Tea leaf frying machine

A frying machine and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems of affecting the efficiency of frying and sticking together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

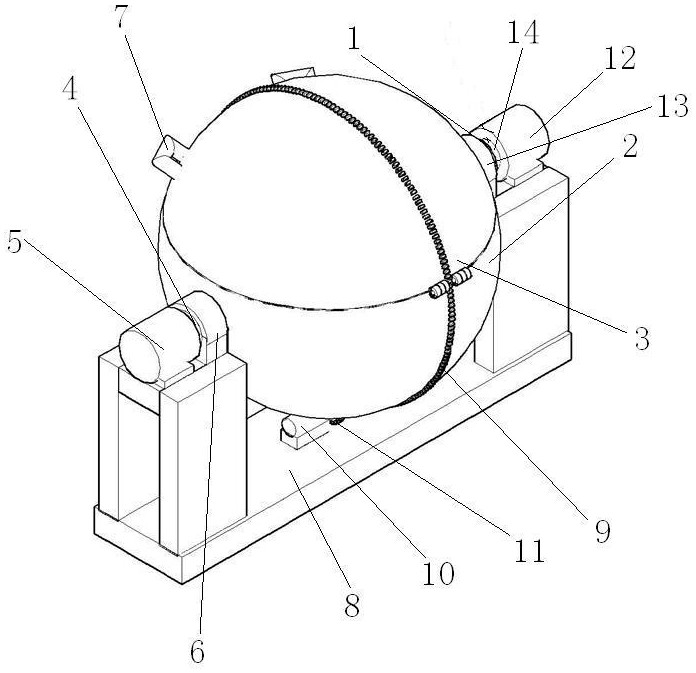

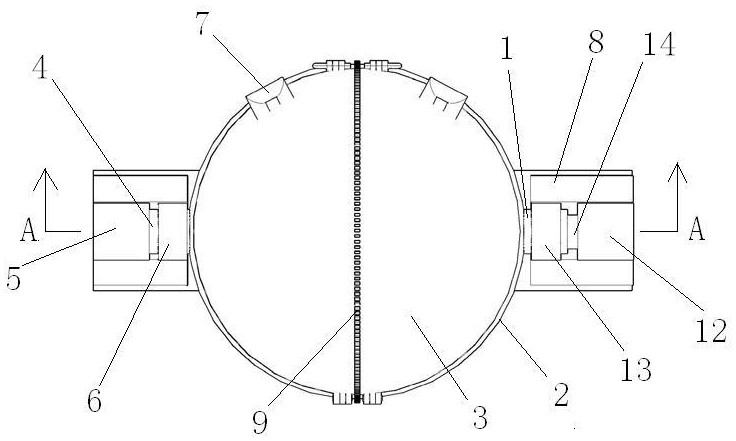

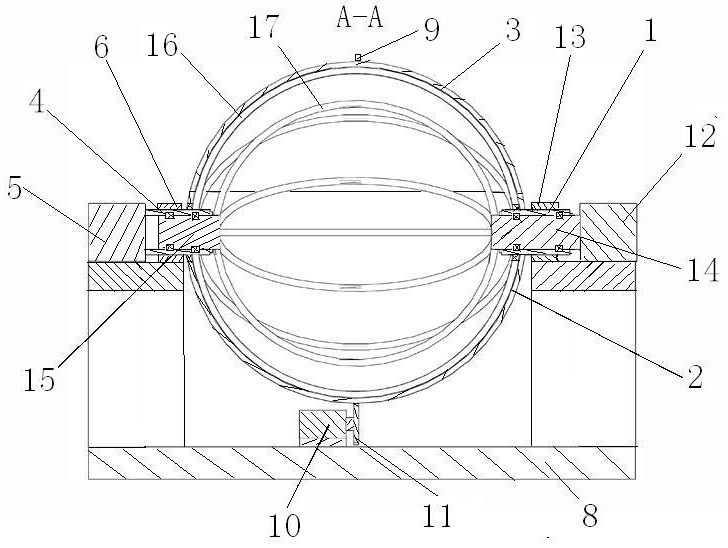

[0025] The specific implementation, structure, features and effects according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0026] A tea frying machine of the present invention is characterized in that: the two ends of the frying cage B17 are respectively connected to the shaft A14 and the shaft B15, and the shaft A14 and the shaft B15 are respectively inserted into the hollow shaft A1 and the hollow shaft B4, and the hollow shaft A1 and the hollow shaft B4 The pot body 2 is respectively connected through bearings, the two ends of the frying cage A16 are respectively connected to the hollow shaft A1 and the hollow shaft B4, the middle parts of the hollow shaft A1 and the hollow shaft B4 are respectively connected to the bracket 7 through the bearing seat A6 and the bearing seat B13, and the hollow shaft B4 is connected to the motor A5, shaft A14 is connected to motor C12, motor B10 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com