Patents

Literature

84results about How to "Fried evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of amber sugar coated walnut meat

The invention provides a manufacturing method of amber sugar coated walnut meat, comprising the following steps of: selecting materials, rinsing, boiling by water, coating sugar, frying by oil, leaching oil, cooling and packaging. The manufacturing method optimizes technological parameters of all links and is reasonable; the manufacturing method is simple, the machining time is short and the finished product rate is high; the manufactured amber sugar coated walnut meat not only better keeps the abundant nutrition of the walnut meats, but also has bright color and luster, uniform thickness of a sugar coat, moderate sweet degree and uniform frying; and the taste is crispy and has no astringent feeling, the meat crushing rate is low and the color, smell and taste are good.

Owner:葛伟

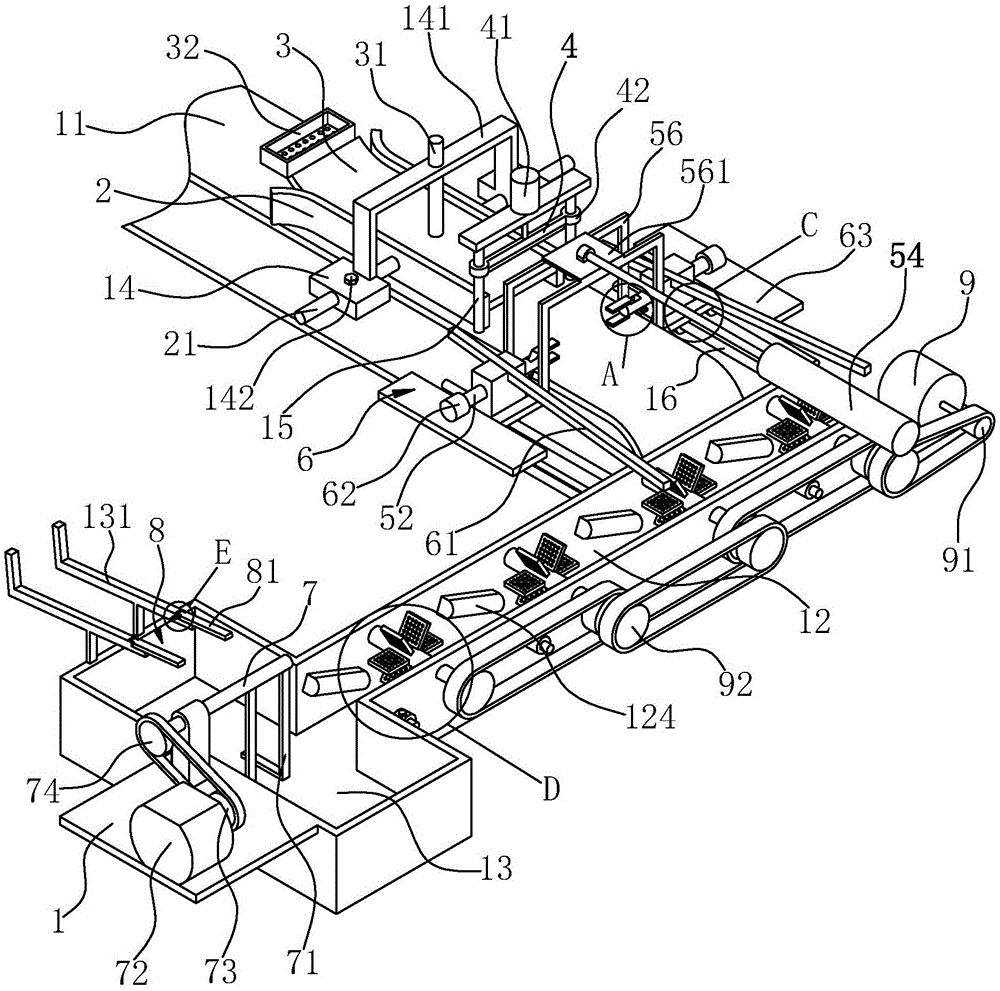

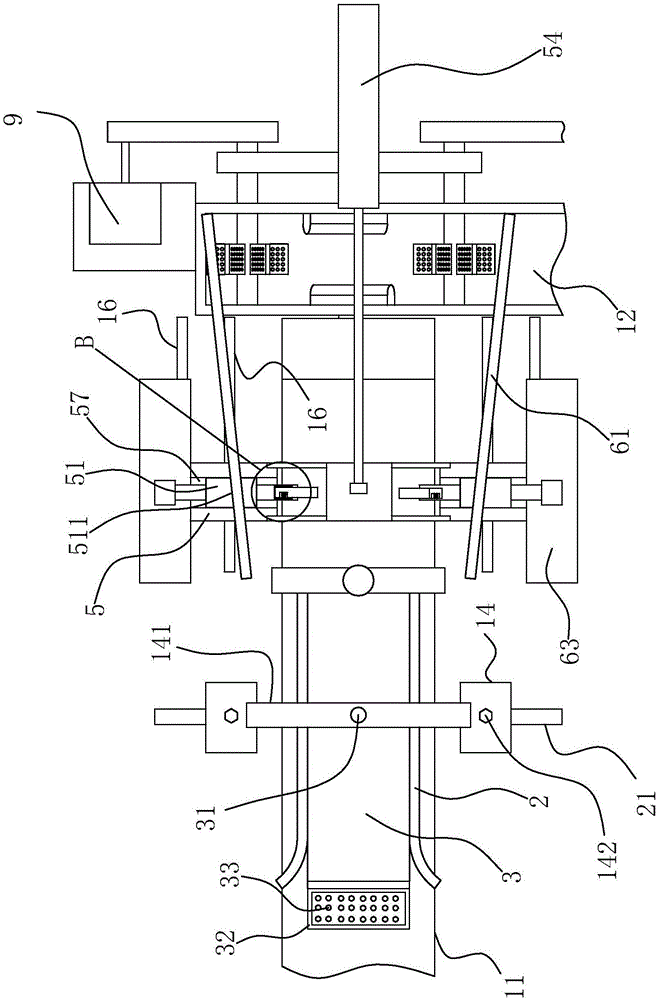

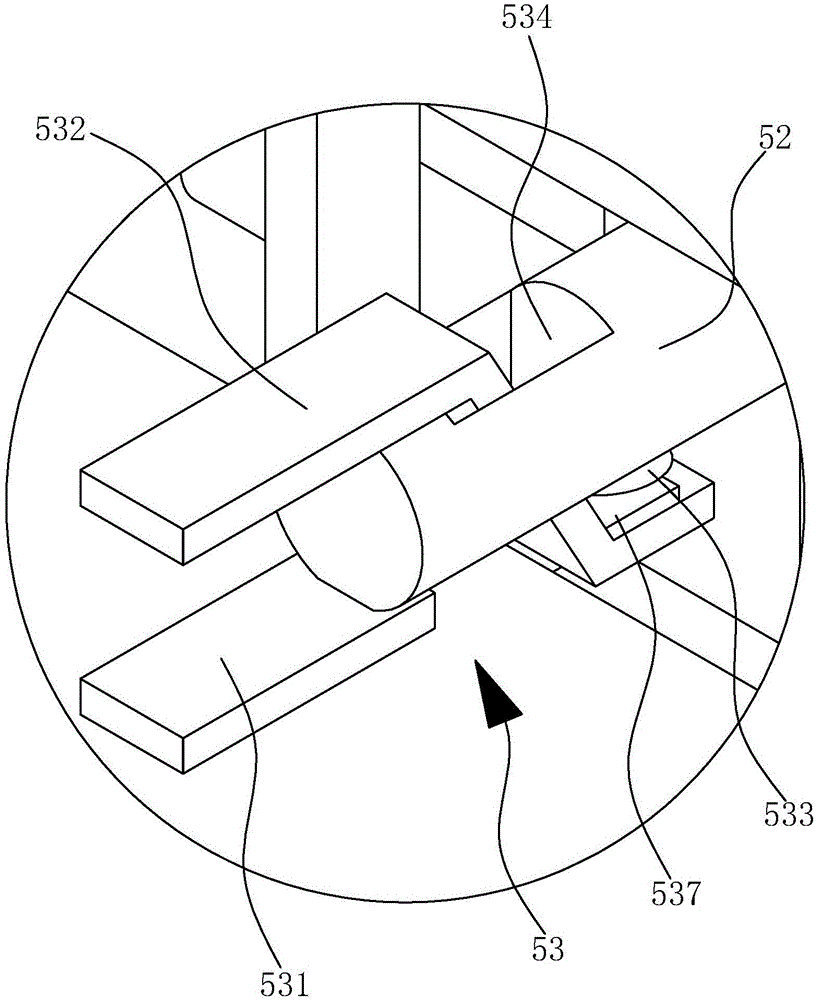

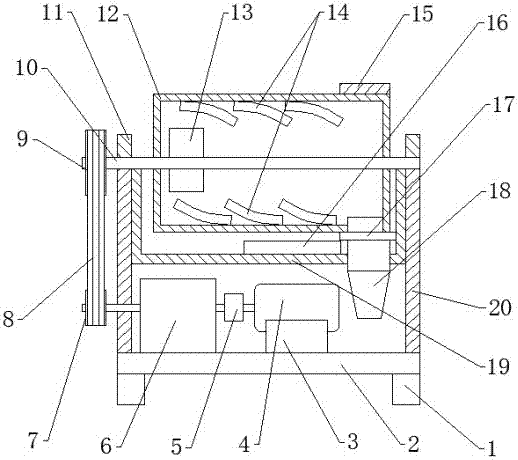

Automatic processing machine for fried bread sticks

InactiveCN105076278AHigh degree of automationImprove processing efficiencyDough shaping and cutting apparatusBaking plantsEngineeringMechanical equipment

The invention provides an automatic processing machine for fried bread sticks, belongs to the technical field of food mechanical equipment, and solves the problems that the conventional automatic processing machine for fried bread sticks is low in efficiency, and fried bread sticks produced by the conventional automatic processing machine are poor in quality. The automatic processing machine for fried bread sticks comprises a rack, wherein a transmission belt is arranged on the rack; the rack is connected with two side plates and a pressing plate; the rack is connected with a cutter and movable plates in a sliding manner; a movable block is connected onto each of the movable plates in a sliding manner; a material grabbing rod is connected onto each of the movable blocks in a rotating manner; a clamping jaw is arranged at one end of each material grabbing rod; the rack is fixedly connected with an oil groove; a plurality of rotating shafts are connected to the interior of the oil groove in a rotating manner; a plurality of material stirring plates are fixedly connected onto the outer circumferential wall of each of the rotating shafts; a material turning block is connected onto each of the two opposite groove walls of the oil groove; a feeding groove is fixedly connected with one end part of the oil groove on the rack; two material placing rods are fixedly connected to a position above the feeding groove on the rack. According to the automatic processing machine for fried bread sticks, paste can be automatically processed into fried bread sticks, and the degree of automation and efficiency are high.

Owner:ZHEJIANG OCEAN UNIV

Production method of fried bean sauce with mushroom and beef

The invention provides a production method of fried bean sauce with mushroom and beef, wherein the main ingredients include beef stuffing or shredded beef, minced mushroom, flour paste and fermented soya paste, the beef stuffing or shredded beef are refrigerated and defreezed under atmospheric temperature, water-loss reducer and anti-oxidizing agent are charged into laminated pan to be boiled, at last soup stock and thickening agent are also charged.

Owner:杨秀敏

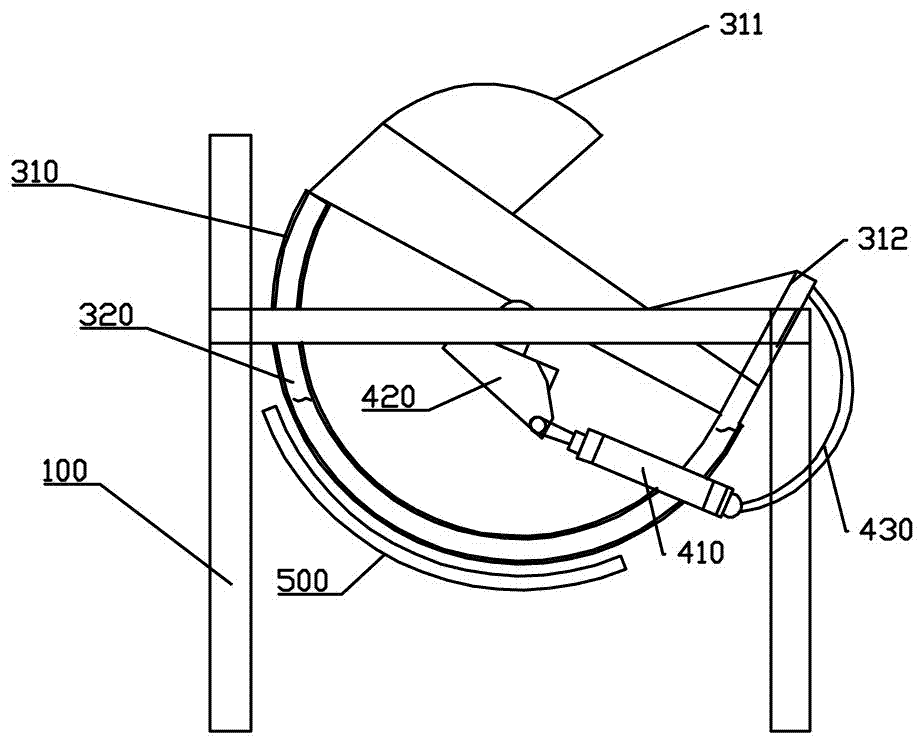

Tea processing equipment

The invention relates to tea stir frying equipment, and concretely relates to tea processing equipment. The tea processing comprises a frame, a pan used for frying, a power member, a heating mechanism and a frying plate member, a liquid storage chamber is arranged in the pan, a liquid inlet valve is arranged in the liquid storage chamber, the liquid storage chamber is filled with water, a returning face plate is fixed at one high side of the pan, a recovery plate is fixed at a lower side of the pan, a frying pan driving mechanism comprises an overturning seat fixed on the pan and a cylinder body, one end of the cylinder body is connected with the overturning seat, the other end of the cylinder body is connected with the frame, the heating mechanism comprises an arc electromagnetic heating plate, the arc electromagnetic heating plate is fixed on the frame and is positioned at the lower part of the pan, and the shape of the arc electromagnetic heating plate is adapted with the shape of the bottom of the pan. The tea processing equipment solves the problem of uneasy control of the stir frying temperature of the tea during a tea shaping process, and is capable of performing stir frying on the tea by using stable temperature.

Owner:遵义茗香康源茶饮发展科技有限公司

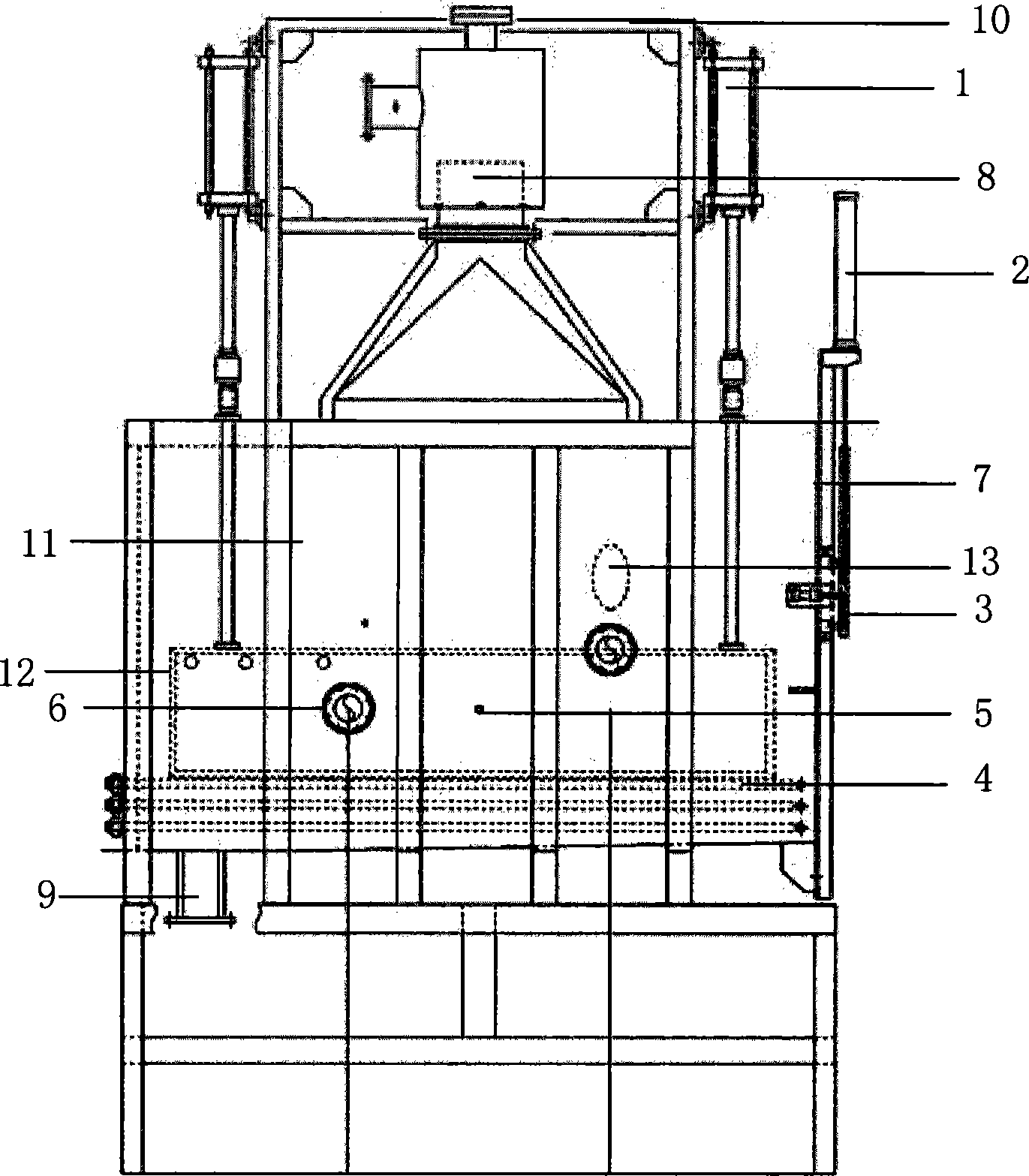

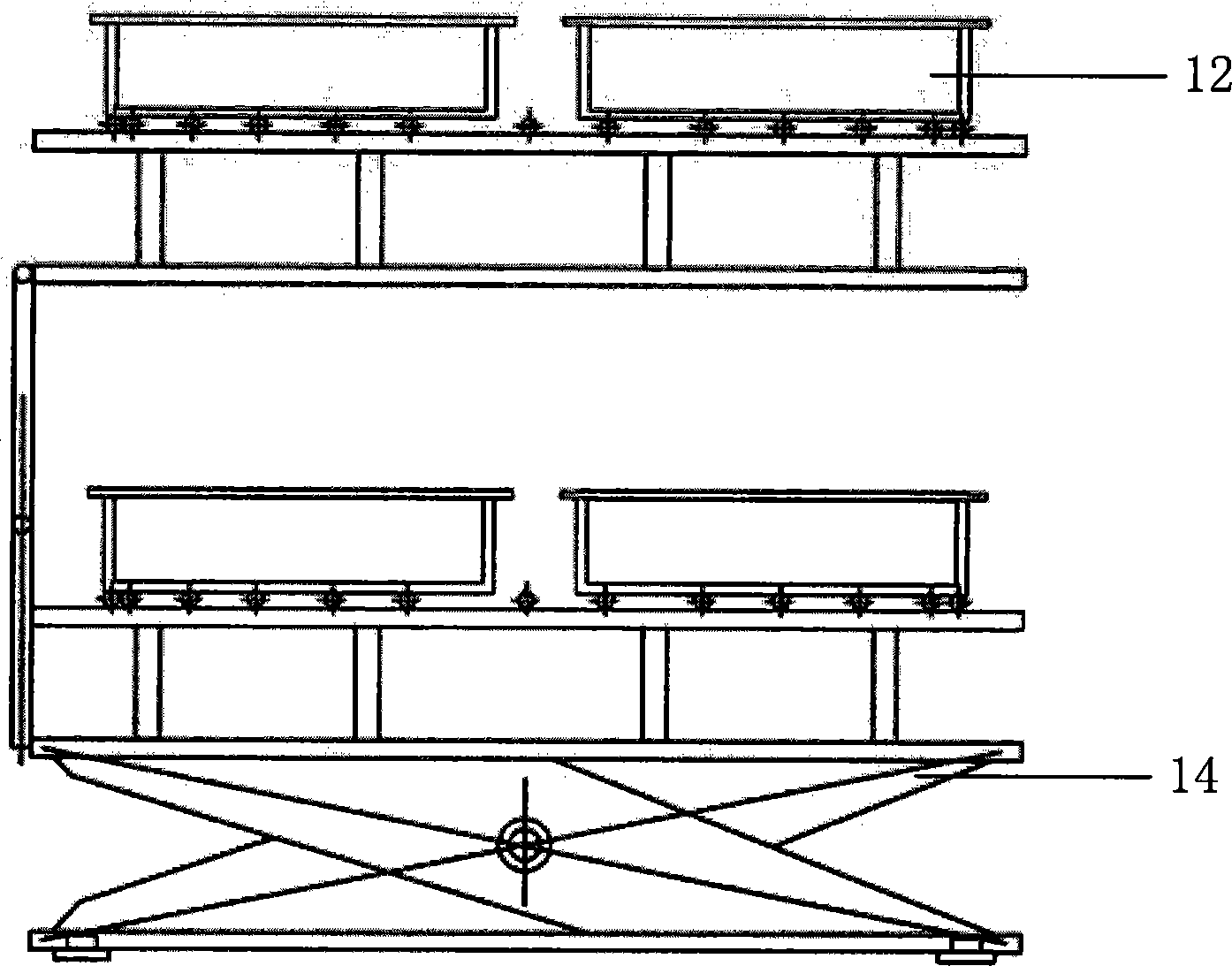

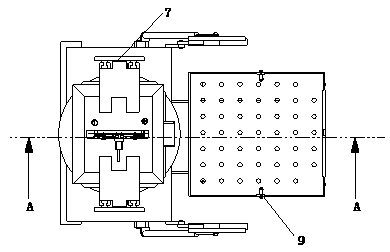

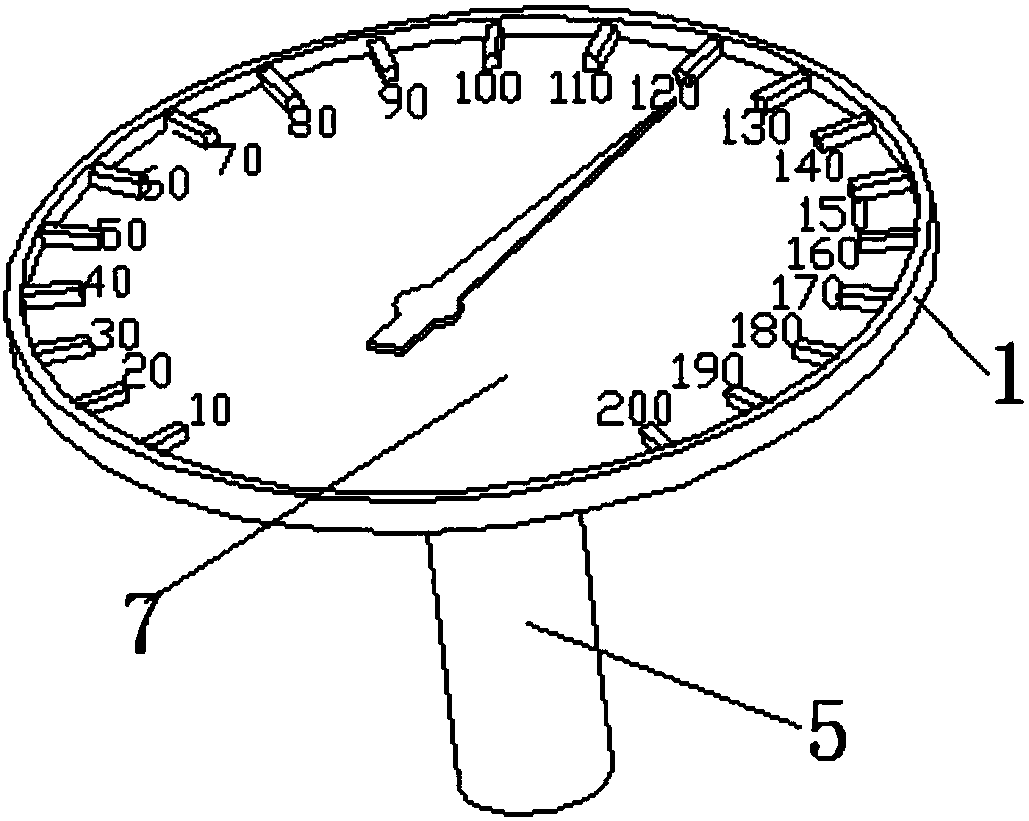

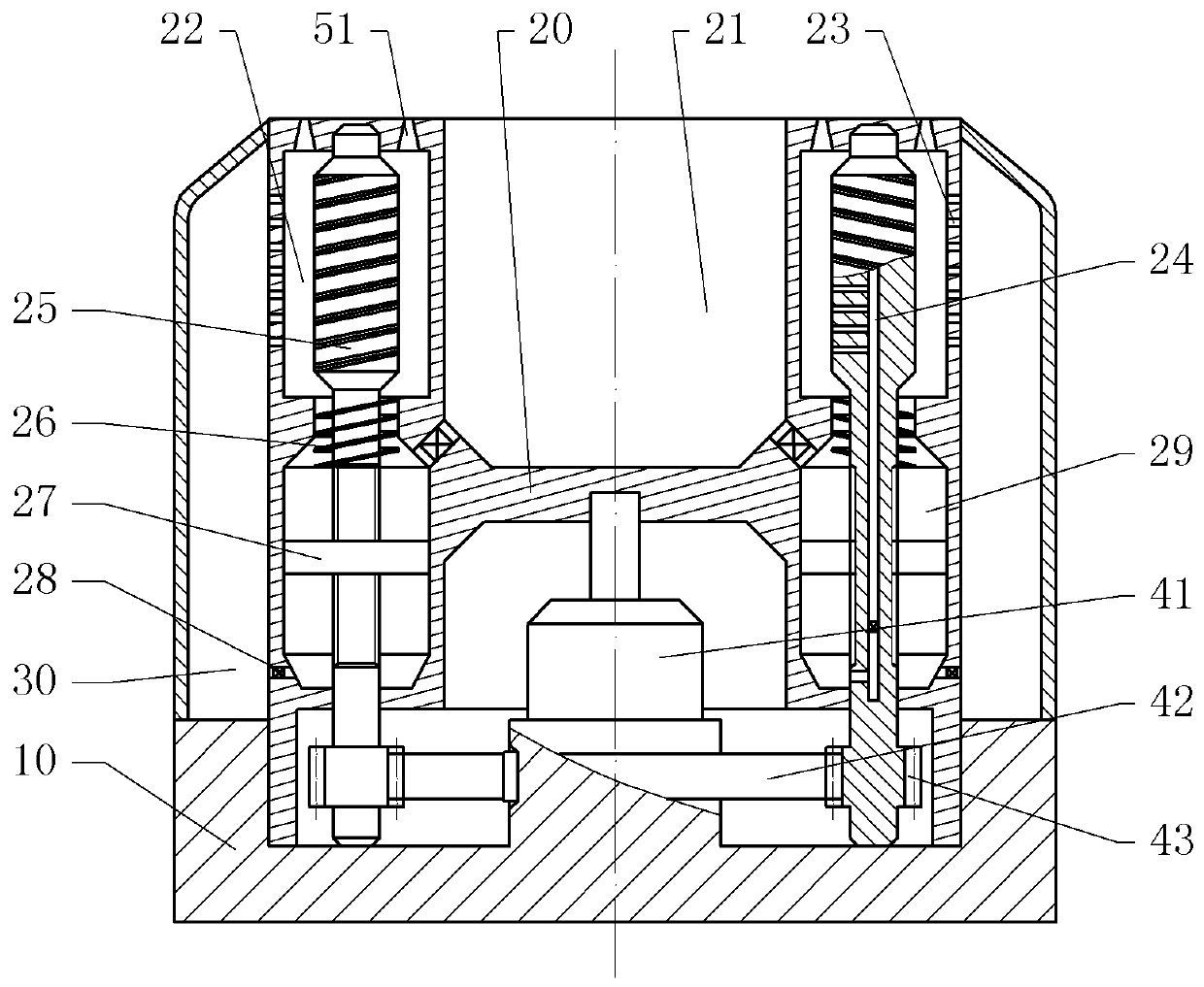

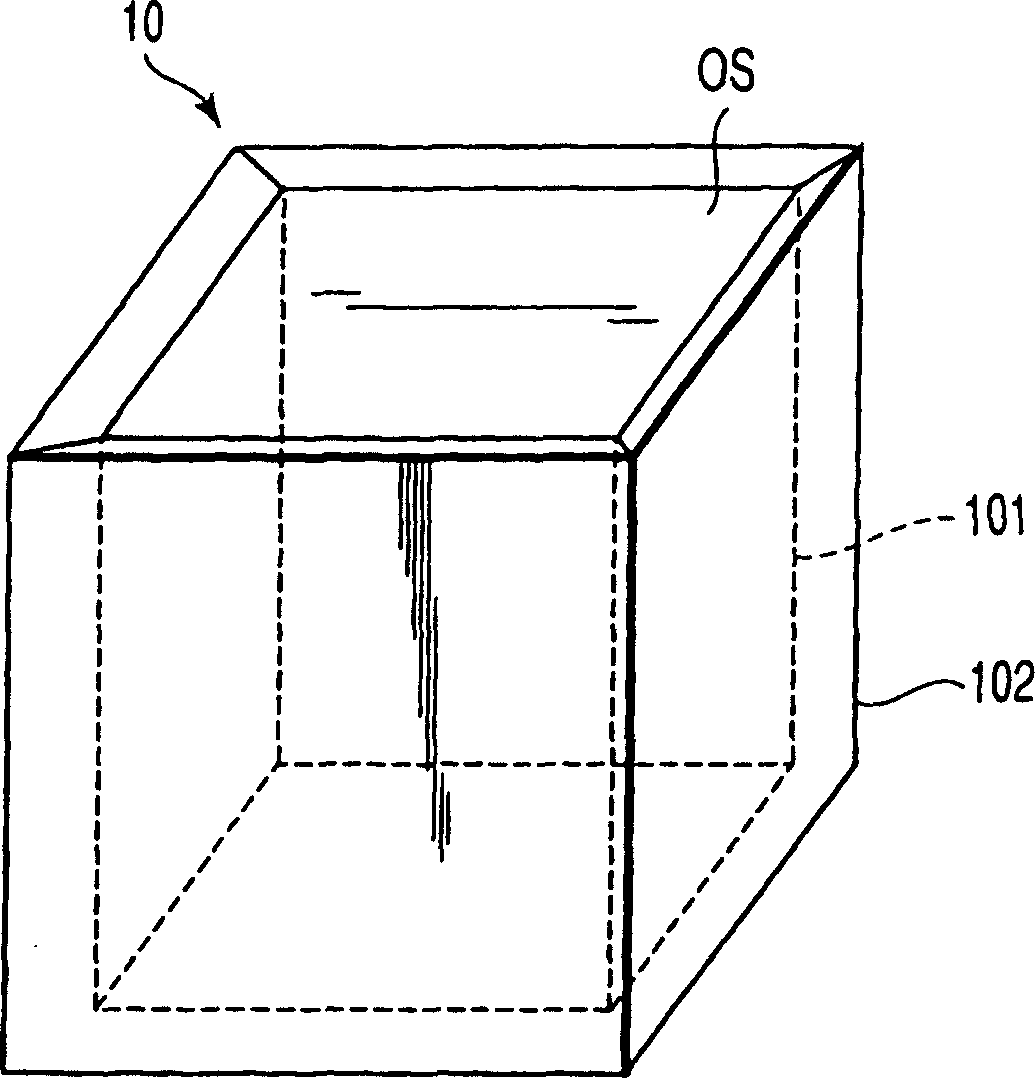

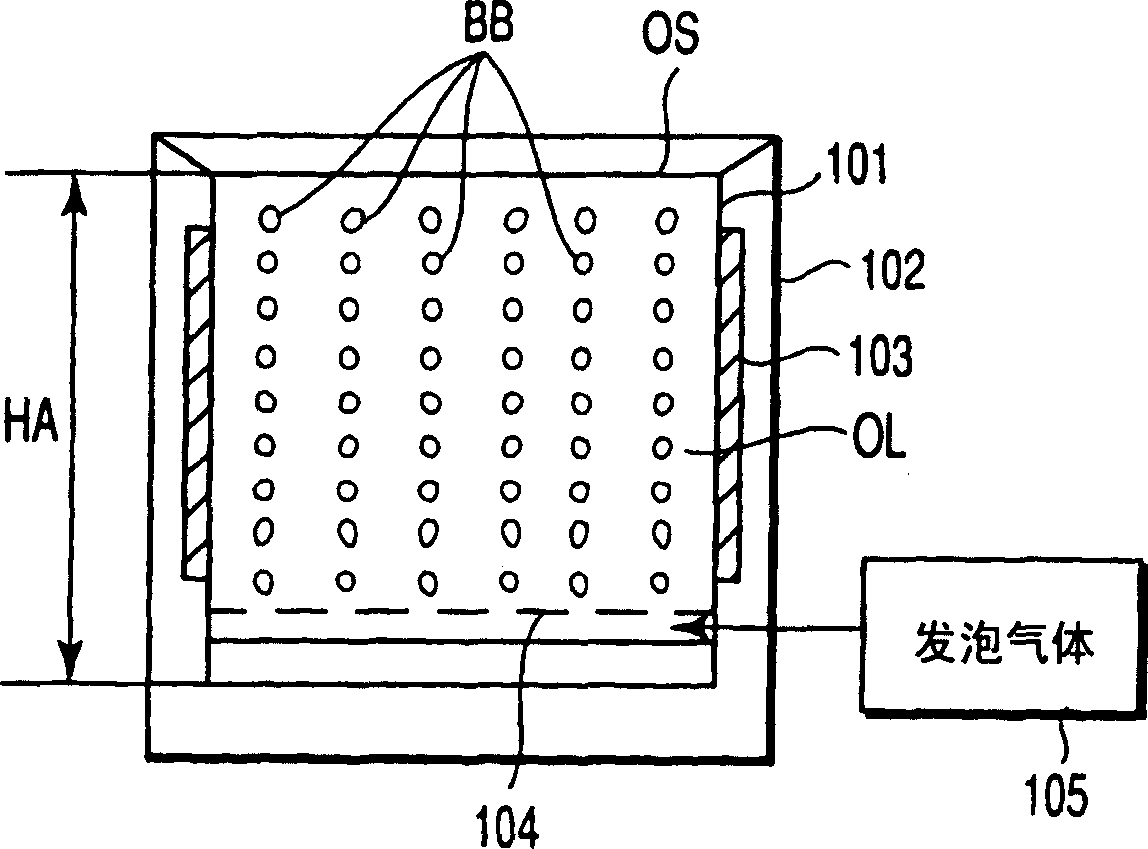

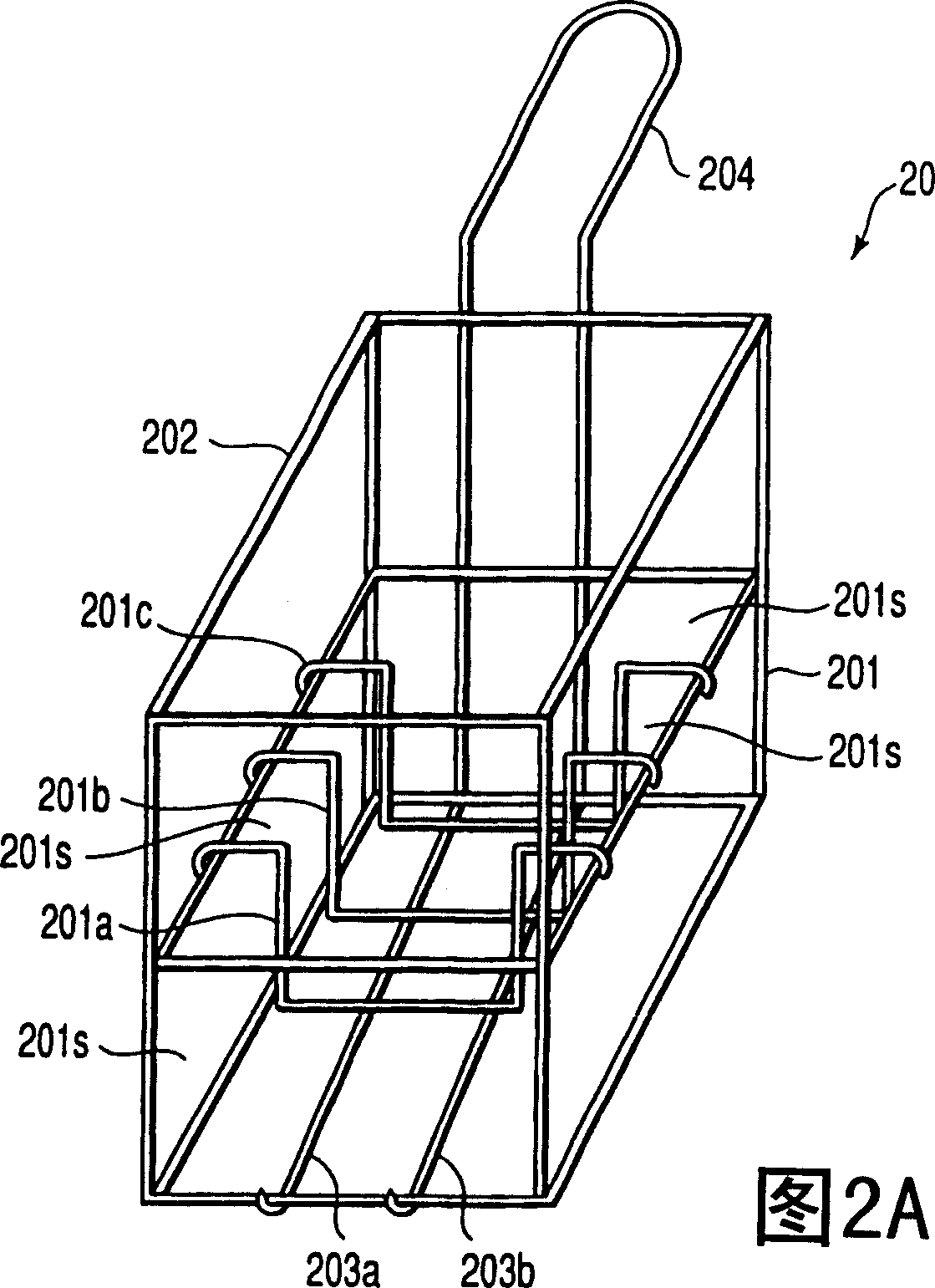

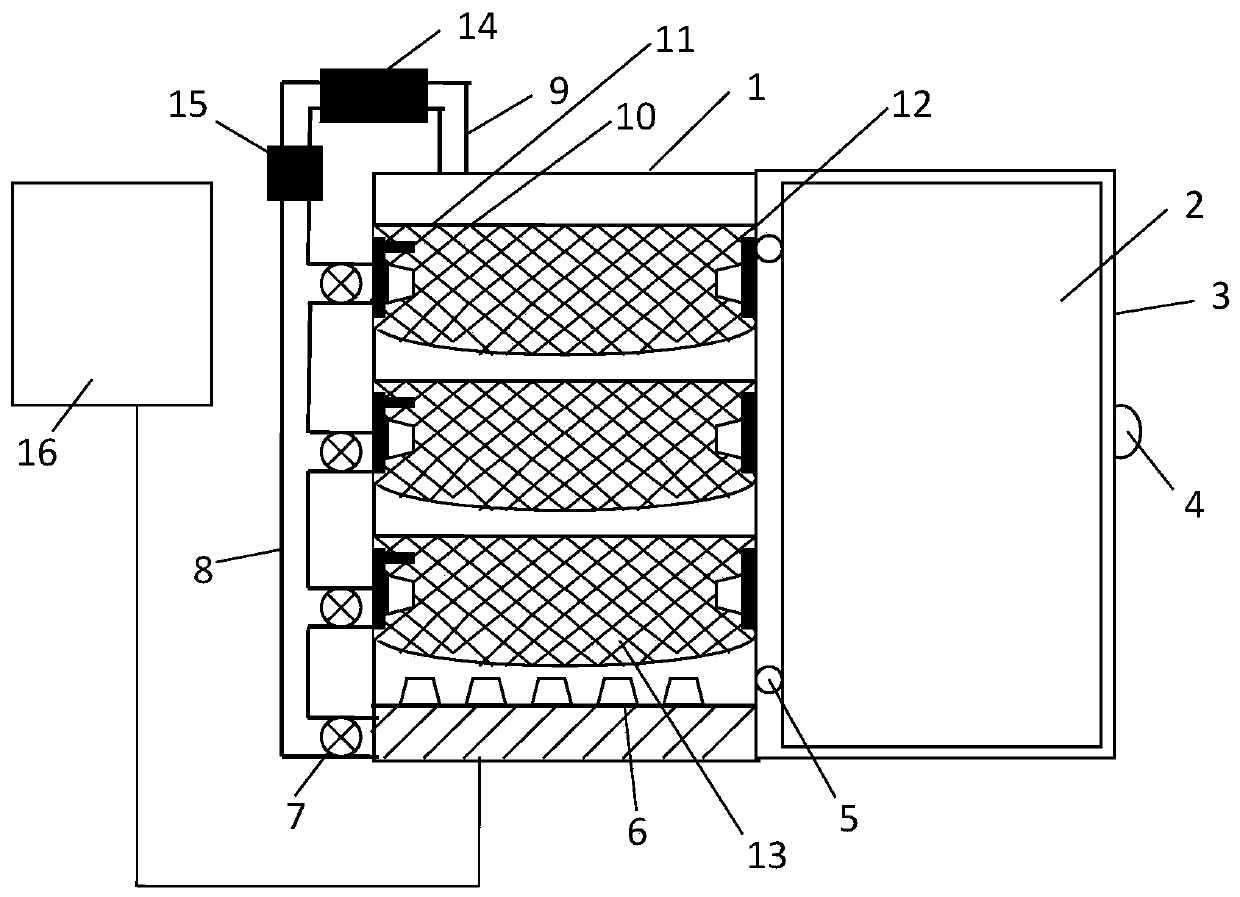

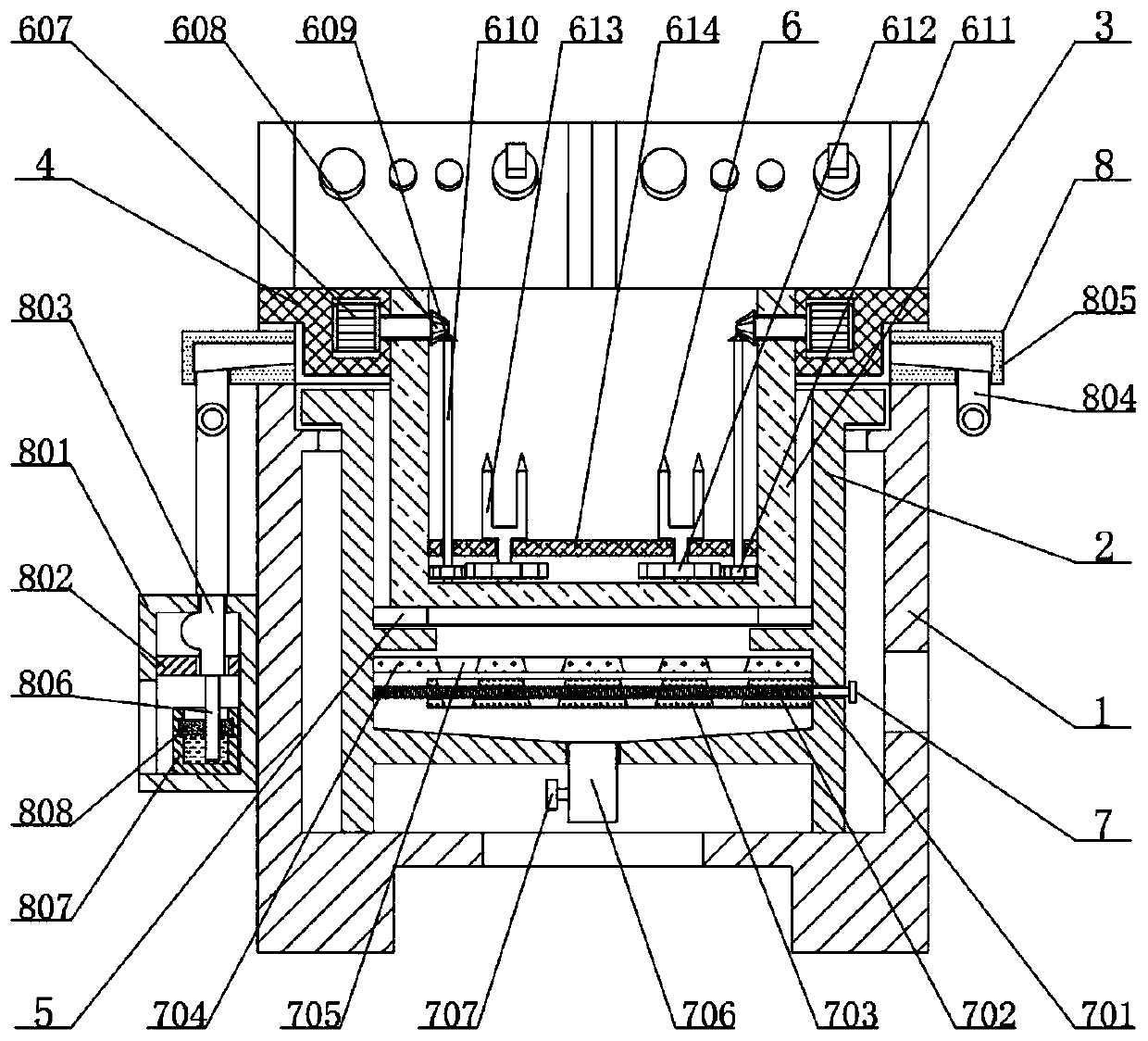

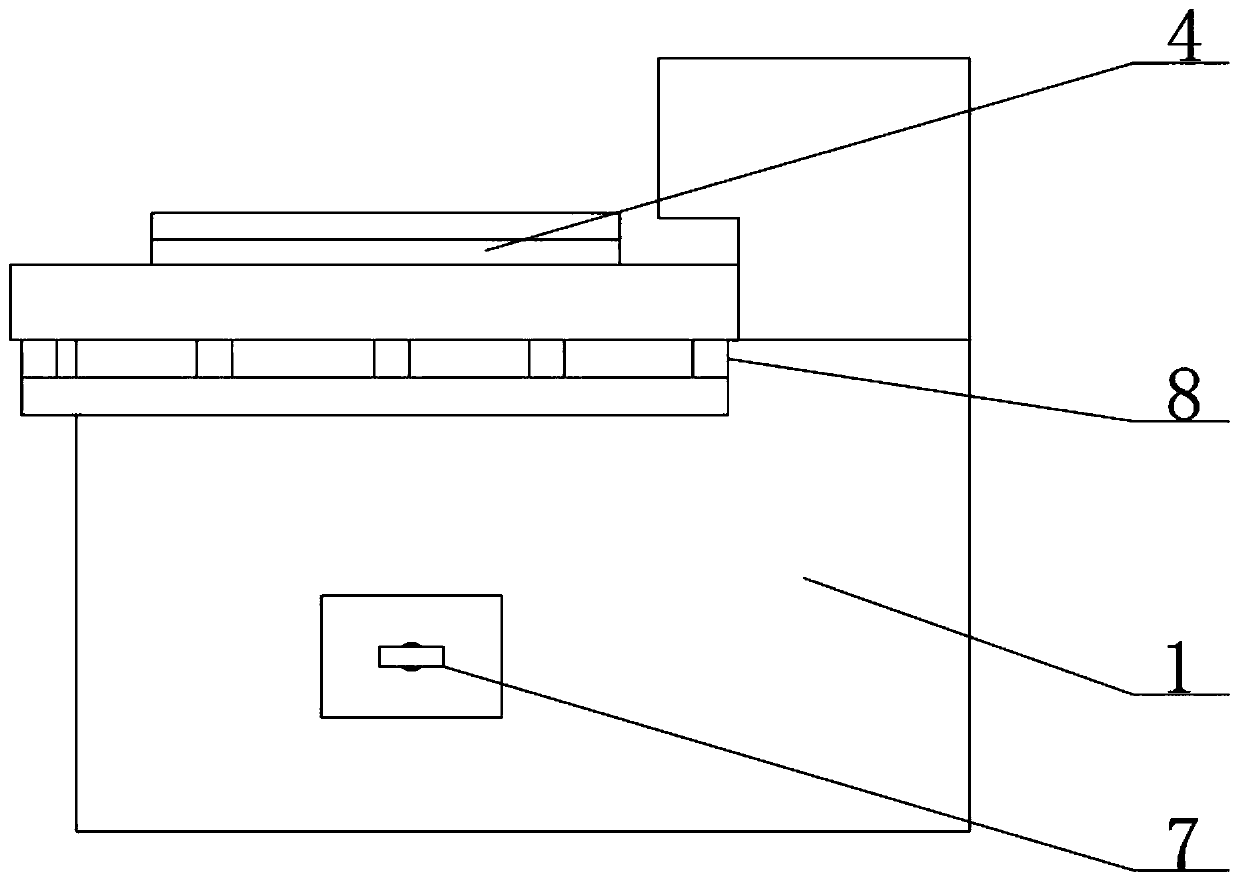

Low-temperature deep frying device and method for deep frying food

ActiveCN104170903ARealize automatic oil fillingReal-time detection of temperatureOil/fat bakingDeep fryingEngineering

The invention provides a low-temperature deep frying device and a method for deep frying food to be deep fried. The low-temperature deep frying device comprises a deep frying groove, a material inlet / outlet door, an oil inlet / outlet, a heating tube arranged in the deep drying groove, a vacuum device for making the interior of the deep frying groove reach a vacuum state, a deep frying main air cylinder for adjusting the deep frying position, a material inlet / outlet door air cylinder a for driving the material inlet / outlet door to descend or ascend, a material inlet / outlet door air cylinder b for driving the material inlet / outlet door to be opened or closed, an oil level meter for detecting the height of the oil level, a temperature gauge for detecting the oil temperature, and an electromagnetic valve used for receiving an oil temperature signal and controlling the deep frying main air cylinder, the material inlet / outlet door air cylinder a and the material inlet / outlet door air cylinder b, wherein the material inlet / outlet door and the oil inlet / outlet are communicated with the deep frying groove. According to the low-temperature deep frying device, the amount of oil injected into the deep frying groove and the temperature of the oil in the deep frying groove can be known through the oil level meter and the temperature gauge; through the deep frying main air cylinder, the position of a material inlet basket can be adjusted so that articles, to be deep fried, in the material inlet basket can make full contact with the oil.

Owner:BEIJING KAIDA HENGYE AGRI TECH DEV

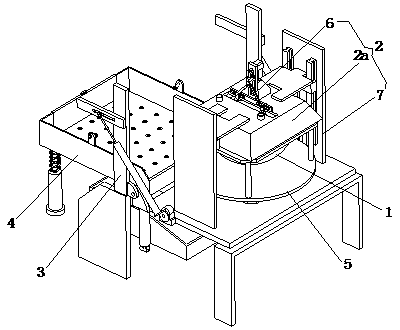

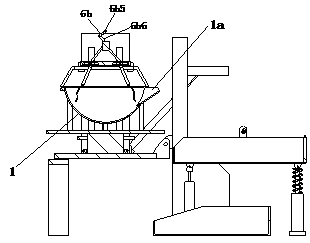

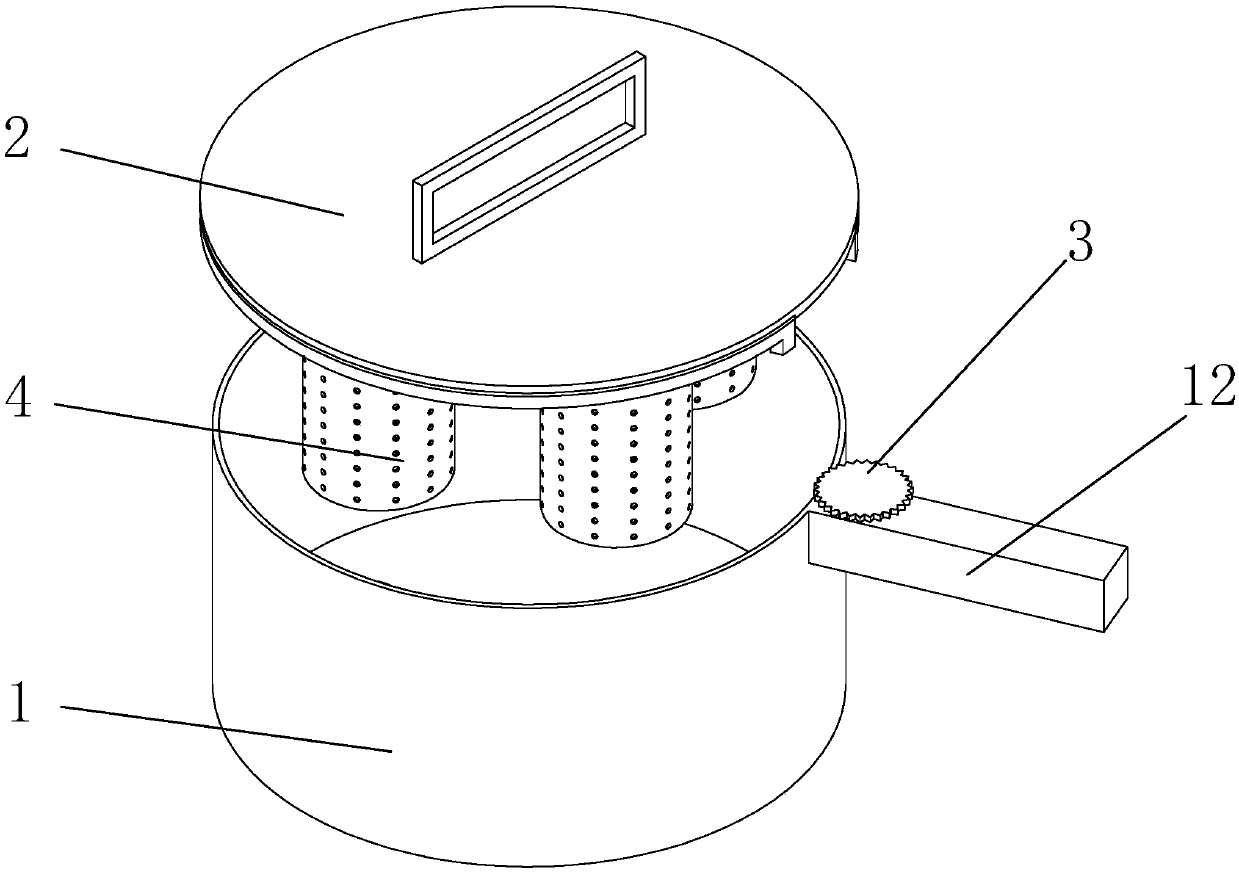

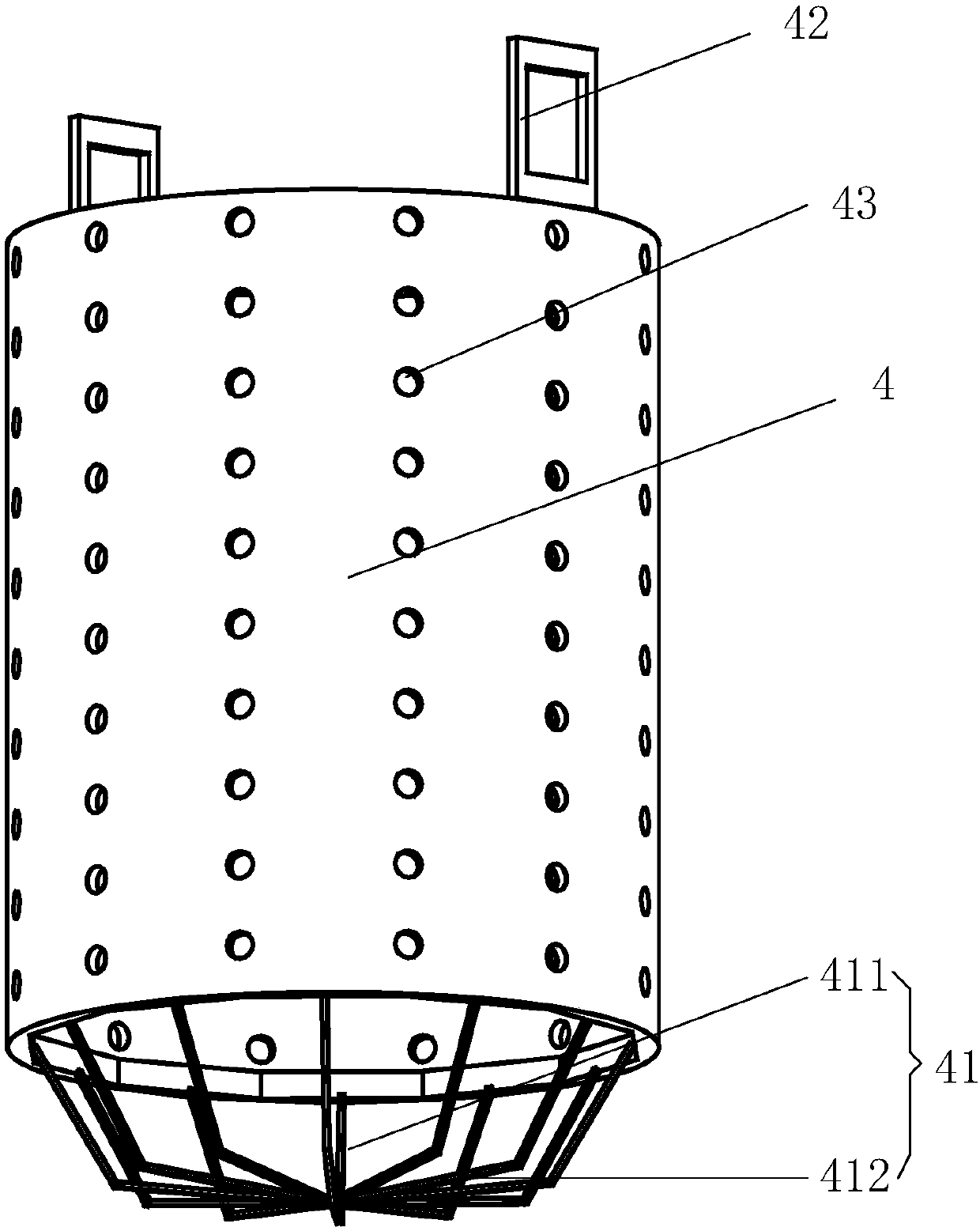

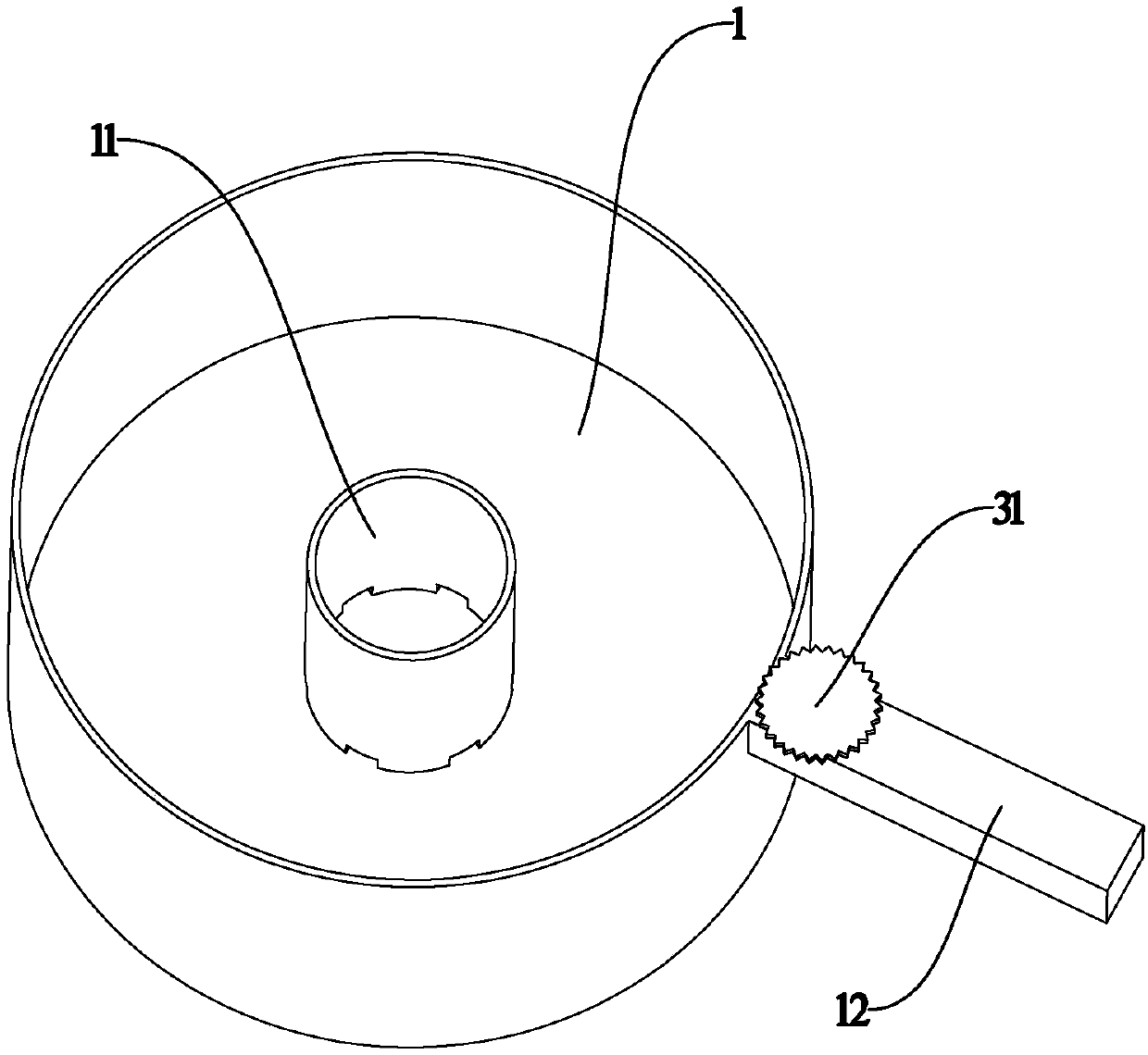

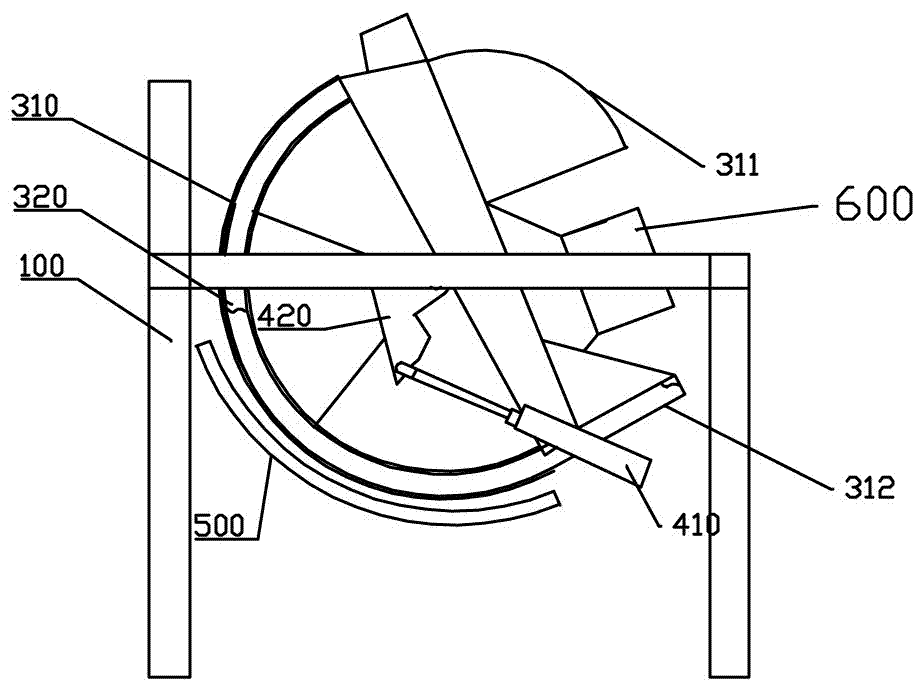

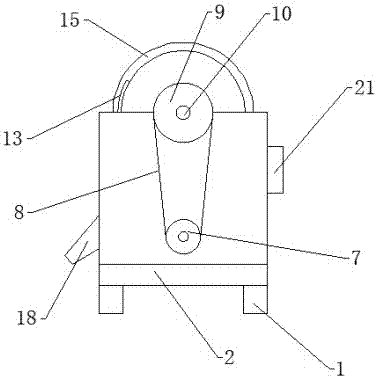

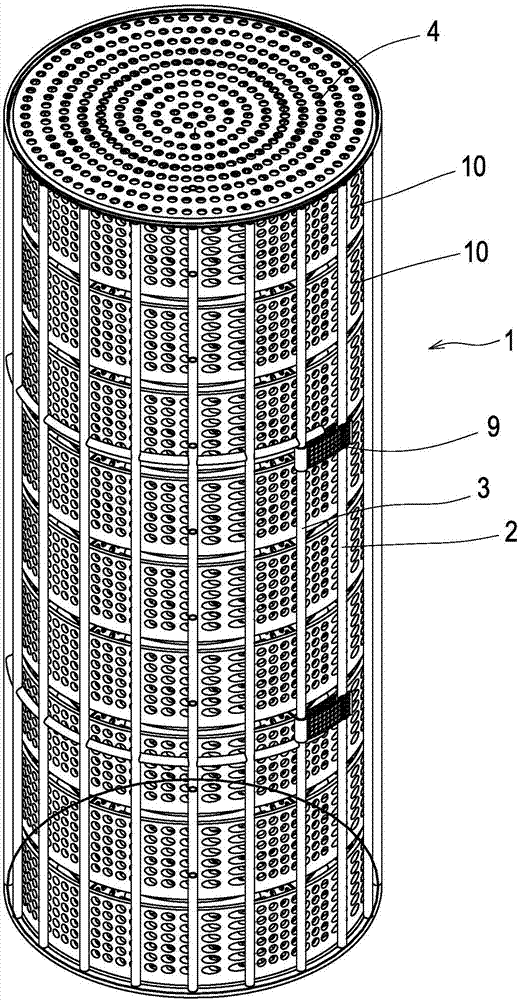

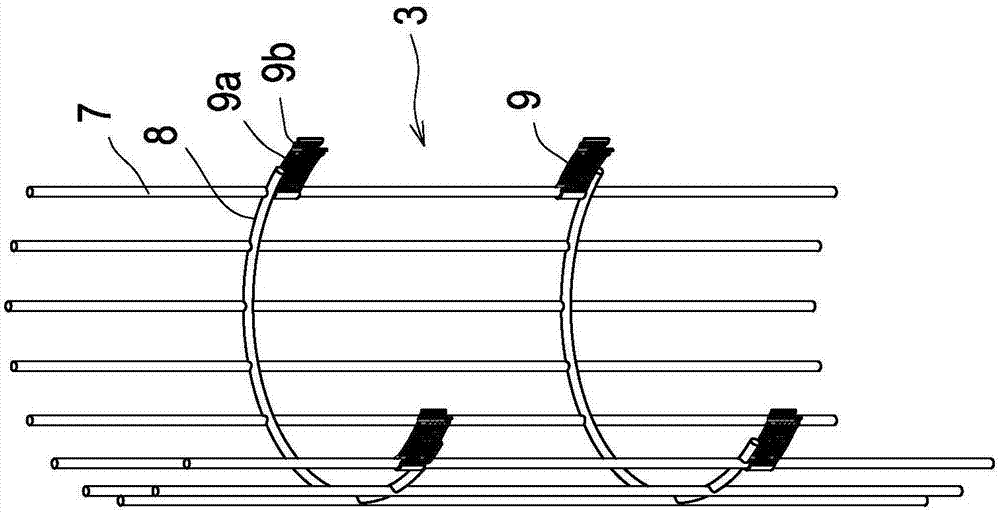

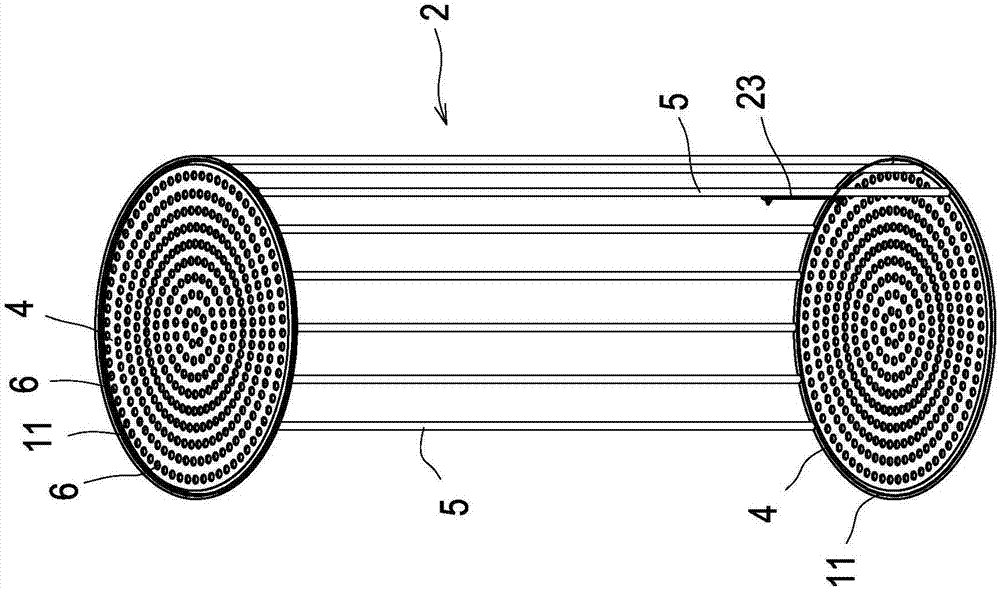

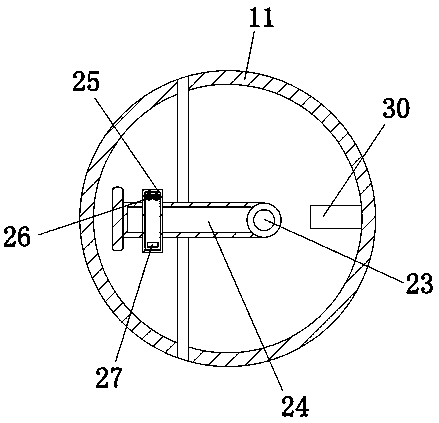

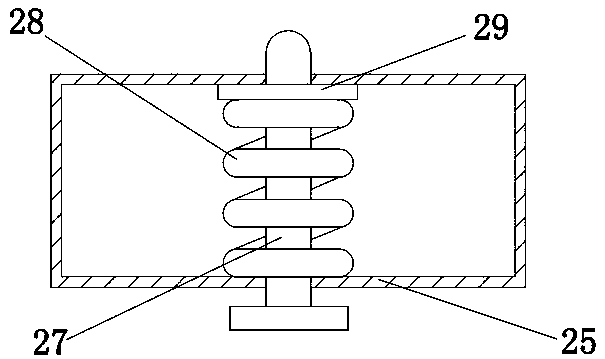

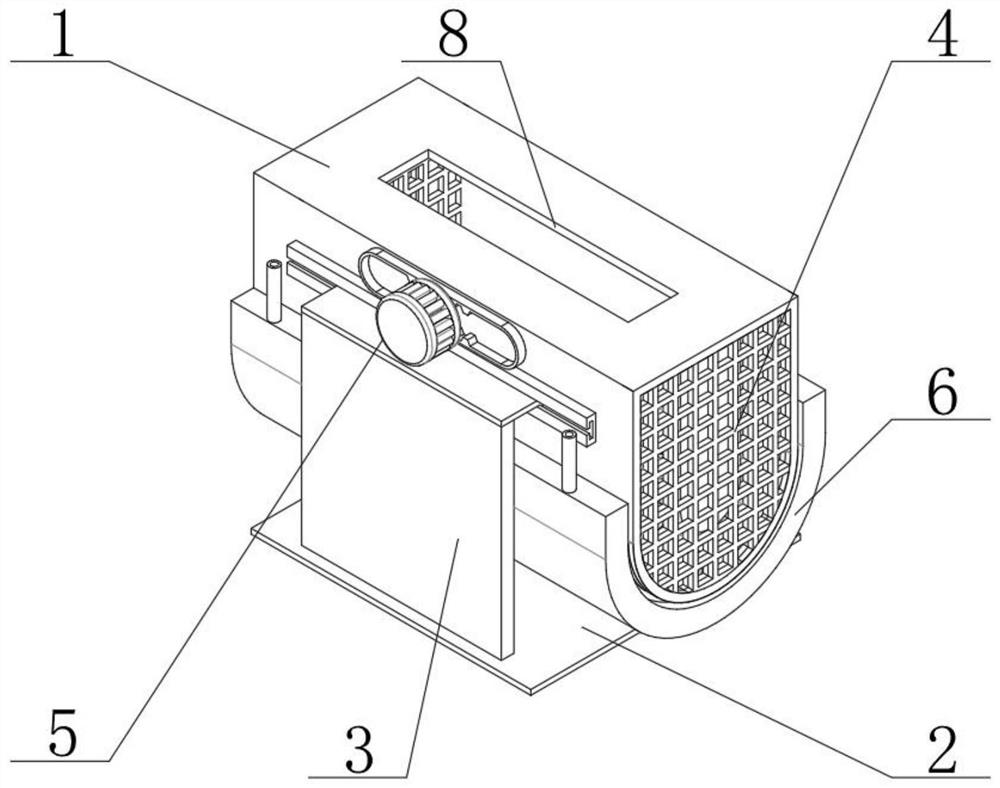

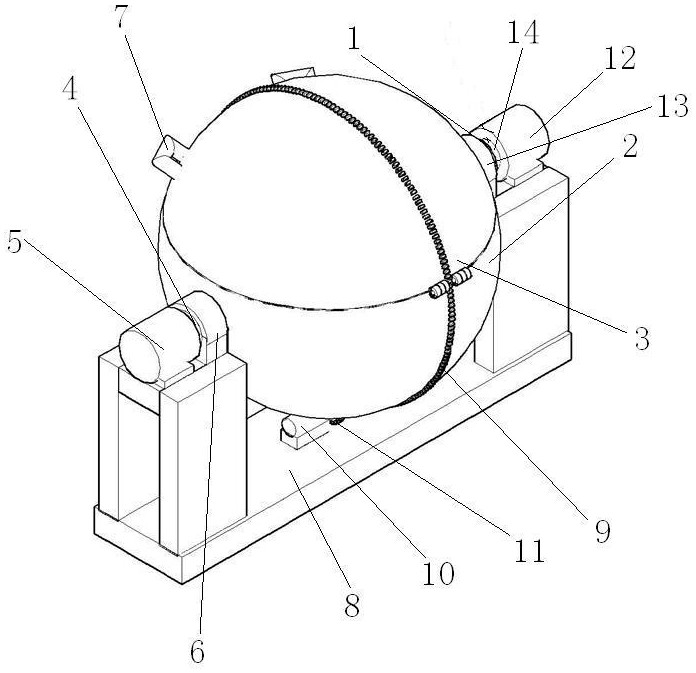

Tea frying device with screening function

ActiveCN109675787AFried evenlyNot easy to go too farSievingPre-extraction tea treatmentSoftware engineeringTea leaf

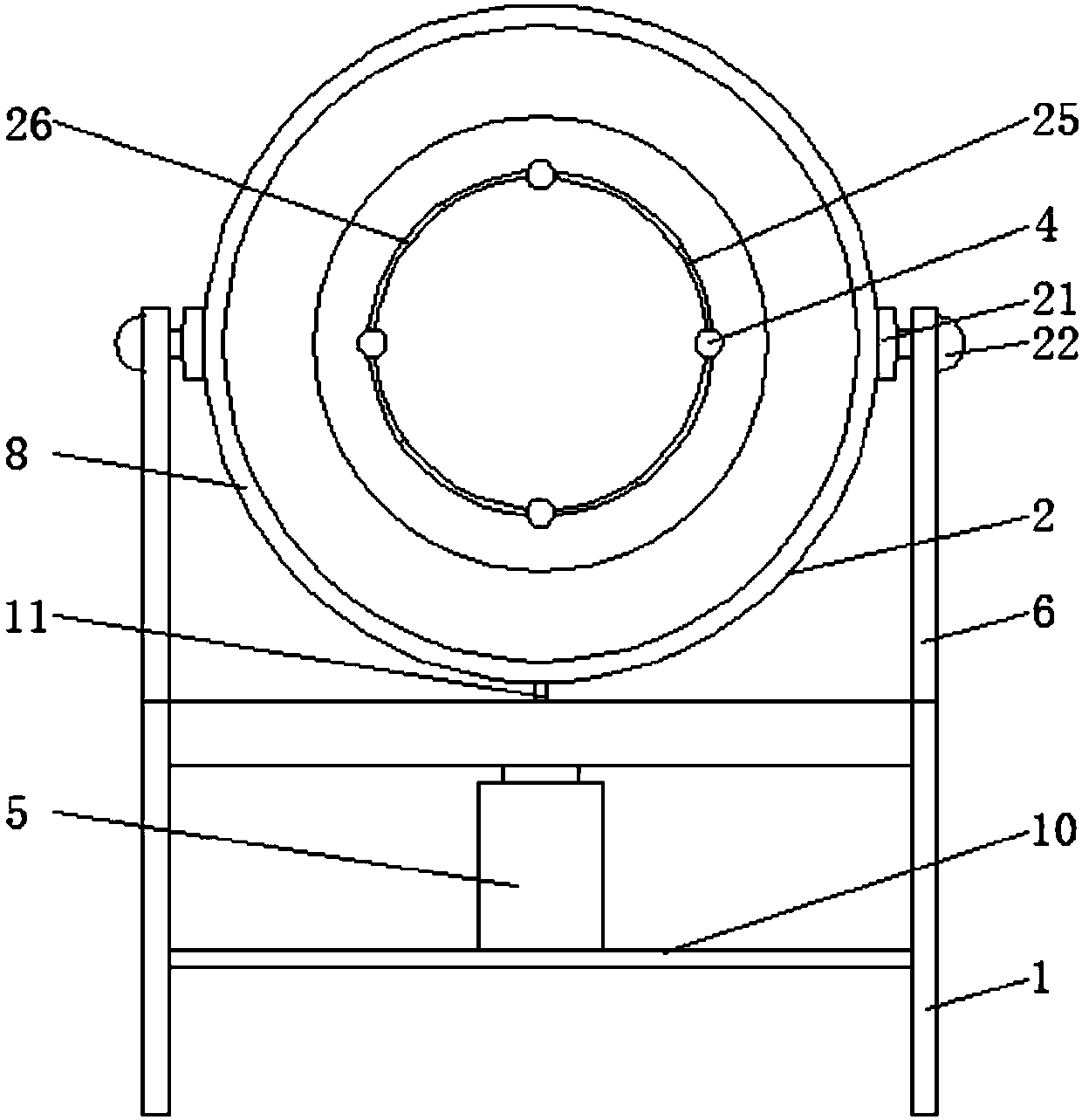

The invention discloses a tea frying device with a screening function. The tea frying device with the screening function comprises an installation structure. The installation structure is provided with a stir-frying assembly and a screening assembly. The installation structure comprises an installation base. The installation base is provided with two installation supports. The upper ends of the installation supports are provided with installation platforms. One installation platform is provided with an installation rod, and the other installation platform is provided with a supporting air cylinder. The stir-frying device comprises a stir-frying cylinder. The exteriors of the two ends of the stir-frying cylinder are sleeved with installation rings. Bearings are arranged between the installation rings and the stir-frying cylinders. One installation ring is hinged to the upper end of the installation rod, and the other installation ring is hinged to the output end of the supporting air cylinder. The exterior of the stir-frying cylinder is fixedly provided with a stir-frying gear. The installation base is provided with a stir-frying motor. An output shaft of the stir-frying motor is provided with a stir-frying motor gear. The screening function is achieved, the situation that tea is broken during stir-frying can be avoided, the tea forming quality is guaranteed, meanwhile, the teacan be automatically put into and taken out, and the labor cost is reduced.

Owner:宁强县千山茶业有限公司

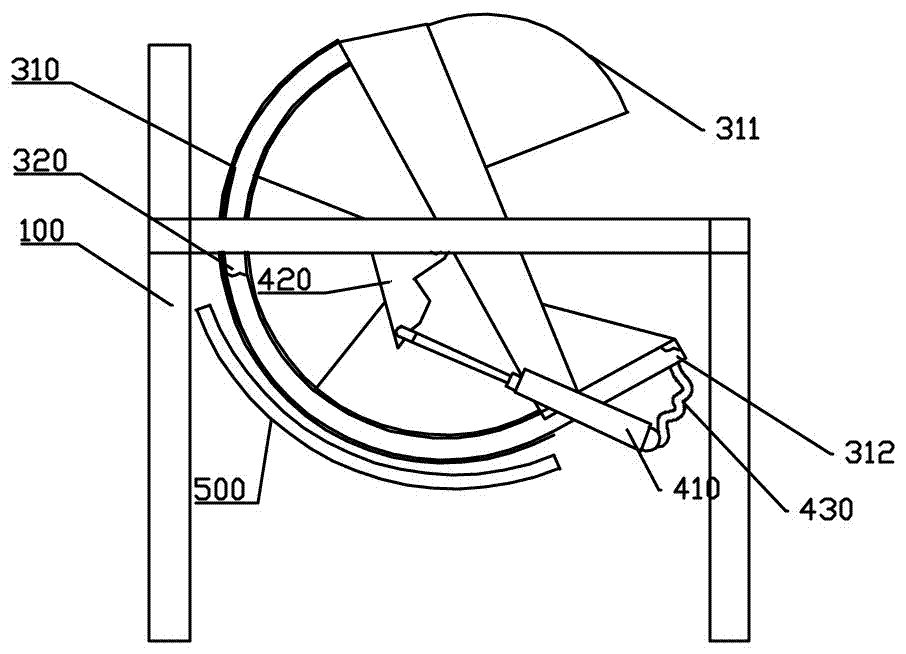

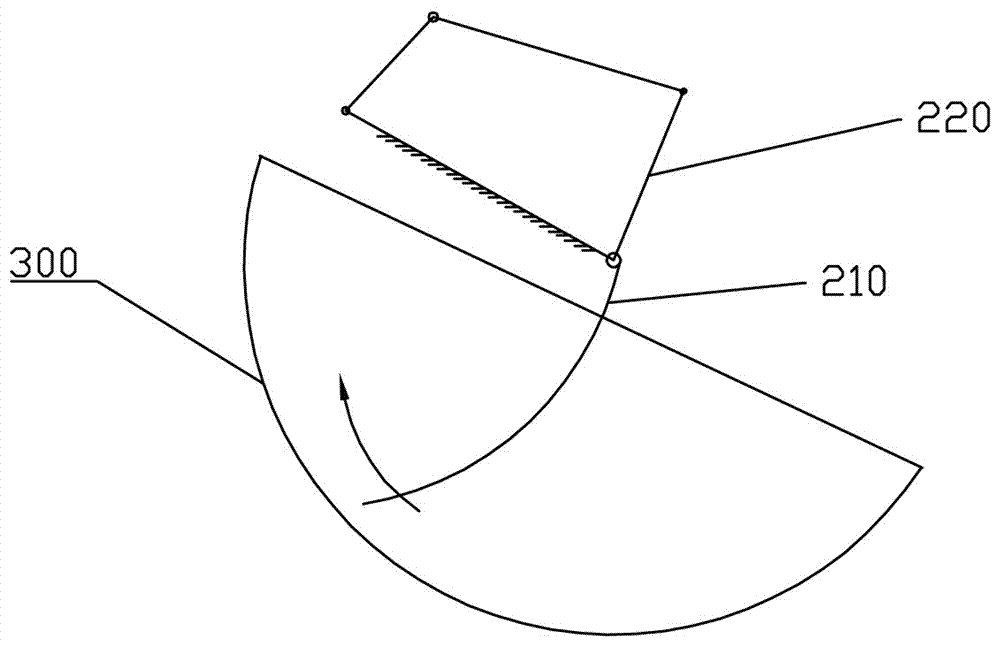

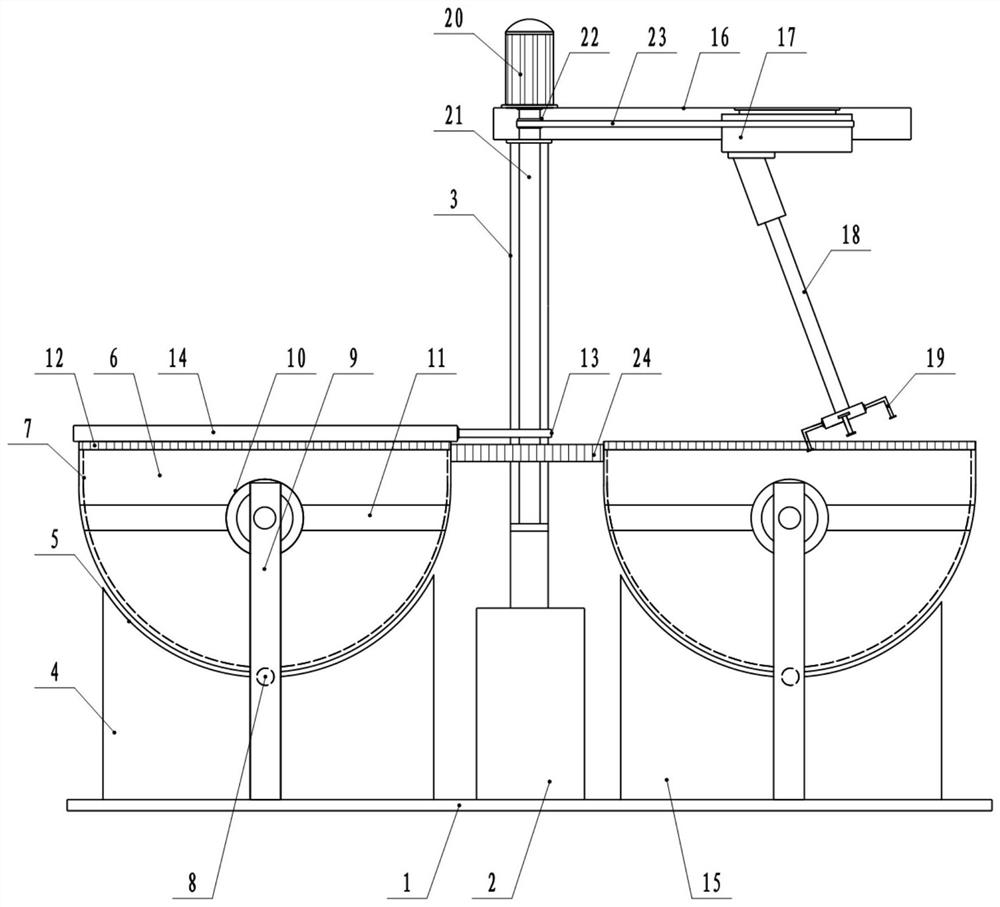

Chinese chestnut frying device

InactiveCN109497592APrevent fallingSolve the technical problems of automatic blankingSievingScreeningEngineeringFood processing

The invention discloses a Chinese chestnut frying device and belongs to the field of food processing equipment. The food processing equipment comprises a frying pan, a stir-frying mechanism, a blanking mechanism and an accessory screening mechanism. The bottom of the frying pan is provided with a slewing mechanism. The frying pan is a semi-circular structure and is provided with a discharge nozzlewhich is communicated with the inside of the frying pan. A heater is arranged on the sidewall of the frying pan. The stir-frying mechanism comprises an anti-drop pot cover, a stirring-up module and alifting module. The stir-frying mechanism is used for stir-frying Chinese chestnut and accessories in the frying pan and can avoid Chinese chestnut or accessories from dropping. Through the blankingmechanism, the stirring-up operation of the frying pan can be automatically performed, and Chinese chestnut in the frying pan can be dumped into a shaking box. In addition, accessories can be screenedout of a mixture of Chinese chestnut and accessories through the accessory screening mechanism without the need of manual screening of workers, and the screening efficiency is high.

Owner:BOZHOU UNIV

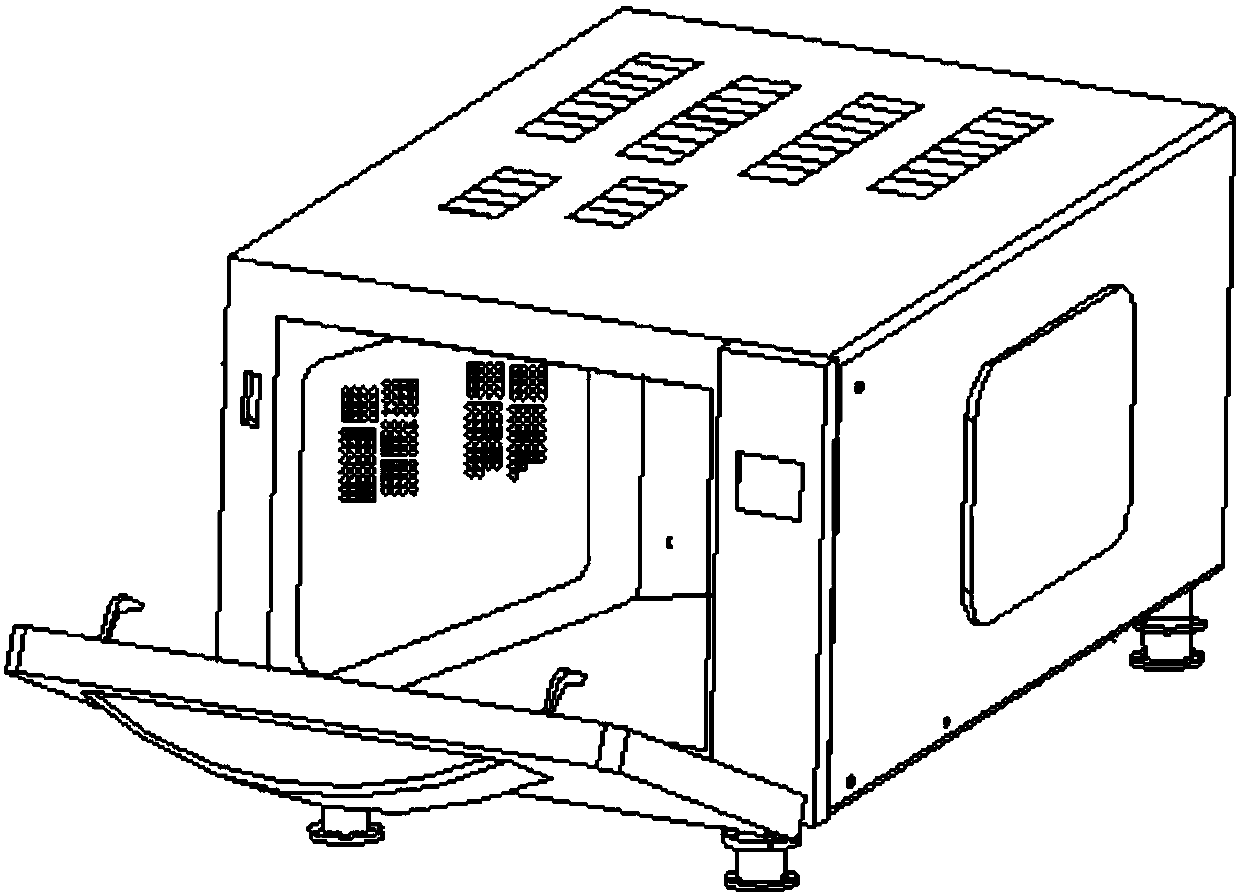

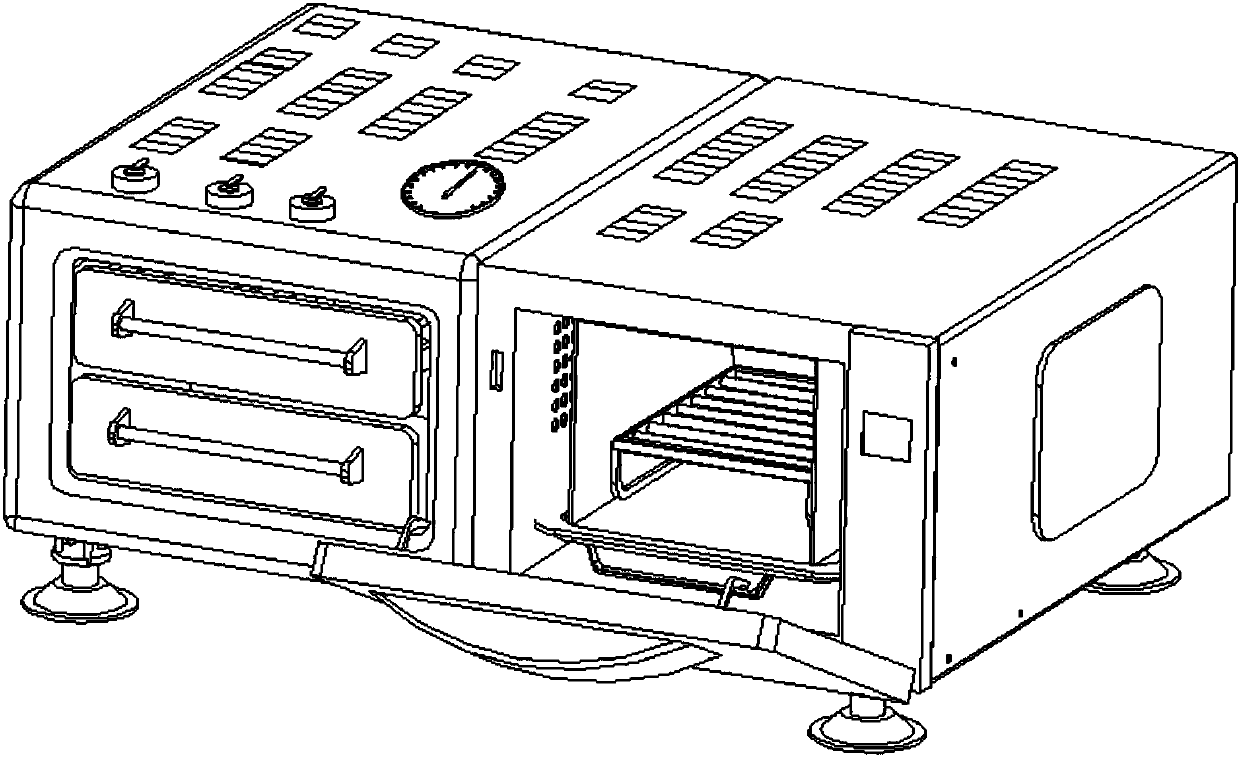

Double door kitchen electric oven with temperature display and displacement prevention functions

InactiveCN107559904ASimple structureImprove performanceDoors for stoves/rangesDomestic stoves or rangesMicrowave ovenEngineering

A double door kitchen electric oven with temperature display and displacement prevention functions comprises a displacement prevention device, a gas frying device, a duplex metal thermometer, a microwave oven body and an oven body. The microwave oven body is fixedly connected with the oven body, and the bottom of the microwave oven body and the bottom of the oven body are each provided with two first supporting feet. The gas frying device is arranged in the microwave oven body. The upper surface of the microwave oven body and the upper surface of the oven body are both provided with louvers. The displacement prevention device comprises the first supporting feet and at least one bowl-shaped suction cup. One end of the outer circle of each bowl-shaped suction cup is provided with a tongue piece used for preventing the situation that the microwave oven body is attracted too firmly so that the microwave oven body cannot be moved. The bowl-shaped suction cups are independently arranged at the bottom of the microwave oven body and the bottom of the oven body or arranged under the supporting feet. The double door kitchen electric oven adopts the overall design of double doors, and is simple and reasonable in structure, reliable in performance, convenient to use, accurate in temperature induction, safe, reliable, high in attraction force, convenient and fast in machining production, low in cost and flexible to operate.

Owner:刘永昌

Tea seed oil pressing process

ActiveCN107650413AEasy to separateAffect the oil extraction effectFatty-oils/fats productionPressesOil processingSpiral blade

The invention discloses a tea seed oil pressing process, and relates to the field of oil processing. Particularly, a tea seed oil pressing device is adopted for pressing. The tea seed oil pressing device comprises a seat body, an oil barrel fixed to the seat body, a rotary body rotating relative to the seat body, and a driving part, wherein the rotary body is arranged in the oil barrel and provided with a stir-frying cavity, an oil pressing cavity and a feeding cavity; the stir-frying cavity is located in the middle of the rotary body; the oil pressing cavity and the feeding cavity are distributed on the periphery of the stir-frying cavity, the feeding cavity is located under the oil pressing cavity and communicates with the oil pressing cavity; the lower portion of an oil pressing screw rod arranged in the oil pressing cavity is provided with a guide section located in the feeding cavity; the guide section is provided with a guide spiral blade; a residue outlet is formed in the upperportion of the feeding cavity; the rotary body is provided with an oil outlet communicating with the oil pressing cavity and the oil barrel; a feeding channel enabling the feeding cavity and the stir-frying cavity to communicate is arranged at the bottom of the stir-frying cavity; and a feeding valve is arranged in the feeding channel. When the rotary body rotates, the oil pressing screw rod rotates relative to the rotary body, oil is pressed, and meanwhile the oil is discharged under the action of centrifugal force.

Owner:贵州南方嘉木食品有限公司

Method for improving flavor of hotpot condiment

The invention relates to the field of food processing, and discloses a method for improving the flavor of a hotpot condiment. The method comprises the following steps of: S1, preparing materials, wherein the hotpot condiment comprises the following raw materials: 27-28 parts of beef tallow, 5-5.5 parts of vegetable oil, 15 parts of shortening, 10-11 parts of capsicum annuum, 3.5-4 parts of thick broad-bean sauce, 1.7-2 parts of common fenugreek seeds, 0.27-0.3 part of pepper, 8-9 parts of ginger and green onion, 0.4-0.5 part of clove, 0.4-0.5 part of costus root, 0.4-0.5 part of cinnamon, 0.4-0.5 part of anise, 0.4-0.5 part of ligusticum chuanxiong hort, 0.4-0.5 part of kaempferiae, 0.4-0.5 part of radix angelicae, 0.4-0.5 part of fructus amomi, 0.4-0.5 part of amomum tsao-ko, 0.4-0.5 partof amomum cardamomum and 0.4-0.5 part of rhizoma nardostachyos; S2, pretreating the raw materials, namely grinding the clove, the costus root, the cinnamon, the anise, the ligusticum chuanxiong hortand the rhizoma kaempferiae into particles with the granularity of 10 meshes, and grinding the radix angelicae, the fructus amomi, the amomum tsao-ko, the amomum cardamomum and the rhizoma nardostachyos into particles with the granularity of 20 meshes; S3, soaking, namely soaking the ground raw materials in water; and S4, frying the materials, namely frying the materials at the temperature of 100-110 DEG C for 40 minutes. According to the method disclosed by the invention, the problem that spices are slow in flavor in the hotpot condiment boiling process in the prior art is solved, and the flavor of the hotpot condiment is improved.

Owner:CHONGQING DEZHUANG AGRI PROD DEV CO LTD

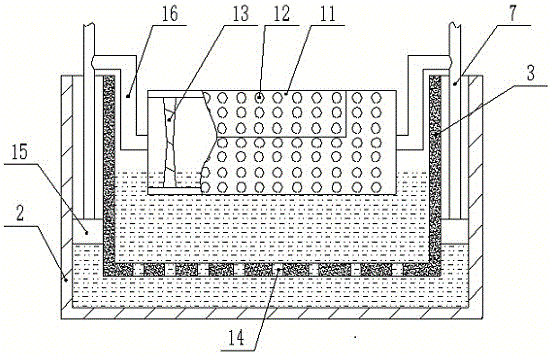

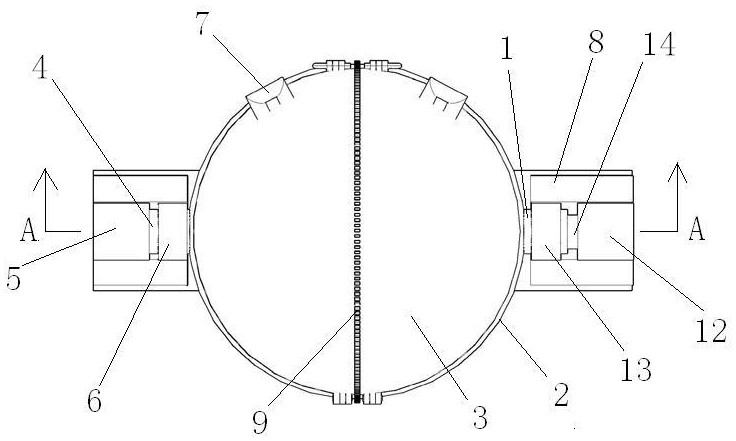

Odd taste broad bean deep-frying device

InactiveCN106797977ALow boiling pointIncrease oil temperatureOven air-treatment devicesOil/fat bakingDeep fryingEngineering

The invention relates to the technical field of food production and processing, in particular to an odd taste broad bean deep-frying device. The device comprises a heater and a vacuum pump, wherein a heating tank is arranged in the heater, a sealing cap is installed on the heating tank, a liner is installed in the heating tank, a cavity is reserved between the liner and heating tank, and a plurality of oil holes are formed in the liner; the two sides of the heating tank are both provided with a piston cylinder communicated with the cavity, pistons are installed in the piston cylinders, the pistons are connected to hollow piston rods in a hinged mode, the piston rods hinged to the sealing cover and one piston rod is communicated with an air inlet pipe provided with a relief valve, and the other piston rod is communicated with an air intake pipe; the open end of the air intake pipe is connected to the vacuum pump, a deep-frying drum is installed in the liner, fan blades are installed inside the deep-frying drum, oil-immersion holes are formed in the deep-frying drum, the two ends of the deep-frying drum are connected to tube shafts respectively, and the tube shafts are communicated with the piston rods respectively. According to the scheme, flowing air is guaranteed in the device in the vacuumizing process, accordingly the temperature of the colza oil is lowered, and oil fume generated in the device is brought away by the flowing air.

Owner:CHONGQING XINTAIFA FOOD

Frying cooking method

InactiveCN1589109AQuality improvementFried evenlyFood preparationDeep fat fryersAdditive ingredientEngineering

Owner:THE NISSHIN OILLIO GRP LTD

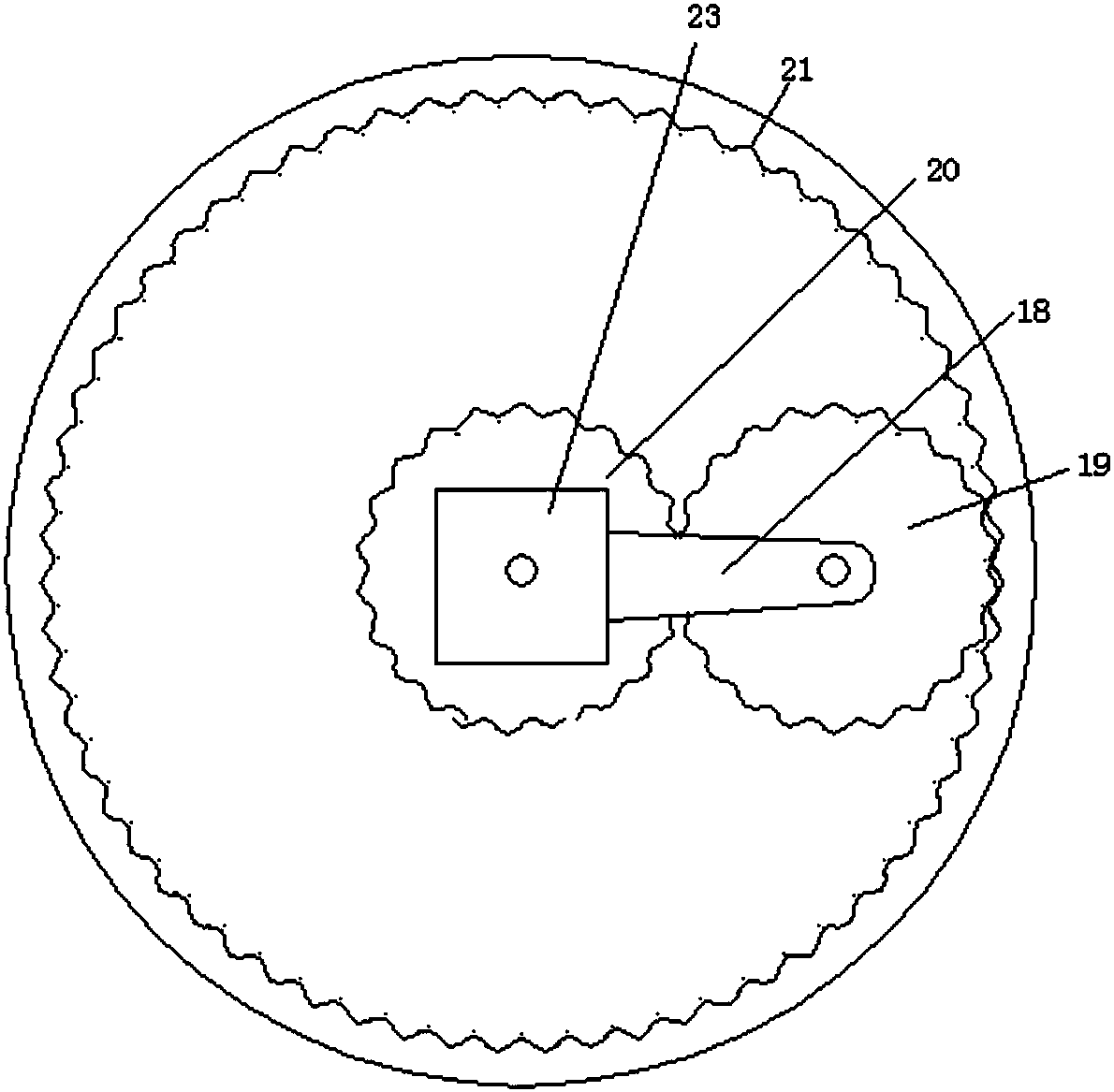

Deep frying pan preventing adhesion of food

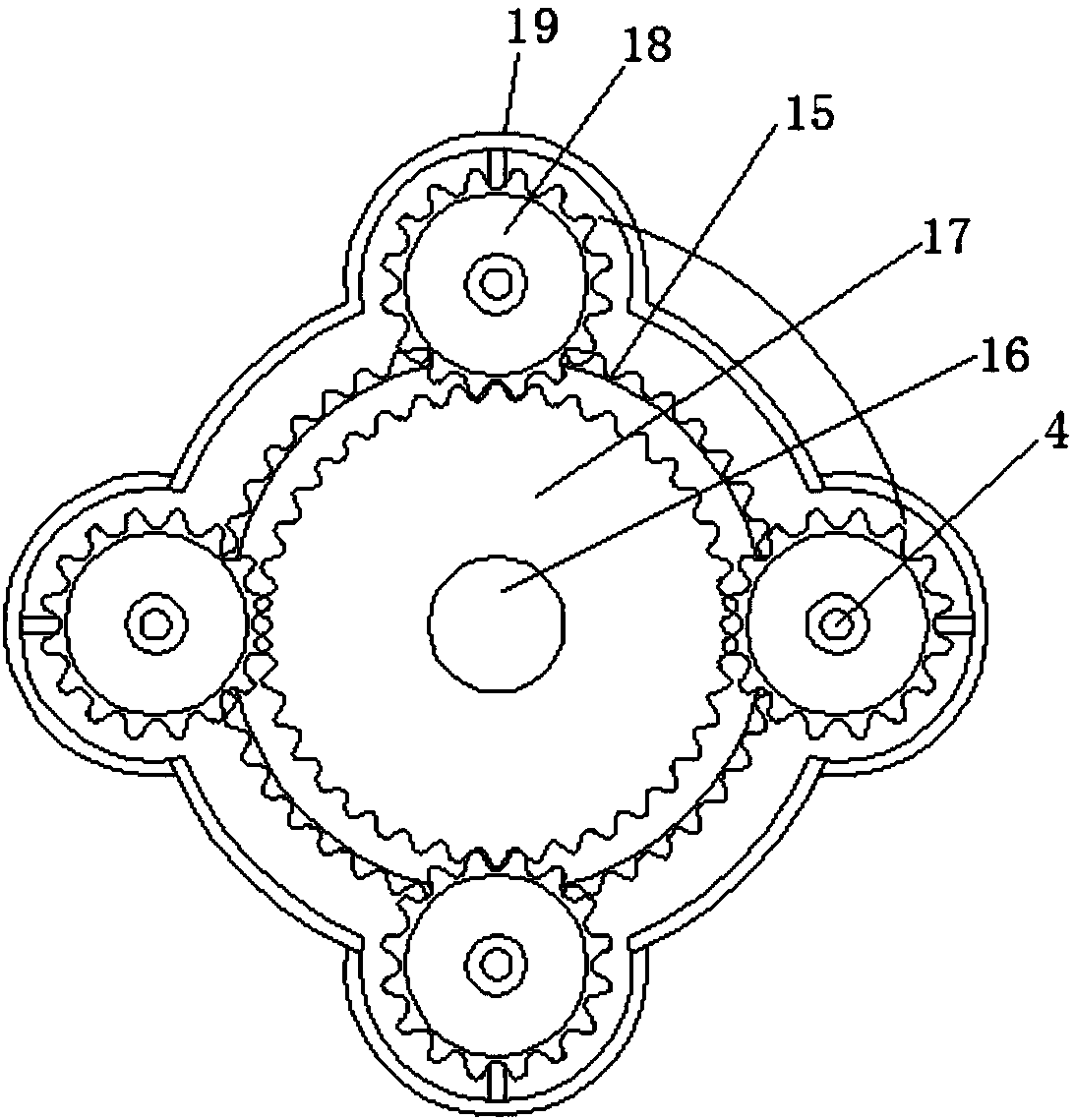

The invention provides a deep frying pan preventing adhesion of food. The deep frying pan preventing the adhesion of the food is characterized by comprising a pan body and a pan cover, wherein the pancover covers on the pan body, a driving mechanism is arranged outside the pan body; the pan cover comprises a gear ring, driven wheels and a driving wheel; the gear ring comprises outer ring gear teeth and inner ring gear teeth, the driving mechanism is connected with the outer ring gear teeth in a transmission manner, the driving wheel is arranged at the center of the gear ring, multiple drivenwheels are symmetrically arranged outside the driving wheel, the driven wheels are respectively meshed with the inner ring gear teeth and the driving wheel; one surface, close to the inner side of thepan body, of the driven wheels is connected with a frying cage; and a connecting rod mechanism which can move up and down is arranged at the bottom of the frying cage. The deep frying pan preventingthe adhesion of the food can prevent the food from being adhered when the food is put into the pan body.

Owner:湖北襄梦食品有限公司

Tea leaf stir-frying machine

InactiveCN107751428AFried evenlyAvoid fryingPre-extraction tea treatmentAgricultural engineeringMotor shaft

The invention discloses a tea frying machine, which comprises a base, a frying barrel, a frying device, a frying rod and a motor. Support rods are respectively fixedly connected to both sides of the top center of the base, and the two sides of the frying barrel The side is movably connected to the support rod, the upper right end of the frying barrel is provided with a material inlet, and the left end is provided with a discharge port, the inside of the frying barrel is connected with an electric heating tube, and the frying device is set On the right side of the frying barrel. The present invention can solve the problem of extremely low efficiency and high labor intensity in the prior art of manual frying, and solves the problem that tea leaves are easily burnt and wasteful. The present invention is simple in structure and easy to use. Tube heating can prevent overheating, and through the turning of the frying rod, it can effectively prevent the scorching of tea leaves caused by long-term heating at the same place, and the frying device can make the roasted tea leaves more uniform, greatly Improve the frying quality of tea.

Owner:ANHUI SHITAI COUNTY XIHUANGSHAN TEA IND

Production method of fried bean sauce with three delicacies and shredded meat

The invention provides a production method of fried bean sauce with three delicacies and shredded meat characterized in, using chicken stuffing or shredded chicken, minced mushroom, flour paste and salted and fermented soya paste as main ingredients, unfreezing the chicken stuffing or shredded chicken under atmospheric temperature, charging water-loss reducer, anti-oxidizing agent and anti-agglomeration agent, frying in laminated pan, charging soup stock and thickening agent.

Owner:杨秀敏

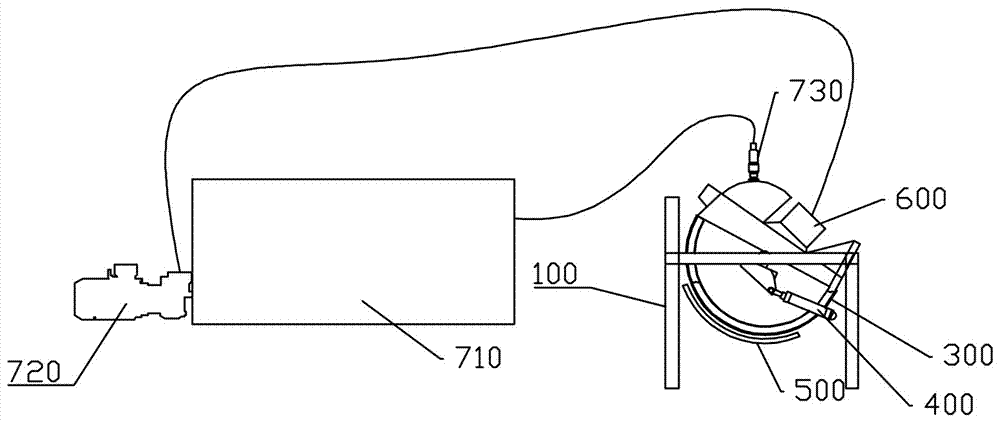

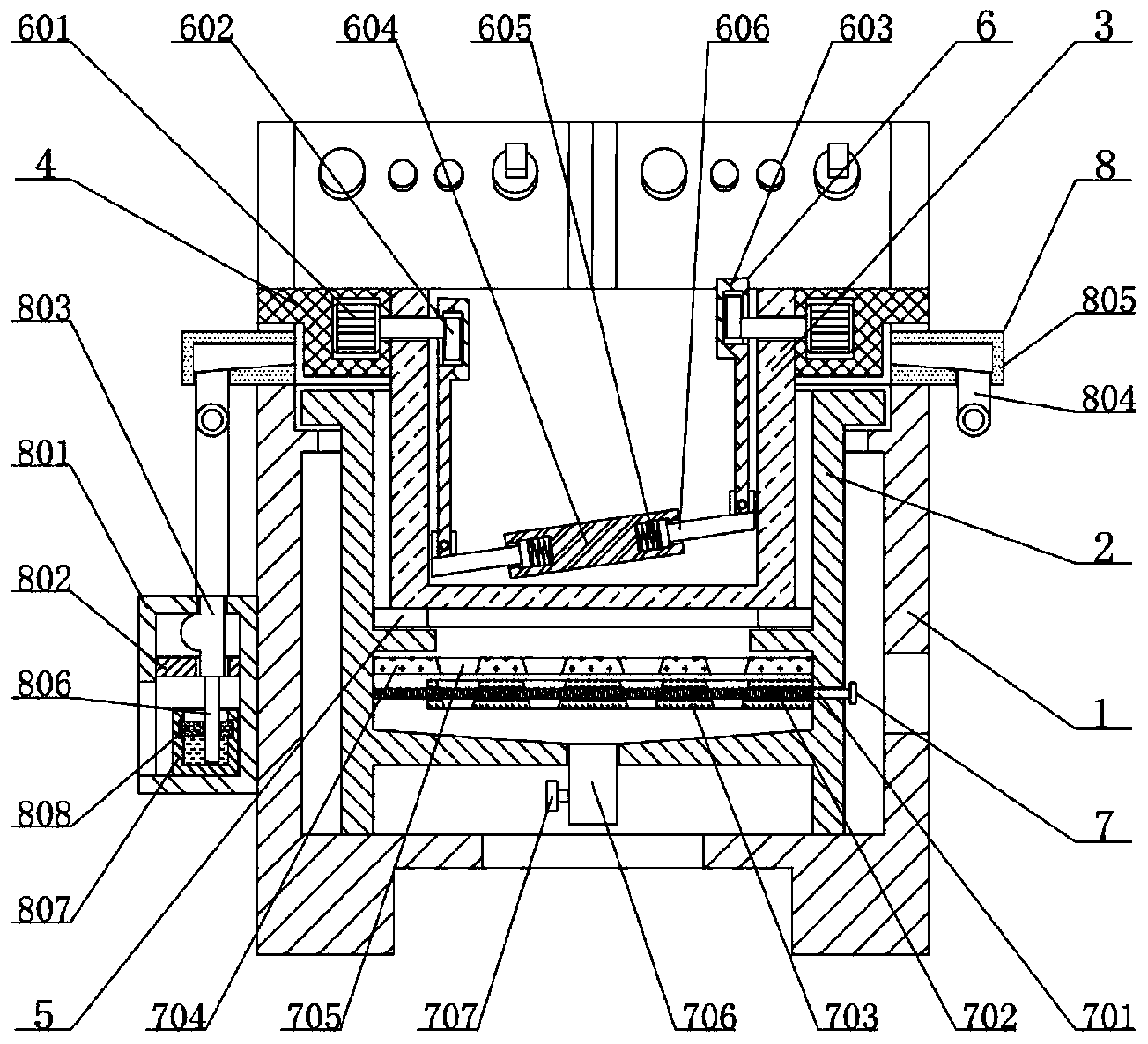

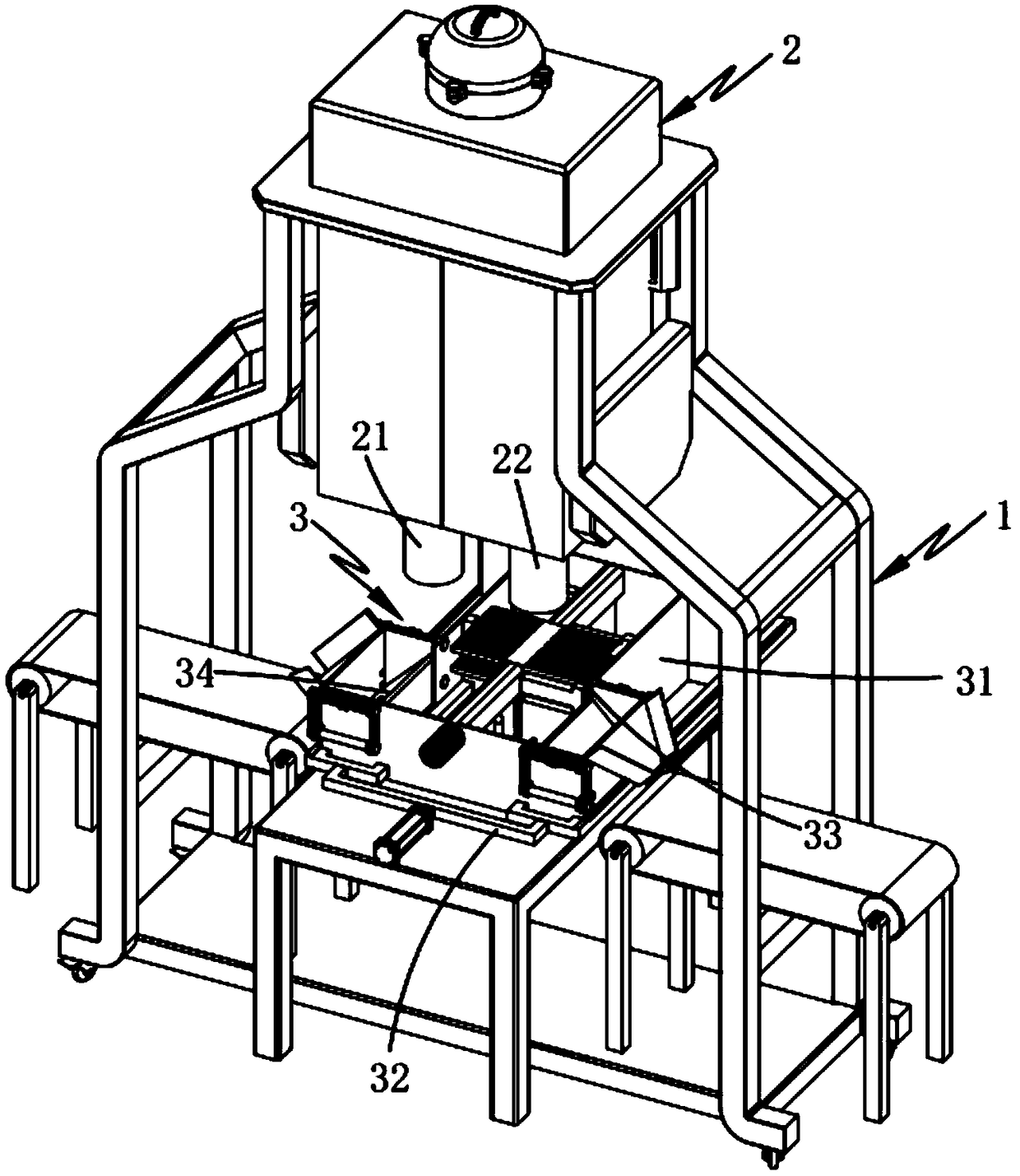

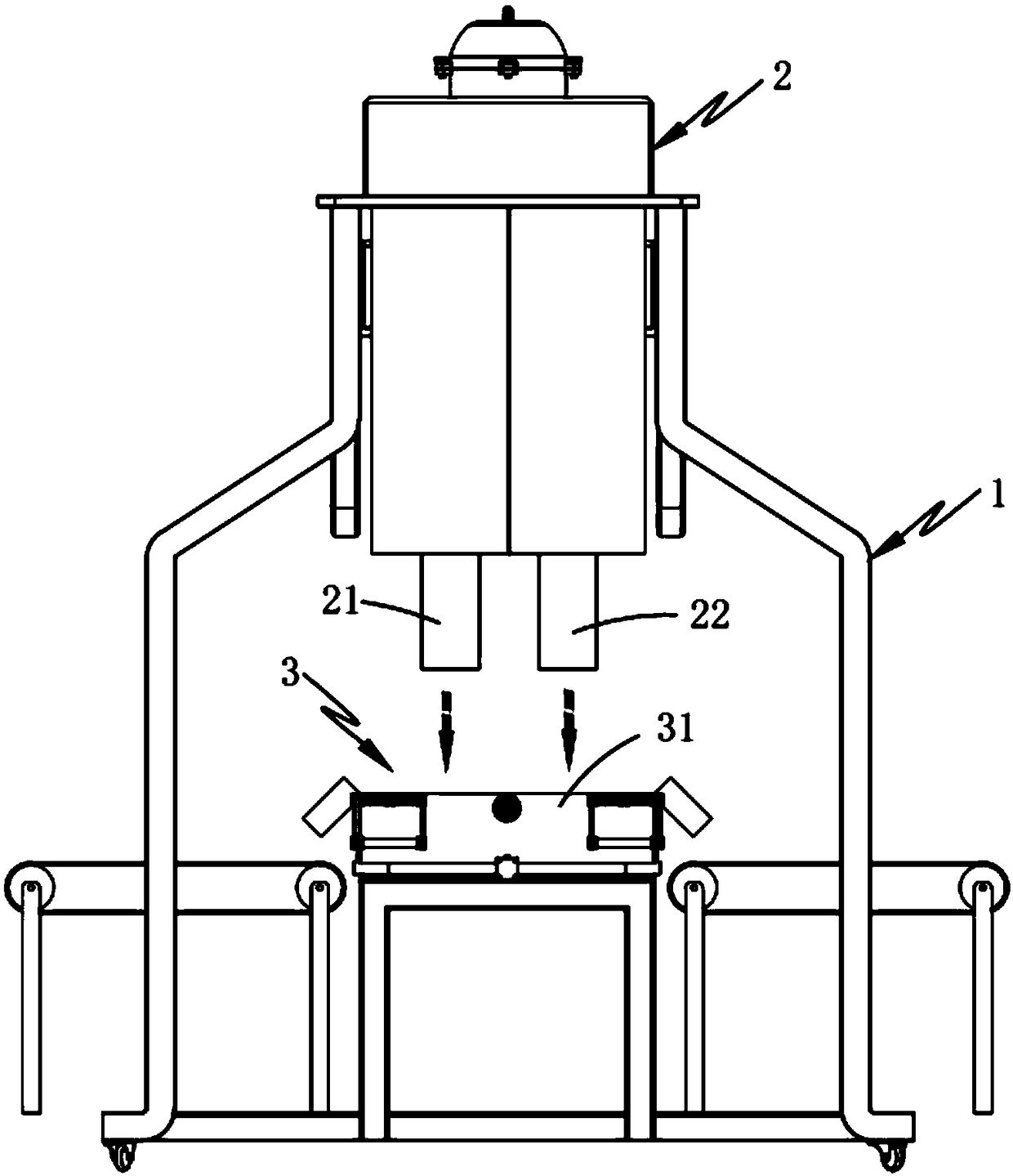

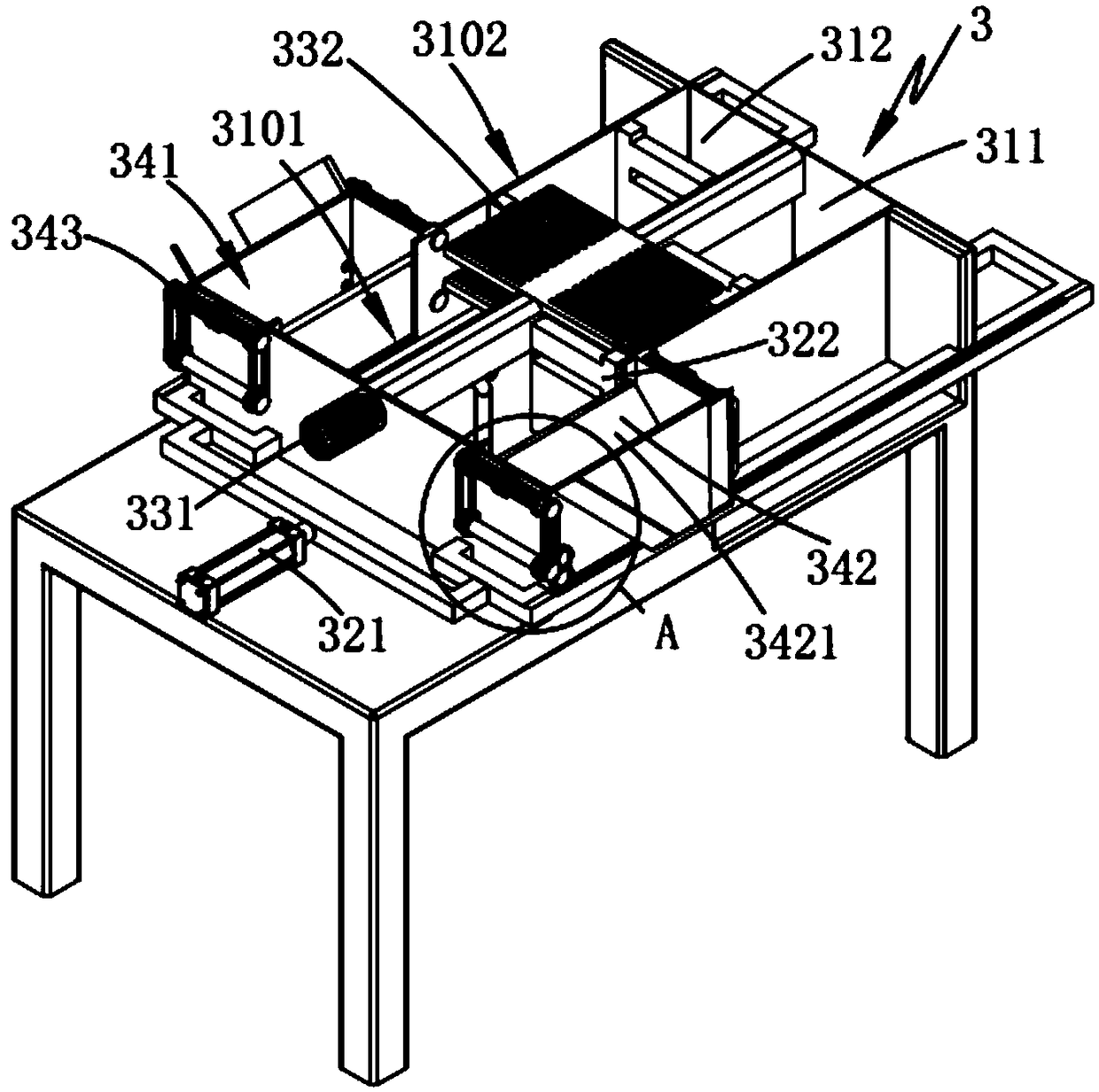

Method and device for stir-frying Chinese traditional medicine decoction pieces by hot air flow

ActiveCN109718108ASmooth flipAvoid local accumulationPharmaceutical product form changeMicrowave heatingMicrowaveEngineering

The invention discloses a method and device for stir-frying Chinese traditional medicine decoction pieces by hot air flow. The device includes an enclosed container, a bottom air inlet pipe, a sidewall air inlet pipe, an exhaust pipe, a circulating pipeline, microwave heating devices, mesh pots and booster pumps; The method includes the following steps: step one, putting stir-fried decoction pieces into the mesh pots with different apertures of the device according to dimensions; step two, starting the booster pumps after the circulating pipeline is heated, adjusting the power of the booster pumps, controlling flow velocity to make the flow velocity of the bottom air inlet pipe being 3-5 times of that of the sidewall air inlet pipe; step three, setting different temperatures during stir-frying according to different stir-frying requirements of stir-fried to yellow, stir-fried to brown and stir-fried to scorch, and starting the microwave heating devices or electrothermal tubes corresponding to the positions of the mesh pots to perform heat supplementing when the temperatures in the mesh pots are lower than required temperatures; and step four, taking out stir-fried traditional Chinese medicine decoction piece finished products from the mesh pots after stir-frying, and performing cooling and packaging. The method and device can enhance the quality and the preserving rates of effective components during the stir-frying of the traditional Chinese medicine decoction pieces.

Owner:湖南药圣堂中药科技有限公司

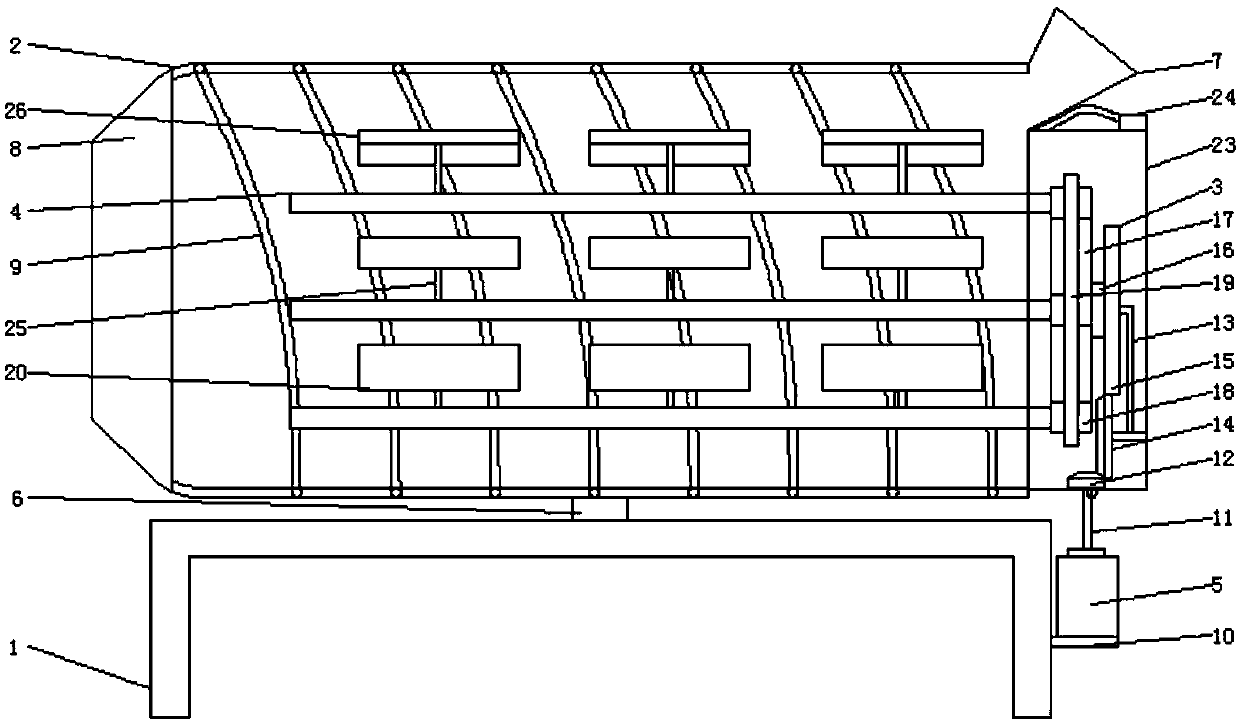

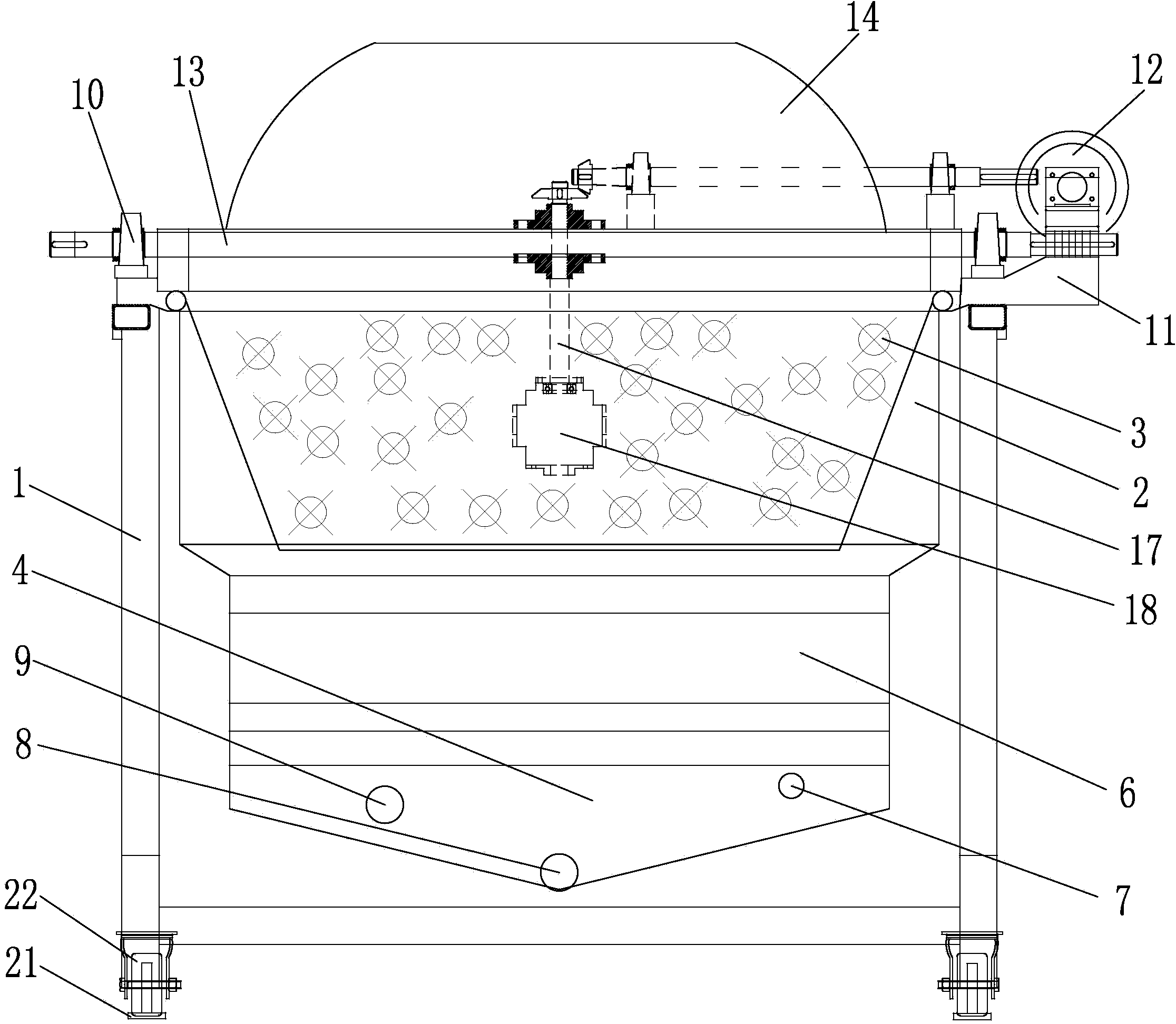

Full-automatic oil and water separation fryer

The invention discloses a full-automatic oil and water separation fryer. The full-automatic oil and water separation fryer comprises a frame, a pot, a frying basket, a cone and a heating tube. The pot is arranged in the frame, a square funnel is connected to the edge of the bottom of the pot, the heating tube is arranged in the portion of connection between the funnel and the pot, the cone is connected to a funnel opening in the bottom of the funnel, an oil draining tube, a dreg discharging tube and a sight glass are arranged on one side of the cone, a discharging motor is arranged on a discharging motor base, a discharging rotating shaft penetrates through a bearing pedestal, a gear is arranged at one end of the discharging rotating shaft and meshed with a gear on the discharging motor, the frying basket is connected to the discharging rotating shaft and located in the pot, and a frying stirring system is arranged on the frying basket. An oil and water separation mode is adopted for frying, dregs in oil settle into water and are discharged out through the dreg discharging tube, the dreg content in the oil obtained after frying is greatly reduced, the quality of the oil obtained after frying is improved, food can be stirred in the frying process and can be fried more evenly, and the quality of fried food can be better improved.

Owner:诸城市金河田机械厂

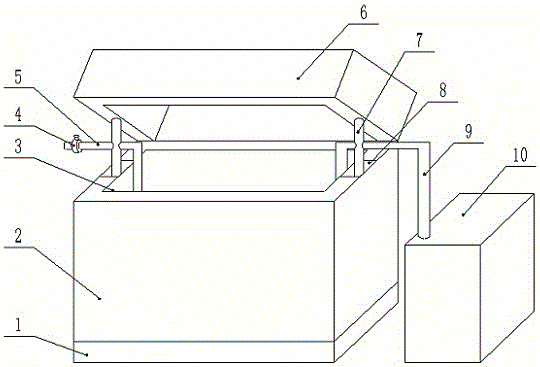

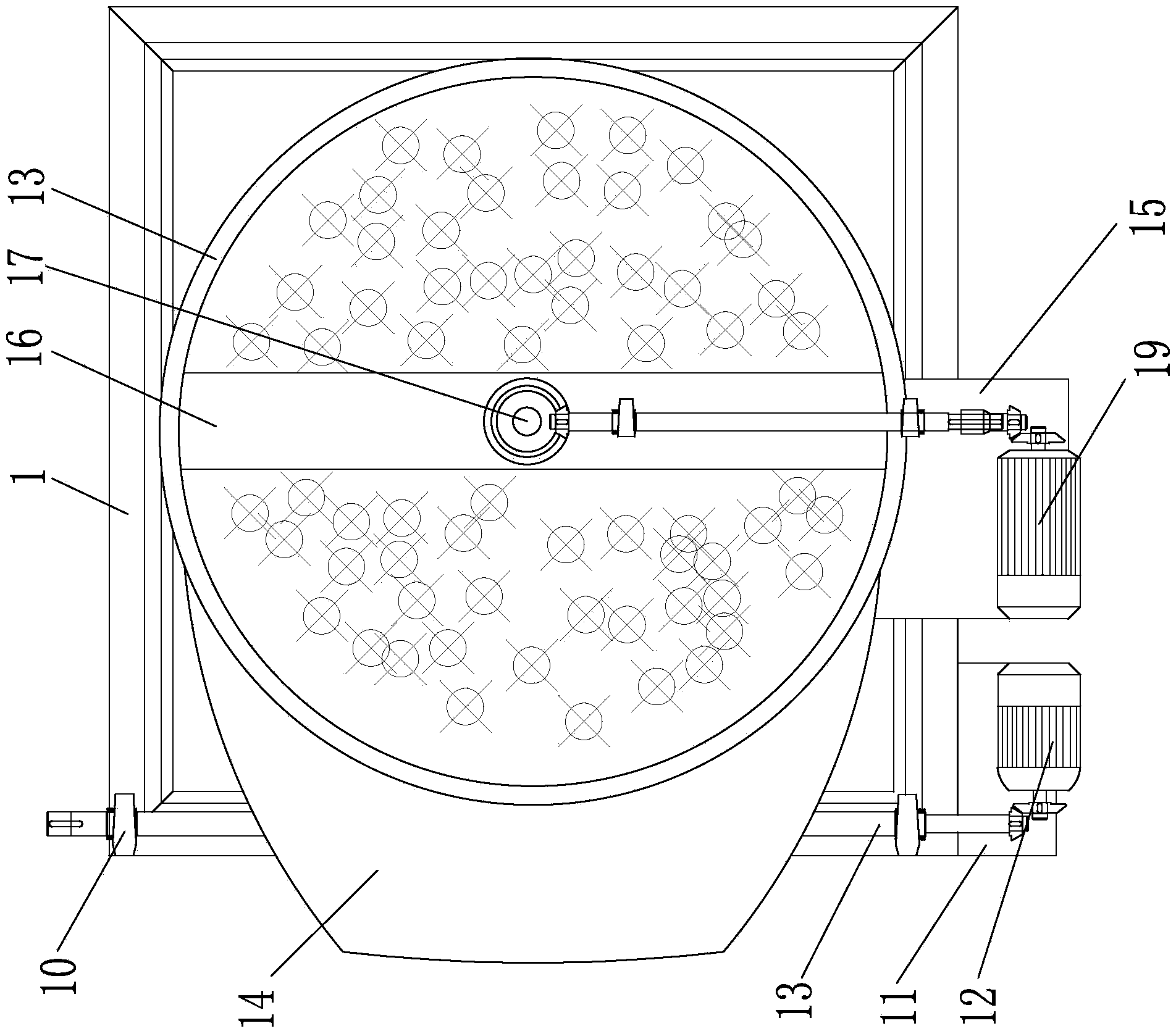

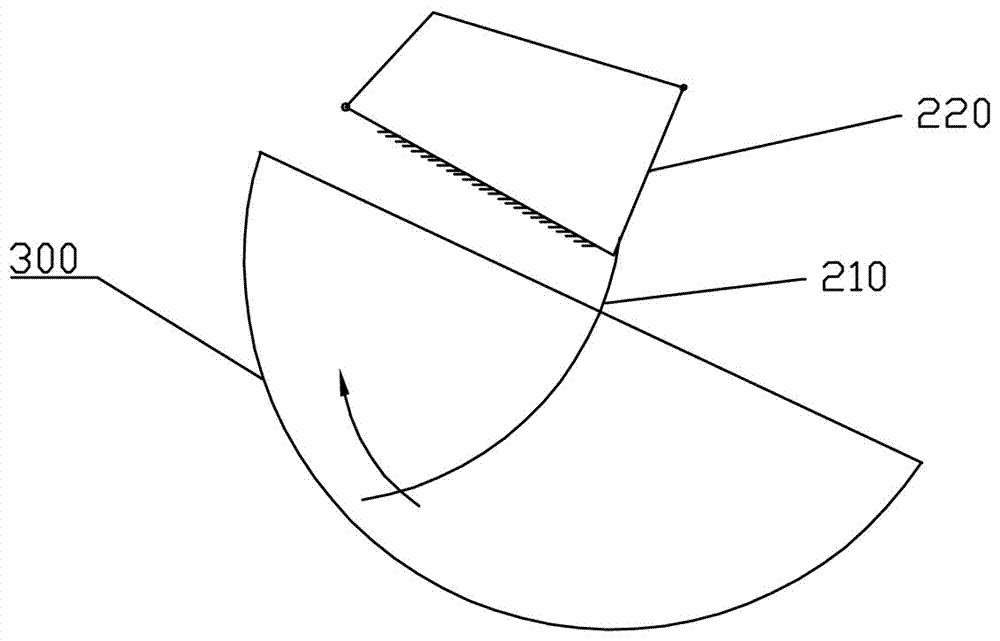

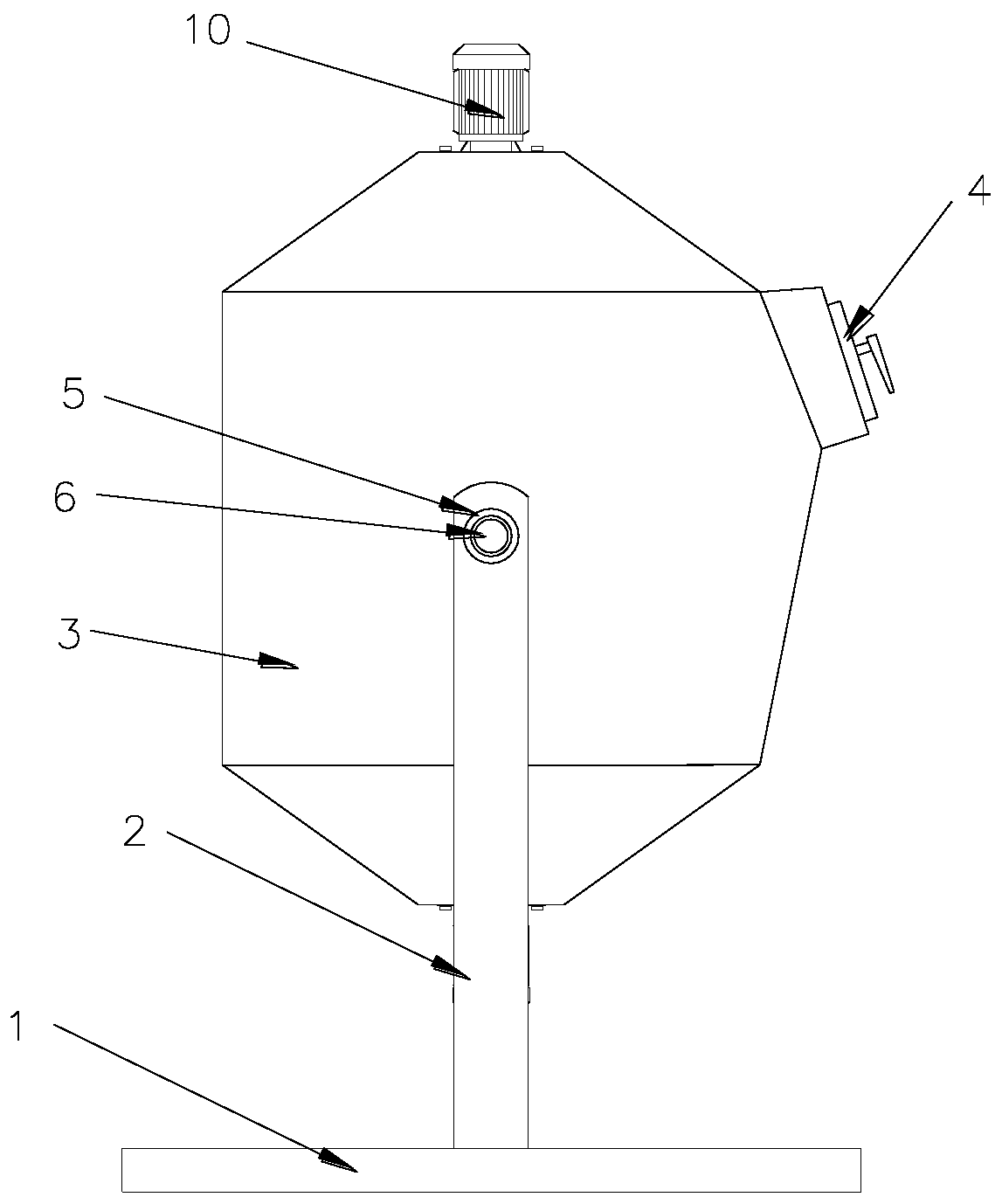

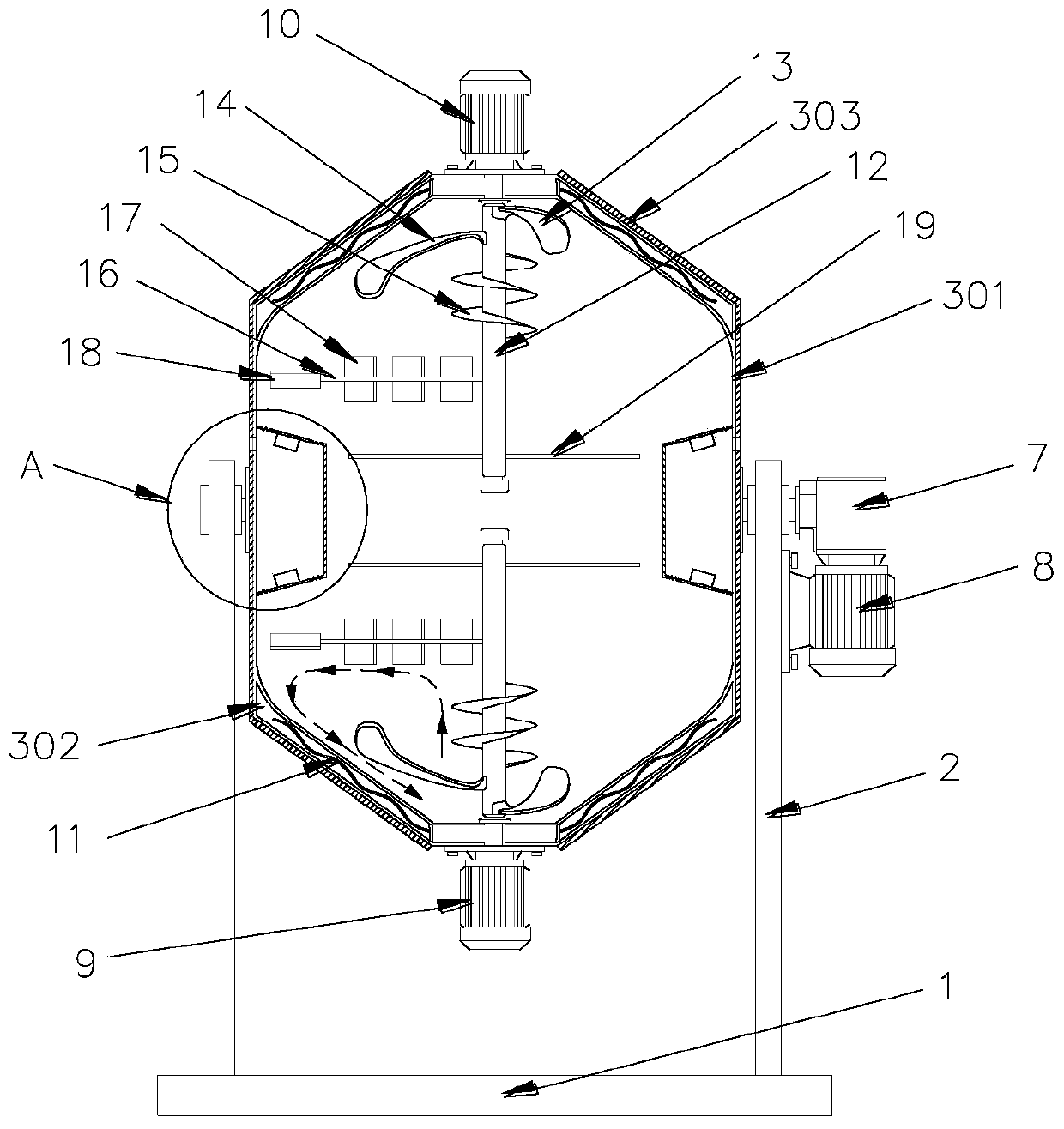

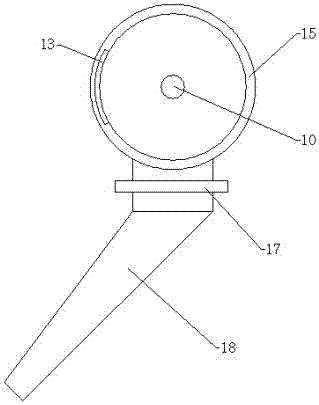

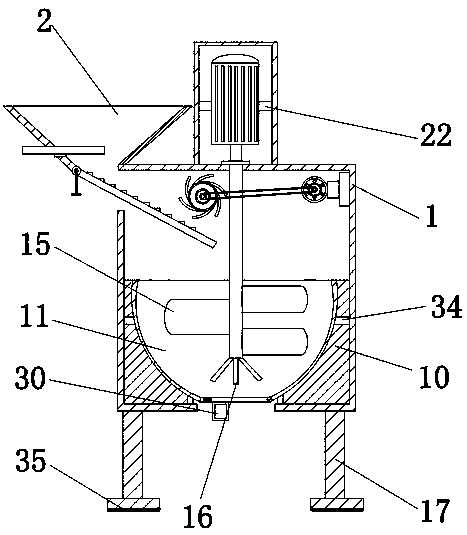

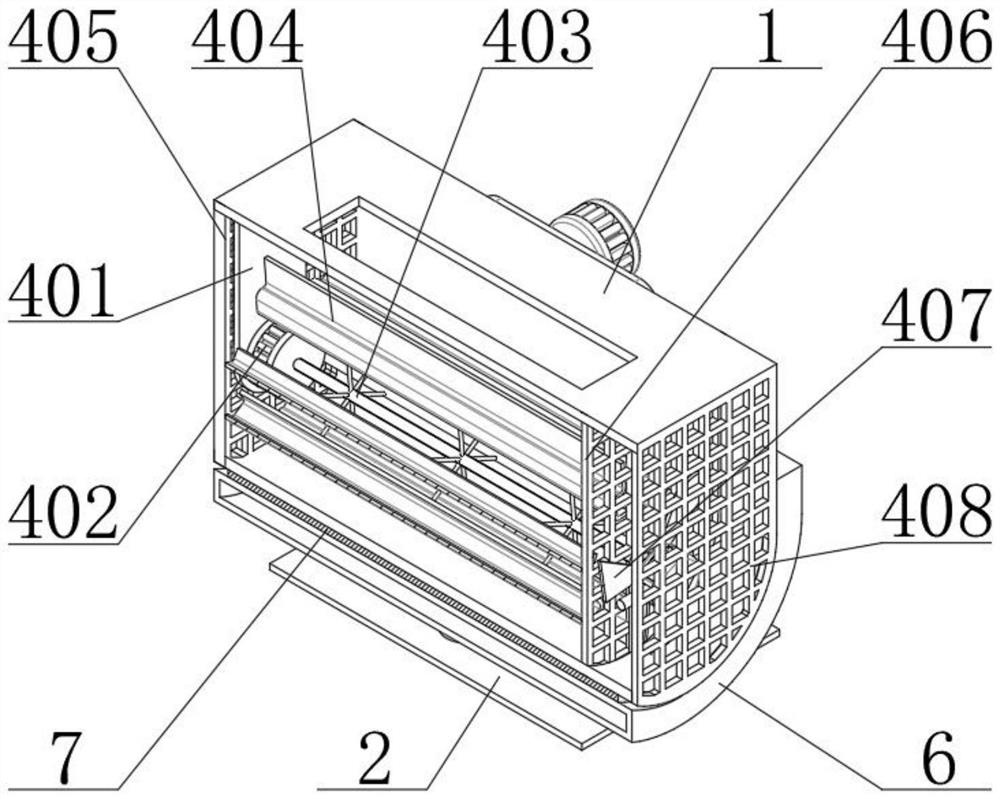

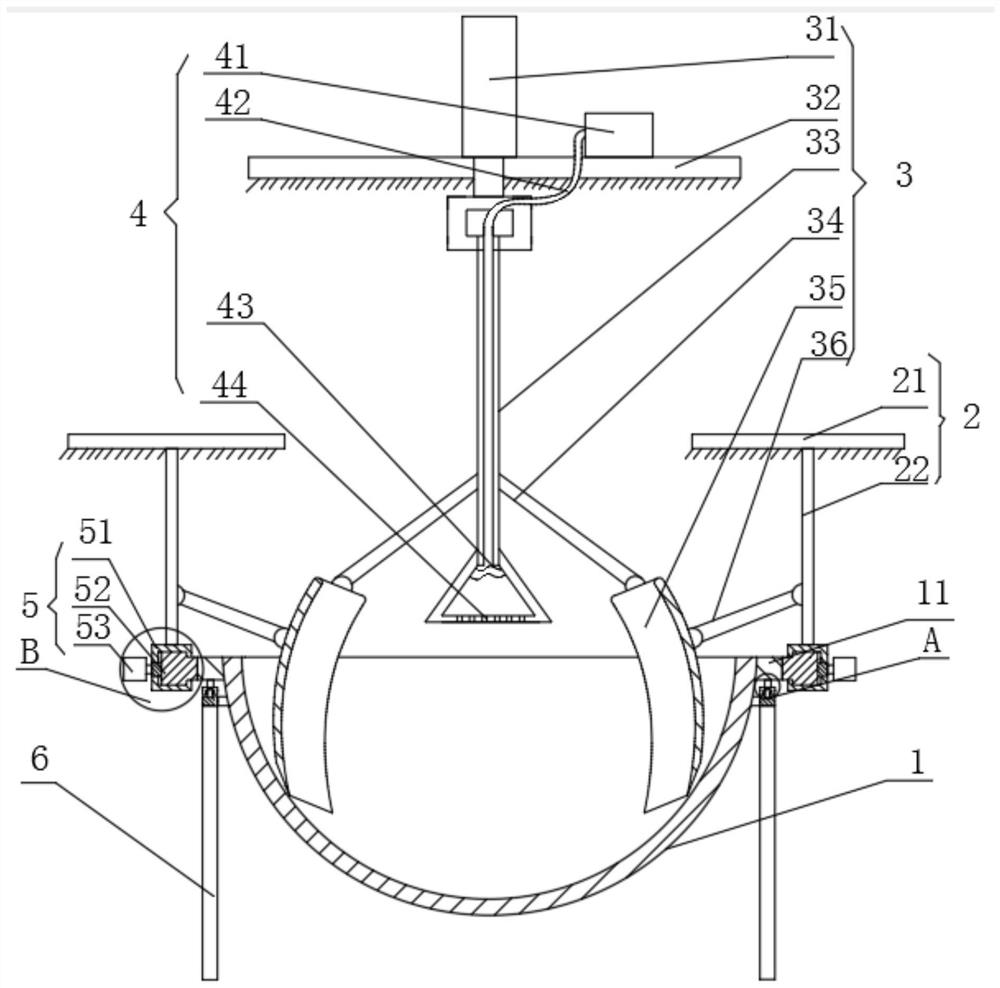

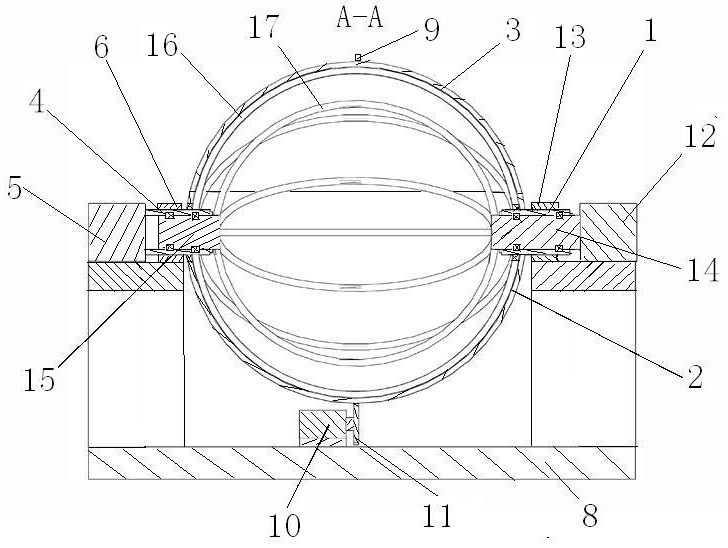

Stir-frying device of tea leaves

InactiveCN106974006AStable tea temperatureStable temperaturePre-extraction tea treatmentAgricultural engineeringVacuum pump

The present invention relates to a processing technology of tea leaves and particularly discloses a stir-frying and shaping device of the tea leaves. The device comprises a body frame, a stir-frying plate assembly, a stir-frying pot, a stir-frying pot driving mechanism, a heating mechanism, a kneading and rolling mechanism and a negative pressure mechanism. The stir-frying pot, heating mechanism, stir-frying plate assembly and stir-frying pot driving mechanism are all arranged on the body frame and a material collection hopper is arranged under a rotating plate; and the negative pressure mechanism comprises a pressure relief valve, a negative pressure tank and a vacuum pump, the pressure relief valve is connected to a material outlet chamber, the negative pressure tank communicates with the pressure relief valve, an air exhaust port and an air outlet are arranged at the vacuum pump, and the air exhaust port communicates with the negative pressure tank. The device aims to solve the problem that during the shaping process of the tea leaves, the temperature of the stir-frying of the tea leaves is inappropriate to control. The present invention aims to provide the device providing the stable temperature for the shaping of the tea leaves.

Owner:遵义茗香康源茶饮发展科技有限公司

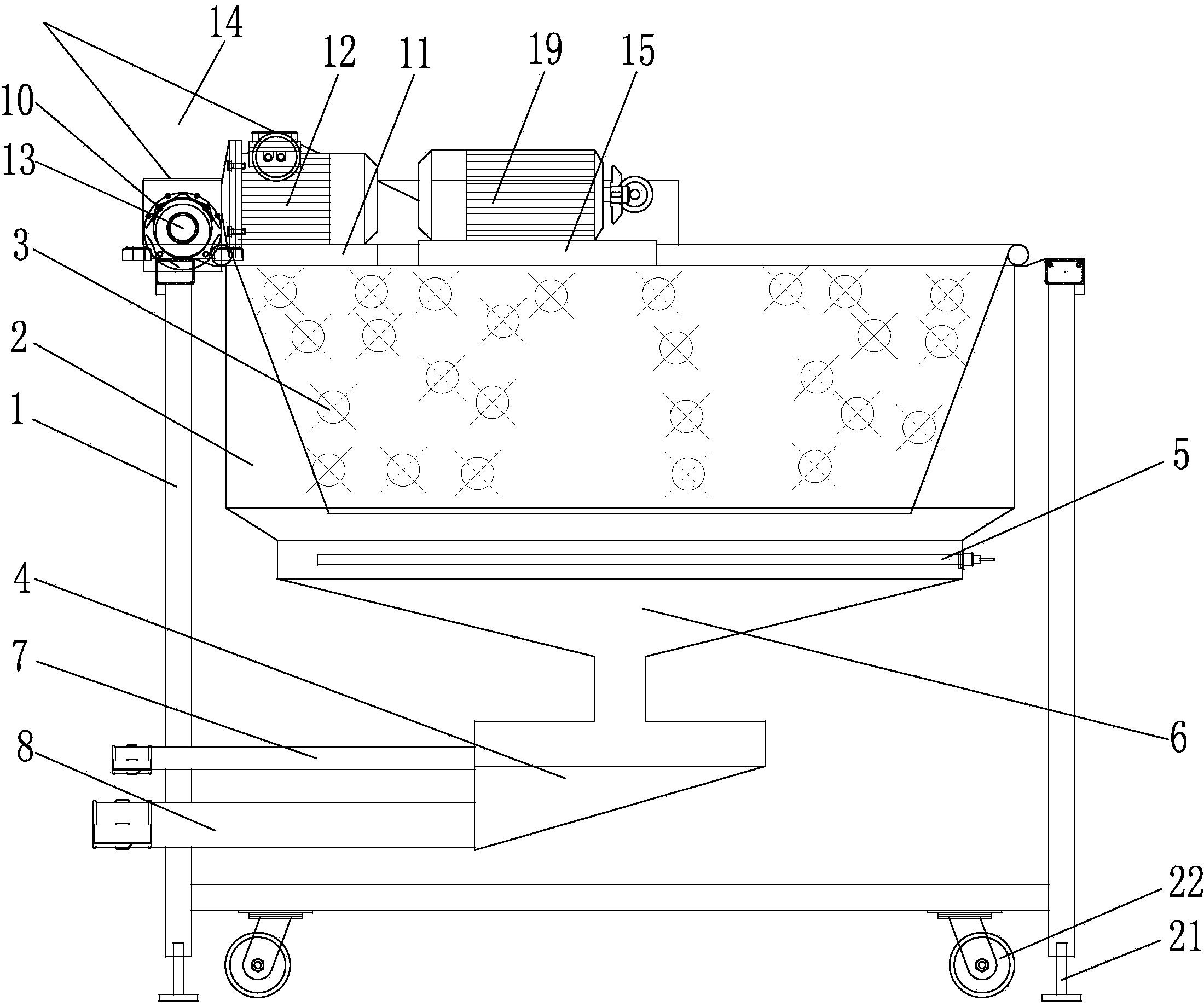

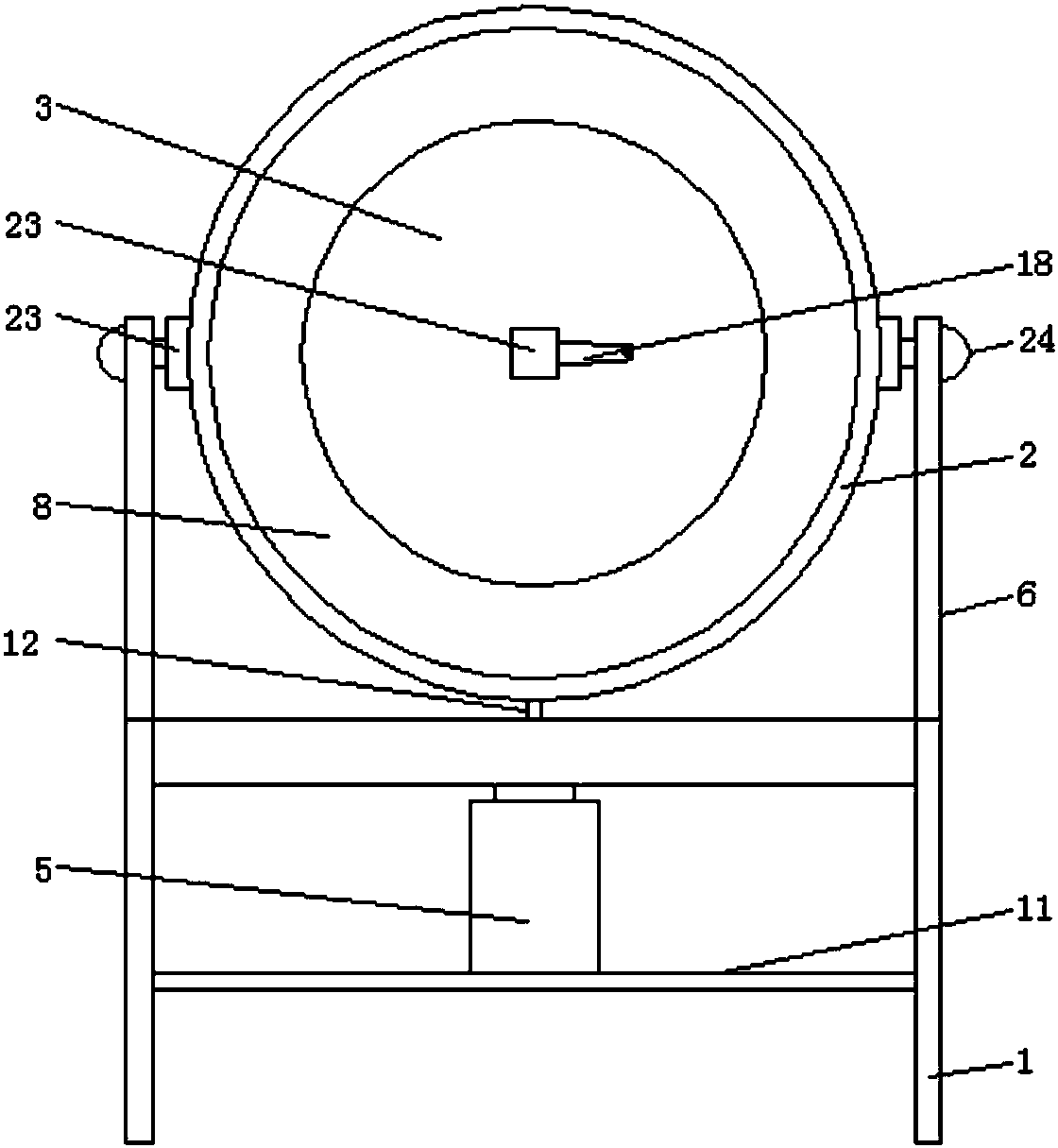

Production device and production process of fresh and crisp melon seeds

The invention discloses a production device and a production process of fresh and crisp melon seeds. The production device adopts an up-and-down turnover roller type structure, electric heating devices and stirring mechanisms are arranged on the top end and the bottom end of a roller, stirring blades of the stirring mechanisms also comprise long blades and short blades, and the long blades and theshort blades are connected with the electric heating device, melon seeds in the center and the edge of the roller bottom can be effectively turned over, so that the melon seeds in the roller body integrally, uniformly and quickly flow along with a stirring shaft; besides, the roller is turned over once every a period of time, so that the melon seeds in the roller are raised and fall back to the bottom of the roller, the melon seeds in the roller can be turned over and flow, the melon seeds can be more uniformly and fully heated in combination with the baking of an electric heating wire, and the probability of insufficient baking or excessive baking of the melon seeds is reduced; the overall quality of finished melon seeds is remarkably improved, and the obtained melon seeds are fresh, crispy and delicious; and the stir-frying mode of matching up-and-down rolling and stirring can enable the melon seeds to be stir-fried more quickly, so that the stir-frying time is shortened.

Owner:福州翁财记食品有限公司

Novel herbal medicine roaster used for traditional Chinese medicine preparation

InactiveCN107875018AFried evenlySimple structurePharmaceutical product form changeDomestic articlesCouplingChinese drug

The invention discloses a novel herbal medicine roaster used for traditional Chinese medicine preparation. The novel herbal medicine roaster comprises a supporting frame, a motor and a herbal medicineroasting chamber, wherein supporting legs are arranged on the lower portion of the supporting frame, the motor, a motor support, a reduction motor and a shell are arranged on the upper portion of thesupporting frame, and a coupler is arranged between the reduction motor and the motor. A reduction motor belt wheel and a V belt are arranged on the other side of the reduction motor, the herbal medicine roasting chamber and a bottom support are arranged in the shell, and a main shaft fixing base is arranged on the upper portion of the shell. Stirring blades and a main shaft are arranged in the herbal medicine roasting chamber, a main shaft belt wheel is arranged on one side of the main shaft, a feeding cover, a discharging baffle and a discharging pipe are arranged on the outer side of the herbal medicine roasting chamber, a discharging valve is arranged on the discharging pipe, and an electromagnetic heater is arranged on the bottom support. A traditional Chinese medicine in the rotating herbal medicine roasting chamber is uniformly roasted through the electromagnetic heater, the structure is simple, an automatic herbal medicine roasting process is achieved, the efficiency is high,and the practicability is high.

Owner:FOSHAN HUIZHONG SENTAI TECH CO LTD

High-temperature oil frying machine

ActiveCN110613082AReduce processing costsKeep healthyFood processingFood shapingHot TemperatureTreatment costs

The invention relates to the technical field of oil frying machines and in particular to a high-temperature oil frying machine which comprises an oil frying machine, a shaking device, a separating device and a processing device, wherein an oil cylinder is arranged on the inner side of the oil frying machine; the oil cylinder is in sliding connection with the oil frying machine; a frying sieve is arranged at the top end of the inner side of the oil cylinder; the oil cylinder is in sliding connection with the frying sieve; a support block is fixedly connected with the top end of the outer side of the frying sieve; the support block is in sliding connection with the oil frying machine and the oil cylinder; a heating component is in sliding connection with the bottom end surface of the fryingsieve; the heating component is in sliding connection with the oil cylinder; and the shaking device is arranged on the inner side of the frying sieve. Due to adoption of a gas collecting frame, and together with communication of the gas collection frame and a gas inlet tube, sliding connection of a gas outlet tube and a water absorption sponge layer and sliding connection of the water absorption sponge layer and a glass cup, oil fume generated in frying can be adsorbed when the device is used, so that not only is the health of operators ensured, but also the oil fume treatment cost can be lowered.

Owner:湖南恒森农业科技股份有限公司

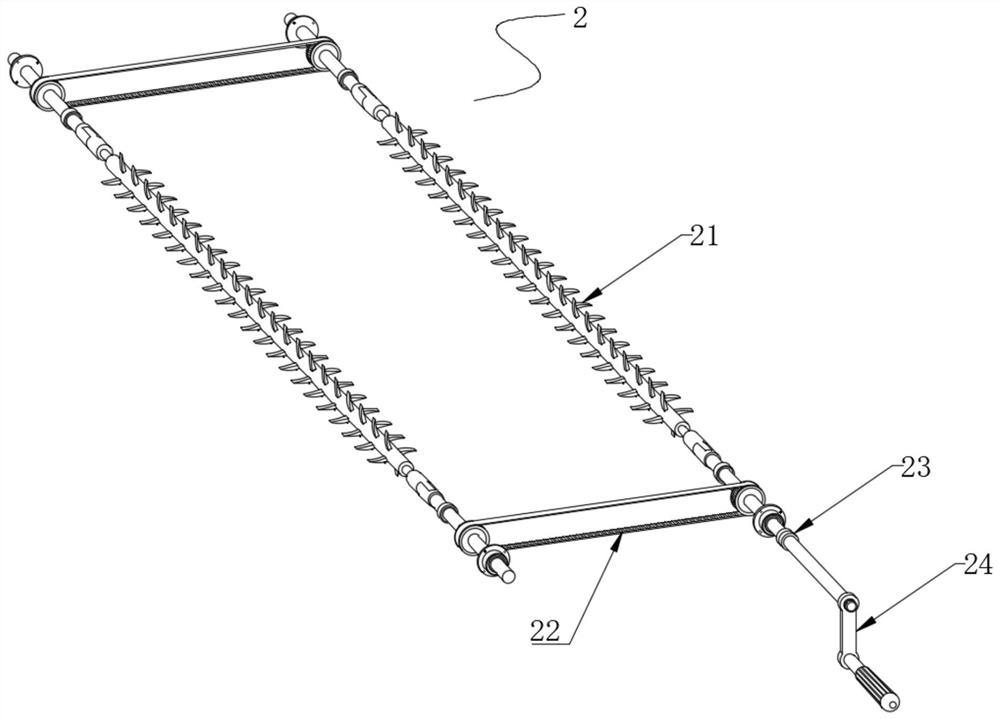

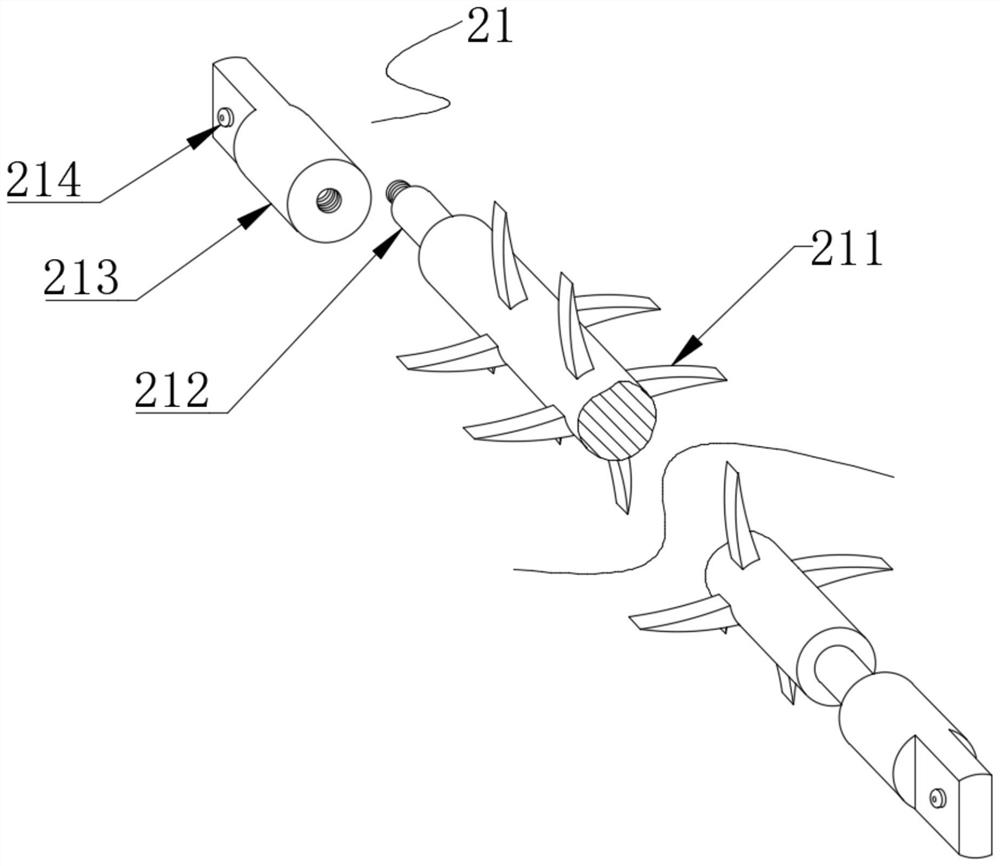

Production equipment for fried small yellow croakers

InactiveCN107484786AGuaranteed qualityImprove efficiencyOil/fat bakingBiochemical engineeringFood processing

The invention provides production equipment for fried small yellow croakers, belonging to the technical field of food processing. The production equipment comprises an engine base, wherein a frying chamber is formed in the engine base; a heating mechanism positioned below the frying chamber is arranged on the engine base; a feed valve assembly is arranged at one end of the frying chamber; a discharge valve assembly is arranged at the other end of the frying chamber; and a plurality of cylindrical frying barrels are arranged in the frying chamber. According to the production equipment disclosed by the invention, a continuous frying manner can be formed, the small yellow croakers are not contacted with dirt or stains in oil in the frying cylinders, and the quality of the small yellow croakers can be ensured in the frying process.

Owner:钱周坤

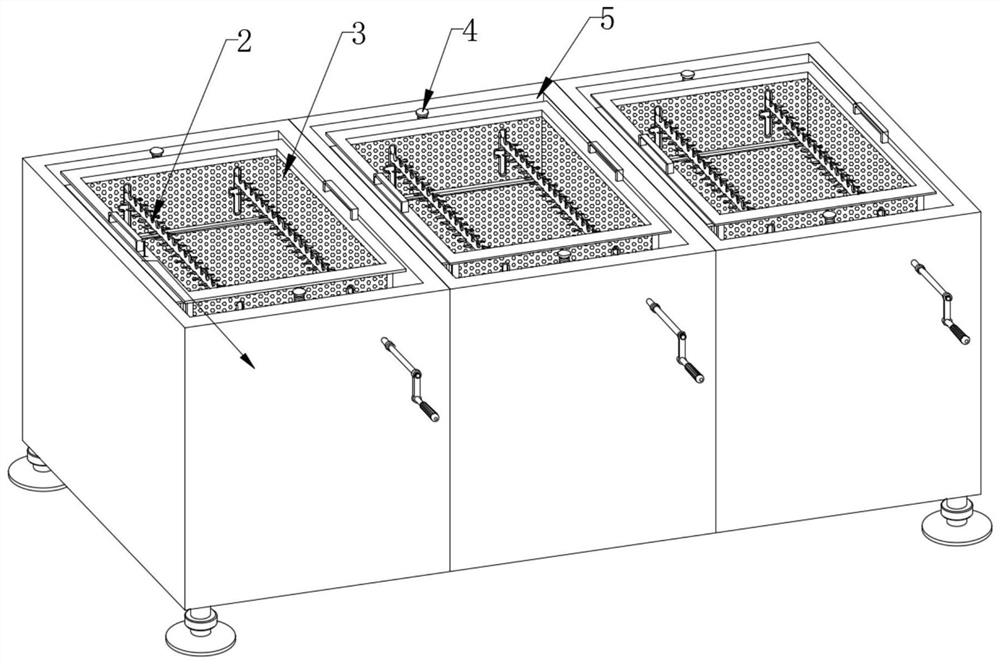

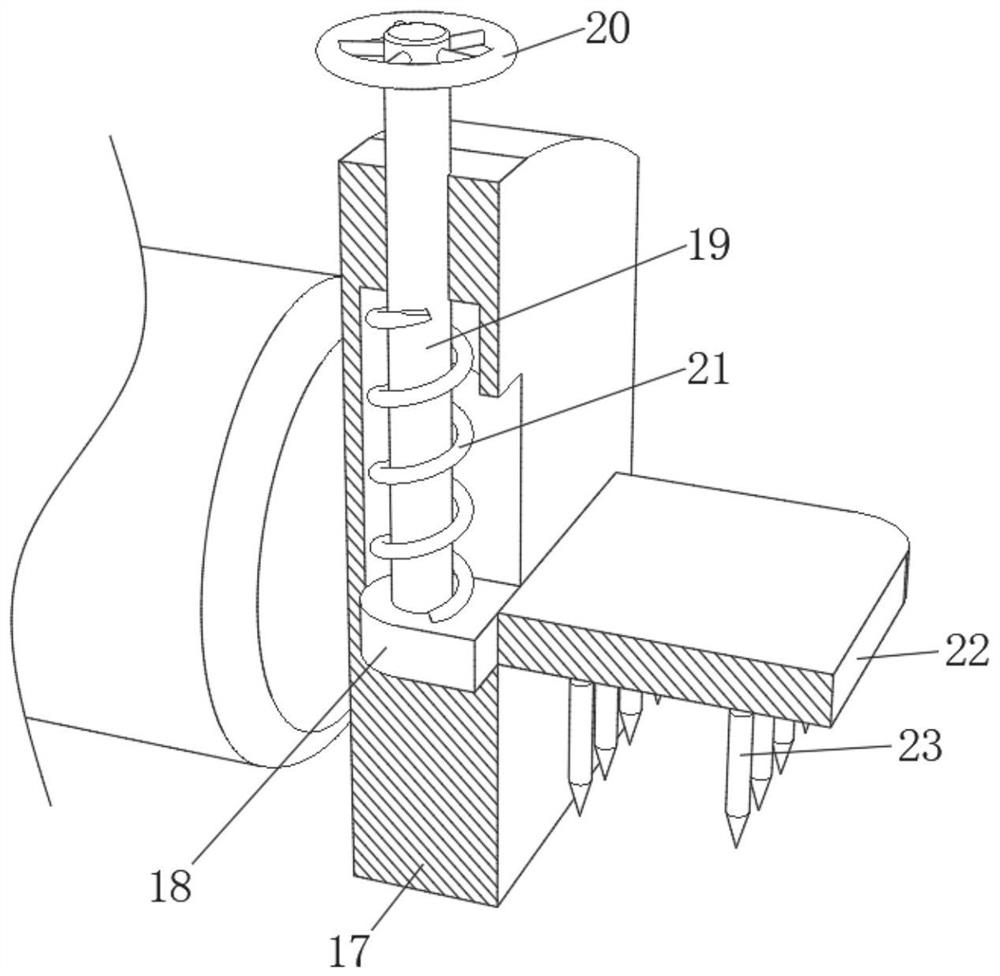

Multi-chamber fryer for making fried foods

The invention relates to the technical field of food making, and discloses a multi-chamber fryer for making fried foods. The multi-chamber fryer comprises a machine body, wherein a plurality of oil chambers are embedded in the top end of the machine body, a filter screen frame is arranged on the inner side of each oil chamber, lifting mechanisms are mounted on the front and rear sides, close to the corresponding filter screen frame, of the inner side of each oil chamber, and a turnover mechanism is arranged on the inner side of each filter screen frame in a penetrating manner. By rotating a crank of each turnover mechanism, a corresponding set of turnover claw assemblies can rotate in the corresponding filter screen frame, foods in the corresponding oil chamber can be turned over, and it is guaranteed that the foods are evenly fried; each nut pair is driven by a corresponding motor to move in the vertical direction along a corresponding lead screw, the corresponding filter screen frame can move up and down, the position of the corresponding filter screen frame is adjusted, and further, foods in different positions can be fried through the turnover claw assemblies; and each chuck head and each second spring column are embedded into a corresponding chuck groove and a corresponding second positioning hole, so that each filter screen frame and the corresponding lifting mechanisms can be easily mounted together, and the effects of being convenient and practical are achieved.

Owner:安徽旭众智能科技有限公司

Tea frying machine

InactiveCN109122948AFried evenlySolve the problem of small quantity and high labor intensityPre-extraction tea treatmentEngineering

The invention discloses a tea frying machine which comprises a box body and an electric frying pot main body. The electric frying pot main body is mounted on the inner wall of the box body, a feed inlet is formed in the top of the left side of the box body, a baffle plate is mounted at the bottom of the feed inlet, a rocker is mounted on a second connecting shaft, a plurality of baffle blocks aremounted on the surface of the baffle plate, a frying pot is mounted on the inner wall of the electric frying pot main body, and a rotating rod is mounted at the bottom of a first motor. According to the tea frying machine, the adjustable baffle plate and baffle blocks are arranged at the feed inlet. When more tea leaves are input, the rocker can be rocked, so that the baffle plate is close to a roller, the roller drives blades to rotate and the blades scatter the tea leaves, and therefore, time is reserved for uniformly frying the tea leaves in the frying pot. The problem that integrally friedtea leaves cannot be fully and uniformly fried when the tea leaves are fried quickly is solved. An adjustable fetch opening is formed in the bottom of the frying pot, so that the problems that materials are difficult to take in the prior art, and time and labor are wasted in taking of the materials by adjusting the rotating rod are solved.

Owner:高伟

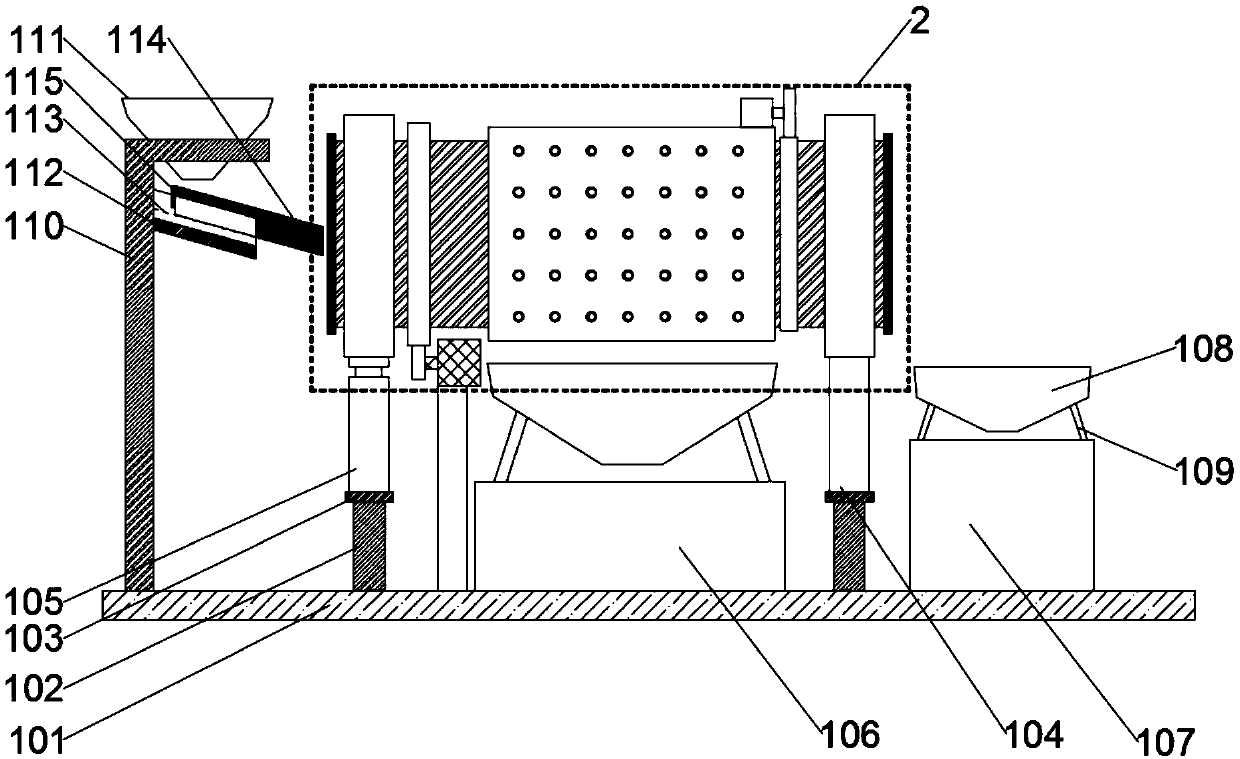

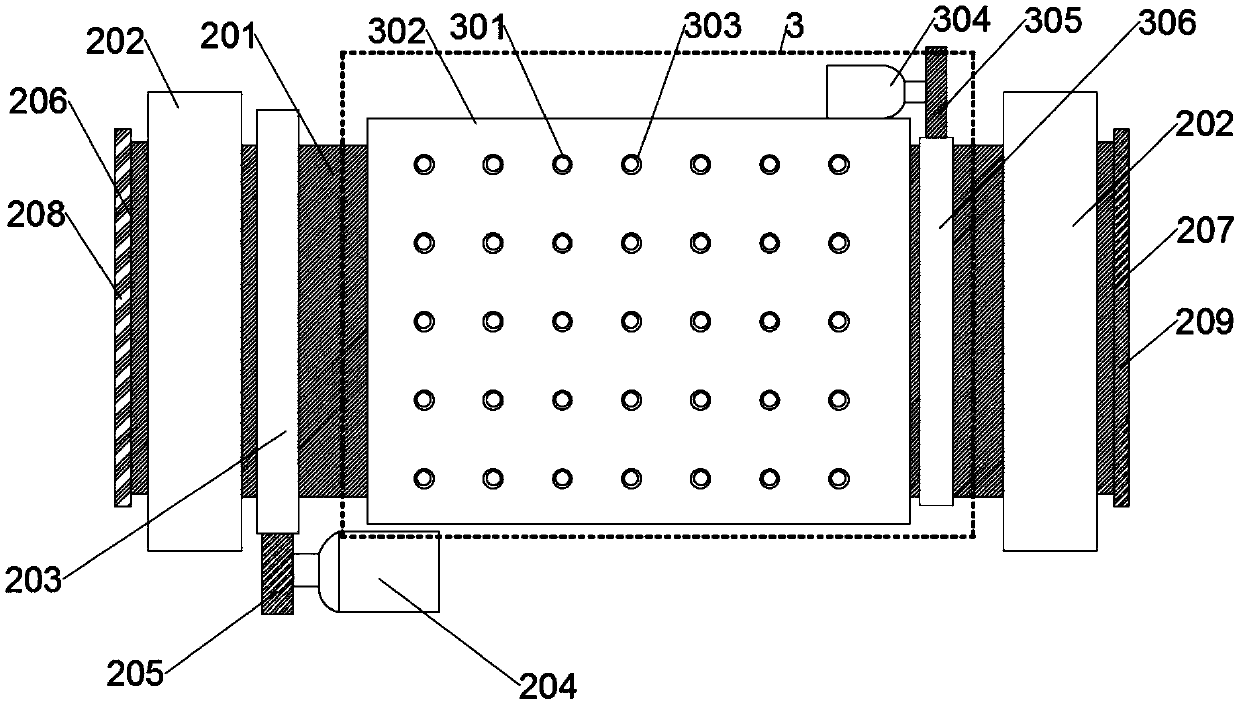

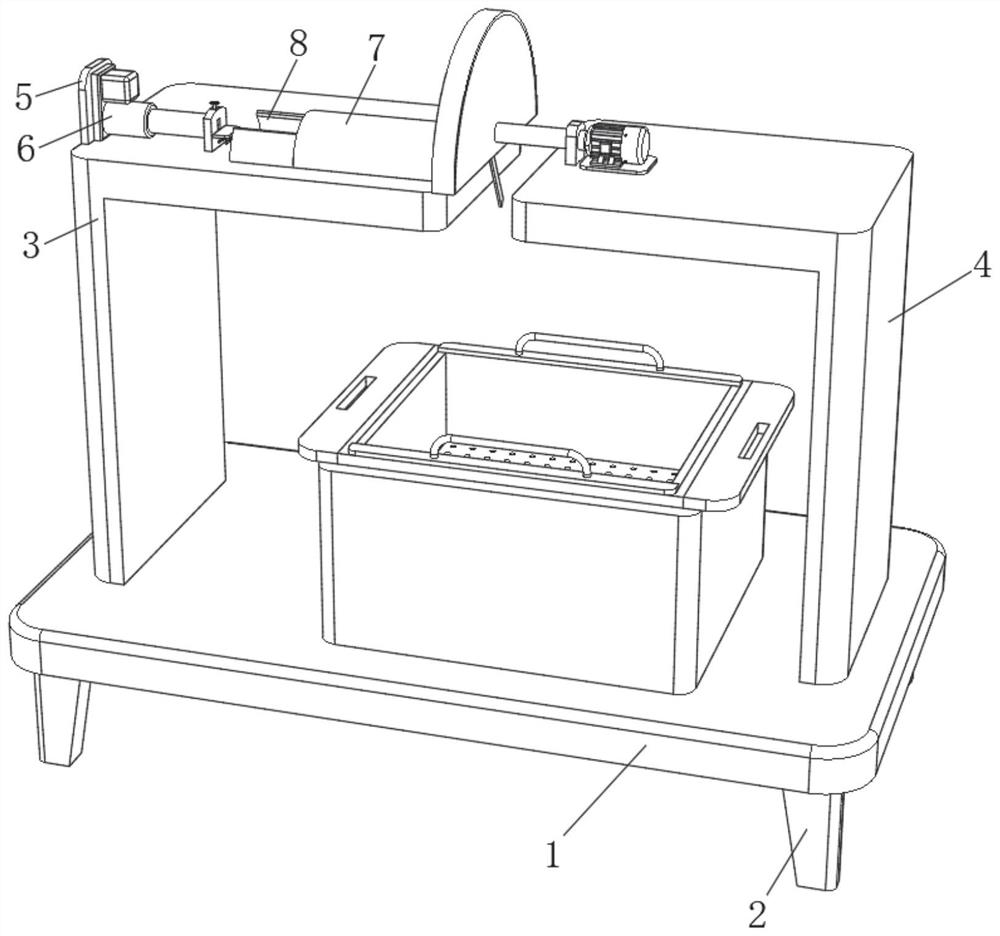

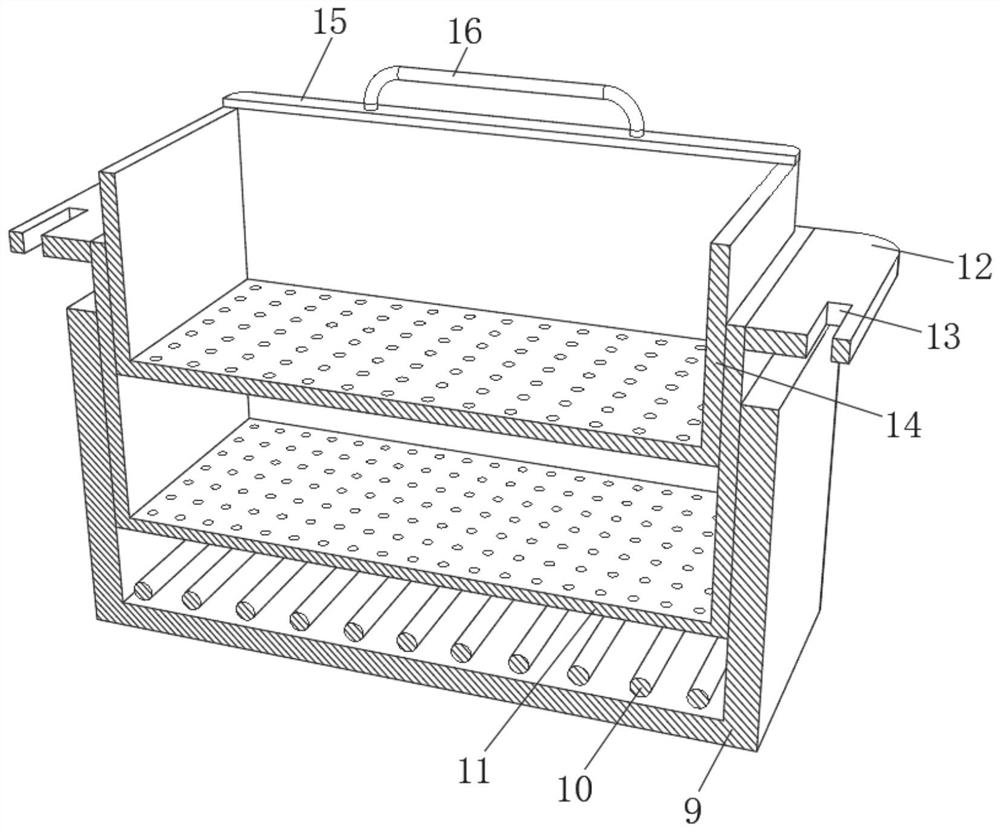

Automatic deep-frying and oil-filtering device for sweet potato slice processing

InactiveCN112121494AFried evenlyUniform sizeOil/fat bakingStationary filtering element filtersEngineeringMechanical engineering

The invention relates to the technical field of food processing machinery, and discloses an automatic deep-frying and oil-filtering device for sweet potato slice processing. The device comprises a supporting plate, supporting legs are fixedly connected to the four corners of the lower surface of the supporting plate, the left side of the upper surface of the supporting plate is fixedly connected with a first vertical plate, and the right side of the upper surface of the supporting plate is fixedly connected with a second vertical plate. According to the automatic deep-frying and oil-filteringdevice for sweet potato slice processing, sweet potato blocks are sliced through arranged plane blades, so that the sweet potato blocks are cut into sweet potato slices with uniform sizes, the thickness error of the sweet potato slices is extremely small, uniform deep-frying of a batch of sweet potato slices can be guaranteed during deep-frying of the sweet potato slices, the taste of the sweet potato slices is guaranteed, and the practicability of the device is ensured. Through the arrangement of a residue filtering box, chippings generated after sweet potato slices are fried are collected, the situation that the chippings enter a frying box, and consequently the chippings are accumulated in the frying box is avoided, the chippings are convenient to clean, and therefore the sanitation degree of the device is guaranteed.

Owner:湖南心海圆农业发展股份有限公司

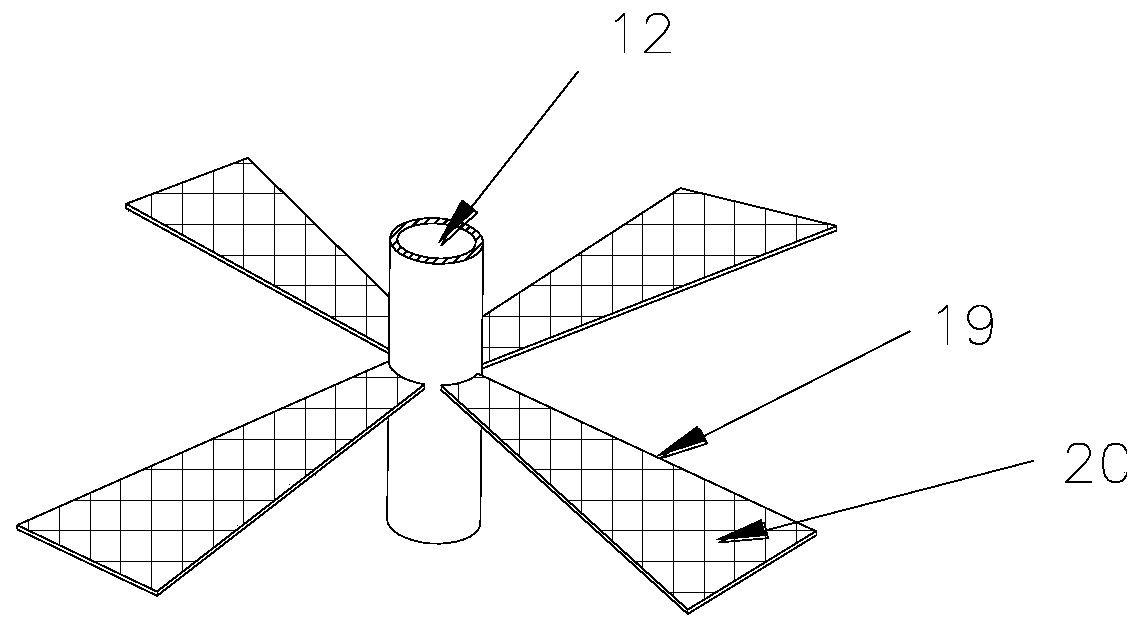

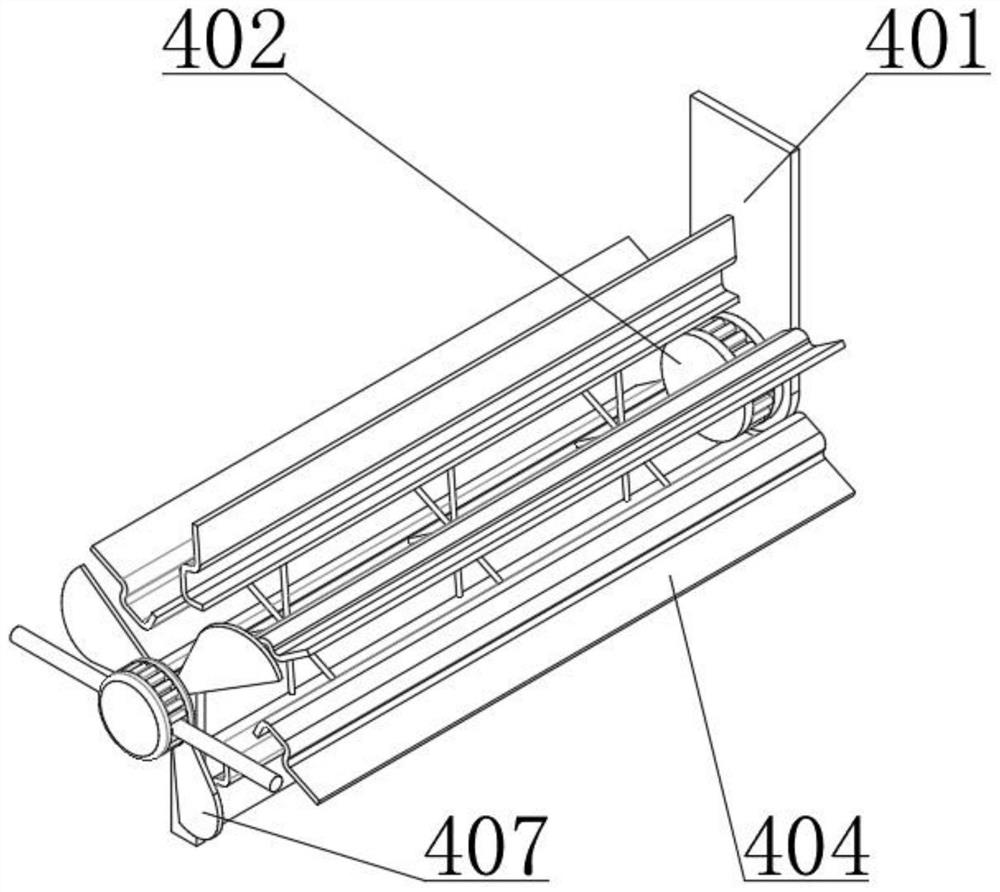

Tea frying machine

PendingCN113812470AFried evenlyImprove Flip EffectPre-extraction tea treatmentCooling/ventilation/heating modificationsElectric machineryTea leaf

The invention relates to the technical field of tea production, in particular to a tea frying machine which comprises a box body, a bottom plate, a supporting frame, a uniform tea frying device, a uniform swinging device and a cooling device, an electric heating plate is fixedly connected to the outer side of the bottom end face of the box body, a feeding port is formed in the top end face of the box body, the uniform tea frying device is installed on the inner side of the box body, the uniform tea frying device comprises a motor frame, a tea frying motor, a transmission shaft and frying plates, the motor frame is fixedly connected to the inner side of the top end face of the box body, the tea frying motor is fixedly connected to one side of the motor frame, the transmission shaft is fixedly connected to the tail end of a main shaft of the tea frying motor, the frying plates are uniformly and fixedly connected to the outer side of the transmission shaft through connecting rods, the outer sides of the frying plates are slidably connected with the box body, and a grooves are formed in the inner sides of the frying plates, so that tea leaves can be stir-fried well, a good stirring effect on the tea leaves is ensured, the tea leaves are stir-fried more uniformly, and the quality of the stir-fried tea leaves is effectively ensured.

Owner:溆浦县金香农业开发有限公司

Stir-frying device for walnut kernels with Pu'er tea fragrance

The invention relates to the technical field of food processing, in particular to a stir-frying device for walnut kernels with Pu'er tea fragrance. The stir-frying device comprises a support frame, apot body and a material turning structure, wherein the pot body is erected at the top of the support frame; the material turning structure comprises a support plate I erected above the pot body, a telescopic structure, a supporting rod, at least one shoveling part, a connecting rod I and a connecting rod II; the telescopic structure is fixed on the support plate I; the telescopic end of the telescopic structure is vertically downward, and the supporting rod connected with the telescopic end of the telescopic structure; two shoveling parts are symmetrically arranged in the circumferential direction of the supporting rod; one end of the connecting rod I is connected to the lower portion of the supporting rod, and the other end of the connecting rod I is hinged to the tops of the shoveling parts; one end of the connecting rod II is hinged to the faces, away from the supporting rod, of the shoveling parts; and the other end of the connecting rod II is hinged to the supporting structure which is erected on one side of the pot body. According to the walnut kernel stir-frying device, walnut kernels are automatically stir-fried, the labor intensity is reduced, and the pot body is heated more uniformly, so that the walnut kernels are stir-fried more uniformly, and the walnut kernel flavoring effect is better.

Owner:普洱学院

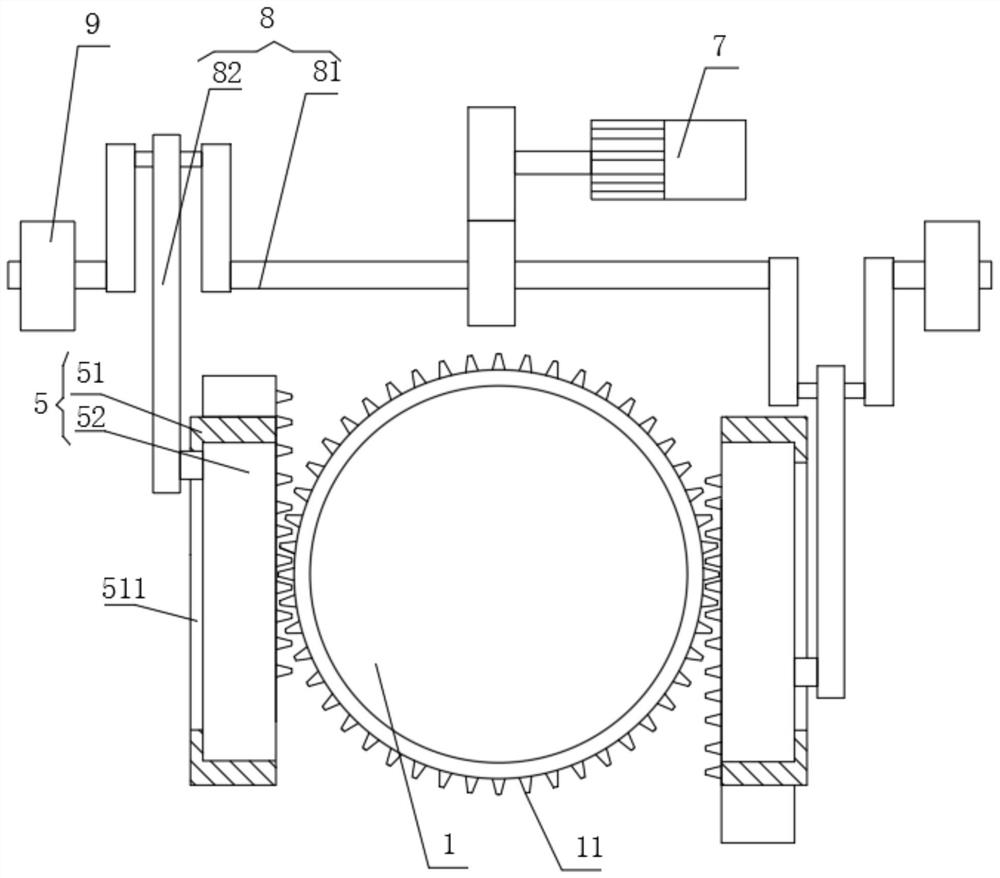

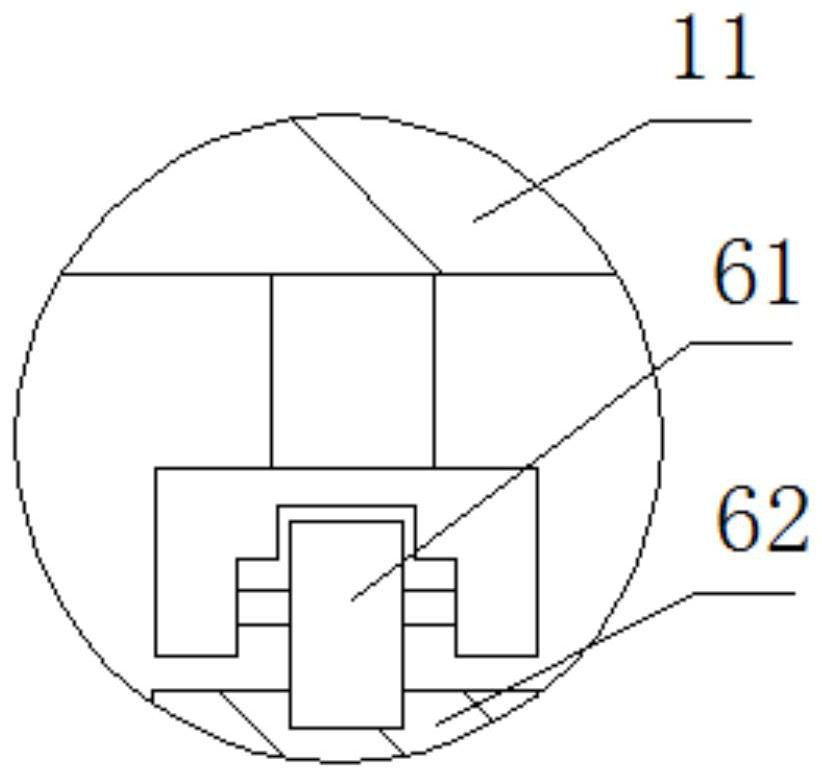

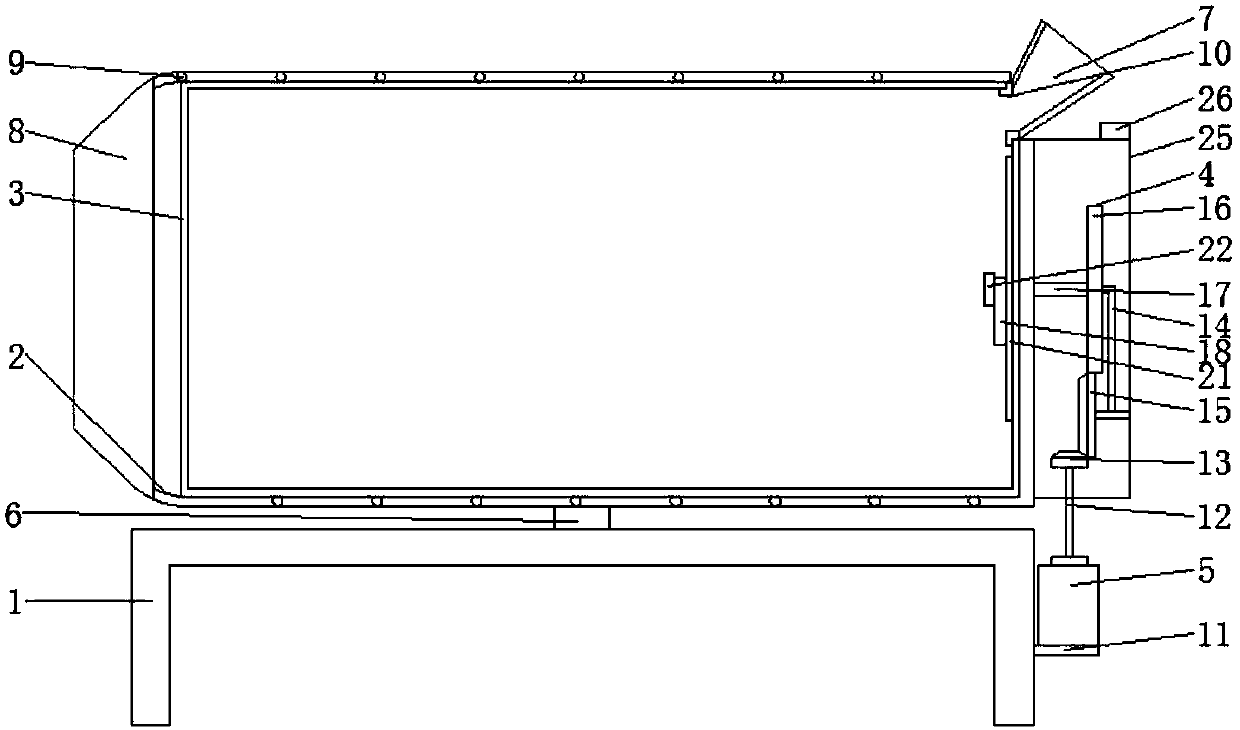

Tea leaf frying machine

PendingCN112244107AAchieve rotationRotation will notPre-extraction tea treatmentElectric machineGear wheel

The invention discloses a tea leaf frying machine. The machine is characterized in that two ends of a stir-frying cage B are connected with a shaft A and a shaft B respectively; the shaft A and the shaft B are inserted into a hollow shaft A and a hollow shaft B respectively; the hollow shaft A and the hollow shaft B are connected with a pot body through bearings; two ends of a stir-frying cage A are connected with the hollow shaft A and the hollow shaft B respectively; the middles of the hollow shaft A and the hollow shaft B are connected with a bracket through a bearing seat A and a bearing seat B respectively; the hollow shaft B is connected with a motor A; the shaft A is connected with a motor C; a motor B is installed in the middle of the bracket and is provided with a gear; the gear is meshed with racks arranged on the pot body and a pot cover; and the pot body is hinged to the pot cover. According to the invention, the stir-frying pot body and the pot cover rotate by 360 degrees,so that frying is uniform, and tea leaves cannot be bonded.

Owner:榕江县继武茶业有限责任公司

Drum type tea leaf stir-frying machine

InactiveCN107581293AFried evenlyEasy to fryPre-extraction tea treatmentAgricultural engineeringEngineering

The invention discloses a drum type tea leaf stir-frying machine, which comprises a base, a heating barrel, a stir-frying barrel, a stir-frying device and a motor, wherein support rods are fixedly connected to two sides of a central position of the top part of the base respectively; two sides of the heating barrel are movably connected with the support rods; a feed inlet is formed in the right upper end of the heating barrel; a discharge hole is formed in the left end of the heating barrel; an electrical heating pipe is connected into the heating barrel; the stir-frying device is arranged at the right side of the heating barrel. The drum type tea leaf stir-frying machine provided by the invention can solve the problems that according to manual stir-frying in the prior art, the efficiency is low and the labor intensity is high, solves the problem that tea leaves are easily burnt so as to cause waste, and is simple in structure and convenient to use; the electrical heating pipe is used for heating, so that overheating can be prevented; the stir-frying barrel is used for stirring, so that the phenomenon that the tea leaves are burnt due to being heat for a long time at the same placeis effectively prevented; the stir-fried tea leaves can be more uniform through the stir-frying device, so that the stir-frying quality of the tea leaves is greatly improved.

Owner:ANHUI SHITAI COUNTY XIHUANGSHAN TEA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com