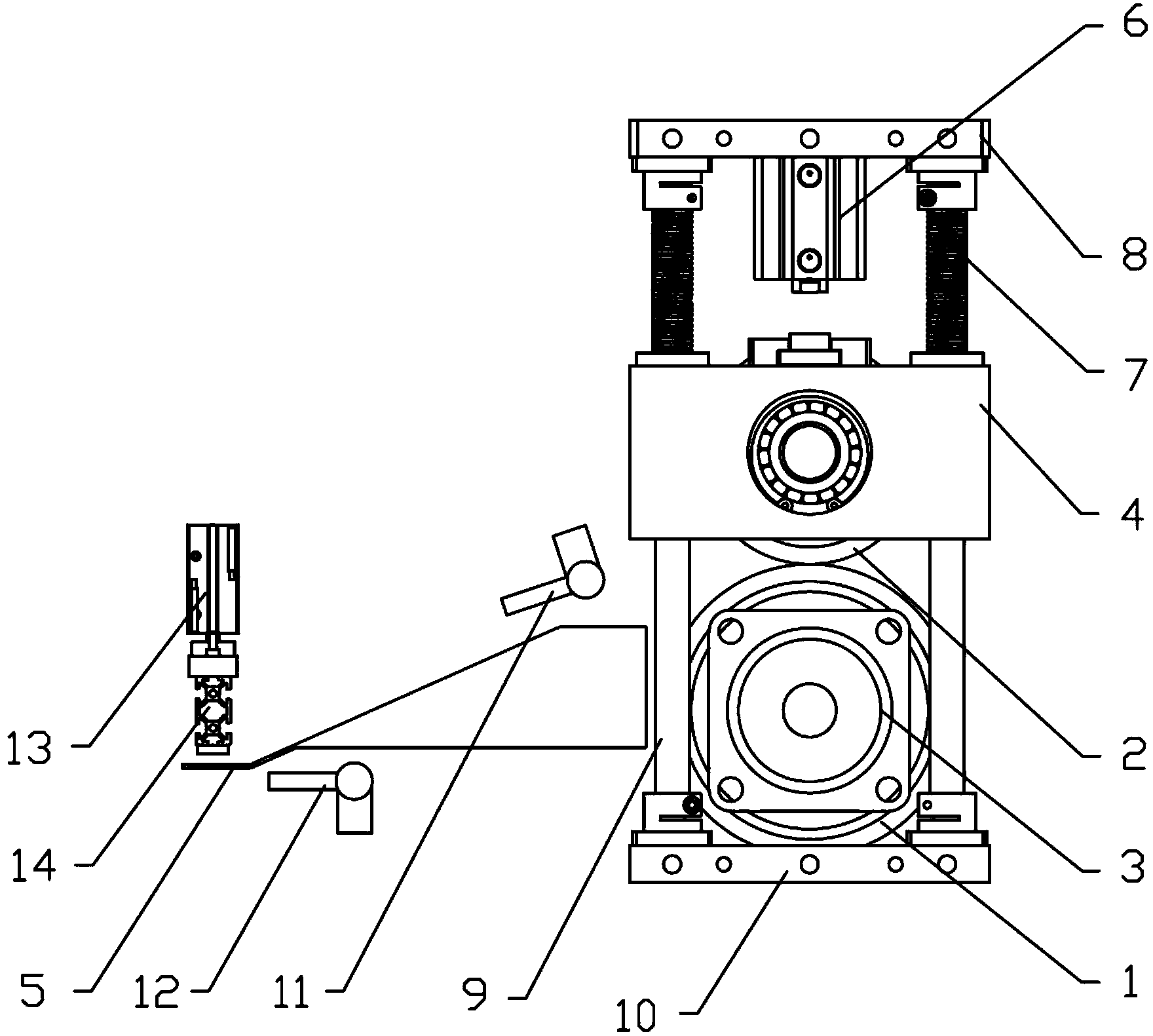

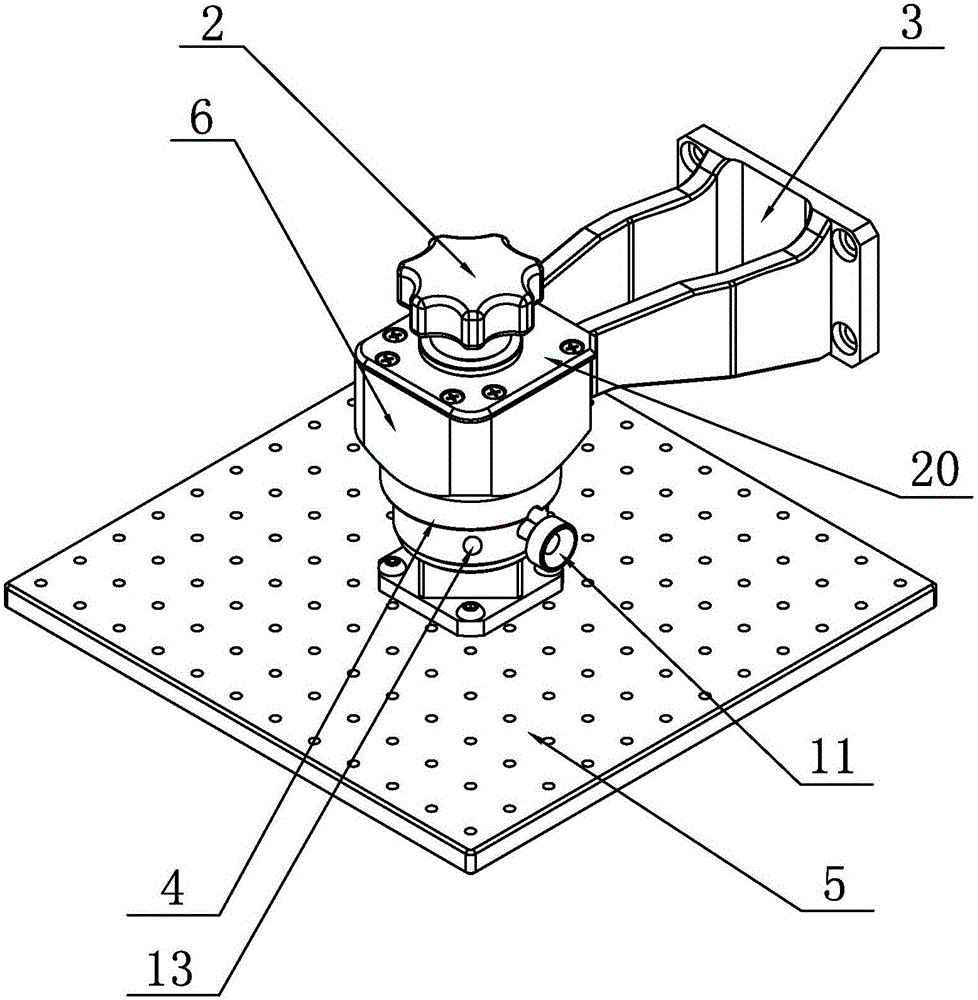

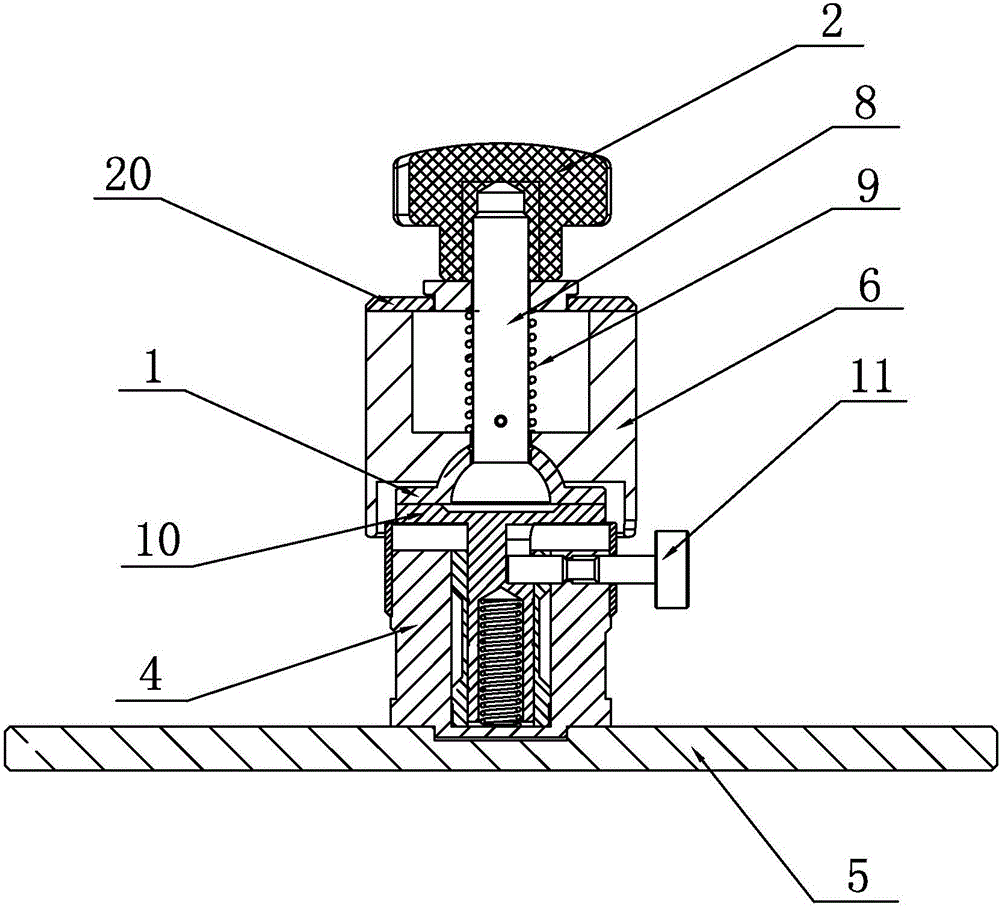

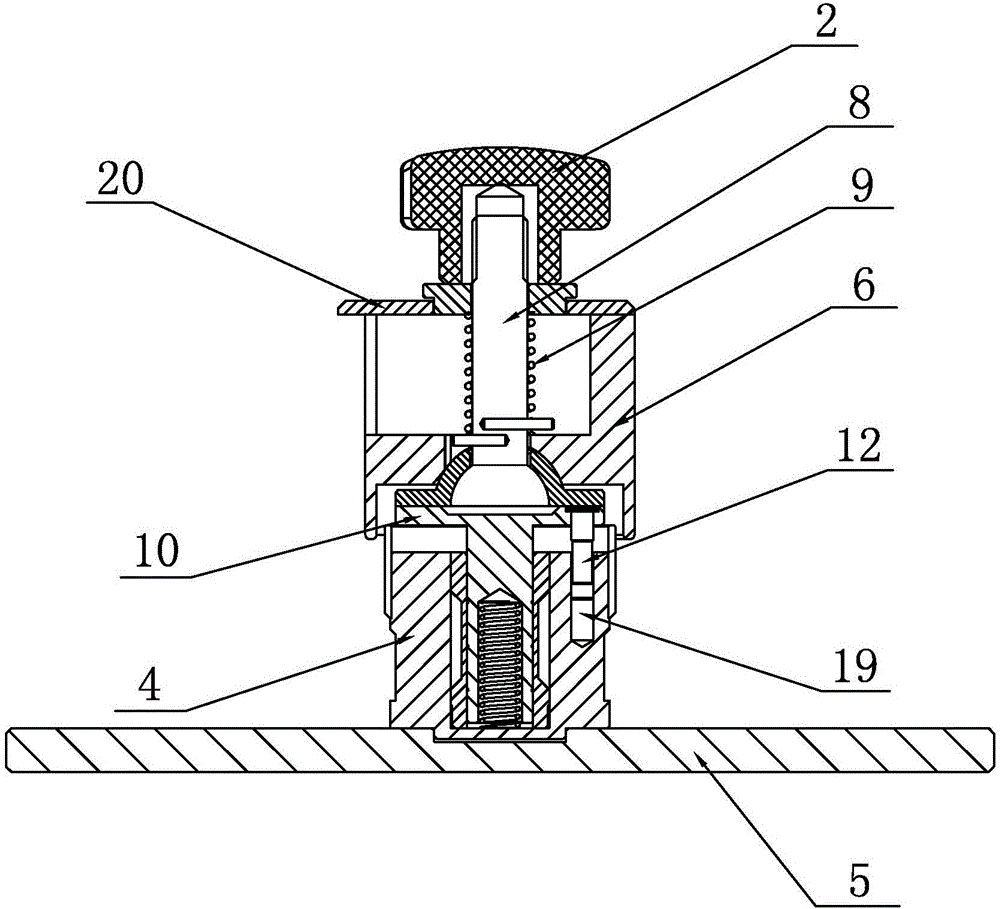

Universal objective table for laser 3D printer

ActiveCN105773982AImprove stabilityAutomatically adjust the tilt angleManufacturing driving meansBall screwArchitectural engineering

Owner:JIANGSU RICH OPTO TECH CO LTD

Laser texturing processing method on surface of roller

InactiveCN101642778BImprove rolling qualityImprove wear resistanceRolling equipment maintainenceMetal rolling arrangementsHelical lineSheet steel

The invention discloses a laser texturing processing method on the surface of a roller, comprising the following steps: leading the roller to rotate with uniform velocity along self axes; simultaneously, leading a laser texturing head to move with uniform velocity along the axial direction of the roller; and periodically transmitting laser beam to the surface of the roller and forming texturing spots on the surface of the roller. The method is characterized in that by accelerating the moving speed V of the laser texturing head along the axial direction of the roller, the texturing spots are distributed along the high inclination-angle helical line with the thread pitch of delta being equal to 2-200mm on the roller. As the roller has no smooth straight line between the two rows of the texturing spots on the circumference of the surface of the roller, when rolling a steel plate, the roller and the steel plate can prevent from jointing at those parts, the iron slag grains can be absorbedby texturing concave holes crisscross distributed on the peripheral direction of the roller, scratch can not be produced on the length direction of the steel plate, and the iron slag grains can not fray and break the texturing spots, thereby greatly improving the rolling quality of the steel plate and the wearing resistance of the roller, and prolonging the service life of the roller.

Owner:苏州市博海激光科技有限公司

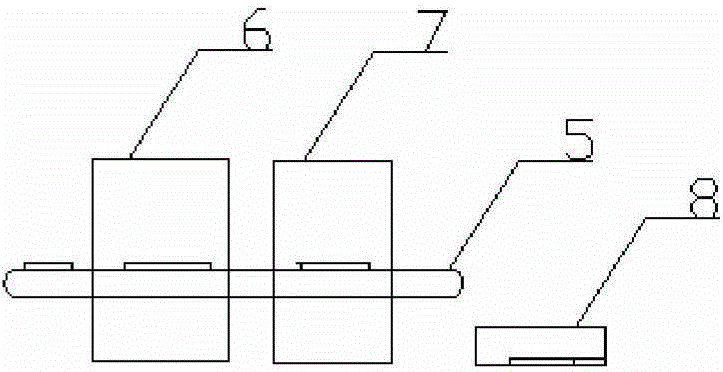

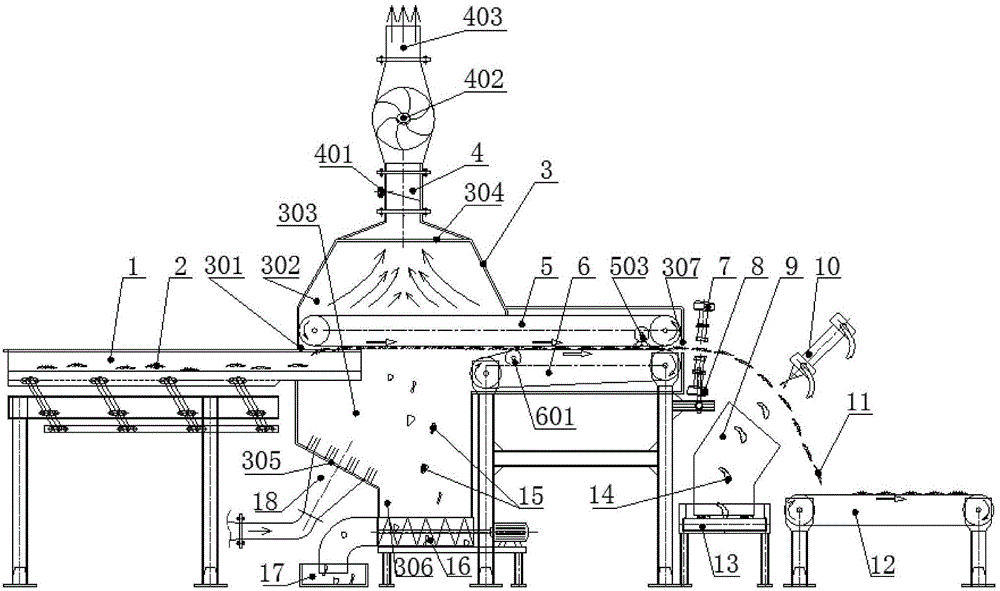

Multifunctional tobacco leaf fine selection device

ActiveCN104824828AComprehensive image recognition without dead endsAchieve attitude controlThrowing machinesTobacco preparationInjection deviceBelt conveyor

The invention provides a multifunctional tobacco leaf fine selection device. The multifunctional tobacco leaf fine selection device is characterized by comprising a tobacco leaf feeding device (1), a sorting box body (3) connected above the tail end of the feeding device (1), a negative-pressure draught fan device (4) mounted at the upper end of the sorting box body (3), a high-speed net belt conveying device (5) covering the inner part of the sorting box body (3) and a high-speed belt conveyor (6) located under the output end of the high-speed net belt conveying device (5). According to the multifunctional tobacco leaf fine selection device, tobacco leaves are thrown out from the outlet of the sorting box body (3) in a mutual clamping manner of the high-speed net belt conveying device (5) and the high-speed belt conveyor (6), so that the flat treatment on the tobacco leaves can be realized; a first air flow injection device (503) is mounted at a discharging end of the high-speed net belt conveying device, so that the tobacco leaves are prevented from being continuously stuck on a high-speed net belt and the tobacco leaves can be smoothly thrown out.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

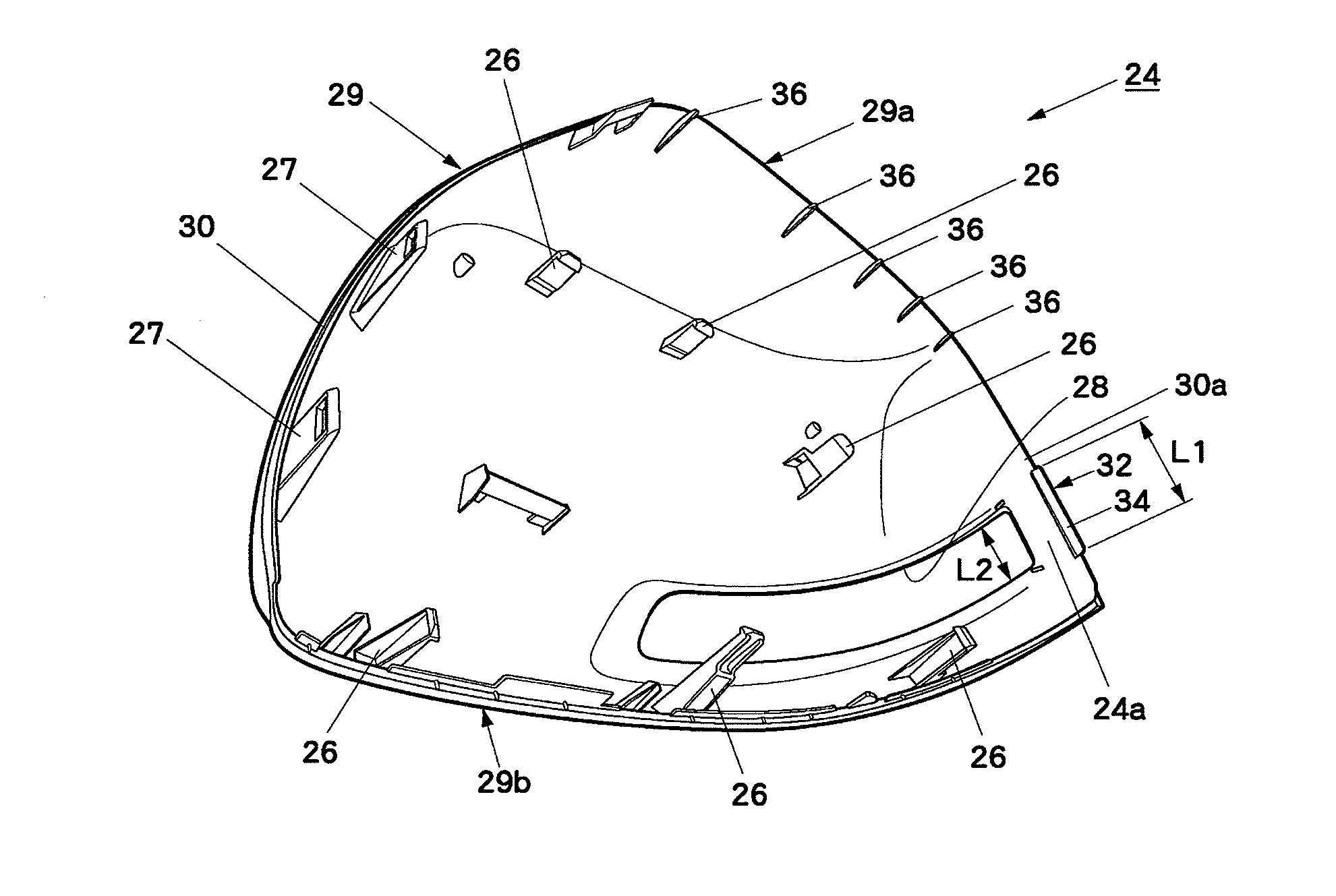

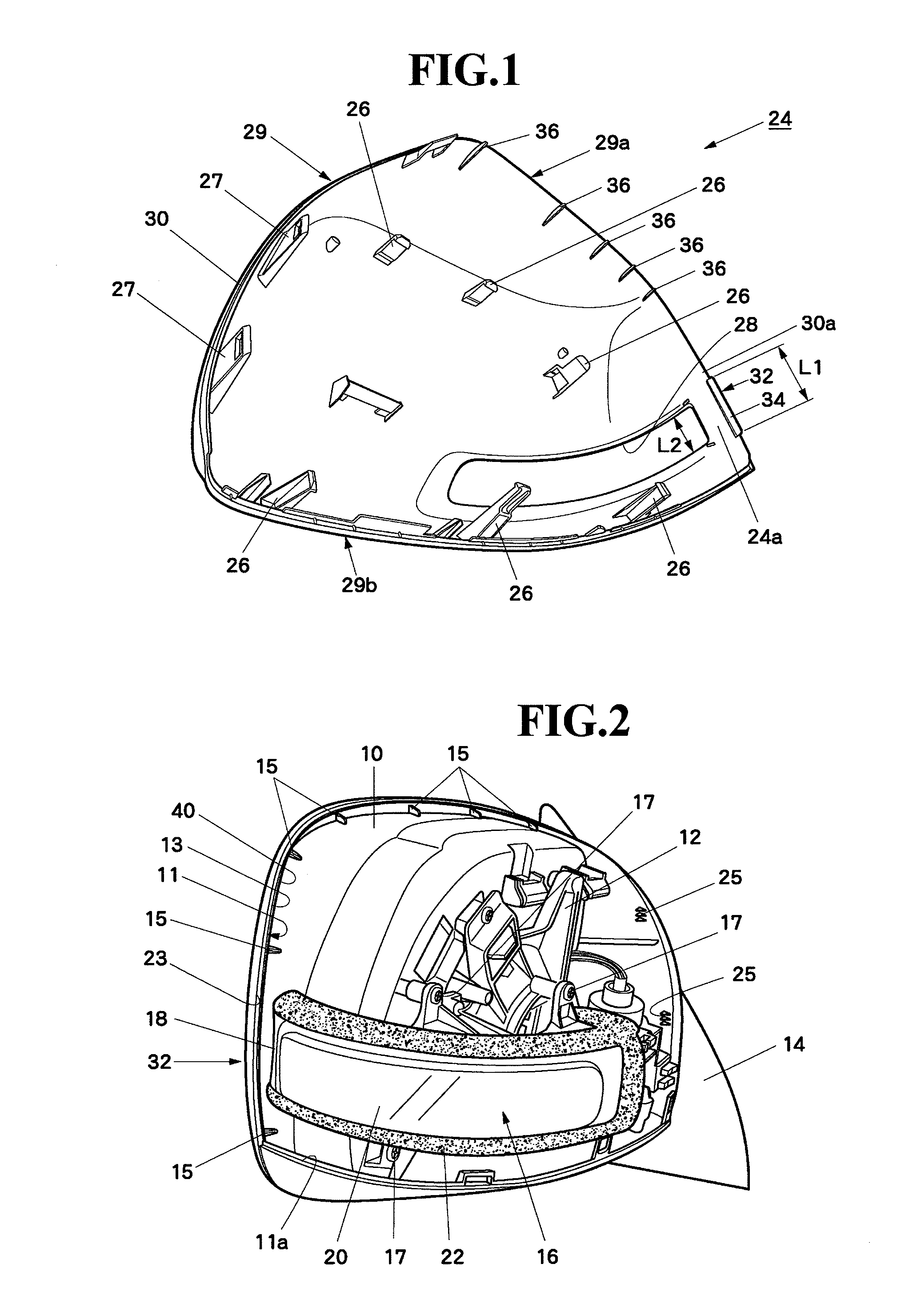

Outer mirror with turn lamp

ActiveUS20110051444A1Reduce number of stepReduce numberElectrolytic capacitorsFluid resistance measurementsElectrical and Electronics engineeringWing mirror

There is provided an outer mirror with turn lamp that facilitates assembling of a housing cover to a mirror housing and increases strength of the housing cover. A turn lamp assembly is mounted to a mirror housing. A housing cover is placed over and mounted to a partial area of the mirror housing. Thus, a lens of the turn lamp assembly is exposed through an opening formed in an outer position of the housing cover. The mirror housing and the housing cover are connected to each other with a ridge and a groove in end surfaces and abutting against and fitting each other. On a wall on an inner side of the mirror that constitutes a part of the component of the groove in the housing cover, at an assembling start position in an outer position outside the opening, an assembling leading rib is formed that protrudes in a direction abutting against the end surface of the mirror housing.

Owner:MURAKAMI CORP

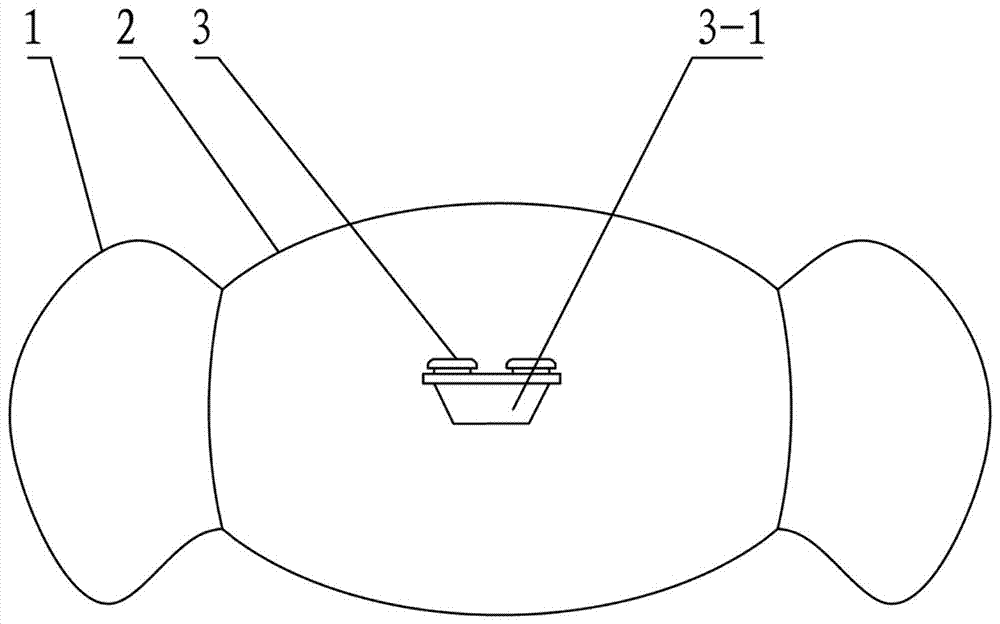

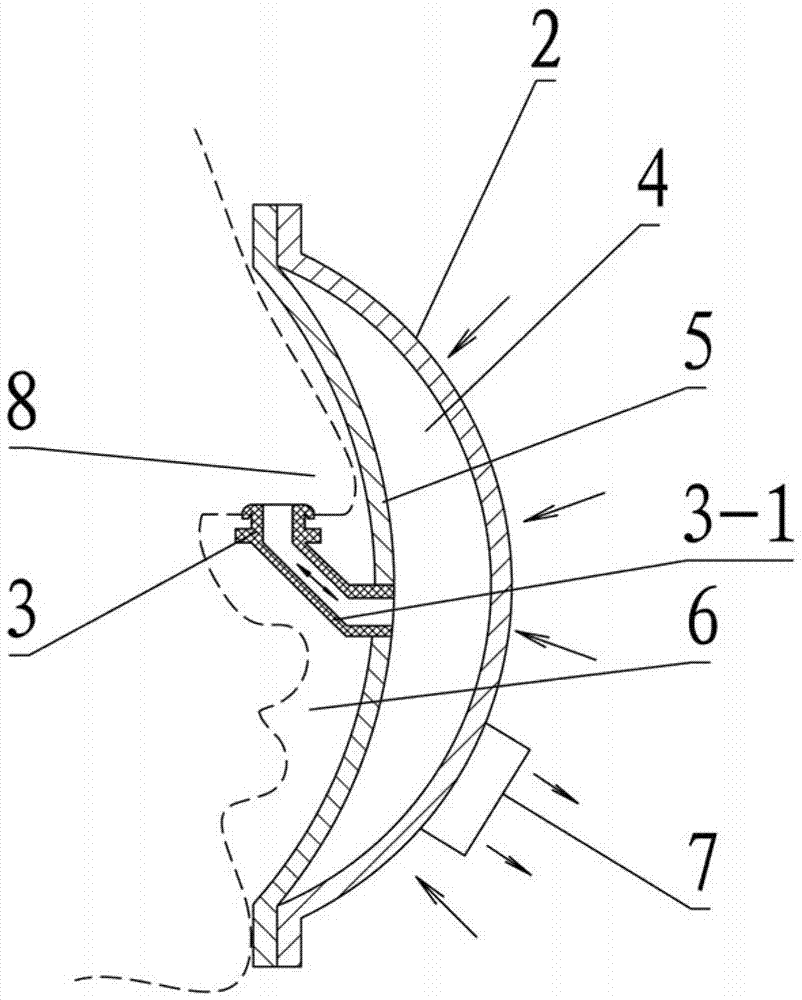

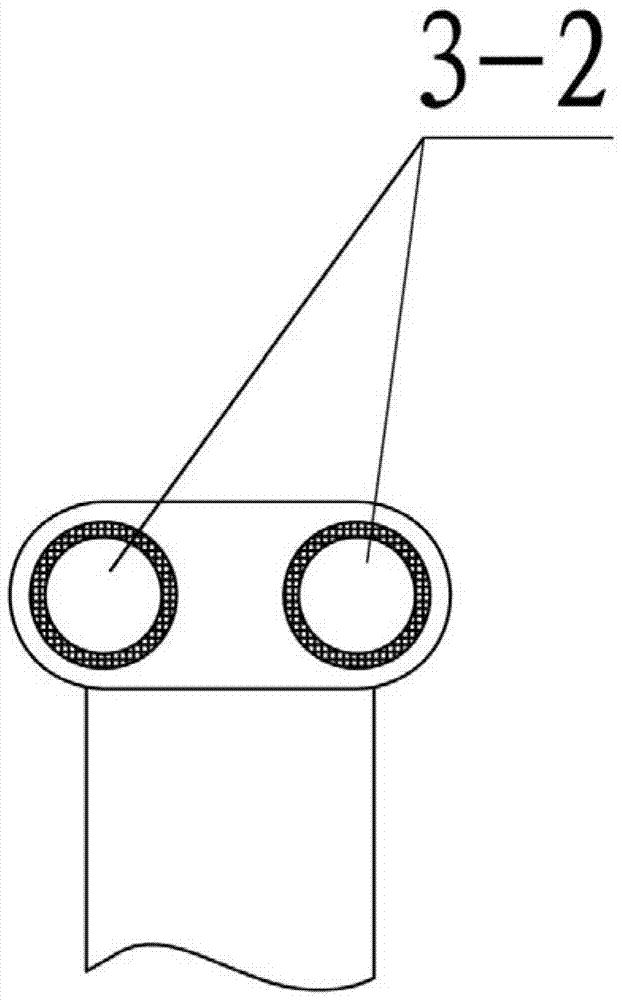

Novel nasal suction type mask

The invention provides a novel nasal suction type mask, for solving the problems that the air tightness of the existing mask is poor, the breathing gas is deposited on the face, so that the stiflingly hot and damp feeling and foreign smell are generated, and the facial makeup-up effect is easily damaged. According to the technical scheme: the novel nasal suction type mask comprises a facial mask part with hanging belts; the technical key points are as follows: the facial mask part is a facial mask body formed by gas filter screen cloth with a one-way air outlet valve, wherein a gas isolating cloth layer is arranged along the inner side edge of the facial mask part, a ventilation cavity is formed between the gas isolating cloth layer and the facial mask part, a ventilation pipe type rubber nasal plug with a supporting section is arranged on the side, facing the human face, of the gas isolating cloth layer, and a ventilation pipe of the rubber nasal plug communicates with the ventilation cavity. The novel nasal suction type mask does not attach to the face, the air tightness is extremely good, the comfort feeling is improved, the phenomenon that the exhaled damp gas is deposited on the face is avoided, so that the face is dry and clean and is free of foreign smell, the novel nasal suction type mask is particularly suitable for wearing of people wearing glasses, the facial makeup-up effect is protected from being damaged, and in addition, the novel nasal suction type mask is simple in structure, light in weight, comfortable to wear and obvious in effect.

Owner:王恒成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com