Universal objective table for laser 3D printer

A 3D printer and stage technology, applied in the field of 3D printing, can solve the problems of inability to adjust the deflection angle, time-consuming and laborious, and influence of 3D printing effect, and achieve the effect of easy installation, easy adjustment, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

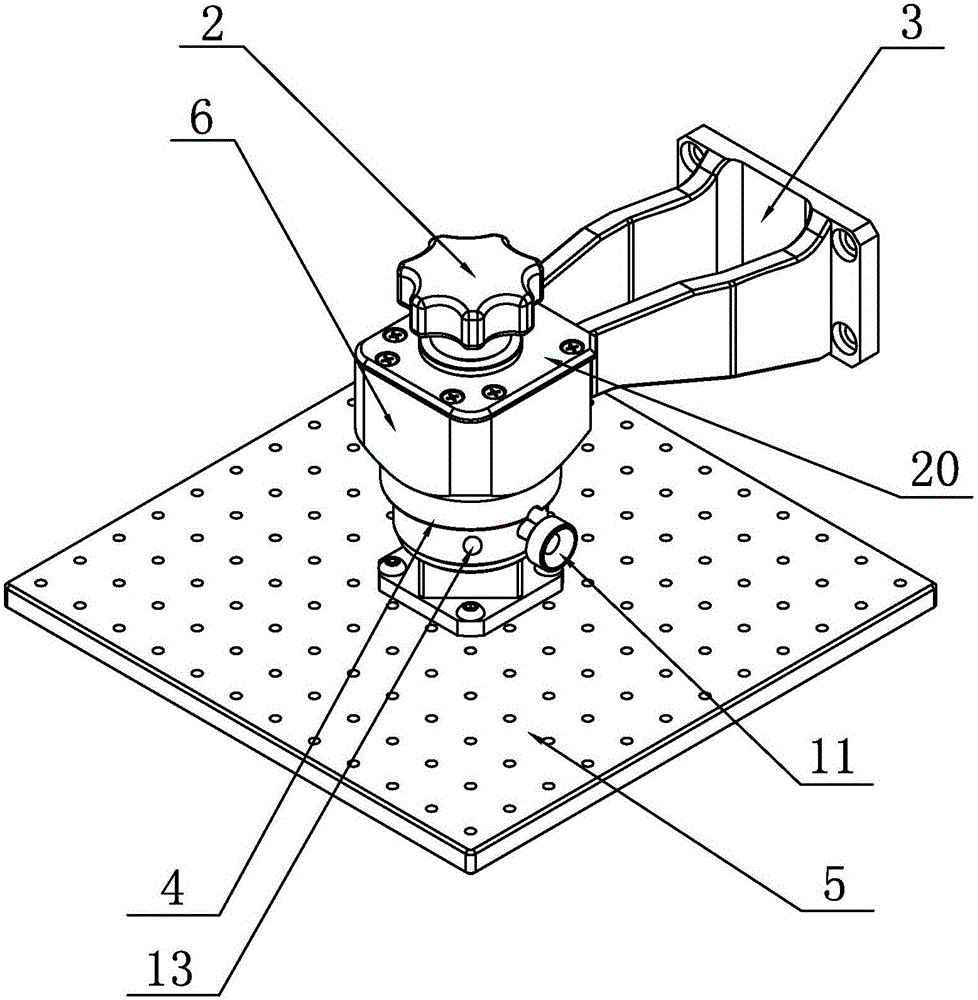

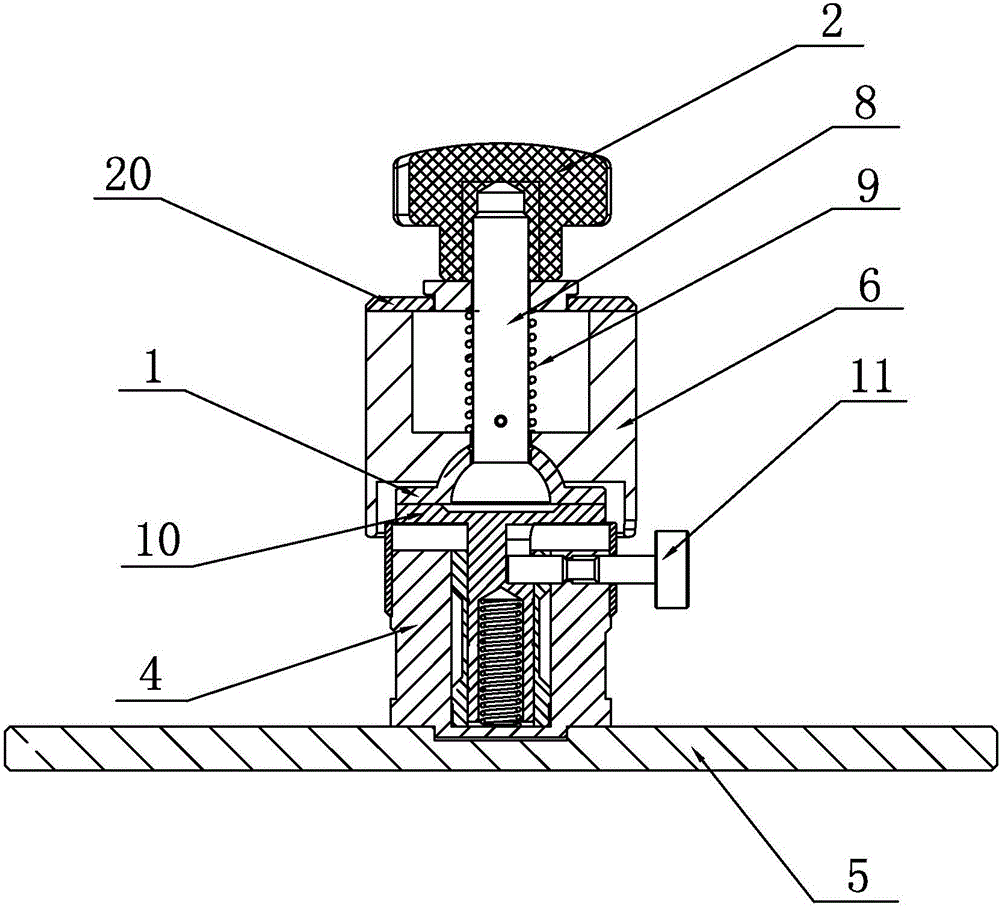

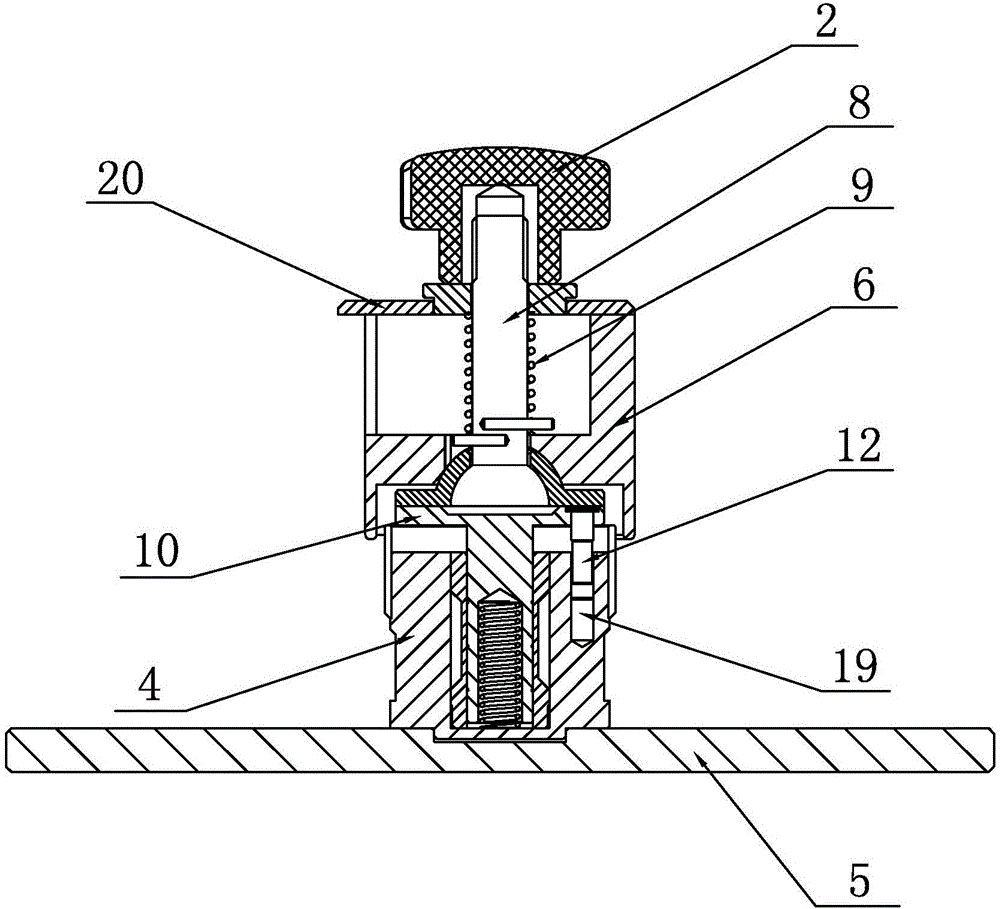

[0015] Such as figure 1 , figure 2 , image 3 As shown, it is a universal stage for a laser 3D printer of the present invention, including a knob 2, a ball screw 8, a telescopic connecting ring 1, a telescopic connecting rod 10, a protective cover 4 and a stage 5, the top of the ball screw 8 and the knob 2 The bottom end is connected by thread, and the outer side of the ball screw 8 below the knob 2 is provided with a spring 9, the outer side of the spring 9 is provided with a fixed connection sleeve 6, and a top plate 20 is arranged above the fixed connection sleeve 16, and the top of the fixed connection sleeve 16 is connected to the top plate. 20 are fixedly connected by screws between the bottom edges. The middle position of the top plate 20 is provided with a ninth through hole. The top plate 20 is sleeved on the ball screw 8 through the ninth through hole. When the end of the lifting mechanism of the 3D printer is connected, the end of the lifting mechanism of the 3D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com