A hot press device for high temperature adhesive curing

A technology of high-temperature adhesive and hot-pressing device, which is applied in the field of strain testing, can solve the problems of narrow application area and cumbersome high-temperature adhesive curing system, and achieve the effects of easy operation, uniform force, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

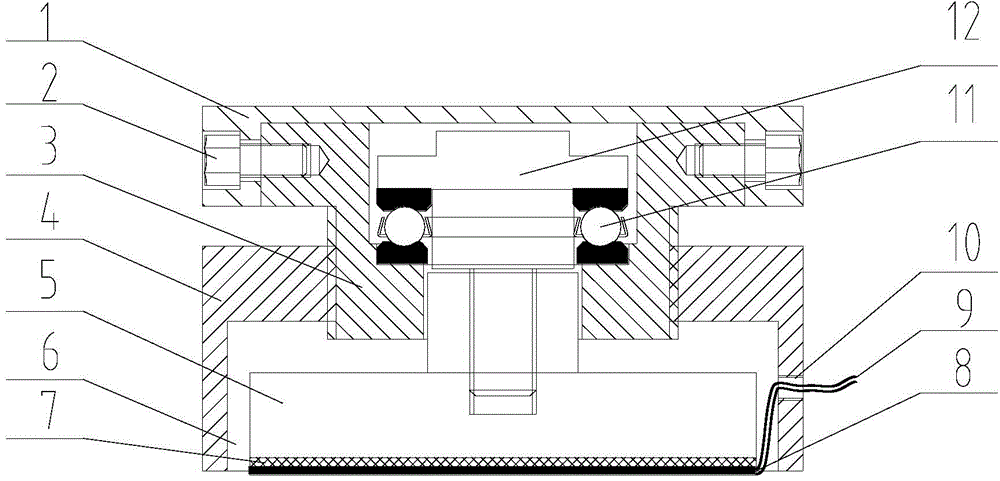

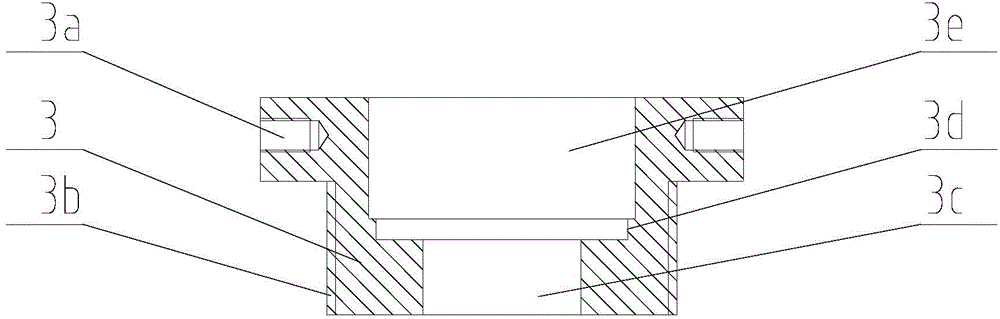

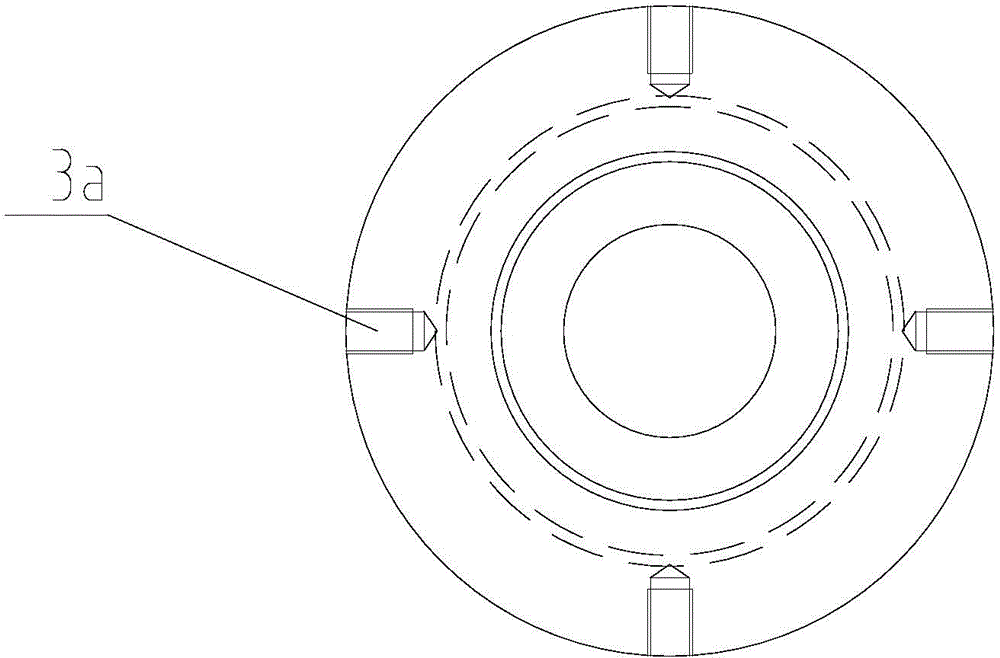

[0057] Embodiment 1 of the present invention is as Figure 5 As shown, the attractive force of the magnet 5 of the present invention is directly adsorbed on the surface of the magnetic workpiece, and the rotating end cover 1 adjusts the threads of the force rod 3 and the base 4, so that the attractive force of the magnet 5 meets the test requirements. Because the frictional force of the bearing 11 is small, the force of rotating the end cover 1 is small, and the magnet 5 will not rotate with the rotation of the end cover 1 and the force rod 3 .

[0058] The magnet 5 applies force evenly to the high-temperature adhesive through the high-temperature rubber pad 7, changes the input of the peripheral power supply connected to the electrode 9, and adjusts the temperature of the electric heater 8 to meet the curing conditions of the high-temperature adhesive.

Embodiment 2

[0060] Embodiment 2 of the present invention is as Figure 6 Shown, two devices of the present invention are symmetrical to both sides of the thin-walled part, and are compressed by the attractive force of the magnet 5. Rotate the end cap 1 to adjust the threads of the force rod 3 and the base 4, so that the attractive force of the magnet 5 meets the test requirements. Because the frictional force of the bearing 11 is small, the force of rotating the end cover 1 is small, and the magnet 5 will not rotate with the rotation of the end cover 1 and the force rod 3 .

[0061] The magnet 5 applies force evenly to the high-temperature adhesive through the high-temperature rubber pad 7, changes the input of the peripheral power supply connected to the electrode 9, and adjusts the temperature of the electric heater 8 to meet the curing conditions of the high-temperature adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com