Patents

Literature

39results about How to "Rotation will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

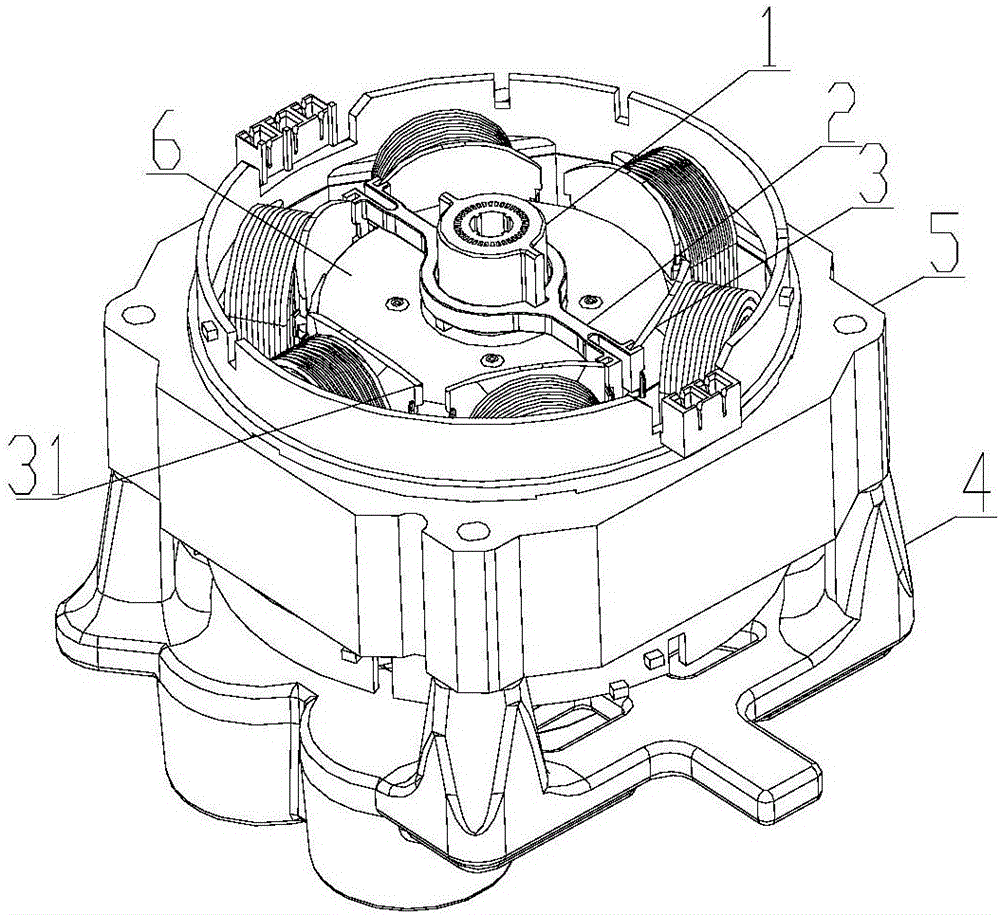

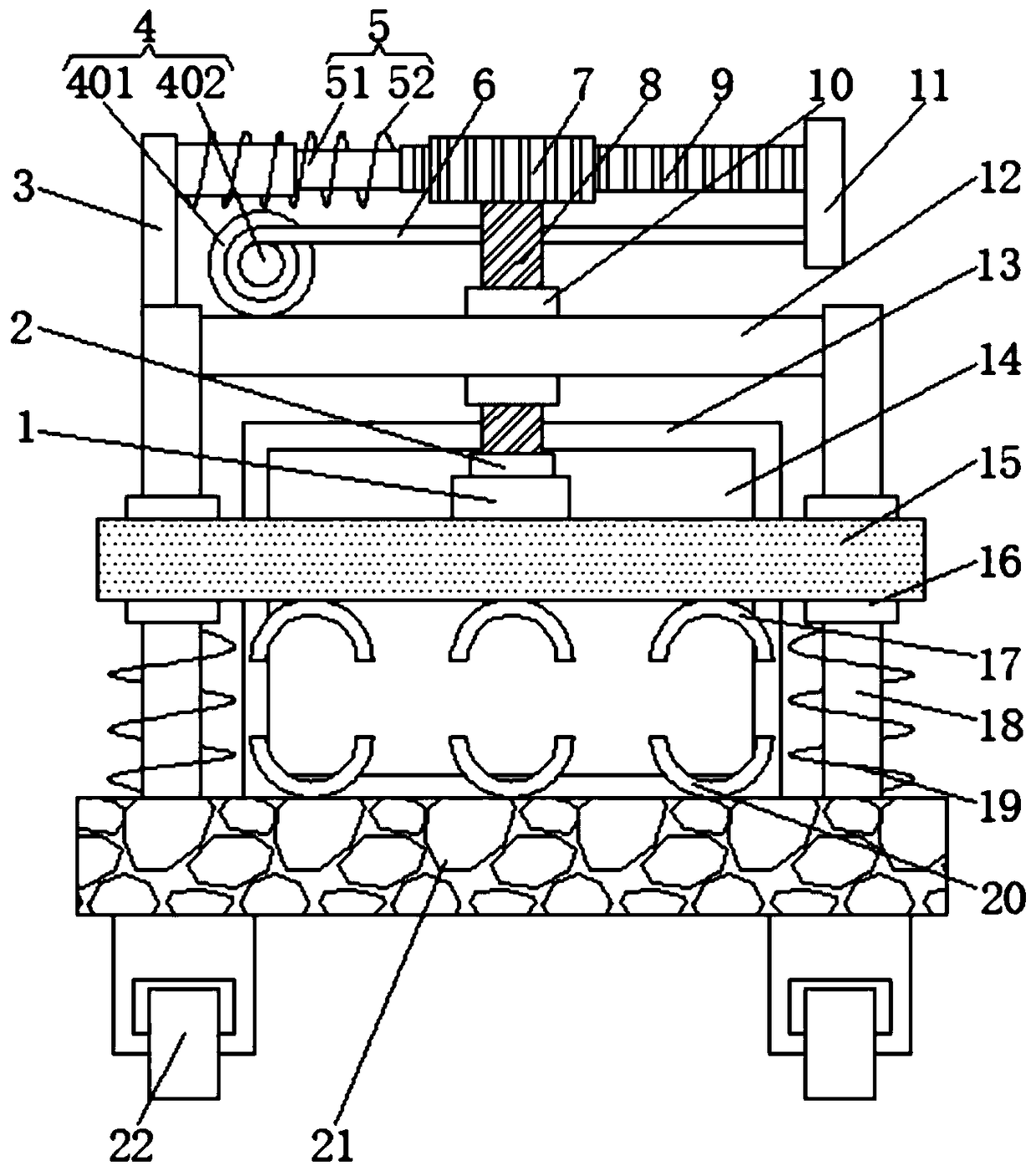

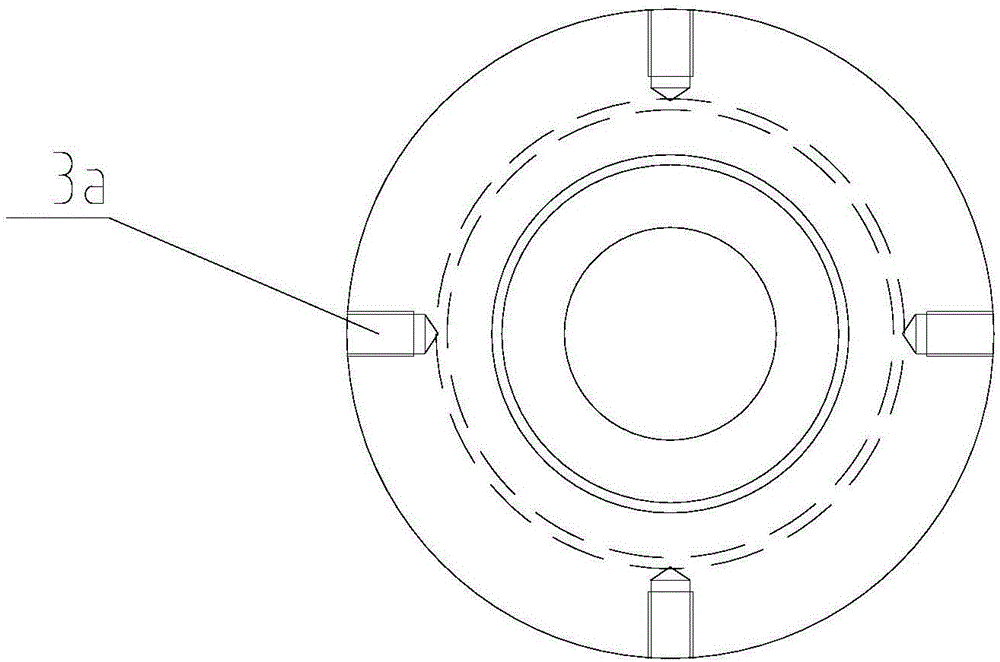

A hot press device for high temperature adhesive curing

ActiveCN105365251AMeet the conditions for multiple curingRotation will notMeasurement devicesPressesAdhesiveEngineering

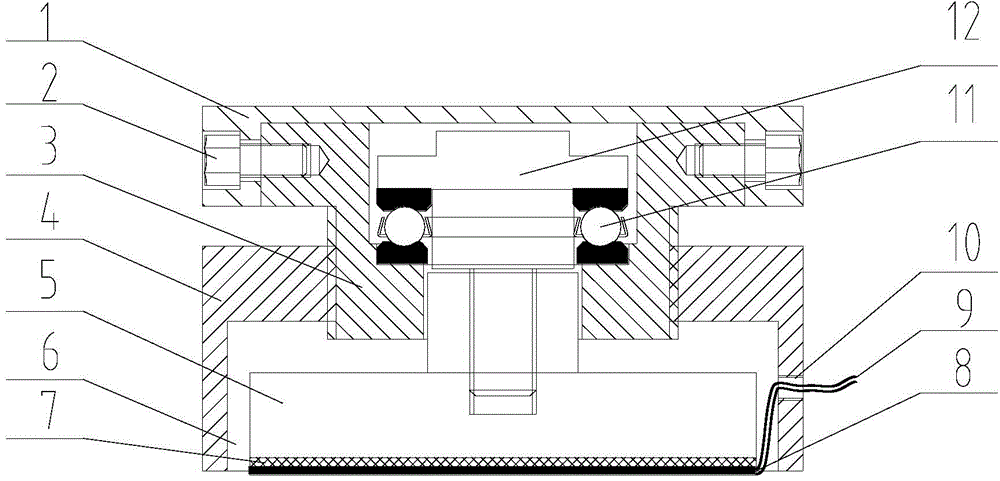

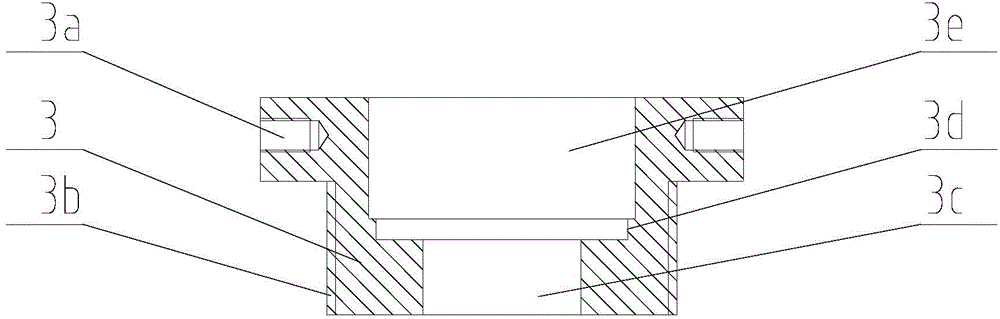

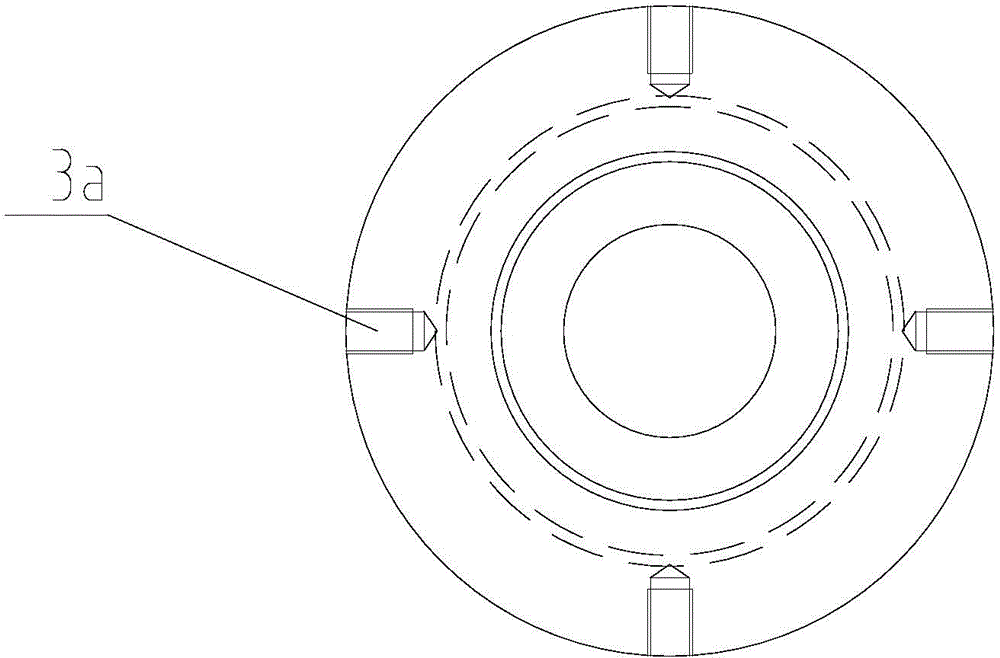

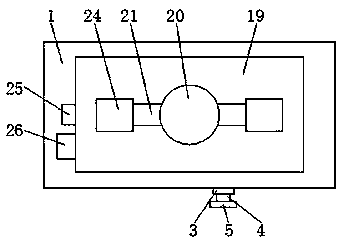

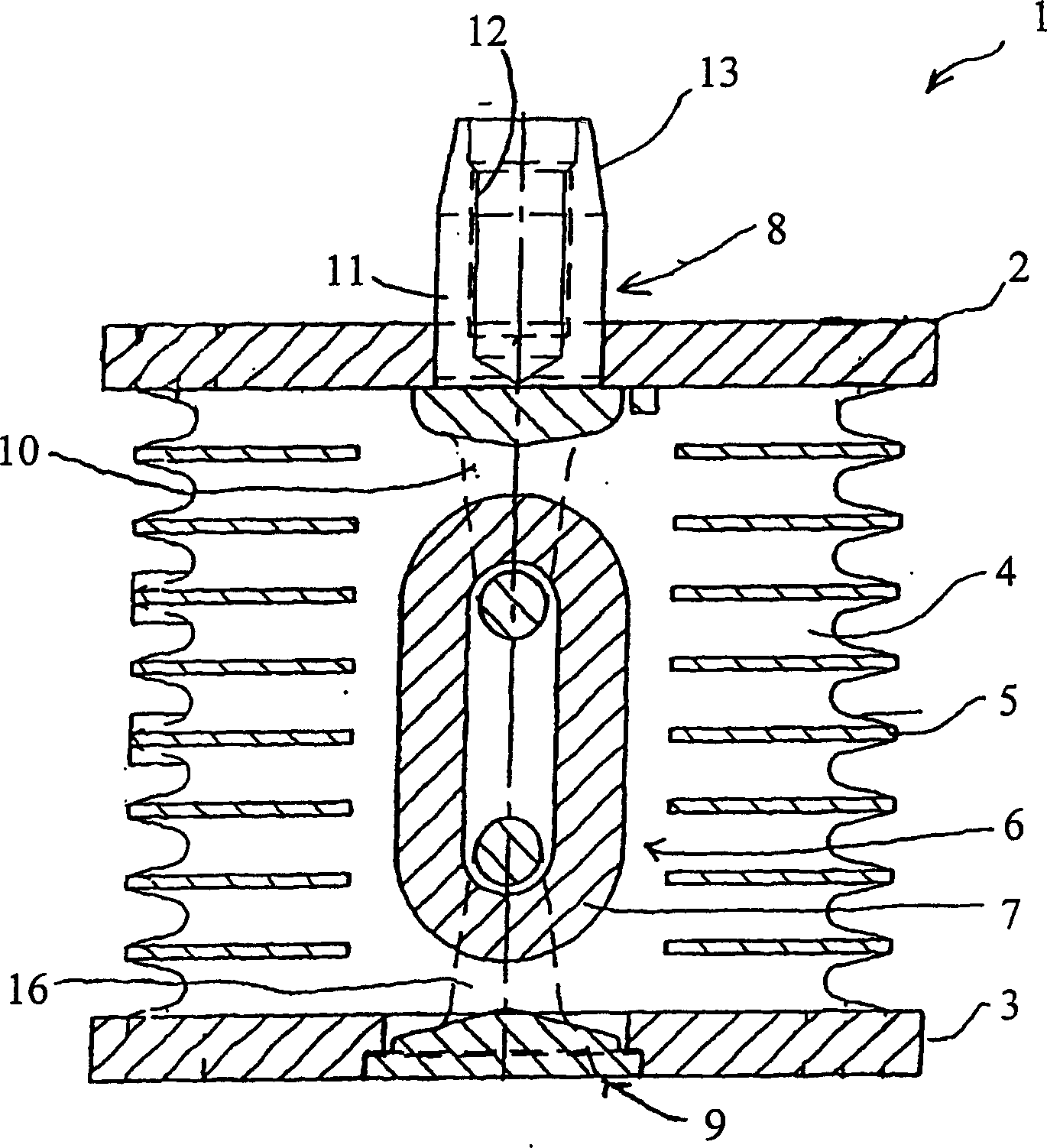

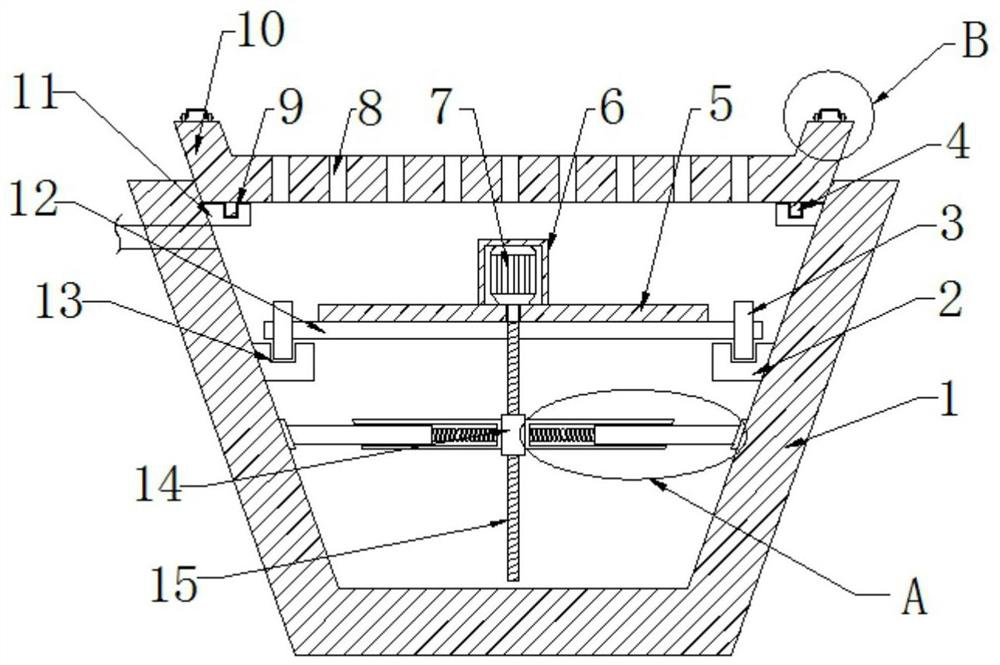

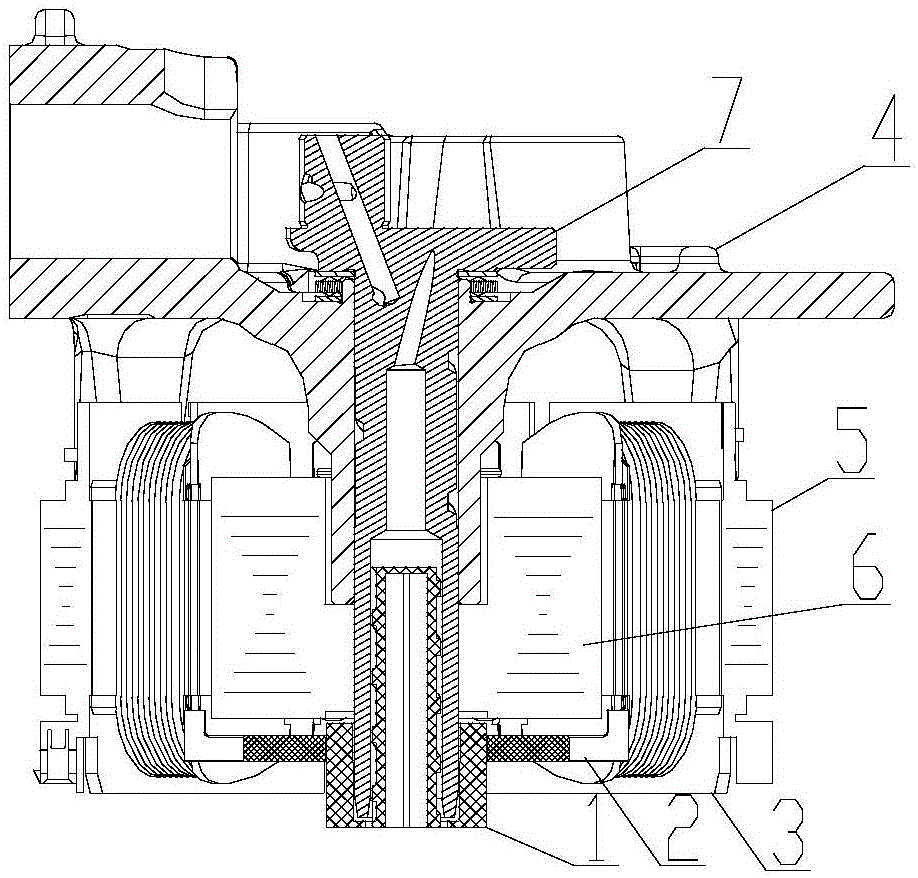

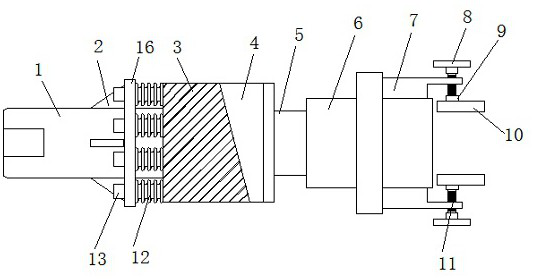

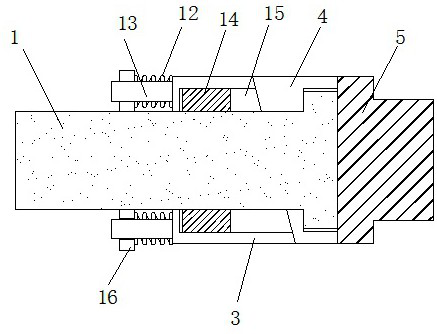

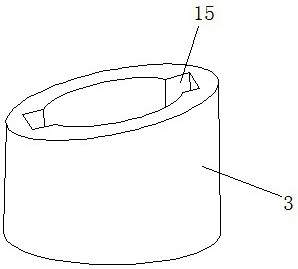

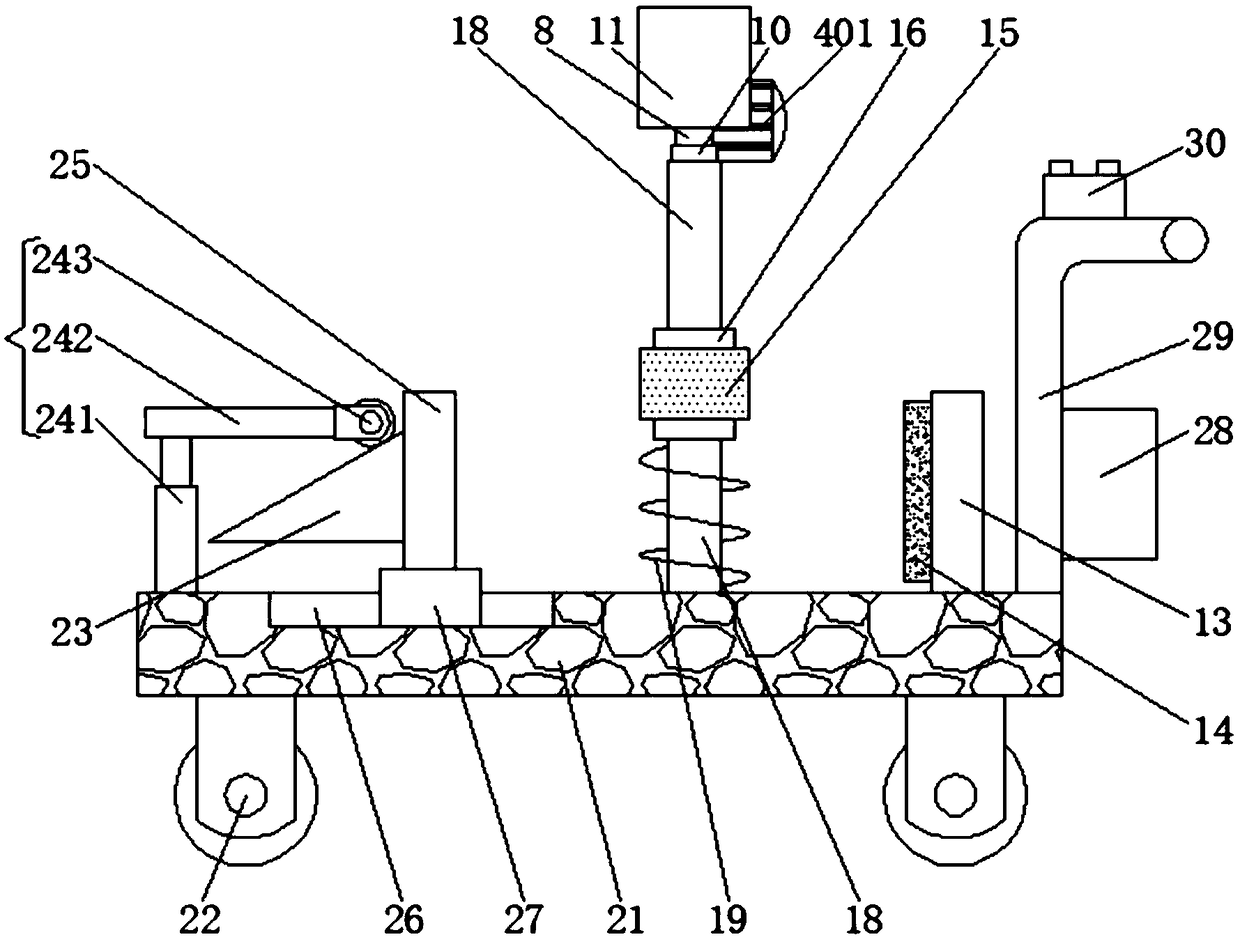

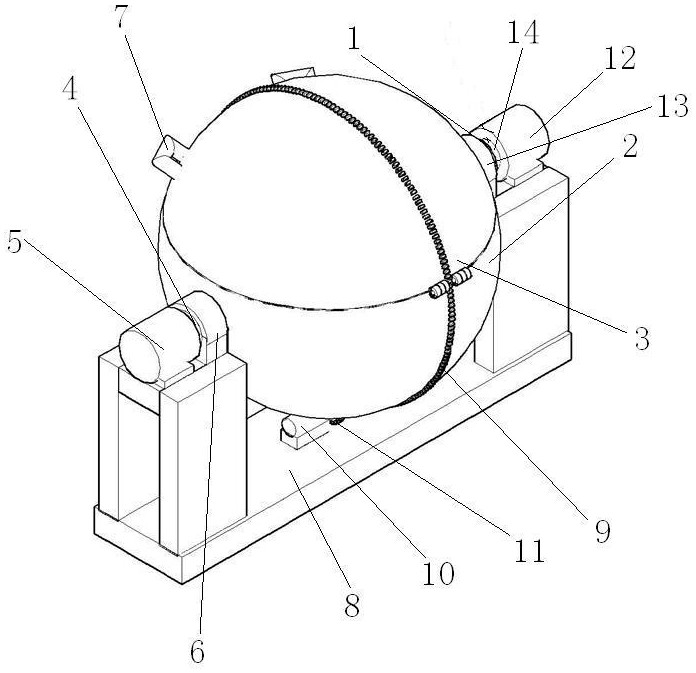

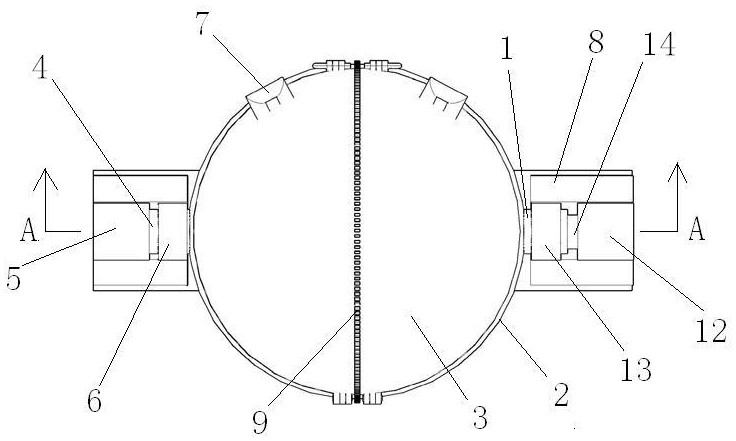

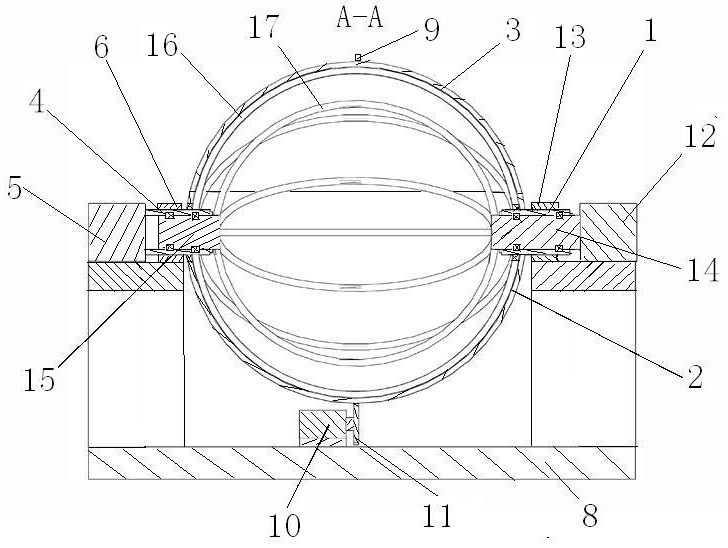

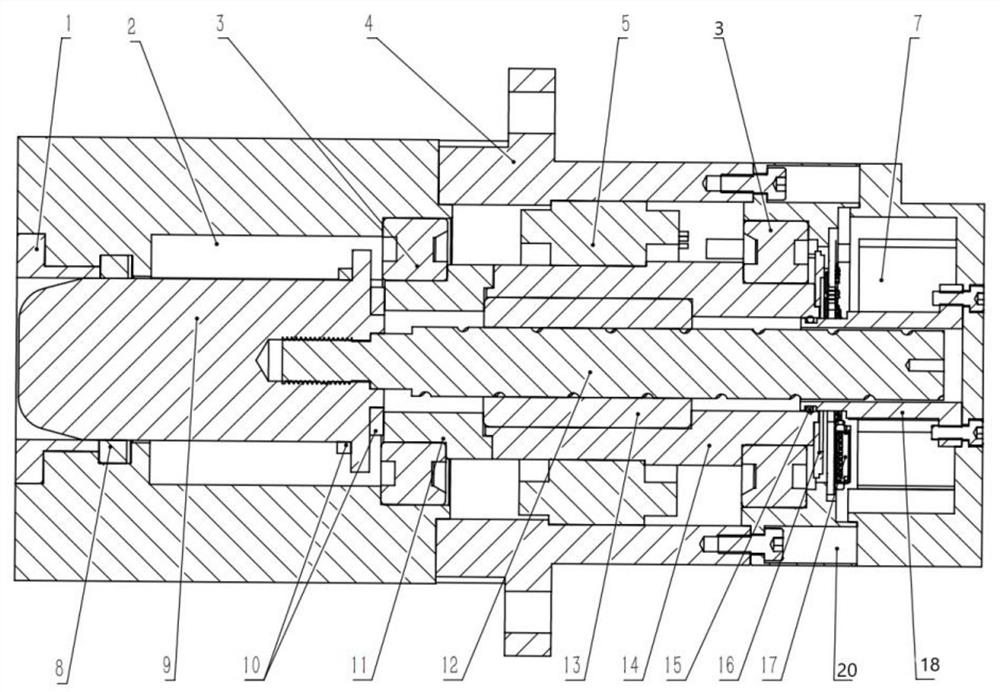

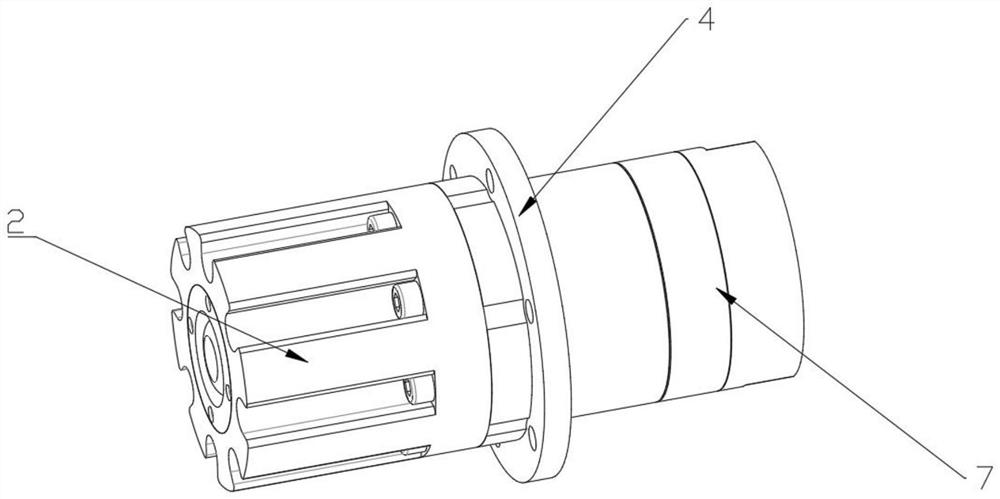

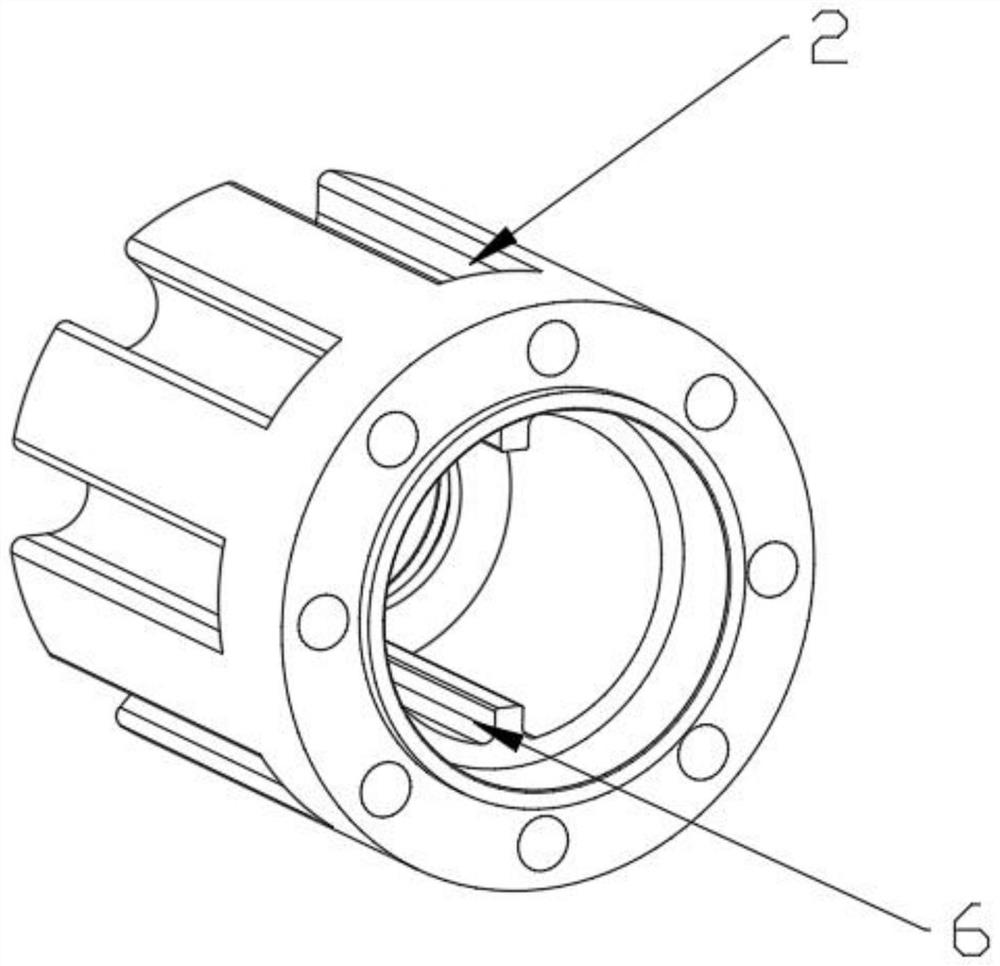

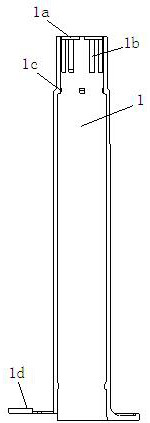

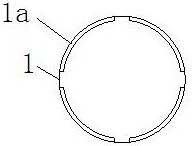

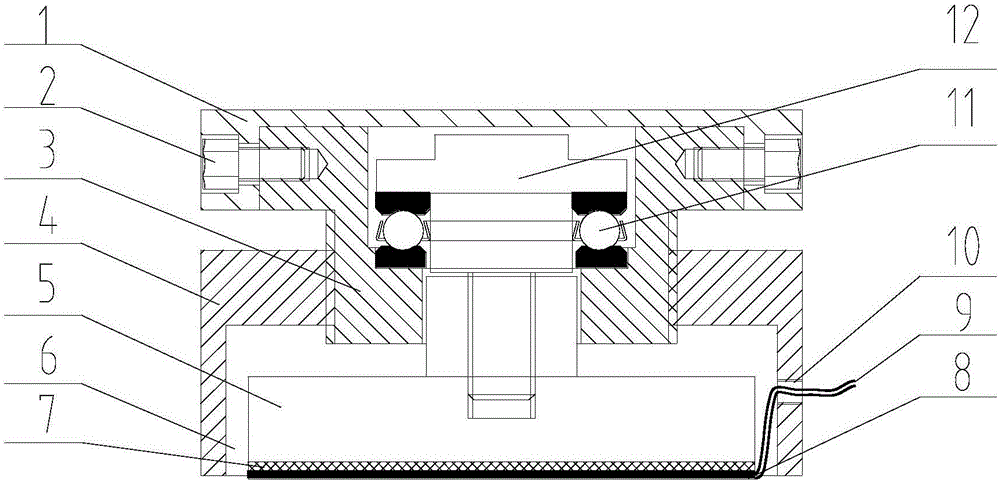

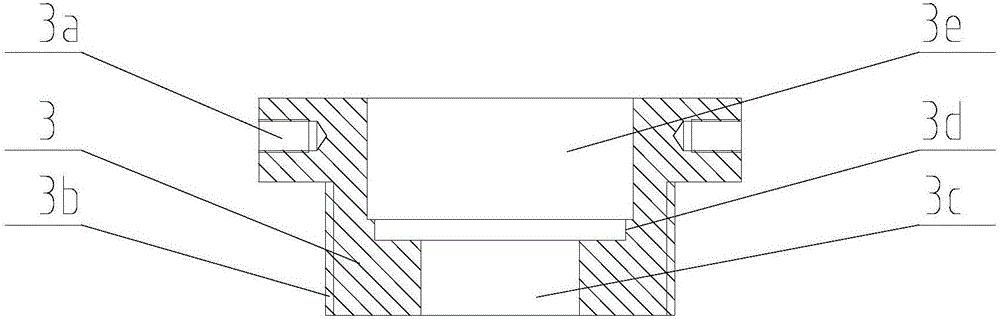

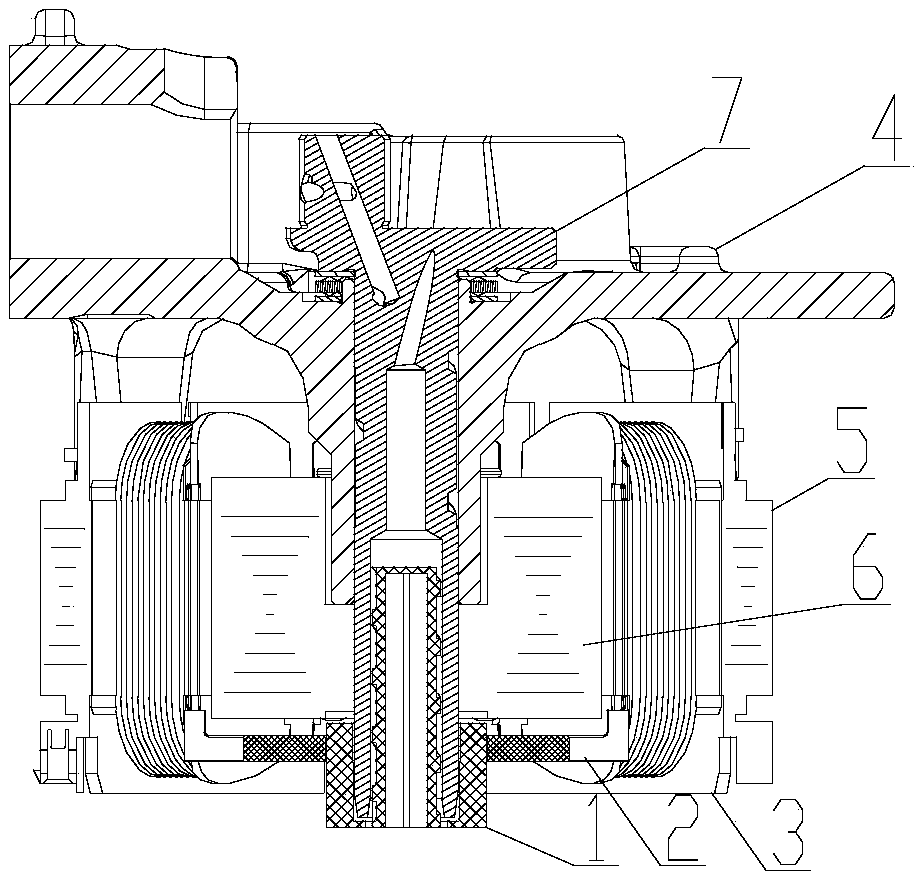

The invention provides a hot press device for high temperature adhesive curing. The hot press device comprises an end cover (1), bolts (2), a force rod (3), a base (4), a magnet (5), a high temperature rubber pad (7), an electric heating sheet (8), an electrode (9), a lead hole (10), a bearing (11), and a core shaft (12). The base (4) is of a cylindrical structure with an inverted U-shaped cross section; the upper bottom surface is provided with a through hole and the inner wall of the through hole is provided with a thread. The base (4) provides support, and the magnet (5), the high temperature rubber pad (7) and the electric heating sheet (8) are arranged in the base (4). The magnet (5) provides attracting force; the upper end of the magnet (5) is provided with an internal thread which is directly connected with a core shaft thread (12c) of the core shaft (12). The hot pressure device allows the temperature and the applied force to be adjusted, thereby meeting the conditions of multiple times of curing of a high temperature adhesive, and is simple in design, accurate in control and easy to operate.

Owner:TIANJIN AEROSPACE RELIA TECH +3

Pressurizing device for Huizhou ink stick production

Owner:HUANGSHAN GUCHENG SHEZHOU INKSTONE CO LTD

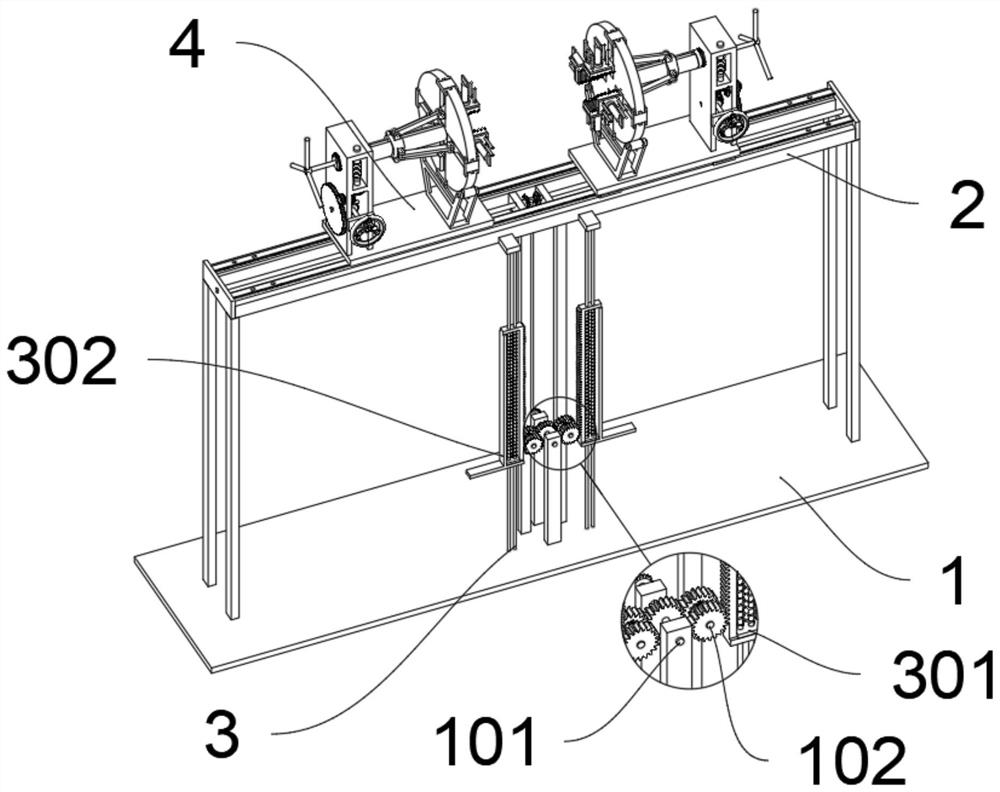

Industrial equipment for quickly impregnating steel plate surface with degreasing agent

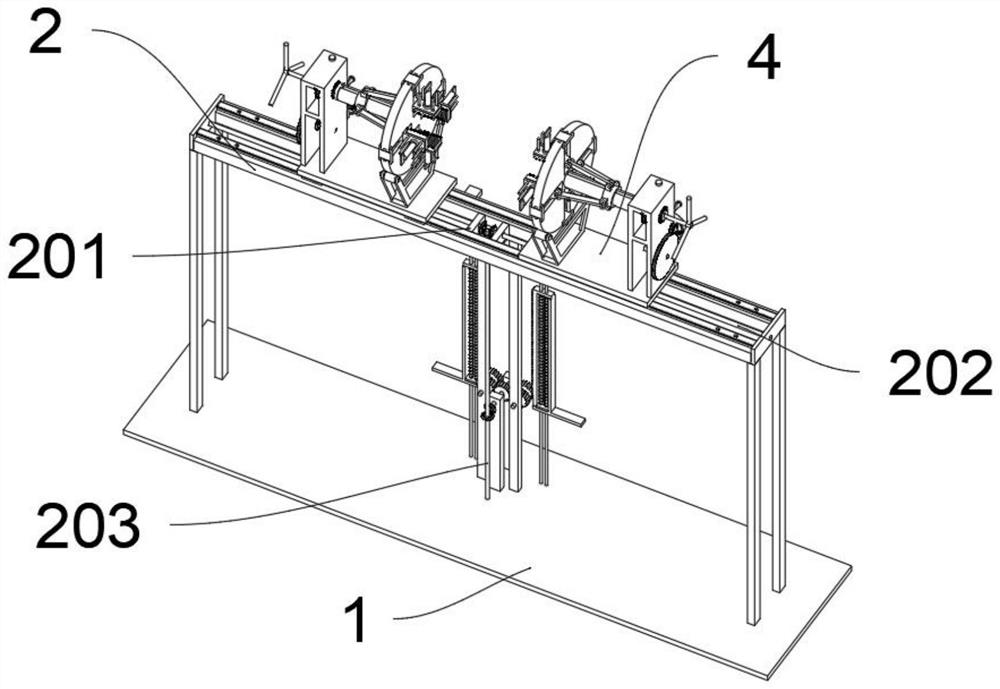

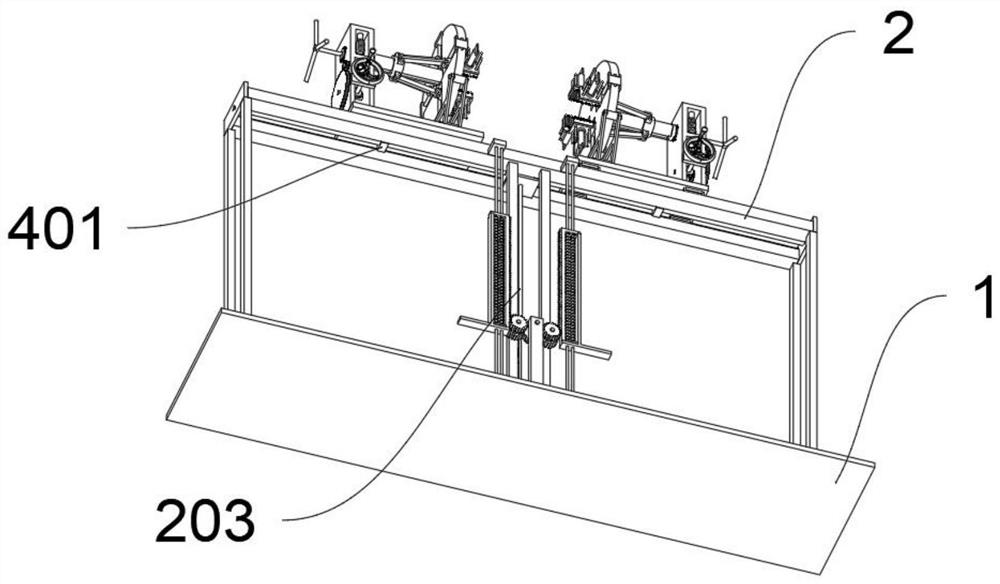

The invention relates to steel plate surface processing equipment, in particular to industrial equipment for quickly impregnating a steel plate surface with a degreasing agent. In order to solve the technical problems, the invention provides the industrial equipment for quickly impregnating the steel plate surface with the degreasing agent, and the industrial equipment is relatively short in impregnating time, is time-saving and labor-saving, and is relatively convenient for transporting steel plates. The industrial equipment for quickly impregnating the steel plate surface with the degreasing agent comprises a bottom plate, supporting posts, an impregnating tank, a first motor, a first stirring blade, a supporting plate, a mounting plate, a first slide rail, a first slide block, a first connecting plate, an electric wire winding wheel and the like, wherein the supporting pots are mounted at the left side and the right side of the upper side of the bottom plate in a welding mode; and the upper ends of the supporting posts are equipped with the impregnating tank in the welding mode. The industrial equipment achieves the effects of being relatively short in impregnating time, labor-saving and force-saving, and convenient for transporting steel plates by rotating the first motor and stirring the degreasing agent on the upper layer through a third motor.

Owner:湖州浪佩智能科技有限公司

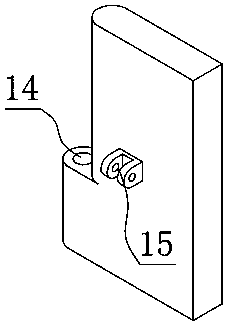

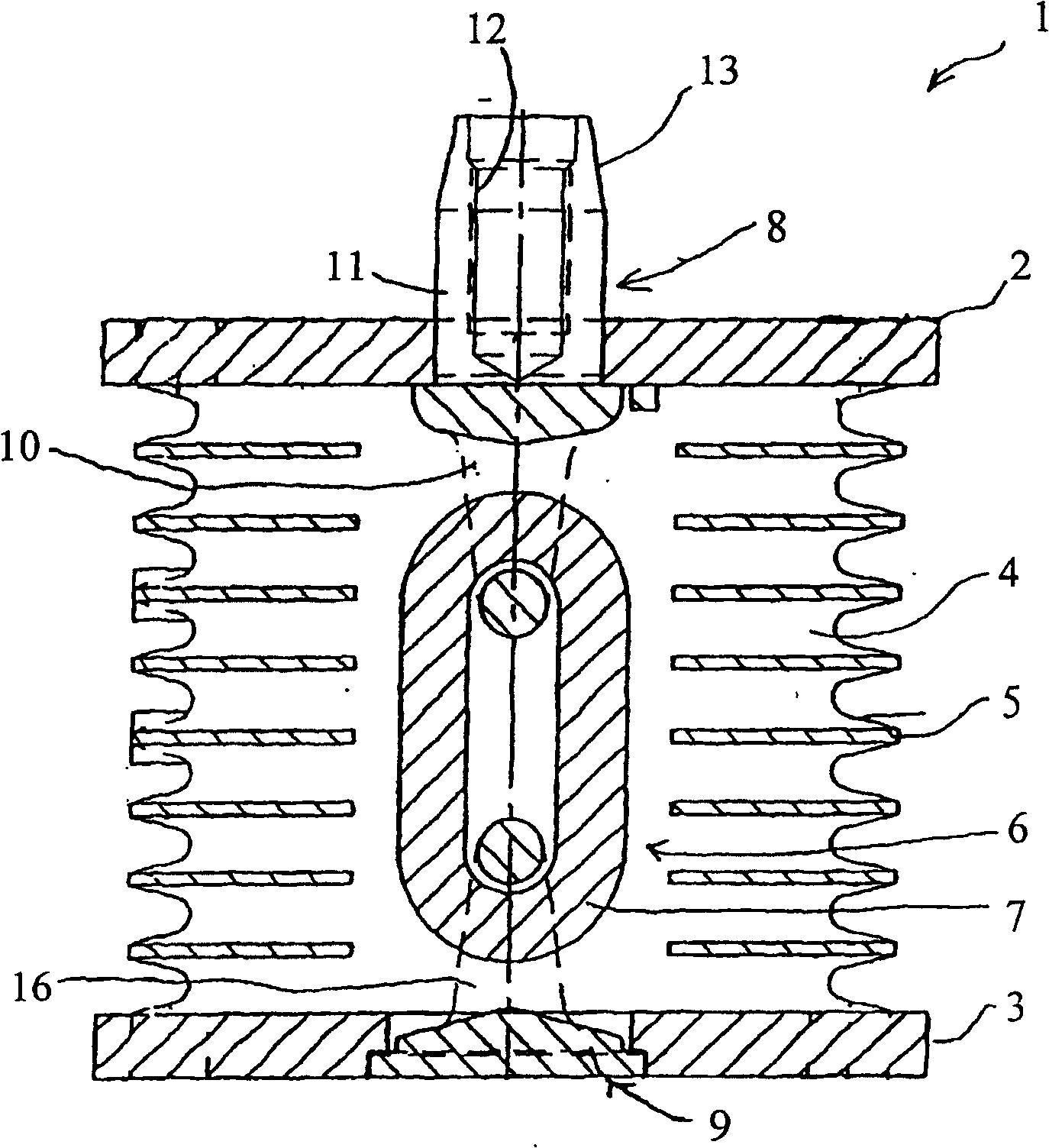

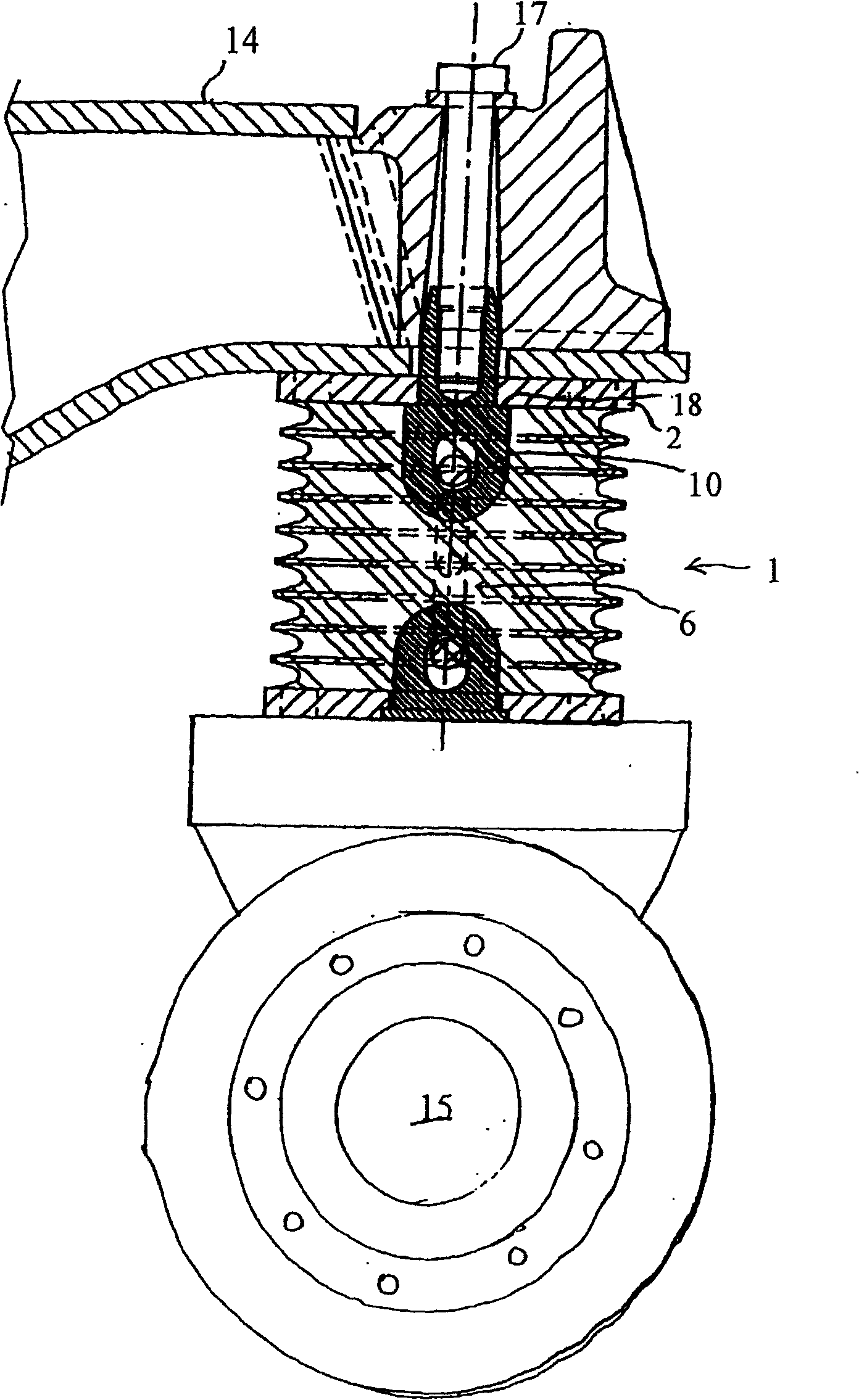

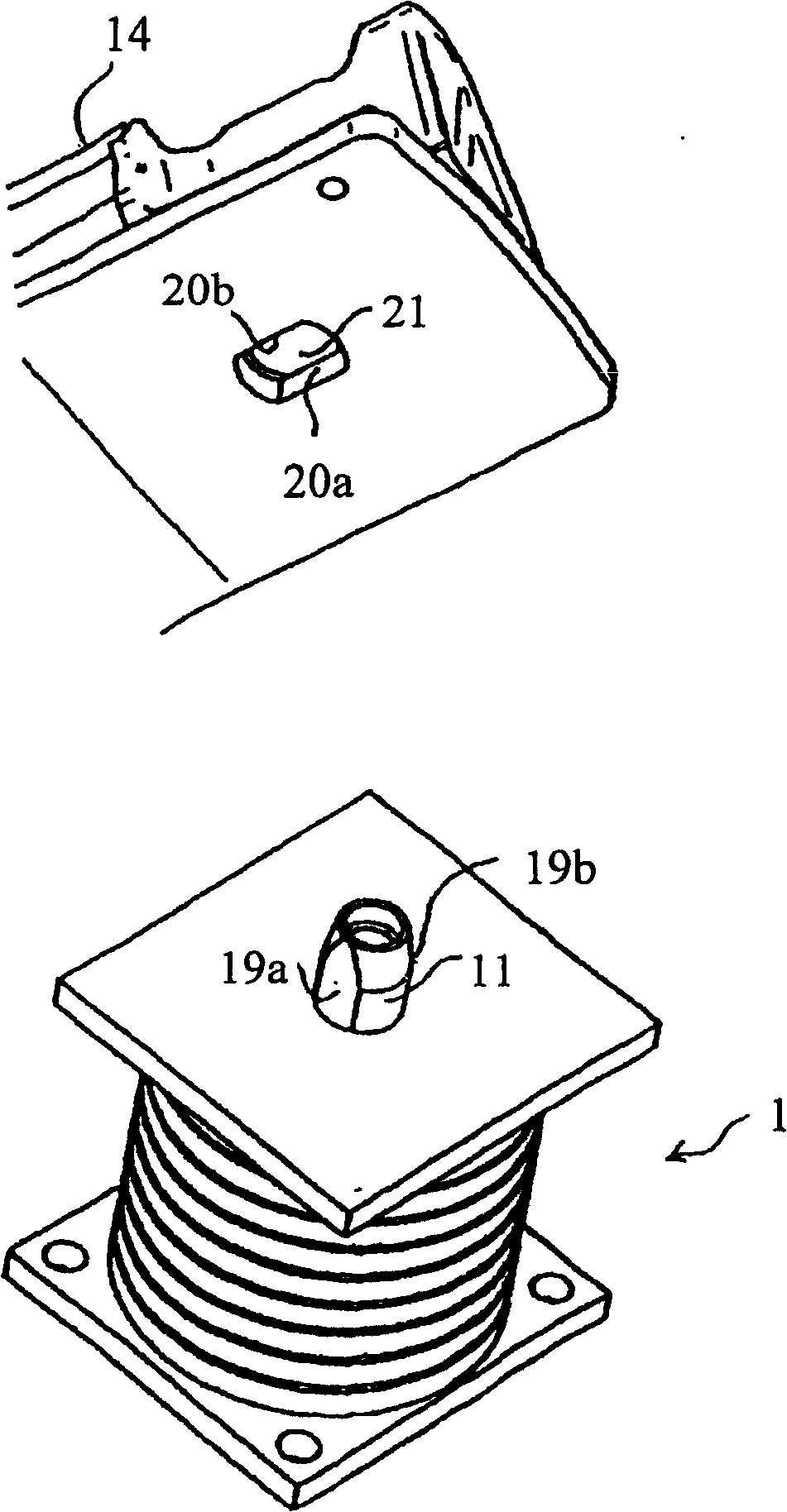

Flexible element

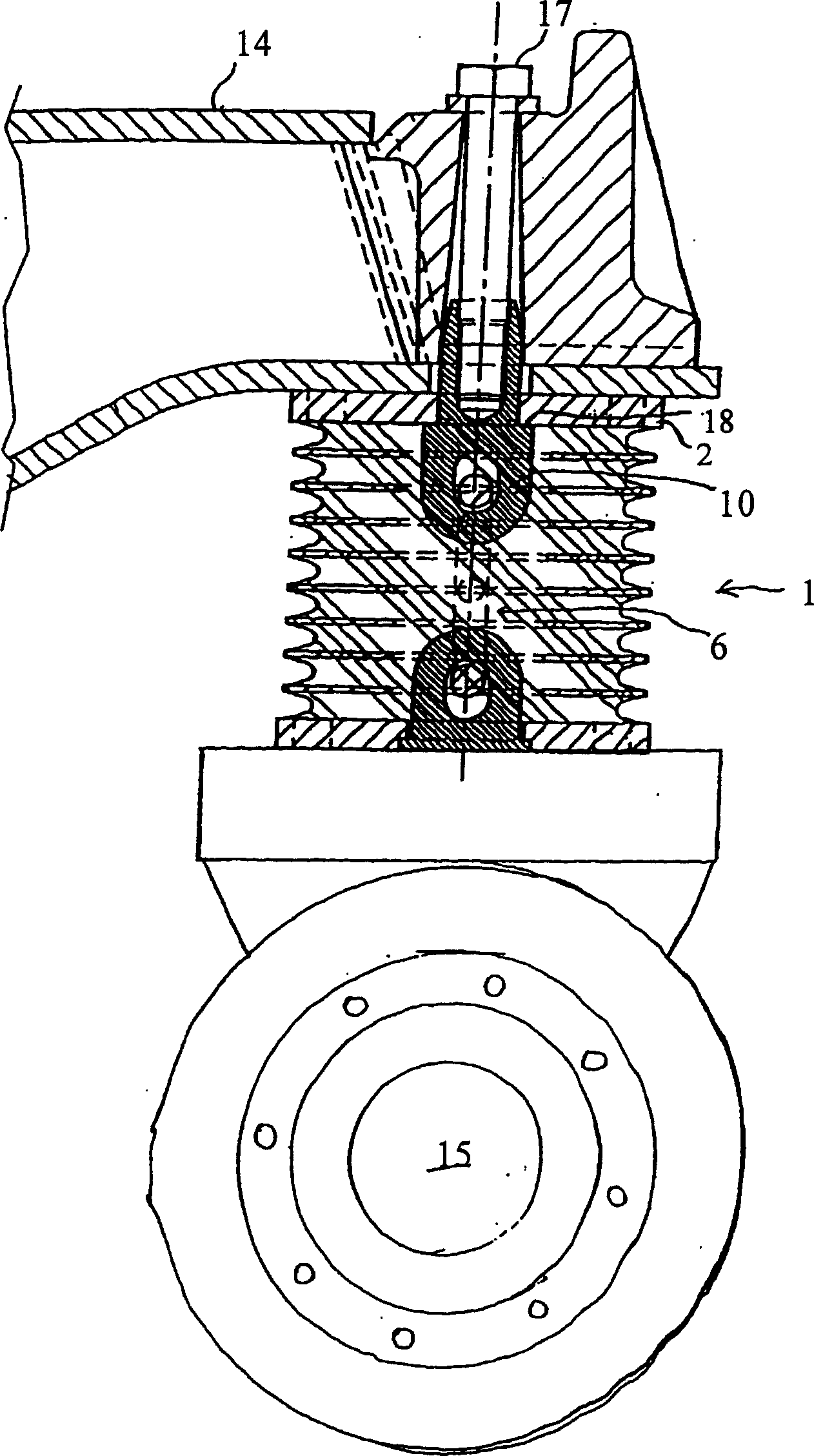

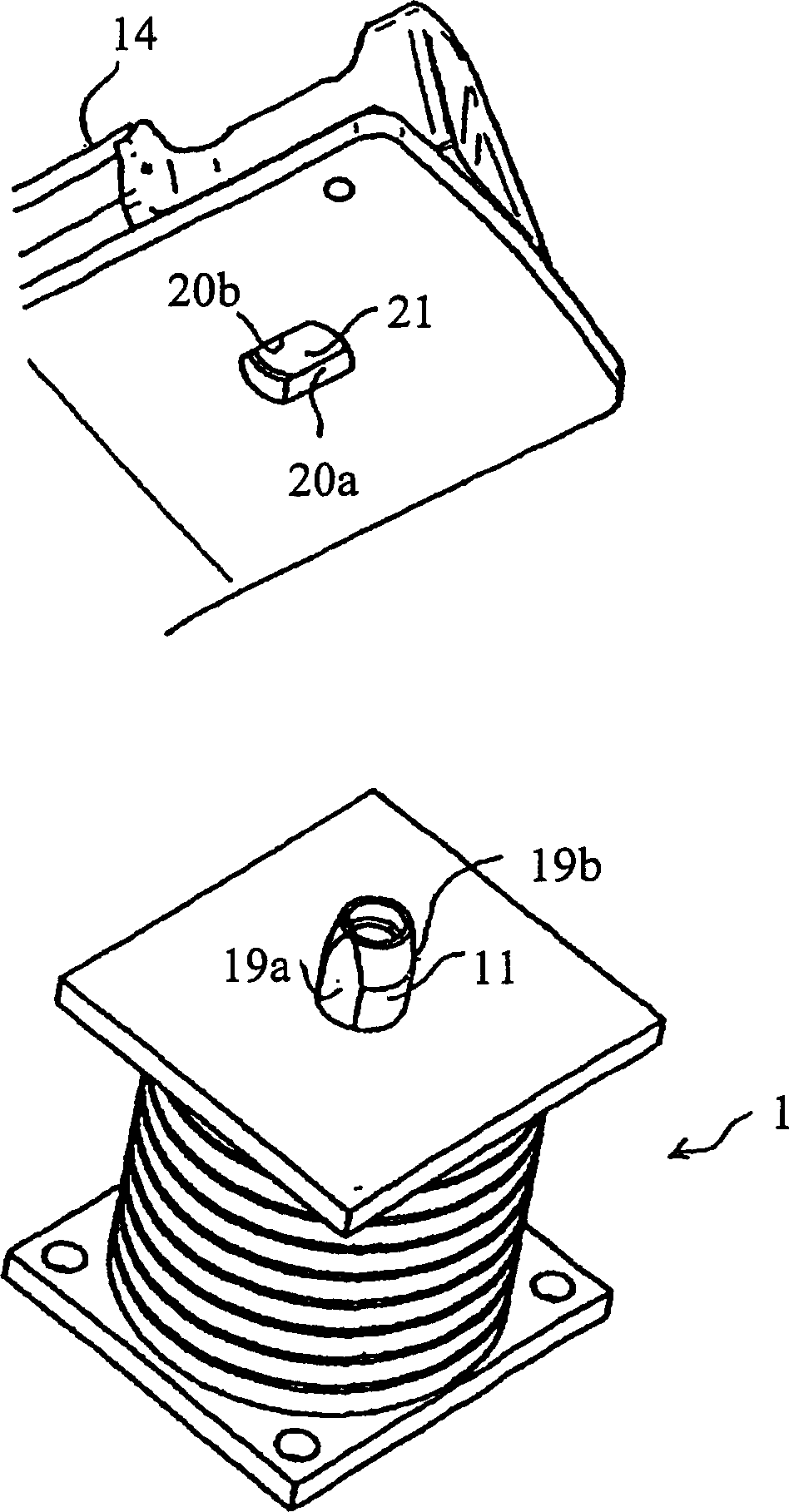

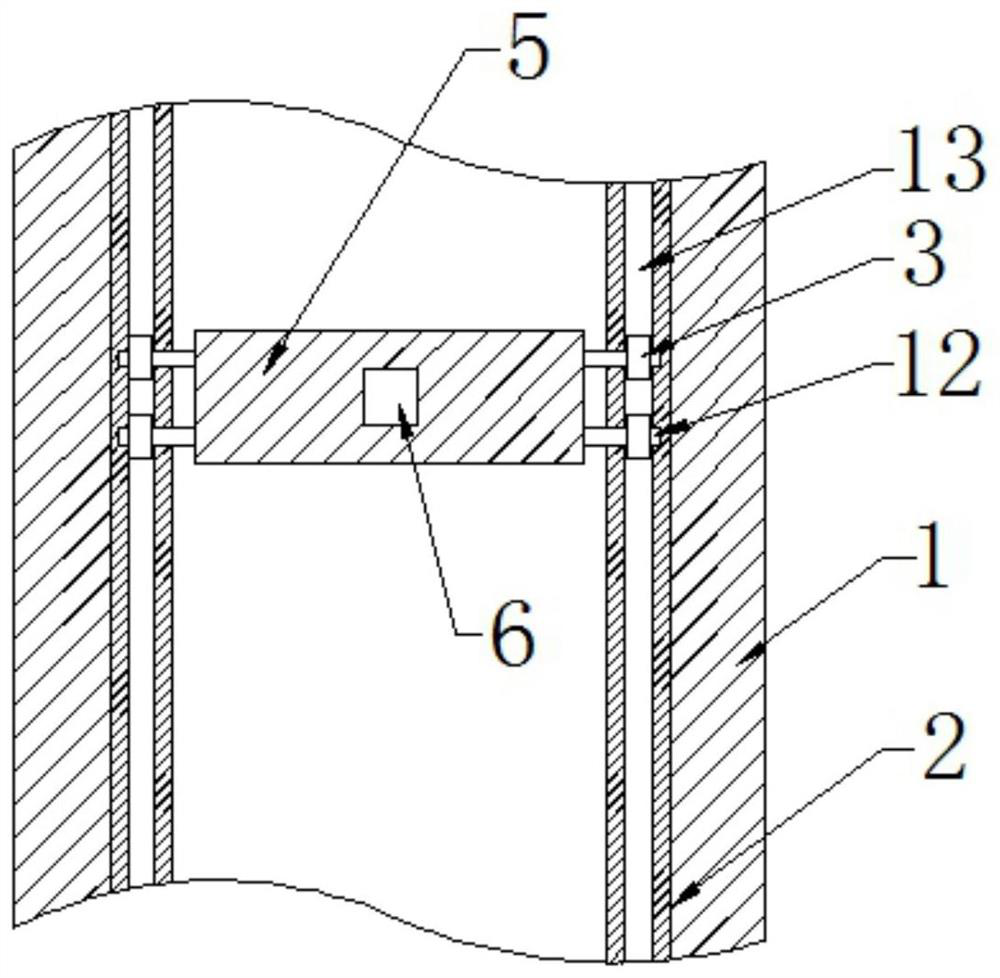

InactiveCN1555319ANo bending momentCompact manufacturingResilient suspensionsPivoted suspension armsBogieVehicle frame

The present invention relates to a spring element 1 intended to transmit compression forces and tensile forces between a vehicle frame 14 and a wheel axle 15 arranged movably in relation to the vehicle frame 14, especially between the wheel axle 15 and the end of a bogie beam mounted pivotably in the vehicle frame 14. The spring element 1 comprises a rubber body 4, and a mechanical connection member 6 which extends through the rubber body 4 and is arranged to limit the distancing movement between said vehicle frame 14 and wheel axle 15. The connection member 6 here comprises a coupling device 8 for coupling the connection member 6 in one of said vehicle frame 14 or wheel axle 15.

Owner:VOLVO ARTICULATED HAULERS

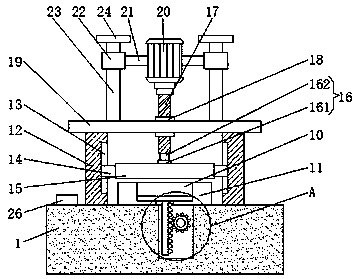

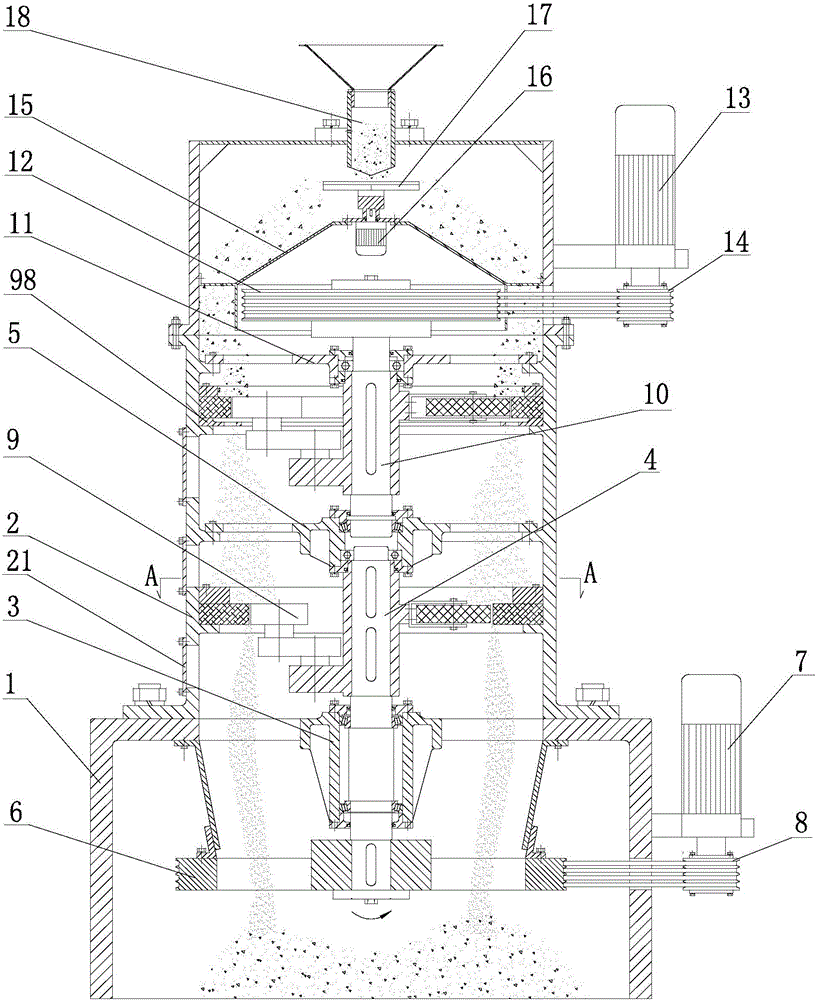

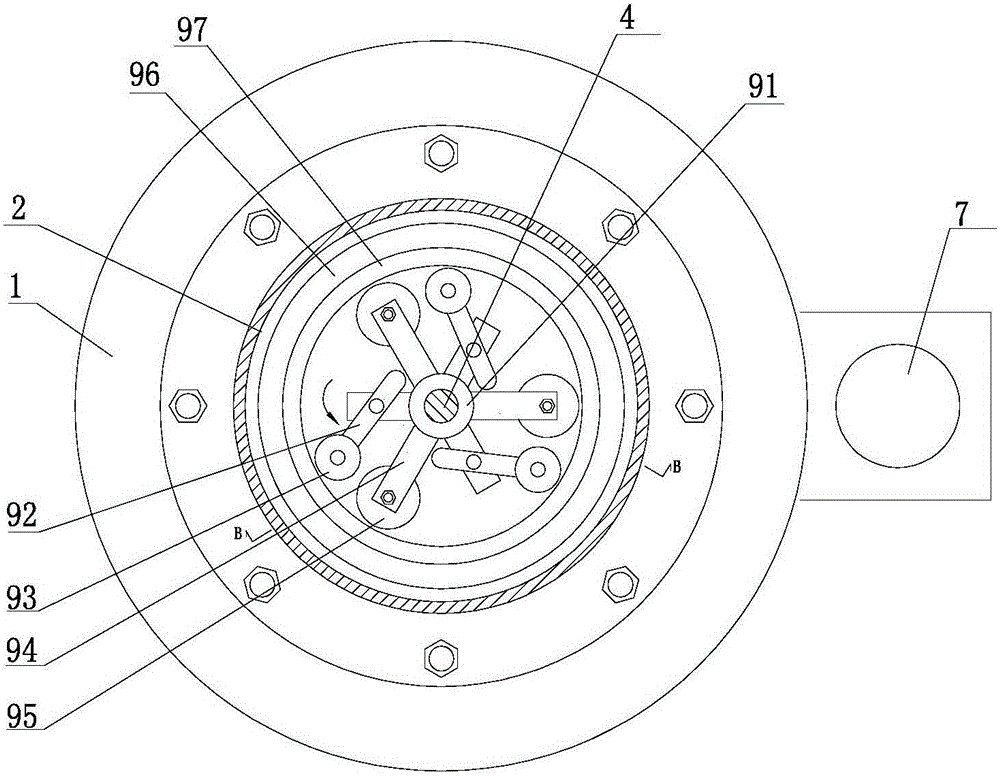

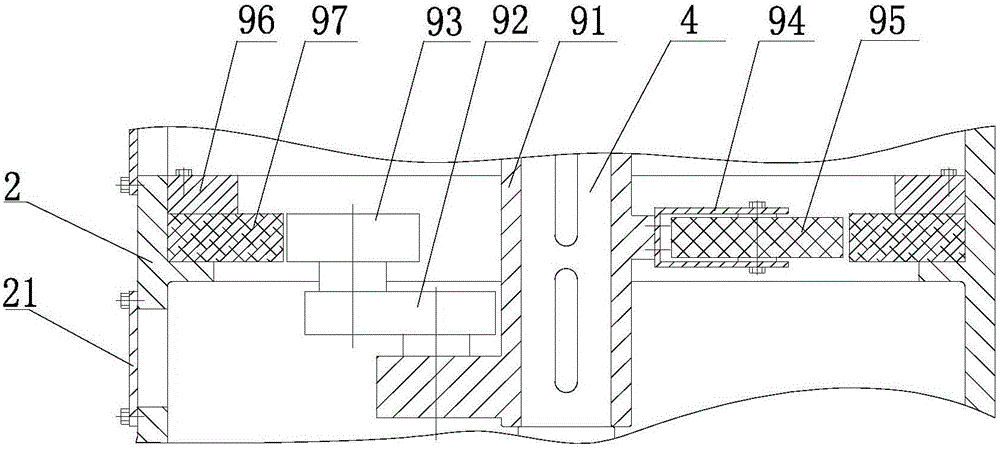

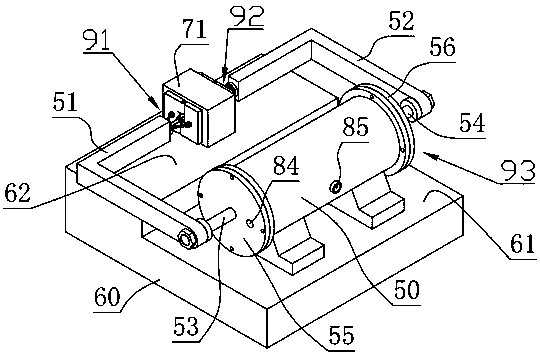

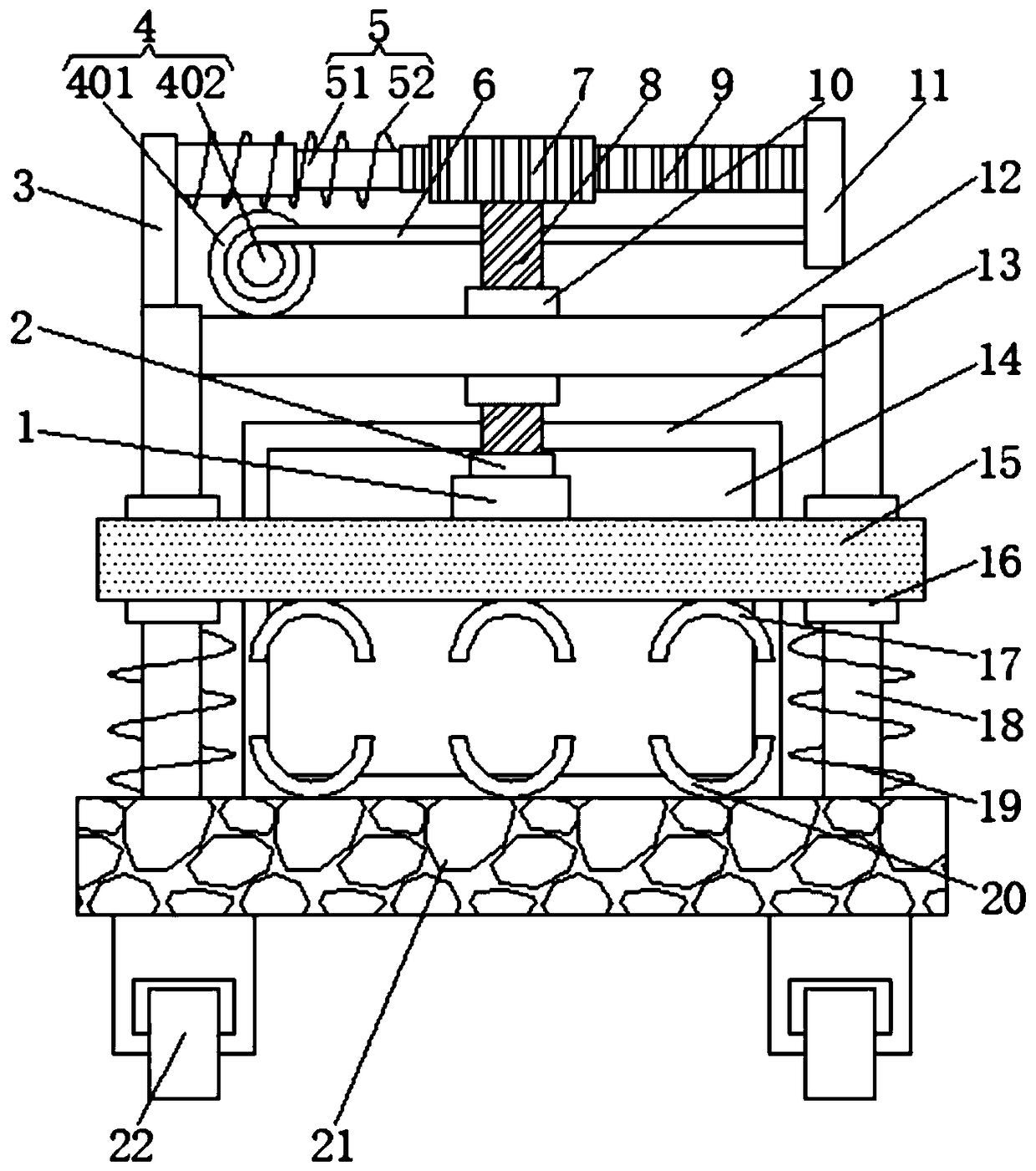

Two-layer dual-drive vertical ring mill

PendingCN105964344AAvoid speeding throughImprove grinding efficiencyGrain treatmentsEngineeringDrive shaft

The invention discloses a two-layer dual-drive vertical ring mill which comprises a machine frame, wherein a barrel is mounted on the machine frame; a material hopper is mounted at the top of the barrel; a material guide disc is mounted below the material hopper; a lower drive shaft erecting frame is mounted in the machine frame; a lower drive shaft is mounted in the lower drive shaft erecting frame; an upper drive shaft erecting frame is mounted at the upper part of the barrel; an upper drive shaft is mounted in the upper drive shaft erecting frame; and ring milling devices are mounted on the lower drive shaft and the upper drive shaft. The two-layer dual-drive vertical ring mill disclosed by the invention has the following technical effects: 1, the velocities of the ring milling devices at the upper and lower layers can be adjusted; and 2, the rotating directions of the ring milling devices at the upper and lower layers can be opposite to each other, so that a material is prevented from rotating in a dropping process, accelerated passing of the material is avoided, and the grinding efficiency is improved.

Owner:湖南红中新材料股份有限公司

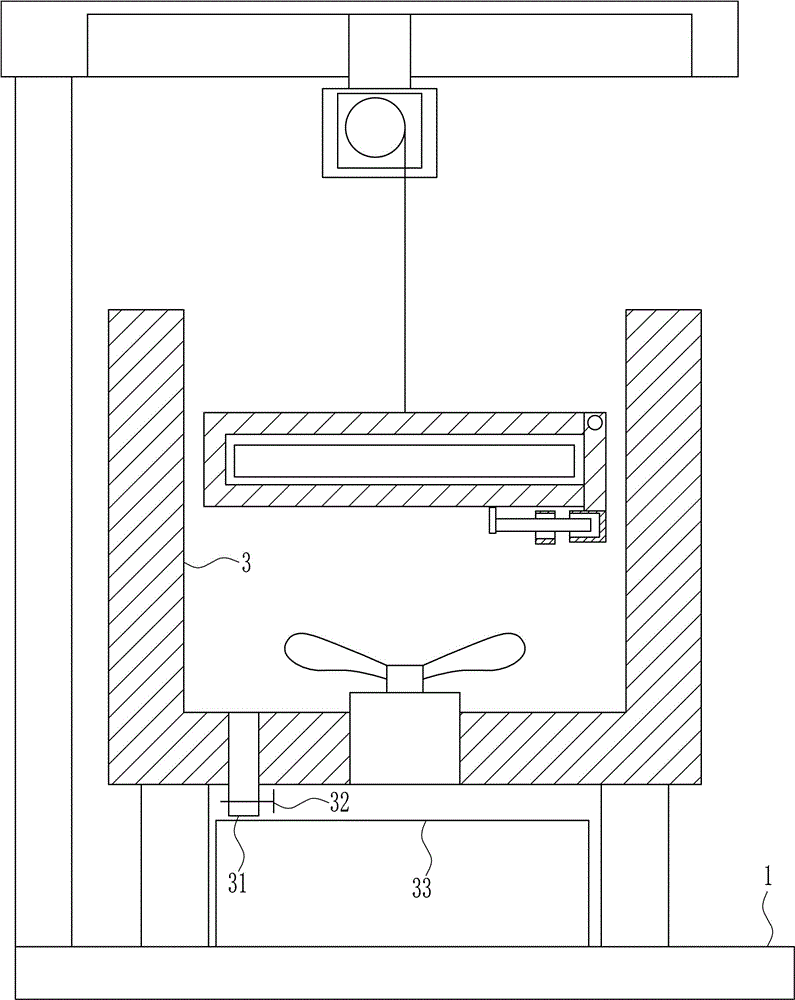

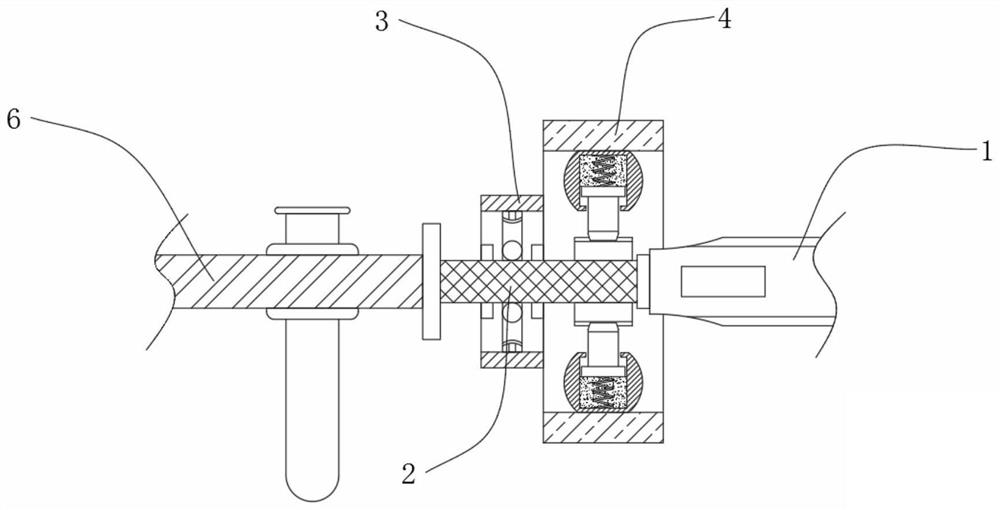

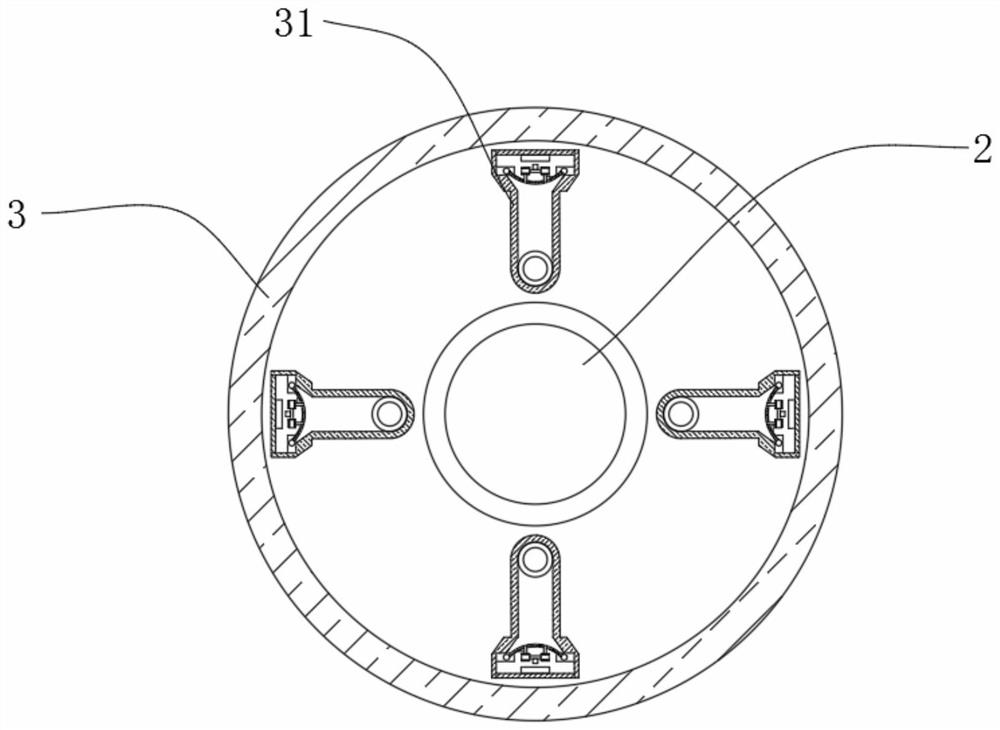

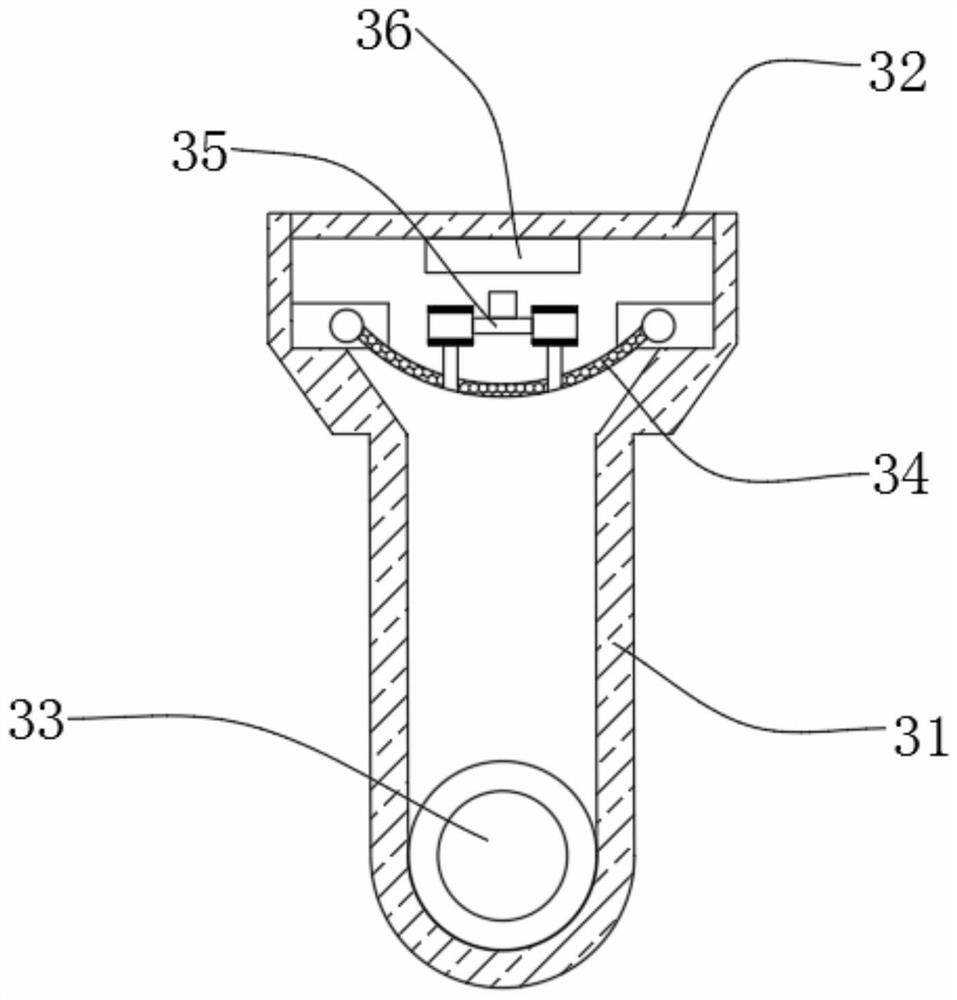

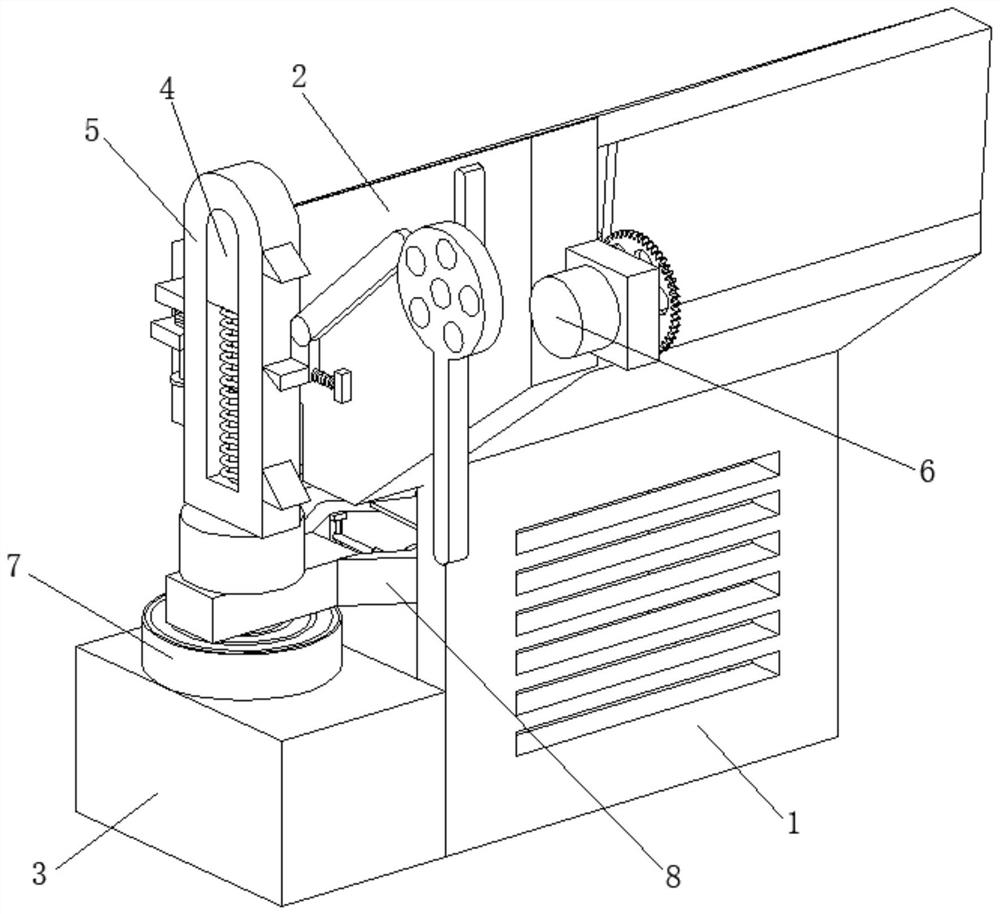

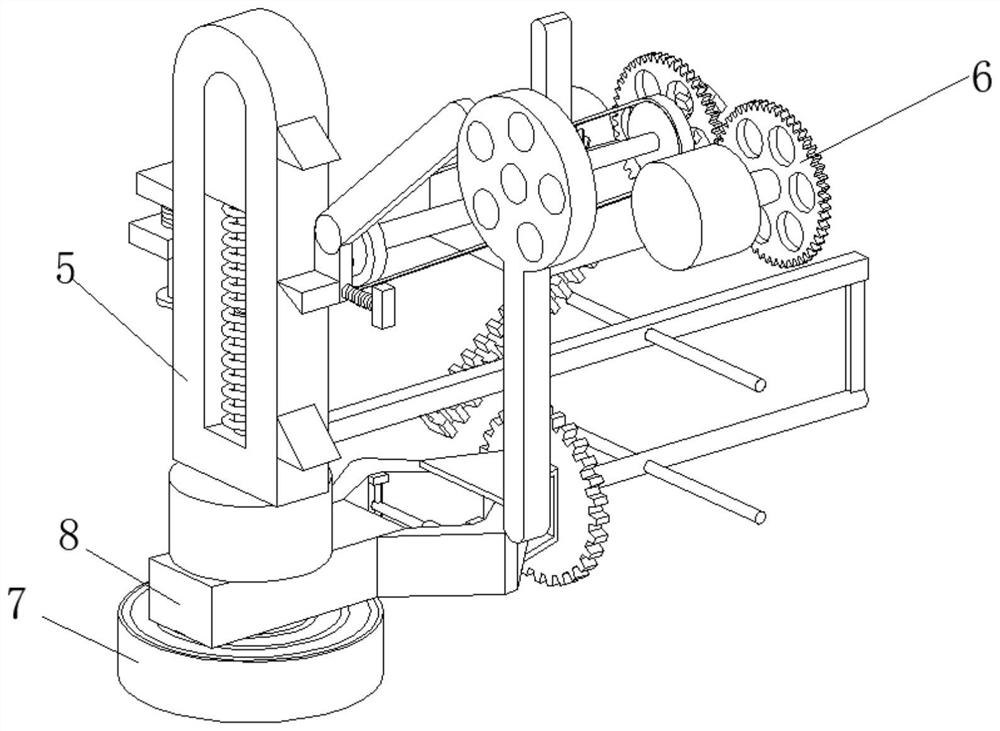

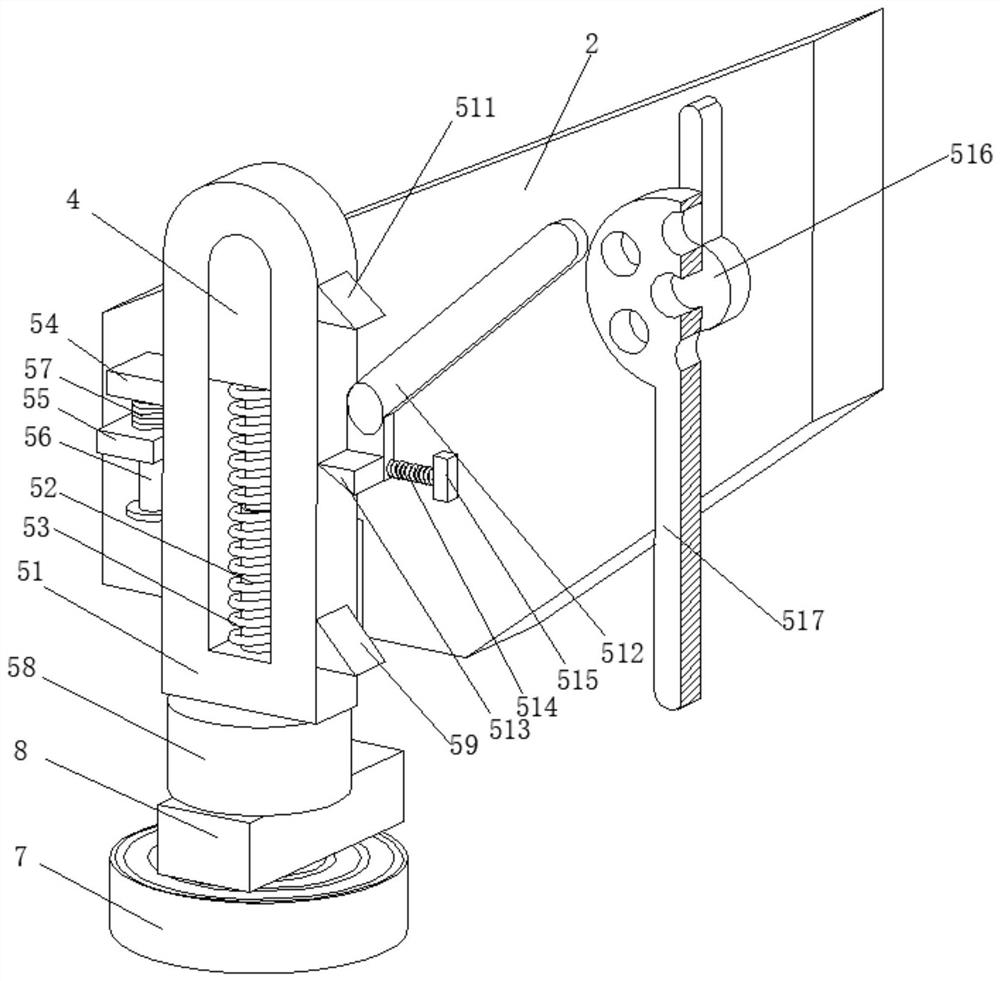

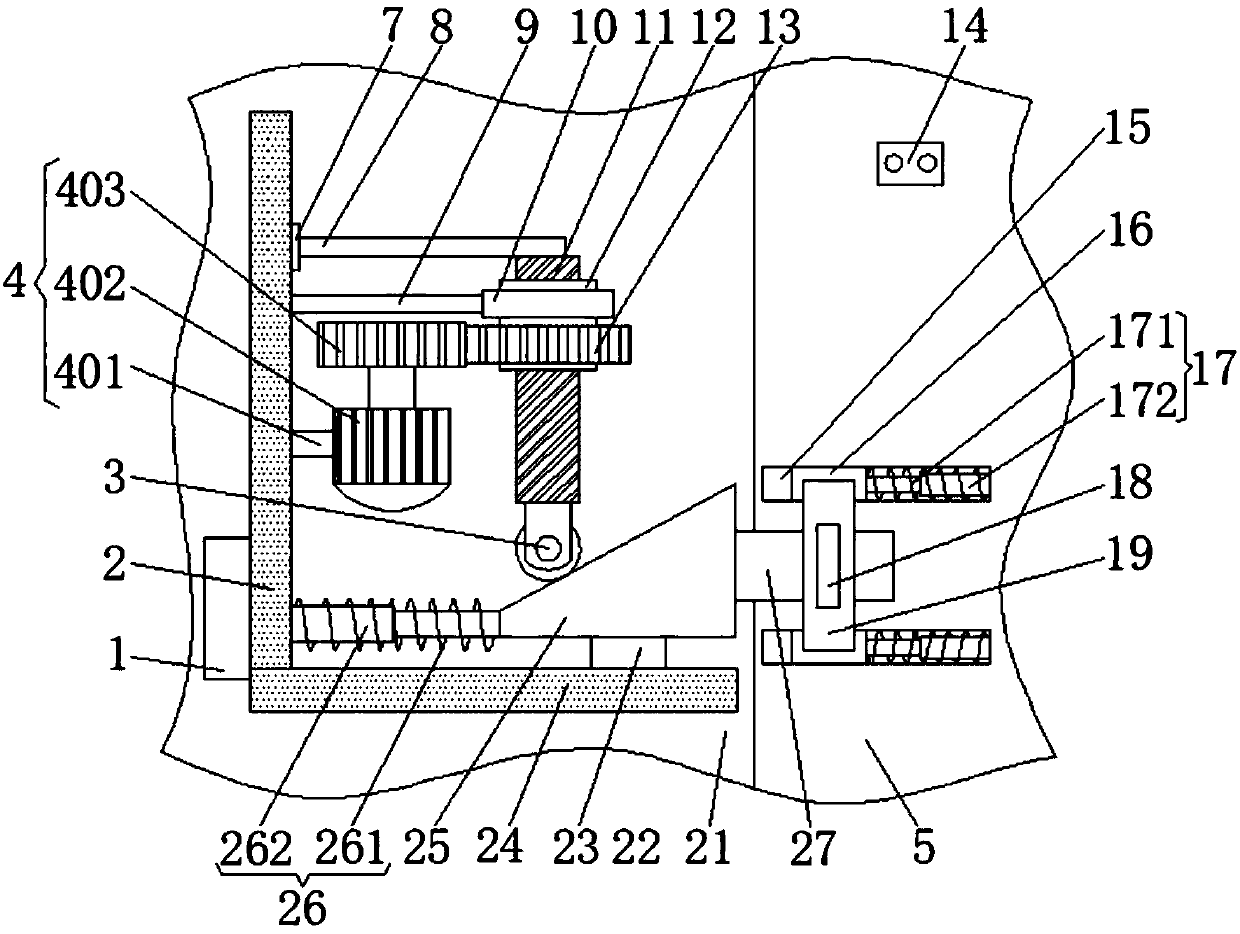

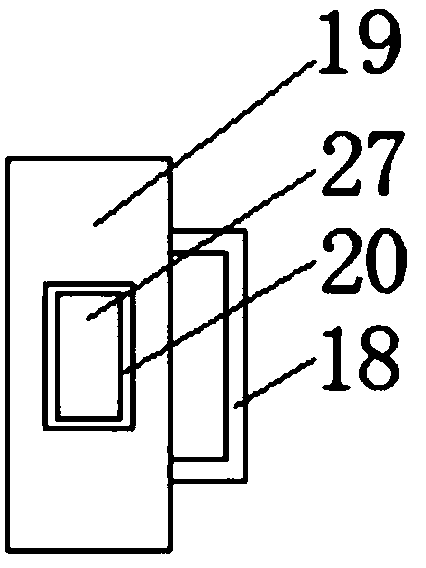

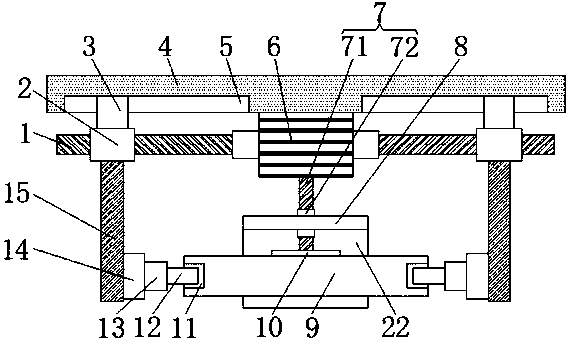

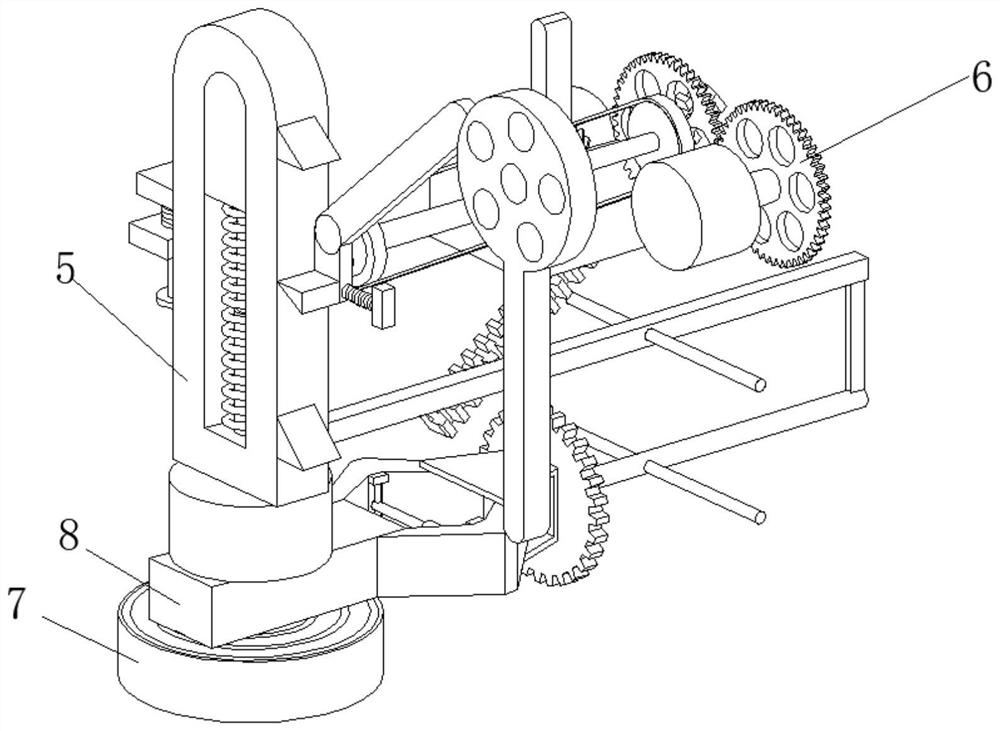

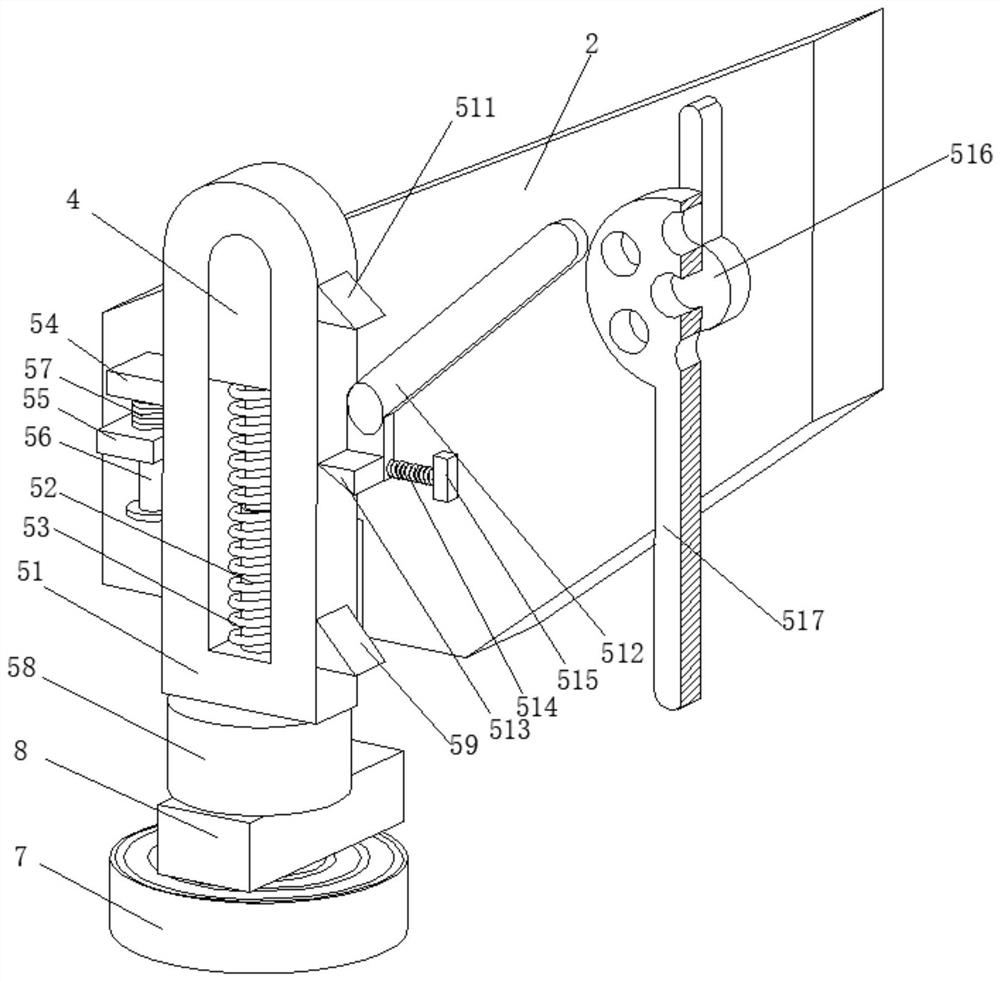

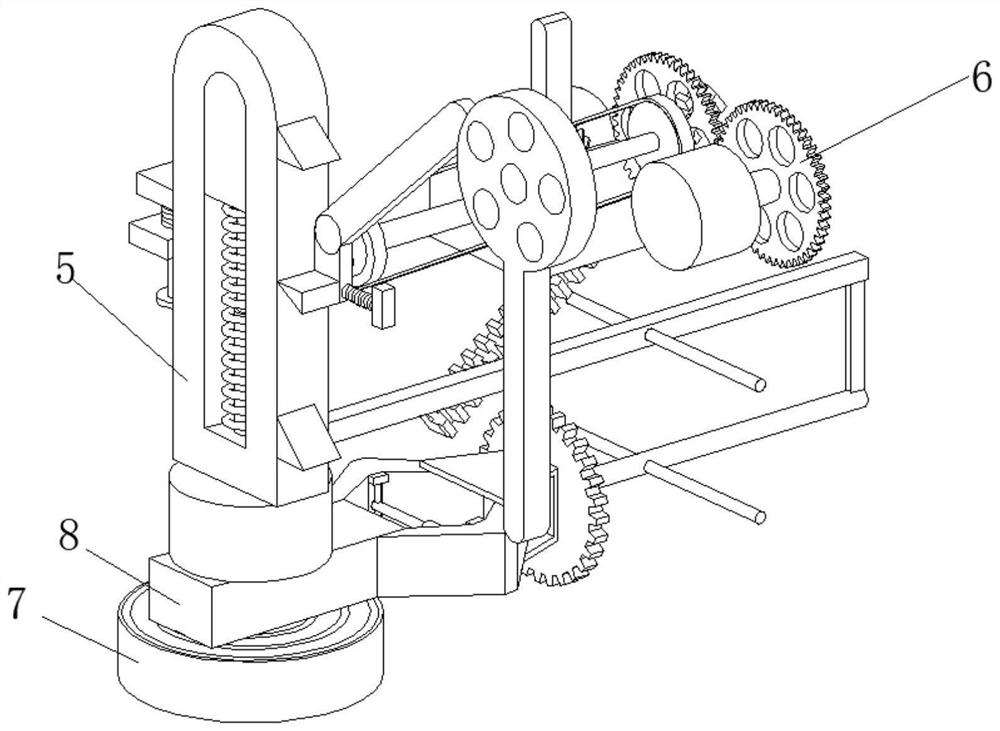

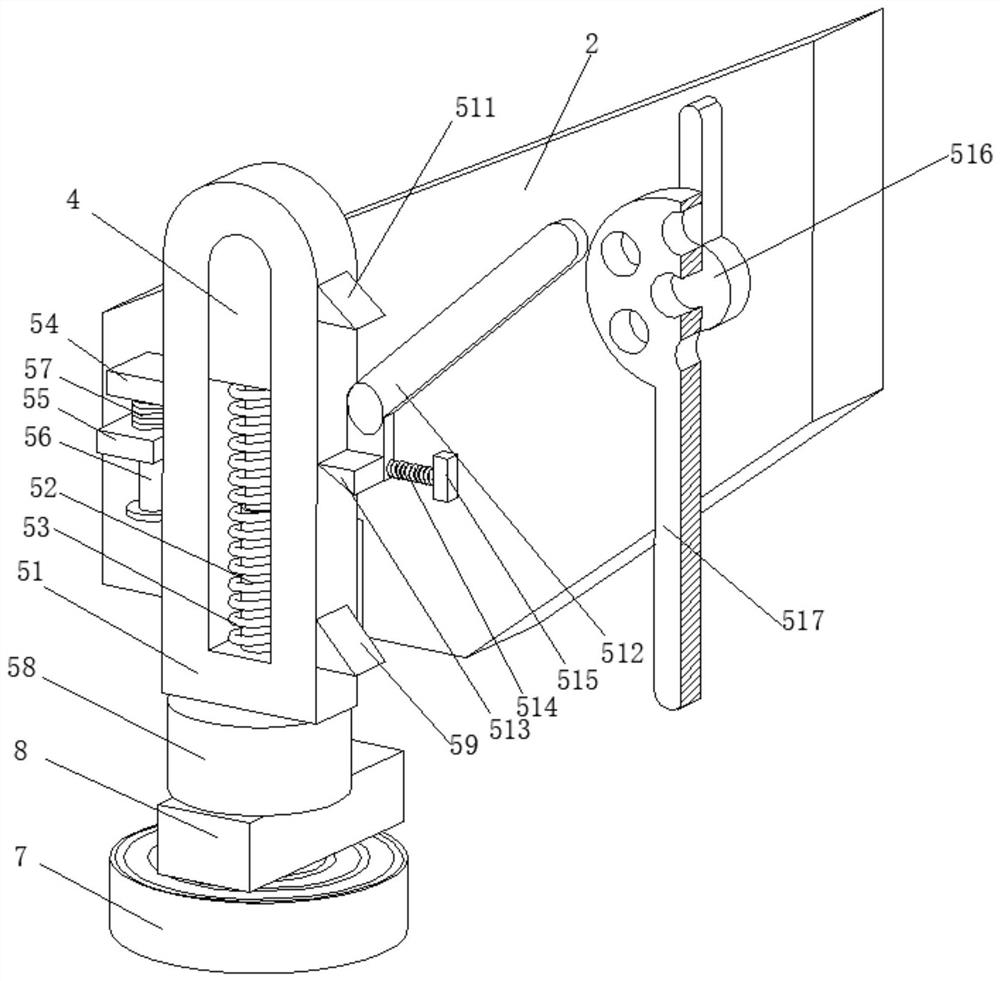

Production clamping device for mechanical equipment and clamping process thereof

InactiveCN113561127ARotation will notQuick circumferential angle adjustmentWork holdersMetal-working hand toolsMechanical equipmentMachining

The invention discloses a production clamping device for mechanical equipment and a clamping process thereof, relates to the technical field of machining, and solves the problem that a currently used clamping device is mainly fixed in a directional manner and does not have an auxiliary function of quickly adjusting a circumferential angle and self-locking after being fixed. The production clamping device for the mechanical equipment comprises a base, supporting columns are fixedly arranged on the periphery of the top of the base, and two top rows are fixedly arranged on the tops of the supporting columns; and a middle shaft and two side shafts are rotationally arranged in the middle of the top of the base, the side shafts are located on the two sides of the middle shaft, by arranging a main shaft sleeve and a rotating disc, the auxiliary functions of quickly adjusting the circumferential angle and achieving self-locking are provided, when a locking lead screw is rotated, a worm and a worm are in a locked state, and the main shaft sleeve cannot rotate.

Owner:嘉兴市阿丽三科技有限公司

Water conveying tank for water conservancy project construction

InactiveCN113047231AEnsure complete removalRotation will notSewerage structuresGeneral water supply conservationArchitectural engineeringElectric machinery

The invention discloses a water conveying tank for water conservancy project construction in the technical field of water conservancy projects. The water conveying tank comprises a water conveying tank body, wherein baffles are arranged in the middles of the inner walls of the left side and the right side of an inner cavity of the water conveying tank body; first sliding grooves are formed in the middles of the upper end faces of the baffles; rollers are evenly arranged in inner cavities of the first sliding grooves; connecting columns penetrate the centers of the end faces of the rollers; mounting plates are arranged on the upper end faces of the connecting columns; mounting boxes are arranged in the centers of the upper end faces of the mounting plates; servo motors are arranged in inner cavities of the mounting boxes; motor shafts of the servo motors penetrate the mounting plates to the lower end faces of the mounting plates; the lower end faces of the motor shafts of the servo motors are fixedly connected with threaded rods; the middles of the outer walls of the threaded rods are sleeved with sliding sleeves; and dredging devices are fixedly connected to the left sides and the right sides of the sliding sleeves. The device is simple in structure and convenient to operate, sludge in the water conveying tank is effectively removed, and the water conveying efficiency is improved.

Owner:SHANDONG PROVINCE WATER CONSERVANCY BUREAU CO LTD

Biological experiment oscillation device for detecting speed limit by utilizing centrifugation

InactiveCN112535978ANo elastic deformationKeep abreast of the shock statusShaking/oscillating/vibrating mixersTransportation and packagingPhysicsTest tube

The invention relates to the technical field of biological experiment equipment, and discloses a biological experiment oscillation device for detecting speed limit by using centrifugation. The biological experiment oscillation device comprises an output shaft, one end of the output shaft is fixedly connected with an oscillation shaft, the outer side wall of the oscillation shaft is fixedly connected with a detection ring and a speed limit ring, and the inner side wall of the detection ring is fixedly connected with a sliding rail; and one end of the sliding rail is fixedly connected with a detection base, and the inner side wall of the sliding rail is slidably connected with a centrifugal lead ball. When the oscillation speed is too high, the centrifugal force borne by the centrifugal leadball is increased, the pressure exerted by the centrifugal lead ball on an arc-shaped spring piece is larger than the elastic force of the arc-shaped spring piece, the surface of the arc-shaped spring piece is elastically deformed, the arc-shaped spring piece drives a trigger frame to move towards one side of an alarm device, the trigger frame triggers a switch on the alarm device, and thus the alarm device gives an alarm, so that an experimenter can know the oscillation state of a test tube in time, and the experimenter can conveniently adjust the device in time.

Owner:泗县谷稻方舟生物科技有限公司

Alloy apparatus adjustable in clamping angle

InactiveCN108356567AEffective clampingOptimize the force structureMetallic material coating processesPositioning apparatusAlloyMachining

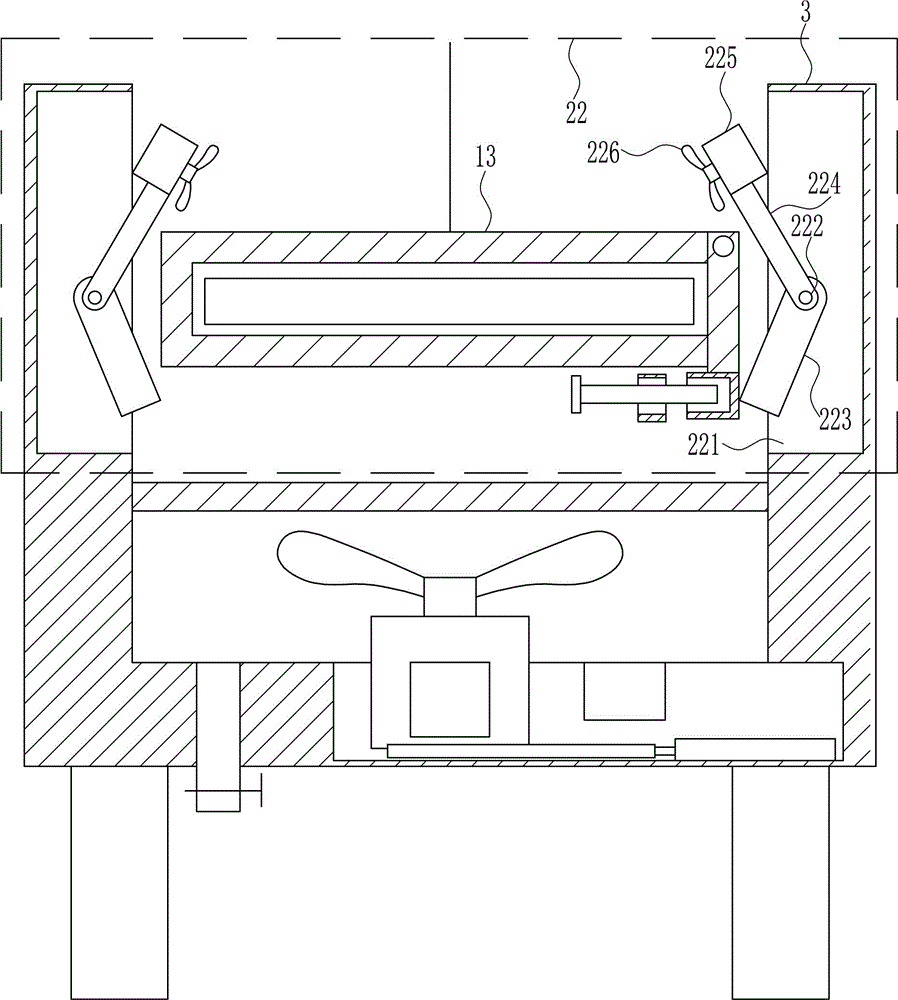

The invention relates to a clamping apparatus for machining and an alloy apparatus adjustable in clamping angle. The alloy apparatus adjustable in clamping angle comprise a left supporting crank arm,a right supporting crank arm, a left clamping device, a right clamping device and a hydraulic driving device; and the two ends of the hydraulic driving device are provided with the piston rod end headof a first piston and the piston rod end head of a second piston correspondingly in a stretching manner. According to the improvement, the right clamping device and the left clamping device are in mirror symmetry, and the left supporting crank arm and the right supporting crank arm are in mirror symmetry; an adjusting hand wheel disk is adopted for driving a position adjusting nut to move forwards and backwards on an adjusting screw rod; by means of linkage of a first connection rod and a second connection rod, a work included angle can be formed between a first clamping plate and a second clamping plate around an included angle shaft pin, a cylinder body is clamped, and the stress structure is improved; and up-down free swinging and rotating around a screw rod sleeve shaft pin can also be achieved, an object on a bevel is effectively clamped, functions are comprehensive, and the alloy apparatus adjustable in clamping angle is practical and convenient; and the clamping faces of the first clamping plate and the second clamping plate are each plated with a layer of hard chromium alloy, and abrasion resistance and durability are better.

Owner:WENZHOU ZHIJIE ELECTROMECHANICAL TECH CO LTD

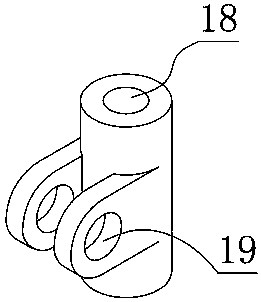

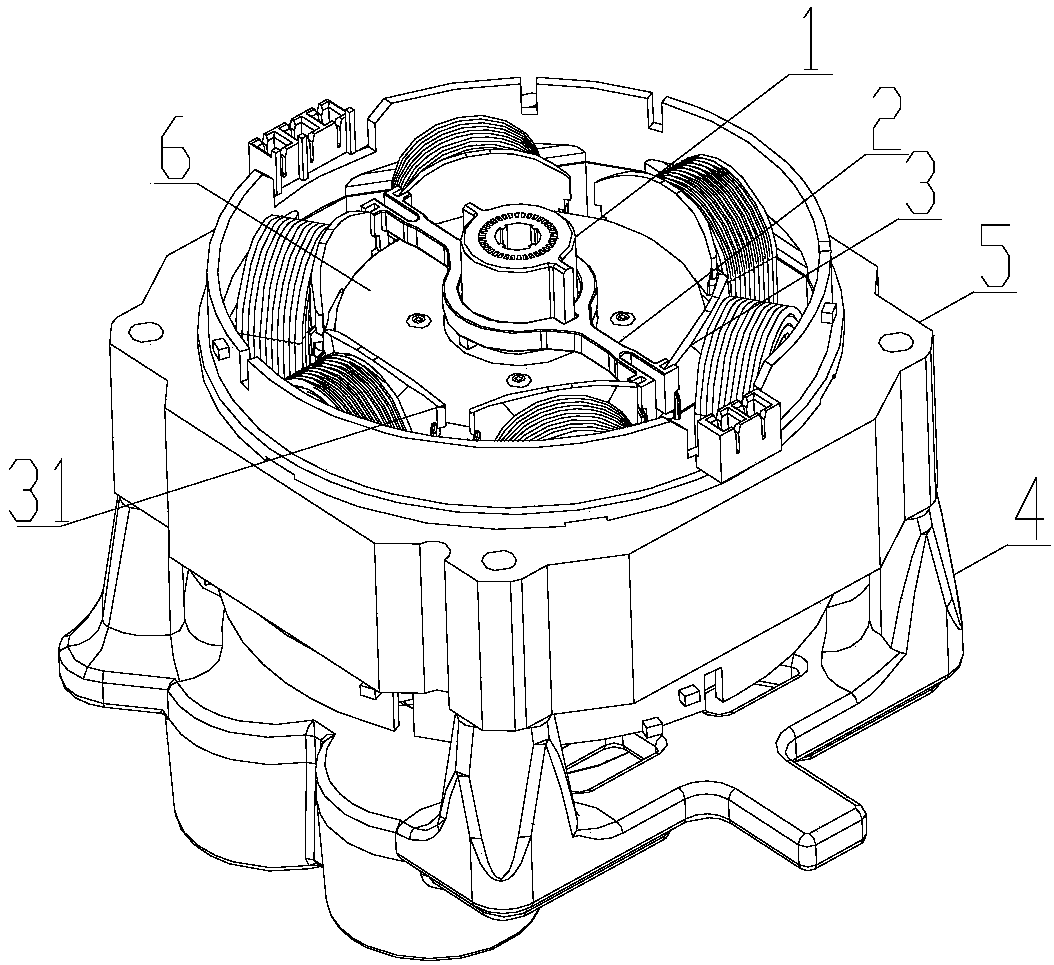

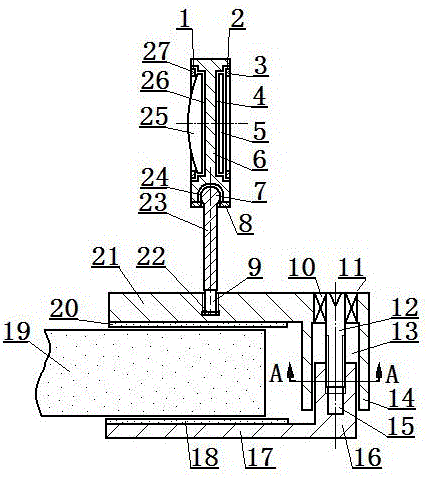

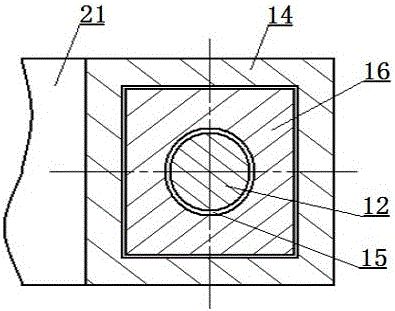

Oil pumping system for crankshaft and compressor with same

ActiveCN106401915AImprove operational reliabilityImprove stabilityPositive displacement pump componentsLubricating pumpsFriction forceCrankshaft

The invention provides an oil pumping system for a crankshaft and a compressor with the same. The oil pumping system comprises an oil pump (1) used for pumping oil into an internal oil hole of the crankshaft. The oil pump (1) comprises a cylindrical pump core (11) and a cylindrical outer sleeve (12) which is connected to the radial outer portion of the pump core (11) in a sleeving mode. A preset distance is spaced between the radial inner wall of the outer sleeve (12) and the radial outer wall of the pump core (11), the spaced preset distance extends in the axial direction to form an annular groove so that the crankshaft can be inserted into the annular groove, and meanwhile the pump core (11) can be inserted into the oil hole. By means of the oil pumping system for the crankshaft and the compressor with the same, the radial spacing between an outer circular pipe and the inner wall of the oil hole in the prior art can be reduced, and therefore friction power consumption between the crankshaft and the oil pump is effectively reduced, and operational reliability, stability and safety of the oil pumping system are improved. The friction force of oil with the oil hole of the crankshaft and the outer surface of the pump core can be increased, and oil pumping capacity of the oil pumping system at the low frequency is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

Transmission mechanism of numerical control vertical machining center

InactiveCN112372353AAvoid loading phenomenonInhibit sheddingMetal working apparatusMaintainance and safety accessoriesNumerical controlDrive shaft

The invention discloses a transmission mechanism of a numerical control vertical machining center. The transmission mechanism comprises a transmission shaft, one end of the transmission shaft is sleeved with a first connecting block and a second connecting block, the adjacent faces of one ends of the first connecting block and the second connecting block are provided with inclined faces with the same inclination, the other end of the first connecting block is provided with a mounting disc, the outer wall of the transmission shaft is sleeved with the mounting disc, and a spring is arranged between the mounting disc and the first connecting block. According to the transmission mechanism of the numerical control vertical machining center, through the designed first connecting block and the second connecting block, the inclined faces of the first connecting block and the second connecting block are in mutual extrusion contact, so that synchronous rotation can be ensured, power transmissionis realized, meanwhile, the first connecting block and the second connecting block are separately assembled, when the first connecting block and the second connecting block are subjected to excessiveresistance, the inclined faces of the first connecting block and the second connecting block generate an acting effect to provide thrust for the two connecting blocks, so that separation is realized,power transmission is stopped, and the load phenomenon of a power source is effectively avoided.

Owner:汉刚机械(南京)有限公司

Glasses

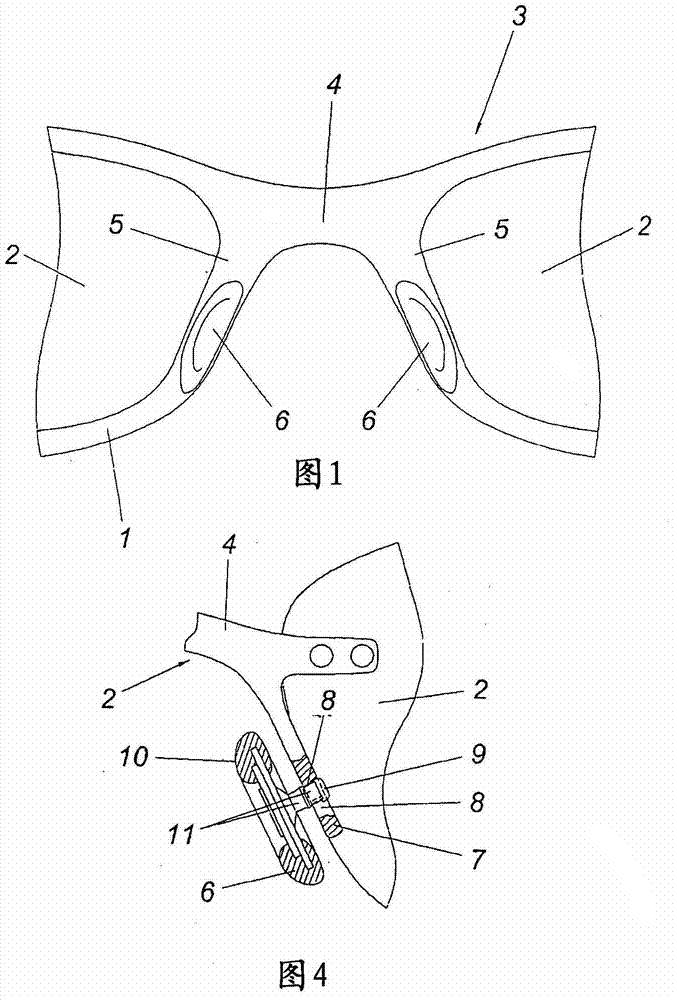

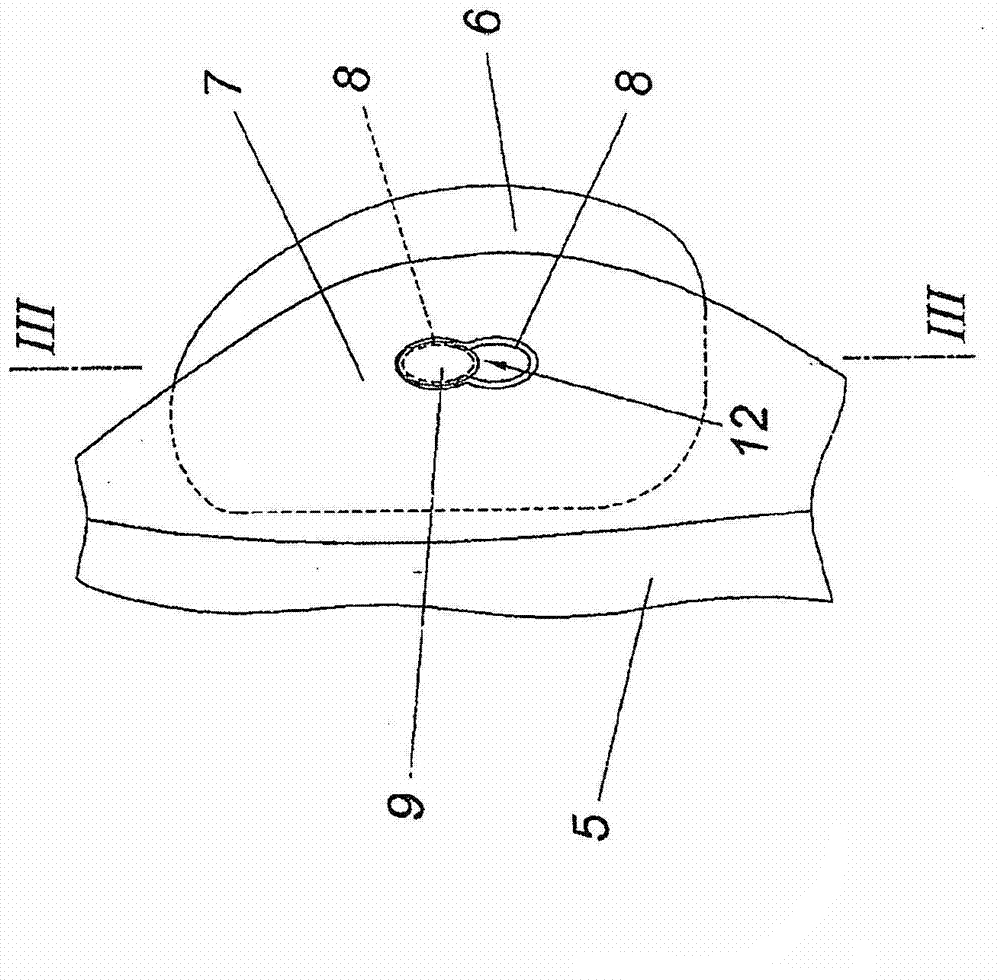

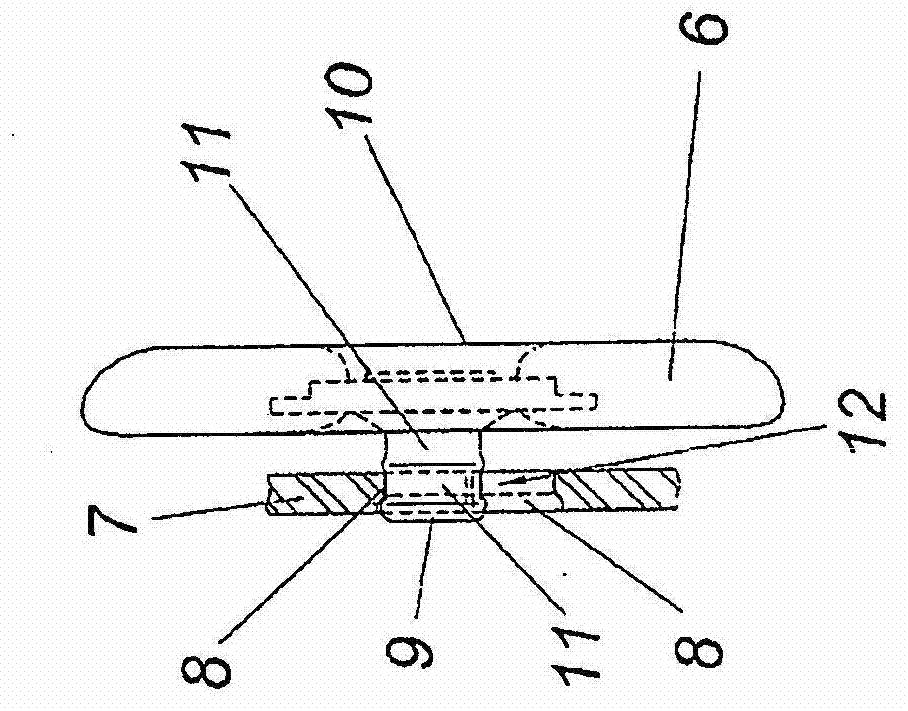

The invention relates to a pair of glasses comprising a frame (3) and nose rests (6) provided in the region of the bases (7) of the frame, said nose rests having stop positions arranged one behind the other in a direction of adjustment. In order to provide an advantageous adaptable system for glasses, the nose rests (6) are provided with an insertable end (9) on the side opposite the resting surface (10) thereof, said end protruding transversely to the resting surface (10) and forming at least two successive stops (11) in the direction of insertion, for selective engagement in a stop recess (8) of the bases of the frame (7).

Owner:SILHOUETTE INT SCHMIED

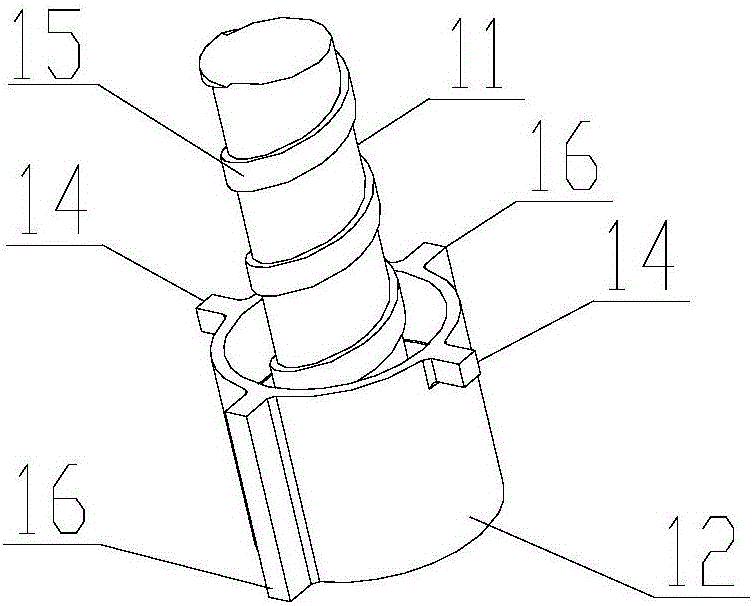

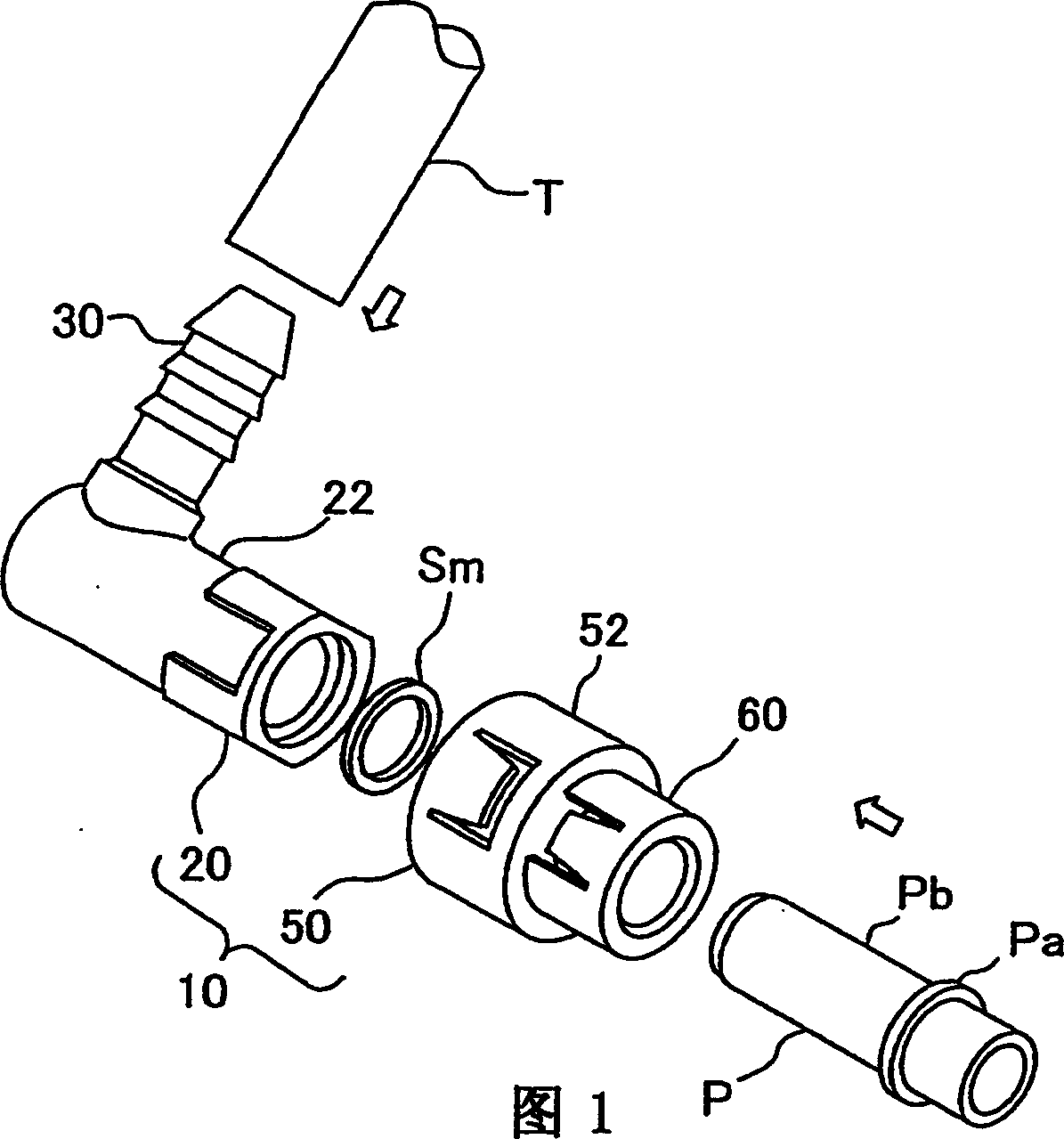

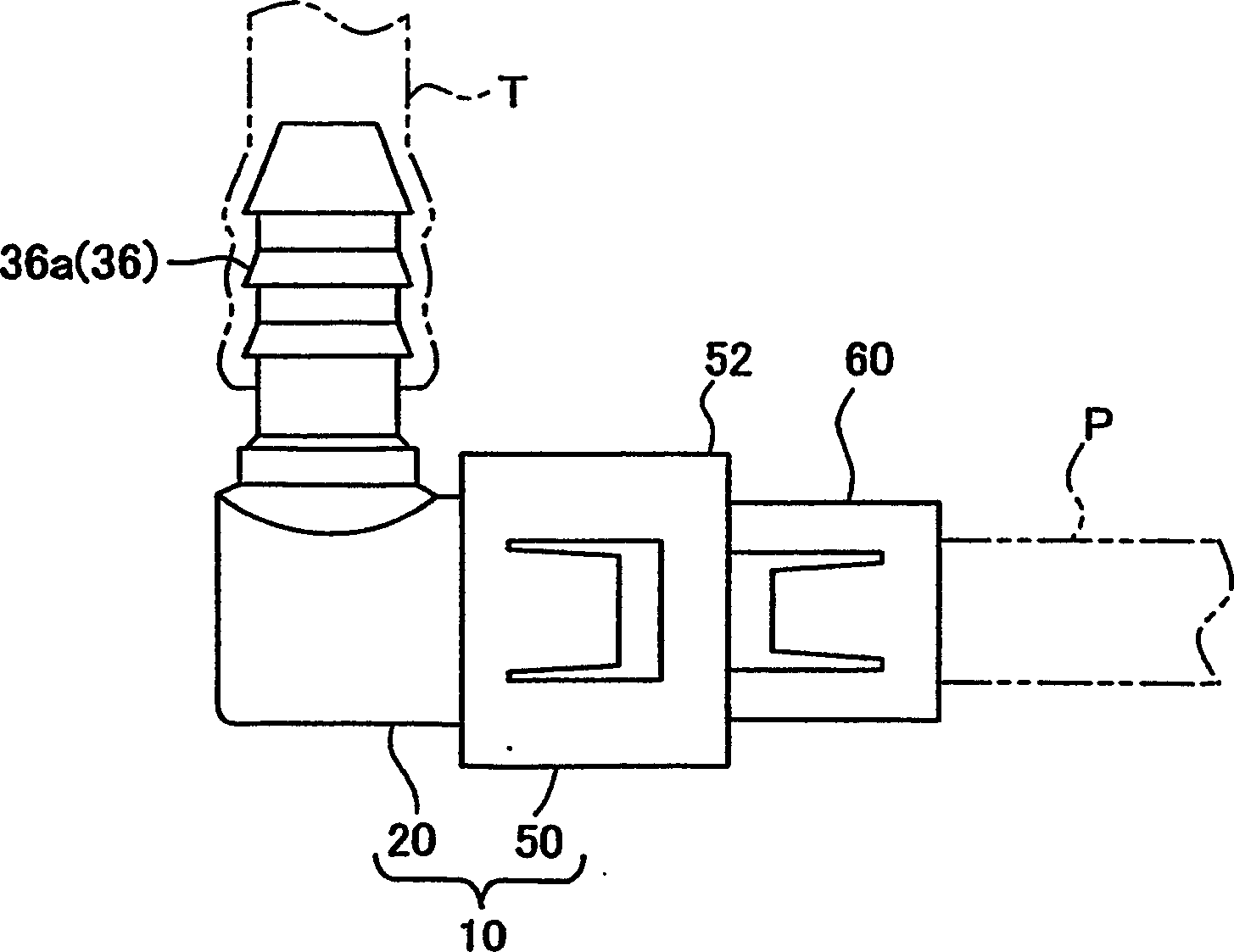

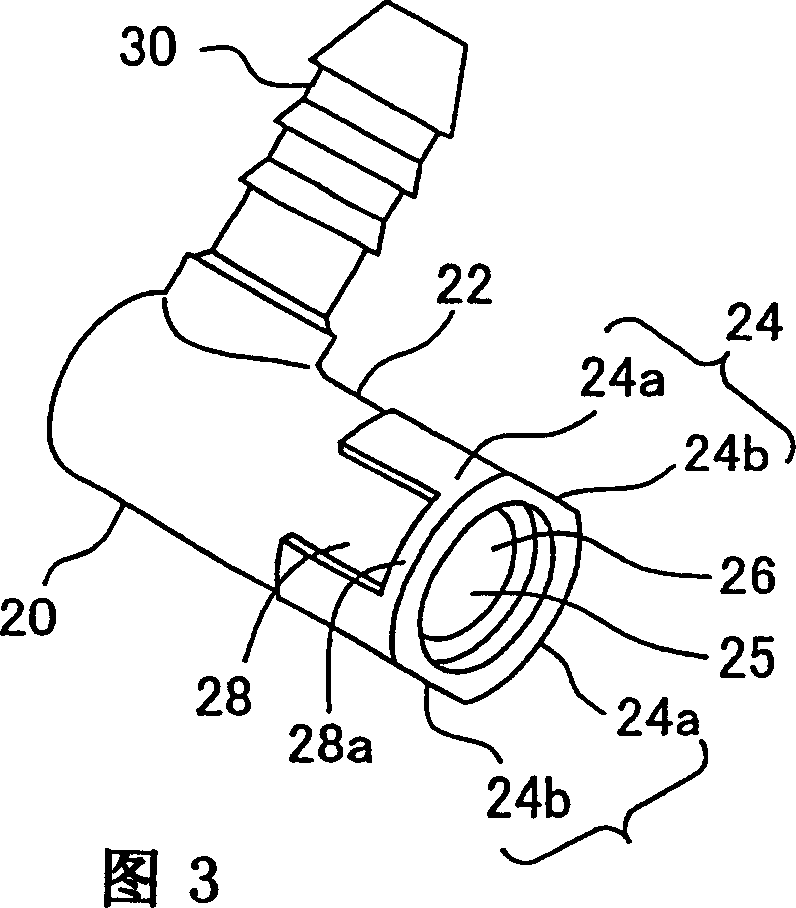

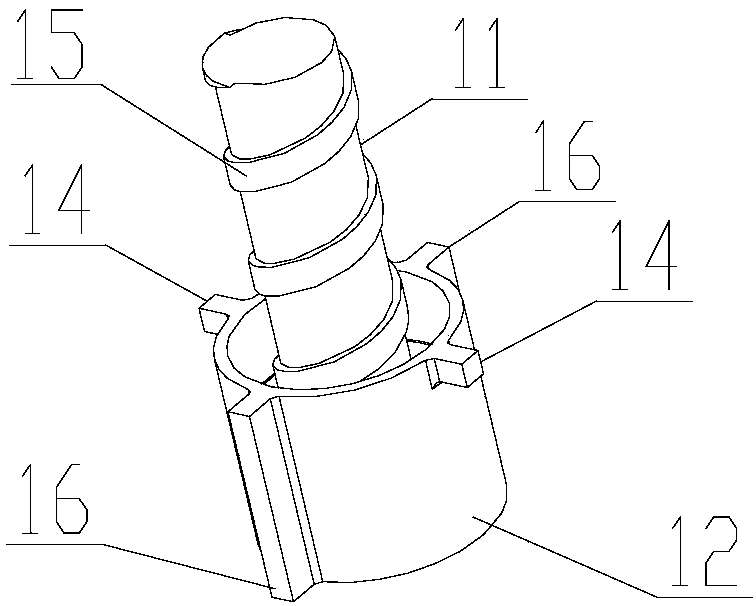

Connector

This invention provides a connector 10 of simple constitution free of the risk to slip off easily with an external force. The connector 10 comprises a connector body 20 and a retainer 50. The connector body 20 is composed of a pipe connection part 22 having a pipe inserting hole 26 and a connector side mounting mechanism for mounting the retainer 50, while the retainer 50 has a retainer side mounting mechanism for mounting on the connector body 20. The connector side mounting mechanism has a non-circular fitting part 24 in which the outside shape of the pipe connection part 22 is formed from a circular arc portion 24a and a straight portion 24b and a connector side engagement part 28. The retainer side mounting mechanism has a coupling hole 54 to be fitted in the non-circular fitting part 24 and a retainer side engagement part 56 to be engaged with the connector side engagement part 28 when the retainer 50 is inserted axially into the connector body 20 with the coupling hole 54 positioned mating with the non-circular fitting part.

Owner:TOYODA GOSEI CO LTD

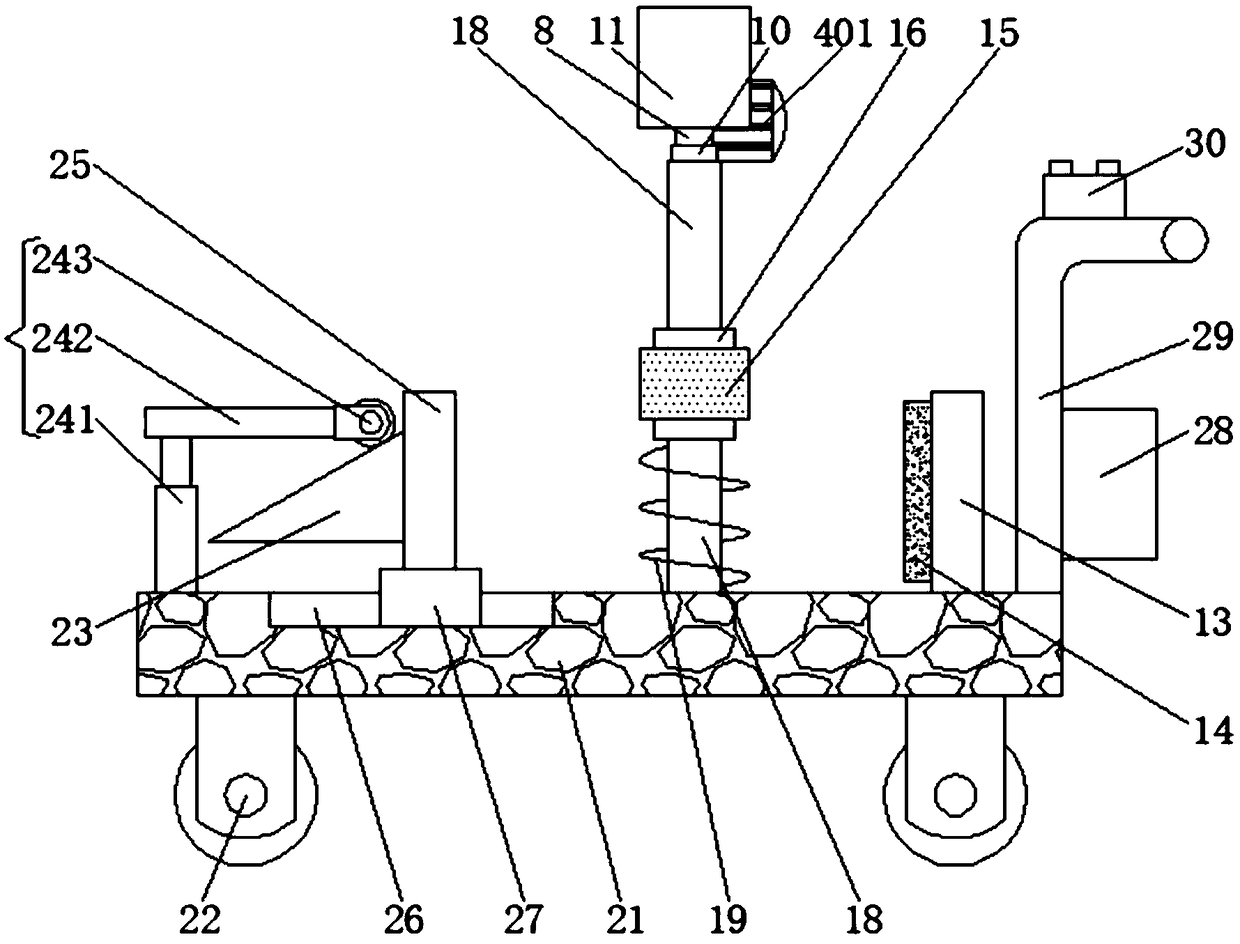

Transporting equipment for multiple lamp poles of solar streetlamp

The invention discloses transporting equipment for a plurality of lamp poles of a solar streetlamp. The transporting equipment comprises a bottom plate, the upper surface of the bottom plate is fixedly connected with three lower clamping plates, the upper surface of the bottom plate is fixedly connected with two sliding rods, the outer surfaces of the sliding rods are connected with second springsin a sleeved mode, and the top ends and the bottom ends of the second springs are fixedly connected with the lower surfaces of sliding sleeves and the upper surface of the bottom plate correspondingly. The transporting equipment for the multiple lamp poles of the solar streetlamp is provided with a motor, a rope, a rope disc, a toothed rod, a telescopic device, a bearing, a threaded column, a supporting plate, upper clamping plates and the sliding rods, the three lamp poles are placed on the three lower clamping plates correspondingly, then an electric push rod is controlled to retract to drive a fixed pulley to move downward through a connecting rod, thus each lamp pole can be well fixed when the multiple lamp poles are transported by workers, the lamp poles do not shake and do not collide mutually during transporting, the lamp poles are not scratched and damaged, and thus the loss of merchants is avoided.

Owner:孙益锋

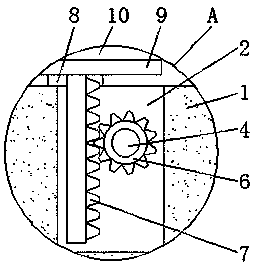

Tea leaf frying machine

PendingCN112244107AAchieve rotationRotation will notPre-extraction tea treatmentElectric machineGear wheel

The invention discloses a tea leaf frying machine. The machine is characterized in that two ends of a stir-frying cage B are connected with a shaft A and a shaft B respectively; the shaft A and the shaft B are inserted into a hollow shaft A and a hollow shaft B respectively; the hollow shaft A and the hollow shaft B are connected with a pot body through bearings; two ends of a stir-frying cage A are connected with the hollow shaft A and the hollow shaft B respectively; the middles of the hollow shaft A and the hollow shaft B are connected with a bracket through a bearing seat A and a bearing seat B respectively; the hollow shaft B is connected with a motor A; the shaft A is connected with a motor C; a motor B is installed in the middle of the bracket and is provided with a gear; the gear is meshed with racks arranged on the pot body and a pot cover; and the pot body is hinged to the pot cover. According to the invention, the stir-frying pot body and the pot cover rotate by 360 degrees,so that frying is uniform, and tea leaves cannot be bonded.

Owner:榕江县继武茶业有限责任公司

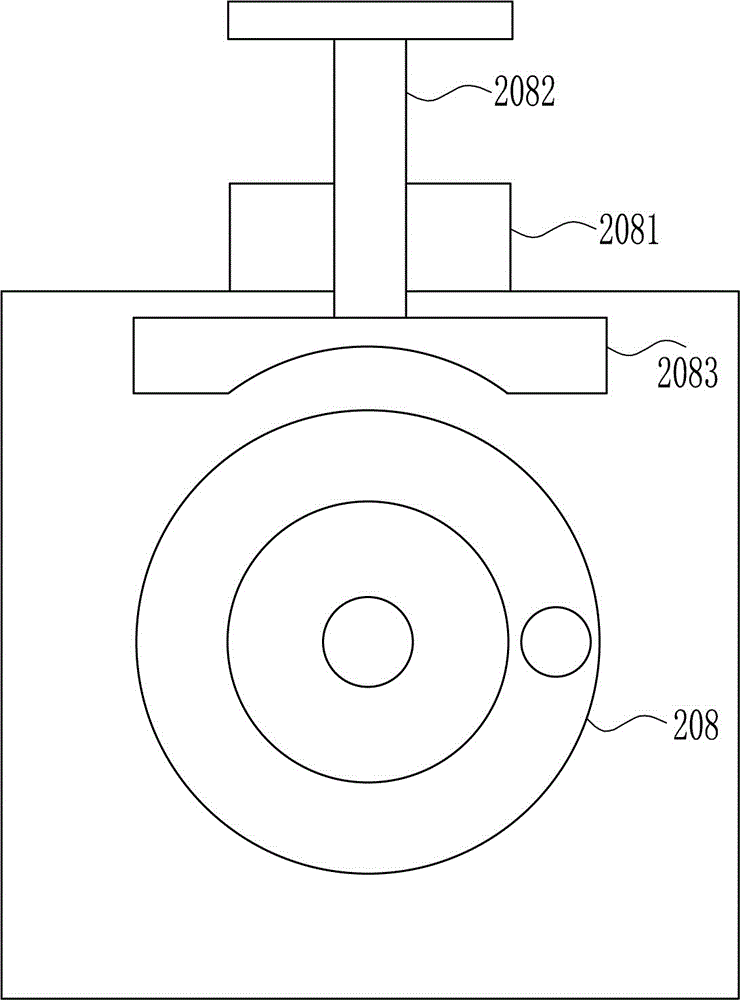

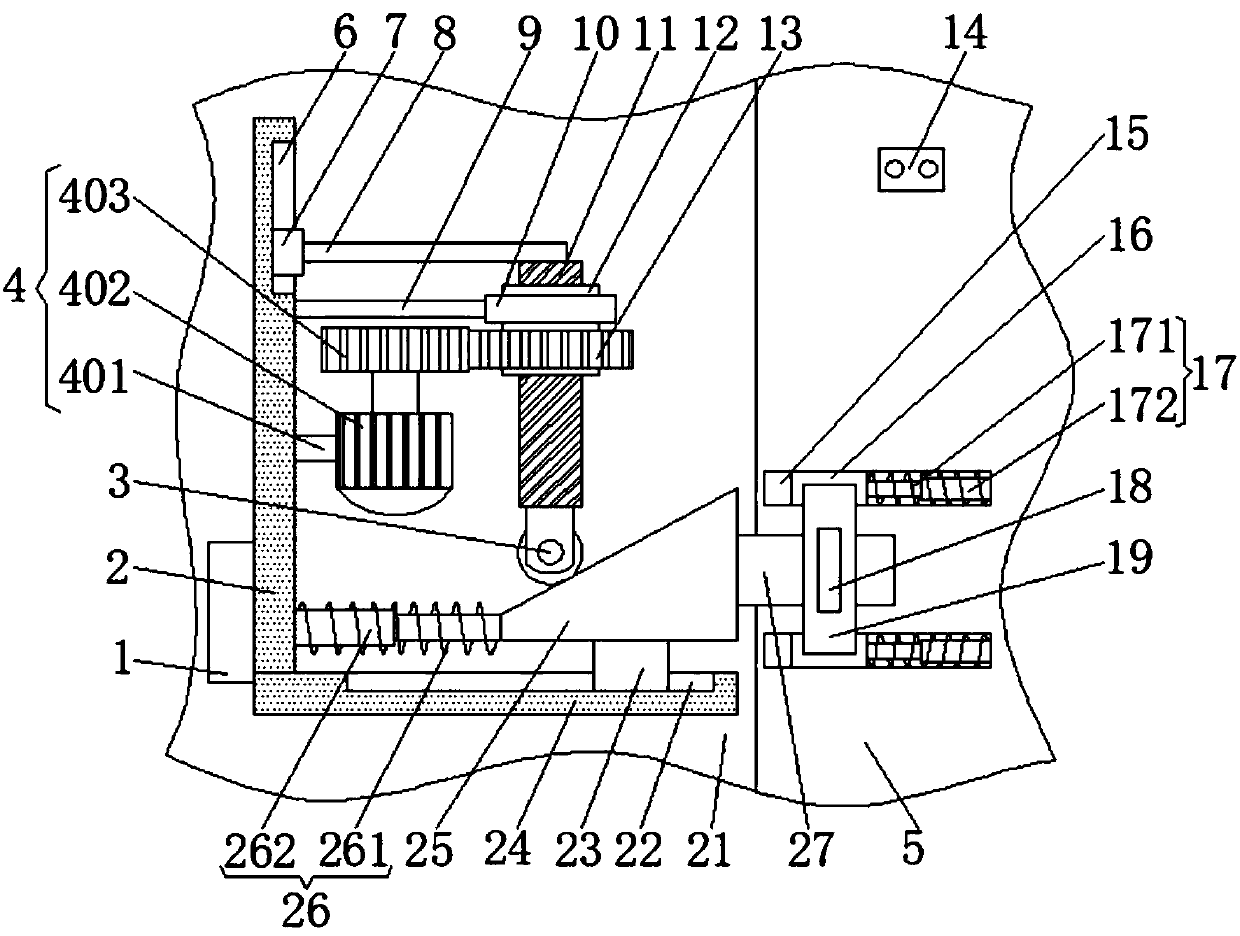

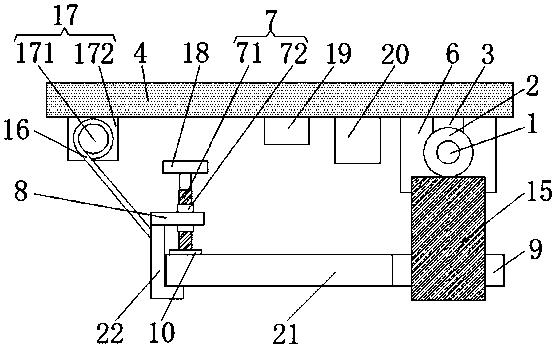

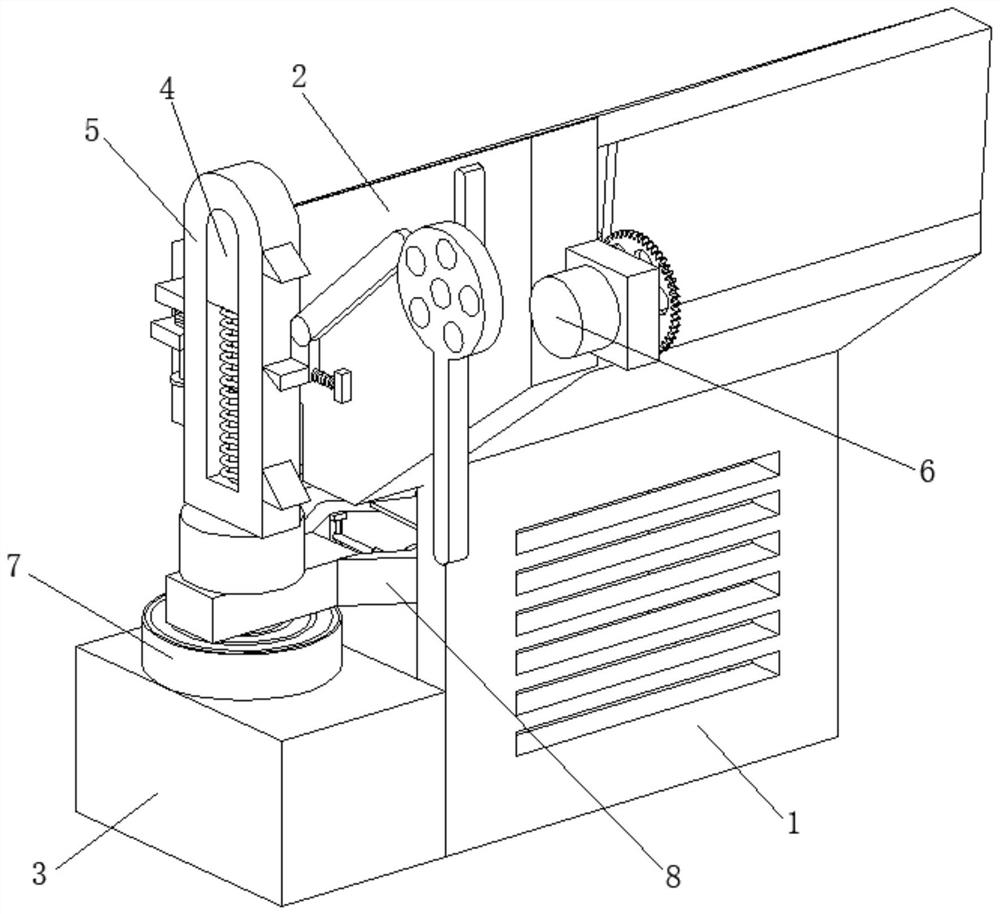

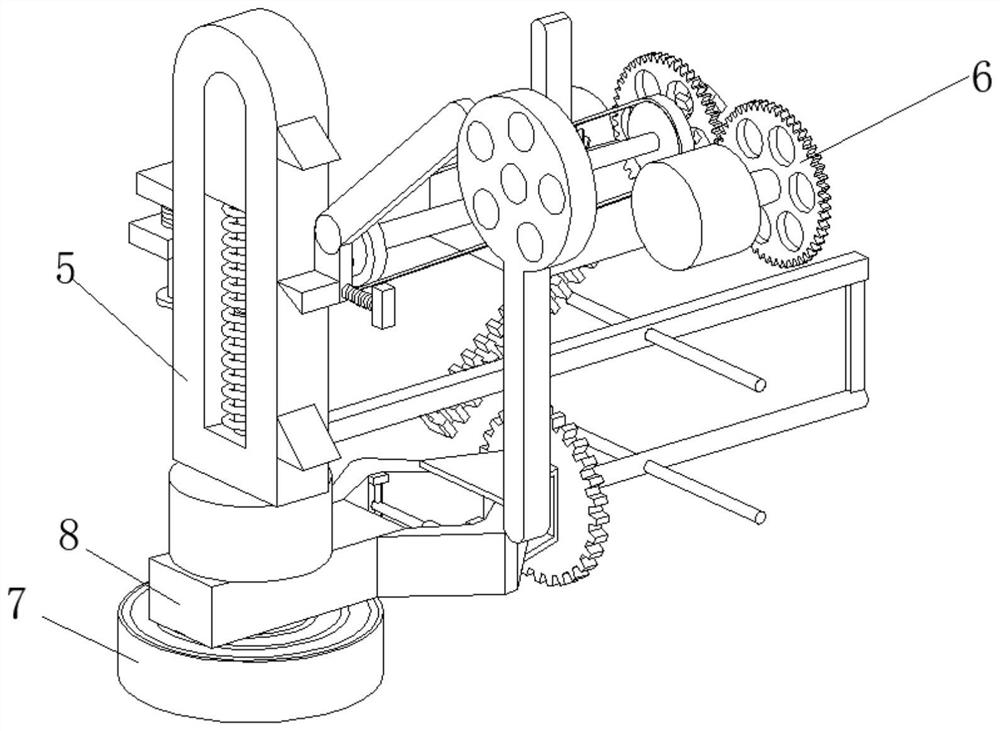

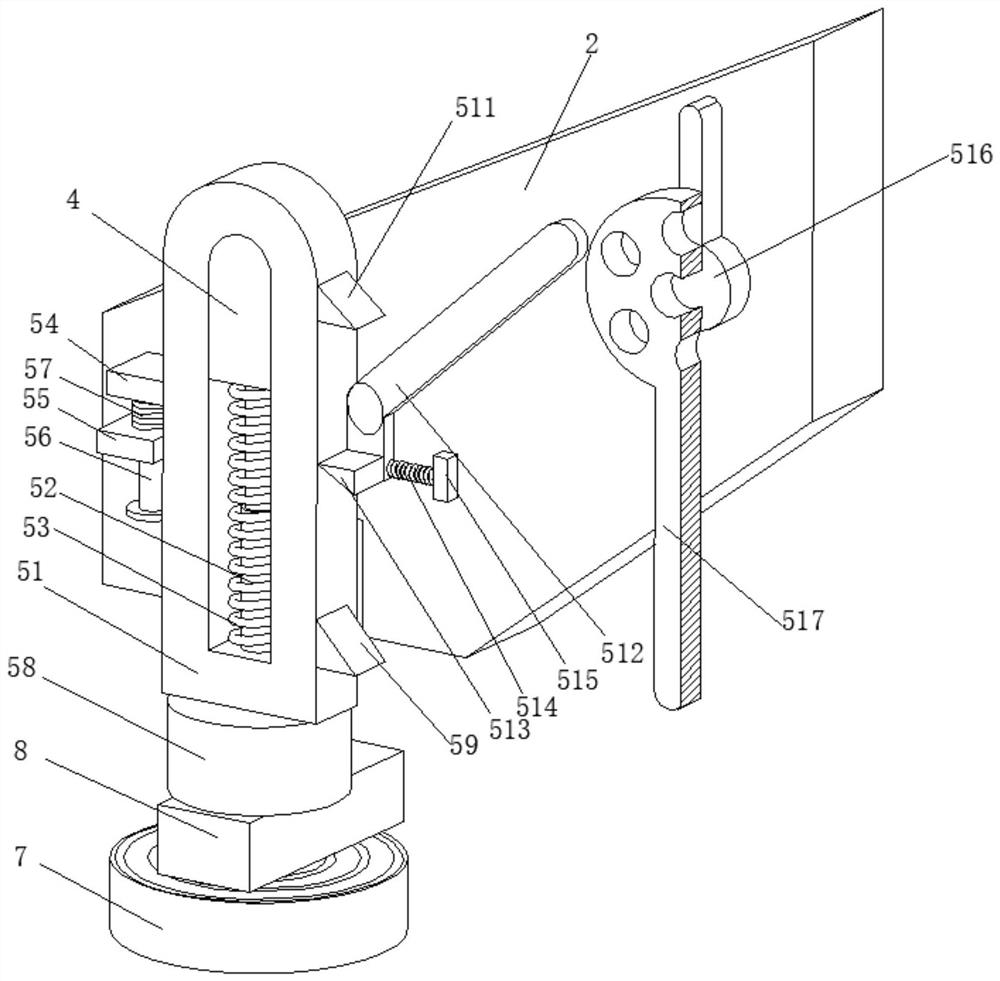

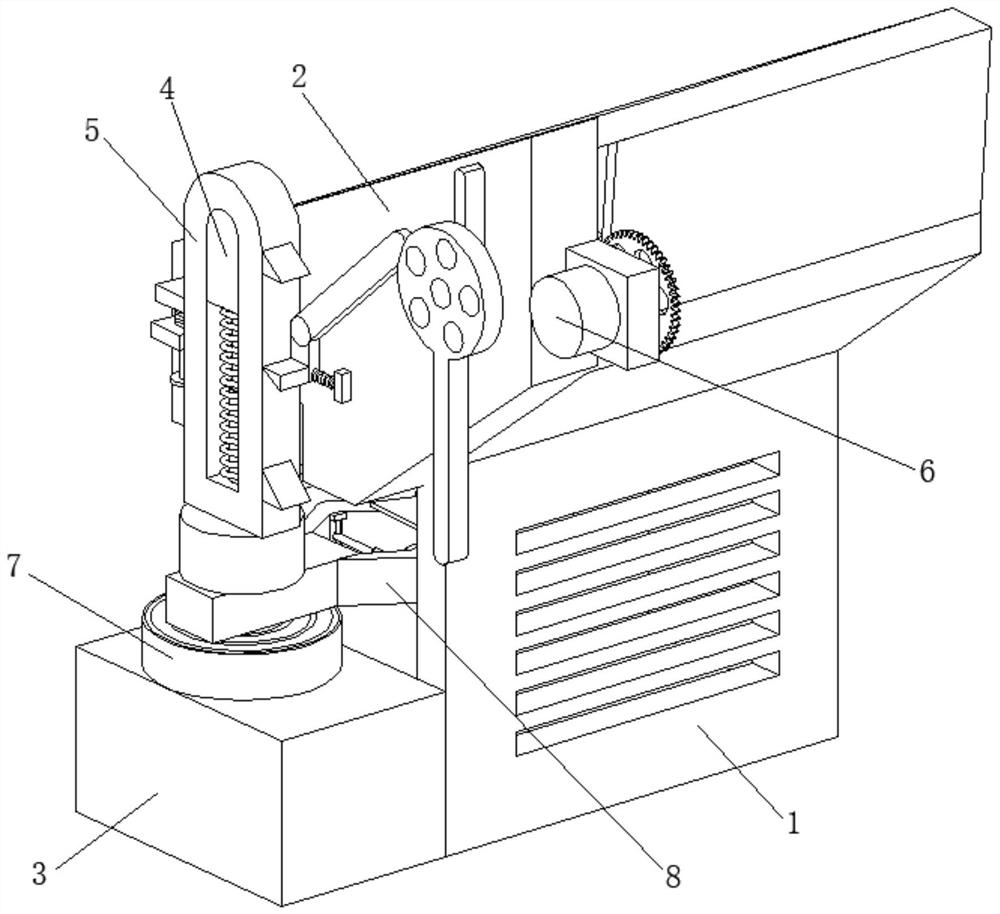

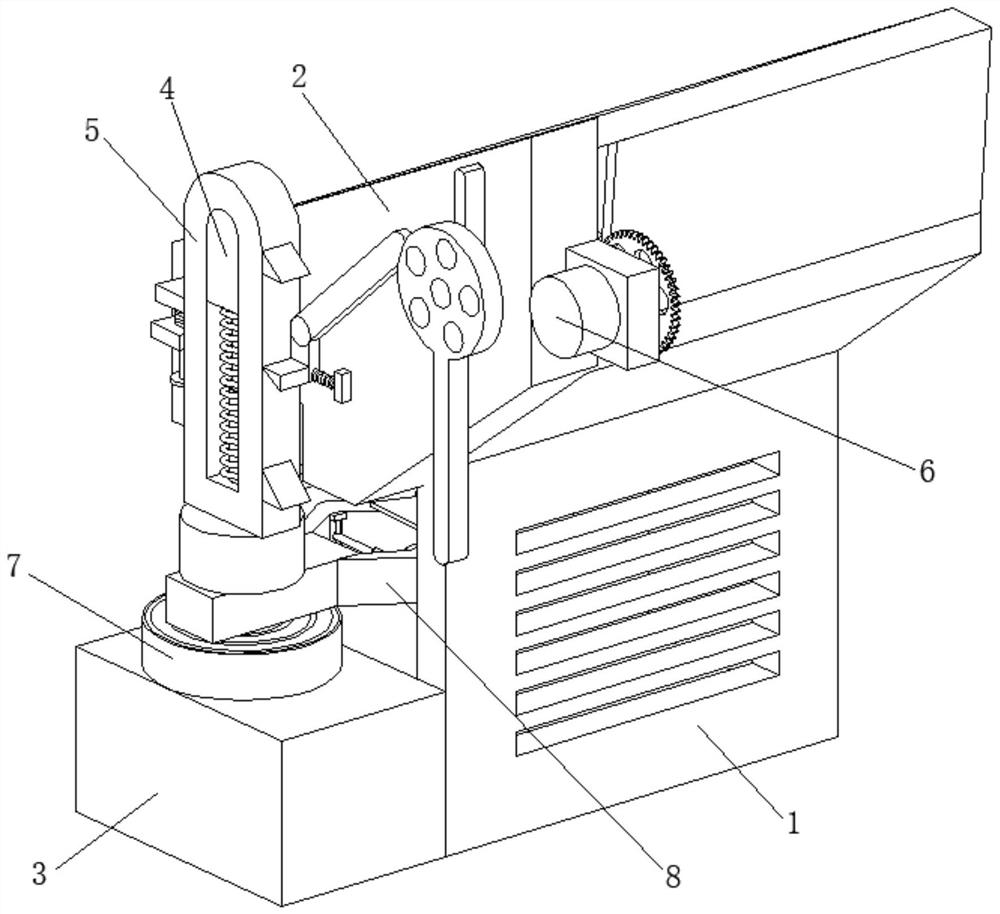

Full-automatic metal forging forming equipment

InactiveCN112475169AReduce the burden onExtended service lifeDrop hammersHammer drivesFully automaticBolt connection

The invention relates to the technical field of forging forming, and discloses full-automatic metal forging forming equipment. The full-automatic metal forging forming equipment comprises a box body,wherein a mounting plate and a supporting box are respectively welded to the front part of the box body; a limiting block is welded to the front part of the mounting plate, and a forging mechanism isarranged on the surface of the limiting block; a transmission mechanism is arranged on the right side of the mounting plate; a placing plate is connected to the top of the supporting box through bolts; and a clamping mechanism is arranged at the top of the containing plate. Through cooperative operation of the transmission mechanism, the forging mechanism and the clamping mechanism, steel can be automatically clamped and overturned while forging is conducted, therefore manual overturning of workers is not needed, the labor intensity of the workers is reduced, and the situation that the workingefficiency becomes low and even safety accidents are caused by fatigue due to long-time work of the workers is prevented. The steel can rotate intermittently through the transmission mechanism, therefore the steel cannot rotate during forging, the steel and a hammer head are prevented from interfering with each other, and the device cannot be damaged.

Owner:谢娟

Escape mechanism of unarmed escort securicar

InactiveCN107816264AConvenient and quick escapeWon't waste timePower transmission/actuator featuresElectrical locking circuitsGear driveEngineering

The invention discloses an escape mechanism of an unarmed escort securicar. The escape mechanism comprises a car body, wherein the front surface of the car body is fixedly connected with the back surface of a bottom plate, a third chute is formed in the upper surface of the bottom plate, a third sliding block is arranged in the third chute, and a trapezoidal block is fixedly connected to the uppersurface of the third sliding block. According to the escape mechanism of the unarmed escort securicar, a motor, a threaded post, a threaded cap, a bearing, a driving gear, a driven gear, a fixed pulley, a first telescopic device, a second telescopic device, a first sliding block, a first chute and a connecting rod are arranged and formed, so that when a driver need to open a car door, the motor is controlled to operate, so that the driving gear rotates, the driven gear is driven to rotate by the driving gear, the driver can open the car door in two modes, the driver can quickly escape in danger and does not need to worry about the damage to a door opening device, the time of the driver cannot be wasted, and the life safety of the driver cannot be threatened.

Owner:成都锦悦智造科技有限公司

Equipment for transporting multiple lamp poles of solar street lamps

InactiveCN109291976AEasy to fixWon't shakeHand carts with multiple axesArchitectural engineeringSolar street light

The invention discloses equipment for transporting multiple lamp poles of solar street lamps. The equipment for transporting the multiple lamp poles of the solar street lamps comprises a bottom plate;three lower clamping plates are fixedly connected to the upper surface of the bottom plate; two sliding rods are fixedly connected to the upper surface of the bottom plate; second springs sleeve theexternal surfaces of the sliding rods; and the top ends and the bottom ends of the second springs are fixedly connected with the lower surfaces of sliding sleeves and the upper surface of the bottom plate. According to the equipment for transporting the multiple lamp poles of the solar street lamps, as a motor, a rope, a rope disc, a rack, a telescopic device, a bearing, a threaded stud, a supporting plate, upper clamping plates and the sliding rods are arranged, three lamp poles are correspondingly placed on three lower clamping plates, and then an electric push rod is controlled to retract to drive a fixed pulley to move down by using a connecting rod so that workers can very well fix each lamp pole during transporting the multiple lamp poles; and therefore, the lamp poles cannot shake and cannot collide with each other during transportation so that the lamp poles cannot be scratched and damaged, and no loss can be caused to merchants.

Owner:孙益锋

Bolt propeller

InactiveCN113531075AReduce volumeRotation will notGearingMechanical energy handlingTorque motorElectric machinery

The invention discloses a bolt propeller which comprises a motor shell. A frameless torque motor is arranged in the motor shell, a nut and a nut adapter are arranged in the frameless torque motor, the nut is in transmission connection with the frameless torque motor through the nut adapter, and a lead screw matched with the nut is arranged in the nut. The bolt propeller further comprises a guide pushing column arranged a the extending end of the lead screw. According to the structural design, a driving rod in a traditional motor is omitted, the lead screw is directly installed in the motor, utilization of the length space in the motor is achieved, and therefore the size of the device is greatly reduced.

Owner:苏州卓誉电气技术有限公司

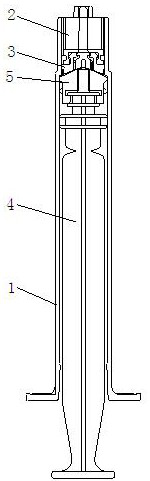

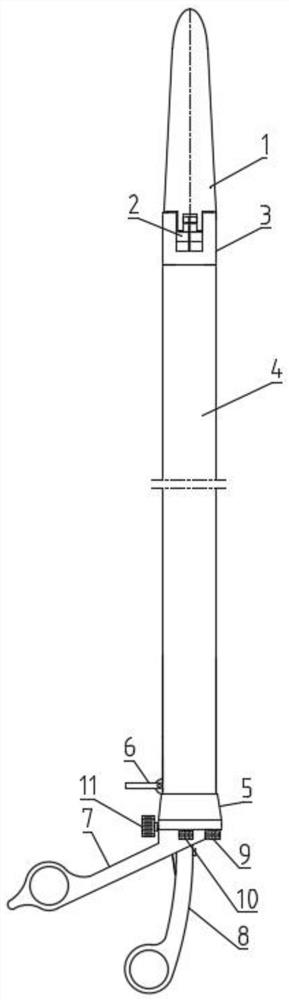

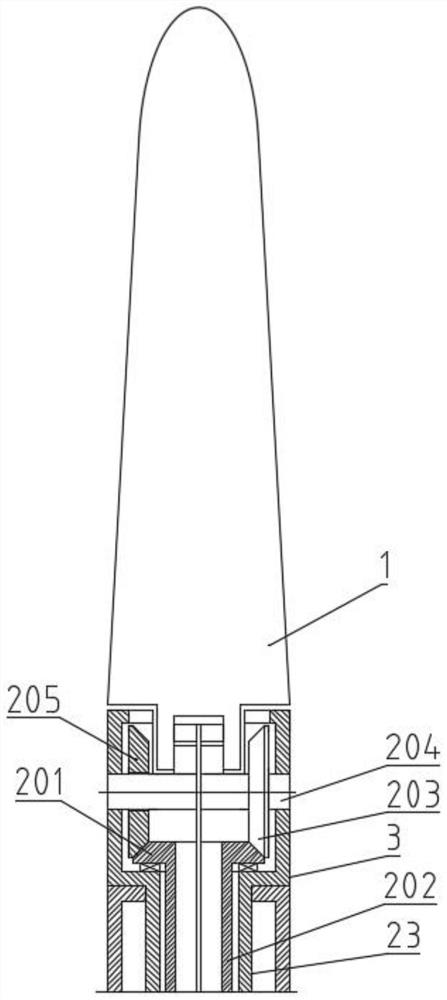

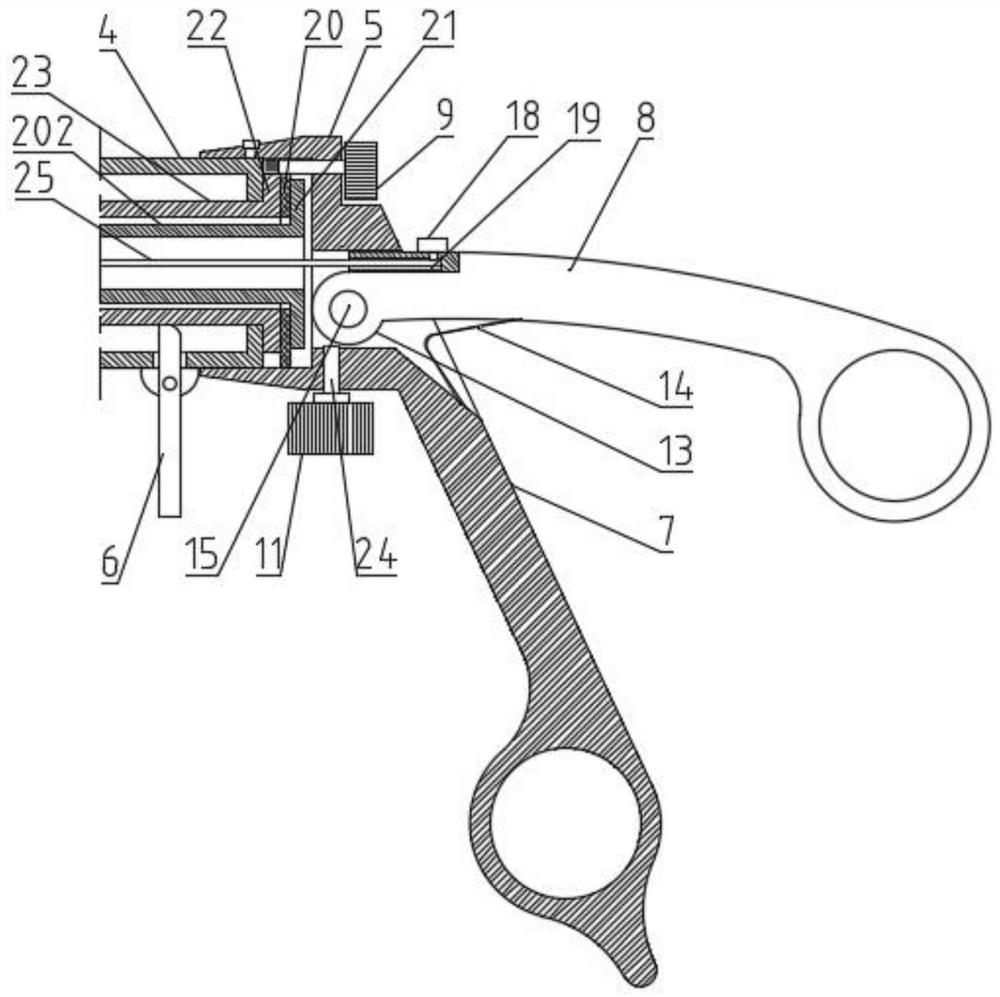

Safety injector capable of automatically rotating and self-destroying

PendingCN113018594ARotation will notImprove experienceInfusion syringesIntravenous devicesEngineeringInjector

The invention discloses a safety injector capable of automatically rotating and self-destroying, and belongs to the technical field of syringes. The injector comprises a needle cylinder, a core rod, a needle head base and a stop ring, N first protruding strips are evenly distributed outside the needle head base, a second protruding strip A is arranged on the upper portion in the needle cylinder, a locking protruding block B is arranged in the needle cylinder and located at the position of the stop ring, and second protruding strips are embedded between the two corresponding adjacent first protruding strips so that the needle head base can only move up and down; An L-shaped locking block B matching a locking convex block is arranged outside a stop ring; the locking block is hooked on the upper side of the locking convex block to fix the stop ring on the needle cylinder; A tenon is provided with C rotation driving protruding blocks, and C rotation guiding protruding strips matching rotation driving protruding blocks are arranged in the limiting ring. After injection is completed, the tenon is inserted into the stop ring, the rotation driving protruding block and the rotation guiding protruding strips are matched to enable the stop ring to rotate towards the unlocking direction till the locking protruding block and the locking block are staggered, the core rod and the stop ring are locked, and the core rod is pulled downwards to enable the stop ring and the needle head base to move downwards.

Owner:湖北科莱德医疗器械有限公司

A hot press device for high temperature adhesive curing

The invention relates to a hot pressing device for high temperature adhesive curing. Including: end cover (1), bolt (2), force bar (3), base (4), magnet (5), high temperature rubber pad (7), electric heater (8), electrode (9), lead hole (10), bearing (11), mandrel (12); the base (4) is a cylindrical structure with an inverted "U" shape in cross section, and the upper bottom surface is provided with a through hole, and the inner wall of the through hole is provided with a thread; the base The seat (4) provides support, and the magnet (5), high-temperature rubber pad (7), and electric heater (8) are arranged inside it; the magnet (5) provides attractive force, and the upper end of the magnet (5) has an internal thread, and the direct core The mandrel thread (12c) of axle (12) connects. The advantage of the invention is that both the temperature and the applied force can be adjusted to meet the condition of multiple curing of the high-temperature glue. The device is simple in design, precise in control and easy to operate.

Owner:TIANJIN AEROSPACE RELIA TECH +3

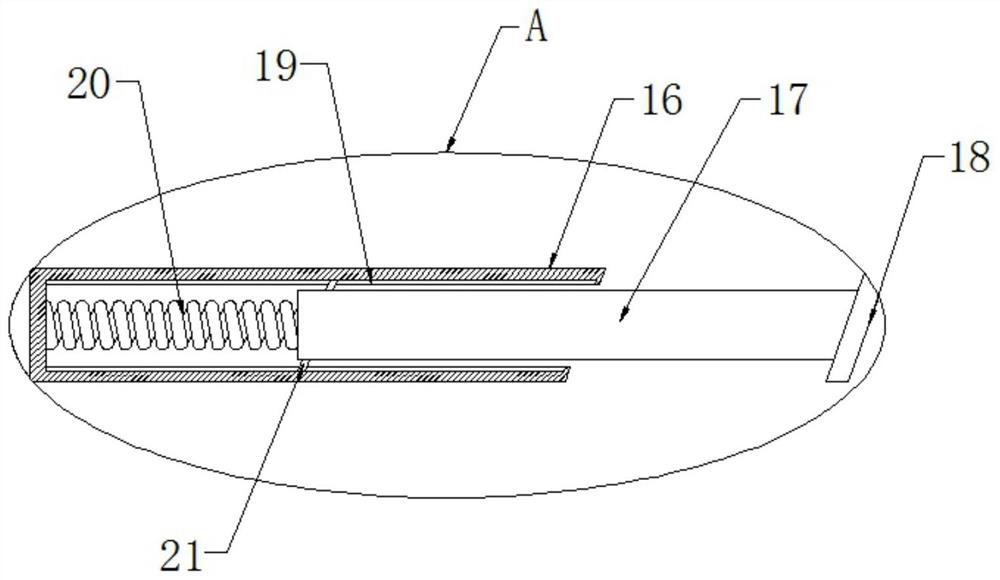

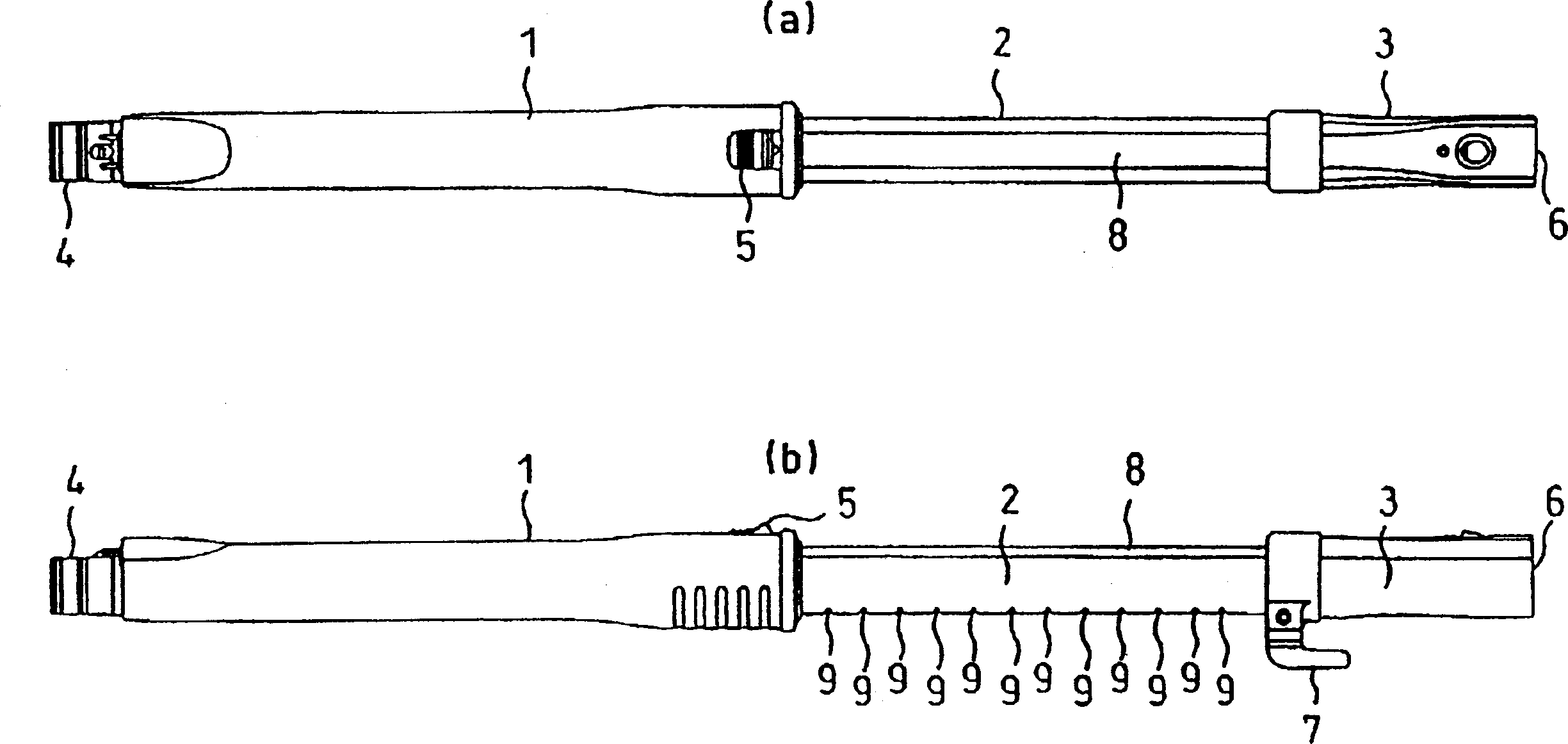

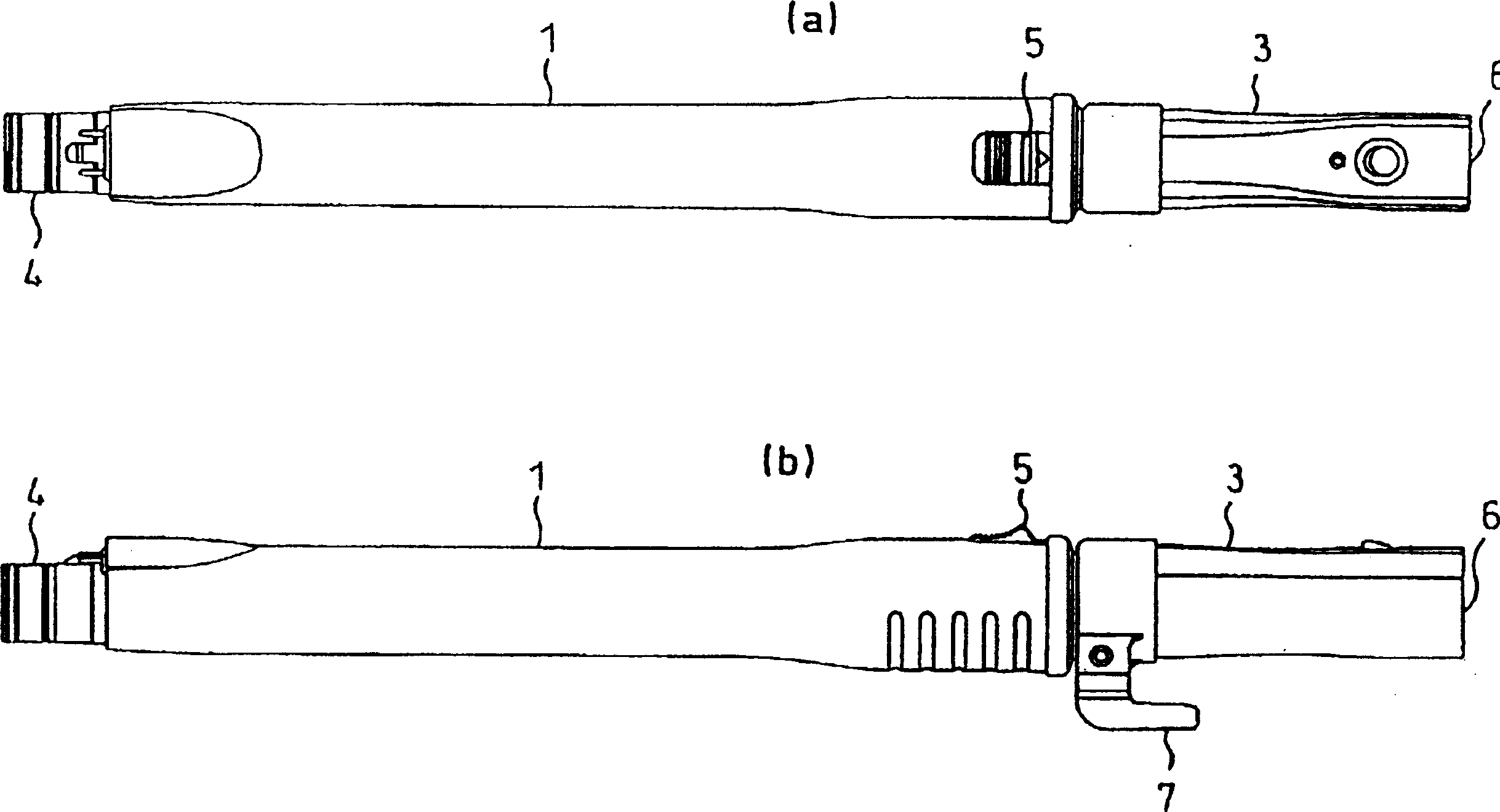

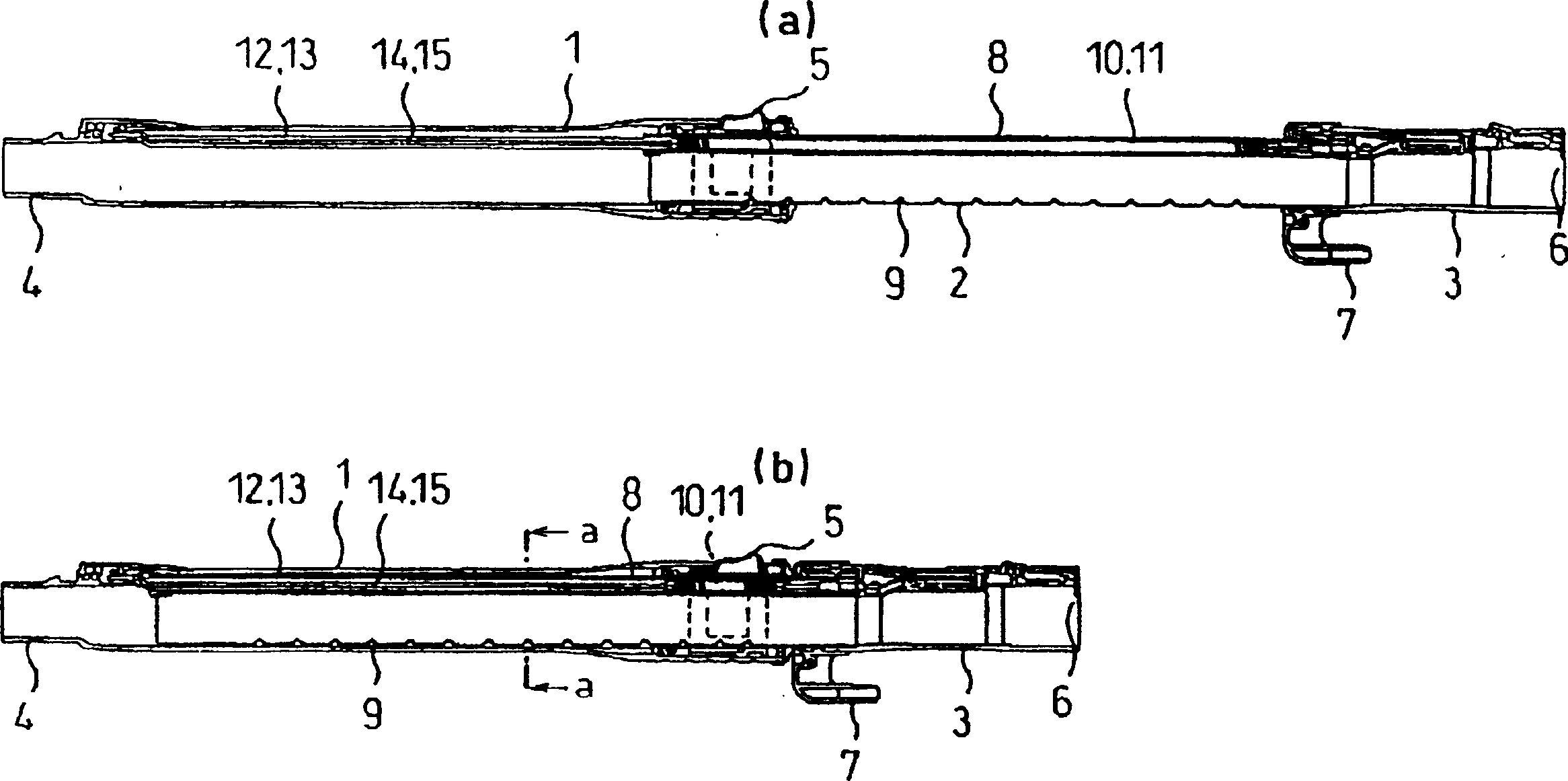

Telescopic pipe for electric cleaner

InactiveCN1136814CAvoid disconnectionWon't bendSuction hosesSuction nozzlesContact failureTorsion spring

Disclosed is an extension tube of the electric dust collector, which is arranged between a pipe installation port of the electric dust collector body and a suction use electric brush. The invention includes an inner pipe which is contained in an outer pipe and can freely go in and out of the outer pipe, an adjustment mechanism for adjusting the protruding amount of the inner pipe, and a wiring mechanism. The invention is characterized in that the wiring mechanism is provided with a first sleeve, an extension spring which can be extensibly contained in the first sleeve, a lead cover part which can cover one end of the extension spring, and a second sleeve which can be freely glidingly arranged in the first sleeve. The invention can prolong the service life of the spring and can prevent bad connections of the interlink part of the down-leads.

Owner:SANYO ELECTRIC CO LTD

Flexible element

InactiveCN100427329CNo bending momentCompact manufacturingResilient suspensionsPivoted suspension armsBogieVehicle frame

The present invention relates to a spring element 1 intended to transmit compression forces and tensile forces between a vehicle frame 14 and a wheel axle 15 arranged movably in relation to the vehicle frame 14, especially between the wheel axle 15 and the end of a bogie beam mounted pivotably in the vehicle frame 14. The spring element 1 comprises a rubber body 4, and a mechanical connection member 6 which extends through the rubber body 4 and is arranged to limit the distancing movement between said vehicle frame 14 and wheel axle 15. The connection member 6 here comprises a coupling device 8 for coupling the connection member 6 in one of said vehicle frame 14 or wheel axle 15.

Owner:VOLVO ARTICULATED HAULERS

Suspension device for computer display

InactiveCN109899660AConvenience to workConvenient entertainmentStands/trestlesDisplay deviceScrew thread

The invention discloses a suspension device for a computer display. The suspension device comprises a top plate, wherein two sliding grooves are formed in the lower surface of the top plate, sliding blocks are arranged in the two sliding grooves, first threaded caps are fixedly connected to the lower surfaces of the two sliding blocks, and the two first threaded caps are internally provided with first threaded columns in a threaded connection mold. According to the suspension device for the computer display, a first motor, the first threaded columns, the first threaded caps, the sliding blocks, a bearing, a rotating shaft, a rope, a rope disc and a fixing device are arranged, the first motor is controlled to work to enable the two first threaded columns to rotate, finally, a second motor is controlled to work, so that an output shaft of the second motor rotates to drive the rope disc to rotate, an L-shaped connecting plate pulls a display body to move upwards, so that the display bodycan be suspended on the top, a patient can operate a computer in a way lying in bed, so that work and entertainment of workers are facilitated, and the patient can use the computer more conveniently.

Owner:西安谷德电子科技有限公司

Novel automatic forging forming device

ActiveCN112475171AReduce labor intensityPrevent long hours of workDrop hammersHammer drivesBolt connectionMoulding device

The invention relates to the technical field of forging forming, and discloses a novel automatic forging forming device. The novel automatic forging forming device comprises a box body; a mounting plate and a supporting box are respectively welded to the front portion of the box body; a limiting block is welded to the front portion of the mounting plate; a forging mechanism is arranged on the surface of the limiting block; a transmission mechanism is arranged on the right side of the mounting plate; a placement plate is connected to the top of the supporting box through bolts; and a clamping mechanism is arranged at the top of the placement plate. Due to cooperative operation of the transmission mechanism, the forging mechanism and the clamping mechanism, steel can be automatically clampedand overturned while forging is carried out; therefore, manual overturning of workers is not needed; the labour intensity of the workers is reduced; the situation that the working efficiency becomeslow and even safety accidents are caused by fatigue due to long-time work of the workers is prevented; the steel can be made to rotate intermittently through the transmission mechanism; therefore, thesteel cannot rotate during forging; the steel and a hammer head are prevented from interfering with each other; and the device is prevented from being damaged.

Owner:格尔德贝克(山西)法兰管件有限公司

An automatic forging device

ActiveCN112475171BReduce labor intensityAvoid limitDrop hammersHammer drivesClassical mechanicsEngineering

Owner:格尔德贝克(山西)法兰管件有限公司

Oil pump system for crankshaft and compressor with same

ActiveCN106401915BImprove operational reliabilityImprove stabilityPositive displacement pump componentsLubricating pumpsFriction forceCrankshaft

The invention provides an oil pumping system for a crankshaft and a compressor with the same. The oil pumping system comprises an oil pump (1) used for pumping oil into an internal oil hole of the crankshaft. The oil pump (1) comprises a cylindrical pump core (11) and a cylindrical outer sleeve (12) which is connected to the radial outer portion of the pump core (11) in a sleeving mode. A preset distance is spaced between the radial inner wall of the outer sleeve (12) and the radial outer wall of the pump core (11), the spaced preset distance extends in the axial direction to form an annular groove so that the crankshaft can be inserted into the annular groove, and meanwhile the pump core (11) can be inserted into the oil hole. By means of the oil pumping system for the crankshaft and the compressor with the same, the radial spacing between an outer circular pipe and the inner wall of the oil hole in the prior art can be reduced, and therefore friction power consumption between the crankshaft and the oil pump is effectively reduced, and operational reliability, stability and safety of the oil pumping system are improved. The friction force of oil with the oil hole of the crankshaft and the outer surface of the pump core can be increased, and oil pumping capacity of the oil pumping system at the low frequency is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

Clamp capable of observing play fingering of guitar simultaneously and comprehensively

InactiveCN105931616AEasy to learnRotation will notStringed musical instrumentsPlane mirrorConvex side

The invention discloses a clamp capable of observing play fingering of a guitar simultaneously and comprehensively. The clamp comprises a clamp, a mirror rod, a circular mirror frame, a circular plane mirror and a circular convex mirror, and is characterized in that the clip comprises an upper clamping piece, a lower clamping piece, an upper rubber layer, a lower rubber layer, an upper clamping handle, a lower clamping handle, a bearing and a crosshead bolt; the center of the upper end of the upper clamping piece is provided with a threaded hole II; the lower end of the mirror rod is provided with a screw, and the screw and the threaded hole II are connected in a matched manner; a sphere is inserted upward into an adaptive spherical concave hole in the middle of the bottom end of the circular mirror frame and is fixed through a check ring I; the left end of the circular mirror frame is provided with a left big circular concave hole and a left small circular concave hole communicated with the left big circular concave hole, and the circular convex mirror is fixed in the left small circular concave hole through a check ring II; and the right end of the circular mirror frame is provided with a right big circular concave hole and a right small circular concave hole communicated with the right big circular concave hole, and the circular plane mirror is fixed in the right small circular concave hole through a check ring III. The clamp disclosed by the invention is clamped on the head of the guitar, thereby being convenient for beginners to observe the guitar play fingering simultaneously and comprehensively when fingers of the left hand and the right hand press strings.

Owner:罗道仟

Cutting type multi-angle adjusting separating forceps for laparoscopic surgery

The invention relates to the technical field of laparoscopic surgical instruments, in particular to a pair of cutting type multi-angle adjusting separating forceps for laparoscopic surgery. A turnover mechanism is arranged in a rotating seat at a front end of a rod body; a clamping part is arranged on the turnover mechanism; a rotating rod at the tail end of the rotating seat is connected with a second fluted disc; a driven bevel gear on a rotating shaft of the turnover mechanism is meshed with the driving bevel gear; the driving bevel gear is connected with a driving rod; the driving rod is connected with a first fluted disc; and the clamping part is connected with the second operating rod through a pull wire. The pair of separating forceps has the beneficial effects that the direction of the separating forceps can be freely adjusted in a semispherical surface when the separating forceps face a narrow operation area in an operation process; the problems that in the laparoscopic surgery, due to the fact that the direction of the separating forceps clamping part cannot be adjusted when the separating forceps clamping part clamps and separates human tissue in the surgery, an operator excessively swings when operating a rod body with force, an external incision of the surgery is enlarged, and normal tissue in the incision is damaged are solved, the non-surgical injury risk is effectively reduced, and meanwhile, the efficiency and the safety of the laparoscopic surgery are also improved.

Owner:岳阳职业技术学院

Full-automatic metal forging forming method

InactiveCN112475170AReduce the burden onExtended service lifeDrop hammersHammer drivesGear driveGear wheel

The invention relates to the technical field of forging forming, and discloses a full-automatic metal forging forming method. The full-automatic metal forging forming method comprises the steps that:a steel block is placed between two clamping blocks; an oil cylinder contracts to drive the two clamping blocks to clamp the steel block; furthermore, the steel block is placed on a placing plate; a motor is started; the motor drives a first gear to rotate; the first gear drives a second gear to rotate; the second gear drives a first belt wheel to rotate; the first belt wheel drives a short pokingplate to rotate; the short poking plate drives a long poking plate to rotate; the short poking plate drives a rotating plate to rotate; a sliding block downwards forges the steel block; after the first forging is completed, the long poking plate continues to rotate to drive the sliding block to move upwards and reset again; a rack drives a fourth gear to rotate; the fourth gear drives the steel block to rotate through the clamping blocks; when the sliding block falls down again, the steel block automatically turns over once; and the sliding block forges the steel block again. Steel can be automatically clamped and overturned while forging is carried out, so that manual overturning by workers is not needed, and the labour intensity of the workers is reduced.

Owner:谢娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com