Patents

Literature

351results about How to "No rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Satellite attitude control method for ground point staring imaging

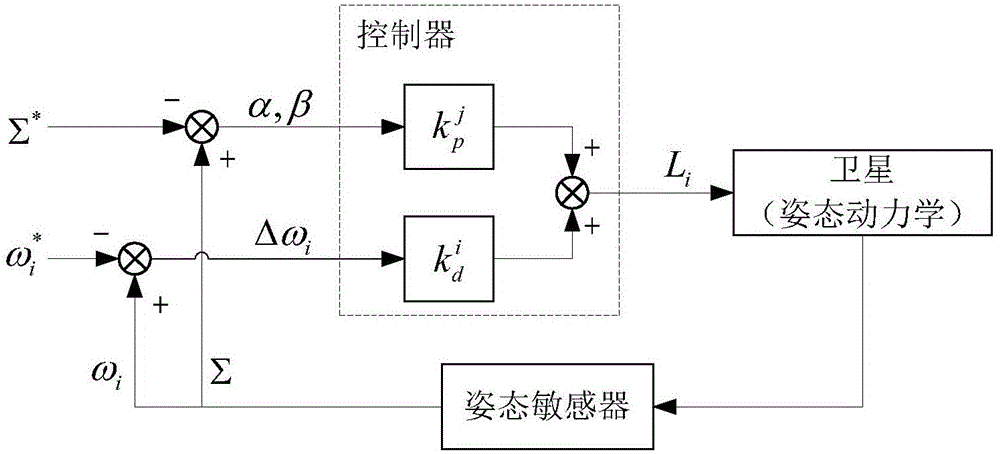

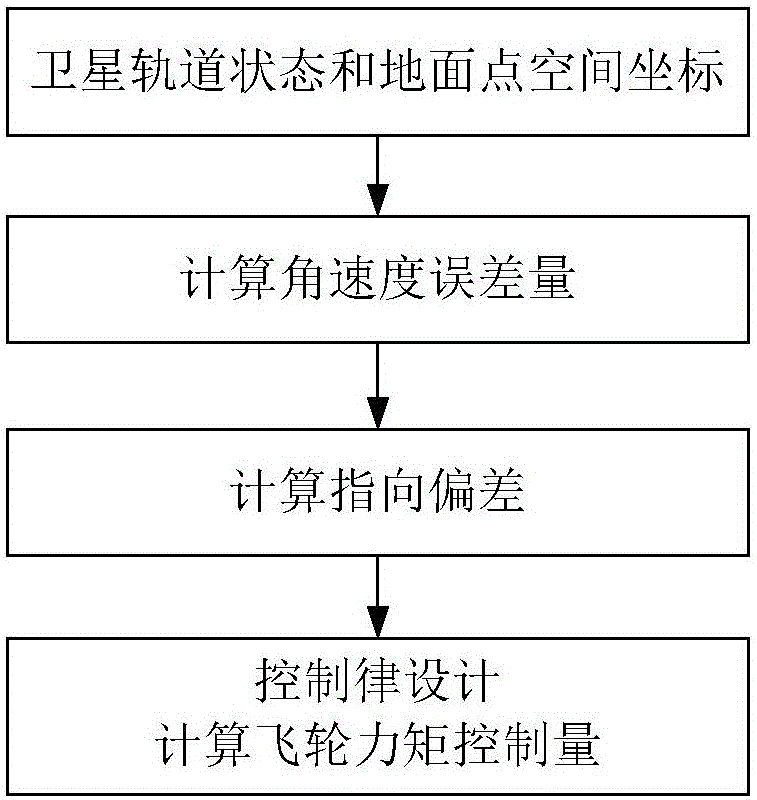

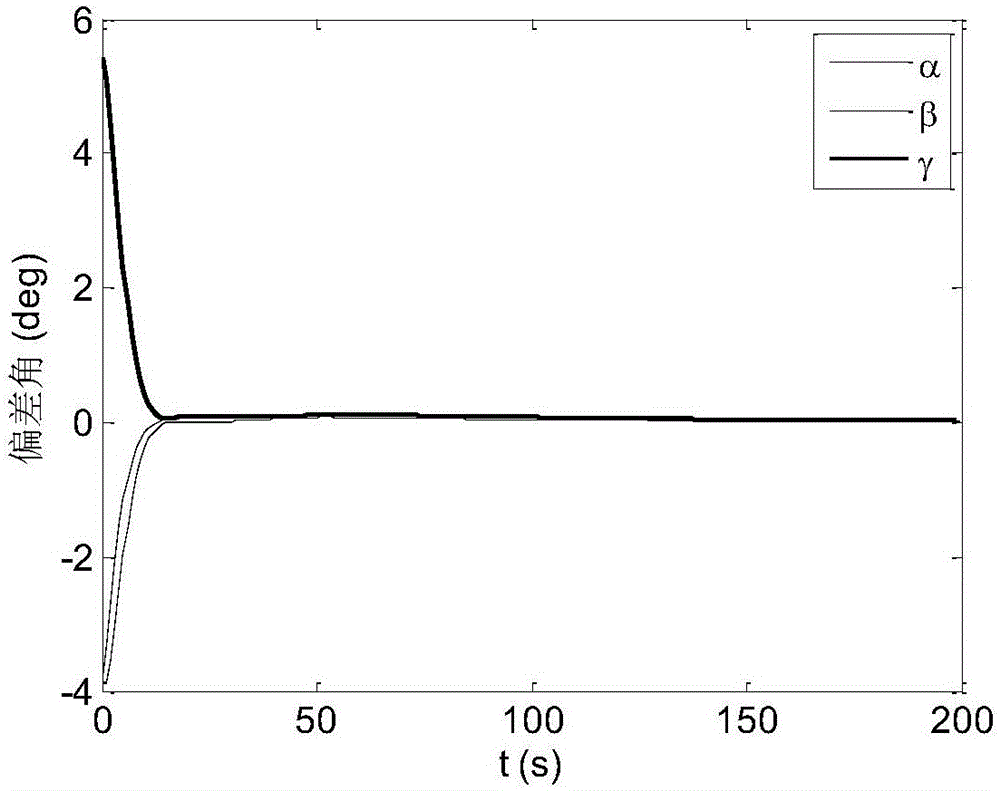

ActiveCN105116910ANo rotationEasy to analyzeAttitude controlControl variableSatellite attitude control

For the problem of staring from a satellite to a ground point, the invention provides a satellite attitude control method for ground point staring imaging. The method includes the steps: calculating an expected staring Euler angle and an expected angular velocity on the basis of a given satellite track state and a given ground point space coordinate, calculating the margin of error between an actual angular velocity and the expected angular velocity, then calculating the value of deviation between an optical axis and a ground point direction on the basis of an actual attitude, selecting a control law parameter, and finally calculating the controlled variable of the moment of a flywheel. In terms of applications, the attitude angle and the angular velocity of a satellite are measured and obtained by an attitude determination system. The controlled variable calculated by the method is transmitted to an executing mechanism, and then a ground point staring attitude control function is achieved. According to the method, a yaw angle can keep being zero, so an image will not rotate within the field of view of a camera, and the image is convenient to observe and analyze. The algorithm of the method is simple, the computation is easy, and the method is easy to achieve in terms of engineering. Moreover, the method exhibits high directional control precision and good directional stability.

Owner:NAT UNIV OF DEFENSE TECH

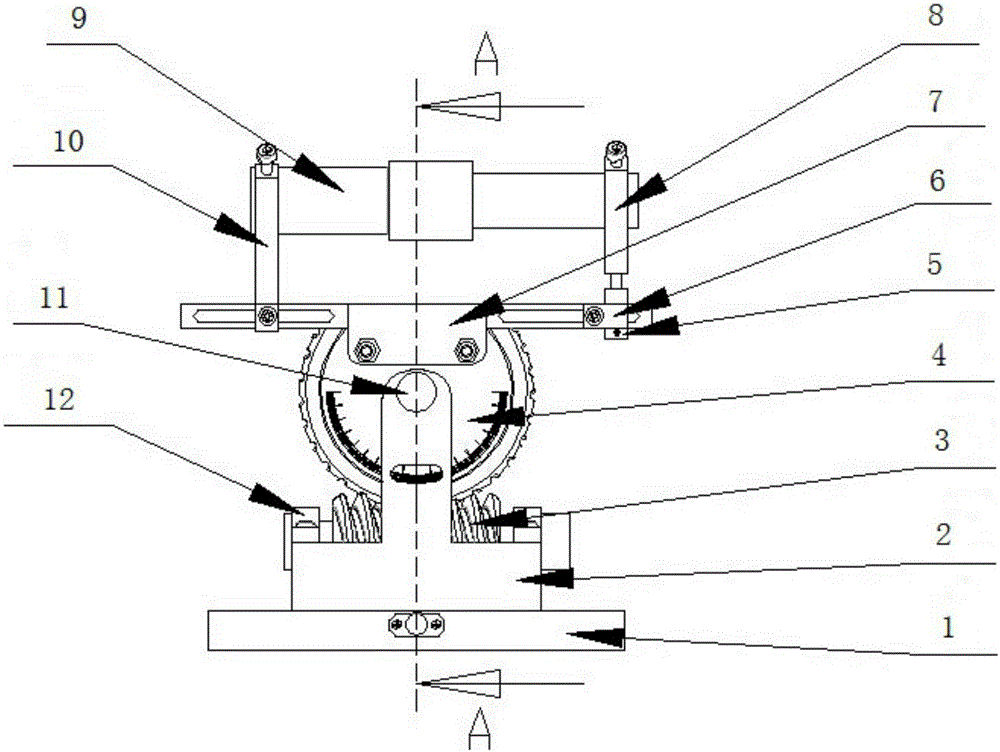

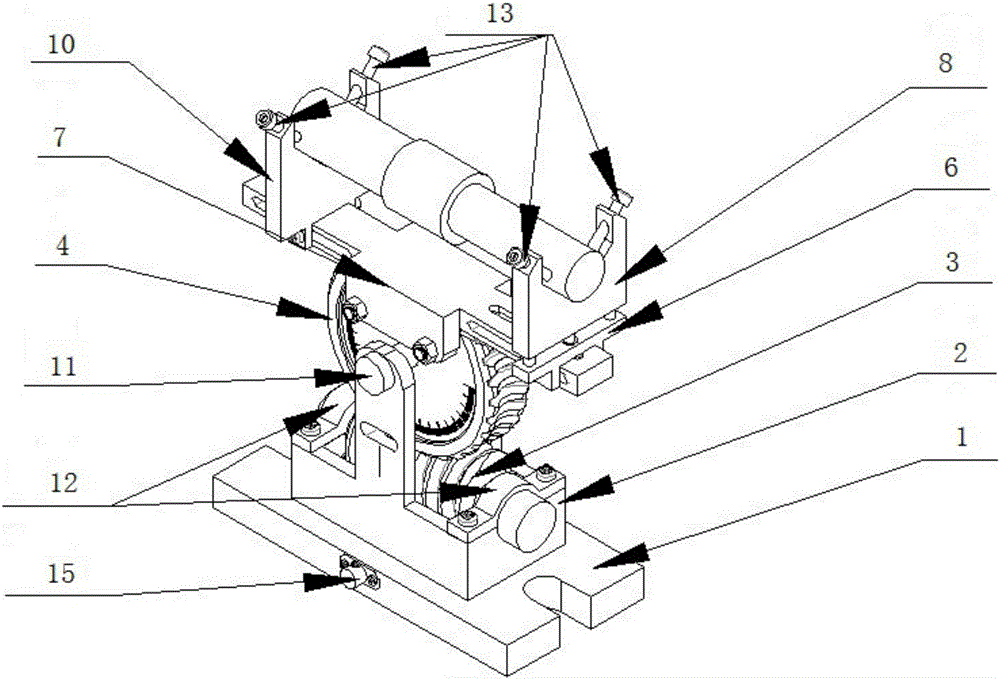

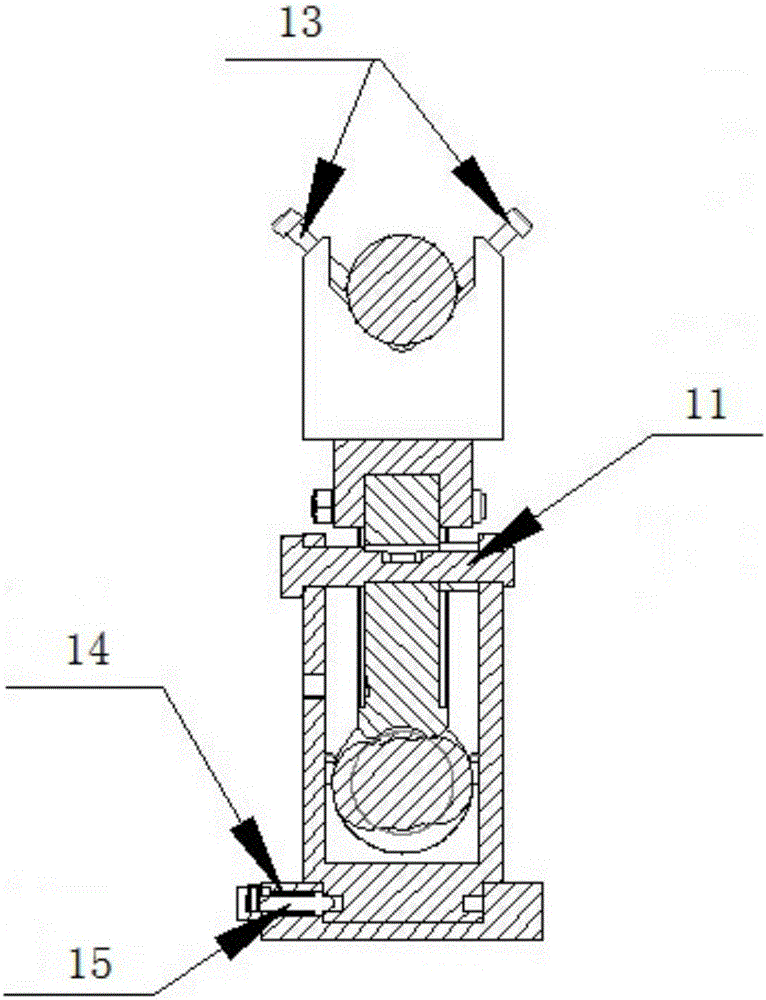

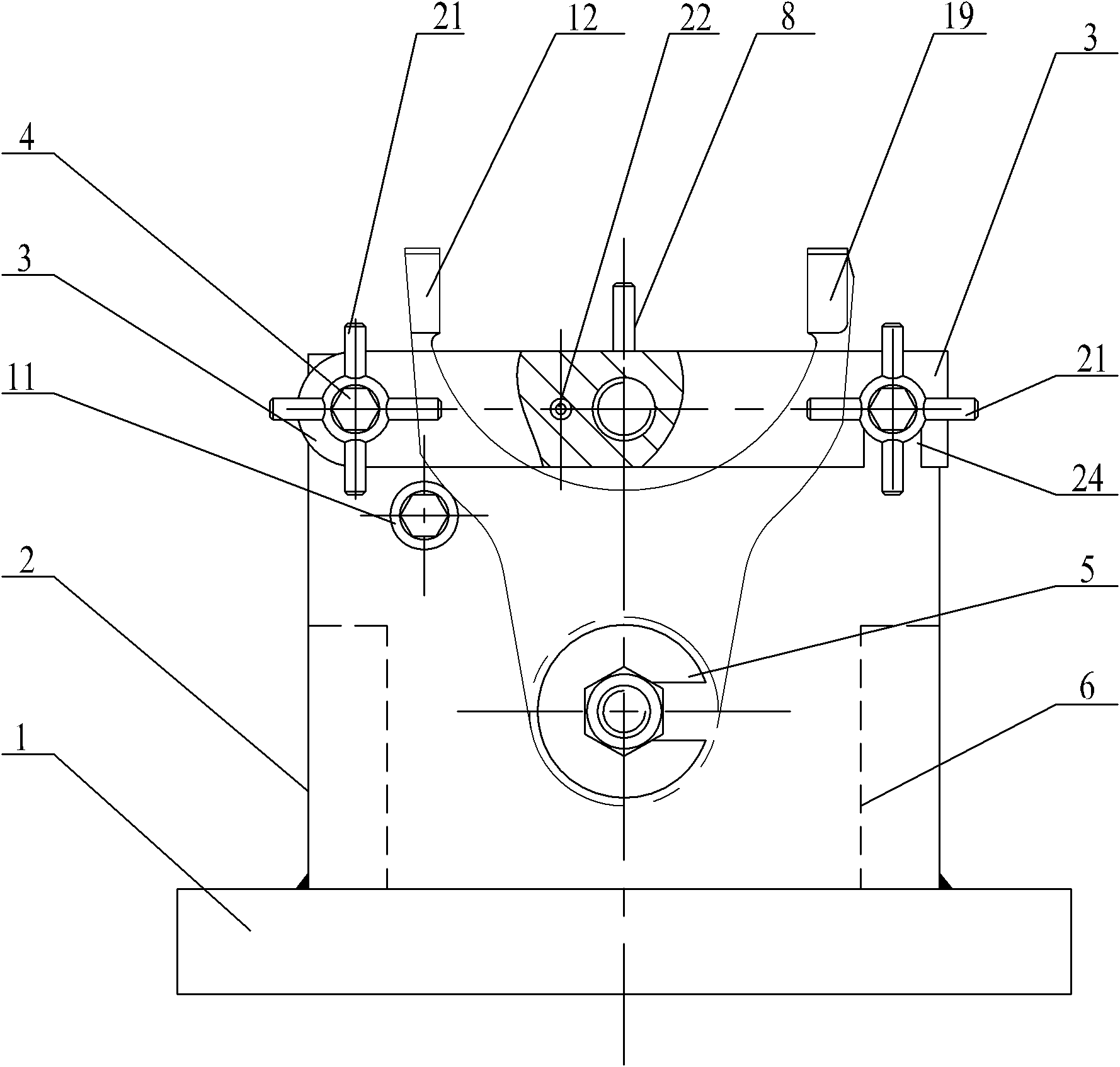

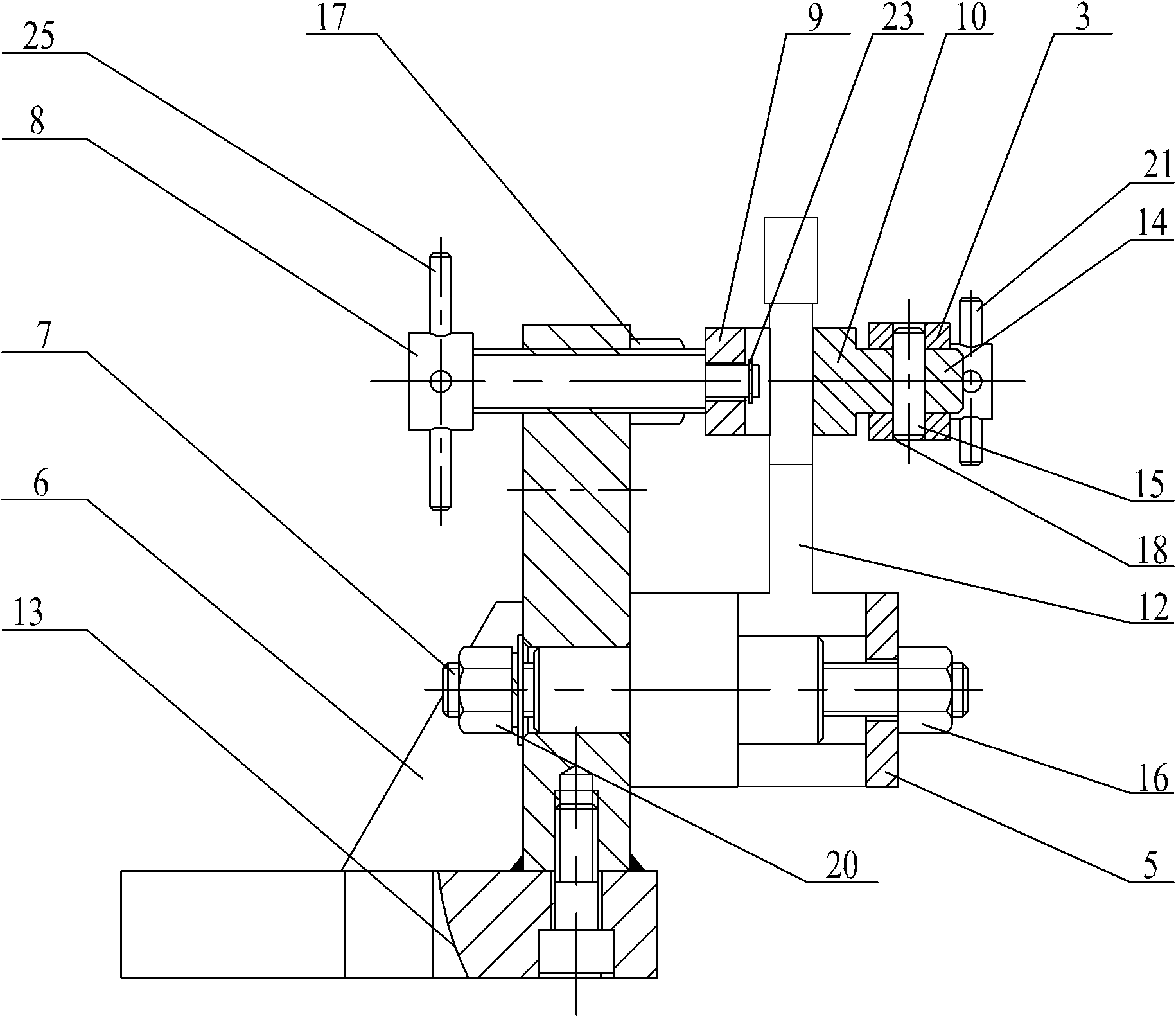

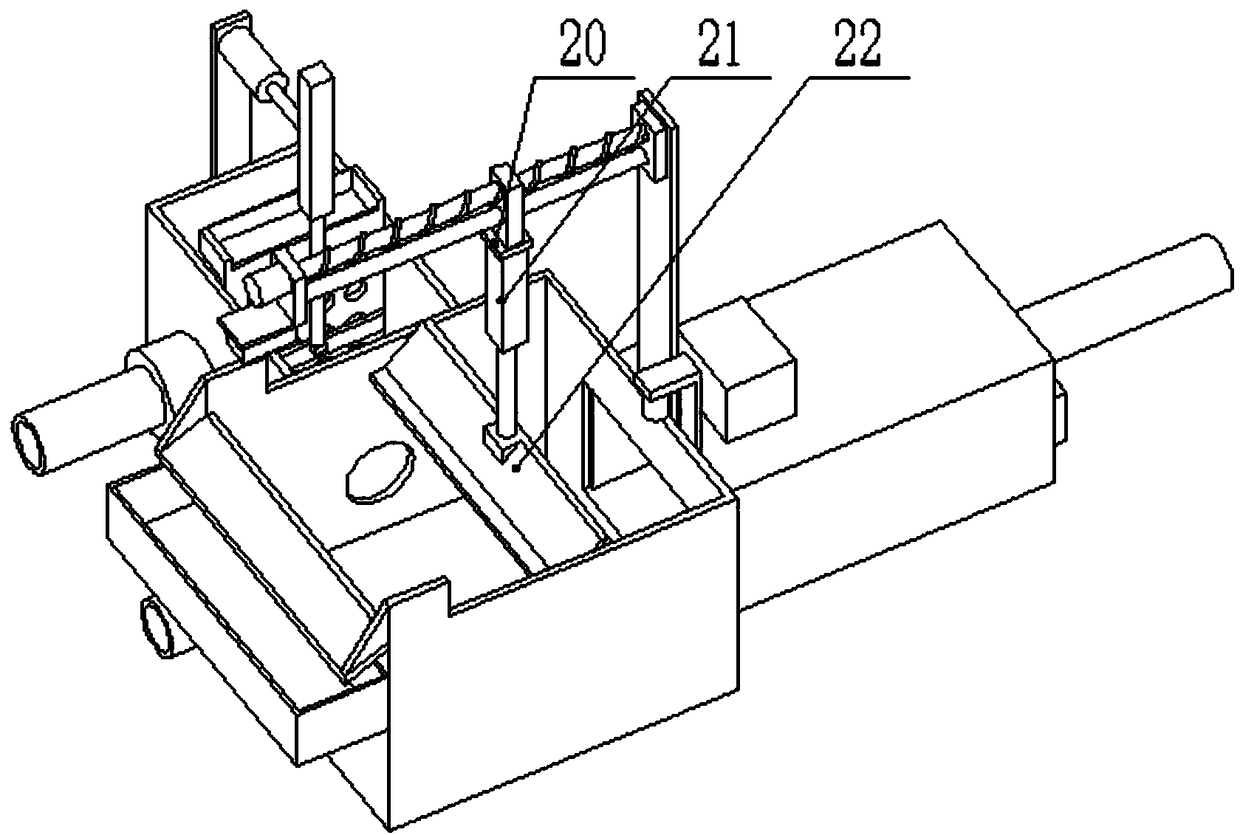

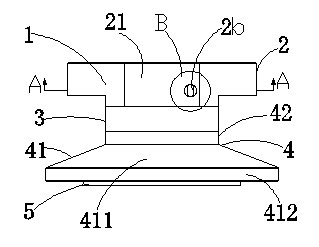

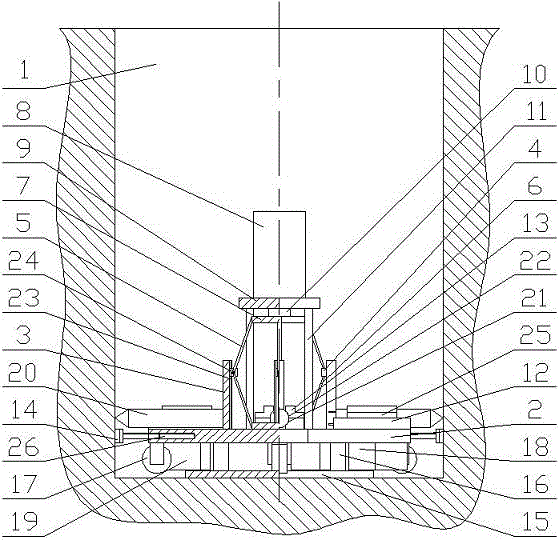

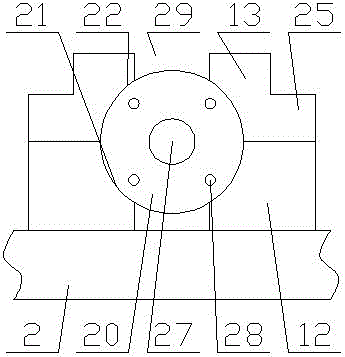

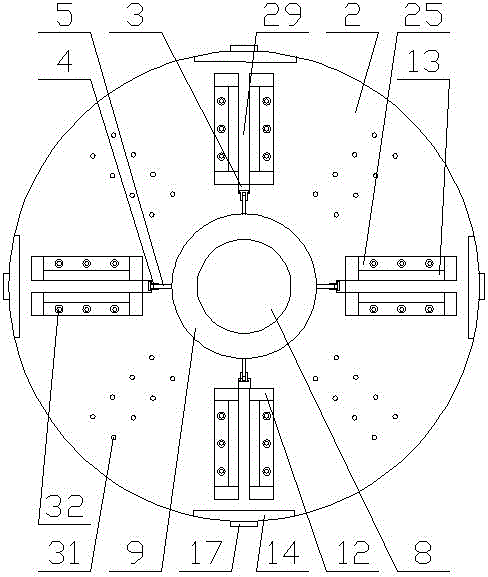

General frock clamp for shaft parts

InactiveCN105855934AConvenient and efficient processingEfficient and convenient detectionPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a universal tooling fixture for shaft parts, which comprises a base fixed on a workbench, a clamping mechanism, an adjusting mechanism and an angle adjusting mechanism. Using the general tooling and fixture for shaft parts described in the present invention, an angle adjustment mechanism is set to realize the placement of shaft parts at any angle and all-round rotation, and the adjustment mechanism is set to adjust different shaft diameters and different lengths. As well as adjusting the clamping position of shaft parts with various shaft diameters on the same shaft, a clamping mechanism with adjustment parts is set up to clamp shaft parts. This device makes shaft parts more accurate during processing, testing and assembly. Efficient and convenient, especially for fast switching when clamping different positions of different shaft parts, which brings great convenience, and can effectively solve the problem of single specification of clamping parts, inflexible placement and troublesome operation of existing shaft parts tooling fixtures, etc. Problem, the device is simple in structure, easy to use, low in cost, and easy to popularize.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

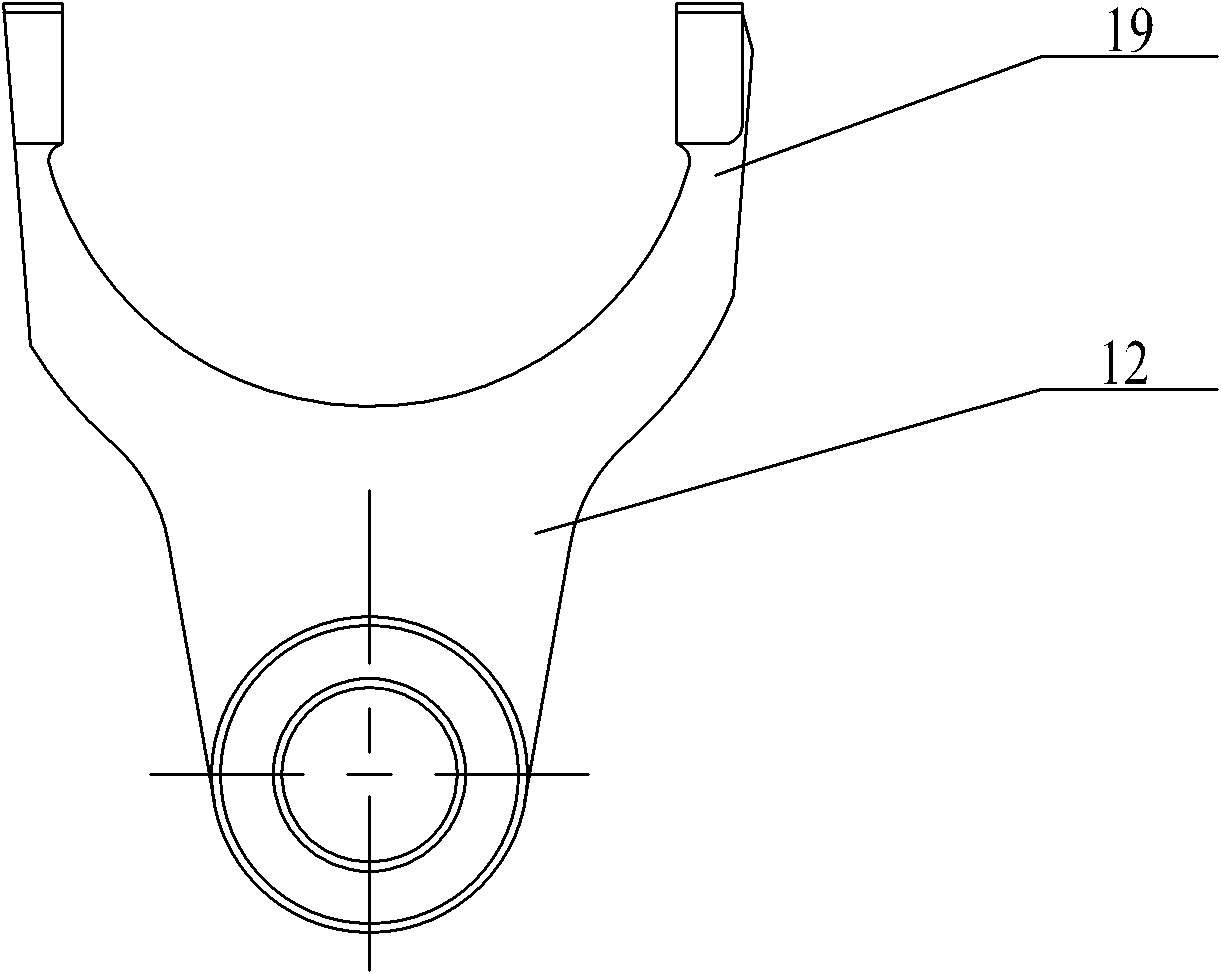

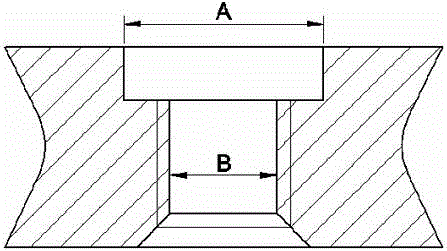

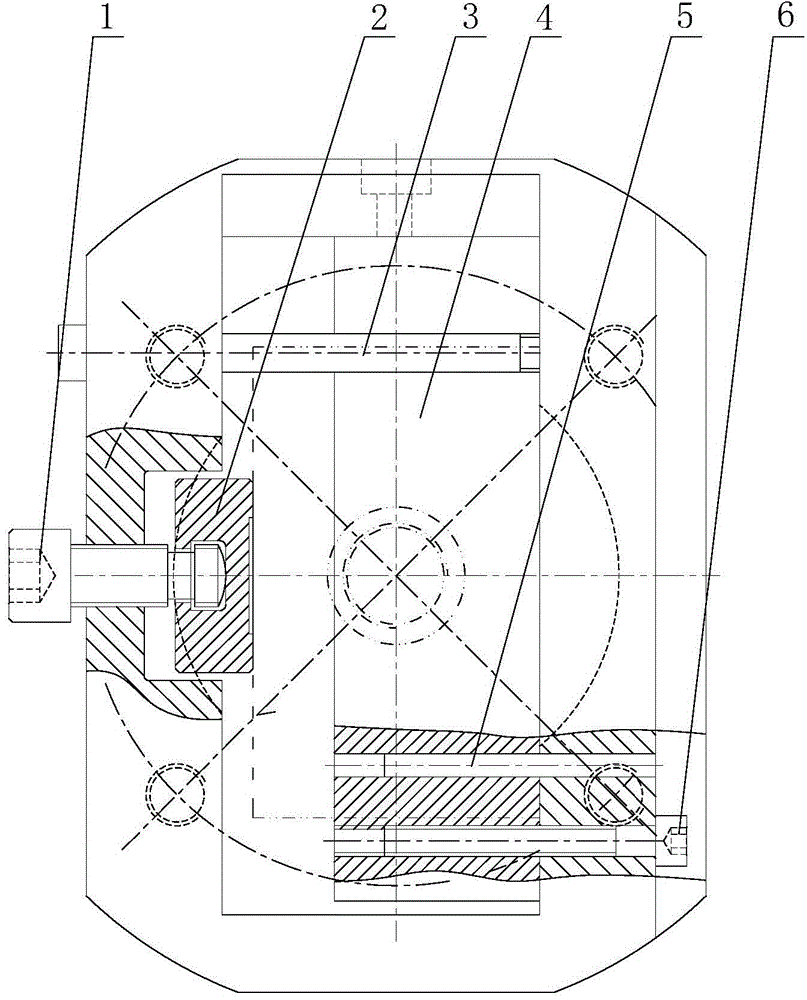

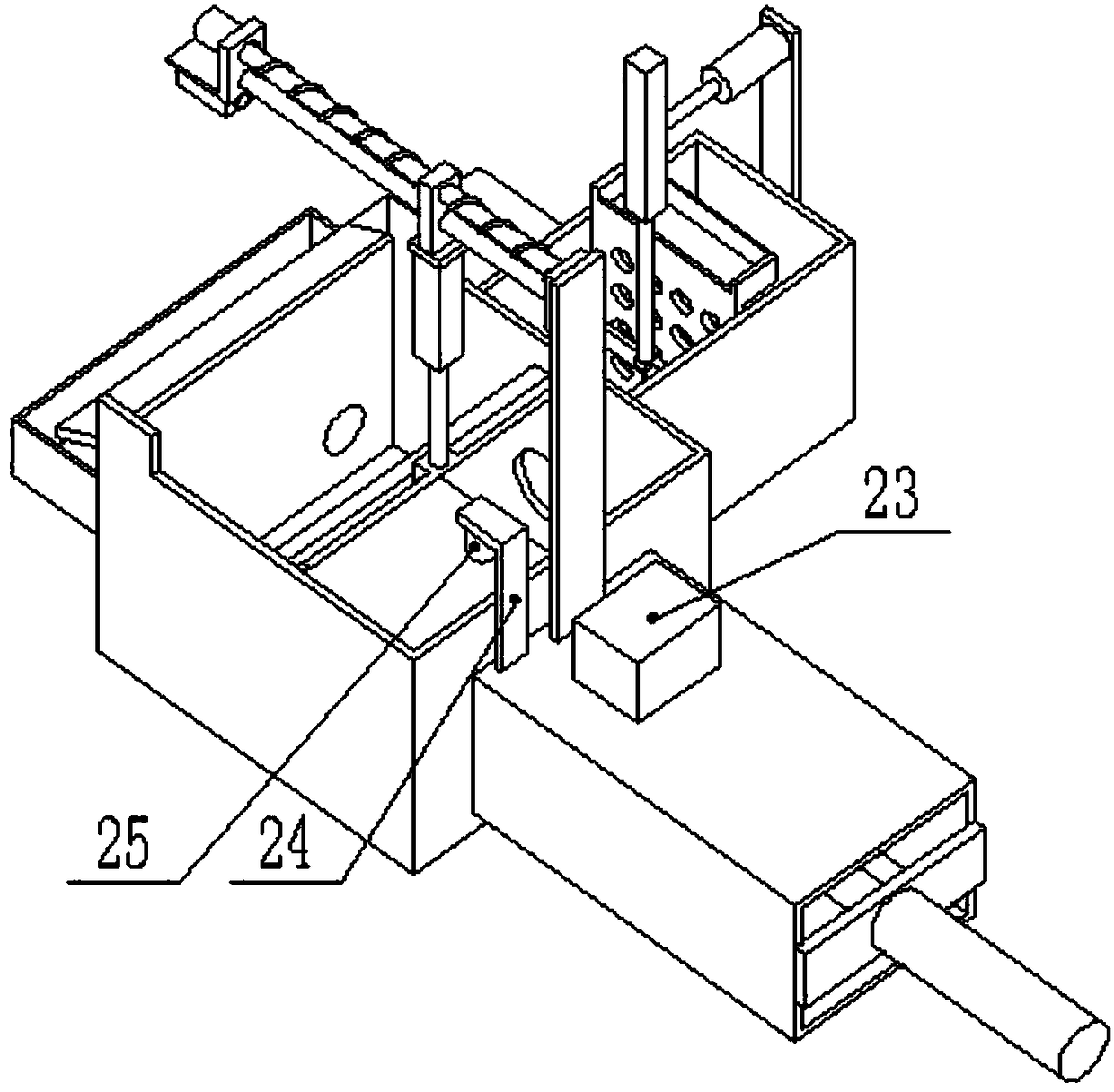

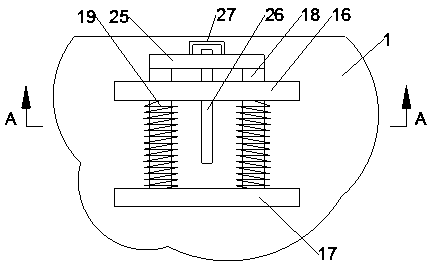

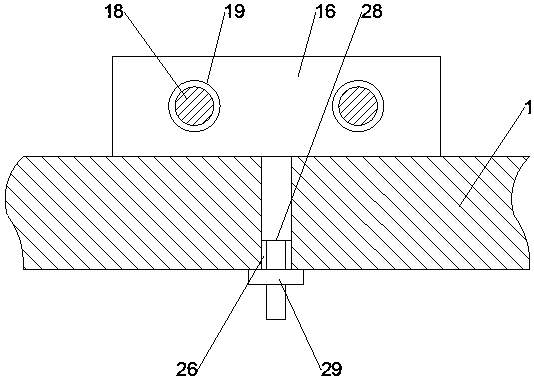

Power takeoff shift fork fixture

ActiveCN102126145AEasy to installNo rotationPositioning apparatusMetal-working holdersEngineeringHigh intensity

The invention relates to a power takeoff shift fork fixture which comprises a base. The base is provided with an open pressure plate for pre-clamping the power takeoff shift fork; the open pressure plate is mounted on a base through a locating pin; and the base is provided with a clamping and locating mechanism for clamping and locating a power takeoff shift fork thin arm. The power takeoff shiftfork thin arm provided by the invention is positioned between a support plate and a movable pressure plate, and can compact the power takeoff shift fork on a flat plate corresponding to the end part with the power takeoff shift fork thin arm so that the power takeoff shift fork thin arm does not rotate during the processing and the accurate processing and locating of the power takeoff shift fork are realized. As the movable pressure plate can move with the clamping pressure plate, the power takeoff shift fork thin arm is conveniently mounted between the support plate and the movable pressure plate; and the power takeoff shift fork fixture is of a compact structure, convenient to mount and use, safe and reliable, avoids the complicated process of high-intensity training as well as processing and locating, improves the production efficiency, lowers the processing cost and realizes high processing precision.

Owner:WUXI WEIFU PRECISION MACHINERY MFG

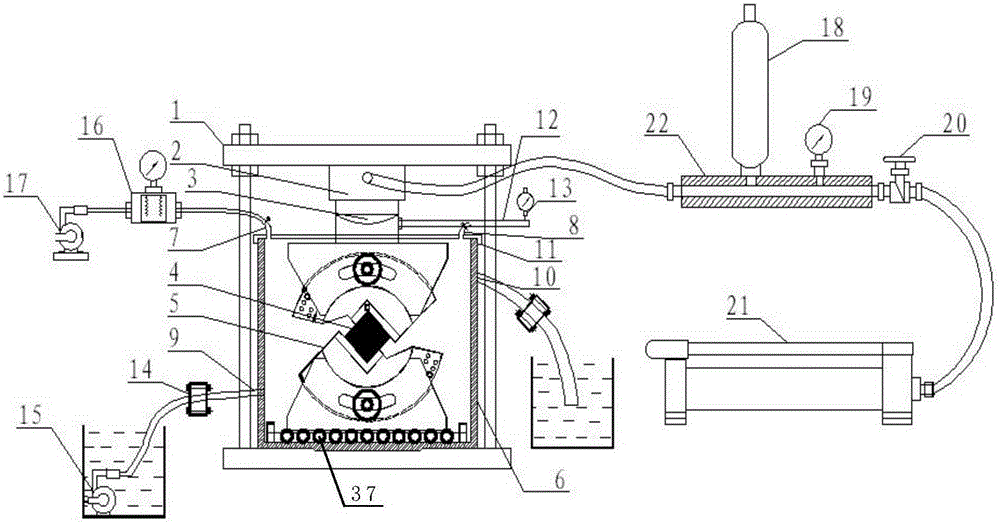

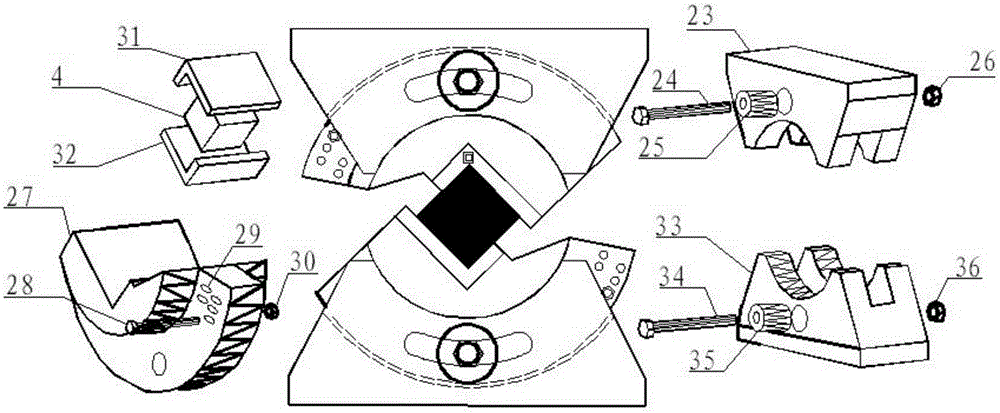

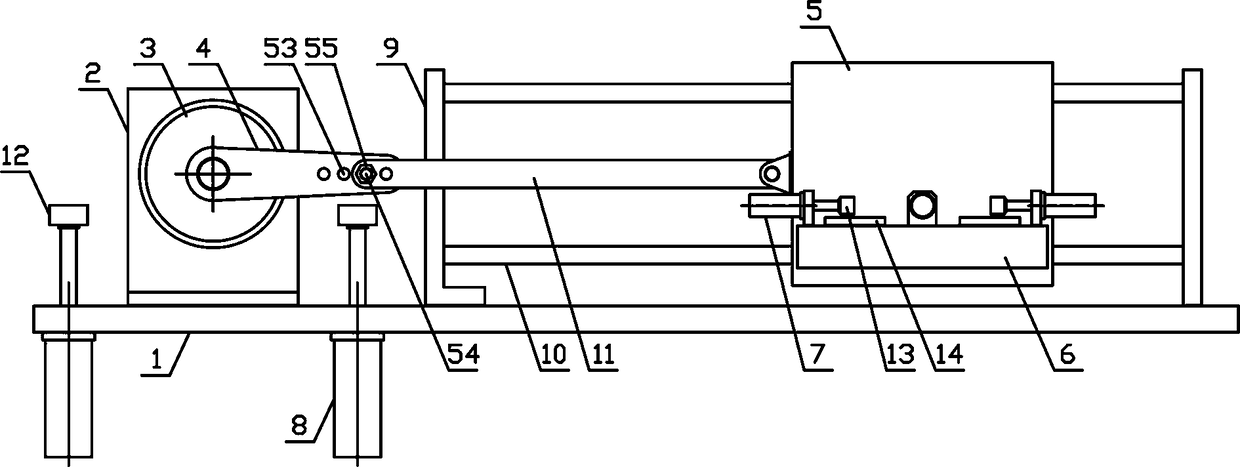

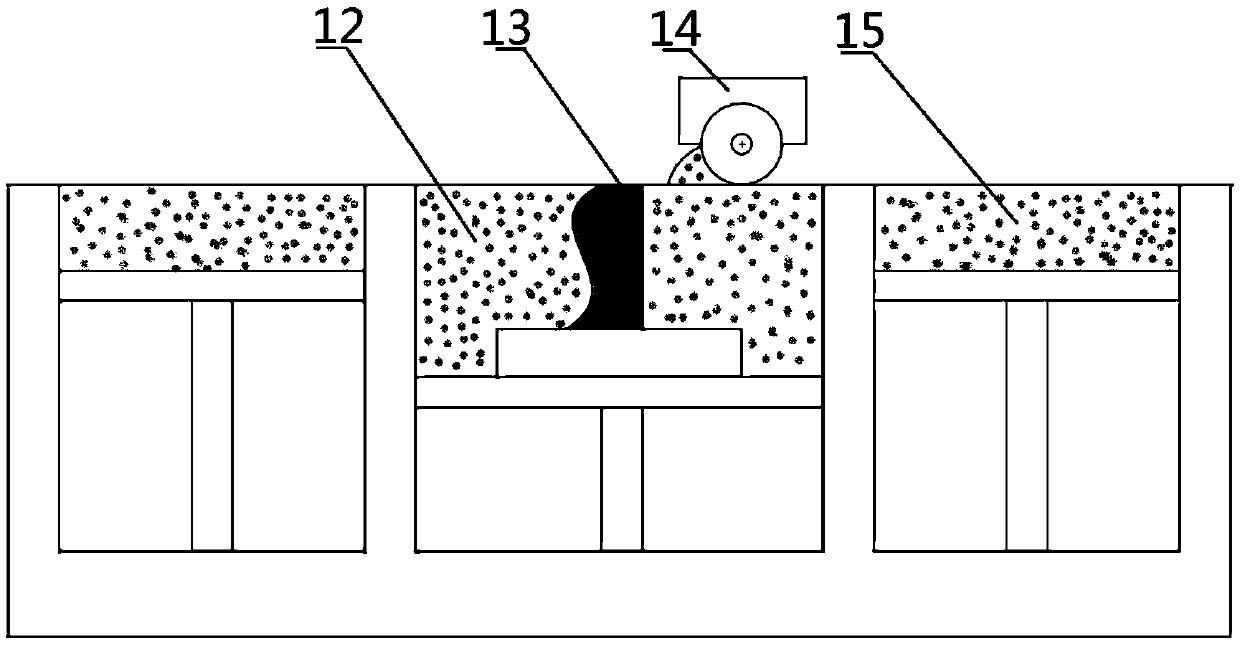

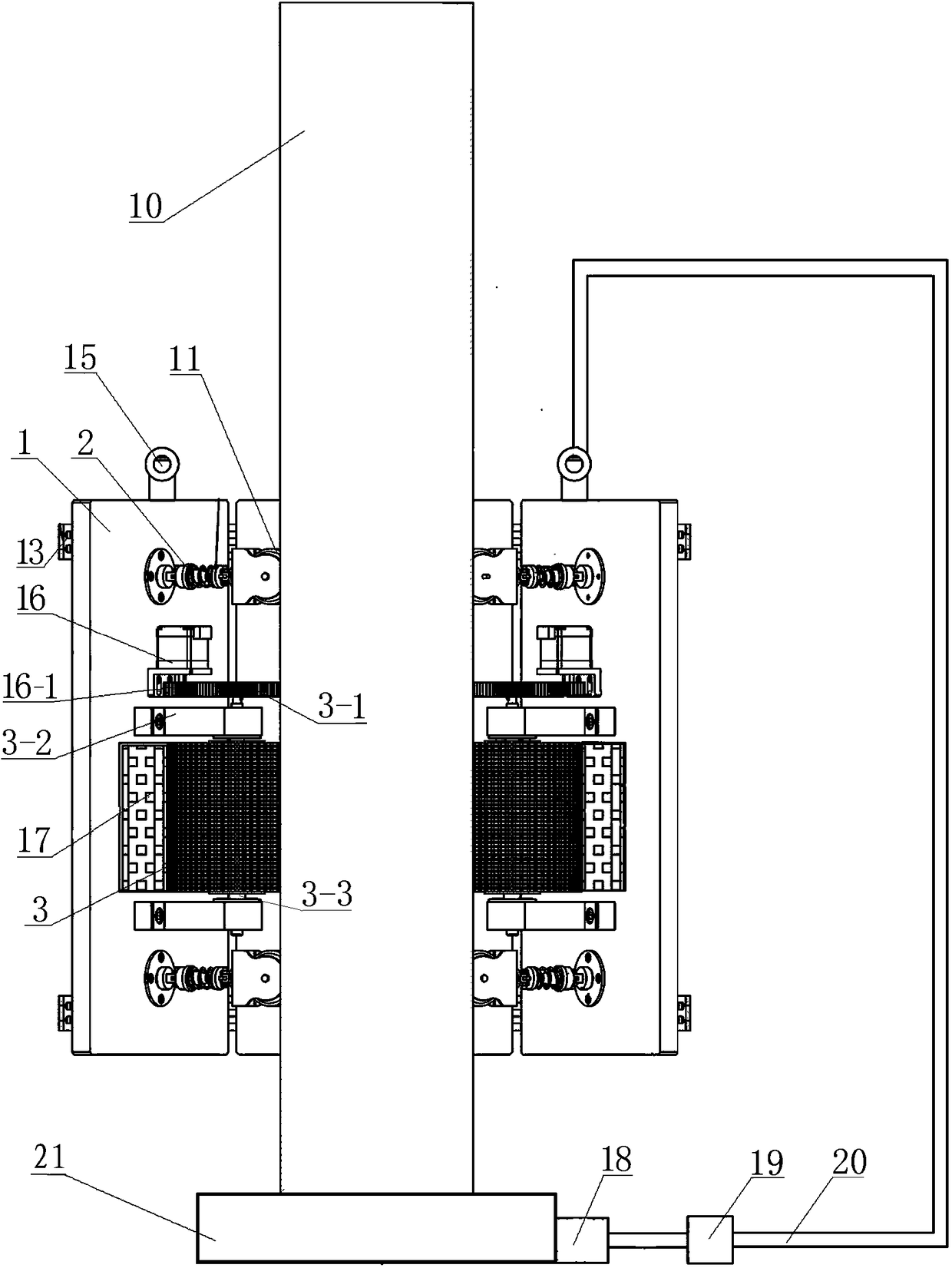

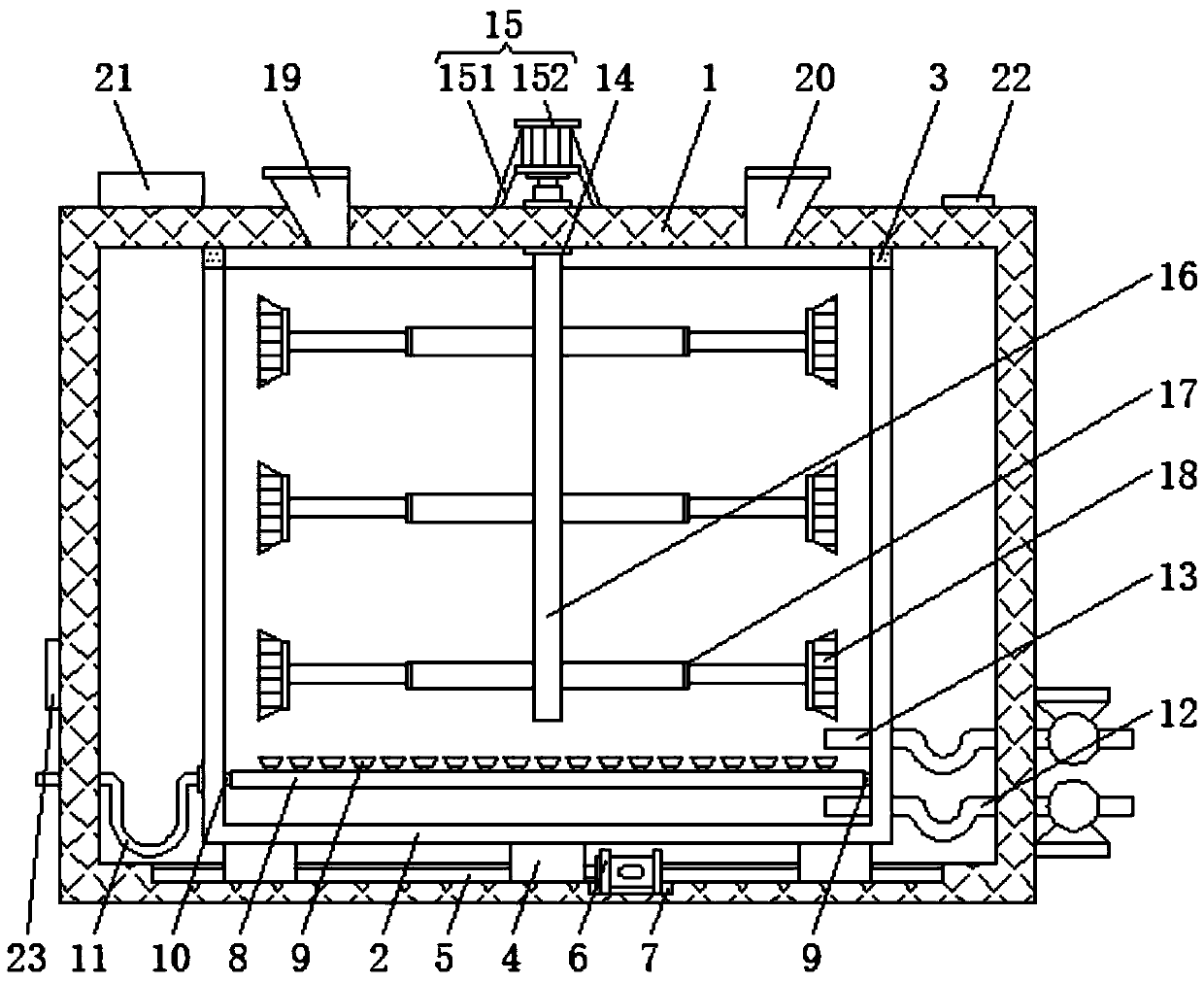

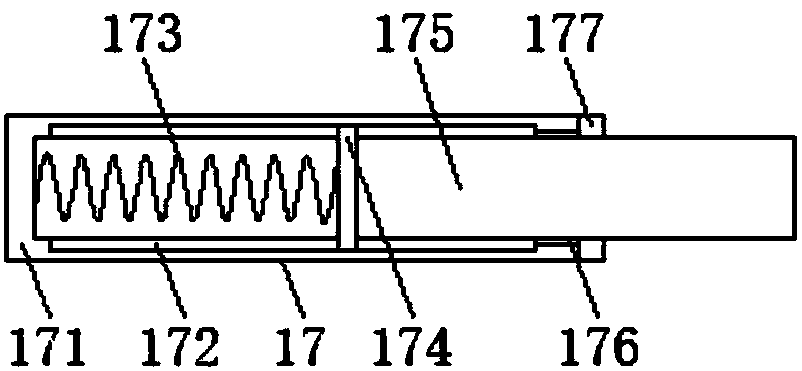

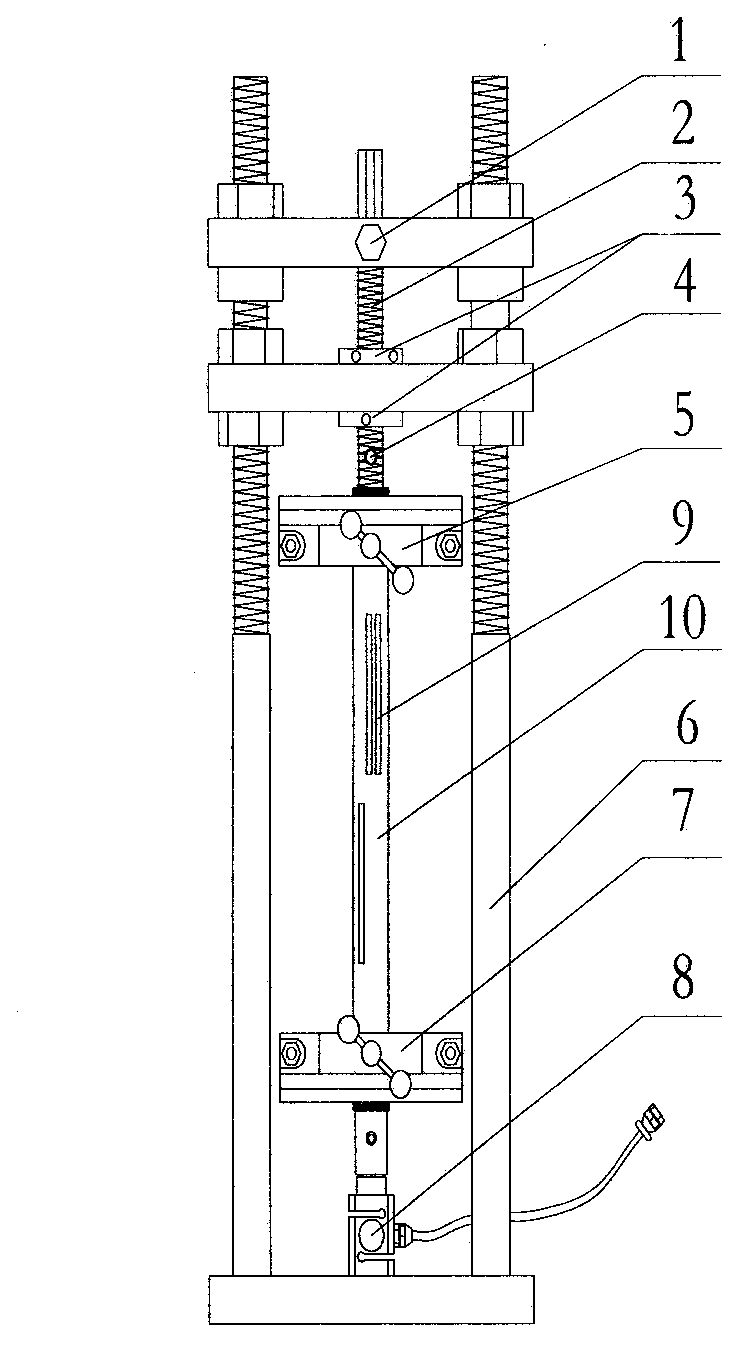

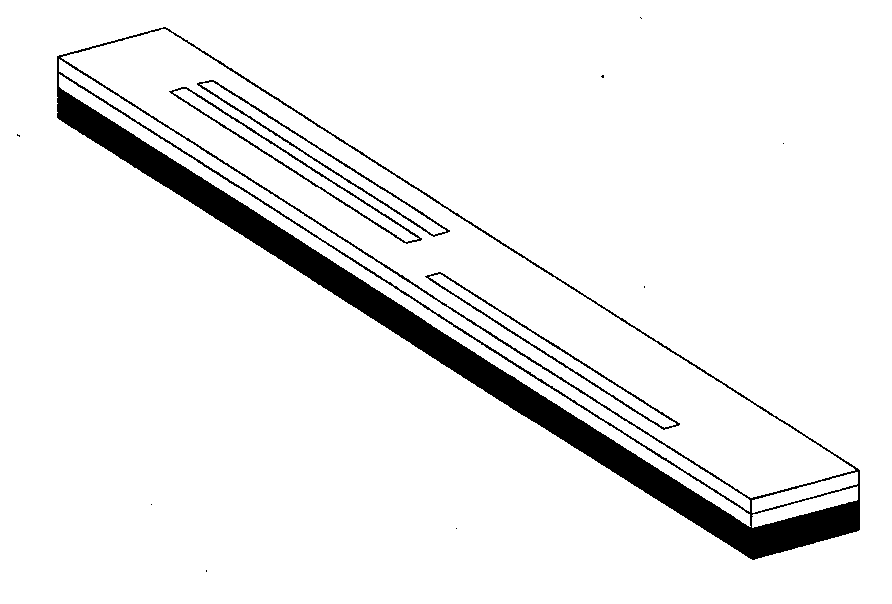

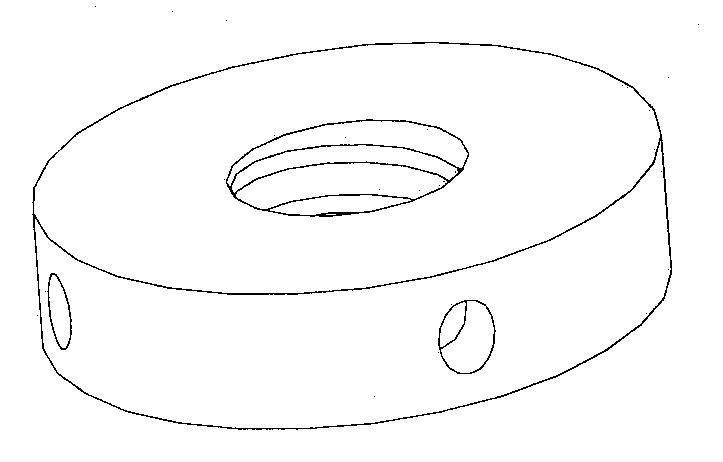

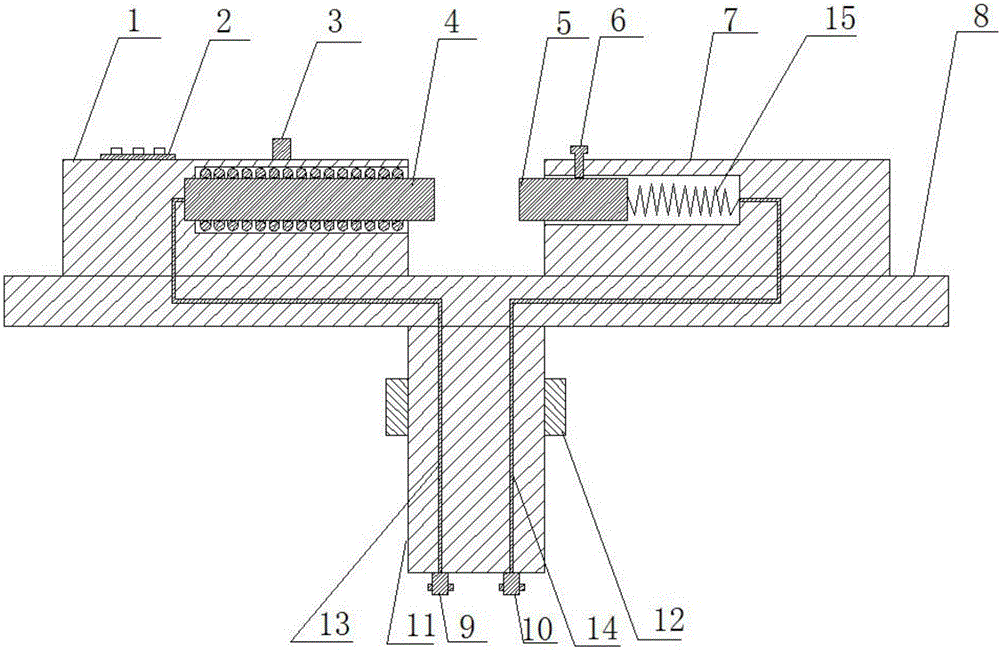

Compression-shear testing apparatus for rock in dry-wet cyclic process

ActiveCN105181483ASimple structureEasy to operateMaterial strength using steady shearing forcesCyclic processEngineering

The invention belongs to the field of geotechnical engineering, and in particular relates to a compression-shear testing apparatus for a rock in a dry-wet cyclic process. The apparatus comprises an angle-variable compression-shear unit, and a compression machine for vertically applying load onto the angle-variable compression-shear unit; the apparatus also comprises a reservoir, water injection equipment for carrying out moisture saturation treatment on a rock sample in the angle-variable compression-shear unit, and heating equipment for carrying out hot-gas drying treatment on the rock sample in the angle-variable compression-shear unit. The angle-variable compression-shear unit is located in the reservoir, and the reservoir is communicated with the water injection equipment and the heating equipment. By adopting the compression-shear testing apparatus, the integration of rock sample dry-wet cyclic treatment and a shear test is realized, and the apparatus has the advantages of simple structure, convenient operation, low cost, wide application range and long service life; the rock samples in different states after different dry-wet cyclic times can be accurately simulated, shear test research is carried out on the rock samples, and moreover, failure load and displacement of the rock samples in the vertical direction in the shear test process can be recorded in real time.

Owner:ANHUI INST OF BUILDING RES & DESIGN

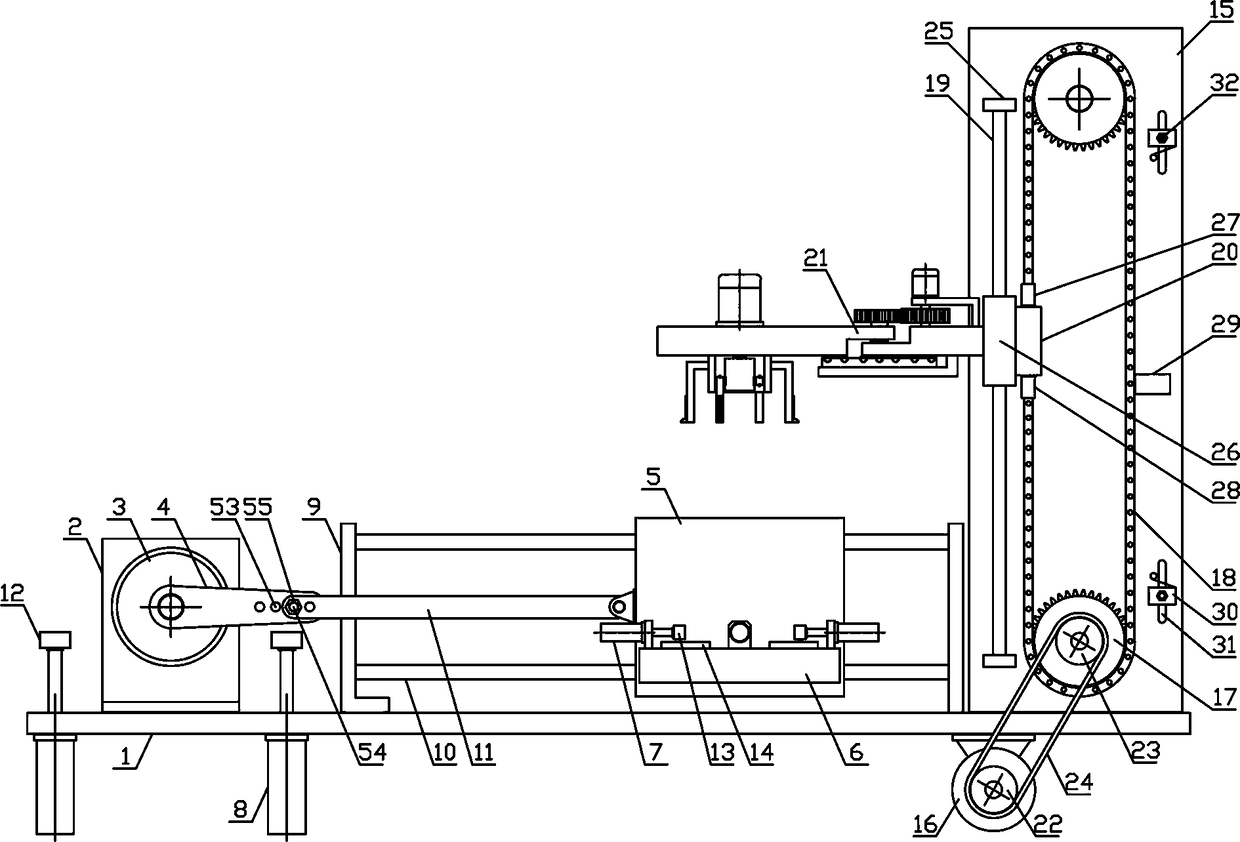

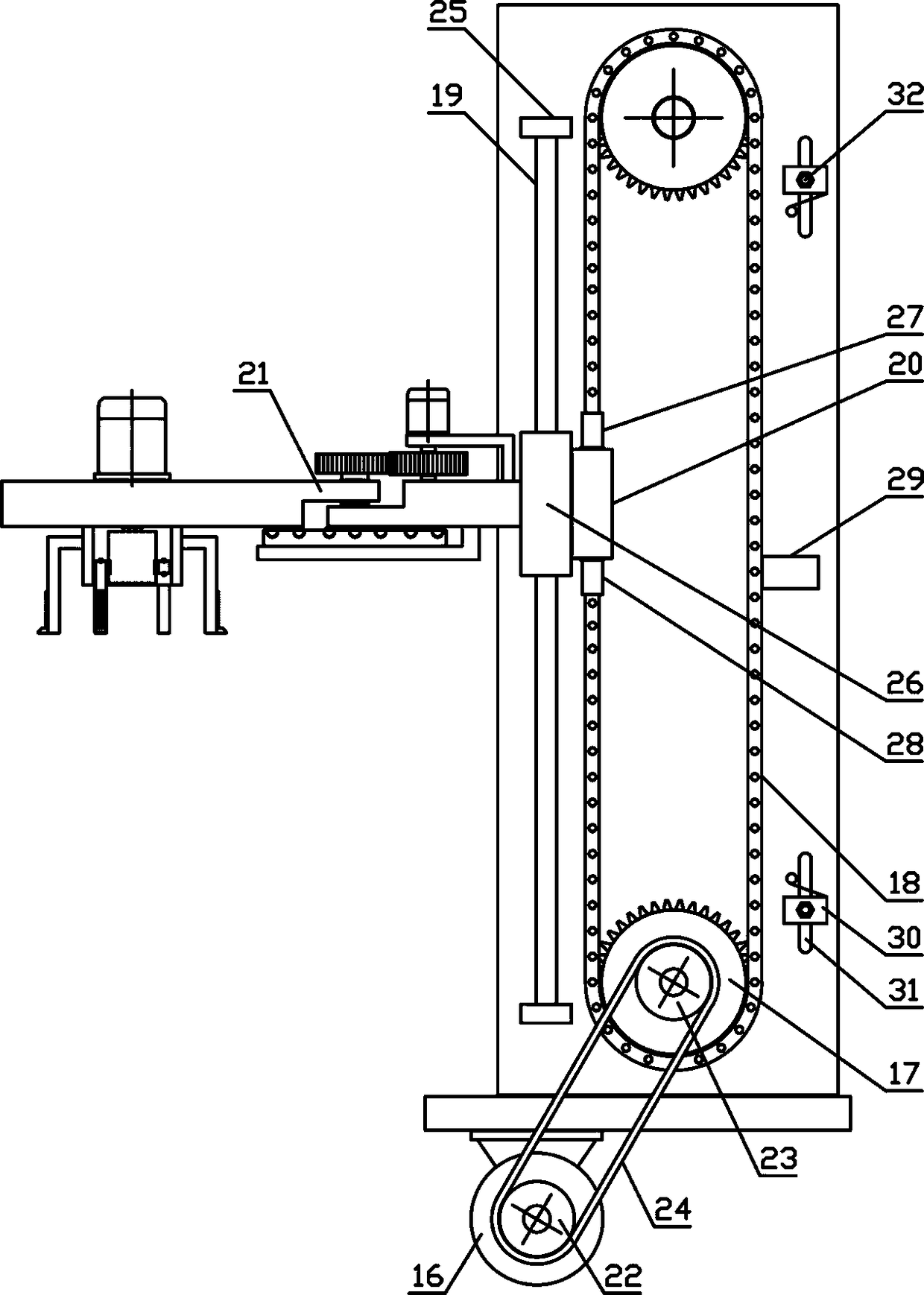

Shaft sleeve continuous vertical lifting mechanism

InactiveCN108861542AAdjust reciprocating rangeAvoid inertia shockLifting framesConveyor partsMechanical equipmentSprocket

The invention discloses a shaft sleeve continuous vertical lifting mechanism, and belongs to the field of workpiece machining mechanical equipment. The shaft sleeve continuous vertical lifting mechanism comprises a fixing bracket, a shaft sleeve transferring mechanism and a lifting mechanism. Buffers are fixedly arranged on the fixing bracket on both ends of one side of a swinging cylinder separately, and the buffers are arranged vertically upwards. A shaft sleeve receiving connection plate is horizontally and fixedly arranged on one side of a translation bracket, rotating sprockets are connected to the upper and lower sides of a lifting bracket, and the upper and lower sides of a lifting chain separately mesh with the rotating sprockets in a winding mode. A lifting guide plate is slidablyarranged on a lifting guide rod in the vertical direction, limiting switches are separately arranged on the lifting bracket on the upper and lower sides of a limiting connecting plate, and a shaft sleeve clamping mechanism is horizontally arranged on one side of the lifting guide plate. The shaft sleeve continuous vertical lifting mechanism is reasonable in structural design, can clamp and fix shaft sleeves of various sizes and specifications conveniently and firmly, and can vertically lift the shaft sleeves more stably and efficiently so that the shaft sleeves can be transferred to requiredworking positions, the automation degree of shaft sleeve transferring is improved, and the needs of processing and use are met.

Owner:晋正正

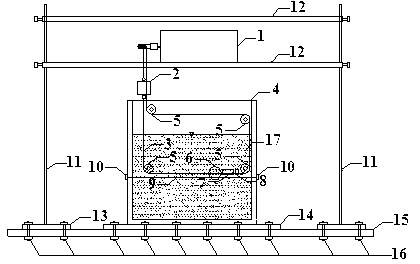

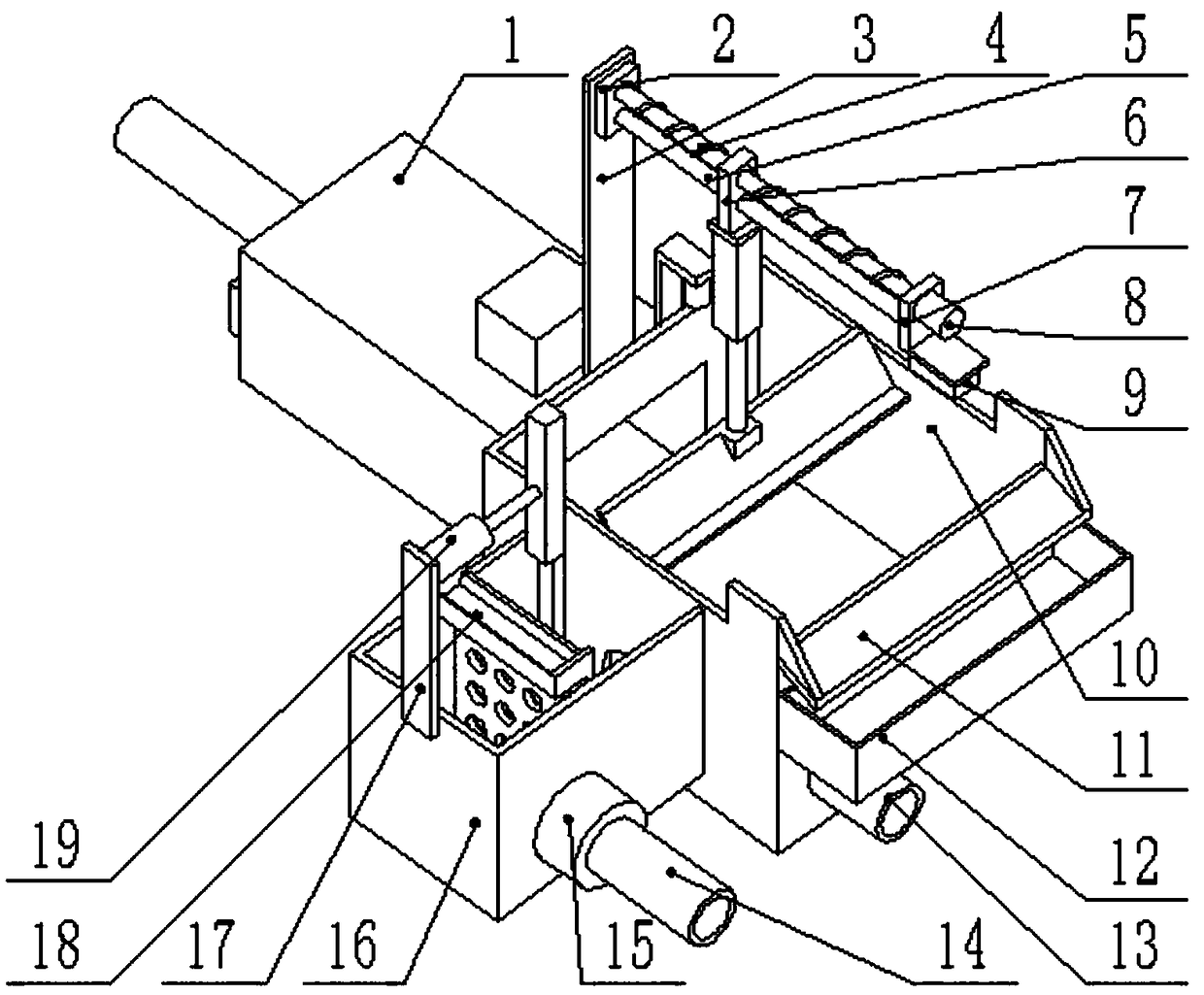

Testing device and method for measuring sandy soil moving states under different liquefaction degrees

The invention discloses a testing device and method for measuring the sandy soil moving states under different liquefaction degrees. The device comprises a model box, a working bench, a support, a speed regulating electromotor and a PIV (peak inverse voltage) platform, wherein the model box is internally provided with pulley blocks and steel wire ropes; the PIV platform is installed on one side out of a panel pasted with a transparent scale grid paper, and consists of two parts including a CCD (charged coupled device) digital camera and a camera support. A using method of the device comprises the following steps of: simulating liquefied sandy soil with different liquefaction degrees by adopting plastic sands with different gradations and a sodium chloride solution with specific density; dragging a carbon wire by the speed regulating electromotor; driving semi-spherical-body slide blocks to move horizontally by the pulley blocks; installing a pull force sensor at the vertical moving section; and measuring the moving state of plastic sand particles around during the moving process of the semi-spherical-body slide blocks by utilizing the PIV platform and the pull force sensor. The testing device and method for measuring the sandy soil moving states under different liquefaction degrees have the advantages that the liquefied sandy soil can be simulated under different pore pressure ratios according to actual requirements; the measurement accuracy is high; the operation is simple and feasible and the like.

Owner:HOHAI UNIV

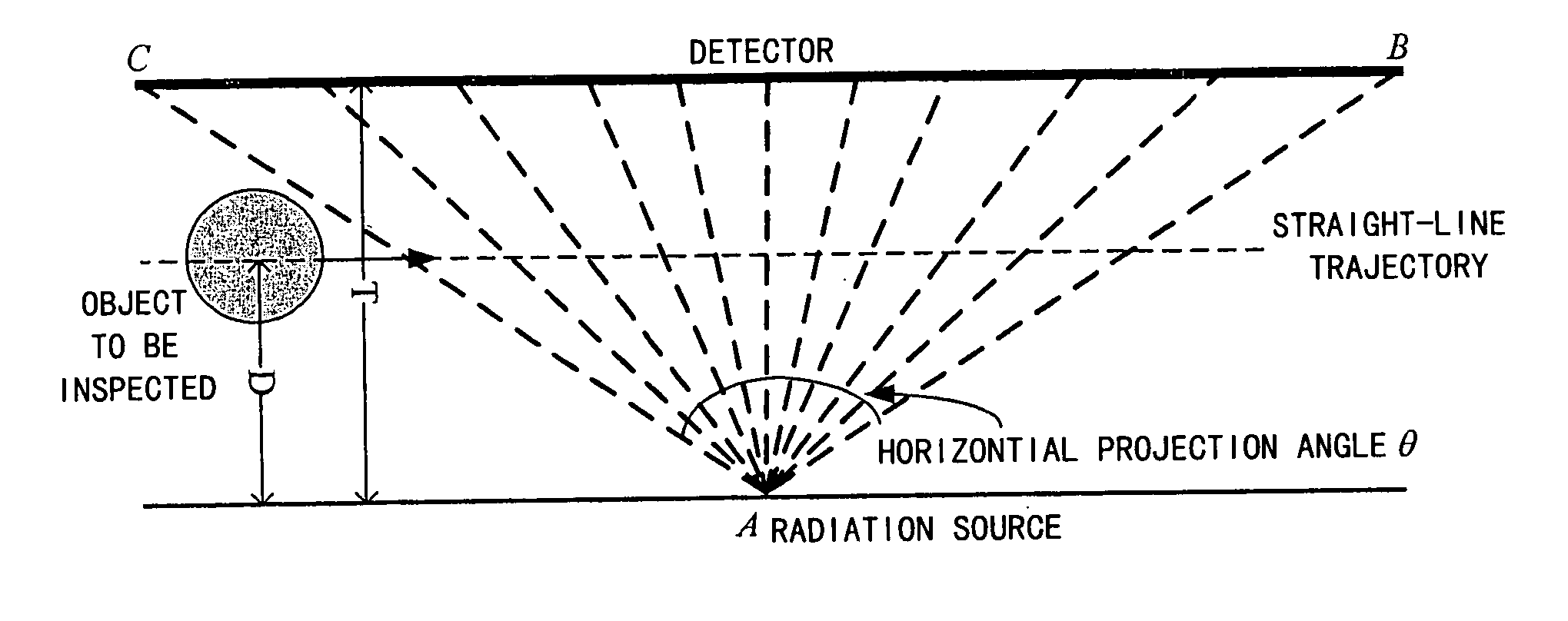

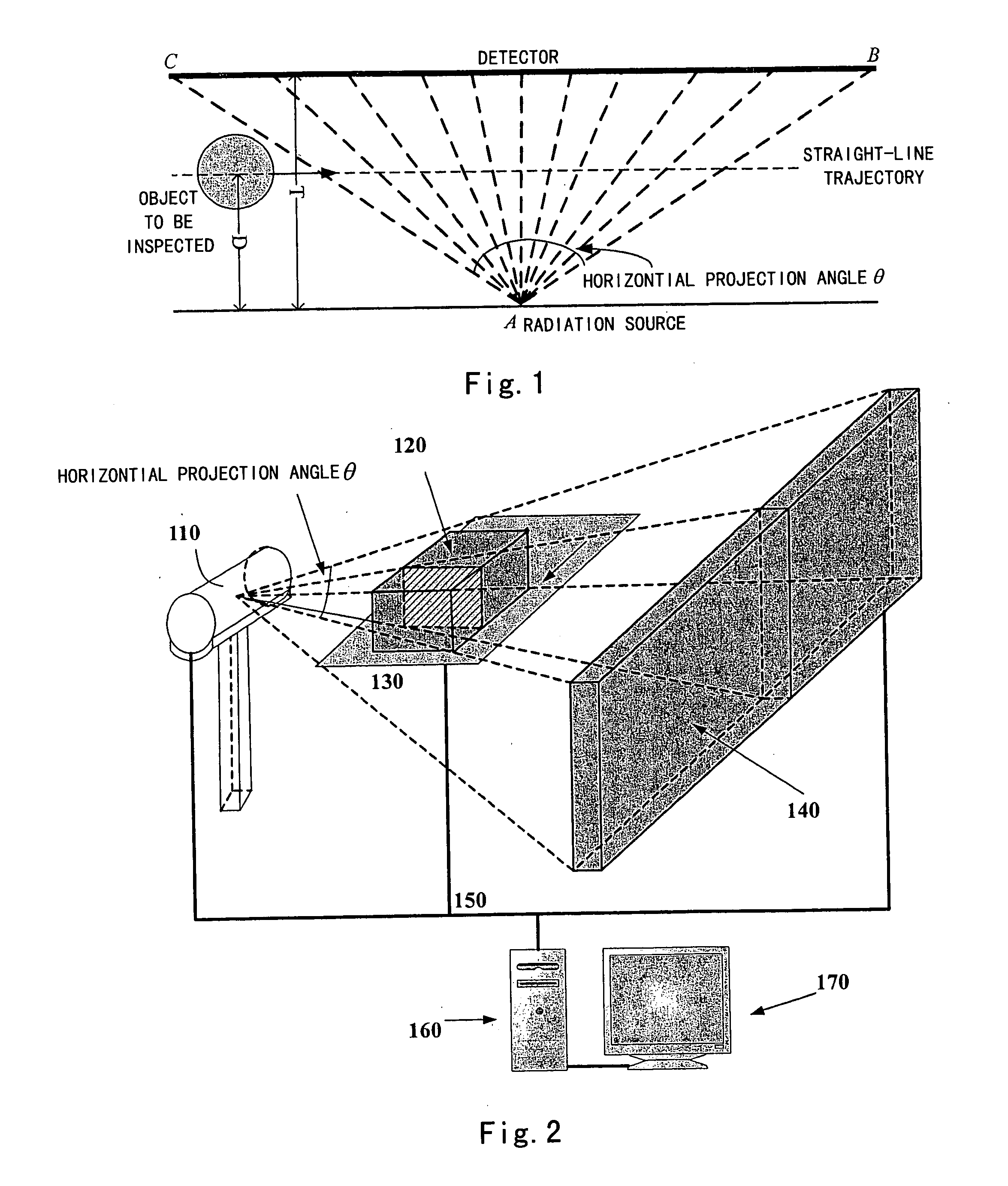

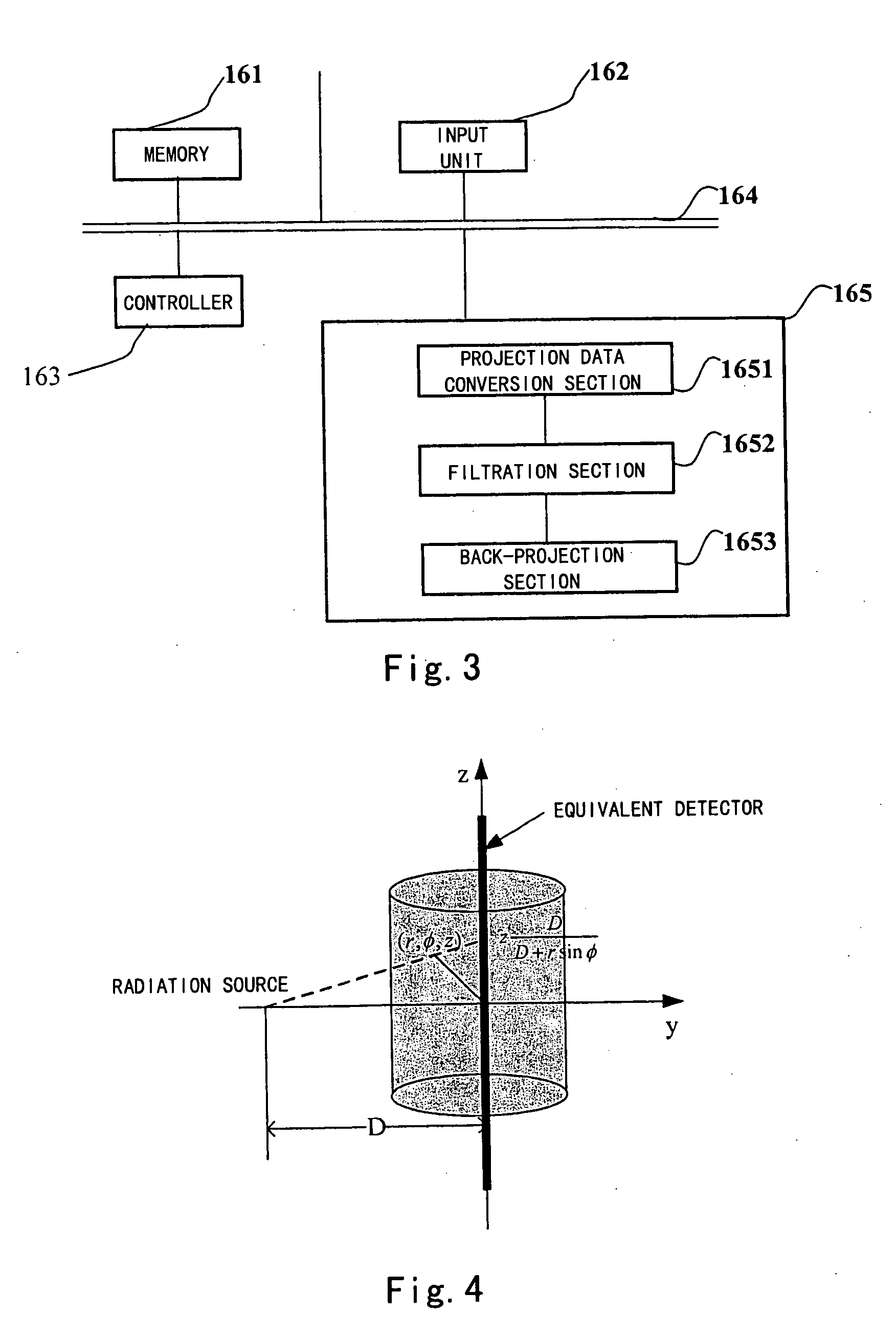

Imaging system

ActiveUS20070116177A1Quick implementationIncrease speedMaterial analysis by transmitting radiationRadiation diagnosticsImaging processingBack projection

It is disclosed an imaging system comprising: radiation generating means including at least one radiation source for generating radiations; data acquiring means including an detector matrix faced the radiation source for obtaining projection data by receiving radiations penetrated through an object to be inspected; transporting means for making the object to be inspected between the radiation source and the detector matrix linearly moving relative to the radiation source and the detector matrix; and controlling and image processing means for controlling the radiation generating means, the data acquiring means and the transporting means, and for reconstructing an image of the object to be inspected from the projection data. The imaging system according to the present invention achieves a real stereoscopic radiography by using straight-line trajectory scan and reconstructing a tomographic or stereoscopic image through a straight-line filtered back-projection algorithm. The present imaging system has advantages of fast examination speed, no rotation, and out of large cone-angle problem in a circular-orbit cone-beam CT.

Owner:TSINGHUA UNIV +1

Casting defect repairing method

A casting defect repairing method is characterized by comprising the following steps of drilling or tapping a threaded bottom hole capable of covering a defect of a casting according to the size of the defect of the casting, boring a pin hole in the upper portion of the threaded bottom hole of the casting, polishing the bottom of the casting and conducting chamfering by 45 degrees by a bench worker, manufacturing a plug in interference fit with the casting, placing the plug in liquid nitrogen to be cooled for at least half an hour, plugging the plug into the casting to be in interference fit with the casting after the plug is cooled, welding the bottom of the casting and the lower end of the bottom of the plug through a welding rod, knocking out puffy surfaces on the surface of the casting after welding of each layer is finished, detecting whether cracks exist or not, continuing to weld the next layer if no crack exists, stopping welding until the welding area is 3-5 mm higher than the bottom of the casting, and polishing protruding portions of the top end of the pin hole of the casting and the bottom of the casting by the bench worker. The casting defect repairing method has the beneficial effects of guaranteeing the quality and shape of a sand core, solving the problem that complex sand cores are difficult to produce, simplifying manual operation and improving working efficiency.

Owner:KOCEL EQUIP

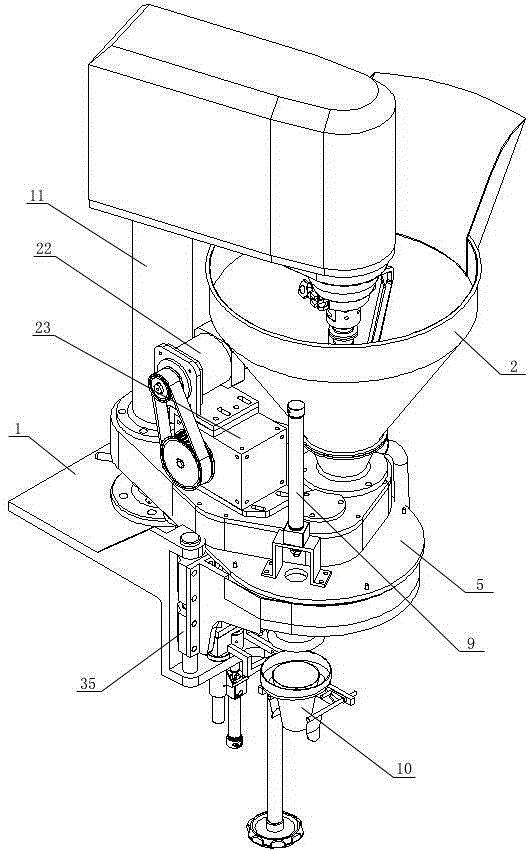

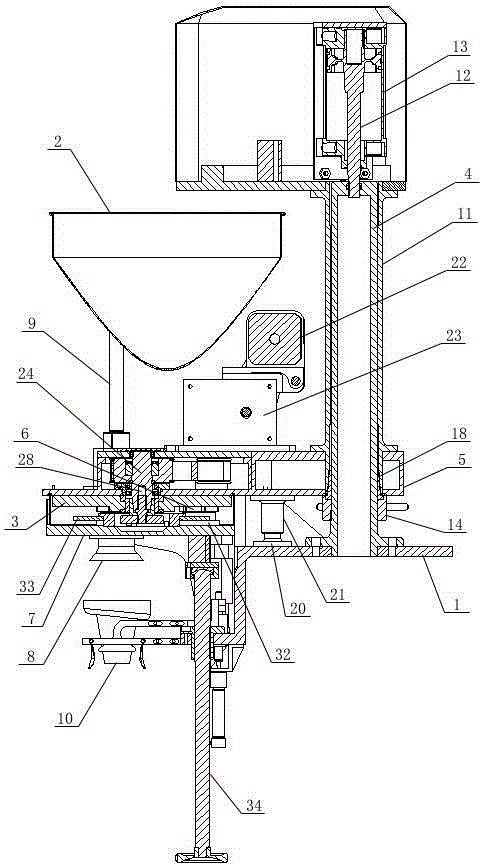

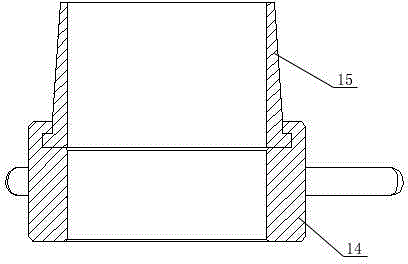

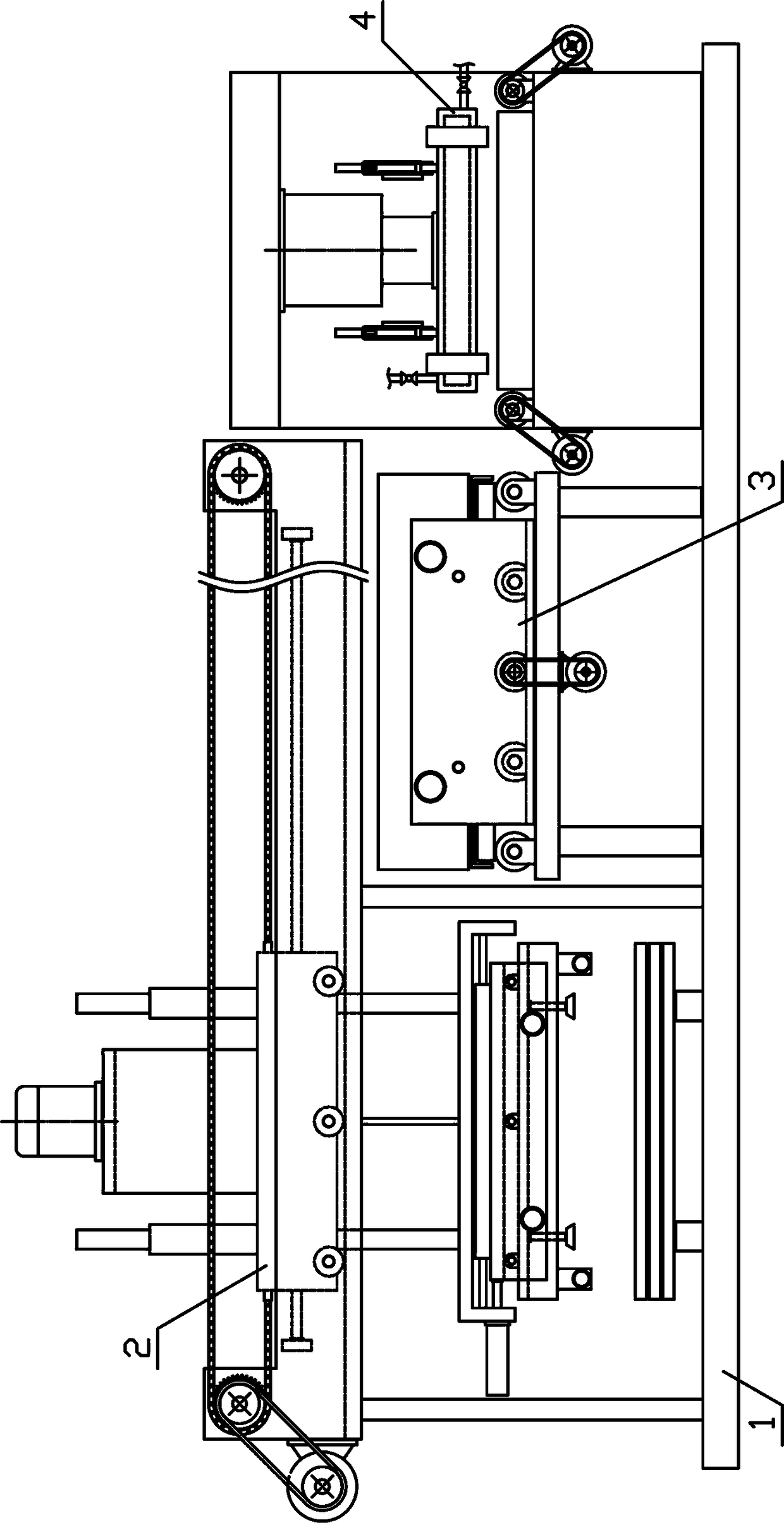

Filling machine

ActiveCN104085546AEasy to clean and maintainImprove running stabilityLiquid materialMechanical engineeringPiston rod

The invention discloses a filling machine which comprises a rack, a storage hopper, a rotary table and a discharging mechanism. A supporting stand column is arranged on the rack and is connected with a mounting frame, the rotary table is connected with a rotary table driving mechanism, the storage hopper is arranged above the rotary table and corresponds to multiple measuring cups arranged on the rotary table, a fixed disc is arranged below the rotary table, a discharging port is formed in the fixed disc, a material hitting mechanism is arranged on the mounting frame, the discharging mechanism is arranged bellow the discharging port correspondingly, the supporting stand column is sleeved with a sliding sleeve, the mounting frame is fixedly connected to the sliding sleeve, the sliding sleeve is connected with the supporting stand column through a locking device, a driving air cylinder is arranged above the supporting stand column, a piston rod of the driving air cylinder is connected with the supporting stand column, and a shell of the driving air cylinder is connected with the sliding sleeve. The filling machine is convenient to clean and maintain, quick to mount and accurate in positioning, and measuring of the measuring cups cannot be influenced after the rotary table is lifted up partially and then mounted.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

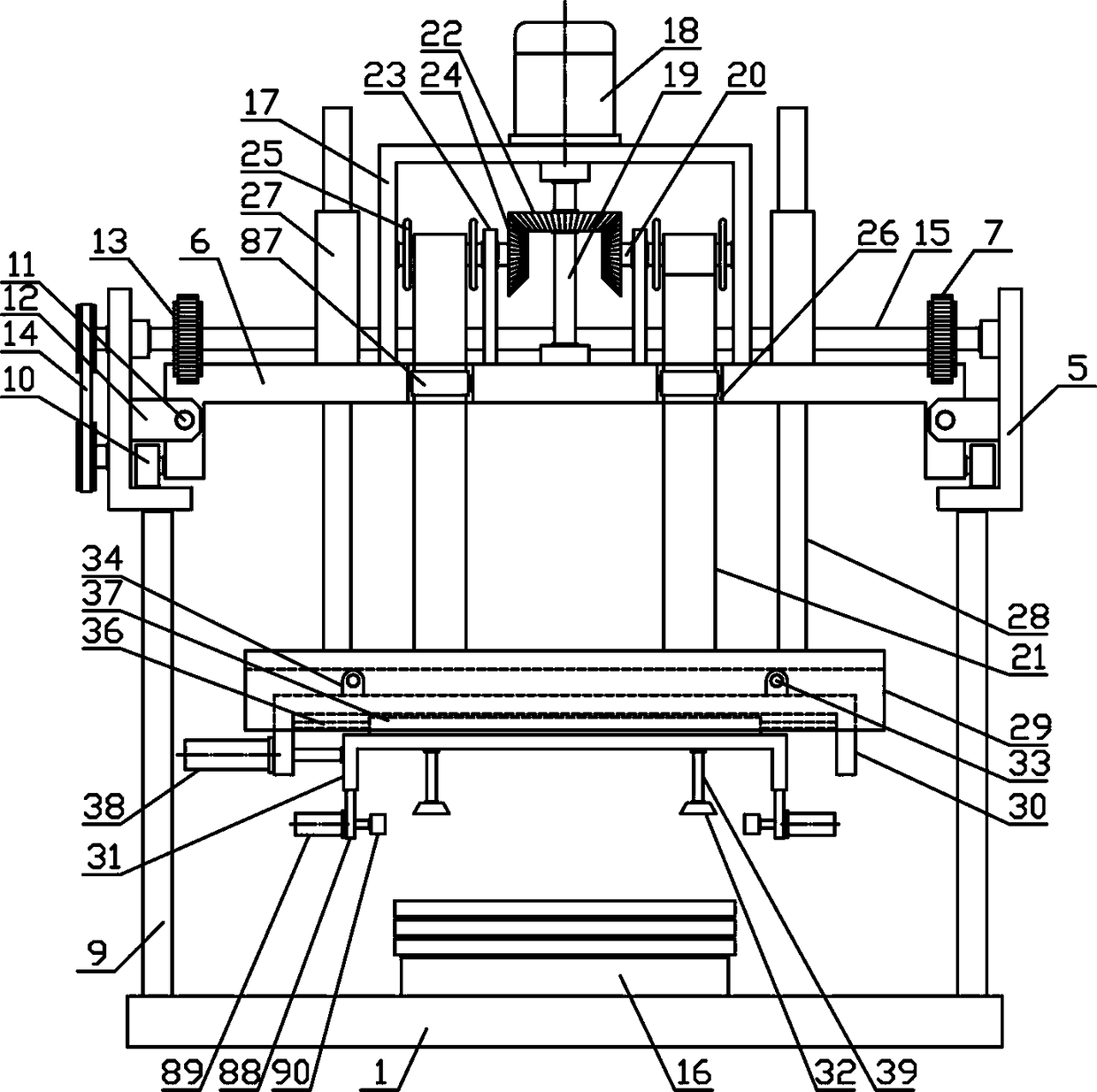

Plate veneering processing device

ActiveCN109015955AReasonable structural designSmooth and accurate adsorption and fixationPlywood pressesVeneer pressesMechanical equipmentHot press

The invention discloses a plate veneering processing device, and belongs to the field of plate processing mechanical equipment. A feeding mechanism, a skin covering mechanism and a surface pressing mechanism are horizontally and fixedly arranged on the upper side of a fixing base in sequence in the horizontal direction. A lifting mechanism is vertically arranged in the middle of the upper side ofa horizontal-moving guide plate, and a plate adsorbing mechanism is horizontally arranged on the lower side of the lifting mechanism. A plurality of plate bearing rotating rollers are horizontally androtationally connected to a plate bearing support sequentially in the horizontal direction. A skin pulling mechanism is horizontally arranged on the positions, on one sides of the multiple plate bearing rotating rollers, on the plate bearing support, and a surface pressing support is vertically arranged on the position, on one side of the skin covering mechanism, on the fixing base. A plate bearing platform is horizontally and fixedly arranged in the middle of the surface pressing support, and a hot pressing support is horizontally located on the upper side of the plate bearing platform. Theplate veneering processing device is reasonable in structural design, plates can be horizontally moved and fed accurately block by block, the plates can be automatically subjected to skin covering processing, efficient and stable veneering processing for the plates is achieved, and thus needs for processing and using are met.

Owner:ZHEJIANG MINGTAO IND

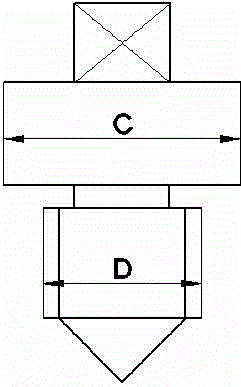

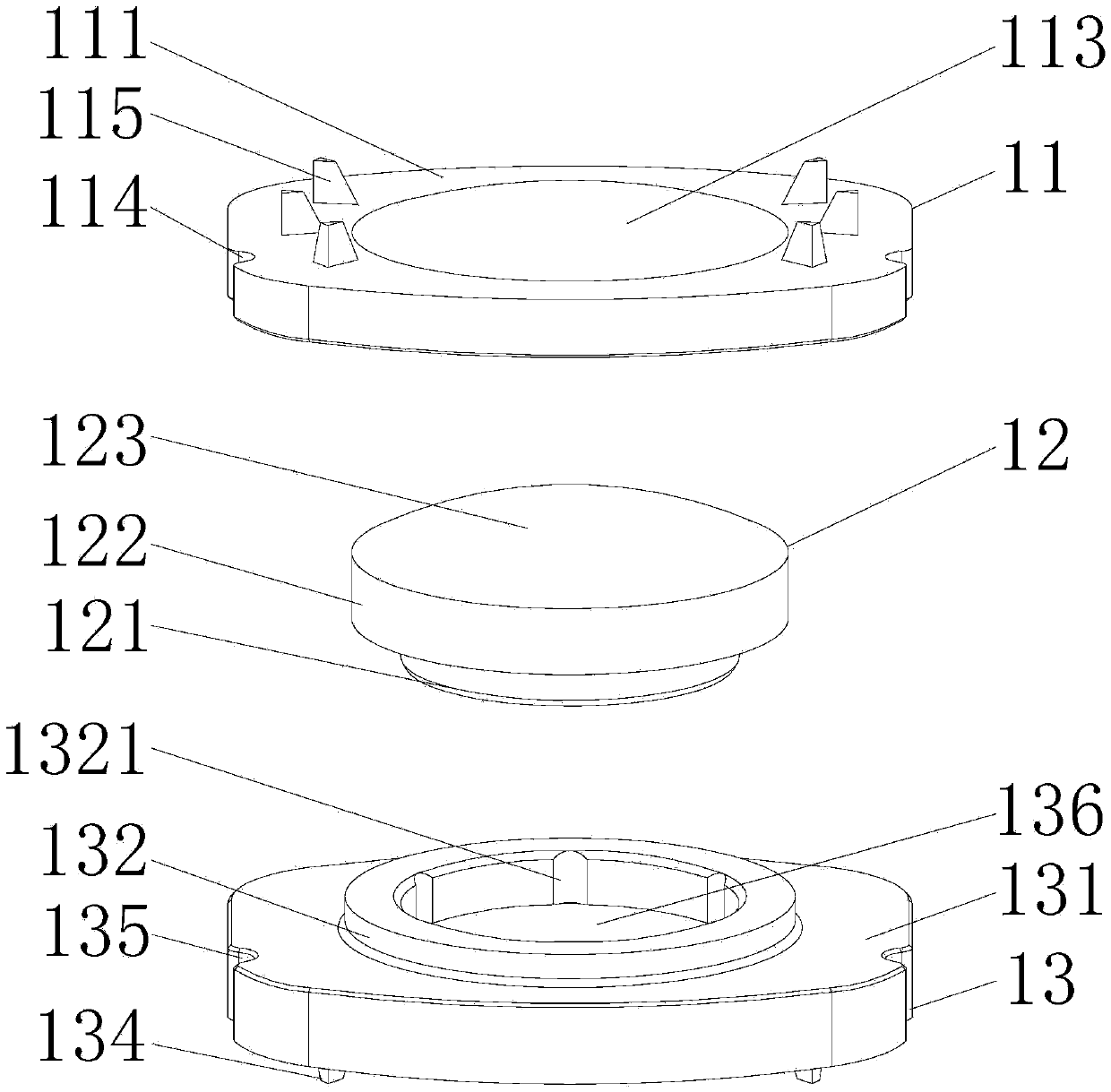

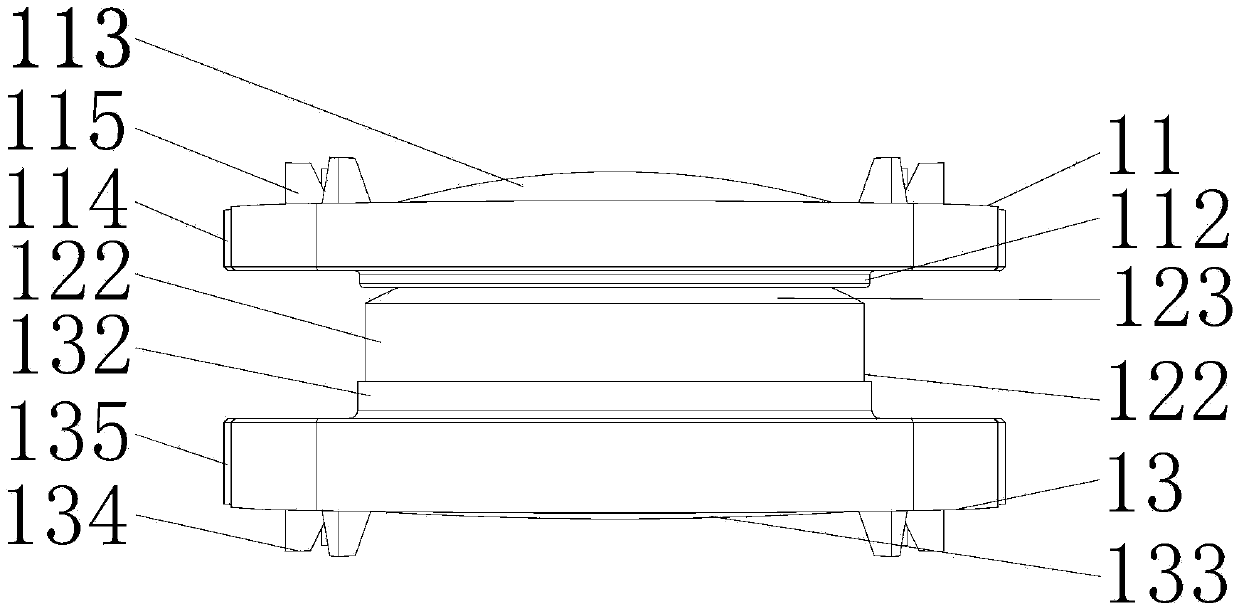

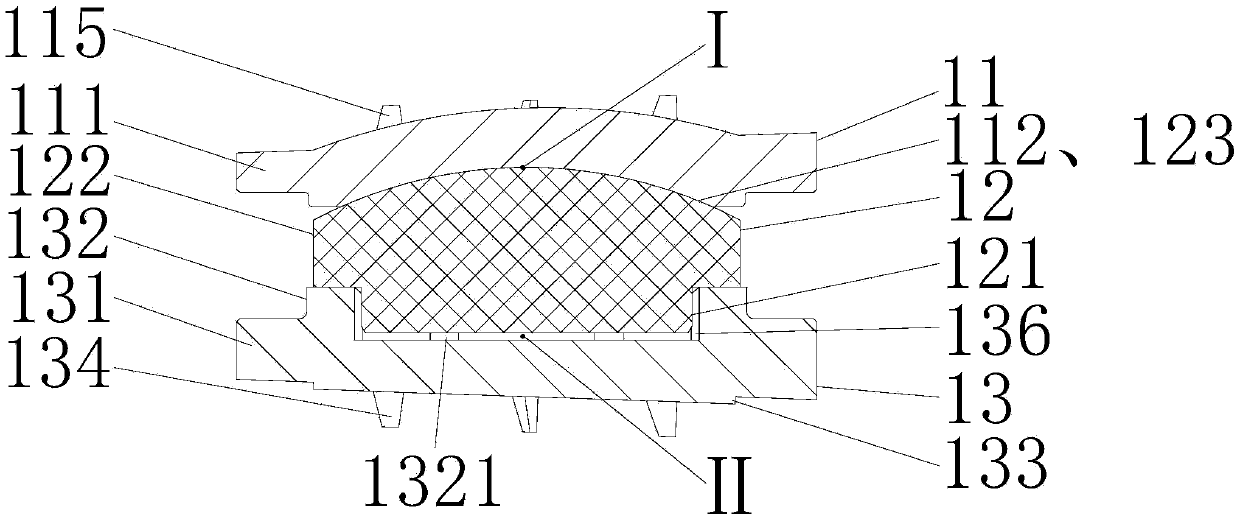

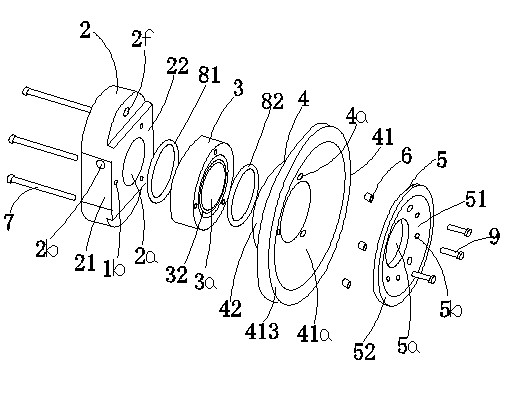

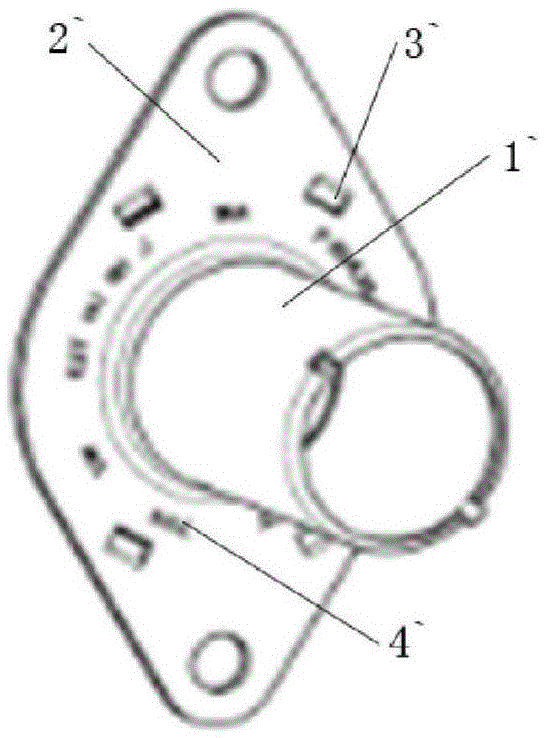

Cervical disc prosthesis, implantable device, cervical disc prosthesis and implantable device combination device and method of implanting cervical implant to cervical vertebra

ActiveCN105266928ASimple designEasy to implementJoint implantsSpinal implantsInterference fitProsthesis

The invention relates to cervical disc prosthesis, an implantable device, a cervical disc prosthesis and implantable device combination device and a method of implanting a cervical implant to cervical vertebra. The combination device comprises the cervical disc prosthesis and the implantable device, wherein the cervical disc prosthesis is composed of an upper endplate, nucleus pulposus and a lower endplate, the upper endplate and the nucleus pulposus form a ball and socket joint, and the nucleus pulposus and the lower endplate are in interference fit to form a cylinder fitting structure; the implantable device is composed of a clamping rod, a sleeve, a rotation handle and a stop pin, the clamping rod is sleeved inside the sleeve in an empty mode, the stop pin prevents relative rotation between the clamping rod and the sleeve, the rotation handle in rotation bolted connection onto the tail end of the clamping rod promotes relative axial movement generated between the clamping rod and the sleeve whose tail end is embedded inside the rotation handle fitting groove, the sleeve squeezes the clamping head of the clamping rod in the case of axial movement of the clamping rod, and relaxation and clamping of the prosthesis are realized through opening and closing of the clamping head.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

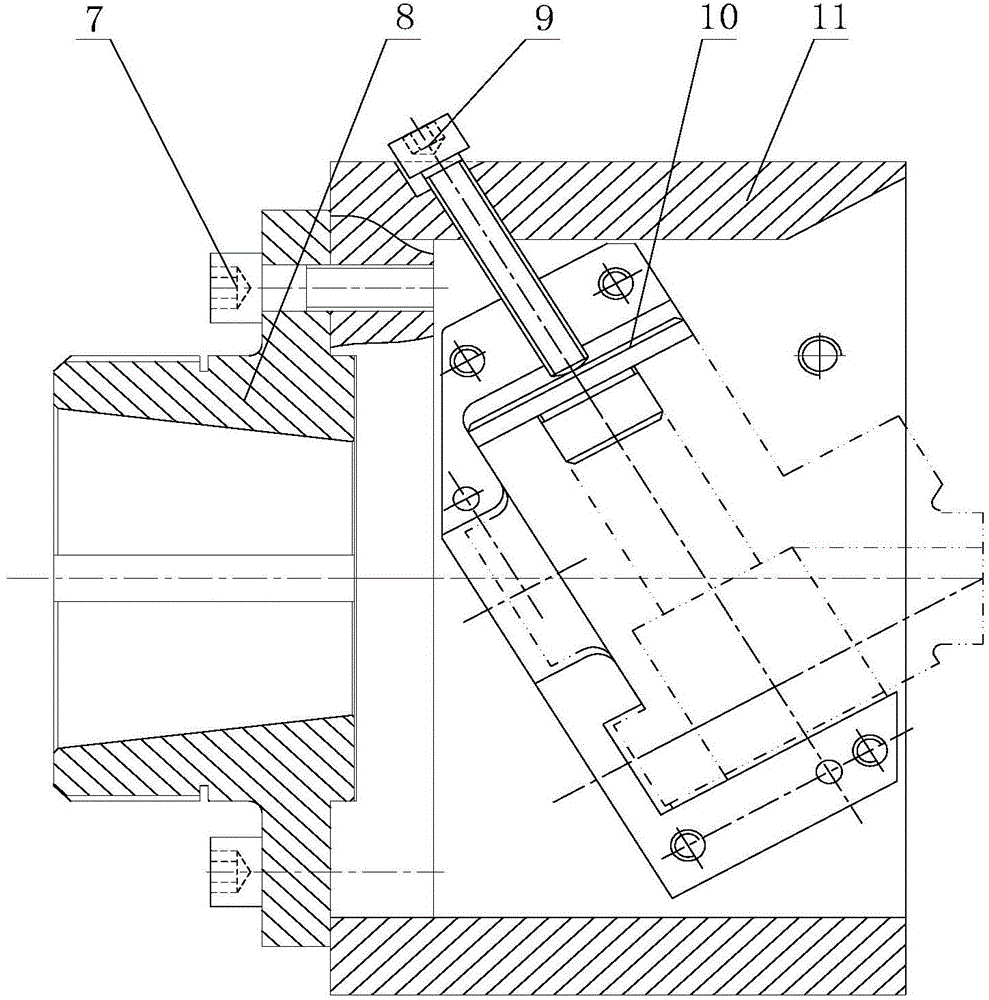

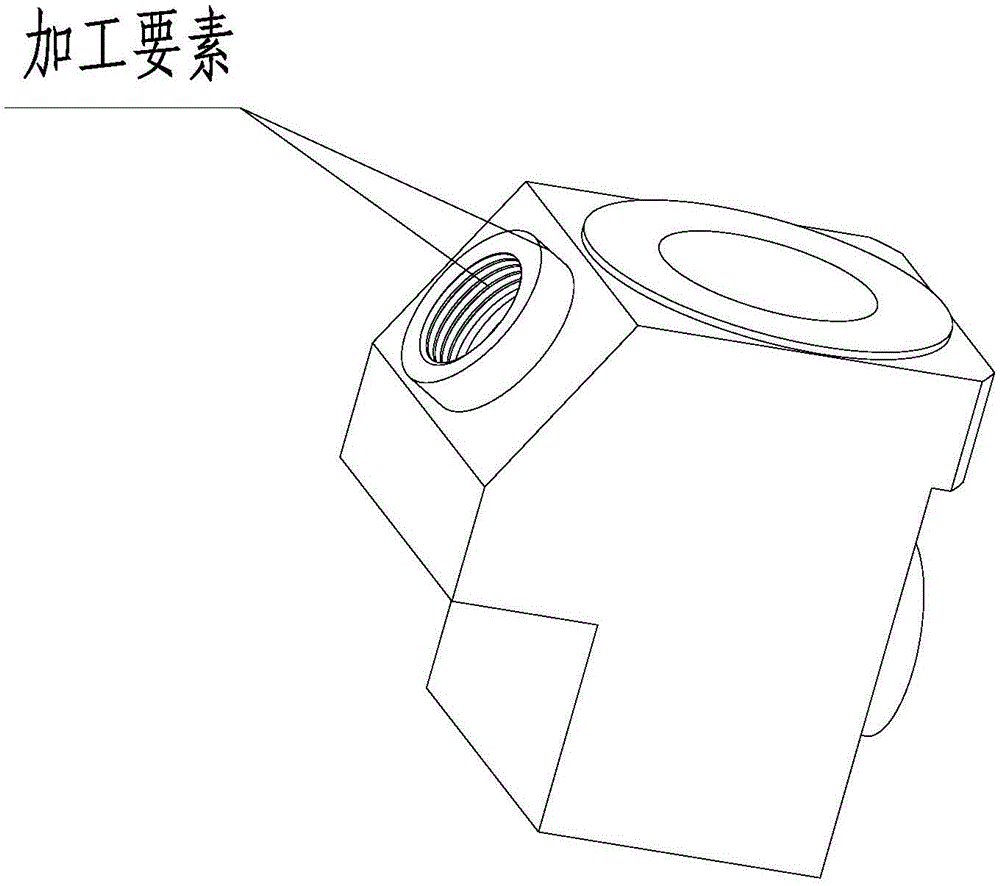

Turning clamp and application thereof

ActiveCN104440329ATurning is possibleGuaranteed accuracyWork clamping meansPositioning apparatusMachine toolSupport surface

The invention discloses a turning clamp. The turning clamp comprises a clamp body, a locating block, a pressing mechanism and a safety screw, wherein the clamp body is provided with a hollow cavity, one end of the clamp body is fixedly connected with a flange plate, and the flange plate is used for being fixedly connected with a machine tool; the locating block is fixed into the cavity of the clamp body through a pin, a certain angle is formed between the locating block and the central axis of the clamp body, the locating block is provided with a locating and supporting surface which is matched with the outline of a workpiece to be machined, and after the workpiece is fixed into the locating and supporting surface, the central axis of a round-ring-shaped machined factor on the workpiece and a spindle of the machine tool coincide; the pressing mechanism comprises a first-direction pressing mechanism body and a second-direction pressing mechanism body, and the first-direction pressing mechanism body and the second-direction pressing mechanism body are used for locking the workpiece in the first direction and the second direction; the safety screw penetrates through the cavity of the clamp body and is fixed to the two opposite side faces, and the safety screw is used for preventing the workpiece in the cavity from disengaging and flying out. The invention further discloses a method of the turning clamp. By the adoption of the turning clamp and the method of the turning clamp, turning of the round-ring-shaped machined factor with the inclined central axis can be achieved, and the problems that at present, the structures of machined workpieces are limited, the clamping stability is poor, and potential safety hazards exist are solved.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

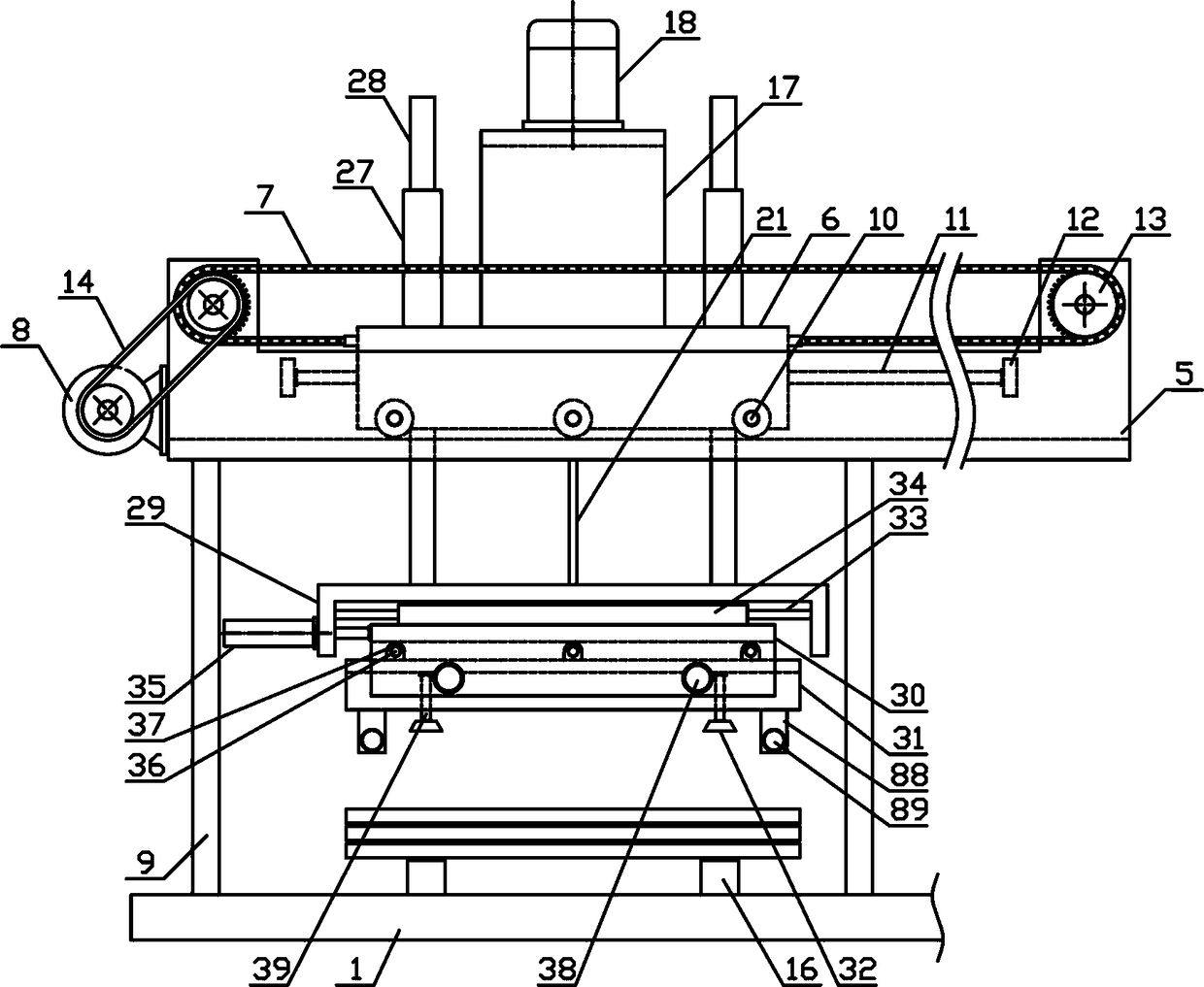

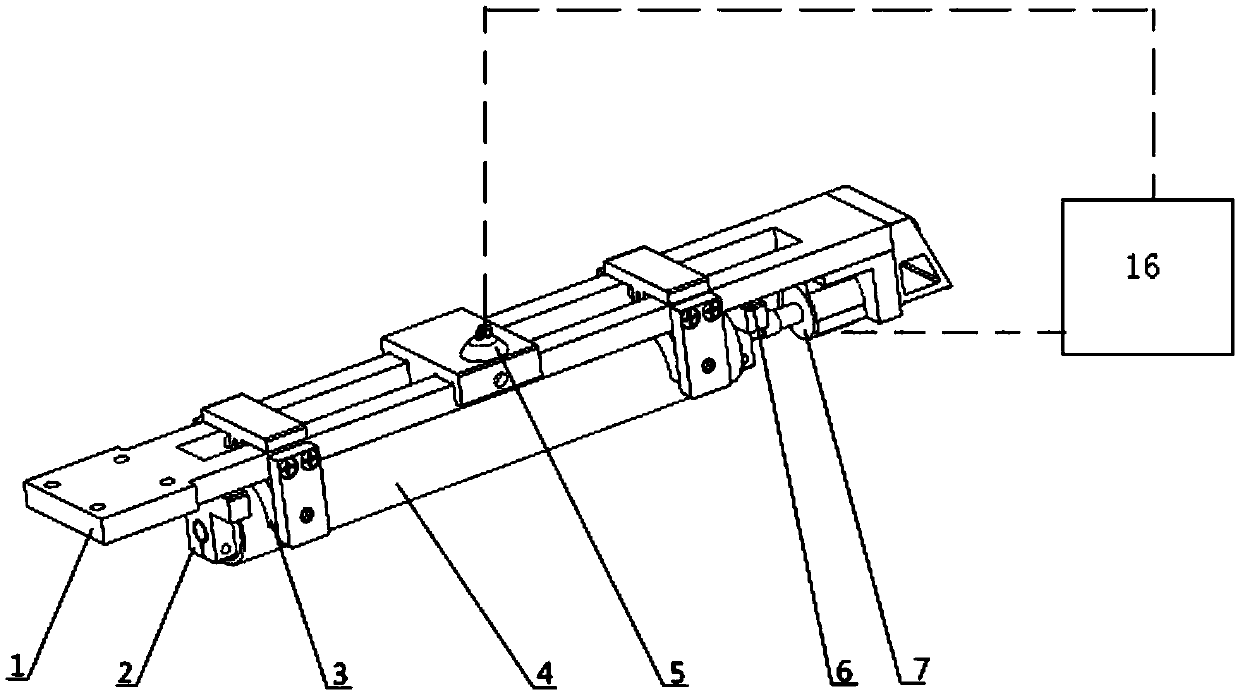

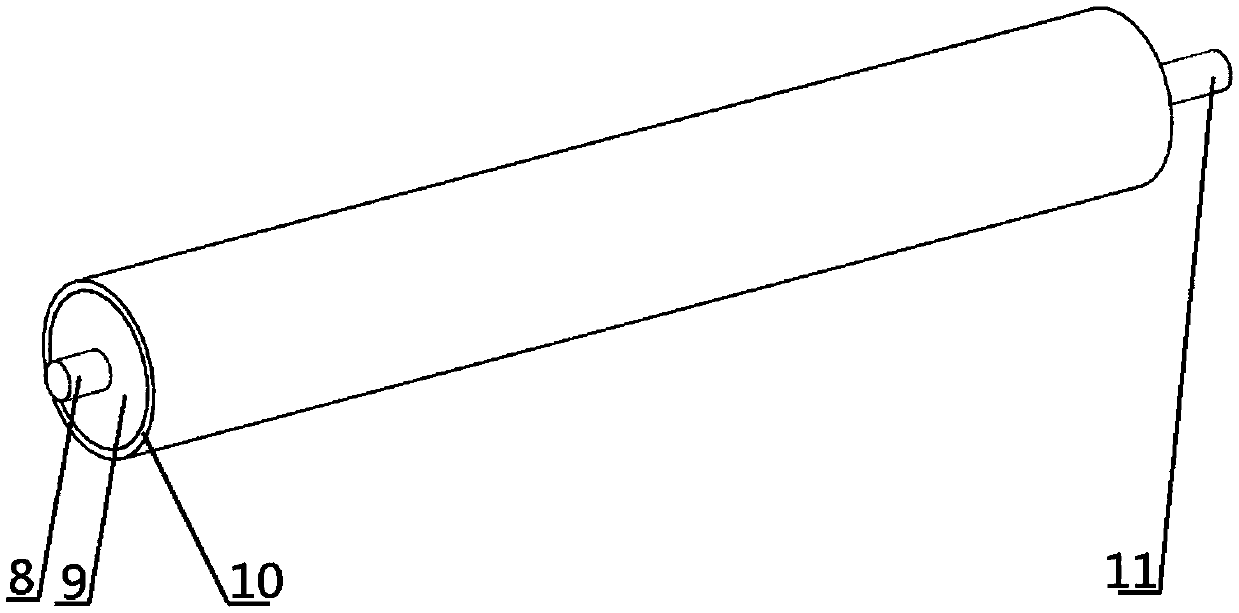

Dynamically-adjustable flexible powder spreading device for selective laser melting system

ActiveCN105499571ANo rotationReduce shear forceAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a dynamically-adjustable flexible powder spreading device for a selective laser melting system. The dynamically-adjustable flexible powder spreading device for the selective laser melting system comprises a movable support, a cylinder core support, a powder spreading cylinder and a drive device, wherein the powder spreading cylinder is connected below the movable support through the cylinder core support; an elastic gasket is arranged between the cylinder core support and the movable support; the powder spreading cylinder is clamped by clamping devices mounted at two sides of the movable support; the power input of the powder spreading cylinder is connected with the drive device fixedly arranged below the movable support; a wireless camera is mounted on the movable support; the signal output of the wireless camera is wirelessly connected with the data input of a computer; the signal output of the computer is wirelessly connected with the control of the drive device. The wireless camera performs image collection on a powder spreading surface, on the basis of computer evaluation, if the quality of powder spreading is unqualified, the drive device is remotely controlled to rotate the powder spreading cylinder, and the powder spreading working face is adjusted in real time, thereby realizing closed-loop control. The quality of powder spreading in the whole manufacturing process can be guaranteed, the impact can be reduced, powder bouncing and powder flying are avoided, and the service life of the powder spreading device is greatly prolonged.

Owner:XI AN JIAOTONG UNIV

Kitchen water purification device used for hotels

ActiveCN108164027ANo rotationAvoid scratchesWater treatment parameter controlFatty/oily/floating substances removal devicesHydraulic cylinderUltrasonic sensor

The invention discloses a kitchen water purification device used for hotels, and belongs to the field of environmental protection equipment. A water cavity is fixed at the front end of a water tank, alead screw is mounted between a lead screw end and a second support, a light rod is mounted under the lead screw, a lead screw nut is mounted between the lead screw and the light rod, an electric motor is fixed at the upper end of the second support, a first ultrasonic sensor is fixed at the lower end of the second support, a first garbage can is fixed at the rear end of the water tank, a filterdevice is mounted in the center of an auxiliary water tank, an electromagnet and a third support form a right angle and are fixed at the top of the third support, a cleaning baffle plate is connectedwith a first hydraulic cylinder, a controller is fixed above the water cavity, a second ultrasonic sensor is fixed at the tail end of a fourth support, and the cross section of a piston is the same asthat of the water cavity in shape. Garbage and oil stains on the surface of kitchen sewage are removed through the cleaning baffle plate, and garbage inside the sewage is removed through a filter screen, so that the kitchen sewage is purified, and the environment is protected.

Owner:临沂产业研究院有限公司

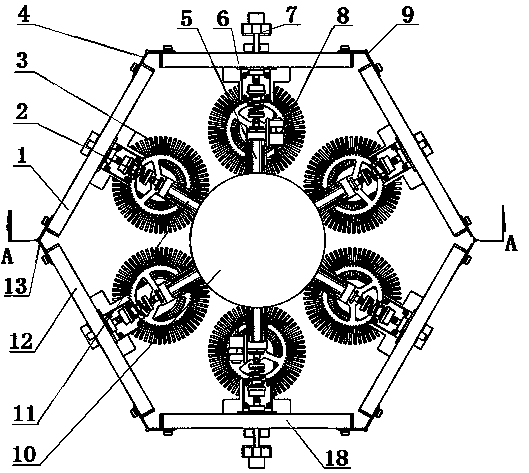

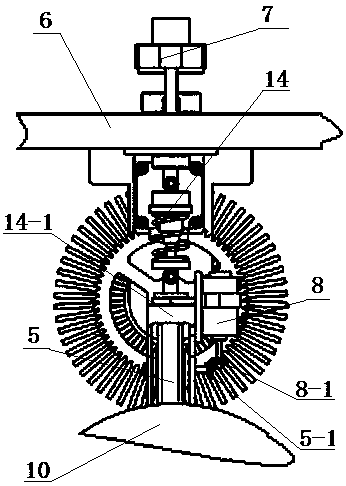

Advertisement cleaning machine

ActiveCN108435629AEasy to removeQuick ClearGeneral water supply conservationDirt cleaningDrive wheelElectric machine

The invention discloses an advertisement cleaning machine, and relates to the technical field of cleaning equipment manufacturing. The advertisement cleaning machine comprises multiple installation plates hinged sequentially, wherein the first installation plate and the tail installation plate are hinged through a detachable hinge for enclosing; a roll brush driven by a first motor is arranged oneach installation plate and is arranged on a vertical shaft; first elastic shafts driven by servo motors are arranged at two ends, close to the vertical shafts, on least two installation plates; driving wheels driven by second motors are arranged at one ends of the first elastic shafts; driven wheels arranged through second elastic shafts are arranged at two ends, close to two ends of the verticalshafts, of the other installation plates; a nozzle is arranged at one end of each installation plate; and the nozzles are sequentially connected with an annular water collecting device through a water pump and a filter. Compared with the prior art, the advertisement cleaning machine provided by the invention can solve the problem that small advertisements on the surface of an existing cylindricalrod piece are hard to clear.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

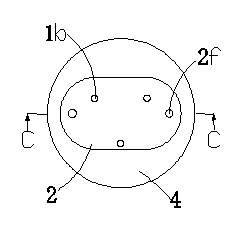

Compound type pneumatic non-contact gas claw

InactiveCN102530548AReduce hoop shear stressReplaceableCharge manipulationConveyor partsRefluxPositive pressure

The invention discloses a compound type pneumatic non-contact gas claw which comprises a gas claw casing and a shunting ring, wherein the gas claw casing is provided with a downwardly opening cylinder cavity; a workpiece grabbing through hole is formed at the center of the shunting ring; the gas claw casing includes a gas claw top cover, a gas claw middle part and a bottom sucking disc, which are detachably and hermetically connected; the gas claw top cover is provided with a gas inlet communicated with the cylinder cavity; the gas claw middle part is provided with a rotary reflux cavity forming the main body section of the cylinder cavity; the bottom sucking disc is provided with a circular sucking disc concave cavity communicated with the cylinder cavity; the shunting ring is in clearance sleeve in the circular sucking disc concave cavity; an annular clearance gas injection channel is defined by the back side of the shunting ring and the cambered curve of the bottom wall of the circular sucking disc concave cavity; three groups of small pressurizing holes surrounding the grabbing through hole are uniformly distributed on the shunting ring in an equal-radian manner; a workpiece to be grabbed is suspended in front of the grabbing through hole to achieve the dynamic balance and the non-contact grabbing and handing functions under the combined action of negative pressure generated at the high pressure gas rotary reflux center, positive pressure generated in high pressure gas overflowing out of the annular clearance gas injection channel and the self-weight of the workpiece.

Owner:NINGBO UNIV

Convenient-to-position wood floor cutting device

PendingCN109262794ASimple structureEasy to operateProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringMechanical engineering

The invention discloses a convenient-to-position wood floor cutting device, which comprises a cutting workbench, a positioning workbench, a first screw rod, a slide rod, a first motor, a second motor,a fixed retaining plate, a measuring plate, a right vertical plate, a movable clamping plate, an adjusting plate, an adjusting rod, a limiting plate and springs. The cutting workbench is placed longitudinally, the positioning workbench is placed transversely, the cutting workbench and the positioning workbench are fixedly connected to form a T-shaped structure, and supporting frames for supporting the cutting workbench and the positioning workbench are arranged below the same. The convenient-to-position wood floor cutting device is simple in structure, convenient to operate, high in cutting efficiency, smooth in cutting plane, capable of cutting wood floors in different sizes and completely independent of manual operation in a cutting process, and accordingly high quality of cut wood floors is guaranteed.

Owner:浙江花景木业有限公司

Stirring device used for circulating membrane contact bioreactor for river water

PendingCN109626560AWell mixedEfficient removalSpecific water treatment objectivesBiological treatment apparatusReciprocating motionEngineering

The invention discloses a stirring device used for a circulating membrane contact bioreactor for river water, and relates to the technical field of MBR membrane bioreactor wastewater treatment devices. The stirring device comprises a box, a stirring barrel is arranged in the box, the upper surface of the stirring barrel is fixedly connected with a seal piece, and the upper surface of the seal piece is in overlapping connection with the upper surface of the inner wall of the box. The lower surface of the stirring barrel is fixedly connected with a plurality of sliders, and the sliders are slidably connected to first sliding grooves in the lower surface of the inner wall of the box. According to the stirring device used for the circulating membrane contact bioreactor for the river water, thestirring barrel can move relative to a stirring rod and a stirring device body, and accordingly, raw materials at the corners in the stirring barrel can be sufficiently stirred and mixed; because theinner wall of the stirring barrel can make contact with a scraper blade in the reciprocating process of the stirring barrel, under the action of the scraper blade, sticky materials adhering to the inner wall of the stirring barrel can be effectively removed, and the work efficiency of workers is improved.

Owner:上海万江环境科技有限公司

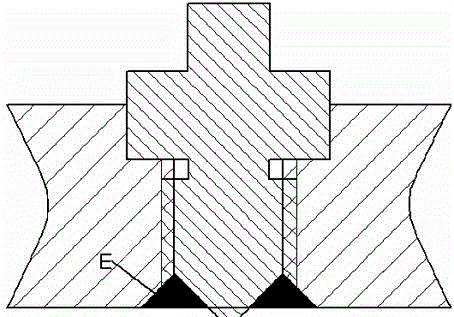

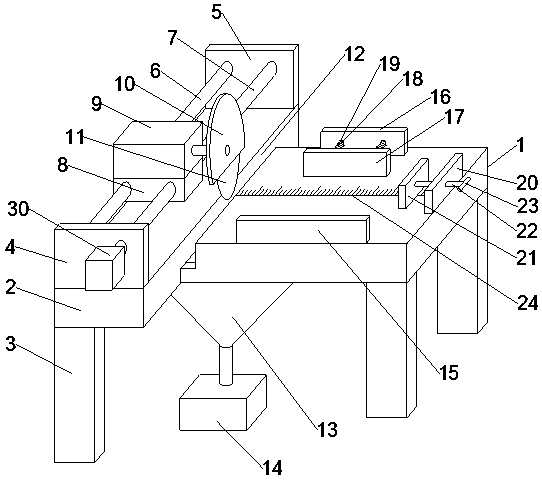

Analog semi-rigid underlying structure temperature shrinkage fracture testing method and device

InactiveCN103076236AAccurate application of tensionNo rotationMaterial strength using tensile/compressive forcesTemperature controlFracture testing

The invention discloses an analog semi-rigid underlying structure temperature shrinkage fracture testing method and a device. The device mainly consists of a bracket, a gripping head, a screw rod, positioning bolts and a force sensor, and the selected materials of an analog test piece are organic glass plate and rubber tire. The testing method comprises the following steps: fixing a test piece pasted with a strain disc on the device through the gripping head, then placing in a temperature control test box, and connecting the strain disc and a strain box through a conducting wire which penetrates through the test box; turning the positioning bolts to apply a tensile force to the test piece through the control of the force sensor, and realizing the purpose of applying the tensile force to the test piece; and while applying the tensile force to the test piece, ensuring that the test piece and the gripping head are in the same plane, and fixing the test piece through a fastening bolt and the screw rod, so as to ensure that the test piece does not generate torsion. The method provided by the invention can simulate the fracture condition generated by fracture of a semi-rigid underlying structure after the action of temperature and load, and provides an effective way for research of underlying structure indoor analog and the fracture condition under the condition of temperature variation; and the structure is simple, the operation is convenient and the effect is good.

Owner:程培峰

Root key construction device for root pouring pile

ActiveCN106677173AImprove construction efficiencyRealize construction at the same angleBulkheads/pilesHydraulic cylinderArchitectural engineering

The invention discloses a root key construction device for a root pouring pile. A hydraulic cylinder is fixed to the position above the center of a base plate. The end portion of a hydraulic rod of the hydraulic cylinder downwards stretches out towards the base plate. A plurality of vertical push rods are evenly distributed on the part, around the hydraulic cylinder, of the base plate. The hydraulic rod is connected with the vertical push rods through a connecting rod mechanism, the vertical push rods move in the radial direction of the base plate, the positions, corresponding to the vertical push rods, of the edge of the upper surface of the base plate are provided with root key limiting devices, and the root key axis points at the axis of the base plate through the root key limiting devices and moves in the radial direction of the base plate. The positions, corresponding to the root key limiting devices, of the bottom of the base plate are rotationally connected with transmission gears, the transmission gears are in transmission connection with respective drive motors, and the transmission gears are in engaged transmission with vertical racks at the tail ends of root keys inserted in the side wall of a pile pit. It can be known from the above structure, the root key construction device for the root pouring pile can construct all root keys on one layer at the same time, automatic ascending in the pile pit can be achieved without the aid of external force so that construction of all the root keys in the pile pit can be finished, and the root key construction efficiency is improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

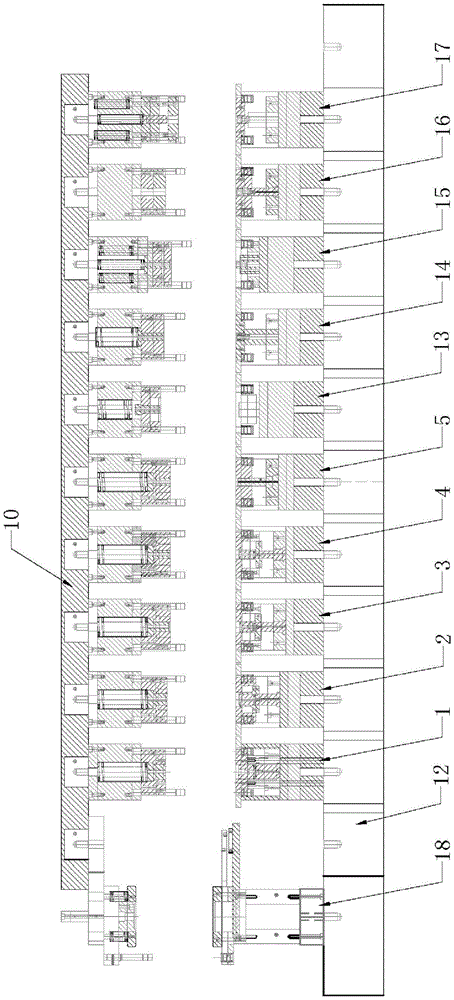

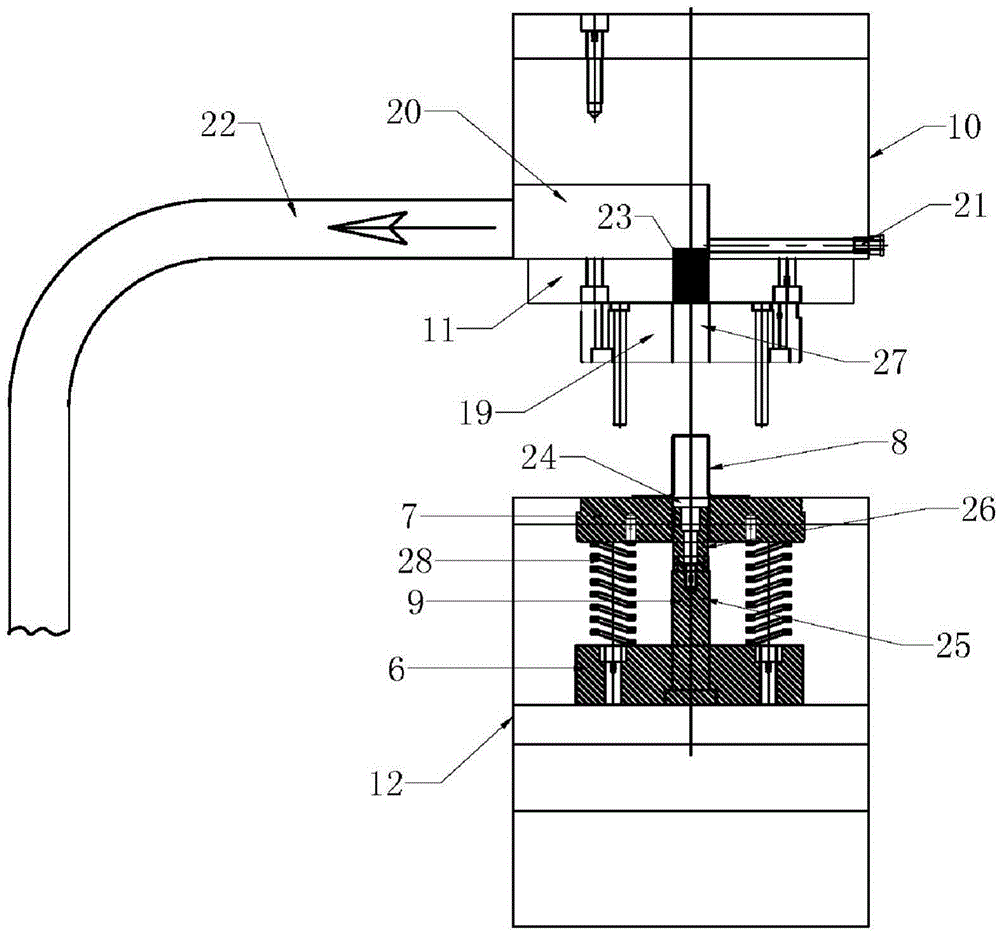

Cylindrical drawn part production and machining equipment

ActiveCN105414349AConvenient punching operationIncrease productivityShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses cylindrical drawn part production and machining equipment. The equipment comprises an upper die base and a die mold base, wherein a plurality of drawing molds, a side-shearing punching mold, a bump blanking mold, a top hole punching mold and a claw blanking mold are arranged on the upper die base and the lower die base; the side-shearing punching mold, the bump blanking mold, the top hole punching mold and the claw blanking mold are sequentially arranged behind the drawing molds; a material falling mold is also arranged in front of the drawing molds; an upper die of each mold is fixedly mounted on the upper die base; a lower die of each mold is fixedly mounted on the lower die base; mechanical arms are mounted at one side of the upper die base and one side of the lower die base. By adopting the structure, various different procedures of synchronous machining can be implemented on the same equipment, so that the production efficiency is greatly improved and the labor cost is lowered; by arranging the top hole punching mold, a cylindrical drawn part can be conveniently blanked; a material can be blanked quite conveniently and rapidly and can also be drained quite conveniently; by arranging a locating plate, product deflection caused in a clamping process or a transportation process can be corrected by a V-shaped groove which is formed in the locating plate, so it is ensured that a product does not rotate.

Owner:镇江泛美汽车零部件有限公司

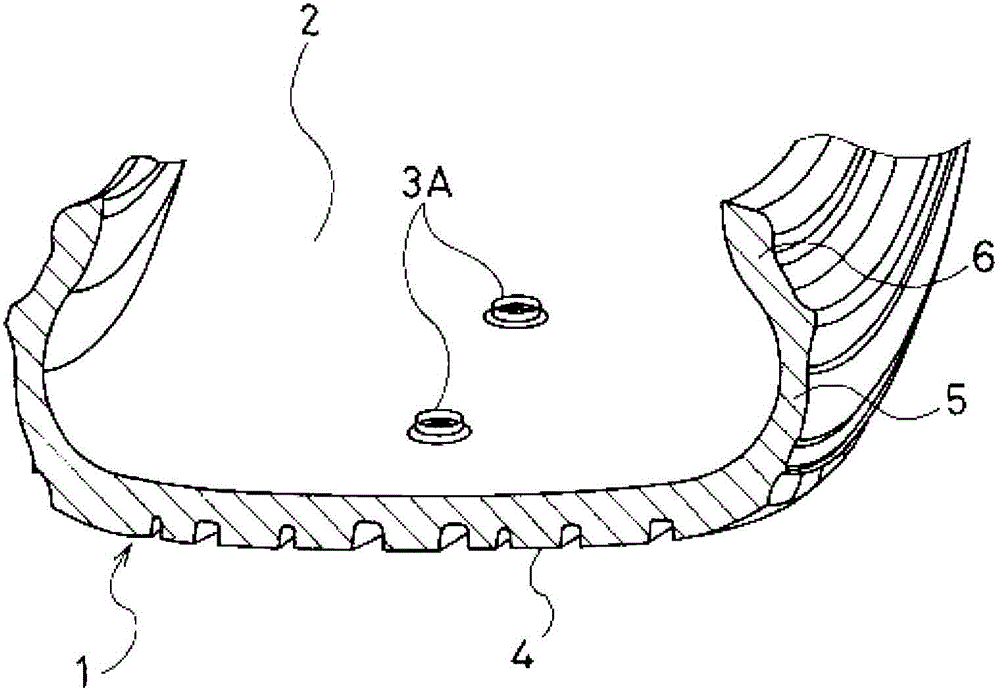

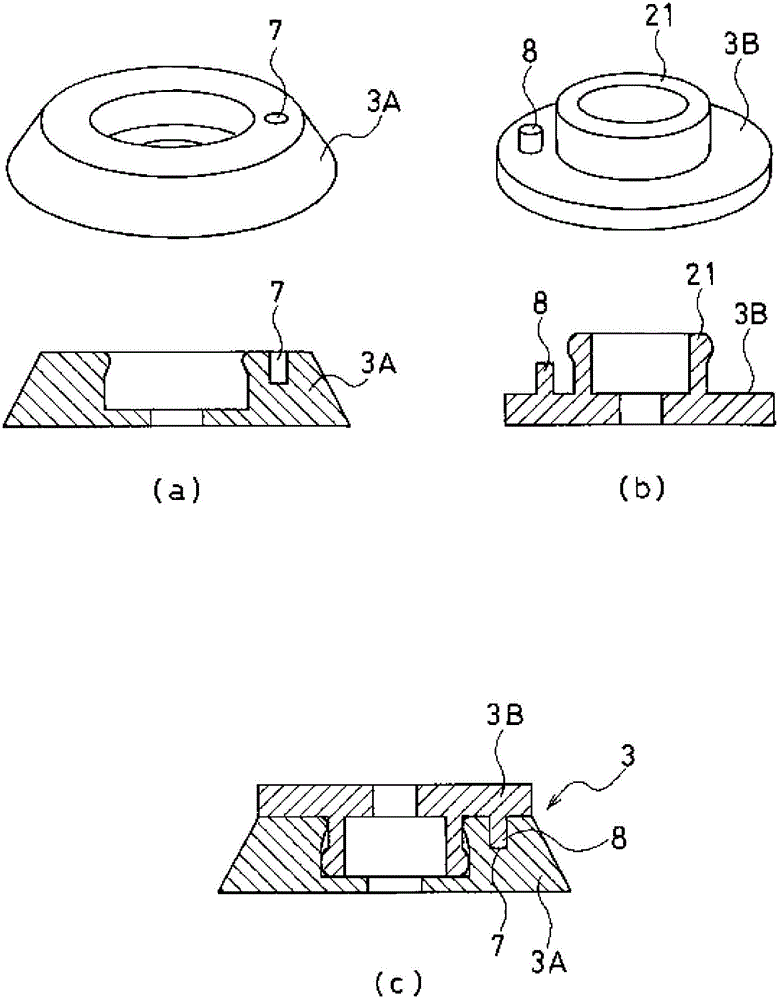

Pneumatic tire

The present invention provides a pneumatic tire that is provided with one fastener of a separatable pair of mechanical fasteners on a tire inner surface, and the mechanical fasteners are provided with a rotation preventing mechanism for preventing the fasteners from mutually rotating when the pair of mechanical fasteners are engaged. Provided is a pneumatic tire that is provided with one fastener of a separatable pair of mechanical fasteners on a tire inner surface, wherein, even in cases where a desired object is engaged / fixed using only one fastener, the object does not rotate having the fastener as a central axis when the tire is in use.

Owner:THE YOKOHAMA RUBBER CO LTD

Construction platform for facilitating root key construction of root type cast-in-place pile

ActiveCN106638585AImprove construction efficiencyRealize construction at the same angleBulkheads/pilesArchitectural engineeringBuilding construction

The invention discloses a construction platform for facilitating root key construction of a root type cast-in-place pile. The construction platform for facilitating the root key construction of the root type cast-in-place pile comprises a base plate; the positions, corresponding to root key limiting devices, of the bottom of the base plate are respectively and rotatably connected with transmission gears; the transmission gears are respectively in transmission connection with respective driving motor; the transmission gears are in engaged transmission with vertical gear racks at the tail ends of the root keys which are inserted into the side wall of a pile pit. From the above structure, the construction platform for facilitating the root key construction of the root type cast-in-place pile disclosed by the invention can climb in the pile pit automatically so as to complete the construction of all root keys in the pile pit without external force, so that the construction efficiency of the root keys is improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

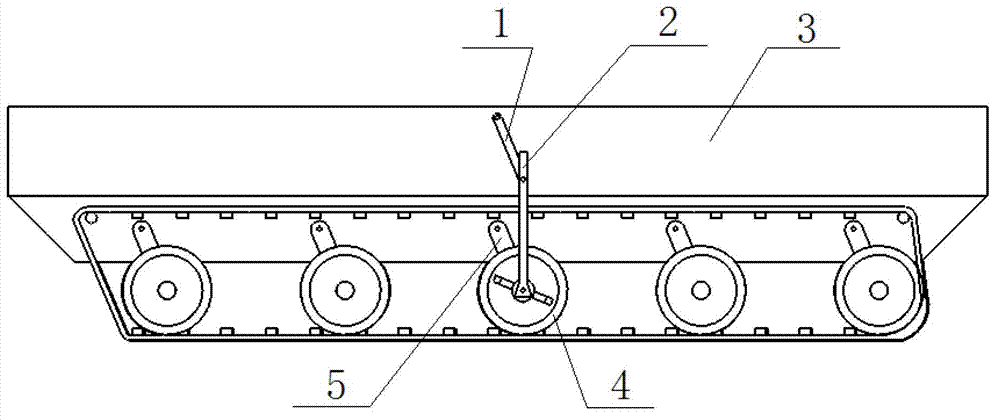

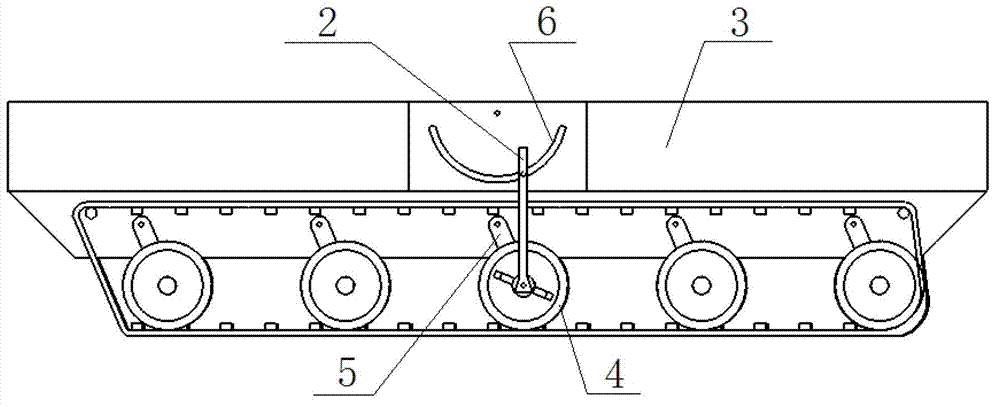

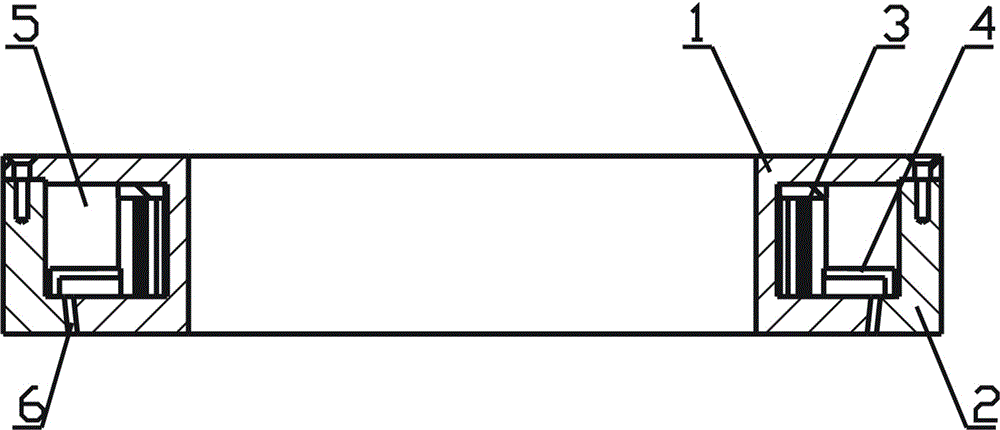

Track-laying vehicle loading wheel load test device

InactiveCN103048033ARealize measurementNo rotationSpecial purpose weighing apparatusEngineeringForce sensor

The invention provides a track-laying vehicle loading wheel load test device, which belongs to the field of the sensor and the test technology. The track-laying vehicle loading wheel load test device aims to solve the problems that the traditional test device can not realize the load measurement of a double-width rim loading wheel in the track-laying vehicle, and measurement is inaccurate caused by that an oriented rod is deviated. The track-laying vehicle loading wheel load test device comprises loading wheels, a multi-component sensor and a sliding ring locating system, wherein the multi-component sensor is arranged between two spokes of rims, the sliding ring locating system adopts a connecting rod system or a guide rail system so as to protect the oriented rod and a sliding ring from relative movement, and the measurement accuracy is guaranteed.

Owner:ZHONGBEI UNIV

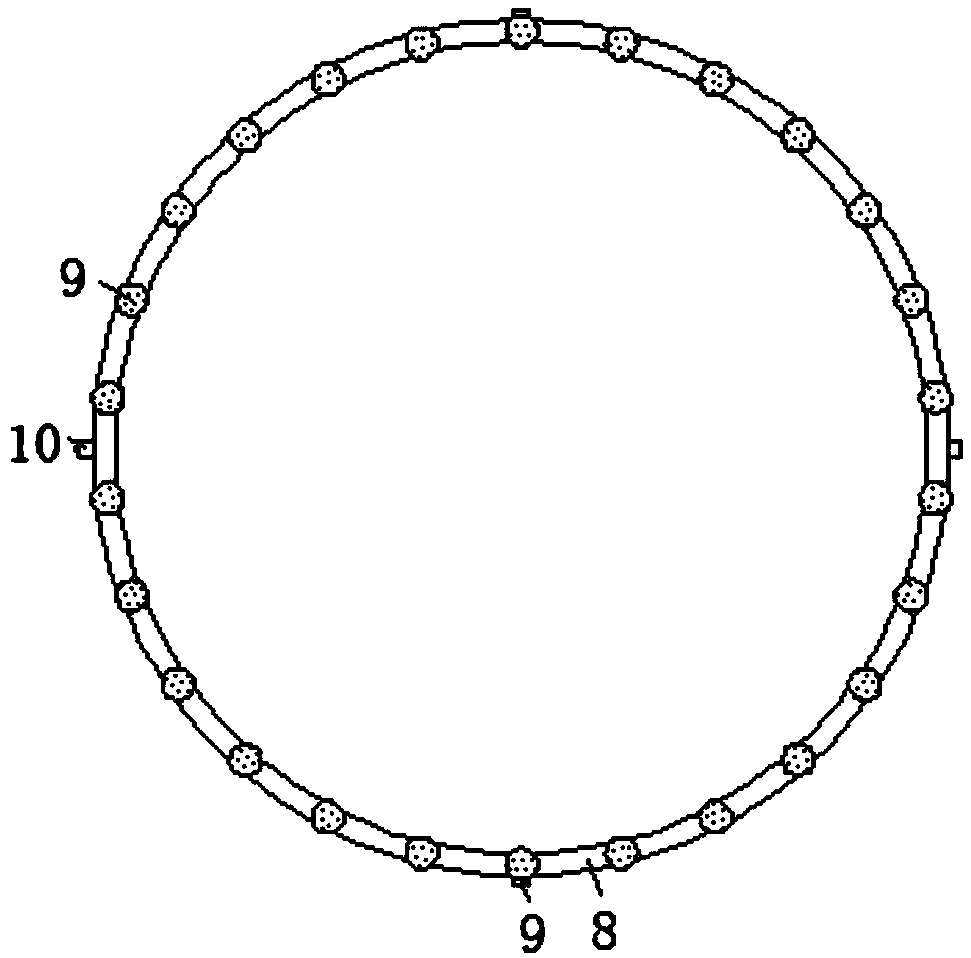

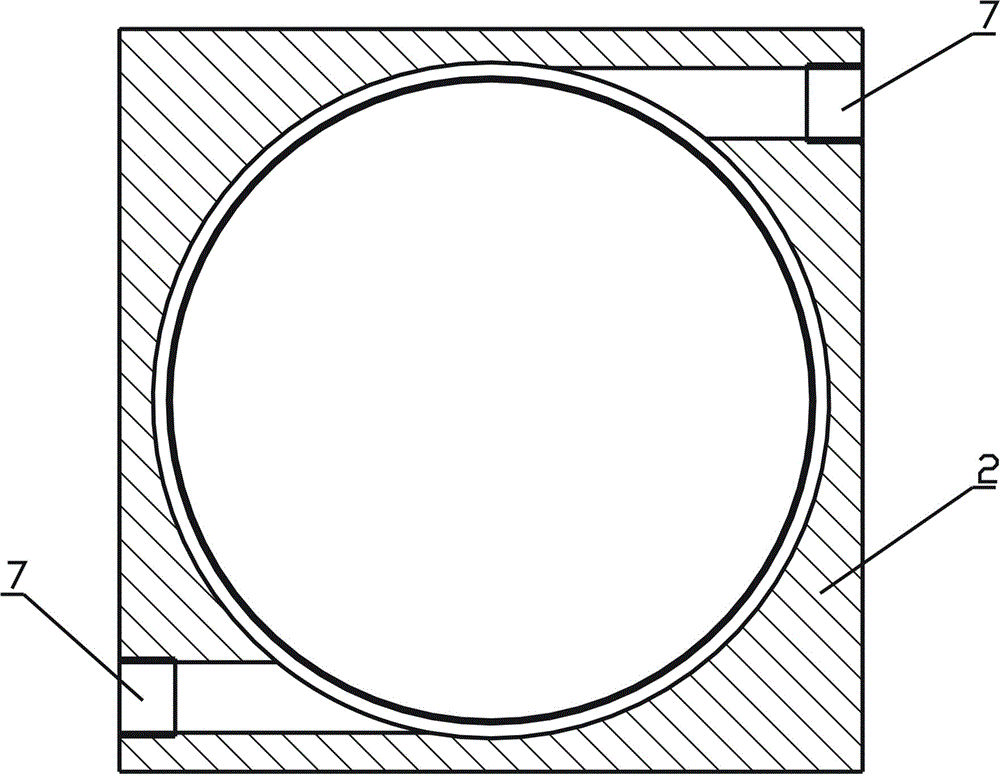

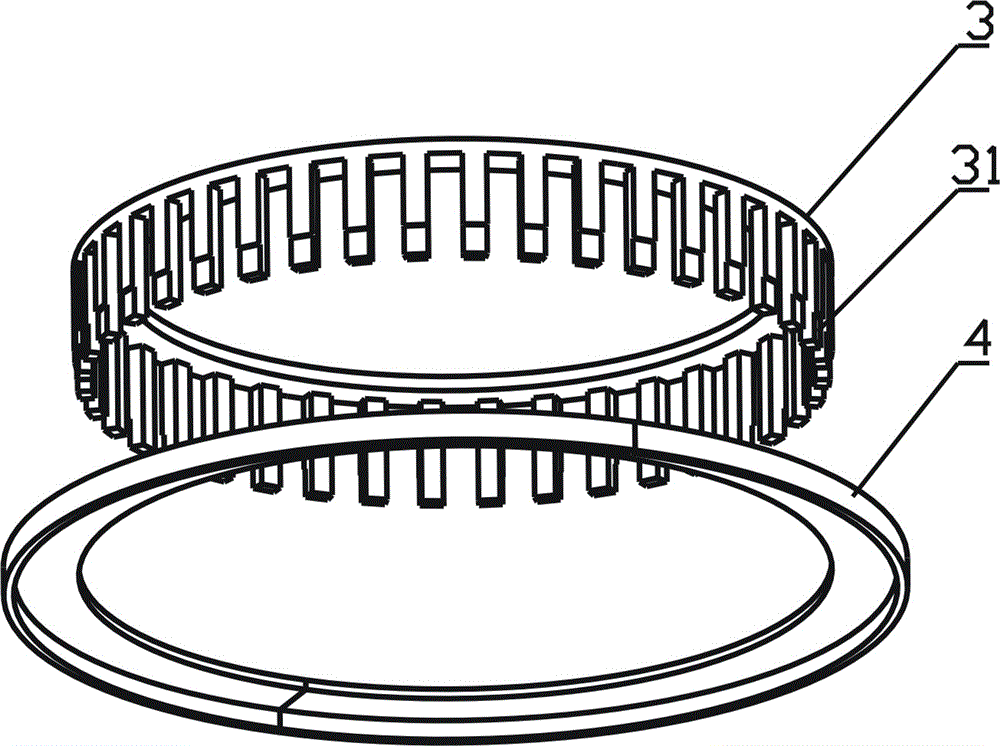

Annular water curtain device

InactiveCN106112685ARealize no dead space coolingSimple structureMaintainance and safety accessoriesCooling effectEngineering

The invention belongs to the technical field of mechanical processing, and in particular relates to an annular water curtain device. The device comprises inner rings of a water curtain, outer rings of the water curtain, inner rings of flowing slowing plates and outer rings of the flowing slowing plates, wherein the inner rings, equipped with central mounting holes, of the water curtain, are integrally mounted to the outer rings of the water curtain; annular water storing spaces are formed in the inner rings of the water curtain; annular tapered water outlets are formed in the bottom parts of the water storing spaces; water inlets which communicate with the water storing spaces are formed in the outer rings of the water curtain; the inner rings of the flowing slowing plates are of an annular comb shaped structure, and pressing slots are formed in the lower ends of comb teeth; the sections of the outer rings of the flowing slowing plates are bent, and the outer rings of the flowing slowing plates sleeve the corresponding pressing slots of the inner rings of the flowing slowing plates and are positioned in the corresponding water storing spaces together with the inner rings of the flowing slowing plates. The annular water curtain device is simple in structure, can form a complete, uniformly-distributed and non-rotating tapered curtain type water curtain, so that a cutting cutter can be cooled in 360 degrees without any dead angle, and as a result, the cooling effect is good.

Owner:BEIJING JINGDIAO GRP CO LTD

Secondary pressure plate capable of remotely monitoring blocking/deblocking state

ActiveCN105932778AAvoid misuseMonitor work statusProgramme controlTransmission systemsElectricityEngineering

The invention discloses a secondary pressure plate for electric equipment and operation method thereof. The secondary pressure plate comprises a pressure plate main body, a clutch mechanism and a fixed shaft; the clutch mechanism comprises a first base and a second base which are all installed on the top surface of the pressure plate main body, wherein an electromagnet is installed on the first baes, and a stretching tongue is installed on the second base; one end surface of an iron core of the electromagnet is opposite to one end surface of the stretching tongue, the on and off of the electromagnet can implement the connection and separation of the stretching tongue and the iron core; the fixed shaft is installed on the bottom surface of the pressure plate main body; a first binding post and a second binding post are installed on the end surface of the free end of the fixed shaft, the first binding post is electrically connected with the iron core, and the second binding post is electrically connected with the stretching tongue. Through the adoption of the method disclosed by the invention, the blocking / deblocking efficiency of the secondary pressure plate is improved, and the tedious degree of the entire installation of the secondary pressure plate is reduced.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

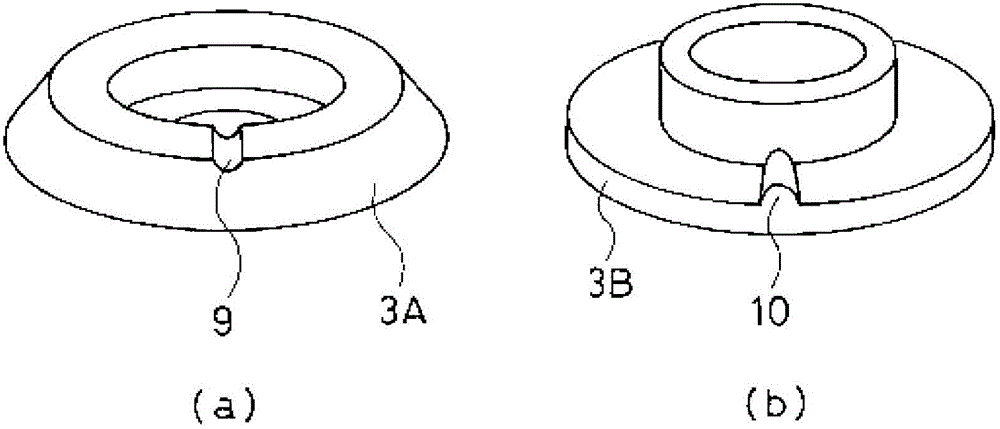

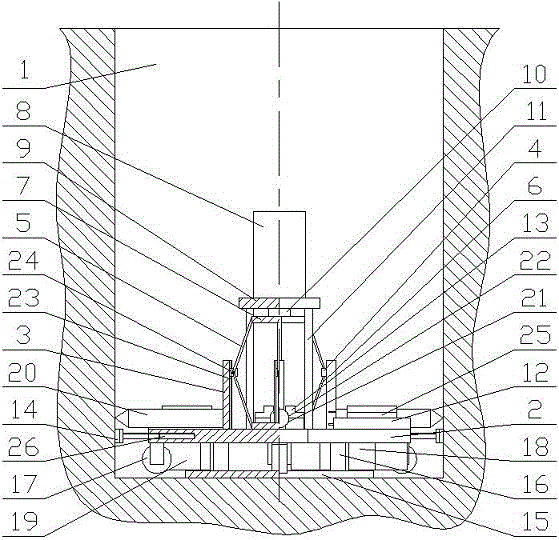

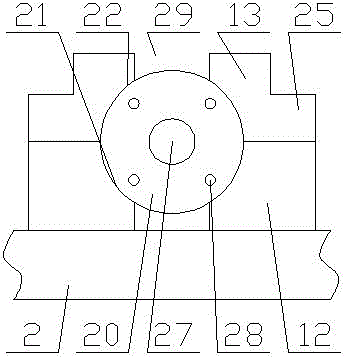

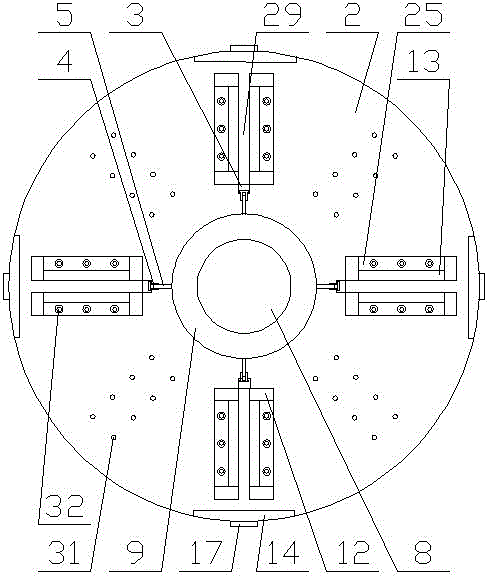

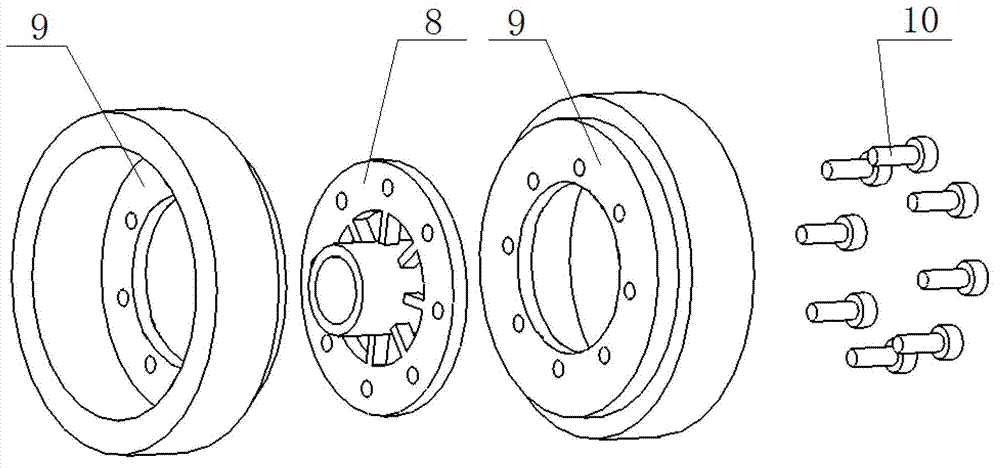

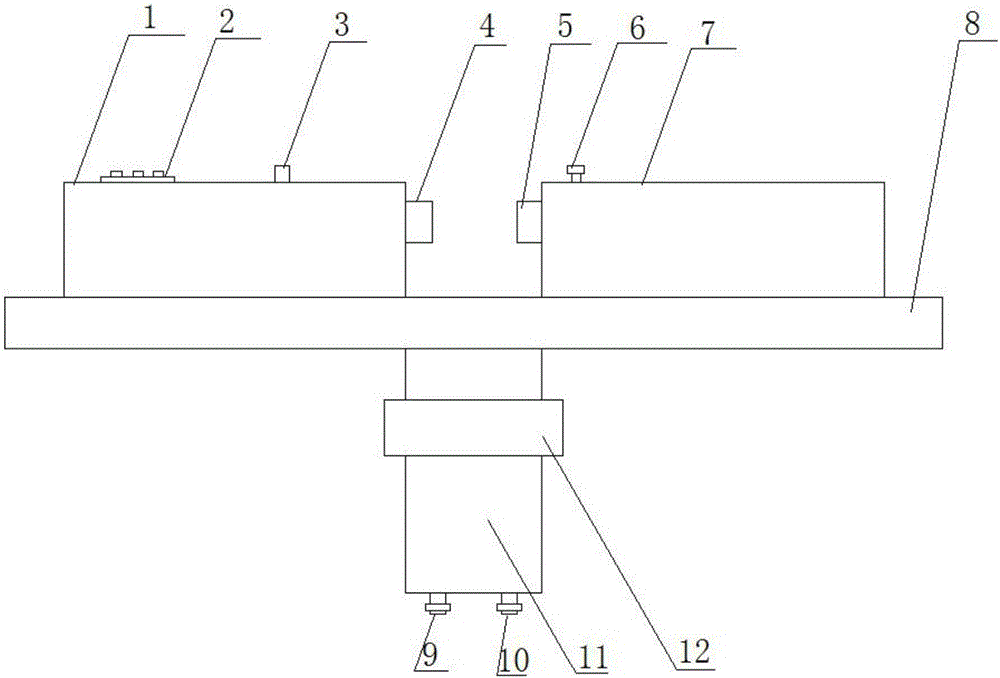

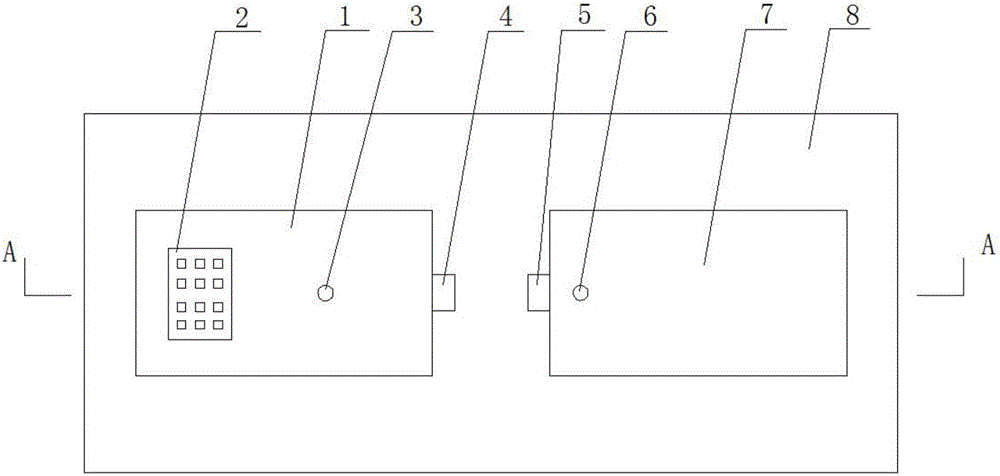

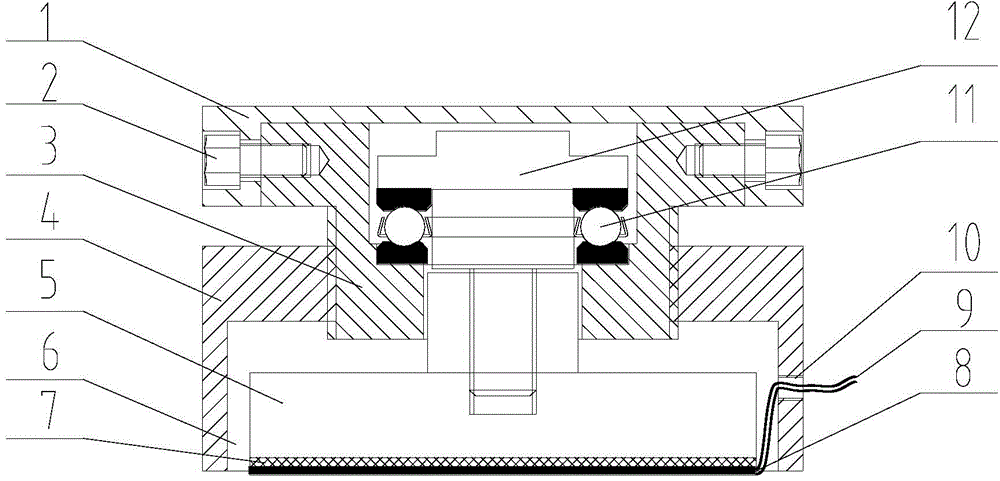

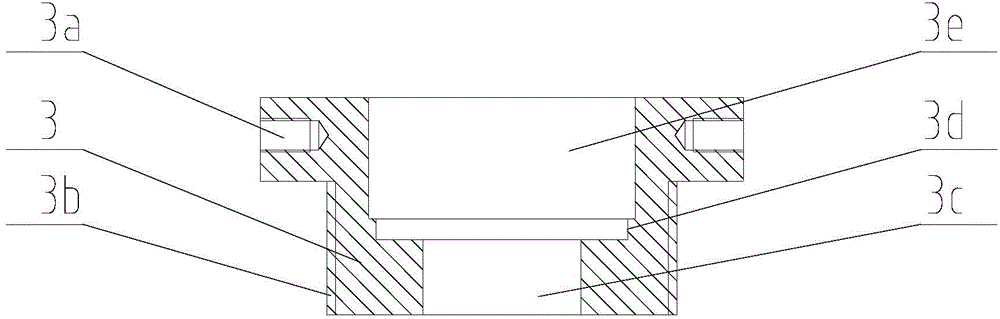

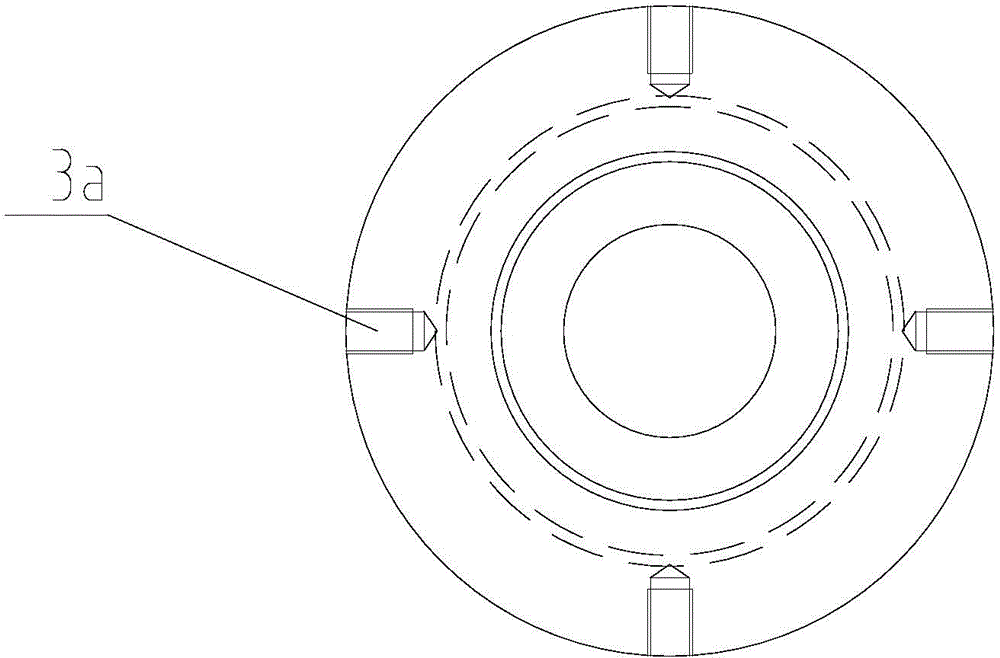

A hot press device for high temperature adhesive curing

ActiveCN105365251AMeet the conditions for multiple curingRotation will notMeasurement devicesPressesAdhesiveEngineering

The invention provides a hot press device for high temperature adhesive curing. The hot press device comprises an end cover (1), bolts (2), a force rod (3), a base (4), a magnet (5), a high temperature rubber pad (7), an electric heating sheet (8), an electrode (9), a lead hole (10), a bearing (11), and a core shaft (12). The base (4) is of a cylindrical structure with an inverted U-shaped cross section; the upper bottom surface is provided with a through hole and the inner wall of the through hole is provided with a thread. The base (4) provides support, and the magnet (5), the high temperature rubber pad (7) and the electric heating sheet (8) are arranged in the base (4). The magnet (5) provides attracting force; the upper end of the magnet (5) is provided with an internal thread which is directly connected with a core shaft thread (12c) of the core shaft (12). The hot pressure device allows the temperature and the applied force to be adjusted, thereby meeting the conditions of multiple times of curing of a high temperature adhesive, and is simple in design, accurate in control and easy to operate.

Owner:TIANJIN AEROSPACE RELIA TECH +3

Multi-connecting-rod independent suspension for drive axle of commercial vehicle

ActiveCN107234934ANo motion interferenceNo concentrated stressUnderstructuresInterconnection systemsVehicle frameCommercial vehicle

Disclosed is a multi-connecting-rod independent suspension for a drive axle of a commercial vehicle. The multi-connecting-rod independent suspension for the drive axle of the commercial vehicle comprises an auxiliary vehicle frame assembly used for being connected with vehicle frame longitudinal beams, an upper longitudinal pulling rod assembly, an upper horizontal pulling rod assembly, a lower horizontal pulling rod assembly, a stable pulling rod assembly, an absorber spring assembly and a bearing base assembly. The auxiliary vehicle frame assembly mainly comprises an auxiliary vehicle frame with a structure of double longitudinal beams and double horizontal beams. The auxiliary vehicle frame comprises an auxiliary vehicle frame front horizontal beam, an auxiliary vehicle frame back horizontal beam and an auxiliary vehicle frame longitudinal beam. The upper longitudinal pulling rod assembly mainly comprises upper longitudinal pulling rods. The upper horizontal pulling rod assembly mainly comprises upper horizontal pulling rods. The lower horizontal pulling rod assembly mainly comprises lower front horizontal pulling rods and lower back horizontal pulling rods. The stable pulling rod assembly mainly comprises stable pulling rods and stable pulling rod connecting bosses. The absorber spring assembly mainly comprises absorbers and springs. The multi-connecting-rod independent suspension for the drive axle of the commercial vehicle has the enough bearing capacity, the comfort performance and stability of the vehicles are improved, the weight of the drive axle is greatly reduced, the fuel oil economy is improved, the space layout can met the electrification demands of the commercial vehicle, and geometric deformation of the suspension does not happen under the extreme load.

Owner:WUHAN UNIV OF TECH

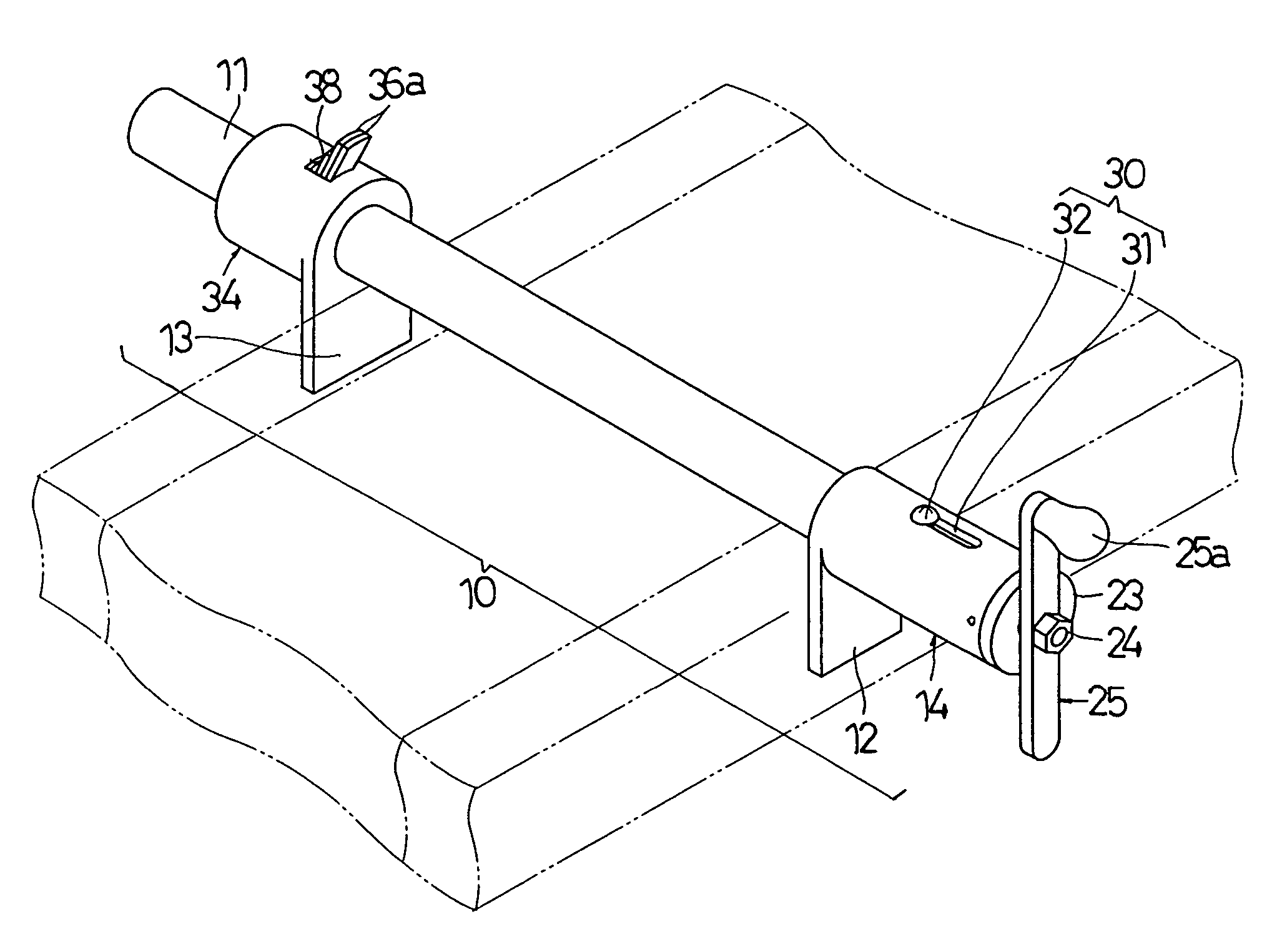

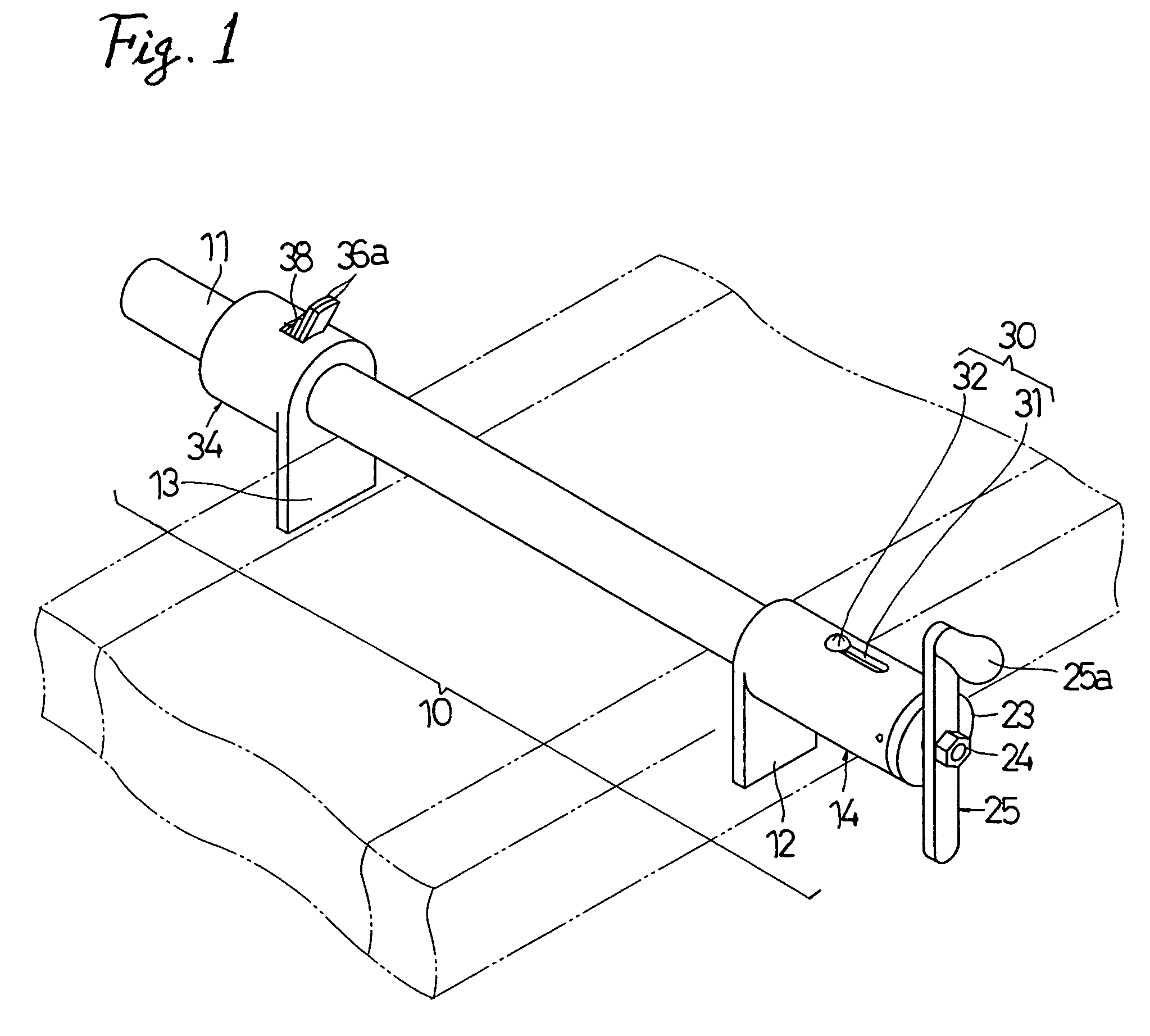

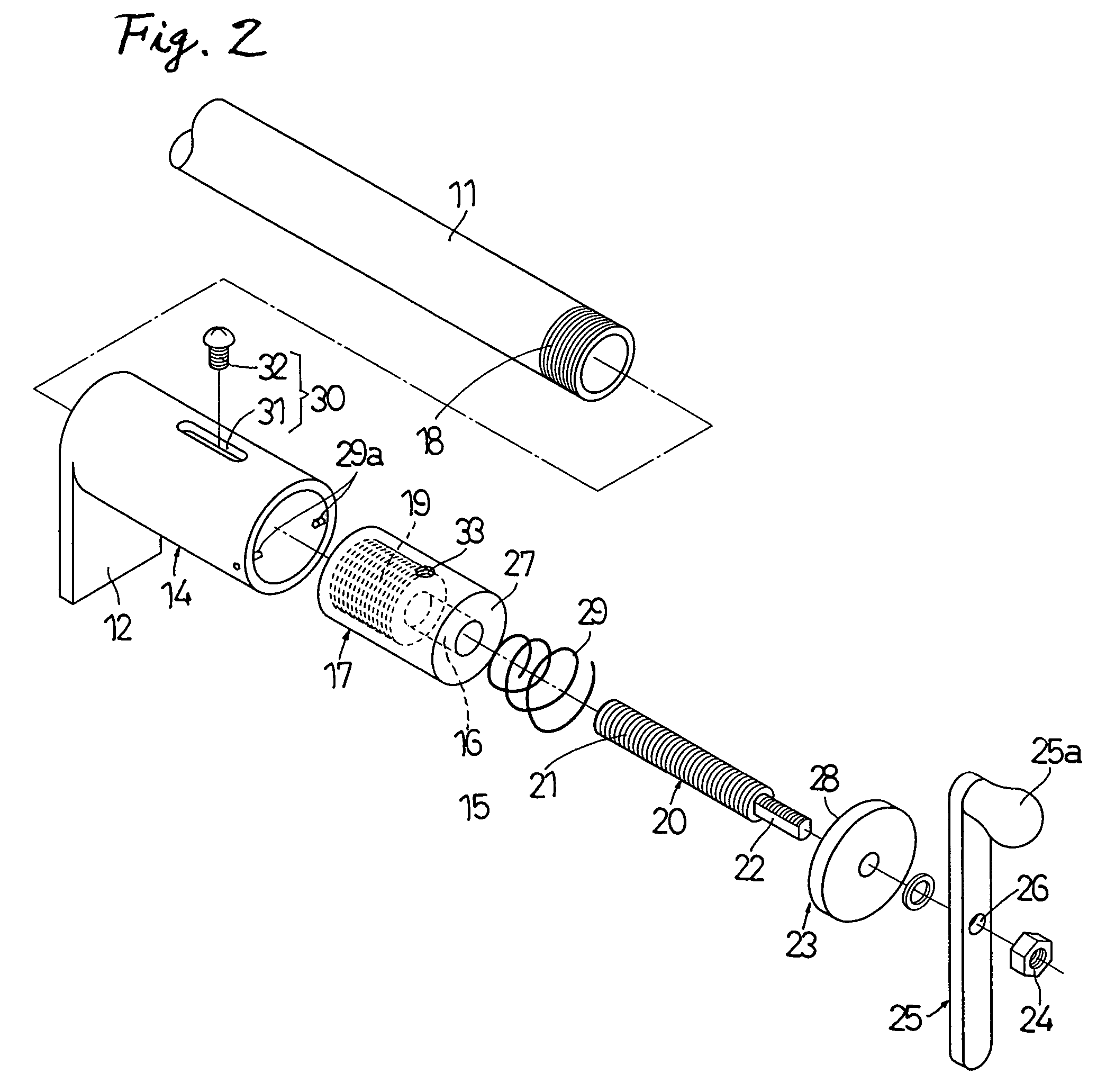

Clamp tool

A clamp tool for woodwork or metalwork in which a screw mechanism is not apart away from a shaft and is not exposed is disclosed. In the clamp tool, a pair of clamping brackets is disposed on a shaft apart from each other and at least one clamping bracket is movable along the shaft to fasten a workpiece in cooperation with the other clamping bracket. Here, a female screw constituting a screw mechanism is disposed at one end of the shaft, a male screw constituting the screw mechanism is rotatable in a slide cylinder disposed outside at the end of the shaft so as to be screwed to the female screw, a handle for rotationally manipulating the male screw is disposed, and a guide portion is disposed between the shaft and the slide cylinder so that the female screw does not rotate but goes straight with the rotation of the male screw so as to allow the clamping bracket disposed outside the slide cylinder to move along the shaft.

Owner:OFF CORP

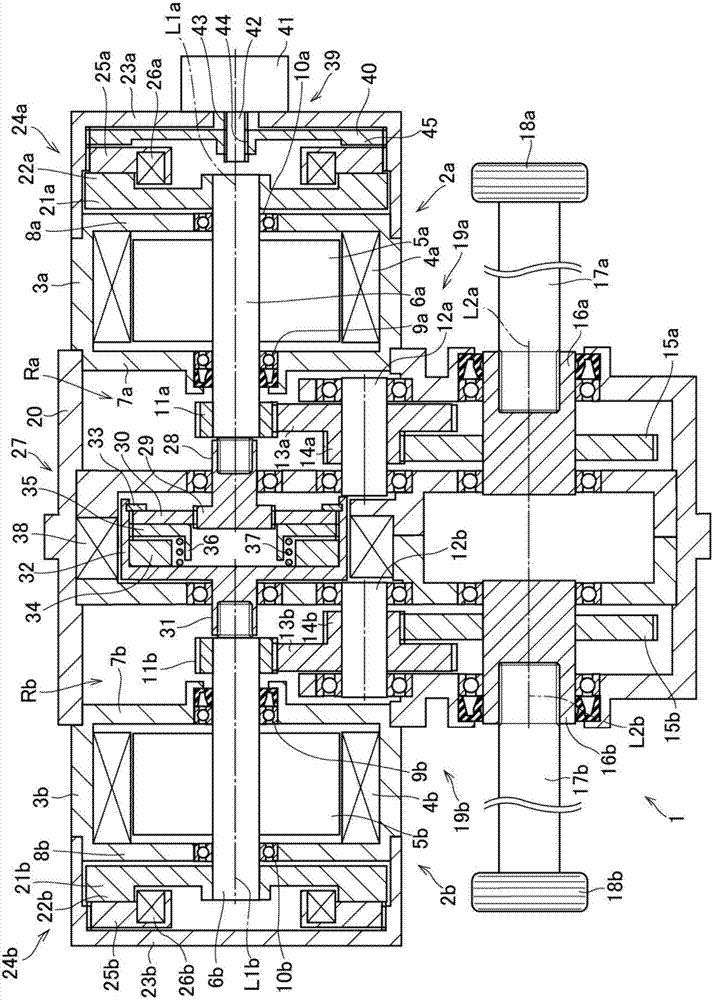

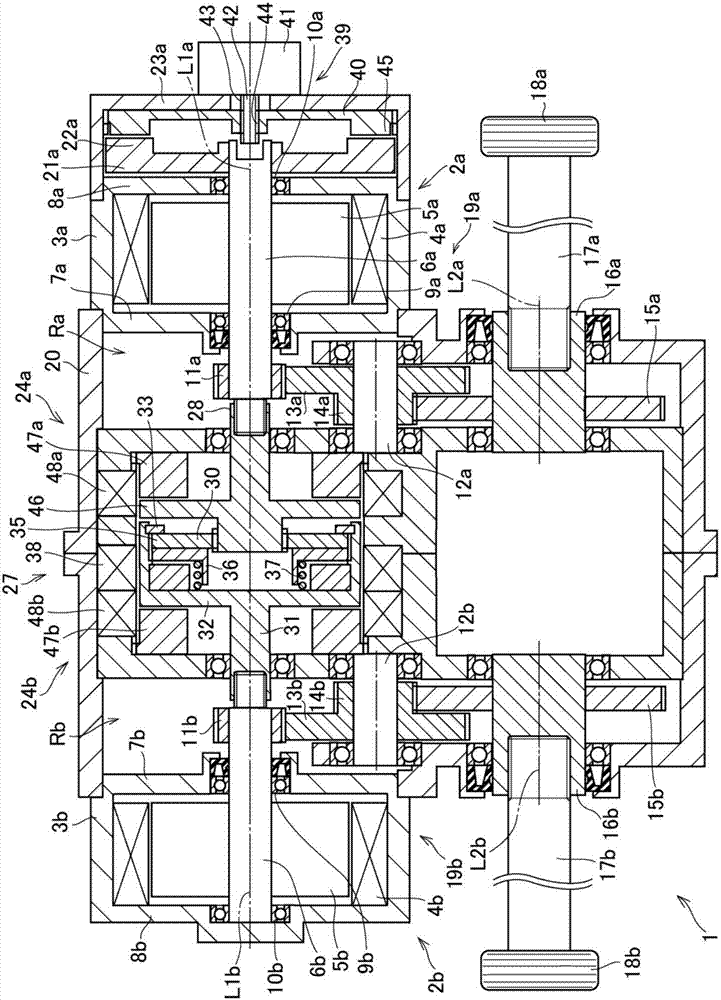

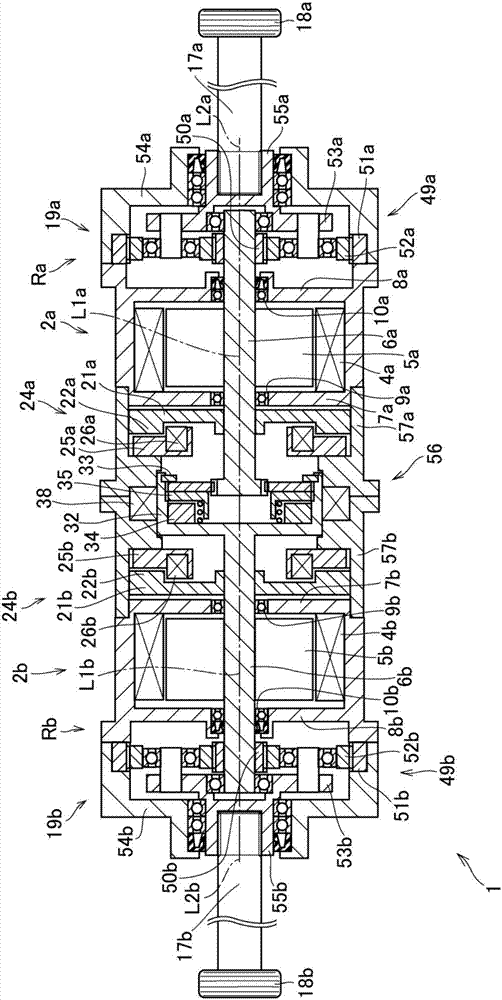

Drive unit

ActiveCN107339399ASuppressing the situation that produces poorImprove driving stabilityAxially engaging brakesElectric propulsion mountingEngineeringControl theory

A drive unit a drive unit which can prevent an occurrence of an unintentional relative rotation between the right and the left wheels is provided. The drive unit comprises: a first motor (2a)connected to the first driveshaft (17a)in a manner of transmitting a torque and a second motor (2b) connected to the second drive shaft (17b) in a manner of transmitting a torque; a first torque transmitting route (Ra) between the first motor and the first drive shaft; a second torque transmitting route (Rb) between the second motor and the second drive shaft; a first rotary member (6a) arranged in the first torque transmitting route; a second rotary member arranged in the second torque transmitting route; and a restriction device that restricts a differential rotation between the first rotary member and the second rotary member.

Owner:TOYOTA JIDOSHA KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com